DEPENDABLE COAL SIZING SOLUTIONS

Over 45 years ago, we innovated the Mineral Sizer™ to help underground coal mines break coal more efficiently and effectively while increasing productivity.

Today the Mineral Sizer has developed into a unique range of dependable solutions and systems that are tailored to each application. The Sizer has been successfully installed in many applications from high capacity primary machines that reduce ROM material to a conveyable size, as well as secondary or tertiary machines designed to deliver a specific product size in the coal preparation plant.

MMD remains a group of committed and experienced professionals who have the skills and knowledge to provide dedicated after-sales service and technical support via a network of local offices. Discover how we can deliver the complete sizing solution for your specific needs.

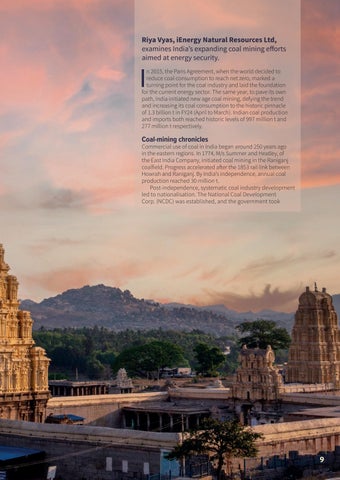

Riya Vyas, iEnergy Natural Resources Ltd, examines India’s expanding coal mining efforts aimed at energy security.

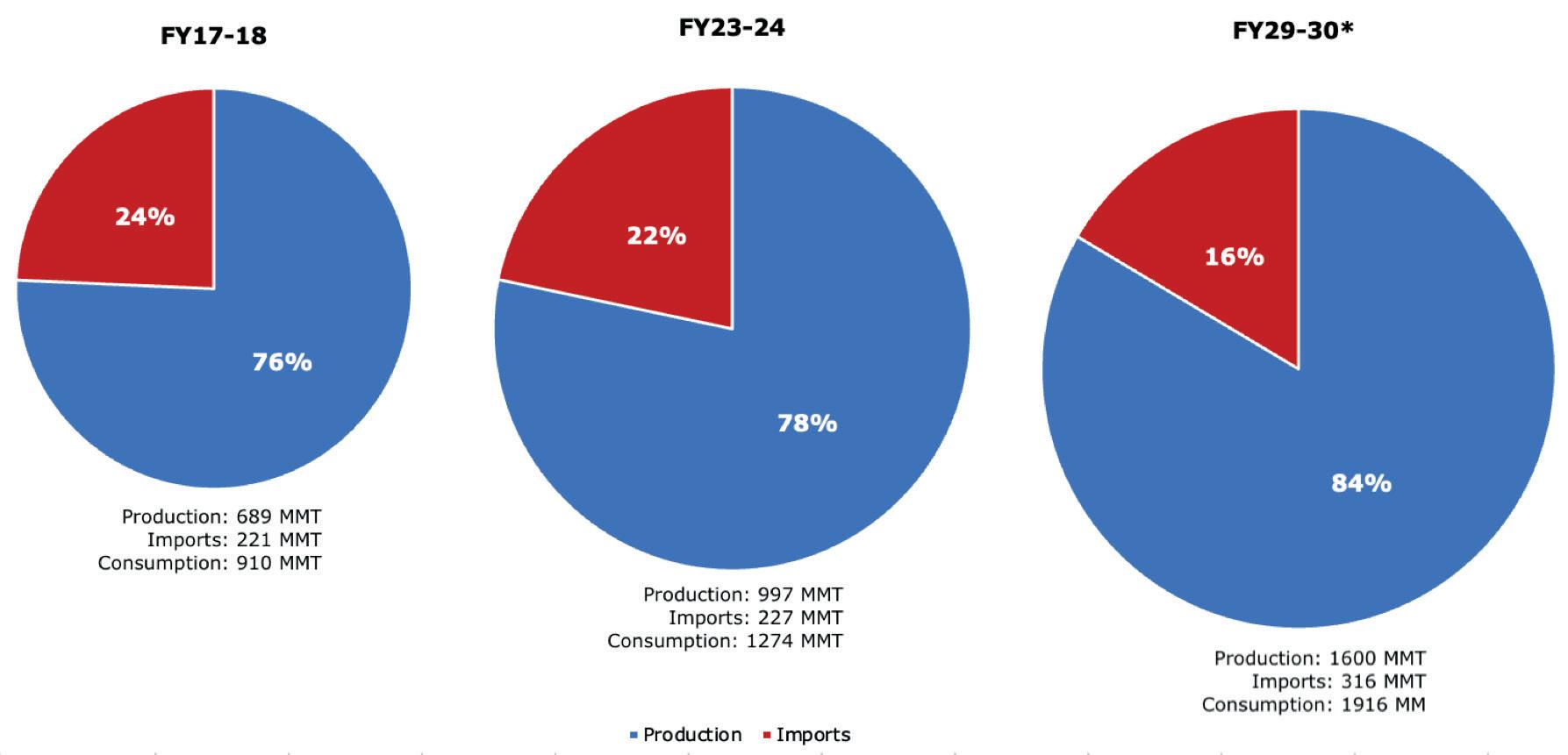

In 2015, the Paris Agreement, when the world decided to reduce coal consumption to reach net zero, marked a turning point for the coal industry and laid the foundation for the current energy sector. The same year, to pave its own path, India initiated new age coal mining, defying the trend and increasing its coal consumption to the historic pinnacle of 1.3 billion t in FY24 (April to March). Indian coal production and imports both reached historic levels of 997 million t and 277 million t respectively.

Coal-mining chronicles

Commercial use of coal in India began around 250 years ago in the eastern regions. In 1774, M/s Summer and Heatley, of the East India Company, initiated coal mining in the Raniganj coalfield. Progress accelerated after the 1853 rail link between Howrah and Raniganj. By India’s independence, annual coal production reached 30 million t.

Post-independence, systematic coal industry development led to nationalisation. The National Coal Development Corp. (NCDC) was established, and the government took

over railway-owned collieries and the Singareni Collieries Co. Ltd (SCCL), now a joint venture of Andhra Pradesh and the Indian Government. Private coal mine owners failed to provide adequate capital investment, often used unscientific mining practices, and maintained poor labour conditions. Consequently, the central government nationalised private coal mines in two phases: coking coal in 1971 – 72 and thermal coal in 1973, culminating in the Coal Mines (Nationalisation) Act of 1973 (CMN Act).

Recognising the need for increased power generation, the government amended the CMN Act in 1993 to permit private participation. Coal mining block auctions began in 1993, limited to captive consumption for approved end users. A total of 218 coal blocks were allocated to various industries. However, the Supreme Court cancelled the allocation of 216 coal blocks in 2014. In 2015, the central government enacted the CMSP Act in Parliament to reallocate and auction the coal blocks cancelled by the Supreme Court, opening coal mining to the private sector.

Navigating the current state of coal mining

As of April 2023, the Geological Survey of India reported coal reserves amounting to 378 billion t, with 35 billion t of coking coal and 342 billion t of thermal coal.

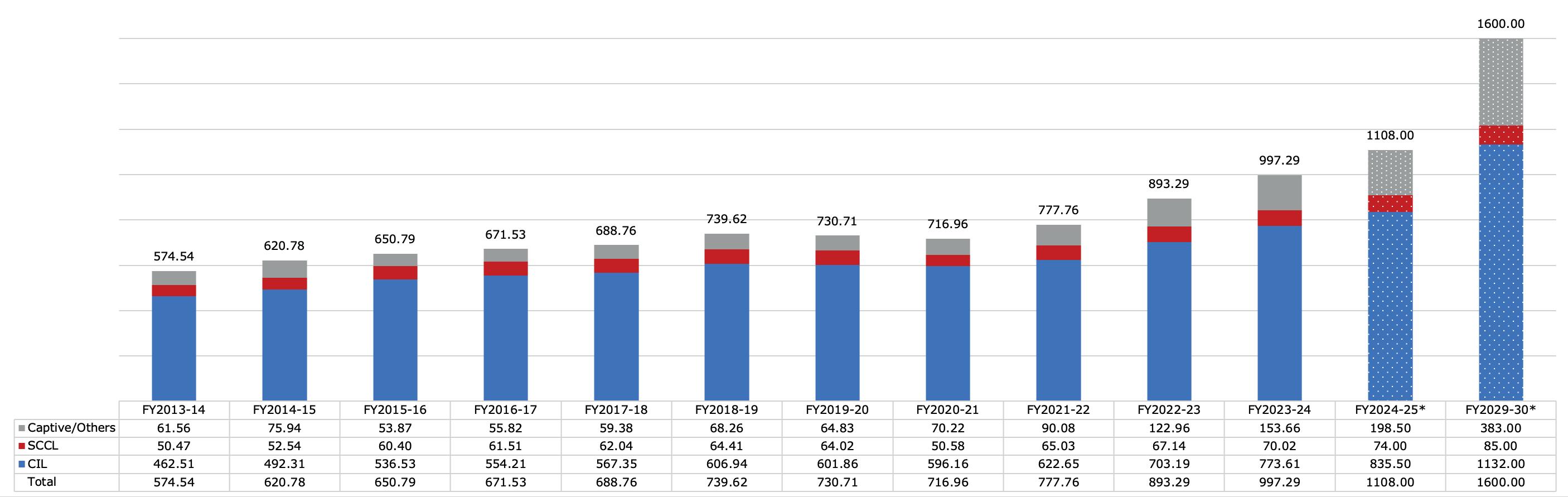

Coal mining in India had a momentum shift in 2014, when the government extensively took

the initiative to surge domestic coal production. India’s coal production has significantly improved in recent years, rising from 651 million t in FY16 to 997 million t in FY24, with a compound annual growth rate (CAGR) of 5.5% in the last eight years. Furthermore, y/y production showed double-digit growth of 12% from 893 million t in FY23, and Indian coking coal production jumped to 67 million t in FY24 from 50 million t in FY22.

Coal India Ltd (CIL), India’s largest coal producer, with eight subsidiaries wholly owned by the central government, accounts for nearly 78% of the country’s total coal production. CIL has produced 773 million t in FY24, up by 10% y/y, compared to 703 million t in FY23. SCCL is the main source of coal supply to the southern region, with the output remaining between 65 – 70 million t over the past three years. The highest growth was registered by captive/commercial miners, whose production increased from 123 million t in FY23 to 154 million t in FY24, a growth of 25% y/y.

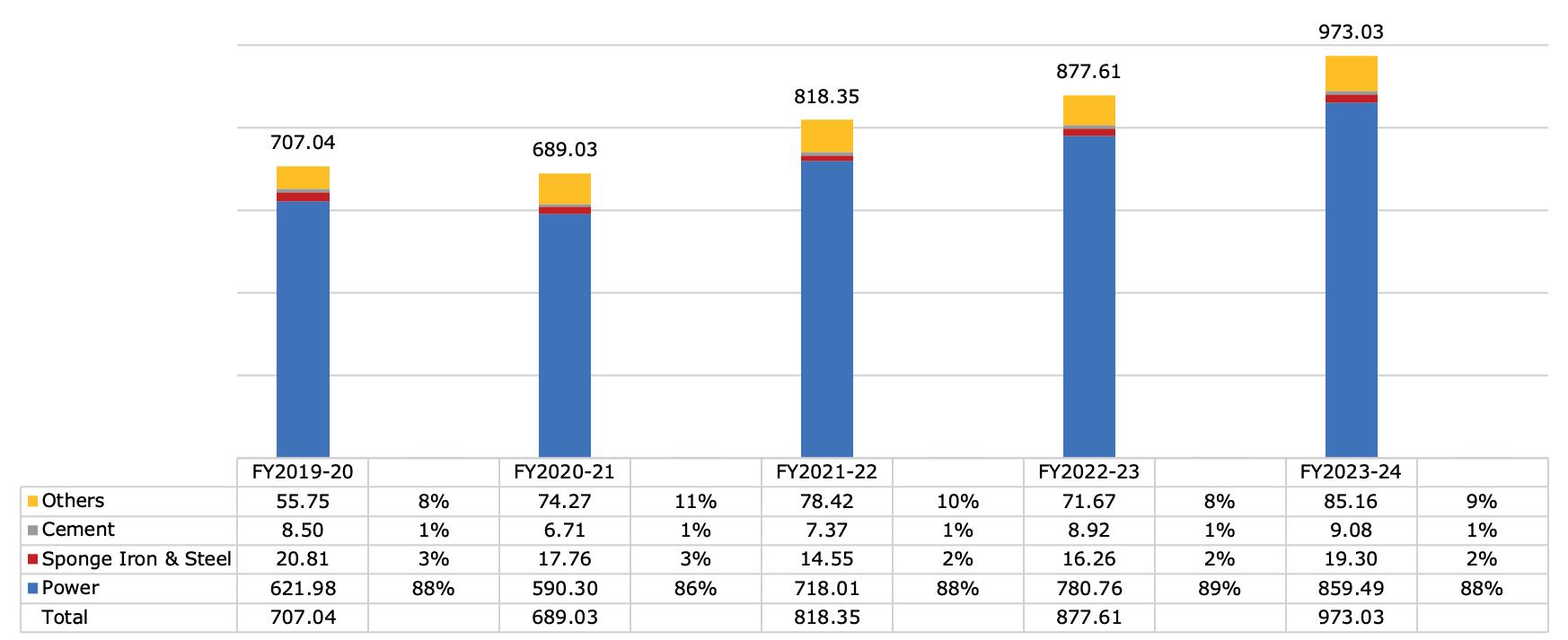

India’s coal dispatch was 878 million t in FY23 and 973 million t in FY24, and the availability of coal expanded by 11% y/y. Around 88% of the coal produced in FY24 was dispatched to the power sector, driven by the government’s goal of prioritising electricity security. The remaining coal went to other sectors, such as cement and steel. The coal sector plays a vital role in fuelling the nation’s energy needs and driving employment growth. Government-owned companies like CIL and NLC India Ltd employ approximately 369 053 individuals, including 128 236 contract workers, and support approximately 310 000 retired employees.

India has the fifth-largest proven coal reserves and is the second-largest coal producer in the world. Despite large resources and affordable mining, India is the second-largest coal importer, with imports totalling 277 million t in FY24, including

Figure 1. India’s coking coal production (million t) (Source: Ministry of Coal).

Figure 2. India’s coal production (million t) (Source: Ministry of Coal/iEnergy).

184 million t of thermal coal and 56 million t of coking coal. India’s total coal and coke imports registered a significant 10% y/y growth from 252 million t imports in FY23. India imports coal amid two major limitations: higher inland logistical costs and the quality of reserves. Coal reserves are primarily concentrated in the eastern and central parts of India, making inland transportation uneconomical and entailing other regions, like the western and northern parts, to import coal. The shortage of high-quality reserves, where India majorly has low CV and high coal ash, is another reason for high imports. The unavailability of quality reserves mandate few industries, especially the steel and allied industries, to depend on imported coal.

Government initiatives to expand coal production

India’s stand, even after climate agreements and international pressures, has remained with coal, in order to become self-sufficient in fulfilling its surging energy needs. India expends a significant amount of foreign exchange on imported coal, exposing it to global uncertainties. To reduce its reliance on imported coal, the Indian Government has taken multiple initiatives to boost domestic coal production.

This includes the introduction of the coal mine auction and mine developer and operator (MDO) model to invite private participation in coal mining. The Ministry of Coal (MOC) conducts regular reviews to expedite coal block development. The MMDR Act of 2021 allows captive mine owners to sell up to 50% of their annual production. Moreover, a single window clearance portal and a project monitoring unit have been introduced to speed up the operationalisation of coal mines. The 2020 auction for commercial mining on a revenue-sharing basis offers a 50% rebate for early production and coal gasification/liquefaction. The adaption of rolling auction clearance mechanism means a pool

of coal blocks will always be available for bidding. Liberal terms include no usage restrictions, reduced upfront costs, transparent bidding, 100% FDI via the automatic route, and a revenue-sharing model based on the National Coal Index.

Along with production, the government aims to improve India’s coal dispatch infrastructure and tackle logistical challenges.

In FY24, India transported 407 million t of coal via rail, accounting for nearly 50% of all transportation modes, while 28% was transported by road. Other modes included MGR at 14%, conveyor belts at 3.2%, and RSR route at 4.6%. To enhance logistics, the Ministries of Railways, Road Transport, and Highways, and Ports, Shipping, and Waterways have developed multimodal connectivity in line with the PM GatiShakti initiative. The MOC is developing the National Coal Logistic Plan, emphasising first-mile connectivity (FMC) through railway sidings near mines. MOC takes up 67 FMC projects with a capacity to load 885 million t of coal annually, expected to be completed by 2027.

Reshaping the landscape: Commercial/captive coal mining

In all of these measures, the major initiative was the opening of the coal mining sector for private participants. Commercial/captive mining proved to be a boon for private industries to secure important

Figure 3. India’s coal dispatch to industries (million t) (Source: Ministry of Coal).

Figure 4. India’s coal and coke import (million t) (Source: iEnergy).

raw materials for captive consumption, as well as for trading purposes.

The commercial auction started in 2020 and nine rounds of commercial auction have been completed, with 107 coal blocks successfully auctioned. The nominated authority/MOC has so far allocated 161 coal mines under the provisions of the CMSP and the MMDR Act. Putting all of the auctioned and allotted mines and commercial/captive mines together, currently, 57 coal blocks are in operation.

Production from the commercial/captive mines is expected to reach 383 million t by FY30.

Mission Coking Coal

The Indian Government is actively working to increase coking coal production, essential for the steel industry, which largely relies on imports due to domestic availability and quality considerations. Despite recent production increases, over 80% of domestic coking coal is still dispatched unwashed to the power sector. Currently, only 20 – 30% of coking coal is washed before utilisation, with yields below 50%. In FY24, Indian public companies washed just 2.25 million t of coking coal, while the steel industry used only 5 million t of domestic coking coal.

According to the MOC, washed coking coal production was relatively static over FY21, FY22, and FY23, with outputs of 4.9, 4.7, and 5.3 million t, respectively. The corresponding yield percentages were 51%, 44%, and 38%. The total installed capacity of coal washeries in the public and private sectors is 214 million tpy for both coking and thermal coal.

To address these challenges, the government has launched initiatives to improve the infrastructure and quality of domestic coking coal. ‘Mission Coking Coal’, launched in FY22 under the ‘Aatmnirbhar Bharat’ initiative, aims to reduce imports by enhancing exploration, production, technological adoption, and private sector involvement. The mission includes establishing new washeries, increasing R&D activities, and improving coal quality to meet the National Steel Policy 2017’s projections. The government targets 300 million t of steel capacity and 140 million t of raw coking coal production by 2030.

Key measures to increase coking coal availability include auctioning coking coal blocks to private entities, revitalising abandoned mines, collaborating with SAIL to supply 1.8 million t of washed coking coal, organising auctions for raw coking coal, and

Figure 6. India’s coal reserves (billion t) (Source: Ministry of Coal).

Figure 5. India’s total coal consumption (million t) (Source: Ministry of Coal/iEnergy).

setting up or refurbishing BCCL washeries to improve quality and availability.

Environmental consideration

The Indian mining sector has been considerate towards the negative impact of mining activities on the environment. This impact cannot be completely nullified; however, initiatives have been taken to minimise it to some extent.

The MOC established the ‘Sustainable Development Cell’ in December 2019 to promote environmentally sustainable coal mining in the country and to address concerns during mining operations and until the decommissioning or final closure of mines. Coal companies are enhancing green cover around mining areas through initiatives like ecological reclamation, plantations, and restoration of flora and fauna. The government launched ‘Vriksharopan Abhiyan’ in 2021 (tree planting campaign).

Additionally, coal companies are developing solar and wind energy projects, with plans to install 5570 MW of renewable capacity by 2030. They are also creating eco-parks on reclaimed mining land, promoting tourism and sustainable practices. Modern dust suppression technologies and FMC initiatives are taken up to reduce environmental impacts.

Presently, opencast mining accounts for 96% of India’s coal production. To promote underground mining, the government targets 100 million t by 2030, offering a 50% discount on revenue sharing for commercial underground mines.

The energy transition process is being carried out by increasing the share of renewables in India’s electricity mix (currently stands at 33% share). However, the actual generation is largely being fulfilled by coal (more than 75% of India’s generation).

Conclusion

The coal mining sector continues to be a cornerstone of the Indian economy, meeting the country’s electricity and energy demands, creating jobs, and ensuring future energy security. Environmental considerations and global climate pressure have caused the mining sector to be

caught in the crosshairs. However, India’s gigantic energy need is defending the use of coal and mining activities.

Developed nations have leveraged fossil fuels to achieve unparalleled development. Taking a page from their book, India is also not expected to phase out the coal until it reaches a developed nation status.

Fossil fuels have always proven to be a reliable source for development, whereas renewables currently in vogue are falling short of expectations. Renewables in India operate below 30% plant load factor, compared to 75% for thermal plants. 4 GW of renewable energy is required to replace 1 GW of thermal capacity, necessitating a substantial investment – an especially challenging task for a capital-constrained nation like India. There are still limitations like sustainability and reliability when integrating renewables into the power grid. Until these are addressed, India remains on a path of increasing coal consumption, which will continue to support domestic coal mining.

While domestic coal mining is booming in India, obstacles also remain against it, compelling India’s high level of imports. In the mid-term, India might be able to become self-sufficient in the case of fulfilling coal demand in the power and cement sector to some extent, but quality issues will continue to enforce other sectors like steel and allied industries to rely on imported coal. Until India has enough coal to supply both the power sector and other industries, and logistical barriers are improved, small retail industries will continue to depend on imports for the time being. Coal production is projected to reach 1.6 billion t, concurrent with imports expected to ascend to 316 million t by 2030.

Post-2030, coal consumption is anticipated to escalate; however, the trajectory of coal imports is foreseen to approach a saturation point and subsequently diminish.

Figure 7. India’s electricity generation April 2024 (Source: Central Electricity Authority, CEA).

Alan Beal, HBT Waratah Engineering PTY LTD, Australia, outlines the benefits of two key pieces of room and pillar mining technology added to HBT’s product portfolio through its acquisition of Waratah Engineering.

In a strategic move to bolster its capabilities in the underground coal mining sector, HBT acquired Australian company Waratah Engineering. This acquisition added two of Waratah’s flagship products for room and pillar operations – the Waracar shuttle car and Warabolter mobile bolter – to the HBT product portfolio.

HBT’s acquisition of Waratah from Questas Group was finalised on 20 July 2023 through a share purchase agreement. Waratah has a long history dating back to 1923, having been saved from bankruptcy in 2009 when purchased by Polish firm Kopex, which later became part of Famur in 2017. Swanson Industries Australia then acquired Waratah from Kopex in 2016, before Swanson joined Questas in 2020.

This acquisition is a strategic step for HBT, aligning with its vision to increase distribution capabilities and broaden its product offerings. By diversifying into new markets, HBT solidifies its position as an industry leader and global single-solution provider.

Headquartered in Argenton near Newcastle, NSW, Waratah is renowned for overhauling and repairing longwall roof supports, continuous miners, and roadheaders, and manufacturing its own proprietary equipment – such as the Waracar shuttle car, Warabolter mobile bolter, and Warabreaker feeder breaker.

This acquisition is more than a mere expansion; it signifies HBT’s commitment to maintaining Waratah’s strong market position, while driving further innovation and growth. The integration of Waratah’s products complements HBT’s existing offerings, reinforcing its global capability as a comprehensive solution provider in the coal mining industry.

This article provides a detailed look at their key features.

HBT Waracar shuttle car

The Waracar shuttle car is the only batch haulage vehicle designed and manufactured in Australia, purpose-engineered to meet the unique demands of the underground mining industry. Since its inception in 2011, the Waracar has earned a reputation for reliability, ease of operation, and low total cost of ownership (TCO). The latest generation 18-3 wide-body variant delivers top productivity and sets the industry standard for cutting-edge design. The Waracar’s continued refinement over the years, based on customer feedback, has cemented its status as a benchmark in the mining industry.

Ergonomic and safe operator cabin

At the heart of the Waracar is an ergonomic and safe operator cabin fully compliant with MDG 41 standards. It features two 160 kg rated

seats with adjustable height and spring suspension, ensuring drivers operate in comfort over long shifts. The high-visibility MDG 1 & 9 approved protection device and three-position adjustable mesh guarding provide a clear view while prioritising safety.

The cabin also incorporates hard piping throughout to reduce maintenance, an electronic interlocking door switch, warning bell, go/no-go lights, and a solenoid-operated boom valve for ease of operation. An emergency stop inside the cabin allows operators to immediately halt the shuttle car if needed, and the extra low voltage electrical system further reduces operator exposure.

Efficient outboard chain conveyor system

Enabling rapid payload discharge is the Waracar’s efficient outboard chain conveyor system managed by HBT’s intelligent control system. Whether the standard or wide-body version, the heavy-duty worm drive conveyor delivers maximum productivity. The conveyor’s design allows for complete discharge of the payload in a matter of seconds.

Four-wheel drive and steering system

Contributing to the Waracar’s agility and responsiveness is its four-wheel drive and steering system powered by two 37kW DC variable speed motors. This system is attached to traction reducer gearboxes to provide ample torque

and traction force. As an added benefit, the Waracar has the unique ability to be steered while being towed with no power applied.

Hydraulic brake system

The hydraulic brake system includes dual brake circuits and separate reservoirs to maximise safety and reliability. This isolates the brake oil from the main hydraulic system, reducing oil contamination risk and preventing heat transfer that could overheat the main circuit. As a result, the brakes can operate at lower temperatures for consistent stopping performance.

Cable reel system

Durability is ensured by the proven cable reel system with proprietary overfill and run-out protection. This prevents cable damage from excessive unwinding or overlapping on the reel. The hydraulic tensioning system matches the reel speed to the shuttle car’s speed, maintaining a consistent cable tension.

A built-in cable minder automatically lays the cable neatly onto the reel to prevent tangling. When the conveyor boom is raised, the cable reel covers automatically lift to decrease potential for snagging or abrasion damage to the cable. The cable reel’s design combines multiple protective features to maximise cable life under the most extreme workloads.

HBT Waracar models

Available in two models, the Waracar platform includes the standard WC18 model and WC18B wide body shuttle car, purpose-engineered to meet seam-specific requirements. The wide-body’s increased width provides greater stability and payload for improved productivity and efficiency.

HBT Warabolter

The Warabolter mobile bolting machine is built for high-level productivity in underground mining operations. Designed and manufactured in Australia, the Warabolter is built to withstand tough conditions and deliver reliable performance, ensuring continuous operation in the most challenging environments. Its rugged bisalloy steel chassis houses six integrated roof bolting modules, capable of simultaneously installing six bolts in a single cycle.

As an Australian-made product, the Warabolter meets all relevant mining industry standards using locally sourced components from the country’s long-established mining supply chain. HBT backs this with 24/7 aftermarket support, a readily available inventory of spare parts, and a team of factory-trained technicians deployable at a moment’s notice. This comprehensive aftersales service minimises downtime and ensures the HBT Warabolter operates at peak performance.

Chassis sizes

Two chassis sizes – standard and wide-body – offer flexible configuration options to suit any underground mine’s needs for single pass bolting at the required coverage,

Figure 2. Waracar conveyor.

Figure 1. HBT Waracar.

bolt size, and density. The modular bolt rigs have fully automatic control over all critical functions like drilling feed and positioning, water flow, and mast extension/retraction during the entire bolting cycle.

Ergonomic design

Operator feedback and safety insights from the Australian underground mining community directly influenced the Warabolter’s intelligent ergonomic design focused on reducing fatigue and optimising productivity. Simple controls and intuitive machine operation combine with the machine’s compact footprint to enable easy manoeuvrability and precise positioning in even the most confined underground roadways and headings.

The robust chassis construction utilises bisalloy wear-resistant steel, which has a yield strength over three times higher than regular carbon steel. This allows for reliable operation in harsh conditions. Additional durability is built in through wider machine platforms incorporating rib protection, strengthened track frames, and upgraded heavy tonne traction planetary drive units.

Onboard materials

A large onboard materials handling and storage pod provides ready access to all necessary roof bolt consumables like plates, resin, mesh, and tray buttons. This ensures the bolting process can continue uninterrupted at full productivity, with operators remaining on the safety of the platform instead of leaving to fetch more supplies.

Versatile mesh handling system

The HBT Warabolter incorporates a versatile mesh handling system to promote faster and safer installation of roof mesh panels. Through intuitive controls, the integrated handler can swiftly manipulate and position mesh sections into place on the roof without manual labour from the operators. This reduces physical strain, fatigue, and lost time associated with this process. The mesh handler can also be customised to meet individual customer requirements for increased flexibility.

Cable reel system

Like the Waracar, the Warabolter utilises a proprietary cable reel system designed for the most demanding applications. This system has intelligent hydraulic tensioning circuits that automatically adjust the reel’s hydraulic motor speed and torque to ensure a consistent cable tension matching the machine’s movement. This prevents cable overloading or sagging.

In addition to the hydraulic tensioner, the reel also features a built-in cable minder that neatly lays the cable to prevent tangling or overlap on the reel, minimising maintenance. As a final protective measure, the reel’s cable cover guards fully enclose the cable to shield against impacts, abrasions, and pinch points that can cause costly downtime.

High-quality mining equipment

By adding two of Australia’s most innovative and productive room and pillar products to its portfolio, HBT has further solidified its position as a full-service solution provider to the underground coal sector.

The Waracar shuttle car, with its ergonomic design, efficient conveyor system, responsive drive and brake systems, durable cable reel system, and model variants, sets a high standard for batch haulage vehicles in underground mining operations. Similarly, the Warabolter mobile bolter – with its robust construction, customisable configurations, ergonomic design, large materials pod, efficient mesh handler, and reliable cable reel system – delivers productivity in the toughest mining conditions.

The Waracar shuttle car and Warabolter mobile bolter epitomise HBT and Waratah’s shared focus on increasing mining productivity, lowering operating costs, and safeguarding the well-being of miners through intelligent equipment design. With optimal efficiency, simplicity, and durability integrated into every aspect, these two products have been engineered from the ground up, in order to withstand relentless duty cycles in the most extreme underground environments, while delivering best-in-class performance.

With Waratah Engineering now part of the HBT Group, this opens up opportunities for more innovation and growth, and strengthens HBT’s position as a single-solution provider of high-quality mining equipment worldwide.

Figure 4. HBT Warabolter.

Figure 3. Waracar responsive drive brake steering system.

Chris McCabe, Becker Mining Australia, explores the technological advances in auxiliary fan design that can significantly improve working conditions in underground coal mining operations.

In underground coal mining, ventilation is a critical factor that influences both safety and productivity.

Auxiliary fans are engineered to move large volumes of air through complex networks of underground ducts.

Proper airflow dilutes and removes hazardous gases and dust, significantly reducing the risk of explosions and long-term health issues for miners. At the same time, efficient ventilation directly impacts operational efficiency by maintaining optimal working conditions.

Innovative auxiliary fan design, coupled with the integration of smart features – such as real-time monitoring, semi-autonomous capabilities, and

predictive maintenance – are unlocking greater safety and productivity benefits for underground coal mining operations, with organisations like Becker Mining Australia leading the way.

These latest advancements allow for remote control of ventilation systems and adjustment of airflow based on current conditions and needs, with a reduction in energy consumption and wear on equipment. By leveraging data and automation, smart fans can adapt to the ever-changing environment of underground coal mining, ensuring consistent air quality, improving wellbeing, and minimising downtime and maintenance costs.

Fundamentals of auxiliary ventilation fan design

When designing ventilation systems for underground mining, two key factors must be considered: air volume and static pressure. Air volume refers to the amount of air that can be moved within a given time, which is crucial for ensuring sufficient airflow to dilute contaminants and maintain breathable air. Static pressure, on the other hand, is the resistance to airflow within the ducting system, which must be overcome to maintain the desired air volume throughout the mine.

A typical requirement in mining operations is to achieve 10 m³/s of airflow at the duct outlets to ensure approximately 0.3 m³/s of airflow in the roadways. To maintain the desired airflow, a static pressure of around 2 kPA is required for every 100 m of 618 mm diameter ducting. The relationship between duct length, diameter, and required static pressure is critical for designing effective ventilation systems.

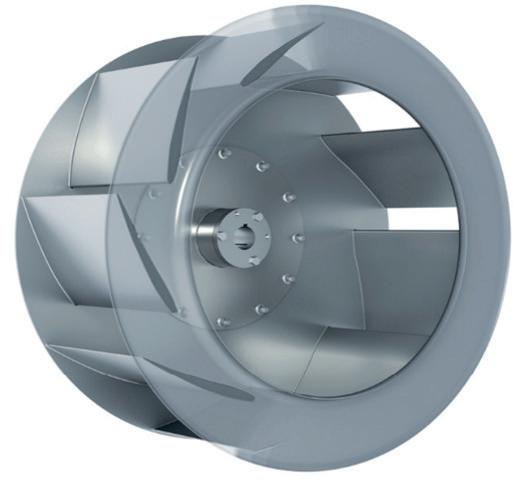

The impeller is the rotating component of the fan that creates negative pressure, which generates a suction effect resulting in airflow at the inlet ducting. It can significantly impact the fan’s efficiency, affecting factors like energy consumption and performance. Factors such as blade shape and number, blade angle and curvature, impeller diameter and width, and impeller clearance can all affect airflow, pressure, and energy consumption.

An efficiently designed impeller can provide numerous benefits, including reduced energy consumption, increased fan performance, reduced noise levels, and extended fan life.

Engineered for enhanced performance

Becker Mining’s smart ventilation fans employ airfoil-type impellers with backward slanted blades, which are the most efficient in producing higher air pressure at higher airflow rates. This innovative design supports longer ducting installations and dual-ducting applications in underground mining. When paired with a 200 kW motor, the fan achieves an airflow of 25 m³/s and a maximum pressure performance of 11.3 kPa. This capacity allows more machines and personnel to work safely in a given area, directly enhancing productivity.

For instance, a single auxiliary fan can efficiently run two ventilation ducts to simultaneously support dual continuous miners or coal headings. Alternatively, operators can extend ventilation ducting length to accommodate larger and longer setups without sacrificing static pressure or ventilation efficiency at the coal face.

This translates into tangible sustainability and operational benefits, including requiring fewer fans to operate and the ability to accommodate more personnel and equipment at the working face, ultimately leading to improved production capabilities and faster progress underground.

The airfoil impeller is located on an inline shaft which is coupled with a flameproof 1000 VAC motor positioned outside the air stream to enable safe performance in all (Group I Zone I) underground coal environments. Ventilation control is achieved with a variable inlet vane (VIV) for air volume adjustment, guiding airflow onto the impeller. The fans are also fitted with a robust air dilution valve (ADV) to prevent damage from debris and dilute methane gas accumulations after fan stoppages. The stone drop-out box, accessible from either side of the ADV, aids in debris removal during operation. By optimising airflow distribution, the fans contribute significant cost savings over its operational lifespan, reducing operational expenditures often associated with ventilation systems.

The solid steel subframe is designed to prevent flex under operating conditions, or when it is installed on uneven ground, ensuring the integrity of the machine and its components during operation. The heavy-duty, in-house designed and manufactured jack shaft and long-life heavy-duty bearings provide superior operating life.

The fans are equipped with state-of-the-art electrical protection and monitoring equipment, and are fitted, tested, and commissioned at Becker Mining Australia’s ISO 9001:2015 certified and AS/NZ 3800:2012 licenced workshop in New South Wales, Australia. The VSF5 flameproof enclosure is certified for Group I applications and designed to contain an ignition of methane within the enclosure and to ensure exterior gas is not ignited. The enclosure features a large viewing window that allows operational status and diagnostic information to be displayed via an HMI screen.

The narrow design – 1450 mm wide – enables the fans to fit into designated spaces easily in the underground production panel, freeing up more space for equipment

Figure 1. Designed and manufactured in Australia, the smart ventilation fans employ advanced sensors and data processing capabilities to monitor critical parameters, such as motor current, airflow, pressure, temperature, and vibration.

Figure 2. The airfoil type impeller with backward slanted blades has the highest efficiency to produce higher air pressure at higher air flow rates.

and enabling operators to ‘get on the coal face’ quicker. The customisable wheel mounting and skid options enable flexibility to move to where the demand is and support all production environments and panel layouts.

Smart ventilation: Integrating intelligent features for optimal efficiency

Integrating intelligent features in auxiliary fan design represents a significant advancement in ventilation technology. Traditional ventilation systems often operate at a constant rate, regardless of the actual demand for airflow. This can lead to inefficiencies and increased operational costs. In contrast, smart ventilation systems can adjust airflow in real time, responding to the specific requirements of different areas within the mine.

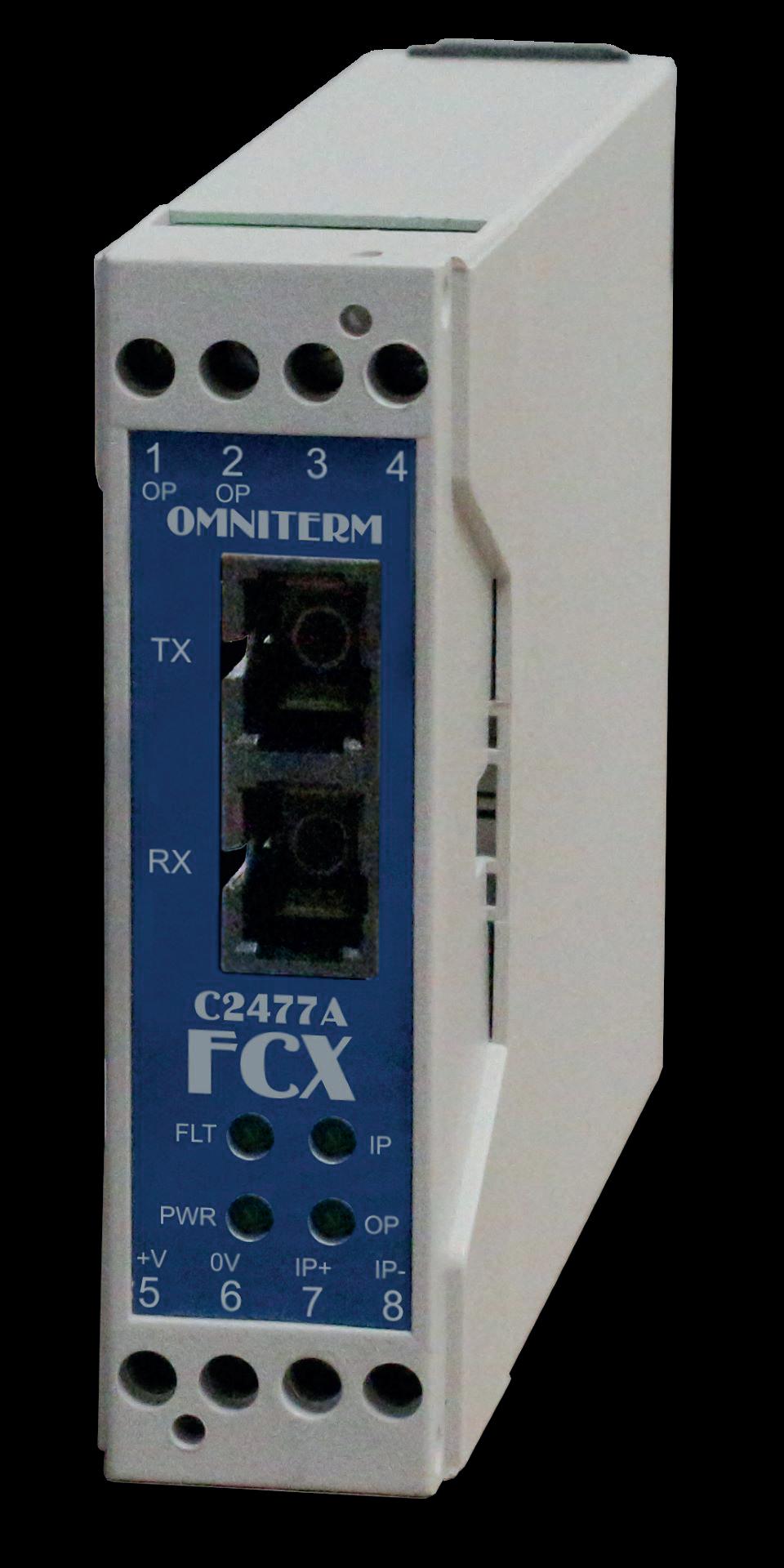

For example, Becker Mining’s smart ventilation fans integrate seamlessly into mine networks via Wi-Fi and fibre optics. This allows the end user to optimise airflow in real time based on operational activities to enhance efficiency and safety. They employ advanced sensors and data processing capabilities to monitor critical parameters, such as motor current, airflow, pressure, temperature, and vibration. Tracking these critical parameters allows operators to detect bearing failure as early as possible and to monitor the movement of the impeller on the shaft or other contributions to excess vibration. This data is processed by a programmable logic controller (PLC) and displayed locally on the fan’s interface and remotely via the mine’s supervisory control and data acquisition

(SCADA) system. This real-time monitoring allows for immediate adjustments and alerts, ensuring optimal performance and safety.

Another key feature of smart auxiliary fans is their semi-autonomous capabilities. They are equipped with constant monitoring and connectivity to mine networks, which enables real-time communication with the surface. They proactively detect blockages, insufficient airflow, or hazardous gas build-up and can automatically initiate shutdowns or alerts, preventing personnel from operating in hazardous conditions.

The semi-autonomous functionality also supports proactive maintenance scheduling, improving overall productivity by anticipating and addressing issues before they lead to costly downtime. When integrated with systems like Becker Mining’s SmartFlow™, these fans provide feedback and information remotely, allowing operators to adjust airflow based on occupancy, equipment usage, and environmental changes.

Early adoption in underground coal mines

Mines are increasingly adopting a newer generation of smart auxiliary fans due to their advanced intelligent capabilities and innovative designs. Becker Mining Australia recently partnered with an underground coal mine in New South Wales, Australia, to deliver 10 of its smart ventilation fans across two mine sites. This initiative was driven by the need to replace an ageing fleet with more efficient and technologically sophisticated equipment.

As the life of the mine extended, and operations moved further away from the surface, the need for additional and supporting ventilation became critical, as the existing surface ventilation infrastructure could not adequately provide for the expanded area. The decision to install the auxiliary fans was also influenced by the significant cost savings compared to installing new surface-level ventilation systems.

The fans, which feature a 910 impellor and 200 Kw motor, were installed throughout the mines, including next to conveyors along the longwall panel to provide both single-duct and dual-duct ventilation to the mine’s continuous miners. They were also used to ventilate older areas of the mine where additional work was required. The fans had capacity to support over 500 m of ducting while maintaining sufficient pressure and flow. These installations enhanced operational efficiency, improved safety, and reduced energy consumption.

Conclusion

The combination of advanced auxiliary ventilation fan design with intelligent features represents a significant leap in underground mining ventilation technology, and significantly improves working conditions in underground coal mining operations. As the underground coal mining industry advances towards greater efficiency, safety, and productivity, the integration of intelligent ventilation solutions is set to revolutionise underground mining ventilation practices.

Figure 3. Performance characteristics graph shows the flow rate, static pressure and motor KW power, and any given flow control position.

Dave Mueller, Martin Engineering, USA, explains how innovations such as impact cradles and belt cleaners can address the challenges of large material conveying.

Mined and quarried raw materials are extremely heavy and oddly shaped large rocks, some with jagged sharp edges. Due to the varying needs of different applications, the material can be transported as is and processed by the end customer. Therefore, beyond the needs of mines and quarries, bulk handlers

– such as ports, cement producers, and power plants – need heavy-duty conveyors to receive some raw materials before loading them onto vessels or sending them to the crusher.

Whether loaded by a hopper or transferred from another conveyor, hard rock punishes the belts and system components like idlers, enclosures, and cleaners. The demand on these systems is daunting, leading to premature equipment wear and excessive downtime. Designers at Martin Engineering’s Center for Innovation (CFI) have reimagined large material conveying and devised components that focus on safety while increasing production and reducing downtime.

Yes, large rocks can create dust

Watching the flow of tonnes of heavy material leaves little doubt that the conveyor system components can only handle so much wear. One of the main safety culprits is dust, which is ever-present as the material impacts the belt and shifts vigorously in the transfer enclosure and beyond.

Environmental and workplace safety organisations like the US Mining Safety and Health Administration (MSHA), Safe Work Australia, and the European Occupational Safety and Health Administration (EU-OSHA) have introduced strict regulations around respirable crystalline silica (RCS) to prevent work-related chronic lung diseases.1,2,3 Commonly found in materials like limestone, coal, and ore, RCS is present in a large percentage of the Earth’s crust, making it pervasive throughout the bulk handling sector.

Pressure from the weight can create deep slumps in the belt that release fugitive spillage and dust along the belt path. Without proper belt cleaning, compacted fines remain adhered to the belt as carryback and drop along the system’s return path, further reducing air quality and increasing labour hours for cleanup.

Supporting the belt

Moving millions of tonnes of raw material exponentially raises the chances of one rock landing precisely enough to damage the splice and create a highly unsafe incident. The force of loading can warp impact idler rollers and the bearings inside, but there are ways to avoid this. One is by restricting the drop height or slowing the descent of heavy bulk material from a direct impact on the conveyor belt. Operators have found that controlling material loading extends the life of the belt and the conveyor support structure. Another way to extend equipment life is to properly and completely support the belt in the loading zone using a cradle.

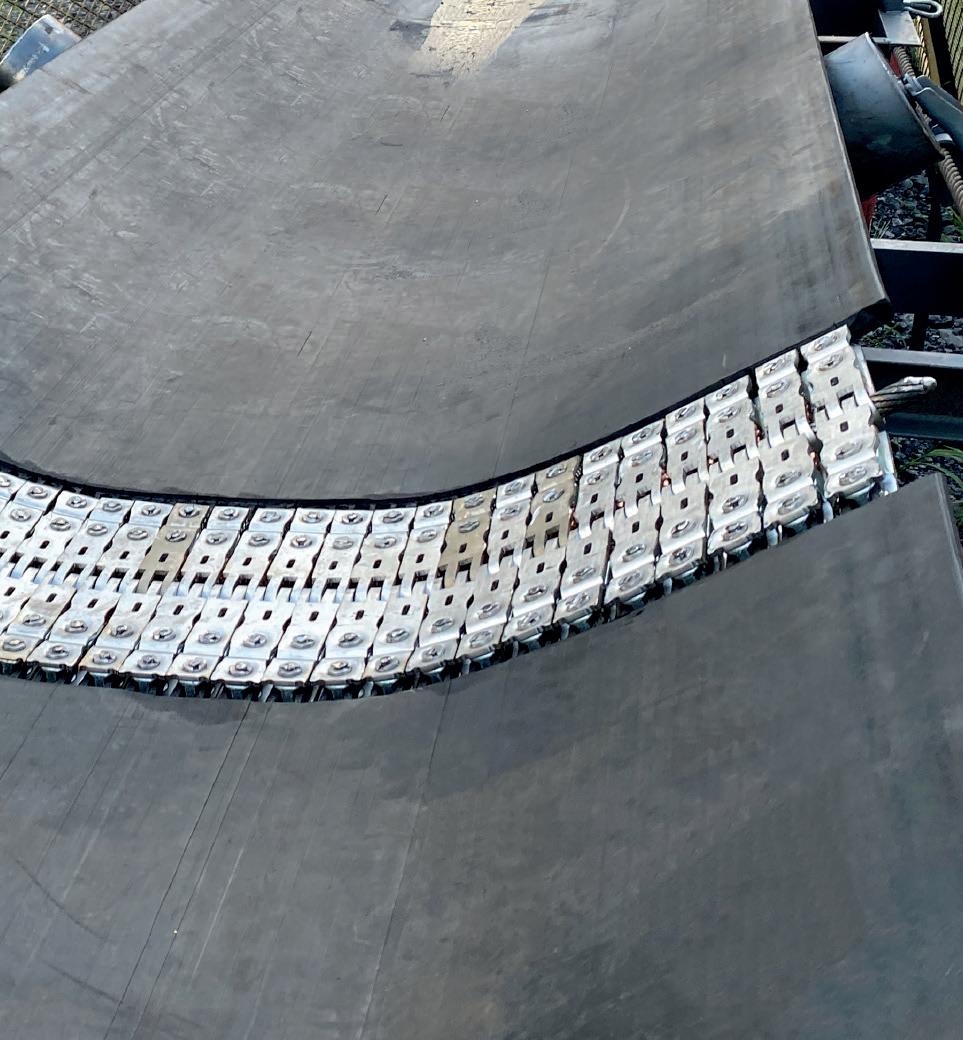

Martin engineers devised a heavy-duty impact cradle that supports the belt and absorbs the impact of loaded material in a consistently sealed environment (Figure 1). In contrast, impact idlers can leave unsupported gaps between idlers where dust and spillage can escape. Additionally, the bearings and rollers can misshapen over time, reducing the efficiency and safety of the conveyor system. Impact cradles are specially designed with a top layer of slick ultra-high-molecular-weight polyethylene (UHMW) moulded to a base of impact-absorbing styrene-butadiene rubber (SBR). The belt slides across them easily with little friction, while the bars give enough shock support that the belt is not damaged from precise hits on sharp edges. By eliminating the gaps between idlers, skirting creates a tight seal against bars, further reducing the amount of fugitive dust and spillage for more compliant and safer operations.

Figure 1. Impact cradles and support cradles are linked by transition rollers to avoid belt sag and retain the seal.

Figure 2. The tracker reacts the moment the belt drifts to make slight adjustments.

Figure 3. Offering edge-to-edge coverage, new cleaner designs are more resilient in punishing environments.

Your integrated single-solution provider for mining & tunneling

The HBT Group is an international association of high-performing companies that have combined their strengths to provide full-service solutions for the mining and tunneling industries. Our headquarters is located in Lünen, Germany, but we are present in every major mining market in the world — as well as emerging markets in mining and other industries.

We are excited for you to join us at MINExpo 2024 as we unveil the full breadth of what we offer our customers. Through new product introductions and an expanded product portfolio, we have dramatically expanded our capability to produce customer-centric solutions including the technology to support them.

Experts from all our brands will be on hand to share everything you need to know about the world-class products, cutting-edge technologies and value-added services we offer for customers in longwall mining, room and pillar mining, tunneling, manufacturing and a wide variety of other heavy industries.

Belt speeds above 650 fpm (3.3 mps) can exceed the limits of impact cradles. For higher-speed conveyors, a specially designed heavy-duty high-speed cradle with four trac-mounted idlers closely spaced to eliminate belt sag can support material impact without excessive drag. Innovative upper connector brackets link idlers throughout the load zone, allowing them to work in tandem as a unified structure. The elastomer bar suspension is engineered to match the CEMA rating specific to the application by absorbing shocks from impact. This maximises the life of the belt support structure and rolling components. Slide-out/slide-in roller frames allow idler service without the need to raise the belt or remove adjacent idlers, drastically reducing the time and labour needed for standard impact idler maintenance and replacement.

Sealing the transfer

Wear liners are ‘wear parts’ that protect the skirtboard wall of the conveyor transfer enclosure from splashing, shifting, and abrasion damage caused by large chunks of raw material hitting a fast-moving conveyor belt. Commonly, wear liners are sheets of steel either welded onto the internal chute wall or the chute is raised to accommodate an external liner design. These are generally accompanied by a long rubber skirt seal extending the length of the chute designed to seal against fugitive dust and fines.

For extra heavy-duty applications, wear liners can deplete quickly and may need extra protection. The canoe liner is made from durable urethane moulded around a rugged steel plate to absorb impact and abrasion. It is an engineered urethane strip moulded directly around a protective steel plate. The protective plate being integrated directly into the urethane liner is unique to Martin Engineering and prevents material from fouling the space between the urethane and the steel causing delamination. Separation tests have shown it delivers superior shielding of the skirt sealing system and skirtboard over other designs.

Replacement involves simply removing the worn units, cutting the end piece to fit and mounting each new cartridge, reducing what used to be a one or two day job to one or two hours. This unique design extends equipment life, offers longer periods of dust and spillage control, improves safety, and reduces maintenance, lowering the overall cost of operation.

Belt troughing and alignment

Retaining a tight seal and ensuring a centred load through the stilling and settling zones of the enclosure is key to a smooth, spillage-free trip to the discharge zone. Due to the weight of the material, friction of any kind can be a power issue, so a combination cradle offers sealed load support with bars on the wings and heavy-duty high-speed rollers at the centred base of the unit where the pressure is greatest.

Although the settling zone helps centre the load, it can shift on its path toward the discharge zone. This is commonly due to travelling over idlers which can create a slight bump, disrupting the material’s position. When large material shifts, it can destabilise the load to one side, causing the belt to drift off centre. This is generally followed by excessive spillage, contact with the conveyor structure, belt edge damage, and inadequate cleaning at the head pulley.

Broken idlers do not just happen at the loading zone. Dust, weight, and wear affect rolling components down the entire system both on the carrying side and return side. A broken or seized idler can cause the belt to drift towards the conveyor structure. High-speed friction contact between the belt and the seized idler and/or the stringer damages the unprotected underside and edge of the belt. Worse yet, heat from friction can exceed the belt’s fire-retardant threshold, potentially leading to catastrophic fires that are quickly carried by the system throughout the site.

The heavy-duty tracker uses sensing rollers that ride on either side of the belt edge and detect slight variations in the belt path. Triggered by the force of a wandering belt, the sensing rollers automatically position a pivoting idler in the opposite direction of the misalignment. The lever action requires less

Figure 4. Broken equipment, spillage, and improper idler spacing all culminated in expensive consequences.

Figure 5. High-speed impact cradle has four rollers that can be interlocked for integrated performance.

force to initiate the correction, so slight adjustments retain consistent contact between the belt and idlers and require less energy to realign the belt. Strategically placing units along the carrying side and return side ensures a true belt path through the entire rotation regardless of load shifts (Figure 2).

Cleaning caked-on carryback

Heavy-duty environments put demands on cleaners that cause the blade to degrade faster, need more monitoring and tensioning, and require replacement sooner than other applications. Moreover, during transfer and transport, vibration and gravity coax fines towards the centre of the belt where the greatest pressure from heavy material is applied. Scratches, cracks, and divots on the belt surface provide a convenient place for pressurised dust and fines to get packed and easily slip past primary cleaners (aka scrapers). Once on the return path, they drop, causing dust emissions, fouling return rollers and piling under the system requiring cleanup.

New designs in heavy-duty belt cleaners have reimagined the approach to cleaner technology. The innovative design incorporates a matrix of tungsten carbide scrapers installed in a three-dimensional helix angle across the face of the discharge pulley. It is tensioned lightly against the belt to prevent damage to the belt or splices and requires no re-tensioning after installation for the life of the blade. Despite extremely low contact pressure, field tests have revealed the unique blade design to have significantly superior results over standard primary cleaners (Figure 3).

The secondary cleaner is designed to clear the remaining dust and fines, resulting in a significant reduction in carryback, dust, and spillage that eludes the primary cleaner. Independent 6 in. wide blades with carbide tips are mounted on a stainless-steel assembly. Each tip is supported by spring-loaded arms at both ends that react to fluctuations in the belt. With up to four times the equipment life of conventional cleaners, the primary and secondary cleaner systems have drastically improved safety with fewer inspections and cleanup, reduced maintenance costs, and significantly lowered the cost of operation.

Coal mine in Witbank, Mpumalanga, South Africa

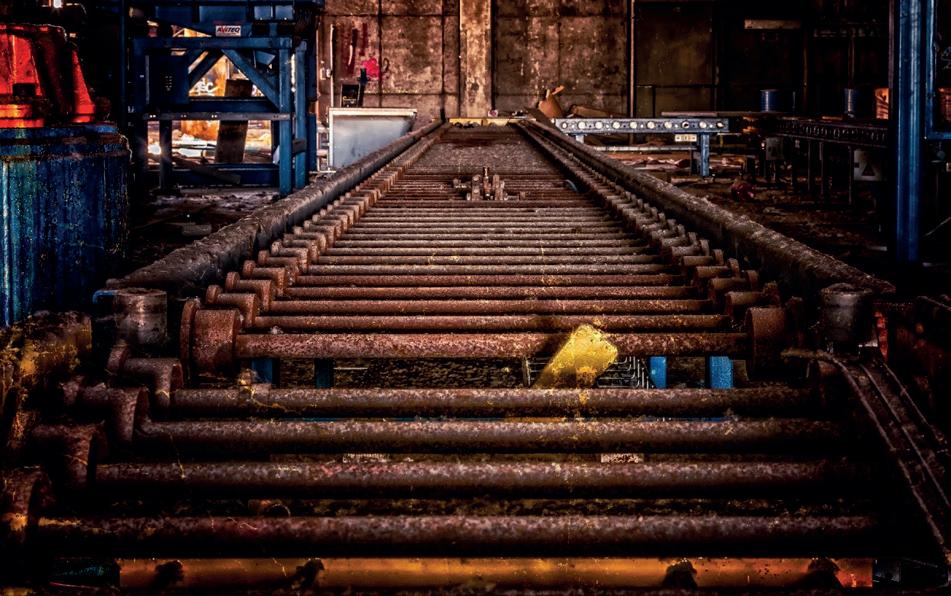

A coal mine in Eastern South Africa producing 3.1 million tpy of coal was experiencing heavy spillage and system damage along the length of a main conveyor due to inadequate loading zone equipment. Impact idlers allowed excessive belt sag, causing high volumes of spillage. Dust and fines fouled idlers, and rocks became lodged between the belt and the skirt, resulting in unscheduled downtime due to frequent equipment failures and

chute liner replacements. Material that had built up threatened to encapsulate the belt return, so labour was diverted for cleanup, further raising operating costs (Figure 4).

Technicians from Martin Engineering South Africa were invited to offer a solution. They recommended the installation of seven high-speed impact cradles along the length of the module 3 feeder unit (Figure 5). Using elastomer bar suspension to absorb shock from impact, the specially designed idlers exceed the operating limits of typical impact bar-type belt support cradles. The rolling components minimise friction on the belt and maximise the life of the belt support structure. Low-friction polyurethane Martin® ApronSeal™ Single Skirting was also installed to contain material and retain a tight seal on the running belt, further reducing spillage.

Six months after the installation, the volume of spillage has been reduced considerably, and the sealing system remains durable because no material is entrapped beneath the seal. The lack of fugitive material has mitigated wear and tear on components and reduced the amount of labour needed for cleanup, maintenance, and replacement of broken equipment. “We’re very happy with the end result”, said a plant manager. “The project was so successful that we are going to convert the other feeders in the plant (up to 14 more transfer points). This has definitely decreased the cost of operation.”

Conclusion

Heavy raw material is unpredictable, which can have a serious effect on conveying systems and operations if the system is not properly designed to handle and adapt to change. A lack of predictability leads to unscheduled downtime and can veer production away from forecasts. The pressure to meet demands often does not coincide with budgets for new equipment that offers a long-term solution.

Conveyor design engineers recommend taking a holistic view of the system and choosing solutions that address the causes of downtime and workplace hazards from loading to discharge. Investing in modern technology that provides a longer equipment life, better results, and a greater return on investment (ROI) over the long term leads to higher production and a lower cost of operation.

References

1. ‘Respirable Crystalline Silica- Final Rule’, US Mining Safety and Health Administration (MSHA), (April 2024), www.msha.gov/ regulations/rulemaking/silica

2. ‘Crystalline silica and silicosis’, Safe Work Australia, (March 2024), www.safeworkaustralia.gov.au/safety-topic/hazards/crystallinesilica-and-silicosis

3. ‘Respirable Crystalline Silica’, European Occupational Safety and Health Administration (EU-OSHA), (May 2023), https://oshwiki. osha.europa.eu/en/themes/respirable-crystalline-silica

Imran Aslam and Nimra Hussain, SECMC, Pakistan, describe the sustainability initiatives that have helped to enhance environmental resilience around a coal mine site and contribute to biodiversity goals.

The Thar coal project is key to the energy security of Pakistan, as it taps into vast reserves of indigenous fuel. The utilisation of Thar coal is directly linked to the prosperity of the nation, providing a sustainable and reliable energy source. Recognising the importance of balancing economic growth with environmental stewardship, Sindh Engro Coal Mining Company (SECMC) has adopted sustainable mining practices and launched multiple projects to showcase its commitment to the environment. One such project is the Thar Million Tree (TMT) project, an ambitious afforestation initiative in the harsh desert conditions of Thar.

Greening the desert

The TMT programme is a visionary initiative aimed at transforming the arid landscape of the Thar Desert into a thriving green ecosystem. Utilising the Miyawaki technique over 70 acres, SECMC embarked on the task

Figure 1. Thar Million Tree (TMT) – One of Pakistan’s largest afforestation projects by SECMC.

of planting 1 million trees. The Miyawaki method, developed by Japanese botanist Akira Miyawaki, involves planting native species in dense clusters to simulate natural forest growth, significantly accelerating the maturation process. This approach was adopted to tackle the challenging conditions of the Thar Desert, focusing on creating a self-sustaining ecosystem that requires minimal maintenance after the initial establishment period.

The project spanned several phases, beginning with extensive soil preparation and the selection of appropriate native species, including Prosopis cineraria, Vachellia nilotica, and Tecomella undulata. Given the harsh desert conditions, ensuring the survival and growth of the trees was a formidable challenge. Multiple innovative irrigation techniques, including drip and pitcher irrigation, were employed to optimise water usage and ensure that each tree received

adequate moisture. In addition to native species, other tree varieties were planted, including Azadirachta indica and Albizia lebbeck, that can withstand high salinity levels, utilising saline water sourced from mine dewatering operations. The coal seams at the Thar project are interbedded between the coal seam roof and coal seam bottom aquifer, necessitating a robust system for continuous dewatering. This saline water is then repurposed for the TMT project, exemplifying an innovative approach to resource utilisation and sustainability.

As part of the broader TMT programme, one of the largest private sector nurseries in the province, with a capacity of 500 000 saplings, was established. This nursery not only supplies trees for in-house plantation, but also donates saplings to various organisations with similar environmental missions. These donations are part of a central strategy to support and collaborate with other entities committed to sustainability, amplifying the impact of their efforts.

In addition to the large-scale afforestation efforts, a green park was developed to provide a recreational facility for the local community. This park, designed as a verdant oasis in the desert, offers residents a place to relax and enjoy nature. The creation of the green park underscores the dedication to enhance the quality of life for the local population, offering a tangible benefit alongside the environmental gains.

SECMC’s commitment to sustainability extends beyond its immediate projects. By donating saplings to NGOs and other organisations, a culture of environmental responsibility is fostered that transcends its operational boundaries. This collaborative approach ensures that the benefits of the afforestation efforts are widespread, enhancing the region’s overall ecological health.

Community empowerment is at the heart of the strategy behind this project. By involving local residents in multiple plantation campaigns and the development of the green park, a sense of community ownership is built. This empowerment is crucial for the long-term success of the projects, as it ensures ongoing maintenance and protection of the newly established green spaces.

Furthermore, the TMT project has had a profound socio-economic impact on the local community. It was ensured that all labour for the project was locally hired, providing much-needed employment opportunities to over 60 residents. This approach not only supported the local economy, but also allowed the workers to witness firsthand the transformative impact of their efforts. These labourers have seen the barren desert evolve into a thriving green space, fostering a deep sense of pride and ownership in the project.

Ecological impact of the TMT project

The International Union for Conservation of Nature (IUCN) was engaged for an in-depth evaluation of

Figure 2. TMT area before execution of project.

Figure 3. TMT area after completion of project.

Figure 4. Top view of Miyawaki plantation at TMT.

the environmental impact of the TMT programme, in which carbon stock assessment in project areas, along with biodiversity factors, were thoroughly assessed using soil sampling and tree biomass analysis. Observation of fauna was achieved using hand netting, passive sampling through pan traps, and nocturnal surveys.

The study revealed that approximately 300 000 t of carbon is stored in trees and shrubs of different plant species that have grown under the ambit of TMT over the period of five years. The strategic, dense planting arrangement and the rapid growth of these trees have led to a substantial increase in carbon capture, making a meaningful contribution to climate change mitigation efforts.

The introduction of a diverse array of native plant species has fostered a thriving habitat for a wide range of wildlife, including various birds and insects. 22 bird species belonging to 14 families were seen in the project area. Two of these species, the tawny eagle and Egyptian vulture, are declared vulnerable and endangered respectively in the IUCN Red list of Threatened Species.

This indicates that the project has played a critical role in restoring ecological balance and enhancing environmental resilience.

Prospects

and continuous innovation

TMT is an ongoing project with a vision for continuous growth and innovation. Future plans include expanding the plantation area, introducing more diverse species, increasing carbon sequestration potential, and enhancing irrigation techniques to further improve water efficiency. Research and development will play a crucial role in these efforts, ensuring that the project remains at the forefront of environmental innovation.

The success of the project has already begun to attract attention from other regions facing similar challenges and SECMC is now exploring opportunities to share its expertise and collaborate with other organisations and governments to replicate the success of the Thar initiative in other arid and semi-arid regions.

Conclusion

The TMT project has created a vibrant ecosystem in the heart of the Thar Desert, contributing to global carbon sequestration and biodiversity goals. As SECMC continues to innovate and expand its environmental initiatives, the transformation of Thar stands as a beacon of hope and inspiration. The project is a testament to what can be achieved when communities, corporations, and nature work together towards a common goal.

Thar is not just changing Pakistan through energy security; it is also contributing to a more sustainable and resilient world.

eft unchecked, spillage and airborne dust can be extremely dangerous and expensive. Fugitive material in any form is a dirty and costly concern, whether to workers’ health or to belt conveyor systems. Martin® Transfer Point Kits and associated components (such as belt support, sealing and tracking) diminish spillage and dust-related problems — helping your overall operations run cleaner, safer and more profitably.

Think Clean®

Visit us in Las Vegas September 24 – 26 Booth 4315

Derrick Jansen, TerraSource Global, considers the importance of understanding the specific requirements of an operation when selecting a crusher, in order to ensure optimal performance.

When it comes to selecting the right type of crusher in today’s coal processing operations, there are a myriad of options and styles to choose from. With over 300 years of combined experience, TerraSource Global has the knowledge and data to help in selecting the perfect crusher for every coal application.

Selecting the right crusher

Feed size and product size are the primary considerations when selecting the best machine. Capacity (i.e. tph) is another important consideration when selecting the proper size machine.

Large to medium feed

Large run-of-mine (ROM) pieces over 24 in. are typically managed by roll crushers (single and double roll) and sizers, due to their high torque and low-speed compression crushing. Roll teeth grip the material, pulling it through where it is compressed and fractures naturally. These machines generally use less horsepower than hammermills or impact crushers for various reasons:

1. The roll assemblies do not maintain a large moment of inertia.

2. Compression crushing generates less resistance compared to impact crushing, where slowing down a rotor due to impact can create significant resistance.

3. Larger feeds are easier to crush due to natural fracture lines – imagine dropping a large chunk of coal from a ladder where impact will likely cause

it to break apart into smaller pieces because of its significant mass and inherent weak points.

4. They spin at lower speeds compared to a hammermill or impact crusher.

Medium to small feed

Crushers in this category – such as hammermills, impact crushers, cage mills, double roll crushers, and roll mills – often serve as secondary or tertiary crushers. At this stage, there are more options available for achieving the desired product size. Impact crushers are the most common, yet require more horsepower as the natural fracture lines of the material are no longer present. Using the same ladder analogy, dropping a smaller chunk of material from a height likely will not cause it to break apart.

Common crusher types for large material

Single roll crushers

Single roll crushers use a large roll with teeth to crush material against an adjustable, curved breaking plate. The teeth help pull large pieces into the gap for crushing, while the plate serves multiple purposes:

1. To generate varying sizes of product.

2. To fine-tune the gap to set exact specifications.

3. To account for wear in the roll teeth or breaker plate.

4. The breaker plate, backed with a system of springs and toggles, swings out when an uncrushable piece (i.e. tramp material) enters the flow.

Due to its low speed (anywhere from 30 – 100 RPM), the single roll crusher generates high torque, allowing it to process a head of material stacked on the roll, which typically comes from a reduction in speed from a V-belt driven motor that rotates a countershaft. The countershaft is then connected to the main roll shaft via a pinion and bull gear for further speed reduction. Typically installed under a large hopper, it handles high volumes and provides steady discharge for downstream metering. Pennsylvania Crusher Corp. (PCC)™ single roll crushers produce product sizes anywhere from 2 in. (50 mm) to 8 in. (200 mm), with a typical reduction ratio of 6:1 to 8:1.

Sizers

Sizers are another common machine for processing heads of material, including coal and hard rock, between two slow-spinning, fixed rolls. This design lacks tramp relief and fine adjustment, but it effectively crushes hard rock mixed with ROM material.

Despite the perceived drawbacks, minor adjustments are generally unnecessary at this stage of crushing. The high torque is achieved through a

Figure 1. PNC single roll crushers crushing action.

Figure 2. PNC Mountaineer II Sizer.

directly driven motor connected to a gear reducer. Sizers can be operated in two distinct ways:

1. With the rolls spinning towards each other; this forces material through the gaps of the rolls (the most common method).

2. With the rolls spinning away from each other; the rolls crush material against the sides of the frame, which are equipped with teeth that pass between the roll teeth.

Sizers are typically low in height, but longer in length, than single roll crushers. Roll lengths can vary anywhere from 30 in. to over 120 in. long. PCC sizers offer product sizes anywhere from 4 in. (100 mm) to 12 in. (300 mm). Sizers have a typical reduction ratio of 6:1.

Double roll crushers

Double roll crushers are versatile machines and another more common means for sizing large feed material. They feature two rotating rolls spinning towards each other at higher speeds (300 – 400 RPM) compared to sizers and single roll crushers. This faster speed enables them to handle higher capacities within smaller footprints but reduces machine torque, so they cannot handle material head. Typically placed after vibratory feeders, screens, or conveyors, their width should match the feeder’s width to ensure material is spread uniformly across the roll for even wear and maximum capacity use. Unlike a sizer, a double roll crusher gap can be adjusted. One roll is typically fixed, while the other can be adjusted, allowing for tramp relief, as using a nitrogen-backed hydraulic piston for larger models often serves as an adjustable ‘spring’. Roll crushers have a myriad of different tooth profiles for varying sizing applications.

Furthermore, the double roll crusher is available in single stage (two rolls) and double stage (four rolls) configurations. Each stage can handle a 4:1 to 6:1 reduction ratio, allowing a double stage crusher to achieve a 16:1 reduction ratio. Depending on the tooth profile and feed size, these crushers can produce as large as 8 in., or as small as ¼ in., product size. Gundlach™ double roll crushers are some of the most versatile crushers on the market today.

Small material crushers

Hammermills

Hammermills have a horizontal rotor with swinging hammers around the outer diameter of the rotor that impact material fed through an inlet chute. The rotor often spins at higher speeds (typically 600 – 1800 RPM) to generate enough force to break the material upon hammer impact, throwing it against breaker plates on the frame as secondary impact. Then, screen grates with customisable sizes control discharge top size material.

Oversized material recirculates until small enough to pass. Due to this control, hammermills have a smaller capacity than other impact crushers. PCC offers the single-direction Granulator™ and reversible hammermills for extended hammer and screen life. Jeffrey Rader™ provides directional hammermills with various hammer options. Hammermills typically have a 14:1 reduction ratio.

Impact crushers

Impact crushers function like hammermills, with a large rotor impacting material against a breaker plate. These machines are often reversible, allowing even wear on both sides of the hammer and the use of

Figure 3. Double roll crusher.

Figure 4. Hammermill crusher.

the opposite breaker plates. The breaker plates wrap around the rotor, providing more impact surface. Unlike traditional hammermills, impact crushers have an open bottom, increasing capacity and handling sticky materials better by allowing material to freely discharge. Impact crushers can handle 4 – 6 in. feed size and produce product sizes from ⅛ in. to ½ in., depending on speed. PCC offers two styles of impact crushers:

1. CAL Impactors™, which can handle up to 10 in. material and generate ½ in. minus product size with a 10:1 reduction ratio.

2. Coalpactors™, which can handle up to 6 in. material size and generate approximately ⅛ in. product size with a 16:1 reduction ratio. Coalpactors were designed to achieve a specified product size distribution for fluid bed boiler power plants.

Cage mills

Cage mills use a circular cage with impact bars instead of a rotor with swinging hammers. Cage mills do not have traditional breaker plates, rather they rely on multiple rows inside the cage for material impact. Some have one rotating cage and one fixed cage, whereas others have two counter-rotating cages. Material enters the cage mill from the middle of the circular cage and impacts material through the various rows before exiting the machine. Several impacts occur rapidly, which makes cage mills effective at generating small product without generating excessive unwanted ‘fines’. As open bottom machines, cage mills achieve high capacities. Gundlach’s CagePaktor™ features single or dual rotating cages, accessible via a large front door, while competitor cage mills require removal of the motor and drive for access. Single rotating cages typically have an 18:1 reduction ratio, while dual rotating cages can achieve up to 40:1.

Double roll crushers / roll mills

As previously mentioned, double roll crushers are versatile and adjust roll gaps for desired sizes. For sizes under ½ in., hard-facing patterns replace teeth. Gundlach’s NanosizR™ works like a roll crusher but is designed to handle smaller sizes (approximately ±⅛ in.) with thick-walled iron rolls surfaced with small, corrugated teeth. They have a precise product size distribution for concerns with unwanted fines, but require a smaller feed size due to their 4:1 reduction ratio.

Conclusion

In summation, the key to selecting the right crusher lies in understanding feed size, product size, and capacity requirements. For large to medium feeds, roll crushers and sizers excel, offering efficient compression crushing with low horsepower usage. Single roll crushers handle large pieces with high torque, while sizers process heads of material effectively. Double roll crushers offer versatility and higher speeds for large feed sizes. For small materials, hammermills, impact crushers, cage mills, and double roll crushers excel at generating the desired product size efficiently. Each type is uniquely suited for specific applications, ensuring optimal performance based on material characteristics and operational needs.

Figure 5. Impact crusher.

Figure 6. GC CagePaktor™ Material Flow Thru Cages.

Franklin Moore, Flexco, USA, addresses the need to be proactive in conveyor belt maintenance, in order to combat downtime and mitigate unnecessary costs.

The world of heavy-duty coal mining is incredibly expensive.

From the initial investment of site setup, to maintaining equipment, to labour needed to complete daily jobs, and ensuring a site is meeting the strict standards set by regulatory organisations, operating costs add up.

But what is one of the most expensive factors that mines often encounter and are typically unprepared for? Downtime. Unfortunately, some plant managers ignore downtime, almost as though if they do not acknowledge it, it will not happen. However, this could not be further from the truth.

One consistent trait among those who are successful in negating downtime is that they are prepared to react. They have a proactive process in place that allows them to diagnose their problem areas and quickly come up with a solution that gets their belt conveyor systems back up and running.

Overall, downtime cost can be difficult to calculate. There are many factors that go into evaluating its impact, and costs can vary widely depending on what sites choose for their belt repair solution.

So, what are the best ways to quantify the impact of a downtime incident, and what can site managers do to decrease their financial impact?

The cost and effect of downtime

Downtime is financially stressful for everyone in heavy-duty mining. However, there are many factors that come into play that determine just how expensive it can be.

The impact of downtime and how sites react to it can be dependent on the type of conveyor and application that a site is using it for. For example, the downtime of a miles-long overland belt will have a much more profound impact than that of a shorter conveyor that has a redundant system in place.

There are some downtime-related pain points that are consistent across applications which will eat into a site’s productivity and profitability. From addressing labour needs to damaging customer relationships to losing out on production, heavy-duty sites should be aware of what their downtime is really costing them.

Diminished output

Arguably the most costly aspect of plant downtime is the loss of product output. Based on common heavy-duty industry production estimates, a site can expect to lose anywhere from US$60 – 70 000/hr for a downed longwall mine and US$50 000/hr with a section mine. The brunt of this figure is because product cannot be moved from point A to point B, meaning demand cannot be met and mines fall behind. In turn, quotes cannot be filled, and checks cannot be cashed.

Furthermore, this lost time can prevent sites from stockpiling material for future use, forcing them to work on a more hand-to-mouth basis rather than be prepared for order requests before they are received. Essentially, downtime reduces a plant’s reserve material from a mountain to just a small pile.

Lost labour

Another very costly facet of running a heavy-duty mine is in the allocation and implementation of labour. When a downtime incident occurs, time becomes a site’s most

scarce resource. Crew members are forced to remove themselves from their current job to help repair the belt, further delaying their ability to finish their tasks in a timely manner. In turn, scheduling becomes hectic and other areas of production can suffer.

If the condition of the belt is severe enough, more workers may need to be brought in to help, with some even needing to work overtime. The amount of labour needed for repair only multiplies the cost of downtime, and finding a solution becomes paramount.

Damaged distribution network

A site can be susceptible to enormous costs if material is not shipped in their designated time frame. An instance where this is relatively common is with handling and conveying coal at transportation hubs and terminals. When a boat is waiting in the port to be loaded with coal and a downtime incident occurs, it becomes a headache to finish queued jobs and coordinate their deliveries. In turn, multiple customer deliveries can be negatively impacted, and the operation may even be liable to pay shipping companies for getting behind schedule.

The true cost of downtime can be volatile due to the ever-changing market price of coal, along with a site’s specific conditions. A certainty, however, is that the financial impact of downtime will increase if a site’s maintenance team does not have the proper tools in place to quickly react.

Solutions to combat belt conveyor downtime

There are a few schools of thought when it comes to choosing the best method to negate downtime at coal mining facilities. Some facilities have a proactive maintenance plan in place that allows them to react quickly, while others are more ‘wait and see.’

For immediate repairs of ripped or damaged belts, maintenance crews will need to choose between their belt repair options and decide how much cost they are willing to eat. Whether a site feels like they can wait or if they need immediate repairs, there are many solutions available.

Vulcanisation

The timeline for a vulcanised repair depends on a site’s location and the availability of a crew and their presses. The technology is incredibly specialised, and the process requires skilled labour to complete the job. When a downtime incident occurs, a site that wants to vulcanise is at the mercy of an outside resource, and the process of scheduling vulcanisation can take some time.

Additionally, complications with vulcanisation can arise when factoring in weather and climate conditions. Bringing specialised equipment to the source of downtime can be challenging in near perfect conditions, but when dealing with heavy rain, high wind speeds, and extreme temperatures, it becomes that much more difficult.

Overall, if the process will take three or more days, consider if production can wait for it, or if a more

Figure 1. Mechanical belt fasteners allow operators to quickly react, getting their belts up from downtime much faster than other methods.

immediate, short-term solution could help. This is a question that a plant manager must ask themselves when making decisions in a moment of downtime.

Mechanical belt fasteners

Depending on the severity of the damage to the belt, maintenance crews might want to consider adopting a simpler measure: mechanical belt fastener repair systems.

As alluded to before, vulcanisation can be a good option for some belt repairs, it can just take a long time to schedule and install. Alternatively, by using a mechanical fastener, a site can get a conveyor belt back in use within hours, using tools it already possesses and that its maintenance teams are comfortable with.

There are many mechanical belt fasteners on the market, and a decent portion of them can be prepared in advance, making installation during downtime that much faster. Not only are they significantly cheaper than vulcanisation, but this cost is only amplified when factoring in the time saved waiting for a third-party service.

Belt repair in action: Coal facility drastically reduces downtime with steel cord belt fasteners

A busy coal transport facility was consistently facing costly downtime incidents and needed a more fast-acting belt repair solution. Deadlines came and went, and costs were

increasing as they were not able to meet their customers’ orders in a timely manner.

Anticipating a busy winter season, the site manager sought out a preventative belt repair solution that could get their future downed conveyor belts back into action quickly. After meeting with a belt conveyor solutions provider, they decided to go with a steel cord belt fastening system. Not only would they be able to install them quickly while they waited for belt vulcanisation, but the site manager was impressed with its pre-splice capabilities.