03 Comment

05 News

10 Winter Has Come

Imran Akram, IA Cement, considers the state of the global cement market and outlines the prospects for what may be a difficult year ahead.

17 Streamlining Dispatch With Drive-Through Storage

Rebecca Long Pyper, Dome Technology, explains why more and more cement companies are inquiring about drive-through dome storage systems.

22 Keen On Cleaning!

Jeff Shelton, Dracyon Corp, discusses why many cement plants are not getting the most out of their air cannon systems, and the steps that can be taken to ensure they perform as effective cleaning devices.

29 Revisiting Rapid Recovery And Repair

Florian Laux, REFKO Feuerfest GmbH, revisits the performance of a lining technology that has been used to repair cement kilns in a number of different plants.

35 The Role Of Refractories In A Sustainable Fuel Strategy

Kayra Kurt and Divyendu Tripathy, Calderys, introduce a new refractory brick designed to offer a flexible and cost-effective solution to the pyroprocessing challenges posed by alternative fuels.

38

The World Cement Refractory Review provides a catalogue of some of the leading players in the refractory sector. This year’s edition includes contributions from: Bricking Solutions, Calderys, HASLE Refractories, SILICON, The Siam Refractory Co., Ltd., and Wahl Refractory Solutions.

44 When In Doubt, Upgrade Your Spout Austin Anderson, Vortex Global, discusses the multitude of devices and accessories developed to improve loading spouts within a cement plant, minimising dust pollution, and optimising loading procedures.

49 Designed For Smart Modification!

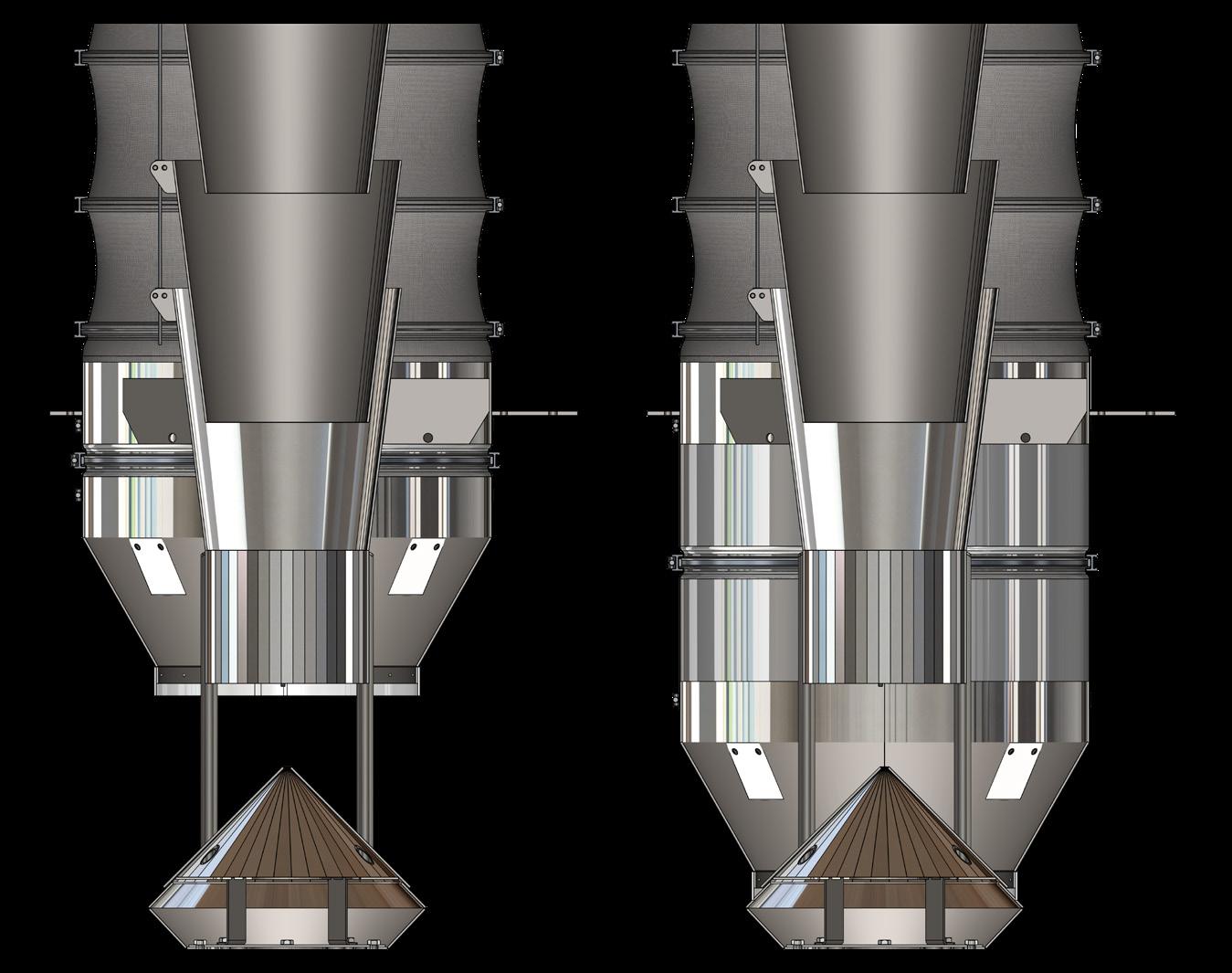

Andre Vos and Ingmar Holst, Claudius Peters, introduce a new development in clinker cooler technology that utilises standard parts to optimise production processes and minimise CO2 emissions.

53 Overcoming Constraints On Kiln Construction

Lisa Hartig and Sebastian Maibaum, IKN GmbH, outline the steps taken during the commissioning phase of a new pyro line at a German cement plant.

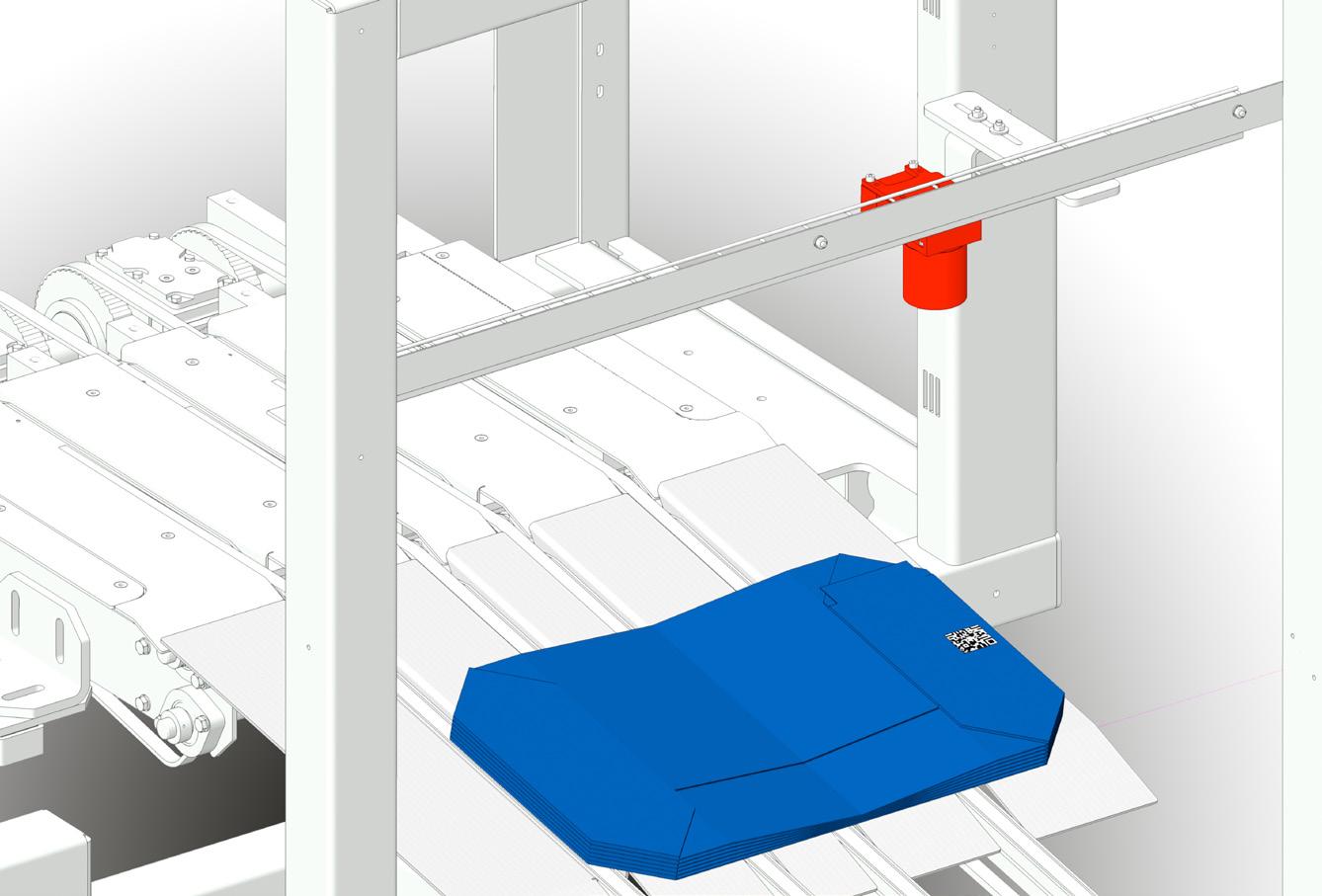

57 Bag Smarter, Not Harder Mirko Hoffmann and Alexander Hering, Haver & Boecker, discuss the impact of Industry 4.0 solutions implemented at a Croatian cement plant.

60 Bearing The Load: Strategies For Protecting Machinery

Ian Walton, SKF, details how taking a proactive approach to bearing management can help overcome the issue of premature machine failure in the cement industry.

65 Moving The Chains

David Page, FB Chain, explains how innovation through design, material, or installation can achieve new performance gains for conveyors.

69 Where Do We Stand With Sand?

Oldemar Meneses, Metso Outotec, illustrates the role of sand in the construction industry and considers what can be done differently to address sand scarcity.

January

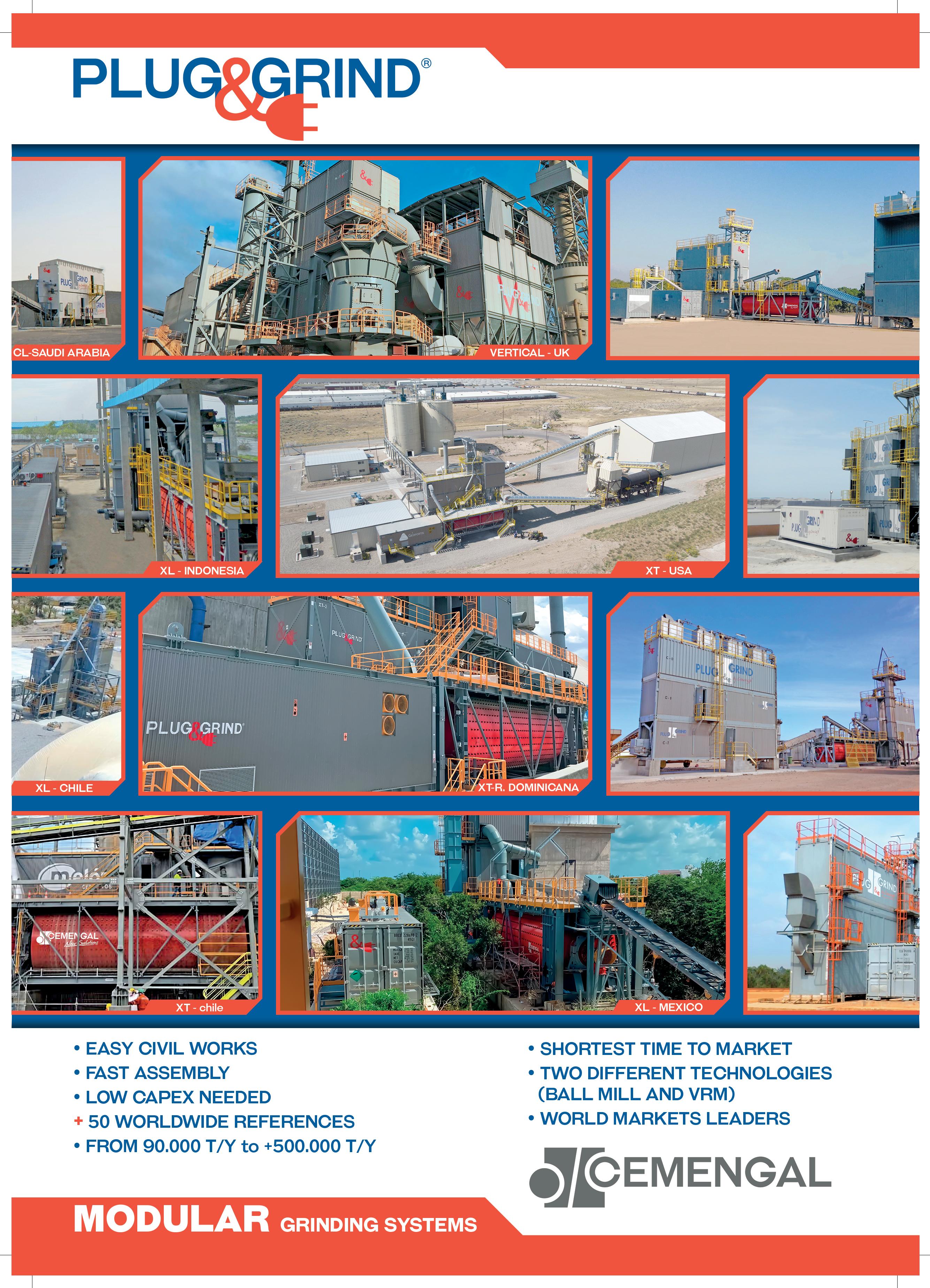

The Plug&Grind® modular grinding system is 10 years old. A decade in which horizontal and vertical grinding solutions have been developed, with four different sizes with production capacities ranging from 90 000 tpy to more than 500 000 tpy were introduced in the market. This has made Cemengal the world leader with more than 50 units sold worldwide.

HEKO offers the whole range of chains, rollers, sprockets and scrapers for reclaimers. HEKO products are proven in thousands of bucket elevators and conveyors, worldwide.

Our components for the cement industry: central chains, link chains, reclaimer chains, sprockets, bucket elevators and clinker conveyors.

Hello dear readers – welcome to 2023 and the January issue of World Cement!

Production: Kate Wilkerson kate.wilkerson@palladianpublications.com

Sales Director: Rod Hardy rod.hardy@palladianpublications.com

Sales Manager: Ian Lewis ian.lewis@palladianpublications.com

Sales Executive: Riccardo Saunders riccardo.saunders@palladianpublications.com

Events Manager: Louise Cameron louise.cameron@palladianpublications.com

Digital Events Coordinator: Stirling Viljoen stirling.viljoen@palladianpublications.com

Digital Administrator: Leah Jones leah.jones@palladianpublications.com

Digital Content Assistant: Merili Jurivete merili.jurivete@palladianpublications.com

Administration Manager: Laura White laura.white@palladianpublications.com Reprints reprints@worldcement.com

Annual subscription (published monthly): £160 UK including postage/£175 (e245) overseas (postage airmail)/US$280 USA/Canada (postage airmail). Two year subscription (published monthly): £256 UK including postage/£280 (e392) overseas (postage airmail)/US$448 USA/Canada (postage airmail). Claims for non receipt of issues must be made within 4 months of publication of the issue or they will not be honoured without charge.

Applicable only to USA and Canada: WORLD CEMENT (ISSN No: 0263-6050, USPS No: 020-996) is published monthly by Palladian Publications, GBR and is distributed in the USA by Asendia USA, 17B S Middlesex Ave, Monroe NJ 08831.

Periodicals postage paid New Brunswick, NJ and additional mailing offices. POSTMASTER: send address changes to World Cement, 701C Ashland Ave, Folcroft PA 19032

Copyright © Palladian Publications Ltd 2023. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior permission of the copyright owner. All views expressed in this journal are those of the respective contributors and are not necessarily the opinions of the publisher, neither do the publishers endorse any of the claims made in the articles or the advertisements. Uncaptioned images courtesy of Adobe Stock. Printed in the UK.

Palladian Publications Ltd 15 South Street, Farnham, Surrey GU9 7QU, UK Tel +44 (0)1252 718999 Email: mail@worldcement.com Website: www.worldcement.com

The holiday season is over and the days are getting longer (for those of us in the Northern Hemisphere anyway); it’s time to clear out what remains of the festive fare (or turn it into soup, freeze it, and forget about it) and make good on those New Year’s Resolutions that you were foolish enough to announce in front of other people.

In addition to those hastily made resolutions, this time of year is routinely accompanied by predictions and forecasts for the months ahead. Nostradamus, for example, is regularly quoted at this time of year for his predictions of momentous events: plagues, wars, the rise of tyrants, natural disasters, and so on. Call me cynical if you must, but I feel that I could also come up with prophecies such as “the lights of Mars will go out” or “Honey shall cost far more than candle-wax” if I knew I was going to be dead hundreds of years before anyone could fact-check me or ask for a bit more detail. Annoyingly, he is actually correct about the honey/candle-wax pricing situation, unless we’re talking about beeswax candles, but I digress… Happily, we don’t have to rely on Nostradamus and his thoughts on apiary-related byproducts to get some idea of what the year ahead might have in store for us. Less happily, the economic forecast for 2023 is mixed at best. Nikolaj Schmidt, Chief International Economist at T. Rowe Price was quoted by The Guardian as saying: “We see the world plunging into a global recession in 2023. The recession is going to be the result of the immense monetary tightening the central banks have administered over the past 12 months. As a silver lining, it will sow the seeds for a substantial retracement of inflation.” J.P. Morgan does little to raise the mood with the introduction for its 2023 Economic outlook: “The 2023 economic outlook for the United States is being defined by decelerating growth, rapid monetary tightening and moderating inflation.”

And whilst wholesale gas prices in Europe have fallen to levels last seen in October 2021 (a result of measures to reduce consumption and diversify supply along with a relatively mild winter), Russia’s invasion of Ukraine and the associated risks of escalation and further disruption continue.

Focusing specifically on cement, if you turn to pg 10 of this issue, you’ll find an executive summary of IA Cement’s Report for the year ahead. Whilst there are some positive notes – India and the Middle East, for example, are both expected to see continued growth – cement demand is generally expected to plateau or decline as inflation and high interest rates eat away at both public and private finances.

It’s not all doom and gloom, however. A few bright spots on the horizon include World Cement’s upcoming virtual conferences: EnviroTech (22 March) and Optimisation (14 June). Once again, these flagship events will be packed with high quality technical presentations and live Q&A sessions with industry experts from around the world. Stay tuned for more details.

And in the meantime, the team at World Cement wish you all a very Happy New Year!

The European Cement Association, welcomed the trilogue agreements struck by EU negotiators on the EU Emission Trading Scheme (ETS) and the EU Carbon Border Adjustment Mechanism (CBAM).

“The agreements on CBAM and ETS are essential to create a global level playing field on CO2 and support our sector in its transition to carbon neutrality. It is positive that the EU institutions strengthened some key aspects of CBAM”, commented Koen Coppenholle, CEO of CEMBUREAU. “We however regret that the adopted texts do not provide a structural solution for exports. Some countries export up to 50% of their domestic cement production and these will be at risk should no concrete export solution be found before 2026”.

CEMBUREAU, the European Cement Association, issued its Carbon Neutrality Roadmap in May 2020. A large number of innovation projects are currently being deployed by the sector to reduce CO2 emissions. Robust EU financing mechanisms, such as a focused ETS innovation fund and carbon contracts for difference, are critical to support breakthrough technologies to decarbonise our sector. A strong CBAM is also key to create a global level playing field on CO2

“Looking ahead, we need to focus on CBAM implementation and its watertightness, to ensure the mechanism fully equalises CO2 costs between EU and non-EU suppliers”, added Coppenholle. “It is also essential that policymakers support EU industries like cement, which are confronted with unsustainably high energy costs at a time some of our trading partners are launching massive subsidy programmes. CBAM, ETS and a strong innovation fund are essential part of the puzzle, but we look forward to Commission proposals for a truly ambitious industrial policy, as requested by the European Council in its meeting of 15th December”.

Topping out at new Menzel motor plant

Menzel Elektromotoren celebrated the topping out of its new headquarters on the outskirts of Berlin, Germany, on 16 December 2022. This modern electric motor plant being built on a 24 000 m2 plot will accommodate approximately 6500 m2 of production area, along with spacious offices and a cafeteria.

The new factory will feature the capacity to manufacture and test larger, heavier drive systems.

The production flow will be optimised, and Menzel will create numerous new jobs. The established, family-run company manufactures large AC and DC motors (up to 20 MW) for industrial facilities all over the world and, thanks to its large inventory, can also adapt drives for any requirements at short notice. The experienced team provides individual and reliable service, high product quality and expert advice on drive applications in all kinds of industries.

Lafarge Canada converts Nova Scotia cement plant to greener portfolio

Lafarge Canada recently announced the full transformation of its Brookfield cement plant’s (Nova Scotia) production to a greener portfolio.

Over the last four years, Lafarge Canada saved more than 140 000 t of CO2 by converting GU cement to OneCem in its plants across Ontario, Quebec, and Nova Scotia – the equivalent to taking 42 891 cars off the road, which would have consumed 59 640 854 l of gasoline. With the recent conversion of the Bath Plant’s GU production to OneCem, these numbers will continue to grow.

While cement typically represents only 11% of a concrete mix, it can account for more than 80% of all energy required to produce concrete.

Across Canada, Lafarge has produced over 6 million t of OneCem since 2011, and users can be confident in its performance whilst reducing the carbon footprint in the built environment and community.

From now on, the site’s production of general use cement (GU) ends and will shift to reduced carbon portland limestone cement – branded as OneCem –the company’s eco-efficient alternative. Brookfield is Lafarge’s third cement plant to be converted in 2022 and the first Atlantic Market plant to convert – the

others being the Bath Cement Plant (ON) in June and the Richmond Cement Plant (BC) earlier this year, in March.

World Cement Virtual Event: EnviroTech 2023 22 March, 2023 www.worldcement.com

SOLIDS Dortmund 2023 29 – 30 March, 2023 Dortmund, Germany www.solids-dortmund.de

OneCem is a sustainable product that presents up to 10% lower CO2 emissions while providing the same performance and durability. “We have been steadily moving the needle forward when it comes to cement decarbonisation and we will continue to honour our commitment in progressing our greener portfolio in Eastern Canada over the coming years. For us at Lafarge Canada, sustainability and profitability go together – our main goal is to keep partnering with our customers to advance sustainable construction and, at the same time, provide innovative world-class products,” commented Andrew Stewart, Vice President, Cement, Lafarge Canada (East).

According to Robert Cumming, Head of Sustainability & Public Affairs, Lafarge Canada (East): “We are excited to take our plant to the next level of decarbonisation. Our teams on the ground have been successfully showcasing our company’s values of passion, collaboration, and grit, and we couldn’t be prouder. This is a very important milestone in our net zero journey in Nova Scotia and in Canada as a whole,” affirmed Travis Smith, Plant Manager, Brookfield Cement Plant.

IEEE – IAS/PCA Cement Conference 23 – 27 April, 2023 Dallas, USA www.cementconference.org interpack 04 – 10 May, 2023 Düsseldorf, Germany www.interpack.com

The IRM India Affiliate has signed a memorandum of understanding (MoU) with UltraTech Cement Limited. IRM is the world’s leading professional body for ERM qualifications across 140+ countries and UltraTech is the largest manufacturer of grey cement and ready-mix concrete (RMC) in India. Both organisations will work towards enhancing ERM and risk intelligence in the Indian cement sector.

Additionally, Mr. Atul Daga, Executive Director and CFO of UltraTech, has joined IRM India Affiliate’s Strategic Advisory Board, to further guide the institute’s strategy and vision through his experience and guidance.

World Cement Virtual Event: Optimisation 2023 14 June, 2023 www.worldcement.com

The collaboration is part of IRM India Affiliate’s long-term vision of building risk resilience and a robust ecosystem of risk-intelligent organisations across sectors. As a part of this knowledge partnership, both IRM India Affiliate and UltraTech Cement will be organising webinars, roundtables, industry meetings, and thought leadership articles towards knowledge building for the sector.

The Indian cement industry ranked second in the world after China in terms of production and consumption, is considered to be one of the most environmentally conscious industries with the lowest carbon footprint. As per a Reserve Bank of India bulletin, India’s cement industry has made ‘remarkable progress’ by reducing CO 2 emissions by 36% between 1996 and 2017, moving from 1.12 t to 0.719 t between these years.

In the next 20 years, over 250 million people are expected to shift to urban areas of India. This will create a huge demand for cement production, likely resulting in a rise in input, and in process

creating requirements for mitigation strategies to avoid risks associated with the industry like environmental, sustainability, health, natural resources, and cybersecurity. The role of ERM will be crucial to ensure achievement of these objectives.

Speaking about the association, Atul Daga, Executive Director and CFO, UltraTech Cement said: “Risk management is key to build a sustainable business.

UltraTech has developed comprehensive risk management framework and integrated ESG into its ERM process.

We are delighted to partner with the Institute of Risk Management to further strengthen our enterprise risk management process and build a risk awareness culture for the industry. We look forward to this association being a mutually enriching one.”

Elaborating on the collaboration, Hersh Shah, CEO, IRM India Affiliate, said: “UltraTech Cement has well defined ERM and Environmental, Social, and Governance (ESG) processes in line with international standards and has also institutionalised sustainability across its value chain future proofing its business.

Our association with UltraTech Cement will set the stage for enhancing risk culture in the building materials sector through sharing of best risk practices across platforms.”

Mitsubishi Heavy Industries Engineering, Ltd. (MHIENG), part of Mitsubishi Heavy Industries (MHI) Group, has been appointed by Hanson UK to deliver the preliminary front-end engineering design (Pre-FEED) for a CO2 capture plant at its Padeswood cement works located in Flintshire, Wales.

The newly awarded Pre-FEED represents MHIENG’s third project involving CO2 capture at a cement plant, following a carbon capture and storage (CCS) feasibility study for Lehigh Cement Company in Alberta, Canada, and a CO2 capture demonstration testing programme currently underway for Tokuyama Corporation in Japan.

The project is part of a comprehensive effort to decarbonise the UK’s cement industry.

This plan constitutes the UK-based cement industry’s first adoption of CCS technology.

This Pre-FEED is part of a project that will deliver a CO 2 capture plant to the Padeswood Works. Once operational, the plant will capture 800 000 t of CO 2 per year and the plan is to store it in spent gas fields off the coast of North West England.

MHIENG will support the project by carrying out the Pre-FEED of a CO 2 capture plant applying its Advanced KM CDR Process™, CO 2 capture technology jointly developed with The Kansai Electric Power Co., Inc.

The UK Government has set ambitious targets for achieving net zero carbon emissions by 2050. To achieve this goal, it has been building the necessary infrastructure, including CCUS clusters that encompass all aspects of carbon capture, utilisation and storage (CCUS) for implementation at designated industrial zones. In October 2021 HyNet and East Coast Clusters were selected as the Track 1 CCUS clusters by the Department for Business, Energy and Industrial Strategy (BEIS). This project was subsequently shortlisted in August 2022 for potential funding when it was selected among a total of twenty CCUS and CCUS-enabled hydrogen projects chosen by BEIS to advance to the due diligence phase of its Track 1 Phase 2 cluster sequencing programme. Operational commencement of the CO 2 capture plant at the Padeswood Works is targeted for 2027.

MHIENG promotes the adoption of CO 2 capture technologies in diverse industrial applications globally: not only in conventional thermal power plants and chemical plants, but also in biomass power plants, steel mills, waste to energy plants, gas engines, ships, and amongst other applications. MHI Group is currently strengthening its position in the Energy Transition, and the development of a CO 2 solutions ecosystem is a core component of those initiatives. MHI Group will continue to help achieve wide-scale greenhouse gas emission reduction by introducing its high-performance CO 2 capture technology globally. It will also press ahead in developing new solutions to contribute to global environment protection.

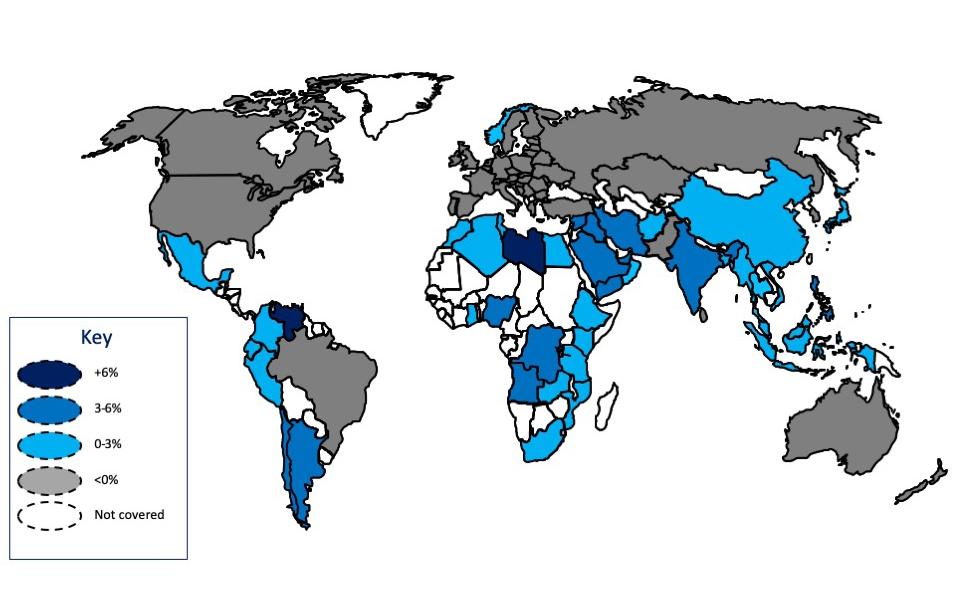

London-based IA Cement has published its Cement 2023 research report, a comprehensive document looking at expected trends in 2023. The report takes a detailed outlook at consumption prospects around the world, as well as a review of key risks, competitive pressures, and trading flows. It examines the world’s leading producers, and analyses the key topics of carbon emissions and the effect of rising interest rates on cement consumption. This article presents a summary from the report, analysing 2023 demand prospects by region.

Global cement consumption is expected to suffer the biggest drop in for decades in 2022. The world economy has slowed sharply since the Russia-Ukraine conflict began, while a double-digit decline in China means global consumption is likely to close 2022 with a decline of over 5%. Soaring energy costs have squeezed cement margins, while efforts to raise prices have begun to cause demand destruction.

In 2023 cement demand is expected to stabilise. Western countries are already in a recession, predicted to be mild in the US and more protracted in Europe.

Rising interest rates threaten a hard landing for housing bubbles everywhere, while public finances have been depleted by the pandemic and are now being diverted toward food and fuel subsidies. Policymakers have struggled to deal with these issues. The Chinese market is expected to stabilise due to a gradual economic reopening, additional support for real estate, and a modest increase in infrastructure spending. The Middle East will continue to benefit from elevated energy prices. Most other emerging markets are expected to see growth slow sharply due to rising inflation. The surge in inflation has raised the prospects of social unrest, industrial strikes, and currency crises in a number of countries.

Seaborne trading markets struggled in 2022, with volumes impacted by weaker demand and a steep rise in production costs. Imports are forecast to drop a further 5 – 10% in 2023, with export prices likely to drop as a result. Shipments to the US and China are expected to decline, with only modest growth elsewhere. Producers with subsidised energy costs are expected to take market share.

The region faces a daunting task to shift away from Russian energy. A spell of cold weather this winter could lead to rationing. Most countries are already in recession, and are engaged in an energy subsidy race that will cost hundreds of billions. EU interest rates of 1.5% do not address double-digit inflation.

Housing markets have already begun to decline sharply, while the EU recovery fund has been slow to disburse due to technicalities.

Norway is the only country where cement demand is expected to actually grow in 2023. Other countries are expected to see a further 3 – 6% drop in cement demand in 2023, with the UK faring the worst at 7 – 9%. France is expected to be relatively resilient; Germany faces a painful adjustment away from Russian gas but has the financial muscle to cushion the downturn; Italy has been hit with very high energy cost increases; while the UK has pivoted in spectacular fashion from tax cuts to severe austerity.

Eastern Europe – the war continues Cement consumption in the region was initially strong despite the onset of the Russia-Ukraine conflict. Cement demand is expected to drop 5% in 2023 however, as inflation and sanctions begin to bite. Central and Eastern European countries have seen inflation climb to 15 – 20%. As a result, interest rates have risen sharply bringing an end to long-running housing booms. Hungary and Poland are expected to see a moderate decline in 2023 due to support from public works, while the Czech Republic is predicted to lag due to its previous reliance on Russian energy. Russian cement demand is expected to fall sharply as sanctions have a greater impact, although the recently agreed oil price cap is largely ineffective in its current form.

The US is expected to undergo a mild recession, supported by energy exports and the Reshoring Initiative. Housing may go through a protracted downturn due to stretched affordability, but with starts already very low most of the pain will be felt in terms of house prices. This limits the impact on cement volumes, where IA Cement anticipates a decline of 2% in 2023. Local production is expected to increase as supply chain bottlenecks ease and more Portland Limestone Cement (PLC) is used. Imports are therefore likely to decline. The industry struggled to push selling prices up during 2020 – 21 when other material costs were surging, but increased success in 2022 has helped to underpin profit margins. Demand for cement is likely to pick up strongly from 2024 onwards, as the US$1.5 trillion infrastructure bill begins to deliver.

Latin America – a mixed picture

Cement consumption in the region is expected to experience a slight decline in 2023. Housing markets are slowing across the board, due to higher interest rates and the cost-of-living squeeze. Argentina is one of the few bright spots, with large private sector projects expected to support cement demand in a hyperinflationary environment. Colombia has seen a sharp slowdown in housing, but cement demand is expected to increase moderately due to public works. Mexico is predicted to be flat as the neighbouring US market enters recession, public works remain lacklustre and housing has already dropped from its pandemic highs. In Brazil, the dramatic rise in interest rates from 2% to 13.75% has crushed the housing market. The return of Lula as President will shift policy back toward social housing and state-led infrastructure, but this will take time. Overall, cement demand is projected to fall 3% in 2023.

Elevated energy prices continue to boost cement demand in the Middle East, where IA Cement expects a 2% growth in 2023. The average GCC budget surplus is forecast to reach 8% of GDP in 2022, following seven years of deficits. The Saudi market is expected to revive with 3 – 4% growth in cement demand, as mega projects including Neom begin construction. In the UAE, the delayed Expo was a great success and led to a strong rebound in both tourism and housing. Public works are set to increase and cement consumption to rise by a solid 3 – 4%, although selling prices remain low

due to excess capacity. Demand growth in Qatar is predicted to dry up following the end of World Cup construction. In Türkiye, a further drop in local demand is expected as the country grapples with an unprecedented mix of hyperinflation combined with single-digit interest rates.

Cement markets in Africa are struggling with housing demand being squeezed by the cost-of-living crisis. Regional cement consumption growth is predicted to slow to 2% in 2023, with cement growth lagging behind the wider economy in most countries. Egyptian demand is expected to increase slightly as public works offset a decline in housing demand. Selling prices have recovered strongly due to the official production cut, which has been extended. Algeria is forecast to see almost 3% growth in 2023 cement demand, boosted by higher public works ahead of the 2024 elections. Exports are likely to rise further as producers take market share from higher cost locations. Lacklustre demand growth is set to continue for another year in South Africa, with subdued public works, a slowing housing market, and new political scandals affecting the outlook. Kenya is forecast to slow to a moderate growth rate following the completion of a number of public works, while the lifting of interest rate caps will also impact construction demand. In Nigeria, IA Cement expects solid demand growth as the gas supply normalises, allowing cement output to pick up.

The Chinese cement market is likely to decline by a double-digit percentage in 2022, before stabilising in 2023. The zero-Covid policy and real estate downturn have been the key drivers of the market correction. Clinker imports have largely stopped in recent months. The outlook is now starting to improve. The comparison basis has eased significantly, the lockdown policy is being gradually eased, additional support measures have been announced for the property segment, and infrastructure spending remains supportive – even if there is no significant stimulus at present. Selling prices have come under pressure, reducing industry margins from being highly profitable to being more in line with the global average.

The Indian economy has proven highly resilient. Inflationary pressures have been contained by reducing food exports and importing discounted Russian oil. Cement demand is expected to grow at a solid 3 – 4% in 2023,

driven by pre-election spending and a further recovery in urban housing. Cement prices have struggled to keep pace with cost inflation, leading to a sharp decline in profit margins. Ambitious industry expansion plans in the wake of the Adani-Holcim deal do not bode well for the supply-demand balance.

Beyond China and India, other Asian cement markets have struggled to recover despite their economies reopening. South Asian countries are major importers of food and fuel, and have been badly hit by rising prices. Sri Lanka is now engulfed in an economic crisis, Bangladesh cement demand has dropped due to high material costs, and Pakistan is grappling with soaring inflation. Far Eastern countries are less dependent on food and fuel imports, and have fared better although cement industry margins have been squeezed in most countries. Solid demand growth is predicted in Vietnam, underpinned by very healthy GDP and an expected pick up in public works. Producers are struggling with a big drop in exports, however. Solid growth is expected in the Philippines as the new Bongbong Marcos administration resumes public works. Indonesia and Thailand are expected to show a modest growth in demand, driven by higher infrastructure spending. The cement industry in South Korea is currently affected by a trucker strike, with demand predicted to fall in 2023 due to public works cutbacks and a weaker housing market. The Japanese market is forecast to be stable at just below the 40 million t mark.

The cement industry faces a tough 2023. A deep recession in Europe seems inevitable. The Middle East and India stand out as relative bright spots. Elevated energy prices have already impacted industry margins. Passing these costs on to customers requires such high cement price increases that it causes demand destruction. Rising interest rates threaten both housing markets and the debt-fuelled capacity expansions in the cement sector. Public funds are being diverted to food and fuel subsidies. On a more positive note, high fuel costs have accelerated industry trends towards alternative fuels and carbon emission reduction.

The full report is priced at US$620 and is available from IA Cement. For details, visit: www.iacement.com, or email publications@iacement.com.

For the past six months Dome Technology has responded to an influx of enquiries from ready-mix concrete users eager to bulk up their storage capabilities.

Receiving sufficient product from producers is not always guaranteed in this high-demand market, and ready-mix companies, without serious storage, are not always able to provide

Rebecca Long Pyper, Dome Technology, explains why more and more cement companies are inquiring about drive-through dome storage systems.

Rebecca Long Pyper, Dome Technology, explains why more and more cement companies are inquiring about drive-through dome storage systems.

customers with exactly what they need. This poses a problem when contractors have been guaranteed material so that they can meet their own deadlines – it is a story that Dome Technology sales manager Lane Roberts hears again and again in conversation with customers.

“The contractors come back to the ready-mix supplier going, ‘You’re causing a delay on this project, and I’m passing that cost on to you,’” Roberts said, adding that one potential client recently disclosed that his company had to pay millions of dollars for such a delay.

More ready-mix teams are eager to find a proactive approach, knowing if they buy more product in the off-season, the price will be lower, and a buffer will be on hand when busy times roll around. But first, they must build a storage facility.

This is where the Drive-Thru DomeSilo system was able to step in. The system directly competes with bolted steel tanks and drive-through concrete silos but provides long-term advantages above and beyond these traditional models. This model has piqued the interest of ready-mix companies, who also appreciate that the Drive-Thru DomeSilo can be quickly constructed and is price competitive. With a Drive-Thru, ready-mix companies can

now buy 5000 – 8000 t of cement (or more) and store it away for the busy season.

Most companies think they know the capacity they can afford before conversations with a contractor begin, but adding a few thousand extra tons of storage might not cost as much as expected. An economy of scale is inherent in the Drive-Thru DomeSilo; the extra costs associated with increasing the capacity come only from making the dome taller and bolstering the foundation reinforcements, and the price of truck loadout and reclaim will not change.

For instance, one company in the United States that opted for multiple Drive-Thrus started out planning on the 5000 t option, but when they found they could increase the capacity to 8000 t without significant cost increases, they opted for that version instead.

Other factors lend themselves to dome longevity, which provides cost savings in the long run. Furthermore, a dome’s monolithic form prevents outside moisture entry – they simply do not have the seams and access points found in silos.

The first company to benefit from the Drive-Thru system was Continental Cement Co. (CCC),

which in 2018 built a facility in Memphis, Tennessee, USA. CCC had recently acquired the site with its silo and adjacent scale. Complete upgrades of these assets along with a new barge unloader, dock upgrades, and Drive-Thru allowed CCC to become a service leader in the Memphis market.

The CCC Drive-Thru flanks the pre-existing silo, and though the two appear similar in size, the steel tank stores 3000 t compared to the dome’s 5000 t. The difference in capacity results from the angle of the floor: 60˚ for the steel tank, compared to 8˚ for the dome.

With dimensions of approximately 100 ft in height and 50 ft in diameter, the Drive-Thru is supplied by barge from any one of Continental Cement’s plants. New aeration in the existing silo allows for a much-increased truck-loading rate. A bridge between the dome and silo provides access between the two.

The Drive-Thru delivers 100% live reclaim using a fully aerated floor. Product flows through the truck spout into the truck; the same system could be used for a rail loadout system. An inline lump crusher on the loadout stack-up ensures that lumps passed through the receiving system do not make it into trucks. The dome can receive 350 tph from the barge unloader and load out at 320 tph.

The Drive-Thru DomeSilo was developed for companies to fill truck or rail directly from the storage structure and to speed up the process of product reception to delivery.

The system typically incorporates an inbound material fill pipe, DomeSilo, stair or ladders access, scale, and appropriate foundations. Companies save by building a single drive-through storage facility that eliminates the need for multiple mechanical systems, operators and structures. This model allows for direct load-out, where stored product flows through a spout for direct loadout into the truck or rail.

The Drive-Thru DomeSilo shape, diameter and height can be unique based on actual site and customer requirements, and there is no practical limit on the amount of storage for the DomeSilo. In addition, the exterior is protected from the elements with a waterproof membrane, eliminating the concern of a leaky silo, and this also significantly prolongs the life of the structure itself.

The double curvature and structural engineering of the DomeSilo render it stronger than traditional structures. These steel-reinforced concrete domes

are some of the most durable bulk-storage structures on the market and have withstood earthquakes, hurricanes and the test of time with a remarkable success rate.

A dome provides ideal conditions for stored materials requiring a controlled environment. A high-strength fabric membrane surrounding the entire dome exterior prevents water and moisture entry, blocking the introduction of outside water into the stored product. The dome’s insulated nature reduces the heating and cooling of the walls as well as the air inside, preventing condensation from forming on the interior.

Foam and concrete provide humidity control and moderate externally generated temperature fluctuations.

A dome’s concrete monolithic construction also provides a tolerance for some differential settlement, as the project permits. These qualities combined with geotechnical engineering and site analysis ensure proper foundation selection and performance. All are within Dome Technology’s expertise.

Dome Technology is also building several projects for cement producers. According to Roberts, 90 million t of cement are produced in the United States annually, but 135 million t are consumed. The balance is imported from other countries and, again, storage capacity becomes an issue.

One thing that companies can do to help projects move as quickly as possible is to work with a design-build company. The team provides geotechnical analysis to determine foundation options, and thanks to the company’s dome models, deep foundations are not the only option. In addition to the storage structure itself, Dome Technology can provide structural-steel fabrication, manufactured in its shop located on the corporate campus.

The company also has expertise covering a wide range of stored products, as well as optimal design for product integrity and subcontractor management. Various types of enclosed reclaim systems work well with domes, protecting product from arrival to storage to shipment. The company’s team designs domes with reclaim requests in mind. With options like mechanical stacker reclaimers, mechanical rotary ploughs, gravity, fluidised floor systems, airslides, mechanical horizontal screw reclaimers, and front-end loaders, customers can access their different stored products quickly and to their specifications.

Even when the stored material is the same, every project in every locale is unique and receives individual attention. Dome Technology meets with customers to determine the details for a dome’s proposed function. The team will also develop the optimal plan for a custom dome and the material-handling systems within and around it.

ir cannons have been in the cement industry for at least 50 years. While there are around half a dozen major air cannon companies, many smaller companies have their own designs as well. When making a decision regarding which air cannon design best fits a given application, the following factors should be considered:

f Air cannon design. What is the available warranty?

f Air cannon volume. The air in the air tank is the cleaning energy of any air cannon. How much energy will provide the best results?

f Not all nozzles are created equal. Which nozzle will allow maximum production from the air cannon?

f Is the air cannon protected from the harsh environment? The leading cause of air cannon failure is the environment.

f Can maintenance be safely performed on the air cannon while the unit is operational.

Poor reliability is related to two main factors: 1) the design of the air cannon, and 2) how the air cannons are installed. Many of today’s air cannon designs are fundamentally good. Since that is the case, the reliability of the air cannons often comes down to how they are installed. Installation, in many cases, is the issue which will lead to greater air cannon failure rates. This is a major reason why Dracyon Corp believes that it can make any currently installed air

cannons more reliable while also improving plant efficiency.

One thing to note is that while several air cannon OEMs build a good air cannon, this is not true with air cannons from China. It is not unusual to see cases where the failure rate is quite high. There have even been cases have been seen where the pressure code ratings on the air tanks have been falsified.

When questioned about this issue, at least one a plant replied by saying, “That’s OK because I can replace the entire air cannon for less money than fixing than the North American air cannon.”

Firstly, this is not true for all North American air cannon OEMs.

Secondly, if a North American air cannon fails quickly then the plant operator should review how it was installed. It is most likely not

Jeff Shelton, Dracyon Corp, discusses why many cement plants are not getting the most out of their air cannon systems, and the steps that can be taken to ensure they perform as effective cleaning devices.

the air cannon design that is to blame, but the environment in which it is installed.

Thirdly, if a plant can replace the entire air cannon, and it fails frequently the question becomes: ‘are you getting what you paid for?’

Is there a better way than to accept such poor performance? Absolutely.

The greatest difference in air cannon performance can be determined by just how much each air cannon can clean. There are two crucial points to consider with regard to any air cannon’s ability to clean:

f Reliability: It does not matter how powerful an air cannon is if it does not work.

f Cleaning power: It does not matter how reliable an air cannon is if it is not cleaning.

The key to any successful air cannon installation is successfully applying these two rules.

The primary factor that limits cleaning performance is the nozzle. In simple terms,

the nozzle serves the same function as a governor on a car engine. One can have a high-performance sports car that has an engine capable of reaching 200 mph, but if this engine has a governor on it set at 55 mph, then 55 mph is the maximum speed. Simply put, the nozzle must be designed to allow for maximum performance. And unfortunately, this does not happen in most cases in the air cannon market.

The second limiting factor in cleaning performance is the air tank size. The air in the pressure vessel is the cleaning energy of the air cannon. If a plant has a 70 l pressure vessel, then 70 l of air pressure is the cleaning energy. If this tank size is increased to 140 l then the cleaning energy is doubled. Doubling cleaning energy also improves the cleaning ability of the air cannon without it needing to be fired as often. Think of using a leaf blower in the fall: when blowing leaves from a front yard, do not turn the leaf blower on and off, hoping a small, repeated burst of air will blow the leaves. Rather, turn the leaf blower on and let it do its work in one go.

The third limiting factor is related to the actual installation of the air cannons. Many air cannon OEMs’ recommendations are that the air cannon must be installed as closely to the discharge point as possible to achieve maximum cleaning power. If the goal is to simply maintain the highest pressure possible, then this is 100% true. However, maximum air pressure is not the only factor to consider, and placing the air cannons right next to the application comes with high risks. Specifically, all air cannons hate two things: high temperatures, and material getting back into the valve. Installing the air cannons as close as possible brings both negatives into play. Moving the air cannon away from the discharge point will reduce the pressure (peak force) of the air cannon blast entering the nozzle, but when this is done properly it will improve air cannon cleaning and reliability.

Consider a couple of facts: f Increasing volume does not increase peak force but it does increase the amount of air at the higher pressure.

f With a smaller air tank, the air cannon must be closer to the discharge point. If moving the air cannon away from the discharge point, then be prepared to increase the cleaning energy so

that the loss of cleaning energy caused by the increased distance is not great enough to eliminate any remaining cleaning power.

f What impacts the cleaning ability of an air cannon? The general rule of thumb is peak force. While this does impact cleaning, it is not the only factor involved. Plants must consider momentum and kinetic energy as well as peak force. In all three considerations, the key factors are velocity and volume. Increasing the volume and/or the velocity, will also increase cleaning power.

f Buildup characteristics are often not considered. The key factor in air cannon cleaning is the fact that the air cannon blast must be able to overcome the mechanical bond that holds the buildup in the unwanted location.

f Cleaning buildup is much more complex than one factor (peak force of the air cannon) and many factors must be considered.

f Not all air cannon applications are created equal. Some applications involve moving a dry buildup which is easy to move, yet in other cases the buildup is sticky and/or wet and can be very difficult to move.

f In many applications air cannons should be used in conjunction with other cleaning devices to achieve the best results.

Dracyon Corp offers their services as an air cannon consultant for the cement industry, seeking to help plants solve a wide variety of issues related to the purchase, installation, and proper use of air cannons. The major issue today is not the air cannon design, but basic air cannon philosophy: how

they are installed, which nozzle is used, and the operational sequence of the air cannons. The benefits of this consulting will include the following:

f Extend the cleaning range of the air cannons, which will allow plants to stop using high pressure water washing or cardoxing to supplement air cannons. This will improve production levels and plant efficiency, increase worker safety, and directly extend refractory life.

f Improve air cannon reliability which will also result in improvements in production and plant efficiency.

f Make online maintenance of air cannons safe. There is no need to use air cannons if they cannot be fixed online. Plants today often stop online maintenance because it is deemed unsafe. For the plants that still perform maintenance, the limitation creates such a hardship that often plant maintenance crews refuse to perform this work.

The purpose of this consulting service is to show plants how they can reclaim their investment in air cannons and achieve the results which are required to justify air cannons.

When new air cannons are required, Dracyon tends to argue that IGS air cannons are amongst the best, both in terms of operational efficacy and cost-effectiveness. With that said, the consultation will also offer pros and cons regarding each system and air cannon.

In many plants, the buildup experienced is not the same, and plants will need a ‘family’ of air cannons to meet these needs. The right air cannon for each application will be recommended. The family of air cannons per tier recommendation will include any existing air cannons as well as all major air cannon OEMs, delivering an unbiased opinion about how to best help each plant.

Air cannon reliability is key to success. Dracyon Corp offers an air cannon maintenance solution. This plan includes the following:

The first step is to understand the air cannon issues, in order to diagnose the problem. Not all plants experience the same issues. Dracyon Corp will perform a ‘walk the tower

service’ in person at the customer’s plant. This will be a two-day service in which a walk down of the installations will be conducted and specific recommendations will be made for each air cannon that is installed. During this walk down, a photo of each air cannon will be taken and a labelling system will be developed. This is critical because this will allow the plant to document when and how often each air cannon requires maintenance.

Included in this trip the company will extend one day to perform maintenance training for the system. Dracyon Corp will then provide a document which will be included which discusses recommendations for each air cannon.

When problems arise, the company will be available through an internet meeting (e.g. Zoom, Teams, etc.) to discuss any customer issues and how to solve them quickly and effectively. ‘How-to’ videos regarding standard air cannon maintenance will also be offered. In addition, Dracyon Corp will include video safety glasses which will allow them to see what plant operators are seeing and help solve the problem. If ‘a picture is worth a thousand words,’ how much is a video worth?

Dracyon Corp will also work with the plant setting up onsite spare parts. When an air cannon needs repair, the quicker, the better. It is recommended that these on-site spare parts be purchased on a consignment basis: paying for the spare parts as they are used. Some air cannon OEMs are open to this type of arrangement and will help customers get set up.

Dracyon’s service includes review and suggestions regarding the installation of any new air cannon recommendations to solve buildup problems. This service will also include two days at the plant’s annual outage for inspection and recommendation.

The goal is not to sell every plant new air cannons, but to make every customers’ existing systems work as well as they possibly can. It is expected that improvements from this service could be as high as US$1 million annually per plant. The objective is to make a small investment in order to make significant long-term savings.

The following is one example of the service process and the projected savings for the plant: A walk down was performed on one tower and the following was found: this plant had 135 air cannons installed, 56 of which had failed.

Air cannon improvements can lead to process improvements in excess of $1 million per year

All cement plants have air cannon issues. We will help you make your air cannon performance more efficient by examining and improving four key factors: air cannon installation, the volume of air used by air cannons, the type of nozzle installed, and the firing sequence of your air cannons. Contact Dracyon Corp today to schedule a call about our consulting services.

Starting in February 2023, the first Tuesday of each month is Air Cannon Tuesday, when we’ll be putting out our new Air Cannon Podcast.

We’ll be talking with industry experts and answering your questions about how to improve air cannon performance in all types of applications.

‘Webinar Wednesday’ will be held on the first Wednesday of each month, where we discuss technical information about how to improve air cannon performance. cannon

First episode will be released on Tuesday, Feb 7, 2023!

Dracyon Corp PO Box 1276 Jacksonville, AL 36265 256-454-1444 www.dracyoncorp.com

Many of the air cannons were installed improperly and the maximum benefit was not being achieved by the plant.

But interestingly, it was also found that at least 35 of these air cannons were not even needed. Furthermore, at least 70% of these air cannons were leaking air. These leaks resulted in the plant having difficulty in maintaining proper air pressure, which was affecting all of its air cannons. The operational pressure for this application should have been at least 80 psi, but it was at an average of only 60 psi.

50% of the nozzles were also a limiting factor on the performance of the air cannons.

Buildup issues were occurring at both the feed shelf and riser duct. A Dracyon Corp recommendation to improve performance included the following:

f Remove from service all air cannons that are not needed. This reduces the clutter around the tower and represents a huge saving in air usage. The result would be an increase in operational pressure for the remaining air cannons, thus improving air cannon cleaning for all the remaining air cannons. This removal is also a great source of spare parts.

f Replace all the wrong/ineffective nozzles with improved nozzles. This is generally recommended to be done when the nozzle already needs replacement, but this is not the case for all air cannons. In the critical areas, the proper nozzle may need to be replaced asap to eliminate the need for high pressure water washing.

f The firing sequence of the air cannons was believed to be improper and will need to be adjusted as required. Many air cannons are fired too frequently and thus use more air than is required. Reduction of the frequency of air being used will help improve air pressure and lead to improved air cannon cleaning throughout the plant.

f Establish a plan for the critical areas which will increase performance to help improve production and plant efficiency.

Based on the above recommendations, the plant in question should save at least an additional US$500 000 annually.

A properly installed air cannon on a material chute. The air cannon is installed close to the discharge points with a high temperature hose which minimises vibration in the chute. This vibration had previously caused many air cannon failures.Florian Laux, REFKO Feuerfest GmbH, revisits the performance of a lining technology that has been used to repair cement kilns in a number of different plants.

ho would have thought that one year later the industry at-large would be facing problems with raw material procurement, fossil fuel supplies, temporarily closed industries, and a completely uncertain future? Things that many took for granted are becoming luxuries, and the refractory industry, with all of the industries both upstream and downstream of it, is also facing major challenges.

This article will revisit some of the points made in an article published in the September 2021 issue of World Cement, and will also report on REFKO’s experiences working with the material over the past two years. 1

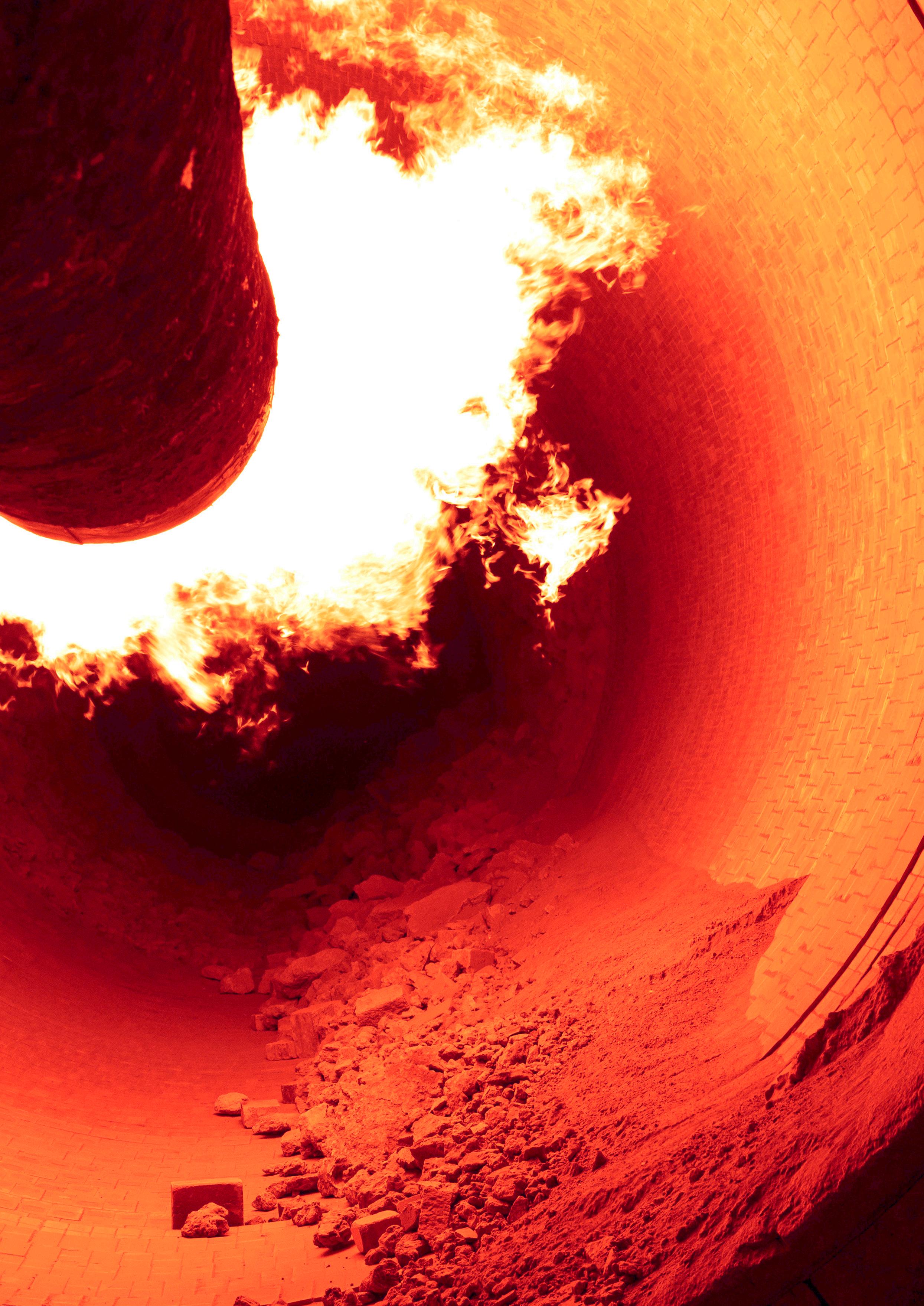

A safely operating rotary kiln over the course of several months, for the best part of a year, within the scheduled inspection periods, is certainly the ambition of every cement producer. Unscheduled shutdowns cause high costs due to production losses and are, of course, anything but beneficial for the refractory material used. Unfortunately, unplanned emergency stops cannot always be avoided due to various factors. This is exactly where the REFKO Recovery system and in particular the concrete REFKO Recovery MG 78 comes in. This product was developed to repair damage in the lining, especially on old

MgO/Spinell bricks. In the best case scenario, the kiln should continue to run safely and trouble-free until the next scheduled annual shutdown.

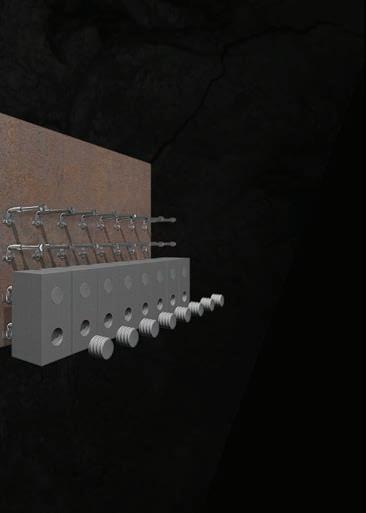

Preparatory operations before any installation are mostly the same. The areas to be repaired must be cleaned and free of loose material from the old brickwork. The rubbish must be removed from the kiln so that it does not roll over the fresh lining during the rotation of the kiln during installation. An appropriate bond preparation of the surface is recommended. The spray application is carried out with a standard dry spraying machine/rotor spraying machine in combination with a booster pump and high-pressure membrane spray nozzle or ‘REFKO nozzle’. The company also recommends a field division of four quarters, which can vary in width, but should be based on the joints of the old brick lining. To date, widths up to 100 cm have been undertaken. The widths are also dictated somewhat by the format of the bricks.

Initial test cement plant: North Rhine-Westphalia, (Germany) January 2021

The initial field trial was carried out in cooperation with a German cement plant in January 2021, in fairly adverse conditions.

On the one hand, a strong, seasonal frost, provided typical European climate conditions, although it is generally assumed that this material and lining concept are more likely to be used in the fall months from September onwards, since most annual overhauls begin in January and the kiln should simply be kept alive until then.

f Furnace length: 60 m.

f Kiln diameter: 3.8 m.

f Installation point: kiln 7 – 10 m (burning zone).

f Layer thicknesses: 10 – 90 mm (partly tapered to 0).

f Running time: 11 weeks.

Good adhesion with the old brick lining was achieved right from the start. In each case, whole quarters were sprayed in the corresponding lining width. After initial stiffening, the kiln was rotated, and quarter after quarter was sprayed. For the lining of an area of approximately 38 m 3 , a time of approximately 12 hours was required. After 24 hours of drying, the kiln was started up with the plant-specific heating-up curve without any problems or disturbances. Regular thermal imaging camera shots of the lining area were inconspicuous over the entire run time, which in any case indicated that there was no major damage to the lining. Even afterwards, during the main inspection, a residual thickness of the spray lining with REFKO Recovery MG 78 was still visible at all points, even where only a few millimetres had been applied.

Follow-up test cement plant: North Rhine-Westphalia, (Germany) January 2022

f Furnace length: 60 m.

f Kiln diameter: 3.8 m.

f Installation location: Furnace inlet, sintering zone, furnace outlet.

f Layer thickness: 20 – 160 mm.

f Running time: 4 weeks.

In the kiln inlet zone, the material held for a while. Once again, no abnormalities were detected by external temperature measurements of the kiln shell. During the inspection, however, the material was heavily worn. Due to low temperatures, mechanical

and chemical abrasion occurs in this area, the wear resistance is most likely insufficient here and must be replaced by another product from the Recovery range. The results in the sintering zone and the furnace outlet were completely different. It was possible to reproduce the results from January 2021. Decent residual thicknesses were visible and the protection of the old brickwork was still given.

Test cement plant: Lower-Saxony (Germany), December 2021

f Kiln length: 50 m.

f Kiln diameter: ~4 m.

f Installation location: sintering zone.

f Layer thickness: 80 – 140 mm.

f Running time: 8 weeks (until annual shutdown).

In this plant, REFKO had the opportunity to carry out the gunning up from a DAT-unit. This unit remained in the kiln because it was decided to use bricks in some areas, and to cover special areas with the Recovery MG 78 system. This gave a time advantage, since the ceiling shells could be sprayed without constant kiln rotation. The kiln was back in operation just 12 hours after the completion of the spraying work. The plant operator was very satisfied with the repair and can imagine

stockpiling the material for unexpected furnace problems.

Test cement plant: South Austria, September 2021

f Kiln length: 49 m.

f Kiln diameter: 3.4 m.

f Installation location: Kiln 14.20 – 15.60 m (burning zone).

f Layer thickness: 20 – 180 mm.

f Running time: 13 weeks (until annual inspection).

A damaged area was also repaired in the burning zone. The approximately 1.4 m was divided into two sections. The refractory consumption for this area amounted to 3.5 t of gunning material. The lining, including all necessary preparatory work, took 10 hours. According to the furnace operator, the lining with bricks in this area alone would have taken at least 24 hours, plus the effort of moving the appropriate equipment into the furnace. After the completion of all the work in the kiln it was brought up to operating temperature within 36 hours. Despite an emergency shutdown of the plant in the area of the cyclones one month after lining, the kiln ran through until the scheduled inspection and showed no abnormalities. Here, too, the Recovery system can be used as a preventive measure to extend kiln downtimes until the next scheduled stop.

Cement plant: Northern Turkey, July 2022

f Kiln length: 60.5 m.

f Kiln diameter: 4.2 m.

f Installation point: Kiln 0 – 1.2 m (outlet zone + outlet cone).

f Layer thickness: 130 – 150 mm.

Cement plant: Northern of Turkey, September 2022

f Kiln length: 60.5 m.

f Kiln diameter: 4.2 m.

f Installation point: Kiln 18 – 23 m (burning zone) + kiln 0 – 1.2 m (outlet zone + outlet cone).

f Layer thickness: 100 – 150 mm.

f Running time: Both kilns are still in operation without any abnormalities.

In cooperation with their Turkish partner DAS Metalürji Makine San. Tic. Ltd. Ș ti, REFKO have been able to offer the Turkish cement

works high-quality refractory solutions made in Germany. This successful cooperation also enabled them to gain a foothold and carry out initial trials with the REFKO Recovery MG 78 outside the EU. Here, too, the company were able to continue the series of successes. The area to be repaired has now lasted for 3 months and the factory has reported no abnormalities. Based on this, several parts in kiln 2 and kiln 3 were scheduled for repair in October 2022. The operator was enthusiastic about the opportunity for dust-free spraying, quick repair, and the possibility to heat up without a specific heating plan. In this particular case, the kiln was back up to operating temperature in less than 24 hours after the gunning work was completed. Whilst this is not a procedure that the company would want to propagate or advertise, it

nevertheless shows the flexibility and properties of this unique product.

So far, REFKO Recovery MG 78 has been able to demonstrate itself as a product that enables fast, safe, and successful temporary repairs in the rotary kiln. The product allows advantages in production speed, flexible-use, and low energy input. Especially in the current situation, this makes an even greater contribution to CO 2 and energy savings. It eliminates the need to break out the old delivery and thus saves time and money.

Based on these results, REFKO constantly strives to expand its product portfolio to cover all the requirements of the repair process in the rotary kiln. New products have already been developed and are currently in the trial phase with end customers willing to try them out. REFKO, and some of its customers, are confident that this material is capable of much more, such that they are planning to monolithically line some areas with this material at the next opportunity.

The company is also considering expanding its warehouse network worldwide in order to enable fast deliveries in many parts of the world within a few days.

1. HOENL. H.,‘Ready For Rapid Recovery & Repair’, World Cement, September 2021, p. 43.

Florian Laux is the head of Product Development at REFKO Feuerfest GmbH. After finishing his diploma thesis in 2013 at the University of Applied Sciences Koblenz in cooperation with the company REFKO Feuerfest GmbH, he started in the R&D and QM department in the eponymous company and was involved in the development of new refractory materials, product concepts, and technical solutions. Florian is now also a Partner in the company.

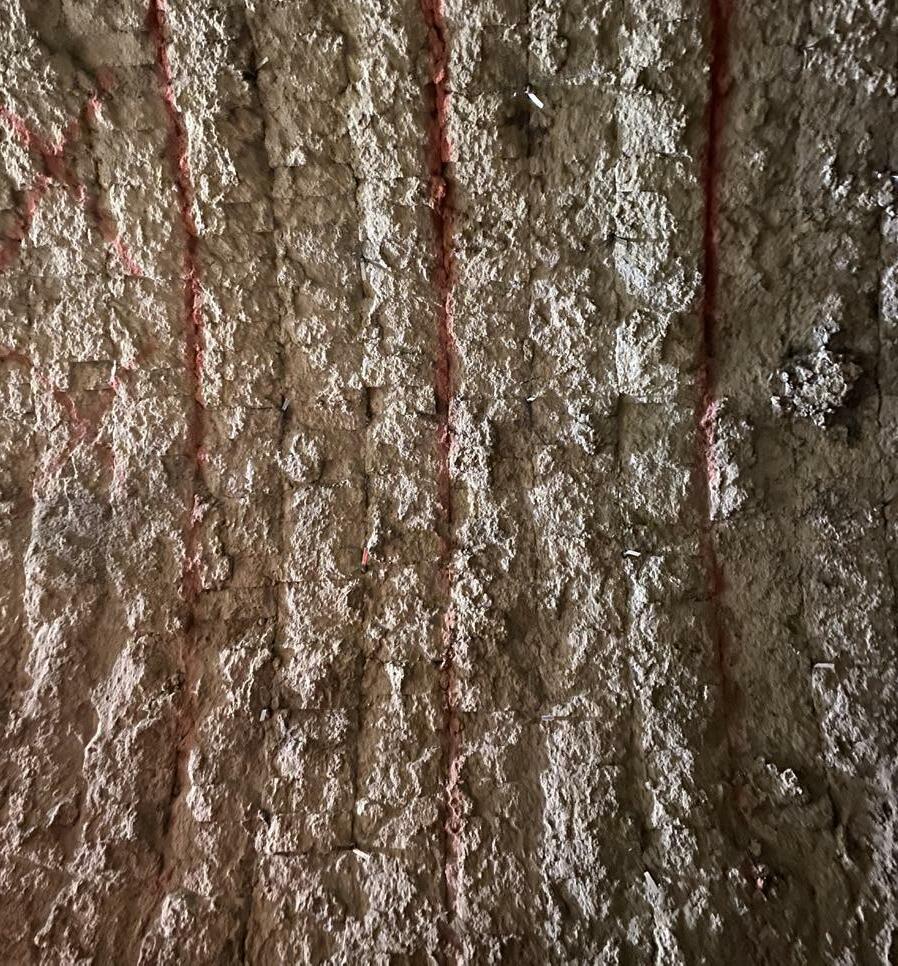

Turkey: Old brickwork outlet zone, before and after installation with REFKO Recovery MG 78.

here is a growing need in the cement industry for innovative solutions that help solve the challenges facing the sector today.

One of the most pressing of these is the industry’s carbon footprint, which accounts for about 7% of global carbon emissions. The industry is currently ‘not on track’ to achieve net zero goals by 2050, according to the most recent IEA report. In fact, direct CO2 intensity of cement production actually increased by about 1.5% per year between 2015 and 2021.

Annual declines in carbon intensity of 3% are now needed to get the industry back on the right path. This will require progress on a range of pathways – from reducing the clinker-to-cement ratio to deploying innovative technologies, such as carbon capture and storage.

The adoption of alternative fuels (AFs) is another critical route to lower carbon emissions and, in contrast to other solutions, has a long track record of success. Quickly increasing thermal substitution rates (TSRs) therefore offers cement plants an accessible way to reduce their carbon intensity.

Kayra Kurt and Divyendu Tripathy, Calderys, introduce a new refractory brick designed to offer a flexible and cost-effective solution to the pyroprocessing challenges posed by alternative fuels.

That is not to say that AFs are without their own challenges. Notably, they can cause changes to the atmospheric conditions inside the kiln, which can, in turn, adversely impact the refractory.

Combining strengths in monolithic refractory technology and refractory bricks, Calderys and its Turkish subsidiary, Haznedar Durer, have developed a complete line of refractory solutions for the cement industry, including a new alumino silicate-based brick that can be used at plants with high TSR. It can be applied in most areas of the cement production process impacted by AF use.

Cement plants around the world are recognising the benefits of switching to AFs. The European industry leads the way, supported by a highly developed waste management industry and decades of experience utilising waste-derived fuels. TSRs are lower in other regions, but uptake is growing, as cement plants seek both to reduce carbon emissions and recognise the additional benefits that AFs can bring. These include lower fuel costs and more stable, local fuel sources, which are insulated from global shocks to fossil fuel supply chains.

However, the use of AFs often results in higher concentrations of alkali gasses in the cement production process. These react with traditional alumina-based refractories, risking premature failure of the lining and damage to the equipment. The usual response has been to apply specialised refractories containing silicon carbide and zircon, which have better resistance to alkali-rich environments.

Although effective, the use of silicon carbide and zircon is becoming more problematic. Demand for both minerals is growing, resulting in tight market conditions and spiking prices.

Consequently, prices for silicon carbide- and zircon-containing refractories are relatively high – a serious consideration for cement plants considering the switch to alternative fuels.

Supply is also vulnerable to disruption, which may slow or even stop production of the refractory, while cement plants also face competition from the

larger steel industry for refractories containing silicon carbide.

With many cement plants operating in competitive market conditions, they simply cannot afford to rely on expensive refractories with a potentially constrained supply chain. It is also true that these refractories require significant energy inputs during their manufacture, and thus come with a higher environmental impact than traditional linings. With some cement companies looking beyond their direct (scope 1 and 2) emissions to those of their supply chains (scope 3), there are now serious questions being asked of refractory providers with regard to the environmental impact of their products.

Calderys and Haznedar Durer recognised the need for a new refractory solution to overcome these interrelated challenges, and developed the HAZAL T 2AR refractory in response. These refractory bricks offer similar resistance to alkali attack as silicon carbide- and zircon-containing refractories, but without the need for either mineral.

The bricks are an alumino silicate-based high-alumina brick that offers enhanced resistance to chemical attack, thermal shock, and abrasion. Key features include:

f A chemical structure resistant to alkali corrosion.

f Very low porosity, which prevents infiltration of alkali gasses into the refractory, and consequent damage to the brick from spalling.

f Higher abrasion resistance, which allows the use of HAZAL T 2AR bricks in multiple stages of the production line, including the dust collector of the tertiary air duct, kiln inlet, hot section and sub-wall of the cooler, and kiln hood.

f Improved thermal shock resistance, which allows the HAZAL T 2AR bricks to be worked under stress at different temperatures.

The result is a refractory brick that can be used in almost all process areas of a cement production line that present an alkali issue – areas that, in the past, would have required different bricks. The use of these bricks therefore also allows cement plants to simplify their refractory supply.

Various industrial trials of HAZAL T 2AR have been undertaken, including in the rotary kiln, cooler, preheater, calciner, kiln inlet chamber, and dust collector chamber of the tertiary air duct. The new bricks achieved high performance in all sections; they have also been successfully used in waste incinerators, proving their ability to withstand environments with highly aggressive chemistries.

A final advantage of these novel bricks is derived from the fact

that they are produced at lower temperatures than silicon carbide and zircon-based alternatives. The production of these bricks therefore comes with a smaller carbon footprint, supporting both the cement industry’s push to improve its environmental sustainability.

While Calderys supports customers in their energy transition, the company also has a clear sustainability roadmap of its own. This includes transparent objectives and concrete actions to significantly reduce the carbon emissions of its operations and develop low-carbon products. HAZAL T 2AR bricks are a demonstration of this commitment, as well as being an important technology that enables the adoption of more sustainable fuel strategies in the global cement industry.

With a history dating back to 1929, Haznedar has long supplied refractories to the cement industry in Turkey and surrounding countries. Trusting the company’s reputation, a number of major cement producers in Turkey now regularly use HAZAL T 2AR bricks in their process. These include cement companies that export clinker and cement to countries in Europe, the Middle East, and Africa.

At one plant, HAZAL T 2AR is used in the cement kiln inlet, dust collection chamber of the tertiary air duct, and security zone of the rotary kiln. The bricks have also been successfully used at another

plant in the calcination and security zone of the kiln, and rising and falling ducts of the calciner. In these applications, the bricks have demonstrated improved performance over other alumina bricks on the market. Indeed, at some plants using HAZAL T 2AR, no corrosion of the shell lining is seen. Some customers have also avoided buildup problems.

The modern cement industry is facing challenges from a variety of directions. The development of the HAZAL T 2AR refractory demonstrates part of the solution. These new bricks deliver a range of benefits including:

f Suitability to various processes, including those that use high levels of alternative fuels.

f Reliable and cost-stable supply.

f Lower-carbon footprint than alternative linings.

f Simpler refractory management with one solution for most areas that require a lining.

f A reduction in refractory coating issues in the inlet chamber.

f Longer refractory lifetime by up to 100%.

The bottom line is a refractory solution with the potential to create a positive impact in cement plants, supporting higher performance in the production process, as well as enabling the industry to take full advantage of the opportunities offered by switching to alternative fuels.

The World Cement Refractory Review provides a catalogue of some of the leading players in the refractory sector.

This year’s edition includes contributions from: Bricking Solutions, Calderys, HASLE Refractories, SILICON, The Siam Refractory Co., Ltd., and Wahl Refractory Solutions.

Bricking Solutions manufactured the first bricking machine in 1966 to give refractory installers a safer, more efficient alternative to manual installation methods. Traditional refractory installation methods like jack and timber, adhesive, and pogo sticks proved dangerous and inefficient. Bricking machines do not just keep the crew safer, however, they also offer increased productivity and better ergonomics for a fast, high-quality refractory installation.

While other manufacturers have dipped their toes in the processing industry, making a small selection of products as part of a larger catalogue, Bricking Solutions is dedicated to refractory maintenance solutions alone and has more than 50 years of experience in the industry.

The company creates products recognised by end users for meeting the highest industry standards. Bricking Solutions works with local vendors to provide materials and parts for its products. Available products range from installation equipment, to brick transport, to safety and removal equipment.

Safety is the key concern for processing plants worldwide. For this reason,

Calderys is a global provider of fully integrated solutions for a wide panel of industries operating in high temperature conditions, benefiting from a worldwide network of local experts and leveraging over a century of experience. Calderys offers thermal protection for industrial equipment with a large range of refractory products (monolithic, bricks, precast) tailored with engineering and installation services. The company has developed end-to-end solutions for the cement industry, combining innovative products (from monolithic to specialised high alumina bricks), engineering know-how, project management, and installation services. Calderys’ refractory solutions help cement producers minimise downtime, reduce their carbon footprint, and decrease maintenance costs.

f Precast services: Calderys’ expert team designs and creates precast pieces for faster turnarounds and greater maintenance efficiency.

f Specialised bricks: The company offers a full portfolio of alumina based bricks for improved performance against alkali attacks and abrasion.

f The company’s team of project managers is experienced in both partial and turnkey assignments. Calderys’ goal is to deliver projects on time and on budget in a seamless

Bricking Solutions custom designs equipment specific to the plant. This sort of custom-design is only available from a full-service solutions provider. Even in industrial manufacturing, new technologies are being developed every day. Bricking Solutions utilises these new technologies not only to improve the quality of its products but to help reduce manufacturing costs. Strict emissions regulations can occasionally lead to price increases from larger industrial factories. Ensuring the efficiency of processes and material usages allows the company to tackle these challenges without greatly impacting customers.

manner and in the safest environment for their customers’ workforce.

f CALDE® SOL SPRAYCAST: Combining the best of the SOL GEL binding technology and the SPRAYCAST installation technique, bringing customers high temperature and best-in-class installation performance.

f UniverCEM®: a high quality refractory solution that helps cement plants meet their sustainability goals.

Installation of UniverCEM refractory castables by dry gunning. Source: Calderys.HASLE Refractories develops, manufactures, and supplies unique refractory solutions for the cement and other high temperature industries worldwide.

The company provides a wide range of strong, chemical- and abrasion-resistant castables as well as offering precast solutions with engineering and supervision services. To achieve the highest and most consistent quality HASLE Refractories is ISO9001:2015 certified.

As the use of alternative fuels grows, cement plants face increasing coating and jamming issues

in their process along with chemical attacks on the lining. Among HASLE Refractories’ most popular products is a unique precast modular lining; this is a flexible, precast refractory lining system for walls, roofs, and curves. It helps production plants maintain a high run factor, maximise capacity by using a thinner lining, and optimise their energy-use.

A very low open porosity of 9 – 10% for the precast elements is achieved by being manufactured and pre-fired in a controlled environment at HASLE’s factory in Denmark.

The HASLE modular lining is highly alkali-, coating-, and abrasion-resistant, making it suitable for areas like the smoke chamber, riser duct, feed pipes, cyclones, or other areas prone to coating and jamming. It has been installed in more than 100 plants around the world, where recent applications include the kiln inlet arch at Ambuja Cement’s Maratha unit, India, and cooler roofs at Holcim and Heidelberg plants in Austria and Germany.

HASLE Precast solutions have been successfully installed in areas facing jamming and coating, such as the feed pipe showcased here in an Asian cement plant (which is still running after 22 months).

In 2022 SILICON moved from being a mass manufacturer of refractory anchors to a company that provides its customers with innovative solutions in the design, production, and installation of heat-resistant anchors for the cement industry. The company also focuses on a customised package of project management services and technical support.

In parallel, SILICON has developed its own rapid arc welding (RAW) system. This smart technology allows the company to not only to reduce installation time and improve the welding quality, but also to eliminate the emission of carbon dioxide and other toxic gases.

SILICON’s mission: To provide the technical and metallurgical expertise required to bring refractory anchors, and their installation, to the next level.

HASLE Refractories aims to provide quality, flexibility, and quick response times in order to avoid downtime, offering professional help to protect cement plants with the best refractory solution possible.

Here are two solutions that SILICON has engineered for two problems often faced by its customers: