11 minute read

The show must go on

Salim Akçaoğlu, Gökhan Özkan and Yavuz Bingöl, Tüpraş, Turkey, discuss how the company managed a battery shutdown under the challenging circumstances of the COVID-19 pandemic.

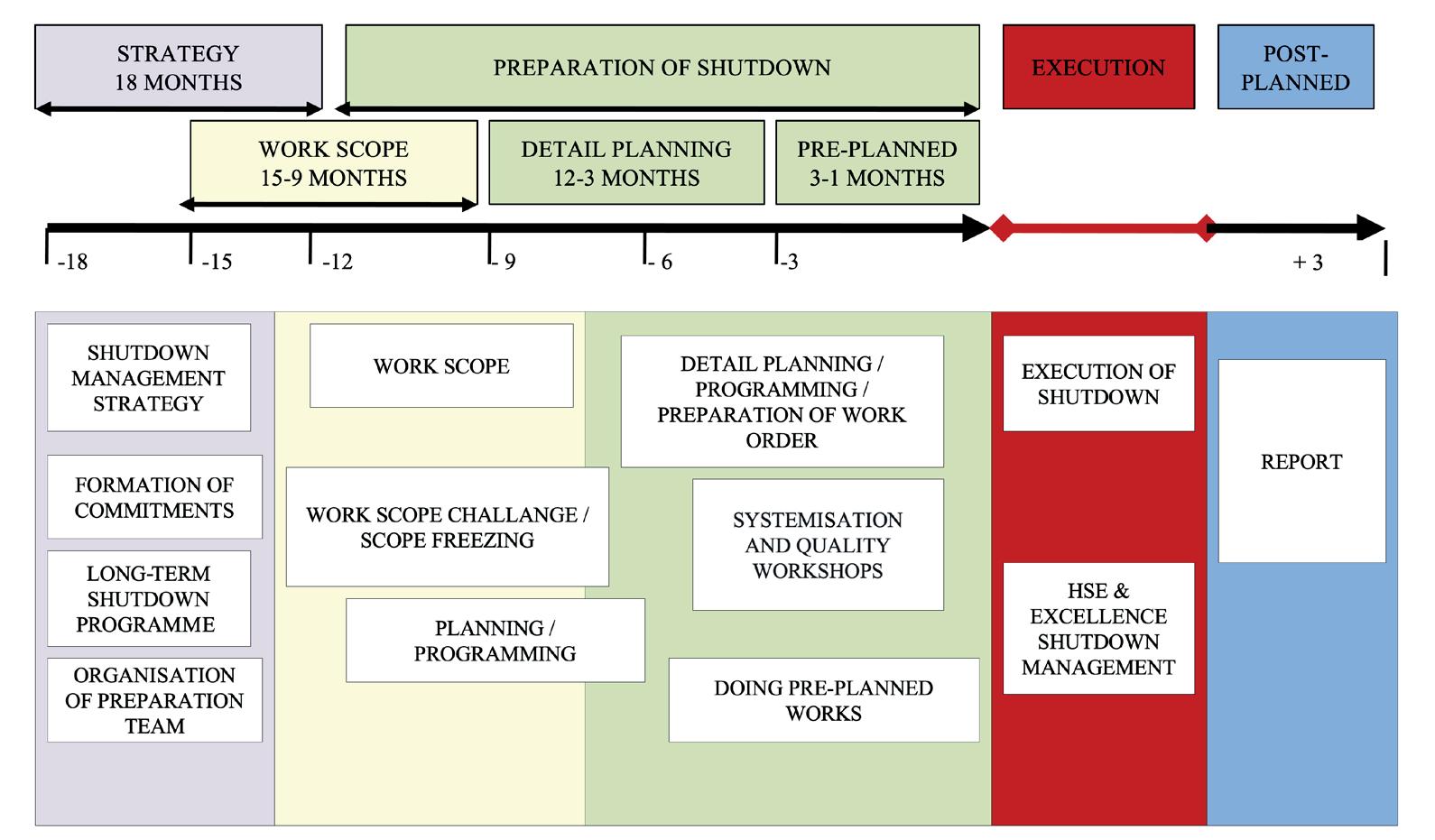

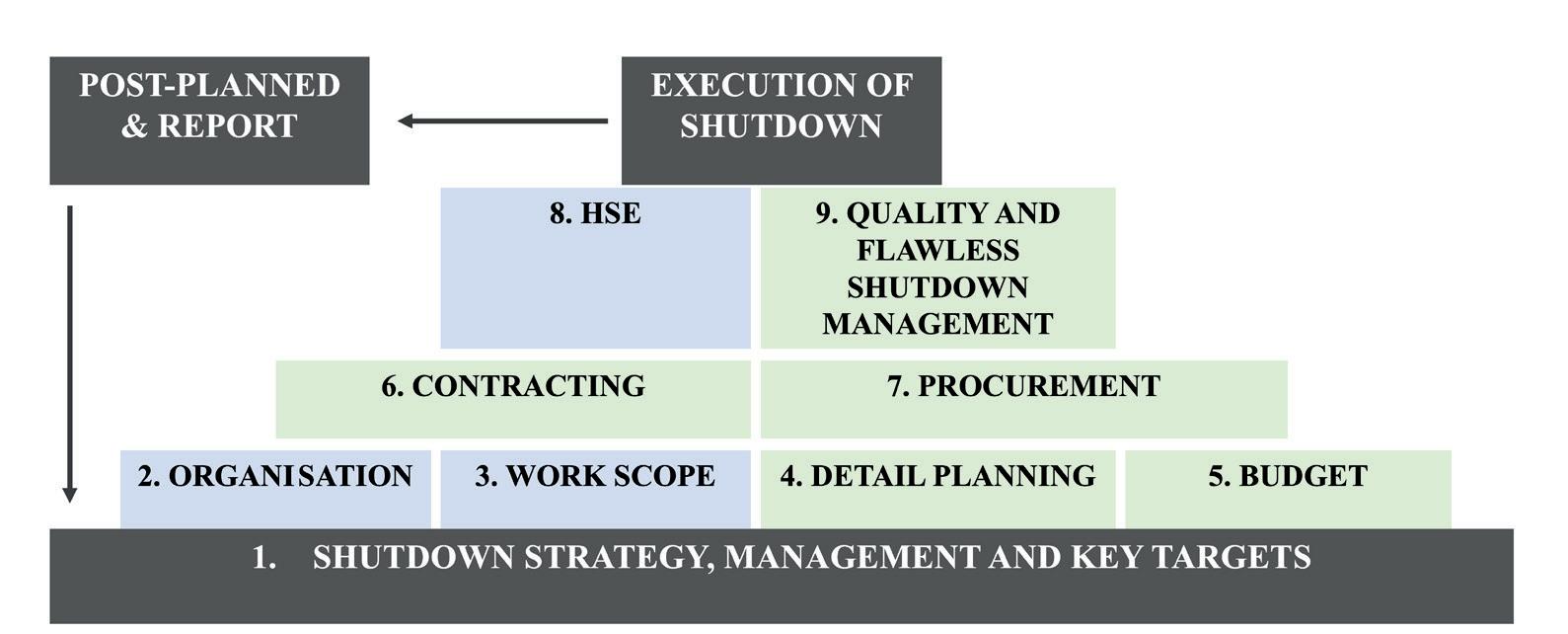

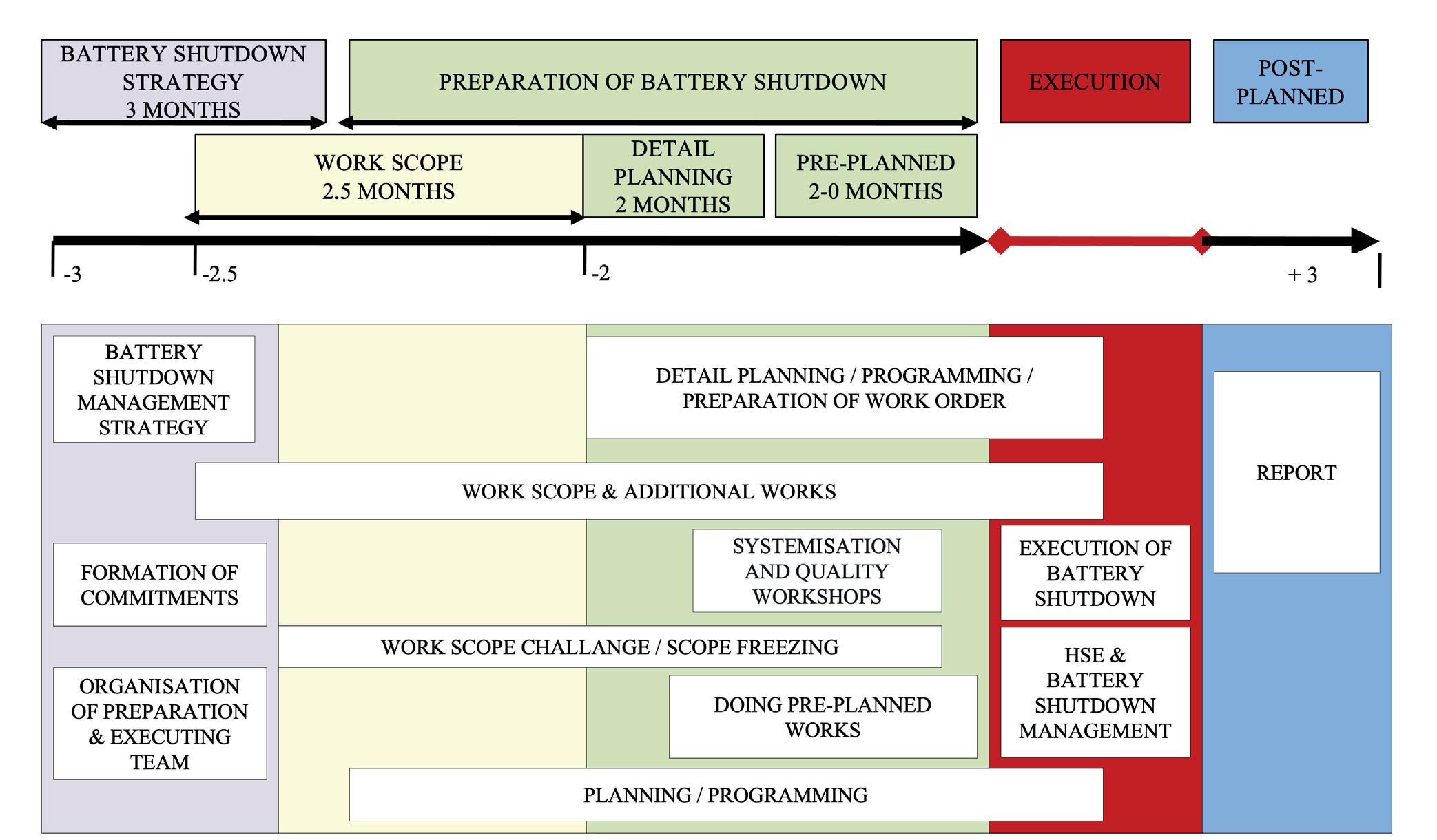

Battery shutdown management is an important process behind the closure of all units in a refinery. Tüpraş recently carried out a battery shutdown at its Izmir Refinery, the purpose of which was to ensure maximum availability of the refinery at minimum costs, by maintaining sustainable performance and reliability with the principles of ‘doing the right things’ and ‘doing the right jobs’. Under normal circumstances, preparations for a battery shutdown of this capacity should start approximately 18 months in advance of the works to ensure excellent shutdown management. This process consists of six main steps, each of which includes specific tasks, outputs, and approval stages: n Determining the battery shutdown strategy. n Establishing the work scope. n Detailed planning and programming. n Carrying out the pre-planned works. n Execution of battery shutdown. n Carrying out post-planned works.

Milestones should be established to allow sufficient time for the planning and preparation of complex and long-term materials, specific resources, and technical constraints. Sufficient time should be allocated to the preparation phase. It is necessary to follow the turnaround management process for efficient and successful shutdown management.

During the shutdown period, there are four important considerations: health, safety and environment (HSE), work scope, resources, and downtime. Normally, HSE, work scope and downtime are constant, while resources are variable. The aim of this article is to express how these four topics change and how they were managed under the unique circumstances of the COVID-19 pandemic.

Turnaround methodologies, methods and practices are generally predictive and plan-driven. In a traditional approach, the needs, requirements and constraints of a turnaround are understood, and the plans are developed accordingly. Turnaround methodologies, especially for the

battery shutdown period, have to be agile and flexible in order to cover all possibilities. The approaches used must change according to specific necessities, updated evaluations, changing work requirements, bottlenecks, and the circumstances of the pandemic. In these situations, agility is the main key benefit felt by teams who work collaboratively to determine and execute a shutdown’s need. At Tüpraş’ Izmir Refinery, modern approaches were implemented in certain steps. In summary, a hybrid approach was used to handle the specific needs of the project.

Strategic planning

Strategy meetings, which would normally last for three months, were completed in a short period of two to three days. With the establishment of the battery shutdown preparation and execution team, steering committee approval of the teams was obtained. Normally, the periods for establishing the turnaround preparation and execution team are different from each other. Since the period was too close to the battery shutdown, the formation of these two teams was adapted as one step, and coordinated in parallel. Under the confines of the pandemic, online meetings were held by organising remote-access, rotative groups.

Based on the strategy, a kick-off meeting was held with the shutdown preparation/execution team and the strategy was explained. Battery shutdown commitments were formatted in a very short time, taking into account the collected data of a previous battery shutdown, which was reported nearly 20 years ago. As it was not clear how long the downtime would last for, due to both the pandemic and for economic reasons, the main strategic focus of the shutdown teams was to prioritise the work. The company chose to carry out works that required a full refinery shutdown as opposed to works that demanded the shutdown of individual units. Due to this uncertainty, an early start-up was a possibility as a result of the support from positive changes in economics and global demand.

Figure 1. Steps of excellent shutdown management.

Preparation of battery shutdown

Figure 2. Turnaround management process.

Figure 3. J factor matrix. The preparation of the work lists, in relation to the strategy of freezing of the scope according to the J factor, were completed in approximately one month. In addition to this, works within this scope were divided into four different categories and placed in order of priority.

On the other hand, the daily report of work that was frozen during the work scope challenge was submitted to the planning/programming team. Subsequently, a detailed plan and programme was completed in one and a half months. While the work scope challenge continued, a shutdown and start-up calendar was created. Since the last battery shutdown had been 20 years prior, and there had been new additions to the units in that time, a number of meetings were held to determine the optimum shutdown and start-up calendar according to the new order. A work orders and shutdown programme was prepared and checked approximately one week before the start of the battery shutdown. In parallel to the preparation, the following steps were taken in the aforementioned one and half month period: n HSE strategy. n Budget preparation and approval. n Preparation of integrated project work packages and publication process for projects. n Contract strategy. n Preparation of temporary facilities (WC, scaffolding area, parking, work permit office, toolbox area, etc.) on the plot plan. n Preparation of risk assessments and method of statements. n Preparation of quality plan. n Deployment of contractors and PCR tests.

n Training of contractors. n Mechanical, energy, battery limits isolation and risk assessment (6000 flanges). n Procurement (detailed materials and equipment studies for refinery shutdowns planned for the next years have helped long-term material supply for this battery shutdown). n Risk assessment of additional work (identification of two focal supervisors, namely utilities and process units). n Publication of eliminated works. n Scaffolding and civil works. n Installation of temporary lighting and power units. n Mobilisation.

As mentioned, the preparations for the battery shutdown were completed in one and a half months, despite the difficulties of the COVID-19 pandemic. Downtime and resources were constantly relevant to this battery shutdown. The work scope was variable. The key factor in keeping the human resources constant or limited in this context was the COVID-19 pandemic. Many precautions were taken in order to eliminate or minimise the contamination of illness. For instance, the areas where personnel had to be – for specific purposes – were expanded or split into more areas, such as permit to work rooms, and multi-purpose field points.

Although all personnel completed periodic PCR tests, there was still some risk of contamination due to many different disturbances from daily life. As such, the optimum number of personnel worked during these challenging periods at the refinery. In addition, social distancing and other precautions had to be taken. The estimated number of personnel selected according to the downtime, scope freeze and the pandemic was periodically managed and revised according to the programme.

Execution of battery shutdown

Table 1. Priority and category matrix

Category Status

1 Certain tasks (legal requirements and HSE) and jobs with a financial return of more than US$100 000 in risk reduction costs 2 Jobs with a financial return of US$50 000 – 100 000 in risk reduction costs 3 Jobs with a financial return or risk reduction cost of US$10 000 – 50 000 4 Jobs with a financial return or risk reduction cost of less than US$10 000

Figure 4. Steps of battery shutdown management. When the battery shutdown process commenced at the Izmir Refinery, the capacity of the programme was 385 253 manhours. When it came to the end of the battery shutdown, the capacity of the programme had reached 432 132 manhours. 59% of the actual programme belonged to the projects, and 41% to the maintenance works.

During the procedure, 6000 flanges were opened and closed; 29 264 certified and non-certified work permits were organised; and 993 HSE reports were written on the system. Every morning, toolbox meetings were held in the field and the progress of each day was followed up with a detailed report via an online meeting at the end of the day. The detailed report included the following: HSE report, current shutdown and start-up calendar, progress graphs, project progress, lost time, critical paths progress, flange quality reports, additional works report, cleaning site report, inspection reports, meeting notes, etc.

Additional work was managed by two focus supervisors, a turnaround (T/A) leader, and a steering committee. At this point, the comparison of the works in the current category with the additional works was made by this team for two months. The work prioritisation list was revised 28 times in total during the downtime, which lasted for approximately two months. The goal was to cover and complete all scope and inevitable additions that came up during the battery shutdown period until the start-up date, as scheduled.

Planning, execution and field teams kept up with this, and the ‘to-do’ list was revised 28 times. If additional work was not affecting the shutdown in terms of budget and downtime, these demands were evaluated between the focus supervisor and the T/A leader. There were two groups for examining the additional works. One was the maintenance department; the other was the steering committee. The maintenance group management department was responsible for budget and downtime, while a steering committee was responsible for high-priority cases. During the battery shutdown, Tüpraş successfully managed to implement the HSE precautions taken during the COVID-19 pandemic period. These precautions were as follows: preparation of contractor pandemic documents and training, PCR tests, daily health surveys,

building additional entrance-exit gates, and organising shuttles according to pandemic conditions. In addition to this, many multi-purpose rooms and points, including places to eat and drink, were created to ensure that social distancing was in place.

The COVID-19 pandemic has initiated changes in business and habits, and companies have taken new actions to create opportunities for maintenance and investment needs. In keeping with this, during this battery shutdown, Tüpraş completed its scheduled maintenance activities and laid the foundations for new investments. The company also carried out critical paths with an engineering approach: the modernisation of a combined heat exchanger (100 t), sulfur waste heat boiler (80 t), and reactor effluent-hot feed exchangers (100 t) with jacking-skidding, gantry and hydraulic jacks. Further modifications were changing flare header pipelines; re-tubing a waste heat boiler; changing cooling water pipelines; civil works of the sulfur area; underground pipeline works; maintenance of flare tips; revamp of catalytic cracking units; changing the stand-pipe in fluid catalytic cracking units, etc.

As mentioned, preparations for a battery shutdown of this capacity should start approximately 18 months in advance. The methodology shifted during the period and was managed by agile approaches. One of the hardest challenges experienced was ensuring that personnel were able to work effectively, as protection methods were not clear and defined.

Conclusion

At the end of the Izmir Refinery project, the report and presentation of the shutdown was prepared and shared with the execution team during an online meeting. In addition to this, video content was specially prepared to record the challenges and some experiences. Another final meeting was conducted with all refinery and contractors’ personnel to openly evaluate the battery shutdown period. The key performance indicators (KPIs), critical paths, best practices, and improvement areas were shared and discussed by examining each department and the team as a whole. The main goal of this meeting was to benefit and record the experiences for the next shutdowns, whether it was a success or not. As such, the company’s organisation and standards continue to improve.

As a team, battery shutdown was managed under the special circumstances of the COVID-19 pandemic. Work was successfully carried out in a total of 432 132 manhours, with an average of 1700 employees and 50 contactors per day.

The pandemic has led to many transformations. With its onset, Tüpraş effectively implemented precautions to establish a safe working environment. During this period, the Izmir Refinery benefitted from this newfound flexible structure and agile approach. Considering the unknown conditions brought by the pandemic, the company broke new ground by executing a battery shutdown, which was an important experience.

Technical excellence and operational improvement for the sulphur and sulphuric acid industries Returning live to The Hague this October

Now in it’s 37th year, the event continues to be an essential annual forum for the global sulphur Hybrid for and acid community to learn, connect and do business. Returning live to The Hague this October 2022 You can expect an expanded market outlooks agenda, including expert insights from CRU’s analysis teams on major supply and demand markets, including sulphur, sulphuric acid and Now in it’s 37th year, the event continues to be an essential annual forum for the global sulphur and acid community to learn, connect and do business. phosphates, plus additional industry updates from key players from across the supply chain. You can expect an expanded market outlooks agenda, including expert insights from CRU’s analysis teams on major supply and demand markets, including sulphur, sulphuric acid and phosphates, plus additional industry updates from key players from across the supply chain.