7 minute read

Staying ahead of the game

Kjell Wold, John Bromley-Barratt and Gaya Somasundaram, Emerson, explain how to identify pipe replacement needs using digital remote corrosion monitoring.

Corrosion poses a significant challenge to operational safety, plant uptime and maintenance costs. With corrosion costing approximately US$2.5 trillion – equal to 3.4% of the global GDP – control practices are estimated to reduce this astronomical amount by US$375 – 875 billion/yr on a global basis.1

Corrosion is not just a maintenance issue; the cost should also factor in that many of the chemical industry processes, for example, have aggressive and potentially dangerous fluids and gases, which can have a significant impact on people, assets and the environment if they leak or spill.

Employing a comprehensive programme for integrity management, including inspection and corrosion monitoring, is part of standard operating procedures at plants. Inspection offers an extensive overview of the overall state of the plant, and corrosion monitoring provides up-to-date information on select, targeted locations. Understanding the root causes of corrosion by correlating continuous monitoring with other process data ensures greater safety. Typically, corrosion control strategies that are based on collecting monitoring data are part of process optimisation or corrosion inhibitor programmes. Therefore, information from a well-designed corrosion monitoring system initiates actions before corrosion damage can cause problems.

The debate over corrosion monitoring

Within industries that are impacted by corrosion, the value of monitoring has been continuously debated. Whilst there is consensus that monitoring is required, best practices have been discussed. Until recently, sensor technologies have been limited, and it has been difficult to

choose a reliable monitoring solution that presents an accurate representation of the true form of corrosion. Delivering required information to the user is essential, and if the information is not reliable, then the value of the system is also limited.

In addition to this, corrosion monitoring is generally not part of most operators’ core competencies. A lack of internal resources, skill and ownership for using and maintaining a corrosion monitoring system, including presenting the information to facility management to prove the value of the system, can hamper the implementation and use of the system. What is needed is a system that does not require in-person inspection or data collection at each monitoring point.

Monitoring data digitally

New technological developments

Fortunately, technology continues to develop, and new solutions to overcome challenges have become available. Fast response sensors and non-intrusive wall thickness monitors have been developed in recent years, which add flexibility when selecting the best combination of monitoring solution(s) related to the actual form of corrosion and use of the data collected. An added benefit to being able to measure pipe corrosion directly is that non-intrusive sensors do not introduce any safety risks or inconveniences to the plant operations.

Acceptance and standardisation of wireless communication, such as WirelessHART®, makes continuous and online monitoring simpler across devices and more straightforward to work with. Continuous monitoring produces better trending data and can show correlation with other production events, helping to determine the root cause of corrosion problems. Online communication ensures that data is available in real time, with a greatly reduced need for personnel to perform manual rounds to collect data.

Another effect of online communication is that data is available in digital format and can be easily shared. Access to digital ‘housekeeping’ data allows for remote diagnostics and maintenance planning – reducing the need for expensive site visits – and enables proactive maintenance (e.g. spare parts, field service plans, etc) for reliable system performance. See Figure 1 for a visual representation of a comprehensive monitoring system.

As mentioned, the understanding and interpretation of data can be a challenge, particularly if teams are reduced and personnel have several tasks to handle. With access to digital data, corrosion and erosion reports can be easily pulled together remotely by subject matter experts (SMEs) who are trained in data assessment and drawing key conclusions from the data.

Figure 1. A selection of in-line and non-intrusive monitoring technologies, online wireless communication, and digital data handling enhances the efficiency and reliability of corrosion monitoring.

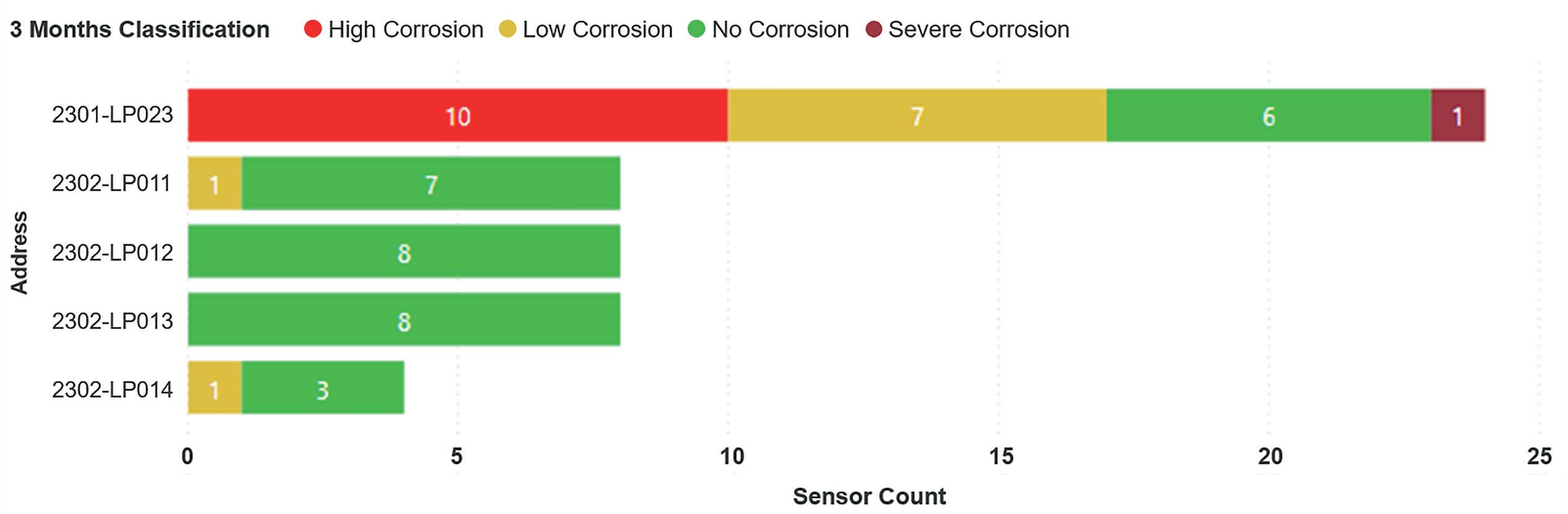

Figure 2. An example plot of corrosion rates over a three-month period for different sections of a plant. As seen in the first area, one sensor shows severe corrosion, 10 sensors show high corrosion, and the remaining locations show low or no significant corrosion. The focus should be on locations showing high or severe corrosion.

Connected services

A clear trend is emerging towards adding data analysis and reporting to the scope of supplying monitoring systems in what some companies call connected services. The result is that the client receives timely reports based on the correct interpretation of data, highlighting the most critical information – such as which locations are showing high corrosion, where corrosion is increasing, or at what time the corrosion rates changed. At the same time, operators can free up resources for core business, assured that the

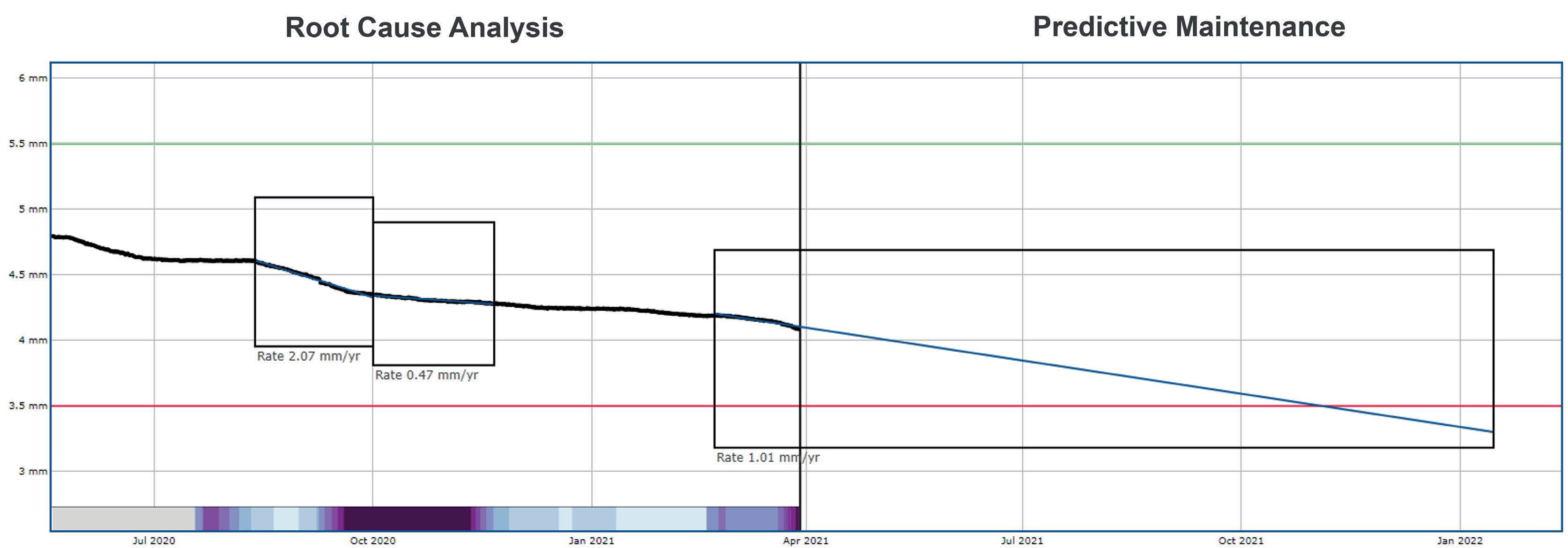

Figure 3. Metal loss vs time plot (left), with the bottom line indicating internal roughness of the pipe, and predicted corrosion (right) estimating the time when retirement thickness of the pipe will be reached.

monitoring programme is functional and the integrity information is captured for qualified actions.

In connected service reporting, the aim is to combine an efficient overview of the plant’s monitoring locations while providing a more detailed analysis of findings of particular importance. Figure 2 shows an example where ultrasonic thickness (UT) monitors are divided into areas in a plant, categorised with corrosion rates according to the National Association of Corrosion Engineers (NACE) classification.

Case study: a petrochemical plant

One example from a petrochemical plant illustrates the use and value of online corrosion monitoring and digital services. The plant experienced corrosion problems and replaced some of its process piping. It opted for an extensive amount of Emerson’s RosemountTM Wireless Permasense Corrosion and Erosion Monitoring Systems to be installed to monitor the corrosion rates after the plant upgrade.

Whilst analysing the data, it was discovered that 95% of the sensors showed corrosion activity over a four-month period, and in some locations to such an extent that the remaining pipe life was estimated to be less than one year.

Figure 3 shows the use of metal loss data vs time plots. The left-hand side shows metal loss vs time; the slope of the curve represents the corresponding corrosion rates. As can be seen, corrosion rates in a period from around August 2020 were high (2 mm/yr), however they decreased to a level of around 0.5 mm/yr from September onwards. The change in corrosion rates may reflect process changes or the effect of corrosion mitigation. The bottom line indicates internal roughness of pipe, which helps better understand corrosion conditions.

On the right-hand side, corrosion rates are used to predict the remaining life of the pipeline, comparing corrosion rates with defined retirement thickness of the pipe. The circle around November 2021 indicates time when corrosion allowance of the pipe will be consumed. Such prediction allows for timely integrity planning, which increases safety and reduces the need for unplanned maintenance/repairs and plant downtime.

Plots for different sensors can be combined and used to identify general trends and locations where corrosion problems are particularly severe. To verify that the measured corrosion rates are reliable, raw data is checked against temperature variations and ultrasonic waveforms, confirming the validity of the data. When compared with pipe wall thickness/corrosion allowance, it was found that for the actual plant, some pipes had a remaining life of less than one year, many between one and five years, and a few with a life expectancy of more than 10 – 15 years.

Based on the monitoring results, replacement of heavily-corroding piping will be carried out earlier than originally planned.

Conclusion

In summary, online monitoring identified high corrosion rates that would have posed a risk to plant uptime and safety if undiscovered. Through remote data analysis and reporting, the following was achieved: n Raw data was checked to validate that measured wall thickness and calculated corrosion rates were correct. n Critical findings were highlighted with corrosion rates, and the remaining life of piping for critical location was calculated. n Corrective actions (replacement of pipes) were planned and implemented before damage or accidents occured.

Corrosion is at the root of many maintenance, integrity, and safety challenges facing operators today. Real-time corrosion monitoring of equipment and associated piping can provide valuable insight into the corrosion status and provide an up-to-date picture of how infrastructure is coping with the ever-changing demands placed upon it.

Reference

1. ‘Economic Impact’, NACE International, http://impact.nace.org/ economic-impact.aspx