8 minute read

A new look at inspection

Kieran Boyd, Avestec, Canada, discusses the use of a non-destructive testing inspection method to monitor equipment at a refinery.

One of the significant onshore refineries in North America processes crude oil from the Pacific Northwest into mainly gasoline, diesel or jet fuel. The refinery, covering 3300 acres, can process approximately 250 000 bpd of crude oil.1 In recent years, the multinational oil and gas company that owns the refinery has prioritised reducing its carbon footprint. It completed a 22-month modernisation project to help reduce source emissions. After completion, the oil producer planned a multi-hundred-million-dollar investment to improve the refinery’s efficiency, reduce its carbon dioxide (CO2) emissions, and increase its renewable diesel production capability.2

During the company’s pursuit to reduce its carbon footprint, Avestec inspected the condition of the equipment that was being used. Non-destructive testing inspection, using a flying robot, was an efficient means to do so. The team inspected three assets at the refinery in August 2021, and the testing successfully provided accurate readings and improvements when compared to conventional methods.

Customer needs

Oil refinery inspections monitor the condition of assets to avoid unscheduled shutdowns for restoration or replacement. The industrial process plants are responsible for predictive maintenance of their equipment every three to five years. Owning companies require a third-party inspection team to ensure that their equipment meets mandatory operating conditions.

Predictive maintenance equipment measures the condition of equipment through non-destructive testing. Non-destructive testing in maintenance is carried out by both visual and contact-based inspections. Visual inspection analyses equipment appearance using cameras, the human eye, and artificial intelligence (AI)-sensing technology. Contact-based assessment measures the thickness of assets using ultrasonic (UT) gauges.3

During the inspection of the large refinery, Avestec performed the UT measurements on various pieces of equipment. Skyron, a flying robot, gauged the flare stack, storage tank, and pipe at hundreds of points throughout each asset. Each asset shared the challenge of having elevated measurement points, further emphasising the safety and efficiency of an aerial approach.

Solution

Before the Avestec inspection method, this refinery’s predictive maintenance was performed using conventional methods, such as scaffolding and rope access.

Modern-day scaffolding is efficient in the amount of material and time needed to set up temporary constructs. Rope access incurs minimal costs, and poses limited risk to inspectors. However, it still requires time and cost, and can put inspectors in dangerous positions.

In the inspection industry, asset owners and inspection teams prefer rope access to scaffolding as it takes less time, and costs less. However, scaffolding still plays a large part in its safety and access. For example, inspections with no ability to hang ropes from structures still need to set up scaffolding. Furthermore, scaffolding is safer than rope access as it provides inspectors with a solid surface at height, instead of a harness.3

Both scaffolding and rope access meet customer needs in providing accurate data from contact-based inspection; however, it is an expensive necessity. Scaffolding is costly due to the need to rent a large amount of equipment, and the time that is taken to build temporary structures. Rope access is faster to set up than scaffolding, but does still require set-up time.

Furthermore, both methods put inspectors in potentially hazardous positions at heights, regardless of surface or no surface. The methods are costly, time consuming, and put inspectors in danger next to contact-based inspections with Skyron.

The method provides accurate NDT inspection data without the baggage. The robot can fly to the points of contact and perform measurements. The inspection team can operate safely using line of sight or first-person view camera on the Skyron. From flight, the time is a fraction of that required by conventional methods. Time is saved when it comes to set-up, as the robot comes ready from its box as opposed to requiring set-up and deconstruction, as with traditional equipment. Lastly, the method addresses the cost of large inspection teams needing only a pilot and an inspector to conduct inspections. The duo can navigate assets quickly and efficiently while gathering accurate data.

The method met the refinery’s needs for non-destructive testing inspection. Furthermore, it provides a shorter timeframe, costs less, and is safer for the inspectors.

Figure 1. The four positions of Skyron on a pipe.

Figure 2. The Avesoft reporting software.

Result

In July 2021, Avestec performed predictive maintenance on three fundamental assets of the refinery. Skyron successfully inspected the shell/roof of a tank, horizontal/vertical pipes, and a flare stack.

The robot demonstrated that it could eliminate human risk and decrease the time and cost of the inspection. Specific to this refinery, it performed UT measurements at any height, on various asset geometries, and on coated or non-coated carbon steel.

On the first day, within 45 minutes of flight time, the robot conducted 155 UT measurements on the first carbon steel asset of the tank. It flew up two tank routes and measured one course on the tank’s roof. It also made 23 attachments, with an average of fewer than 2 minutes per attachment.

The following day, the robot inspected an assortment of angles on pipes. It demonstrated that it can successfully measure different curved surfaces by attaching to horizontal elbows, vertical elbows, and horizontal pipes. It performed 94 readings within 35 minutes, on 17 attachment points.

On the final day, the robot demonstrated its high-temperature rating and its steady performance at heights, and in wind. When flying up 130 ft in winds, it attached to an operation flare stack. It performed 27 UT measurements on two attachment locations in 8 minutes.

Within three operation days and just 88 minutes of flight time, the robot took 276 UT readings on 42 attachment locations of hard-to-reach assets. The operation time included: n Onsite permit acquisition. n Set-up and safety checks. n Pre-attachment in-flight preparation. n Real-time data verification and recording. n User comment. n Detachment.

Advantages

Wide range of use

The flying robot was able to attach to the targeted assets that presented challenges in terms of their shape, angle and positioning. This was best demonstrated in the pipe system with bottom, top, horizontal and vertical elbows, as seen in Figure 1. Skyron’s robotic arm rotated to the best position to attach to the measurement point.

Safety of operation

The inspector and pilot could avoid putting themselves in any dangerous position during operations, even when measuring a flare stack 130 ft above ground, while burning gas. The robot accurately measured the wall thickness of the flare stack, with no impairment from the heat. Using the line of sight and first-person-view video, the inspection team stood safely away from any potential hazards while conducting flight and measurements.

Secure contact to surface

When carrying out aerial robotic inspections, the greatest challenge is making consistent contact with an asset while in flight. The robot overcomes this challenge by using an attachment arm to maintain constant contact with the asset. Once attached, the UT gauge can perform scans in the same spot. Furthermore, from the secured position, its UT gauge can move within 2 in. x 2 in. to scan 25 different points to avoid immovable obstacles. This ability allows inspectors to ensure accurate UT readings from each attachment point.

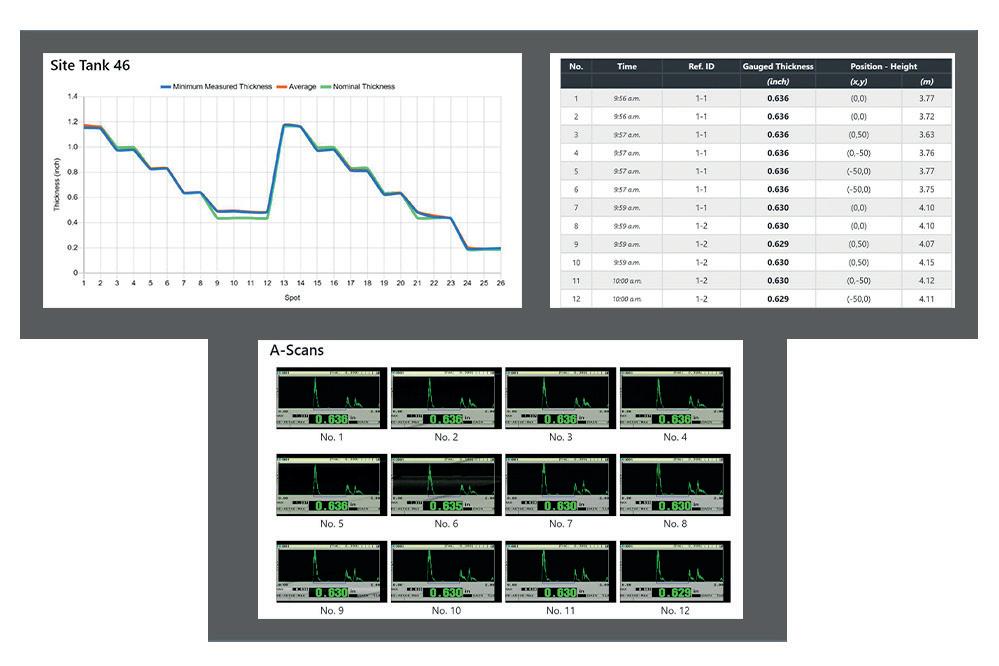

Figure 3. Data visualisation. Surface preparation

To provide accurate UT measurements for the asset owners, inspectors needed to overcome potential obstructions in UT readings. Specifically, these included dirt and corrosion, as well as unevenness of the surface, each of which would hinder accurate UT measurement. To manage these obstacles, the robot carries a surface brush and couplant reservoir. The surface brush removes physical particles, such as dirt and rust. A brushed and clean surface ensures that UT transducers couple properly to the surface and to produce accurate thickness readings. On the prepared surface, couplant gel fills any remaining air pockets and gaps between the transducer and surface, further improving the UT coupling that is required for an accurate measurement.

Unlimited flight time

Each asset to be measured at the refinery had multiple attachment points. The many points required to fly to, attach, and measure demanded that Skyron stay powered for a long time. It remained so for the entire time that it took to inspect the assets, as it was continuously supplied from the ground. Whereas most aerial robots have a limited supply of energy from their onboard battery, Skyron has an unlimited flight time by connecting to the Avestec Smart Tether System. The system generates and distributes power to the robot through a flexible tether cord.

Real-time data verification and recording

The reporting software AvesoftTM (see Figure 2) simplified the inspection process for both inspections and asset owners. The proprietary software performs data analysis and automates report generation simultaneously. A data presentation module has an intuitive interface for everyone involved with the inspection. The software offers asset visualisation and data tagging, images with interactive tags, and labels. Clicking them reveals information about each measurement. The visible and easy-to-understand layout helps inspectors to keep track of process and offers asset owners the optimal representation of data in real life, as seen in Figure 3. Avesoft eliminated the time spent tracking down data and enabled timely, well-informed decision making.

Conclusion

The inspection successfully provided the refinery operators with accurate readings while delivering improvements upon conventional methods. In using the Skyron, the inspection duo performed contact-based measurement on a flare stack, tank and pipe.

Inspectors were able to overcome a number of obstacles in order to provide accurate and timely inspections.

References

1. ‘Washington: bp’s economic investment’, BP, https://www. bp.com/content/dam/bp/country-sites/en_us/united-states/ home/documents/where-we-operate/states/bp%20in%20 Washington.pdf 2. ‘Refineries’, BP, https://www.bp.com/en_us/united-states/home/ what-we-do/production-and-operations/refineries.html 3. ‘Overview of Maintenance’, Inspectioneering, https://inspectioneering.com/tag/maintenance