7 minute read

Keeping an eye on corrosion

of the pipe, which will result in a continuous thinning, or wall loss, of the solid structure. Pitting corrosion is the local deterioration of a more limited surface area that leads to cavities or ‘pits’ that may puncture the pipe and cause leakage. Some forms of deterioration, such as erosion corrosion, which results from the movement of fluid and its interaction with the inner surface of a pipe, are not visible with just an exterior visual inspection.

While there are several ways to hinder the corrosion of critical assets, such as cathodic protection or sacrificial anodes, there is no substitute for regular monitoring along the pipeline.

In most cases, a company will perform a corrosion risk assessment. This involves an identification of the facilities that are at risk, ranking their proneness to corrosion, and identifying options to remove or mitigate the risks. In order to combat this ongoing process of corrosion, inspection, assessment, replacement, and the regular monitoring of assets should be viewed as a strict necessity.

Monitoring asset integrity in the critical energy segment has typically been carried out by manual and visual inspection or invasive technologies such as coupons focused on likely-affected locations across given time intervals. Allocating manpower to physical locations for inspections is not only costly in terms of financial compensation, but there is also an element of physical danger involved in the examination of pipelines that are located in adverse environments.

Figure 1. Ultra-high-temperature microPIMS attached with a band clamp.

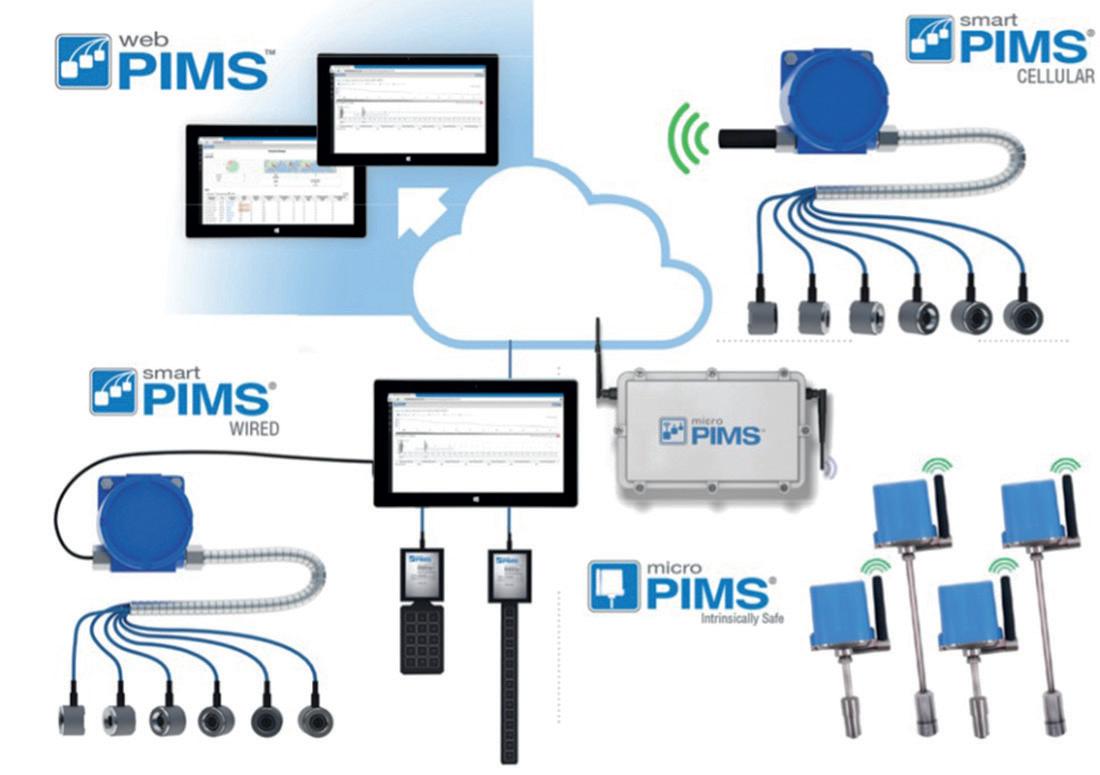

Figure 2. Three networked system types all feed into the cloud, or a private server, with one common, back-end web portal for data management.

A history of monitoring

While periodic monitoring for corrosion can decidedly decrease incidents of failure of critical assets, a more permanent solution was needed in order to accurately ascertain continued asset viability.

In February 2014, two ex-GE employees, Dr. James Barshinger and Bruce Pellegrino, saw the need for a more efficient and comprehensive alternative to these traditional monitoring techniques. Their solution was the use of wireless sensor networks (WSNs). As a result, asset owners could install wireless, battery-operated ultrasonic (UT) sensors at strategic locations, virtually eliminating the necessity for costly and unnecessarily-dangerous manual inspections. These UT sensors continuously monitor asset integrity without the need for onsite, physical examination and assessment.

The spring of 2015 saw the debut of a hardwired version of a permanently-installed monitoring system. This non-intrusive UT monitoring system connects directly to a PC or laptop and is geared more towards infrequent data collection. Over the next few years, the duo worked steadily on creating and improving UT transducers and various other product lines that included cellular-connected systems, WiHART, and LORA-WAN wireless protocols.

In 2016, the company formed by Barshinger and Pellegrino, Sensor Networks Inc., decided to build a UT division from the ground up, providing the industry with an assortment of transducers ranging from phased-array to angle-beam and immersion transducers. In addition to transducers, a vast line of asset maintenance apparatus, including remote visual inspection tools and remote retrieval solutions, were designed for an array of industrial applications.

Today, due to the inclusion of UT transducers, oil and gas pipeline integrity can be closely monitored without costly and often dangerous manual inspection of assets in the field.

By October 2021, advancements in technology allowed for the development of a third-generation, permanently-installed monitoring system (microPIMS® Intrinsically Safe). This star-network topology system operates using long range sub-gigahertz LoRaWan® wireless connectivity. Each microPIMS sensor can be programmed to record thickness readings at any user-defined time interval. Data is automatically sent to a private webPIMSTM, cloud-based or on-premises LoRaWAN system, and software with back-end data analysis, trending and more. These units can be easily installed either temporarily or permanently, with either a band clamp or a magnetic base for tanks and vessels. Two D-sized batteries provide each unit with 15 years of life atone reading per day. The microPIMS can also help to lower costs by reducing scaffolding and insulation removal/refitting for internal corrosion monitoring.

Case study

The problem

One of the more critical areas for refineries to be able to manage and maintain from an Environmental Compliance and Safety perspective is the amine treating unit, often part of sulfur recovery and tail gas teating units (SRU and TGTU). The TGTU converts any remaining sulfur compounds into hydrogen sulfide (H2S), which is then reprocessed by the SRU. The SRU tail gas is heated and sent to a catalytic reactor where it is cooled and sent to the absorber column in the amine treating unit (ATU). It is during both this and the succeeding processes that many experience corrosion/erosion events, which can cause setbacks in asset integrity planning. In this case, it was determined that the design of a nozzle in the horizontal position in one of the exchangers was a poor industry design that caused turbulence (eddies) and increased the corrosion rate in specific areas.

The solution

Due to the intermittent nature of this erosion-corrosion damage mechanism, achieving a reliable corrosion rate and focusing in on the most likely affected locations was challenging. After years of repeated manual UT thickness inspection at different intervals, with limited success, the asset owner decided that instead of a periodic manual inspection, they would monitor continuously.

Along with personnel from Sensor Networks Inc., the owner mapped out the areas that would most likely be of concern and performed some baseline screening and inspection to identify where to monitor. Then, automated, wireless, battery-operated UT sensors were temporarily installed at strategic locations on the asset. The asset owner was able to programme reading intervals for the sensors to take daily wall thickness measurements which were then plotted over time. The installation process only took one day, and each sensor was installed in less than 20 minutes per monitoring location by their own site personnel.

Figure 3. A dual element microPIMS attached with a band clamp and magnetic base. The outcome

Using the monitoring approach via the installation of SNI wireless UT sensors, the asset owner was able to quickly and accurately (to within 0.001 in./0.025 mm) trend the corrosion rate at each point where the sensors were located. Furthermore, with the help of the operations and corrosion teams, the asset owner was able to remediate or reduce the corrosion at this location of the unit.

Financial impact

Since the unit was built, there have been > 6 unplanned outages over a 15-year period which have been traced back to this issue, at an estimated US$12 million in maintenance cost and US$200 million in downtime. The ability to trend and, in this case, remediate the corrosion rate for the tail gas unit (TGU), allowed the asset owner to safely operate the unit for an estimated 4.6 additional years, saving maintenance activities and US$4.8 million. A US$40 000 investment in an SNI microPIMS starter kit yielded a return on investment (ROI) of 98% and payback period of less than three months. The rest of the site will also benefit from the long-range wireless infrastructure investment and place sensors across the entire facility to monitor other critical assets.

By scaling this strategy across its facility, this refiner expects to expand its digital asset integrity and monitoring programme to identify many other locations, with the potential of safely extending the life of its assets, and saving millions of maintenance dollars annually.

While asset monitoring will always be a necessity for the oil, gas and petrochemical industries, the manner in which these assets are inspected does not always need to be a financial or operational burden. The implementation and use of these remotely-accessible UT monitors has proven to be a recognisable resource industry-wide, and as more critical energy companies avail themselves of this technology, the incidence of pipeline failure could become less of a catastrophe and more of a minor nuisance.

Conclusion

Metal loss, due to corrosion or erosion, can manifest itself in numerous ways: random, general, highly-localised, episodic, unit and site specific. The tools discussed in this article have evolved over the past decade to accommodate the wide range of issues facing corrosion, life extension and facility managers at upstream, midstream, downstream and petrochemical facilities. Sensors and software that are accurate, reliable, reasonable in cost, and easy to attach, manage and deploy as needs change, are increasingly becoming the norm and recommended best practice.