APRIL 2023 VOLUME 6 ISSUE 3

flender.com FLEX-A10065-00-7600

SERVICES. ORIGINAL

Stephen

17 A Technological Transformation

Luca

20 A Productive Partnership In Idyllic Surroundings

Epiroc outlines how the iron ore mine at Noamundi, India, is taking productivity and sustainability to the next level.

23 The Solution Is Boring

Dennis Ofiara, Robbins, USA, details how non-circular tunnel boring can answer the need for the mechanical excavation of mine development tunnels.

27 An Electric Alternative

Gianfranco Conti and Lyndon Dean, Emerson, explain how electric actuators are quickly becoming a preferred alternative over pneumatic actuators for the mining industry, driven by advances in functionality and performance.

31 Fine-Tuning Frothy Waters

Quinton Sutherland, Weir Minerals, Canada, reviews how pumps can be utilised to solve the problems that occur in mineral froth tanks.

35 The Journey Of The Electric Submersible Dewatering Pump

Electric submersible pumps have a solid history in mining applications. Bart Duijvelaar, Atlas Copco Power and Flow, illustrates how the mining industry should rely on manufacturers that can provide the right solutions to meet mining challenges.

39 Improving Equipment Performance Through MPC

Kerryn Sakko and Grant McHenry, Rockwell Automation, Australia, discuss how machine-learning technology, and specifically model predictive control, can help mine and plant processes run closer to their constraints.

43 Go The Distance With Galvanisation

Burkhard Scherf, Thiele GmbH & Co. KG, Germany, considers how improved materials and galvanising on AFC-chains can promote better endurance and test results.

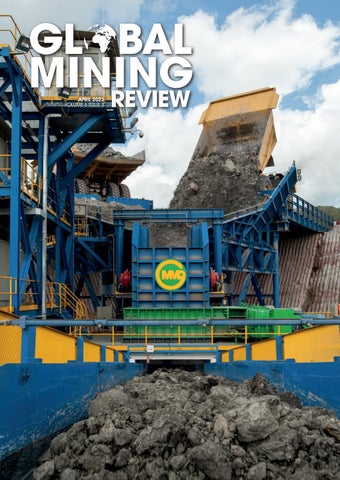

ON THE COVER

MMD Group is a global leader in the design and manufacture of Mineral Sizing and In-Pit Sizing and Conveying (IPSC) technology. The company’s groundbreaking fixed, semi-mobile (pictured) and fully mobile IPSC solutions are improving the performance and efficiency of numerous mines around the world by enhancing safety and reducing environmental impact, while delivering low operating and maintenance costs.

03 Guest Comment 05 World News 08 Mining In The Americas Amelia Haines, Fitch Solutions, UK, provides a detailed overview of the current state of the mining industry in North and South America.

CONTENTS

Fresh Air

13 A Breath Of

air in enclosed spaces, subsequently reducing risks to mining personnel.

Gledhill, Freudenberg Filtration Technologies, Australia, explores how flexible filtration solutions can deliver hospital-grade

highlights the

improved operations at a site in

Malpighi, Tesmec, Italy,

upsides of continuous surface mining technology and how it has

New Zealand.

Copyright © Palladian Publications Ltd 2023. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior permission of the copyright owner. All views expressed in this journal are those of the respective contributors and are not necessarily the opinions of the publisher, neither does the publisher endorse any of the claims

in the advertisements. Printed in the UK. MiningReview like join Global Mining Review @Mining_review follow CBP006075 VOLUME ISSUE 8 April 2023 // global mining review 9 global mining review April 2023 08

made

Guest Comment

2022 was marked by a plethora of tumultuous global events: from conflict to inflation, climate disasters, and market volatility. Despite these challenges, against the backdrop of a difficult economic climate, a recent study from Harvard indicates that the majority of institutional investors plan to increase their allocations to environmental, social, and governance (ESG) investments over the next two years.1 As these years unfold – and the challenges the world faces continue to be interconnected from an economic, political, social, and environmental standpoint – a wider range of focus areas will be seen coming into the ESG agenda for mining companies, supported by new environmental and sustainability performance targets, and far more stringent regulations.

MANAGING EDITOR

James Little james.little@globalminingreview.com

SENIOR EDITOR

Callum O’Reilly callum.oreilly@globalminingreview.com

EDITOR

Will Owen will.owen@globalminingreview.com

EDITORIAL ASSISTANT

Isabelle Keltie isabelle.keltie@globalminingreview.com

SALES DIRECTOR

Rod Hardy rod.hardy@globalminingreview.com

SALES MANAGER

Ryan Freeman ryan.freeman@globalminingreview.com

PRODUCTION MANAGER

Kyla Waller kyla.waller@globalminingreview.com

ADMINISTRATION MANAGER

Laura White laura.white@globalminingreview.com

EVENTS MANAGER

Louise Cameron louise.cameron@globalminingreview.com

EVENTS COORDINATOR

Stirling Viljoen stirling.viljoen@globalminingreview.com

DIGITAL ADMINISTRATOR

Leah Jones leah.jones@globalminingreview.com

DIGITAL CONTENT ASSISTANT

Merili Jurivete merili.jurivete@globalminingreview.com

Previously, the main drivers behind ESG initiatives were financial and corporate institutional concerns, or opportunities in response to sustainable development goals and regulations. The focus has largely been on the environmental aspects, with some further clarity required around expectations and measurable objectives on the social and governance agendas. Today, the focus is more on measuring ESG performance against a broader set of goals that satisfies the needs of all stakeholders.

Get this right, and mining companies with strong ESG performance will be in a position to reap the benefits of the competitive advantages ESG can deliver. Success, however, will be largely dependent on how the industry innovates together to make the possibility of ultra-efficient mines, that have a better interaction with nature, a reality.

Over the coming years, standards and regulations around social management practices are expected to evolve, with various industry and commodity-specific standards, principles, and protocols being developed. The Global Industry Standard on Tailings Management (GISTM) sets high expectations for community engagement, participation and collaboration, as well as socio-economic assessment alongside other International Council on Mining and Metals’ (ICMM’s) Performance Expectations.2,3

Whilst the extent to which ESG policies are being implemented in practice is still evolving, it is clear mining companies will be under ever-increasing scrutiny. A good example is the recent launch of the independent Global Tailings Management Institute (GTMI), to oversee implementation and conformance of the GISTM in the core areas of assurance, awareness, knowledge sharing, and disclosures. The GTMI will review how the standard is being applied across all operations, with transparency and independent verification.

While this is one example of a measurable performance accountability, there are many others.

Data management is a key area of focus. Better insights from data, using digital technology to manage, analyse, and utilise data allows mining companies to not only claim adherence to ESG initiatives, but also to provide evidence of their work practices.

When data is well-organised and easily accessible, it enables teams across a company’s operations to come together; creating opportunities for collaboration, bringing better insights, and driving improvements in ESG performance. With the right software and data management practices in place, companies are empowered to make better decisions and provide the evidence they need to demonstrate compliance. Transparency is key to reporting environmental performance, and it can only be achieved by wielding the power of accurate, reliable data. The challenge is that data often resides in different systems, architectures and platforms, making it difficult to break down silos and enable collaboration. By obtaining, combining, and analysing data from across a mine’s lifecycle, mining companies can easily demonstrate their commitment to sustainable operations.

Geoscience and engineering innovations continue to evolve to help deliver efficient mines, while minimising the environmental effects of waste during operations and following mine closures. Creating and working with accurate geological digital twins capable of handling large data sets and generating detailed models, mining companies can quickly visualise and interpret modelled data, allowing teams to connect, discuss and make decisions, even when they are in different parts of the world.

Sophisticated model management platforms, which provide a repository for all modelling data, can give operators easy and ready access to the information they need, when they need it.

Seequent is working hard to develop a deeper understanding of industry challenges, and deliver supporting technologies and workflows that help companies comply with stricter regulations. Technology is the key to supporting mining companies achieve and measure their ESG compliance, as well as implement more efficient practices across operations and better management of risk.

References

Available on request.

Palladian Publications Ltd, 15 South Street, Farnham, Surrey, GU9 7QU, UK t: +44 (0)1252 718999 // w: www.globalminingreview.com

GLOBAL MINING REVIEW (ISSN No: 2515-2777) is published by Palladian Publications Ltd. Annual subscription (nine issues) £50 UK including postage, £60 overseas (airmail). Claims for non-receipt must be made within four months of publication of the issue or they will not honoured without charge.

PIETER NEETHLING SEGMENT DIRECTOR MINING OPERATIONS, SEEQUENT

WIRTGEN GmbH · Reinhard-Wirtgen-Str. 2 D-53578 Windhagen T: +49 26 45 / 131 0 A WIRTGEN GROUP COMPANY 280 SM(i): Surface Mining combines safe mining operations with modern cost-effectiveness: the 280 SM(i) replaces the entire equipment otherwise needed for blasting, drilling and pre-crushing. It cuts costs, delivers mined raw materials of higher quality, and ensures more efficient exploitation of the deposits. Take advantage of innovative solutions from the technology leader. www.wirtgen.com www.wirtgen.com/mining Blasting? No! Safety? Yes!

WORLD NEWS

Teck Resources and Agnico Eagle Mines have entered into a joint venture shareholders agreement whereby Agnico Eagle, through a wholly-owned Mexican subsidiary, has agreed to subscribe for a 50% interest in Minas de San Nicolás, S.A.P.I. de C.V. (MSN) for US$580 million, to be contributed as study and development costs are incurred by MSN.

For governance purposes, Agnico Eagle is deemed to be a 50% shareholder of MSN from closing, regardless of the number of shares that have been issued to Agnico Eagle or its subsidiary.

Teck and Agnico Eagle are now 50/50 joint venture partners at San Nicolás, working together to advance permitting

and development of the high-quality copper-zinc project, located in Zacatecas, Mexico. The joint venture partners are planning to submit an environmental impact assessment and permit application for San Nicolás in 1H23, and are targeting completion of a feasibility study in early 2024.

Concluding the San Nicolás joint venture, initiating permitting, and completing the next stage of technical studies is another positive step in Teck’s strategy to advance its industry leading Copper Growth portfolio in a timely and prudent manner; and for Agnico Eagle in leveraging its Mexican operating experience and know-how to pursue growth in a high-quality, copper-zinc mineral deposit located in a premier mining jurisdiction in Mexico.

AUSTRALIA Newmont to enter into confirmatory due diligence on Newcrest

Newmont Corp. has submitted a revised non-binding indicative proposal to the Board of Directors of Newcrest Mining Ltd to acquire 100% of the company’s issued share capital.

The acquisition is being undertaken by way of an Australian Scheme of Arrangement, under which Newcrest shareholders would receive 0.400 x Newmont shares per each Newcrest share held. In addition, Newcrest would have the right to fund and pay to its shareholders a special dividend of up to US$1.10 per Newcrest share. Newmont’s improved offer on these terms is best and final, subject only to no superior proposal emerging.

The Newcrest Board of Directors has agreed to grant Newmont confirmatory due diligence access to enable Newmont to put forward a binding proposal. Due diligence is expected to be completed within approximately four weeks. Newcrest has indicated that it intends to grant exclusivity to Newmont during the due diligence period, with the terms of that exclusivity still to be agreed. Newcrest will also undertake confirmatory due diligence on Newmont during this period.

Tom Palmer, President and CEO of Newmont, comments: “We are entering a new era in which mining companies must hold themselves to a higher standard of sustainability and long-term value creation. This transaction would strengthen our position as the world’s leading gold company by joining

two of the sector’s top senior gold producers and setting the new standard in safe, profitable and responsible mining.

“Together as the clear gold-mining leader, we would be well-positioned to generate strong, stable, and lasting returns with best-in-class sustainability performance for decades to come.”

The proposed combination creates the industry’s best portfolio of world-class assets with the highest concentration of top-tier operations, primarily in favourable, low-risk mining jurisdictions. Newmont would further strengthen its portfolio by increasing annual copper production, as well as adding nearly 50 billion lb of copper reserves and resources to its balanced and diverse asset base.

By applying Newmont’s long track record of safe and profitable mining, the combined group is expected to deliver significant annual synergies and create long-term value for all stakeholders. The business would be immediately supported by Newmont’s scalable, integrated operating model, with a deep bench of subject matter experts and existing regional platforms in Australia and Canada. This would allow the business to leverage the combined group’s global supply chain, and generate substantial synergies through the implementation of Newmont’s proven Full Potential continuous improvement programme.

5 GLOBal mining review // April 2023

MEXICO Teck and Agnico Eagle announce completion of the San Nicolás copper-zinc project joint venture

WORLD NEWS

Diary Dates

Expomin

24 – 27 April 2023

Santiago, Chile

www.expomin.cl

Mines and Money Connect: London 2023

25 – 26 April 2023

London, UK

https://minesandmoney.com/connect

CIMTL23 Convention and EXPO

30 April – 03 May 2023

Montreal, Canada

https://convention.cim.org

Discoveries 2023 Mining Conference

30 May – 01 June 2023

Mazatlán, Mexico

www.discoveriesconference.com

Mines and Money Connect: Melbourne 2023

14 – 15 June 2023

Melbourne, Australia

https://minesandmoney.com/melbourne

AIMEX 2023

05 – 07 September 2023

Sydney, Australia

www.aimex.com.au

China Coal & Mining Expo 2023

25 – 28 October 2023

Beijing, China

www.chinaminingcoal.com

To stay informed about upcoming industry events, visit Global Mining Review’s events page: www.globalminingreview.com/events

SOUTH AFRICA Epiroc completes acquisition of AARD Mining Equipment

Epiroc, a productivity and sustainability partner for the mining and infrastructure industries, has completed the acquisition of AARD Mining Equipment, a South African mining equipment manufacturer.

AARD, based near Johannesburg, South Africa, designs, manufactures, services and supports a wide range of mining equipment, specialising in low-profile underground machines for mines with low mining heights.

The company’s product offering includes drill rigs, bolters, loaders, scalers, and more. Its customers are mainly located in the Southern Africa region.

AARD has approximately 200 employees and had revenues in the fiscal year ending 30 June of approximately MSEK 650.

CHILE Sandvik expands its automation solutions at El Teniente

Codelco, the world’s largest copper producer, has chosen Sandvik Mining and Rock Solutions to supply its leading AutoMine® Fleet automation solution and 13 autonomous loaders for the Recursos Norte operations at the El Teniente mine in Chile. The contract will run from 2023 through 2027, supporting Codelco’s goal of operating the world’s most automated and digitalised mine.

This is a continuation of multiple automation solutions orders Sandvik has received from Codelco since 2019. After full implementation of the projects, Codelco will have more than 40 autonomous Sandvik trucks and loaders in operation at the El Teniente mine.

The new order will be supplied in two phases. During 2023, Codelco will receive six Toro™ LH514 loaders, as well as an AutoMine Fleet system capable of being scaled to support up to 13 machines and AutoMine production area hardware for future expansions over several years. Toro LH514 loaders belong to Sandvik’s mid-size offering with a 14 t payload capacity. The loaders’ reliability, robust structure, and Sandvik Intelligent Control System enable the use of highly advanced digital solutions, such as AutoMine.

The first phase of the order, which also includes support contracts for equipment maintenance, AutoMine lifecycle services and software licensing, will be used by Codelco Recursos Norte in a new block caving area in El Teniente. As a key productivity partner, Sandvik will support Codelco in its shift towards automated mining operations and increasing its workforce knowledge on these technologies.

The second phase of the order will be delivered from 2024 through 2027, in which Sandvik will provide seven more Toro LH514 loaders and an expansion for the AutoMine Fleet system.

6 GLOBal mining review // April 2023

Telephone: (+39) 039.5320739 Email: cicsa@cicsa.com CHAINS AND COMPONENTS FOR BULK MATERIAL HANDLING www.cicsa.com 80 years handling bulk materials, globally Round steel link chains Conveyor chains Central chains Mechanical chains Sprockets Wheels Components

8 April 2023 // global mining review

9 global mining review // April 2023

the value of the domestic coal industry, as a result of prices dropping from record levels seen in 2022.

With the Biden administration focused on increasing the availability of critical minerals produced onshore to improve resource security, critical mineral production will be the driver of output growth in the coming years. Downward pressure from the US coal sector, however, will offset any increases to the mining industry value in the coming decade, with the US’ MIV set to decline by 15.5% from US$177.9 billion to US$150.3 billion in 2024, with an average annual rate of decline of 7.2% over the period 2024 – 2032.

The Americas: Key themes for 2023

Critical mineral projects to dominate pipeline with renewed focus on resource security

Analysis indicates a common theme playing out in the region is the rise in the development of critical mineral projects, such as copper and nickel, needed for the production of electric vehicles (EVs) and renewable energy grids. Global demand for critical minerals is set to rise significantly as the green energy transition accelerates. The race to secure sufficient supply of critical minerals as demand surges and deficits loom will encourage an influx of

new project investment across the Americas. Critical mineral project growth in the Americas will be buoyed by the IRA, which provides tax credits for EVs produced using critical minerals mined in the US or in US free trade partner countries. Canada, Peru, Chile, and Panama all hold free trade agreements with the US and have vast mineral reserves, providing upsides for countries across the region.

US-China tensions are putting pressure on authorities, in the US and Canada in particular, to introduce new policies targeted at reducing dependency on Chinese supply and the nation’s dominance in the market. The introduction of the Securing America’s Mineral Supply Chains Act of 2022, for example, aims to increase onshore critical mineral project development by simplifying the regulatory permitting process that allegedly stalls the development of new projects. The Canadian government is also implementing measures aimed to increase critical mineral production with the 30% Critical Mineral Exploration Tax Credit, applicable to critical minerals – including cobalt, copper, graphite, lithium and nickel, among others – to boost investment activity. Alongside this, are policies aimed at improving the national security of domestic resources. For example, the Investment Canada Act, introduced in October 2022, puts forth a new system to review investments into critical mineral projects by foreign state-owned companies and private investors closely linked with foreign governments. In late 2022, the Canadian government ordered three Chinese investors to divest holdings in Canadian listed lithium companies due to national security concerns.

As resource security becomes a key focus for major economies in the region, Fitch Solutions expects critical mineral output to grow across the region. Latin America holds vast, untapped mineral resources and will attract investors from the US as the Biden administration makes efforts to localise critical mineral supply chains.

Gold production set for steady growth

An influx of new gold projects will also drive future mining growth across the continent, with miners attracted to the region’s vast reserves and elevated gold prices. As evident in Figure 2, a healthy gold project pipeline will boost production in the coming years. Although Fitch Solutions’ analysis indicates that gold prices will gradually decline over the period 2023 – 2027, they will remain elevated compared to pre-pandemic levels and incentivise exploration activity.

Resource nationalism a growing threat to miners

Another trend Fitch Solutions expects to see across the region is a rise in resource nationalism, in response to the green energy transition and the influx of new projects. In 2022, a number of national governments, particularly in Latin America decided to either introduce new

10 April 2023 // global mining review

Figure 2. Source: Fitch Solutions Global Mines Database.

Figure 1. e/f = Fitch Solutions estimate/forecast (Source: USGS, Fitch Solutions).

YOUR COMPLETE SOURCE FOR IN-PIT SIZING SOLUTIONS

Lower costs and increase energy efficiency with MMD IPSC solutions

MMD remains at the forefront of In-Pit Sizing and Conveying (IPSC) technology, developing ground breaking sizing systems that optimize efficiency, improve safety, and delivers high productivity.

The Twin Shaft MINERAL SIZER™ sits at the heart of every IPSC system, providing a controlled product to the conveyor system and downstream processes whilst keeping dust and fines generation to a minimum. To cater for today’s variety of modern mining methods, MMD has deployed many successful modular Sizing stations and systems worldwide to take advantage of cost effective long haul by conveyor. High throughputs and short relocation times enable mines to achieve their efficiency and productivity goals.

MMD’s worldwide structure, technical expertise and service excellence ensures your system always delivers optimum performance. Discover how we can deliver the complete IPSC solution for your specific needs.

WWW.MMDSIZERS.COM

policies to increase royalty rates or nationalise domestic critical mineral reserves. For example, in Chile, a new mining royalty bill increasing royalty rates on copper was approved in January this year by the Chilean mining and energy commission, and is now close to being passed. In April 2022, Mexico nationalised lithium mining, and has recently made a statement that the move was made to prevent exploitation of the nation’s rich lithium reserves.

Resource nationalism often creates an unfriendly investment environment as tax hikes negatively impact miners’ profitability, and the nationalisation of resources creates a difficult operating environment. In response to Chile’s proposal of a new mining royalty bill, major miners, who contribute significantly to the MIV, warned congress that the rate hike could lead them to reconsider their investment portfolios. BHP, for example, told congress that the proposed bill may lead them to examine their US$10 billion investment portfolio. In 2023, Fitch Solutions’ analysis suggests that the focus on resource nationalism from local governments could put downwards pressure on

investment activity in key Latin American nations – such as Mexico, Panama, and Chile – given the large volume of multinational miners operating in the space.

Heightened risk of community opposition and environmental protests in 2023

Fitch Solutions expects community and environmental opposition to pose a challenge for miners across the region in 2023, having the potential to significantly impede output volumes. Community opposition has long burdened miners across the region, with projects delayed as protestors raise concerns that mining activities will inflict harm on Indigenous communities and the environment. Additionally, local communities often argue they do not receive fair compensation for the inconveniences caused by miners. In 2022, for example, Southern Copper’s Cuajone mine in Peru halted operations as locals blocked access to water supply and key transport routes, claiming the company has not provided fair compensation to surrounding communities for the damage caused by mining activities.

Environmental protests will also present a challenge to miners. Environmental activists have often put a wrench in the cogs of mine development, and, with climate change a growing concern, miners in the region will have to continue to face issues during the permitting process, which may lead to delays to (or the rejection of) project plans. In the US, Northern Dynasty Minerals’ subsidiary Pebble’s copper-gold project in Alaska was blocked in January 2023 on account of the alleged harm the mine would cause to Bristol Bay, an area with a rich ecosystem. As of February 2023, activists in Nevada continue to fight against the construction of Lithium Americas’ Thacker Pass mine, situated on large lithium reserves needed for the production of EVs. As the number of new projects set to begin construction grows over the coming decade, alongside the acceleration of the green energy transition, Fitch Solutions expects to see an increase in opposition to mining activities across the region.

As a result, Fitch Solutions’ Industry Risk Score has declined in 2023 relative to 2022 levels for key markets across the region. Though the company is seeing governments actively focused on loosening permitting processes, environmental activists, and community opposition will continue to put downwards pressure on the likelihood of new mine developments coming online. This will present a major obstacle for miners in the coming years.

Notes

1. Represents mining gross value added (GVA). GVA measures the contribution to the industry of each individual producer. Simply put, GVA is the total of all revenues from final sales and(net) subsidies, which are incomes into businesses.

12 April 2023 // global mining review

Figure 4. Note: Scores out of 100; higher score = more attractive market (Source: Fitch Solutions Mining Risk/Reward Index).

Figure 3. e/f = Fitch Solutions estimate/forecast (Source: Bloomberg, Fitch Solutions).

Stephen Gledhill, Freudenberg Filtration Technologies, Australia, explores how flexible filtration solutions can deliver hospital-grade air in enclosed spaces, subsequently reducing risks to mining personnel.

For centuries, mining valuable raw materials has been an important global economic driver. However, one of the most valuable resources underground is the health of mining vehicle operators. Modern filtration solutions can help ensure the safety of both staff and equipment. Especially multi-stage systems that meet the requirements of the ISO 23875 standard and can provide a viable solution for effective filtration and pressurisation monitoring in mining vehicles.

13 global mining review // April 2023

Mining is a profession that requires special attention to operator safety. Since the early days of the industry, miners have been exposed to hazards such as falling rock, overturning mining machinery, or even gas and dust-related explosions. Even after the introduction of safety and health regulations in the wake of mass mining during the Industrial Revolution, worker health too often played second fiddle to the rush for ever greater efficiency and productivity. The explosion at Cymmer Collier’s Old Pit in Wales in 1856 finally marked a turning point in the history of British mining and prompted Parliament to enact a comprehensive health and safety act for miners in 1860. The subsequent Mines Regulation Act of 1872 introduced further health and safety regulations for coal and non-metal mines into the law, which still forms the basis for legislation today.

A matter of value

Despite its difficult working conditions, the mining sector has grown considerably over the decades, with revenues for the world’s 40 largest mining companies totaling US$692 billion annually. 1 Fossil fuels such as coal, diesel, and iron ore continue to secure the world’s power grids. And entire industries rely on rare earths: not only are they essential to LEDs, PCs, and many smart devices. The alternative energies industry also relies heavily on resources buried deep beneath the earth’s surface to build state-of-the-art photovoltaic or wind power plants. With demand for these products remaining high, the sector’s growth is likely to remain vigorous. Protecting operators and equipment is hence of paramount

importance to secure mining’s long-term success, as hazards still abound underground.

From asbestos and silica, to pollutants from sand, coal and ash, aerosols can enter the cabins of mining vehicles – such as haul trucks, wheel loaders, and bulldozers –through ventilation slots, with sometimes fatal consequences: inhaled coal dust is a major cause of serious lung diseases such as pneumoconiosis (also known as ‘black lung’ or ‘miner’s lung’), tuberculosis, chronic bronchitis, and chronic obstructive pulmonary disease (COPD). In addition to these serious health risks, contaminated air also causes dust-related damage to mining vehicles, leading to premature mechanical and electrical failures. Therefore, international standards define strict operator safety criteria, giving rise to filtration innovations for challenging scenarios.

Meeting the requirements of ISO 23875

International standard ISO 23875 tightens the safety regulations for heavy equipment cabs and other operator enclosures in mining. It unifies the design, testing, operation and maintenance of air quality control systems, aiming for high filtration efficiency, limited CO 2 concentrations, and balanced pressurisation levels within mining vehicle enclosures.

What does this mean for mining site operators?

According to the ISO mining operator safety standard, fresh air supply and/or recirculated air must keep particulate matter concentrations below 25 mcg/m 3, while meeting pressure and CO 2 limits. Minimum continuous pressure in the driver's cabin is 20 Pa, with a maximum of 200 Pa. Likewise, the permissible CO 2 levels are strictly regulated: CO 2 concentrations inside mining vehicles must not exceed the ambient CO 2 plus 400 ppm. By comparison, the standard CO 2 present in the earth’s atmosphere ranges between 250 and 500 ppm.

And that’s not all: mine site operators are required to install a real-time monitoring system in the vehicles’ cabins, capable of alerting staff when CO 2 concentrations or pressure levels exceed

14 April 2023 // global mining review

Figure 1. From asbestos and silica, to pollutants from sand, coal and ash, aerosols can enter the cabins of mining vehicles such as haul trucks, wheel loaders, and bulldozers through ventilation slots. Sometimes with fatal consequences.

9th International Conference on Tailings Management

REGISTER TODAY!

20% O until May 14

• +170 Works Received by Authors from 24 Countries

• +50 Presentations from Mining Industry sush as Anglo American, Cía. Minera Doña Inés de Collahuasi, Codelco, Freeport-McMoRan, Minera Chinalco, Peñoles, Teck Resources, Twin Metals Minnesota LLC, Vale, Antofagasta Minerals and More!

• Technical Courses given by the Co-organizer institutions: e Advanced Mining Technology Center (AMTC), Universidad de Chile; Tailings Center (Colorado School of Mines, Colorado State University & University of Arizona consortium), USA; TAILENG (Georgia Tech, Colorado State University, UC Berkeley & University of Illinois consortium), USA

• Networking Activities!

confirmed keynote presentations

tailing 2023 chair

kimberly morrison

Senior Director Global Tailings Managment, Newmont Mining Corporation, USA

geraldo paes

Global Director for Tailings, Vale, Brasil

phil newman

Head of Innovation, Anglo American, UK

priscilla nelson

Professor, Colorado School of Mines, USA

andrea lópez

Principal HDS Technology Development, Anglo American T&S, Chile

david machin

Tailings Strategy Senior

Manager, Antamina, Peru

More information in gecamin.com/tailings

JUNE 14 - 16 | SHERATON SANTIAGO HOTEL, CHILE organizers

their respective limits. Ensuring the health and safety of vehicle operators, as well as the functionality of mining equipment thus calls for filtration solutions capable of addressing several challenges at once. Leading specialists in air treatment for vehicle cabins have devised matching solutions that alleviate some of the extreme conditions to which miners are exposed in the field.

Technology for safe operations

Multi-stage filtration solutions with ISO 23875-compliant pressurisation and filtration of mining vehicle cabin air cover several requirements at once. Many vehicles only have basic air conditioning, offering zero or only inadequate systems for thorough dust filtration. Fine dust particles, for instance, can enter cabin enclosures via the miners’ clothing or boots, or as airborne particles when cabin doors are opened and closed. These particles subsequently remain in these confined spaces for a long period of time, as cabin air is often recirculated without proper filtration. Even retrofitted systems using filtered and compressed air usually do not meet the high ISO standard, which calls for filtration efficiency above 94% at 0.3

0.5 microns.

Futhermore, since the vehicles are sealed to achieve high cabin pressure, CO 2 easily remains in the cabin and quickly rises to dangerous levels in cases of insufficient air exchange. Fatigue, headaches, and nausea are the result – significantly increasing the risk of accidents underground.

Several stages of filtration

Multi-stage filtration systems offer a viable solution to prevent these situations altogether. They are often comprised of two pre-cleaning filters as well as two high-flow HEPA filters for effective particle separation. The two pre-cleaning elements protect the HEPA filters from heavy dust exposure and ensure longer filter life.

Air entering those systems first passes through a cyclonic dust ejection system that filters out heavy dust particles (>5 µm), before the second pre-cleaning filter takes care of coarse dust particles (1 – 5 µm). Two stages of HEPA filters then eliminate 99.995% of sub-micron particles, achieving a full cabin air exchange within 20 seconds. In addition to filtration of outside air entering the cabin, multi-stage filters also draw and filter air from within the cabin, ensuring cabins are dust free according to ISO 23875 requirements.

The HEPA-filtered air re-enters the vehicle cabin via the air vents into the occupants’ breathing zone, while also allowing some air to exit the system for fresh air exchange. Flexible filtration solutions can deliver hospital-grade air with ambient CO 2 levels and continuously monitor CO 2 levels in the vehicle and remotely via telemetry. With significant effects: fatigue and drowsiness due to high CO 2 concentrations no longer poses a risk to miners.

Protecting people and equipment

When it comes to sealed enclosures, maintaining the pressure inside the cabins while at the same time ensuring effective air circulation poses another challenge, which multi-stage solutions readily meet. They can provide a constant minimum cabin pressure of 100 Pa, which prevents contaminants from entering the interior from the outside, for example through worn door seals. In vehicles without an operator, they protect the electrical control units of autonomous vehicles, significantly reducing dust-related downtime and maintenance. HEPA filtration of the circulation air further protects air-conditioning components, such as fans and evaporative coils from dust-related damage – e.g. overheating due to clogged ventilation.

This is particularly interesting for sites that rely entirely on automated processes and equipment. The filtration systems transmit key data – such as temperatures, pressures, gas and dust values, as well as complete air conditioning parameters – via radio, satellite or 4G technology to any device, including mobile apps. Mine operators can analyse the data remotely to adjust the filtration systems accordingly. These monitoring devices can be used to maintain automated vehicles, as well as ensure the safety of staffed operations – perfectly compliant with the requirements of ISO 23875.

References

1. ‘Mine 2020: global Top 40 mining companies resilient in face of COVID-19’, PwC, (10 June 2020), www.pwc.com/gx/en/news-room/ press-releases/2020/mine-2020.html

–

16 April 2023 // global mining review

Figure 2. Multi-stage systems that meet the requirements of the ISO 23875 standard provide a viable solution for effective filtration and pressurisation monitoring in mining vehicles.

Technological innovations are having a huge impact on global mining industry. Recent years have seen some New Zealand quarries adopting continuous surface mining technology to extract material instead of drilling and blasting or ripping with excavators, with impressive sustainability and productivity outcomes and reduced onsite labour and training requirements.

A compact and digital next-generation surface mining machine has improved operations at a Canterbury limestone quarry operated by Palmer Resources, New Zealand. The company became one of the first in this territory to begin using a dedicated surface mining machine, with the test and consequent adoption of a Tesmec 975 EVO Rock Hawg.

First of all, it is necessary to describe the context. The Palmer Resources limestone quarry is used for the extraction of calcareous material, and it is characterised by very variable hardness: from punctual analyses, the shear varies between 50 and 80 MPa, with a variable conformation from moderately to highly fractured.

As with all extractive sites, the primary objective of Palmer Resources in this quarry is to obtain sustainable production per cubic meter in terms of earnings, therefore it is necessary to:

n Extract as much volume of material as possible per shift.

n Avoid external contaminants (even if not entirely possible).

n Avoid scraps.

n Avoid downtime.

n Contain the cost of extraction.

For five years now, the extraction approach has consisted of using a modified cold milling machine with direct loading towards trucks/dumpers. Overall, the surface miner process improved significantly compared to what was previously used – such as drill and blasting and hammer excavators –both in terms of production and in terms of site time management. However, it had been noticed that using this equipment had two huge disadvantages. The first

A Technological Transformation

17 global mining review // April 2023

Luca Malpighi, Tesmec, Italy, highlights the upsides of continuous surface mining technology and how it has improved operations at a site in New Zealand.

disadvantage consists of the residual unexcavated material, due to the centrality of the rotating milling drum, with relevant repercussions on the productivity of the quarry: in fact, the potential extraction surface was reduced and made the quarry owner dependent on the use of other equipment for the removal of the unexcavated rock. Furthermore, the

operators complained that the machine was difficult to use due to its complexity.

A compact, digital, and efficient solution

After evaluating all the different solutions available on the market, Shaun Cleverley, Palmer Resources Group General Manager, opted for the 975 EVO Rock Hawg, the smallest surface miner model among the three members of the Tesmec Rock Hawg family.

The 975 EVO Rock Hawg is a 40 t class machine with a 375 hp CAT C9.3B US EPA Tier 4 Final / EU Stage V engine. The machine is equipped with a 2.9 m rear mounted drum that is larger than the tracks and allows the excavation of vertical walls and square corners, fixing the first issue. Its compact size makes it easily transportable from one site to another and improves manoeuvrability, even in narrow environments.

To answer the issue reported by Palmer Resources operators, the machine is equipped with digital and electronic systems for maximised excavation efficiency and ease of use:

n TrenchTronic, the user-friendly electronic system with an onboard HD display that eases machine operation and makes it less dependent on operator skill.

n TrenchIntel, the extra-high precision DGPS guidance system for automatic depth and grade control, autosteering to predefined path, pass optimisation, and fleet control.

n Re.M, the Remote Monitoring System for machine data remote monitoring, fleet location management, troubleshooting and operating conditions information.

EVO technology guarantees the best performance on hard and abrasive rocks, increasing productivity and decreasing teeth consumption and maintenance costs: the 975 EVO combines high chain pull and low chain speed thanks to its upgraded flywheels gearboxes and new hydraulic components.

By changing the attachment, the machine can operate in ‘upcutting mode’, discharging excavated material laterally with a conveyor belt; or in ‘downcutting mode’, with the drum leaving extracted material behind to be loaded onto trucks. Besides, this model has been conceived with a modular and versatile approach: the Rock Hawg-Chainsaw swap kit expands the application range by converting the 975 EVO to a hard rock trencher for utilities projects such as fibre optic, electric cables, water conduits, and pipelines.

Impact analysis

The introduction of the Tesmec 975 EVO RH model with drum mounted in downcutting mode has set a new standard for improving the mining process for Palmer Resources, which now consists of cultivating the entire available area of the quarry during one shift and loading the material during the next shift, which usually takes place at night.

In detail, the advantages of using the 975 EVO RH surface miner found by Shaun Cleverly in his New Zealand quarry are: n The drum position of the Tesmec surface miner allows 100% of the material to be extracted, thanks to its vertical walls.

Figure 2. The rear mounted drum of Tesmec 975 EVO RH is larger than the tracks and allows the excavation of vertical walls and square corners.

18 April 2023 // global mining review

Figure 3. The Tesmec 975EVO RH can work both in upcutting and downcutting mode. In a first test, the drum was mounted in upcutting mode, discharging excavated material laterally with a conveyor belt. Palmer Resources opted for the downcutting mode, which best suited its site management.

Figure 1. A view of Canterbury limestone quarry operated by Palmer Resources, New Zealand.

n The size of the extracted material is such that the first screening and crushing phase is not necessary, with a consequent significant reduction in extraction costs.

n By not loading the excavated material immediately, the trucks are not obliged to be always at the disposal of the machinery; therefore, there is no waste of resources in that sense.

n The smart control technology of the machinery, equipped with the TrenchTronic 5.0 electronic system, is easy and intuitive for operators already accustomed to the use of excavators, which made it possible to increase staff turnover even without training support from the manufacturer.

n The compact size of the 975 EVO RH model allows it to be transferred to other Palmer Resources mining sites with relative ease and without significantly affecting operating costs.

n The implementation of the TrenchIntel system allows an orderly and safe cultivation of the quarry for the other vehicles.

Performance analysis

Generally speaking, the extraction process has improved in terms of organisation and impact on production costs, for the same amount of material extracted. With today’s diesel prices, the fuel savings of a surface miner have a very significant impact in terms of operating costs. Although a comparative analysis of the productivity data between the methods and models is not available, the data from this site’s experience suggests the 975 EVO RH can produce twice as much as a cold milling machine, with half the engine horsepower.

Another interesting fact concerns the unexpected performance of the machine at another Palmer Resources production site, where it was planned to be used for a week-long extraction; however, the work was successfully completed in just three days, with production peaks around 200 m3/hr.

The after-sales service and the local presence

The machine is equipped with the Re.M remote control

system, which allows remote monitoring and management, provides fault diagnostic data, productivity, and fundamental analytics for its optimal use.

Palmer Resources can take advantage of the remote support activities of the Tesmec assistance centre, which operates from the Grassobbio (Italy) headquarters, as if it were virtually sitting next to the operator in the cab, in order to optimise the management and maintenance of the vehicle. If necessary, the assistance service is available to offer ad hoc service and training opportunities for future new operators of the New Zealand quarry.

Conclusions

Overall, the technical concept of this Tesmec compact surface miner is appreciated and provides the opportunity to work smarter, not harder. Nonetheless, there could be significant opportunities for this technology to transform the New Zealand and Pacific markets in an unprecedented way.

YOUR MINING MACHINE DESERVES THE BEST CHAINS

Cincinnati Mine Machinery Company designed and installed the first Dual Sprocket Conveyor Chain. Our unique design utilizes superior metals and a proprietary heat treatment process for unparalleled strength. Our Dual Sprocket Conveyor Chain runs longer and stronger which means less downtime and lower cost per ton. So when it's time to choose, choose the strongest chain under the earth. For over 90 years, Cincinnati Mine Machinery continues to be THE STRONGEST L INK

Contact us at 1•513•728•4040 or visit cinmine.com to learn more about Cincinnati Mine Machinery products.

A productive partnership in idyllic surroundings

Epiroc outlines how the iron ore mine at Noamundi, India, is taking productivity and sustainability to the next level.

20 April 2023 // global mining review

Figure 1. The SmartROC D65 offers precise capability in terms of providing the drilling data, enabling accurate drilling and blasting.

Green landscapes, fresh air, a tranquil atmosphere, vast open farmlands, followed by lush forest areas… the five-hour drive from Ranchi airport, in the state of Jharkhand, to the Noamundi mine is a treat for the senses. Closer to the site, the surroundings are green and serene, seemingly unaffected by almost a hundred years of mining.

Indeed, it was in 1926 that iron ore was discovered close to Noamundi, a town located roughly 130 km from Jamshedpur. Today, Tata Steel, one of the top steel manufacturers in the world, produces approximately 30 million tpy of iron ore from its ore mines and quarries division (OMQ), consisting of four mines: Noamundi, Katamati, Joda East, and Khondbond. The Noamundi mine never ceases to operate, and activities are carried out in three shifts per day.

Progress through new technologies

Much like any mine operator, Tata Steel rates equipment reliability, availability, and productivity as success factors for uninterrupted mining. To ensure productivity and safety, and to enhance its digital mining capability, the company commissioned Epiroc’s SmartROC D65 surface drill rig and the BenchREMOTE operator station at Noamundi in 2020.

Arriving at the mining site, the sturdy SmartROC D65 is clearly visible in operation at the centre of the captive iron ore resource, but not its operator. They are seated in the BenchREMOTE operator station, approximately 100 m away. While the SmartROC D65 provides high-quality drilling, enabling accurate blasting and fragmentation, the BenchREMOTE helps safeguard operators’ safety by keeping them away from any potential hazards surrounding the rig. It also drives productivity and elevates drilling performance.

Enhanced operations

Sanjit Kumar Adhya, Head of Operations at the Noamundi mine, has said that since Tata Steel’s focus is digital, and that it is solutions like this that help take mines to the next level. The SmartROC D65 rig can achieve a penetration rate of 2 m/min., and an average drill rate of 35 m/hr in hard sedimentary iron ore strata.

From interactions with the onsite team, and further delving into the automated rig’s advanced features – such as ‘full drill cycle automation’ and ‘hole navigation system’ – AJ George, Head of Equipment Maintenance at Noamundi & Katamati Iron Mine, affirms that these features have helped the systems and operations group improve its performance.

The hole navigation system guides the machine, and the level of accuracy is high enough to determine the rig’s position within 10 cm. The depth to which it drills is controlled precisely, leading to clearly observable benefits for blasting operations in mines such as Noamundi.

Another important Epiroc solution is ‘measure while drilling’. A lot of data, including the properties of the rock, is generated while drilling, and several parameters are captured. With all data directed to one platform, it can be used for predictive analysis to identify areas that need attention. This feature also helps detect the precise location for drilling.

Furthermore, a peek into the operator cabin reveals a touchless screen, which displays every minute detail about

21 global mining review // April 2023

the drilling activity. The cabin is air-conditioned and spacious enough for the operator to be comfortably seated, and operator safety is paramount. According to Bira Soren, Senior Drill Operator, while previously used machines had to be operated manually, the SmartROC D65 is supported by an

automated system. The machine can drill to the metre setting, which improves operations as well as safety. Soren is also a strong advocate for the comfort and safety of the BenchREMOTE, distanced from the machine. At the Noamundi mine, the operator station has been prepped for one operator to operate three machines at a time, made possible by the fact that they are all in auto drilling mode.

Training

The saying goes that there is no end to learning and training, and this holds true for Tata Steel’s operations at the Noamundi mine site. Whenever there is a new product or technology available, training is mandatory. Here, too, training has been offered from the manager down to the line field operations team.

Safety

Introducing and operating new technologies bring challenges, but the SmartROC D65 and BenchREMOTE were warmly welcomed by Tata Steel and its employees, as they would help enhance productivity and achieve higher safety standards.

For Tata Steel to get the most out of the equipment, Epiroc personnel are present year round at the Noamundi mine. Since this is the first deployment of this kind of technology in India, there could be operational challenges. To address them, Epiroc has trained the customer at different levels, including the operators. Problems are analysed daily, and training plans are put together accordingly.

Monitoring and maintenance

To ensure best service and minimum downtime, Epiroc has developed several monitoring systems – the life of every component is measured and parts are arranged accordingly. This results in immediate replacement in the event of a breakdown of any component, be it in the rig or the BenchREMOTE. To ensure such timeliness, a service and maintenance team is visibly stationed onsite, and machines and components are serviced and checked. While this is located in the mine site area, it is still away from the main area of mining activity.

Conclusion

Tata Steel’s service agreement with Epiroc has proved very valuable. One example of this value is that it has helped with enhancing and improving the drilling meterage per month. In terms of maintenance, spare parts and inventory – and to ensure a smooth supply chain process – Tata Steel has also entered a Vendor Management Inventory (VMI) contract with Epiroc. Selling is a sacred trust between buyer and seller, and this is evident onsite when you see the Epiroc and Tata Steel teams interacting with each other. It is no wonder this trust has prevailed between both companies for over 30 years.

There have been mutual discussions between Tata Steel and Epiroc over the years to improve safety features. The performance of Epiroc’s equipment has impressed greatly, and thus Tata Steel has taken a step forward on digital and remote operations with the adoption of BenchREMOTE. Performing such activities remotely, away from

workplace,

22 April 2023 // global mining review

the

is the next step.

Figure 2. Thanks to the BenchREMOTE operator station, the drill rig can be safely operated from up to 100 m away, eliminating the need for operators and surveyors to work in hazardous areas.

Figure 3. Epiroc’s Rig Control System (RCS) is at the core of onboard automation solutions for surface drill rigs. The SmartROC D65 has a graphical interface with a touch screen inside the comfortable air-conditioned FOPS and ROPS-certified cabin.

Figure 4. Intelligent, automated and with improved fuel consumption, the SmartROC D65 has features described by AJ George, Head of Equipment Maintenance, as: “a delight for the maintenance engineer and operator because the information is available online and, in most cases, real time.”

Dennis Ofiara, Robbins, USA, details how non-circular tunnel boring can answer the need for the mechanical excavation of mine development tunnels.

There are many thousands of kilometers of mine development tunnels driven in rock each year. Currently, most of these tunnels are excavated by the drill and blast technique. This technology has advanced, with more effective drilling, loading, support, and muck removal equipment. However, the process is still cyclic and slow compared to TBM excavation rates. Blasting is inherently dangerous and causes delays for mine evacuation, equipment movements, fume removal, etc.

Mining is becoming more challenging. Mines are getting deeper, or farther from the shaft or portal, and are often in more difficult geology. Modern society will not accept hazardous working conditions, and desires sustainable and carbon neutral industrial production. There are many plans for autonomous mining, with as few people as possible routinely underground. Indeed, some autonomous underground mining equipment and operations have already been implemented.

23 global mining review // April 2023

This, and all the other factors already noted, has accelerated the age-old desire for mechanical excavation of mine tunnels. The mining industry would like to achieve the progress rates and efficiency achieved by the civil tunneling industry when using TBMs for tunnel excavation. However, there are many difficulties and demands that are unique to the mining industry. These must be recognised, addressed, or re-thought for a mechanical excavation system to be successful for mining.

Mine tunnels: rectangular or circular profile

The mine industry usually demands rectangular, or flat-bottomed tunnels to enable use of a rubber-tired mining equipment fleet. There have been some exceptions, where the mine accepted a circular tunnel profile. Some of these have been coal mine entry slopes, such as Australia’s Grosvenor and the UK’s Selby Coal Mines. Some metal mines have accepted the circular profile and have effectively used TBMs. These include White Pine Copper, Magma Copper, and Stillwater Mine, where four circular TBMs have been utilised. However, the mining industry generally demands tunnels with a flat bottom.

The two cross sections shown in Figure 1 compare a circular cross section to a rectangular profile.

A rectangular cross section of 5 m W x 4.5 m H will accommodate a 30 t mine truck. In order to provide a similar roadway width, the circular tunnel would need to be approximately 6.5 m diameter. That is a lot of wasted excavation and more material to remove from the mine.

In the circular tunnel, the flat roadway must be created by laying a precast concrete invert or slab, or by partial filling and compacting. These are expensive secondary operations.

It is easy to see the attraction of the rectangular profile, for most mining requirements.

Historical efforts for flat bottom mechanical excavation

Mechanical rock excavation machines have been under development for many, many decades. Most of these efforts have been for circular machines. However, several efforts have been made to provide a rock excavation machine that could produce a rectangular, or flat bottom profile.

24 April 2023 // global mining review

Figure 3. Mobile Miner TBM, which cut a near rectangular profile.

Figure 1. Circular and rectangular tunnel comparison. The rectangular tunnel has 32% less volume.

Figure 2. Mini Full-Facer non-circular TBM.

One such non-circular machine was the Atlas Copco Mini-Fullfacer, shown in Figure 2, produced in the 1970s and 1980s. This machine had a swinging drum with a rotary cutterhead that was dressed with robust carbide milling type teeth. A more or less flat bottom profile with an arched roof was produced. This cross section was useful for small pipe and utility tunnels. However, in harder rock the carbide teeth needed frequent replacement, which proved to be the nemesis of these machines.

Some of these Full-Facer machines were produced that had four such rotating cutterheads and could produce a 4.8 m rectangular profile. It is interesting to note that the Full-Facer machine geometry is similar to the MDM5000 mentioned later. There is a robust front gripper that the cutterhead swings about, and a rear gripper on the machine frame.

the cut. This limits the thrust that is delivered to the rock face, in spite of the high numbers of cutters installed.

Developmental history, Robbins MDM5000

The creation of the MDM5000 (Mine Development Machine) in recent years was the result of a long collaboration between Mina Fresnillo in Zacatecas, Mexico, and Robbins. This silver mine is one of the oldest mines in the world, operating since early colonial times. Fresnillo has always embraced technical innovation, even utilising an original Watts steam engine to dewater the mine, when this was new, bold technology.

Fresnillo was eager to consider mechanical methods to drive mine development tunnels. Robbins collaborated with Fresnillo and AMC mine consultants to study the

www.LElubricants.com | 800-537-7683 | info@LE-inc.com | Wichita, KS Provide superior protection for your open & enclosed gears while extending intervals We love a challenge! Contact us today to get started. ON TARGET LUBRICANTS FOR MINING DUOLEC INDUSTRIAL GEAR OIL PYROSHIELD SYN OPEN GEAR LUBRICANT Gear performance is vital to your success. LE’s Pyroshield® and Duolec® gear lubricants – with high-quality base oils and proprietary additives – perform even in difficult conditions in which conventional lubricants fail, including mining operations around the world.

cross section developmental tunnels. As these discussions evolved, Robbins presented a concept for disc cutter mechanical excavation to produce a rectangular cross section. This was based on a ‘swing arm’ type machine. The concept was based on machine designs that used a swing motion of the cutterhead to produce a rectangular cut. This concept was originally developed in

the 1990s by retired, but active, Robbins engineers John Gibson and Andy Anderson. The effort was to develop a machine to mine rectangular drives in the platinum ore veins, known as ‘reefs’ (Figure 4). These reef miners cut a 1 m H x 5 m W tunnel within the platinum ore reef.

The reef miners had a cutterhead that swung about a vertical axis. Muck removal was handled by a vacuum system. The reef miner did cut, but was considered low priority in the context of the entire mine operation. This seems to be a typical outcome when promising technology is given a rather short-term review, and lack of commitment.

This reef miner concept formed the basis for the MDM5000 design. The reef miner swung the cutterhead about a vertical axis and used vacuum muck removal. For the MDM, the judgement was made that swinging about a horizontal axis was preferred. This prevented gripping on the crown, which could be risky in poor ground conditions. The large front gripper of the MDM serves as the swing axis for the MDM cutterhead. This avoids gripping on the crown, provides good stabilisation of the cutterhead, and allows the swing motion of the cutterhead to scrape the excavated muck up onto an apron for disposal by a chain conveyor within the MDM.

As the MDM was designed, many coordination meetings were held between Fresnillo, Robbins, and Topo Machinery. Topo is the local Robbins agent who operates the MDM. This coordination and commitment is vital and continues today.

The MDM was manufactured by Robbins and delivered to the mine. The machine was taken on a tracked carrier 7 km underground on the mine ramp road. It was transported in three main modules that were essentially driven into one another and bolted up. No heavy hoists or large chamber was needed at the launch site. A view of the MDM and the tunnel that it produces are shown in Figure 5 and 6, respectively. The machine is a ‘tunnel factory’. A finished tunnel is produced with a smooth roadway, roof support, vent line, tunnel conveyor, and life-of-mine piping all installed in a single operation.

To date, the MDM has cut approximately 1.7 km of tunnel. It has produced at rates of up to 191 m per month, which is very favourable compared to drill and blast. The machine is currently being relaunched and a second tunnel about 4 km long is planned.

Future flat bottom mechanical excavation, MDM, and other machines

The mines certainly approve of the profile excavated by the MDM. There is demand for this kind of equipment. Robbins is making efforts to improve the productivity of the MDM by increased cutter capacity, faster swing cycle, and other improvements.

In addition, Robbins has developed a design for a circular TBM that can produce a horse-shoe shaped profile. This machine should provide advance rates comparable to conventional circular hard rock TBMs. The continuous rotary motion of the TBM type machine will excavate faster than the cyclic swing motion of the MDM.

Figure 5. MDM5000 Rectangular Machine.

Figure 6. Rectangular tunnel 5 m W x 4.5 m H produced by the MDM5000.

Figure 5. MDM5000 Rectangular Machine.

Figure 6. Rectangular tunnel 5 m W x 4.5 m H produced by the MDM5000.

26 April 2023 // global mining review

Figure 4. Reef miner cutting 1 m x 5 m rectangular opening.

Gianfranco Conti and Lyndon Dean, Emerson, explain how electric actuators are quickly becoming a preferred alternative over pneumatic actuators for the mining industry, driven by advances in functionality and performance.

The worldwide drive for electric cars has driven a global demand for lithium and other rare earth metals. However, the same environmental, social, and governance (ESG) trends that are pushing for electric vehicles are also being applied to mining operations, forcing the industry to improve its own ESG efforts, even as it expands and grows to meet burgeoning mineral demands.

This article explains the role electric valve actuation plays in achieving mining ESG goals, and it discusses the selection criteria that drive the decision between traditional pneumatic and electric valve actuators.

27 global mining review // April 2023

A changing environment

The increasing focus on decarbonisation and sustainable commerce across all industries is driving a multitude of market changes, including: a transition to electric vehicles, increased green energy production, and more efficient electrical devices. Since these technologies require rare earth metals and lithium, mining efforts to recover those products have accelerated in response.

Of course, the same ESG forces driving these changes are being applied to the mining industry as well. It is not acceptable to address one environmental problem by creating another, so the mining industry is forced to reassess what has always been done by thinking in new and more environmentally conscious ways.

In addition to these challenges, the mining industry also faces difficulties associated with reduced staff, water scarcity, remote locations, and high operating costs. A mine must operate continuously and efficiently to be financially successful, so equipment reliability and long-term operating costs are critical for long-term viability.

Valve actuation decisions

Automated valves play a large part in mining and ore processing. Historically, hydraulic valves have been utilised for high-pressure applications, and pneumatic valves have been used for nearly everything else. Until recently, electric valves captured very little of the market due to their limited torque and lack of a fail-safe response on power loss.

However, pneumatic valves have limitations as well. They require a source of high-quality air, which can be difficult to supply in remote applications. They also tend to be less reliable in the long term, especially if the quality of the air is not carefully monitored and maintained. Regardless, pneumatics have historically dominated because electric valves simply could not meet the demands of the applications.

That thinking is changing due to recent improvements in electric actuation technology. Electric actuators can now generate the torque and speed

requirements required for most applications, and some actuators can now be fail-safe.

While electric actuators can be more expensive initially for some applications, they tend to cost less when one considers the operational cost of the air system itself, along with the pneumatic actuator expense. Electric actuators also tend to have better reliability in the long term, requiring less maintenance and repair.

Which actuator is best?

Like any other technology, both pneumatic actuators and electric actuators have their advantages and disadvantages. The best choice depends upon a number of factors.

Pneumatic actuators may cost less initially, but more over time; with operating costs varying depending on the size and utilisation of the compressed air system. A well-sized air compressor and distribution system provides comparatively low operating costs, but an oversized or poorly maintained compressed air system will result in very high operating costs.

The technology itself is not efficient when one considers the cost of treating and compressing the air, which is exhausted with each stroke. Pneumatic actuators tend to be smaller for a given torque size, but are not inherently good at positioning, so more expensive positioners are required to achieve tight valve position control. These same positioners can also provide advanced diagnostics and remote connectivity, but that functionality comes at an added cost.

Pneumatic Electric

- Initial cost lower but lifecycle cost higher.

- Operating costs tied to compressor size and utilisation.

- Tight positioning options significantly raise cost.

- Higher failure rate due to solenoid, tubing, positioner, and dependence on air.

- Partial stroke testing possible with add-on.

- Advanced diagnostics and connectivity available as options, but supply of electric power required.

- Winter freezing possible with poor air quality.

- Stroke can be controlled, torque control limited.

- Configuration tied to hardware calibration, so fast changeover is not typically feasible.

- Reliable operation dependent on air supply pressure/quality.

- Initial cost higher, but lifecycle cost lower.

- Efficient operation.

- Very fine positioning possible.

Design enhancements have made electric actuators much more competitive (Table 1), but they are inherently more efficient. They may cost more initially, but over time the improved reliability and independence from an air system make them less expensive to operate. Very precise positioning and advanced torque control are usually part of the actuation package, allowing the valve to execute any number of positioning and torque profiles. Different profiles can be stored and remotely executed, allowing an electric valve to alter its characteristics quickly and easily. Advanced diagnostics and connectivity are usually part of the standard electrical actuator package, providing further advantages in terms of reduced maintenance costs and increased uptime.

- Significantly reduced failure rate.

- Integrated feedback and partial stroke testing.

- Advanced diagnostics and connectivity easy to include.

- Operates reliably down to -50˚F.

- Fully adjustable stroke and torque options.

- Altered configuration can be downloaded, providing fast changeover options.

- Can run on solar batteries in remote areas.

- Requires only electricity.

Historically, the lack of a fail-safe position drove many users to choose pneumatics over electrical actuators. The introduction of spring return electric fail-safe actuators allows electric actuators to achieve SIL 3 safety

Table 1. Significant advances in electric actuator functionality and performance have altered the economic landscape for valve actuation selection

28 April 2023 // global mining review

Go smarter.

Emerson programmable automation control solutions securely connect to the industrial internet for optimized operations, maximizing productivity and minimizing downtime.

Learn more at Emerson.com/PACSystems

shutdown ratings, while providing a predictable response should power be lost.

Electric actuator designs have improved dramatically in recent years, and the diagnostic capabilities of modern valve actuators can be used to monitor and improve valve and actuator performance.

Both actuation technologies can be connected to a host system, via wired or wireless digital networks (using an adapter), reducing installation costs when valves are spread across a large area. WirelessHART TM networks are self-configuring and self-healing, providing advantages over some competing wireless technologies.

Electrically actuated valves are particularly well suited for wireless applications, since power is always available. However, a battery-backed power module in an electrically actuated valve can allow it to continue to broadcast valve position data wirelessly, even if the main power supply is lost.

Picking the right option

The best technology often depends upon the relative size of the valve, along with the existence of a compressed air system. If a pressurised air system already exists, adding a few more pneumatic valves to it is most likely the best choice. In a greenfield application, an all-electric actuation solution may well be the better option, especially when the capital and operational cost of a new compressed air system is factored into the decision. A large capital expansion might also favour electric valves, if the addition of valves will require a major upgrade to the existing air compressor or air header system.

Some other factors that may impact the decision include:

n A requirement for variable stroke/torque profiles or very precise positioning.

n The ability to power smaller electric actuators with solar power in remote applications.

n Water constrained environments may not allow low-cost water cooling to run the air compressor, increasing operating costs.

n Availability of skilled personnel to maintain pneumatic valves and associated compressed air systems.

Electric valves in mining service

In one application, a mine utilised a solar powered solution to control a remotely located off-the-grid water truck fill station. Running air or electrical lines was cost prohibitive, but a solar powered electrically actuated valve solution allowed the system to be remotely controlled and monitored, improving operating efficiency.

Recent regulatory changes in Chile require all new mines to provide their own water supply, so many mining operators are installing desalination plants (Figure 1).

The dusty, salt laden environment for these projects makes the cost of running and maintaining a compressed air system very high, so many mining operations are utilising all electric valves to reduce operating costs

A third mining site is utilising electrical valves for a significant portion of their operation. In a bid to go carbon neutral by 2030, the company is employing electric valves as part of a site wide system of solar power to achieve their ESG goals. The advanced diagnostics and higher efficiency of the electric actuators are expected to reduce energy utilisation, while significantly cutting operating costs due to reduced required maintenance and increased uptime.

Conclusion

Recent design advances have provided improved reliability and functionality, altering the decision landscape for pneumatic versus electric actuators. While the ultimate decision will depend upon the existing infrastructure and specific application, electrically actuated valves are increasingly becoming a financially superior option for many mining applications.

When faced with a major control upgrade, it is worth taking the time to discuss the options with the automation vendor and investigate the latest valve actuation alternatives. While pneumatic actuators have historically been the only acceptable choice, there are now other options worthy of consideration.

30 April 2023 // global mining review

Figure 1. Greenfield desalination plants often use all electric valve actuators instead of pneumatics. While initially more expensive, the operating costs for electric valves is substantially less in this application.

Fine-tuning frothy waters

31 global mining review // April 2023

complicates suction conditions, and can result in an air lock condition at the impeller eye. The slurry at the eye of the impeller is at a lower pressure than the slurry at the pump discharge and, since fluids and gases move from high pressure to low pressure areas, the air entrained in the slurry builds up in the impeller eye and can block the pump from pumping.

Understanding mineral froths

Mineral froths can range from brittle on one end of the spectrum, consisting of large bubbles that break easily, to tenacious on the other end of the spectrum, consisting of small bubbles that can remain in the liquid for many hours. The characteristics of the froth can change frequently depending on the varying process parameters. Combinations of various flotation

techniques push the limits of the flotation process, in order to recover more of the valuable minerals and improve flotation process efficiency. This can result in a mineral froth with a high froth volume factor (FVF), which is a measure of the air contained in the froth, defined as the ratio between initial mineral froth volume and final slurry volume after the sample is left to de-aerate for 24 hours:

Pumping froth is challenging and requires specialist equipment. Depending on the application and existing plant, operators can select from a range of both vertical and horizontal froth pumps.

Pump evolution

In the past, Weir Minerals’ Warman® AF vertical pumps were a common sight in flotation circuits around the world. However, as flotation technology has evolved the requirement to meet larger plant throughputs and process demands have increased, it has become impractical for the traditional vertical froth tank design to increase in size to meet tonnage and flow performance demands.

In the 1980s, Warman design engineers began experimenting with the Warman AH slurry pump to manage mineral froth in hard rock processing sites in Queensland, Australia. These trials led to the development of the Warman AHF™. After further work, this offering was expanded to include the range of Warman MF and LF froth pumps, featuring a large suction and open scoop impeller, which prevents air gathering in the pump. These pumps can accommodate most froth pumping applications; however, in the instance where the froth is particularly tenacious and/or has a high FVF, pumps with a non-vented froth impeller can still become air locked, causing surging and unstable pump performance. The operator can try to reduce the FVF in the suction tank before the froth gets to the pump, but these measures are often cost prohibitive.