SEPTEMBER 2025

VOLUME 8 ISSUE 8

SEPTEMBER 2025

VOLUME 8 ISSUE 8

Our commitment to you, our customers, is guided by three words; SAFETY, SERVICE, and INNOVATION. We are constantly moving forward creating products of the highest quality and providing you with the services which make the impossible possible.

At JENNMAR fabrication takes place in our numerous strategically located manufacturing facilities associated with our affiliated brands. From bolts and beams to channels and trusses, to resin and rebar, and more, JENNMAR is ideally positioned to meet the industrial fabrication demands of our customers. Our ability to provide our customers with a complete range of complementary products and services ensures quality, efficiency, and availability resulting in reduced costs, reduced lead times, and increased customer satisfaction!

From our Engineers to our Technical Sales Representatives we work tirelessly with you to ensure your safety is at the forefront. We will be with you every step of the way.

05

08 Elucidating Invisible Mining

David Tait, CEO of the World Gold Council, explains how we can reshape the global gold ecosystem to ensure regulated and sustainable ASGM practices.

12 Reframing Mining Automation: It’s About People, Not Just Machines

Angie Vlasaty-Peterson, Director of Marketing and Communications at Komatsu Global Mining, USA, outlines how a people-first approach to automation will continue to transform mining for the better.

17 The Future Of Sustainable Blasting

Jen Ence, Dyno Nobel, USA, explores the importance of the mining and explosive industries for a sustainable future.

21 Leading A New Era in Blasting Services

Pablo Manfredi, Austin Powder, considers the transition of blasting services at Veladero Mine in Argentina.

25 Vibration Monitoring for Blasts

Ola Al Hassani, Vice President – Blast Design and Execution, Orica Digital Solutions, demonstrates how technology is able to protect critical mining infrastructure and nearby communities.

29 Mining In The Age Of AI

Glenn Kerkhoff, AVEVA, USA, describes how AI and data analytics are connecting modern mines, driving down costs, and revolutionising uptime.

34 Global Mining’s New Digital Canaries

Andres Losada, Motorola Solutions, USA, details how advanced safety and security technologies are transforming threat detection and efficiency for mining operations.

41 Reliable Connectivity Is Mission-Critical

Andy Kowalik, Rajant Corporation, USA, examines how intelligent networking is redefining mining operations.

44 How AI Is Driving The Mining Digital Revolution

David de Lancellotti, Nokia, USA, addresses the increasingly pivotal role of AI in optimising efficiency, sustainability, and safety in mining.

49 Levelling Up Valve Selection

Adan Venegas, Emerson, Chile, discusses how advanced valve technologies are key to addressing ever-evolving mining industry challenges.

53 The Use Of Geotextiles In Mining

Dr. Paul Wormald, Terram, UK, evaluates the role of geotextiles in enhancing mining infrastructure and environmental protection.

57 From Black To Green, Powered By Orange

Mike Whitelock, Hitachi Construction Machinery Americas, USA, reviews how new technologies are helping to create a safer, more sustainable, yet increasingly productive mining industry.

61 Treading New Ground

Josh Griffiths, Bridgestone Americas, USA, highlights how developments in tread compound formulation can be used to optimise performance for use in mines worldwide.

MANAGING EDITOR

James Little james.little@globalminingreview.com

SENIOR EDITOR

Callum O’Reilly callum.oreilly@globalminingreview.com

EDITOR

Will Owen will.owen@globalminingreview.com

EDITORIAL ASSISTANT

Jody Dodgson jody.dodgson@globalminingreview.com

SALES DIRECTOR

Rod Hardy rod.hardy@globalminingreview.com

SALES MANAGER

Ryan Freeman ryan.freeman@globalminingreview.com

PRODUCTION MANAGER

Kyla Waller

kyla.waller@globalminingreview.com

ADMINISTRATION MANAGER

Laura White laura.white@globalminingreview.com

DIGITAL ADMINISTRATOR

Nicole Harman-Smith

nicole.harman-smith@ globalminingreview.com

DIGITAL CONTENT ASSISTANT

Kristian Ilasko kristian.ilasko@globalminingreview.com

JUNIOR VIDEO ASSISTANT

Amélie Meury-Cashman amelie.meury-cashman@ globalminingreview.com

HEAD OF EVENTS

Louise Cameron louise.cameron@globalminingreview.com

DIGITAL EVENTS COORDINATOR

Merili Jurivete merili.jurivete@globalminingreview.com

EVENT COORDINATOR

Chloe Lelliott chloe.lelliott@globalminingreview.com

The continued electrification of society has intensified the quest for critical minerals, which are essential for clean energy technologies, electric vehicles (EVs), and energy storage devices. Deep-sea mining is the retrieval of mineral deposits found on the seabed, between 4 and 6 km deep. The most well-known of these mineral deposits are polymetallic nodules, which are mineral concretions on the seabed formed of concentric layers of iron and manganese hydroxides around a core of organic or basaltic debris. The polymetallic nodules contain four essential battery metals – cobalt, nickel, copper, and manganese – in a single ore. It is estimated there is an enormous quantity of nodules on the seabed, with around 21 billion t of nodules in the Clarion-Clipperton Zone (CCZ) alone.

The escalating global demand for critical minerals continues to expose vulnerabilities within current supply chains, which remain heavily dependent on terrestrial mining concentrated in a limited number of jurisdictions and with processing and refining sectors dominated by China. This concentration poses significant geopolitical and supply risks, necessitating diversification strategies to ensure stable access to these vital resources. Governments are acutely aware of these weaknesses in the supply chains and have focused in the last few years on developing critical minerals strategies aimed at accelerating domestic capabilities and enhancing collaboration with international partners.

Deep sea mining emerges as a pivotal alternative, offering the potential to expand and diversify the global supply of critical minerals beyond traditional terrestrial sources. Under the International Seabed Authority’s (ISA) regime, any contractor company sponsored by a member of UNCLOS can apply for a licence. This means that resource-poor UNCLOS members can secure a supply of polymetallic nodules or other seabed minerals for domestic processing/refining or within the territory of a strategically aligned partner. In addition, countries such as Norway and Japan are actively advancing deep sea mining initiatives within their exclusive economic zones (EEZs), further expanding and diversifying the supply chains.

Moreover, securing a stable and diversified supply through deep-sea mining can enhance energy security by reducing reliance on politically concentrated sources and shielding clean energy sectors from price volatility. A broader supplier base and increased market competition can promote more predictable and competitive mineral pricing, directly contributing to reduced costs for clean energy technologies and energy storage solutions. This in turn supports policy goals related to the acceleration of the global energy transition and the achievement of sustainability targets.

A pivotal moment in the policy discourse came earlier this year with the Trump administration’s executive order on deep-sea mining, which broadened the narrative beyond a means to securing the energy transition. The order emphasised the strategic and national security dimensions of seabed mineral development. Specifically, the executive order directed the Secretary of Defense and the Secretary of Energy to ensure that seabed resource development is integrated into national strategies for securing access to materials deemed critical under the Strategic and Critical Materials Stockpiling Act.

While deep-sea mining holds the potential to address supply chain vulnerabilities and promote long-term market stability, several uncertainties remain. These include: long lead times required to reach commercial-scale recovery; a lack of existing processing infrastructure for seabed minerals; and the rapid evolution of green technologies, which may shift demand profiles. As legal frameworks continue to evolve, stakeholders must navigate a complex regulatory environment while balancing environmental, economic, and strategic priorities.

References

Available on request.

In the demanding environments of mining and metals, equipment stress, safety hazards and unplanned downtime can take a serious toll on productivity and profitability. Cordant™ delivers a powerful, AI-enabled solution to tackle your toughest operational challenges – enhancing asset health, optimizing maintenance strategies, and eliminating defects at the source. Modular and scalable, Cordant™ evolves with your operation, unlocking greater resilience and performance across the asset lifecycle.

Explore how Cordant™ can help your mining operations move faster, perform better and adapt with confidence.

bakerhughes.com/cordant

Epiroc has partnered with Luck Stone to deploy the first fully autonomous SmartROC D65 drill rig in the US. This marks a historic milestone, as it is also the first fully autonomous surface drill delivered to the quarry market worldwide.

The SmartROC D65 MKII is equipped with Epiroc’s advanced automation technology and is capable of executing complete drill patterns without an operator in the cab. Compliant with the Global Mining Guidelines Group (GMG) Level 4 standard for full autonomy, the rig operates under remote supervision via Epiroc’s Common Automation Panel (CAP) and Link Open Autonomy (LinkOA) platform, enabling seamless data integration and fleet management.

“Luck Stone’s leadership and commitment demonstrate that autonomy in quarries isn’t future vision – it’s current reality”, said Ron Hankins, Business Line Manager at Epiroc USA. “Our partnership is not about a proof-of-concept, it’s about meaningful operational gains that the next generation of drilling will bring in the US.”

Luck Stone, known for its early adoption of autonomous plants and autonomous haulage systems (AHS), continues to

set the pace for innovation in the industry, and the company views automation as a strategic investment in safety, operational excellence, and talent attraction.

James River Equipment, a trusted Epiroc dealer, played a key role in facilitating delivery of the SmartROC D65 MKII, and will be instrumental in providing the ongoing local service, training, and technical support that are essential to ensuring the project’s long-term success.

The US aggregate market is the largest globally and presents significant growth potential for autonomous technologies. Utilising the same automation platform proven in mining, the SmartROC D65 MKII makes it easy for any operation to scale toward full autonomy. By enhancing operational safety, optimising machine fleet size, and addressing skilled labour shortages, this deployment represents a transformative shift in how quarries can operate.

Both Epiroc and Luck Stone have committed to sharing performance data following the implementation period, offering valuable insights for the broader industry and paving the way for future advancements in automation.

ABB and Codelco have announced their latest collaboration to optimise the Chilean state-owned copper mining company’s maintenance programme.

As part of the LTSA, ABB will provide ongoing lifecycle management for Codelco’s four key GMD systems, three at Ministro Hales mine in Antofagasta region and one at Andina mine in Valparaíso region. While these mines are more than 1500 km apart and distinct in design, this contract brings both sites under centralised service management. ABB will support sustainability and innovation goals by improving operational efficiency and asset availability, and evolving technology solutions over time.

GMDs are increasingly integral to the operation of copper mining plants, ensuring efficient ore grinding while minimising energy consumption and emissions. With copper production expected to face increasing demand over the next decade, maintaining the reliability of these critical systems is vital to

meeting market needs. This agreement supports Codelco’s goal to maximise uptime and enhance asset availability while avoiding unscheduled downtime and sustaining productivity.

“There’s commitment from both ABB and Codelco to integrate innovate solutions within Chilean mining operations, which is vital to reach production targets in the most efficient and sustainable manner”, said Francisco Herrera, Service Manager for Chile.

ABB’s GMDs are designed to eliminate all mechanical drivetrain components and are used to run some of the world’s largest grinding mills, essential mine infrastructure that crush ore, separating the valuable mineral from the remaining rock.

These GMDs deliver more efficient, reliable operations with lower emissions, helping the industry meet the demands for minerals critical to a low carbon future. Maximising the output of various critical minerals and metals is vital as the world electrifies and decarbonises.

Metals and Mining Summit

09 – 10 October 2025

London, UK & Online https://mining.live.ft.com

International Mining and Resources Conference

21 – 23 October 2025

Sydney, Australia www.imarcglobal.com

China Coal & Mining Expo

28 – 31 October 2025

Beijing, China www.chinaminingcoal.com

The Mining Show

17 – 18 November 2025 Dubai, UAE www.terrapinn.com/exhibition/ mining-show

Resourcing Tomorrow

02 – 04 December 2025

London, UK www.resourcingtomorrow.com

SME MINEXCHANGE 2026

22 – 25 February 2026

Salt Lake City, USA www.smeannualconference.org

PDAC 2026

01 – 04 March 2026

Toronto, Canada www.pdac.ca/convention-2026

CONEXPO-CON/AGG 2026

03 – 07 March 2026

Las Vegas, USA

www.conexpoconagg.com/ conexpo-con-agg-constructiontrade-show

To stay informed about upcoming industry events, visit Global Mining Review’s events page: www.globalminingreview.com/events

This collaboration aims to provide cutting-edge technologies and real-time adaptability to Komatsu’s next generation mining equipment, helping customers boost productivity, reduce downtime, and operate with greater precision and efficiency. With Applied Intuition’s proven capabilities across vehicle operating systems, autonomy stacks, and tooling, and Komatsu’s extensive expertise in off-highway autonomy and mining applications, the companies will co-develop a unified software-defined vehicle (SDV) and autonomy platform that will serve as the central brain of Komatsu’s next generation of mining equipment.

The jointly developed platform will introduce a new era of machine intelligence through key features such as: SDV architecture that will enable continuous feature delivery over the life of the machine, with native integration of data management, digital security, and connected support; flexible autonomy capabilities ranging from advanced operator assist to full autonomy on a common platform, adaptable across fleets, commodities, and operational complexities; and embedded machine learning and AI that supports functional enhancements and continuous learning, enabling site-specific optimisation as conditions change.

Metso has signed an agreement to acquire Q&R Industrial Hoses, a privately owned Australian company specialising in the manufacture of pinch valve sleeves, rubber hoses, and other rubber products and linings.

This acquisition marks another step in Metso’s commitment to offering comprehensive, end-to-end slurry handling solutions and services for its customers. Following Metso’s valve and process control offering acquisition of Jindex Pty Ltd. in 2024, the addition of Q&R Industrial Hoses will further enhance Metso’s portfolio.

"We are delighted to become part of the Metso family and look forward to working together to deliver innovative, customer-focused solutions to the mining and minerals sectors”, says Brett Robinson, General Manager and owner of Q&R Industrial Hoses.

The acquisition is expected to be closed during the fourth quarter of 2025. The parties have agreed not to disclose the transaction value, which has no material impact on Metso’s financials. Metso offers complete solutions for slurry handling, including equipment and parts, as well as optimisation and maintenance services. The equipment offered includes slurry pumps, pipes, hoses, valves, and hydrocyclones.

Metso has globalised its slurry hose supply chain during recent years and now has an extensive slurry handling manufacturing and service centre presence close to key mining markets.

David Tait, CEO of the World Gold Council, explains how we can reshape the global gold ecosystem to ensure regulated and sustainable ASGM practices.

Amajor trend reshaping the global gold industry today is the surge in the level of artisanal and small-scale gold mining (ASGM). What was once viewed as a peripheral activity is now one of the most consequential forces influencing the market, economically, socially, and geopolitically. ASGM accounts for an estimated 20% of global mined supply, employs over 20 million people directly, and supports the livelihoods of more than 100 million worldwide.

Yet for all its economic weight, ASGM remains overwhelmingly informal, underregulated, and high-risk. It is a sector marked by significant environmental degradation, widespread mercury use, poor safety conditions, and a growing intersection with illicit finance, organised crime, and armed groups. ASGM was once viewed as an equivalent to subsistence agriculture, and its lack of legal status and regulation was seen by many as just reflecting endemic informality in the economies of many developing countries. However, the surge in the price of gold, growing mechanisation, and the increasing presence of organised crime has changed all that. The scale, scope, and urgency of these challenges are now undeniable, and so too is the opportunity to deliver meaningful reform.

In response, the World Gold Council, together with an expanding coalition of public and private sector partners, has been working to support the responsible transition of ASGM from informality to legitimacy. Through collaboration with governments, central banks, industrial mining companies, multilateral institutions, and technology providers, the World Gold Council and its partners are contributing to the design of practical solutions to strengthen ASGM ecosystems. These include improving traceability, reducing mercury use, expanding access to formal markets, enhancing coordination with law enforcement, and supporting the development of more responsible supply chains.

As the scale and impact of ASGM continue to grow, it is becoming increasingly clear that this segment of the gold market cannot be viewed as peripheral. Its evolution has direct implications not only for gold supply and price dynamics, but also for geopolitical stability, environmental sustainability, and the integrity of global markets.

Addressing its risks and unlocking its potential requires a coordinated and technically grounded approach, rooted in local realities but informed by global best practice.

At the turn of the 21st century, ASGM contributed around 4% of the global gold supply. Today, that figure is closer to 20%; up to 1000 t annually. This significant growth reflects a confluence of factors: the sustained rise in gold prices during this time period from around US$250/oz to over US$3500/oz in 2025, the gradual decline in employment opportunities within other rural sectors, and increasing demand from local and regional buyers, including state actors.

For many countries, particularly in sub-Saharan Africa, South East Asia, and Latin America, ASGM is now a pillar of rural economic life. In some regions, it provides one of the only viable alternatives to poverty or migration. It is also an important source of foreign exchange, often exceeding the value of traditional exports such as coffee, cocoa, or timber.

But this expansion has come with systemic costs.

Most ASGM production takes place outside formal legal and regulatory frameworks. According to the OECD, more than 80% of ASGM globally is informal or illegal, unlicensed, untaxed, and unregulated for environmental or safety standards. The consequences of this informality are often profound and severe. At the community level, this informality can mean:

Miners lack secure tenure or access to credit.

Health and safety risks are pervasive, especially for women and children.

Mercury use is widespread, leading to toxic exposure and severe costs for human health and environmental damage.

For governments, the consequences are equally significant:

Tax and royalty losses in the billions annually.

Difficulty enforcing environmental and labour laws.

Corruption that can weaken the integrity of both political and law enforcement institutions.

Conflict over land use between informal miners and industrial concession holders.

Smuggling networks that channel gold out of the country and into opaque trading hubs.

Perhaps the most concerning is the growing infiltration of ASGM by organised crime, armed groups, and corrupt actors. Illicit gold has become a critical currency in trafficking networks, insurgent financing, and money laundering. The links between ASGM, insecurity, and conflict are increasingly documented, particularly in regions such as Colombia, the Sahel, the Amazon basin, and the Democratic Republic of Congo.

The illicit gold economy may now exceed US$75 billion annually; funds that, if properly harnessed, could be redirected to support education, infrastructure, healthcare, and sustainable development in mining communities and producing countries.

It is against this backdrop that the integration of ASGM into legal, fiscal, and regulatory frameworks emerges as a strategic imperative for governments, miners, and the global gold market alike. This process involves:

Providing responsible small-scale miners with legal rights, training, and technical support.

Enabling access to responsible markets, processing facilities, and traceability systems.

Integrating ASGM into national mineral development strategies and value chains.

Improving transparency, reducing risk exposure, and disrupting illicit flows.

Far from a purely regulatory challenge, this integration is central to addressing some of the gold market’s most pressing concerns: securing supply chain integrity, enhancing ESG credibility, safeguarding supply security, and aligning with global sustainability goals.

Delivering this transformation at scale requires more than policy alignment; it demands real-world solutions, trusted partners, and shared commitment to long-term impact. Over the past two years, the World Gold Council has launched or supported a suite of strategic interventions to catalyse change on the ground with an emphasis on measurable outcomes and scalable models. These initiatives are grounded in three core principles: incentivising responsible behaviour, strengthening institutional capacity, and building trusted pathways from mine to market.

In collaboration with a group of seven central banks, including those of Mongolia, the Philippines, Brazil, Colombia, Ecuador, Tanzania, and Zambia, the World Gold Council has co-developed a good practice framework for national ASGM gold purchase programmes. These initiatives are designed to:

Offer fair, stable, and predictable prices to artisanal miners.

Provide an offtake mechanism that channels gold into the formal sector.

Encourage mercury reduction through linked improvements in processing technology.

To help small-scale miners to secure access to ‘clean’ sources of finance.

By creating domestic markets for responsibly sourced gold, these programmes help stabilise prices, improve fiscal transparency, and incentivise miners to operate within formal channels. In doing so, they can also support central banks’ broader goals of reserve accumulation and economic resilience.

Transparency is fundamental to successful integration. To address this, the World Gold Council is supporting the development and deployment of digital traceability platforms tailored to the ASGM sector. These tools enable reliable origin data, support compliance with international standards, and create conditions for greater market trust.

The use of mercury in ASGM remains one of the sector’s most pressing environmental and public health challenges. Technical assistance is not enough – what miners need is

access to alternative processing facilities that are viable, trusted, and proximate. In response, the World Gold Council is working with stakeholders to explore what would be required to roll-out a network of centralised, mercury-free processing plants in key ASGM regions. These hubs are designed to deliver multiple benefits:

Replacing the use of mercury with the use of cyanide and other forms of gold recovery. Mercury typically delivers a gold recovery rate of about 40%, whereas responsible cyanidation can double gold recovery rates and ensure higher yields and greater value retention for miners.

Creating nodes of formalisation and capacity-building where gold, data, and geological services converge to support responsible mining practices.

Providing regulatory pinch-points that enable governments to secure some revenue and to prevent the gold from disappearing into illicit channels.

This has the potential to be the foundation of a new infrastructure model for responsible small-scale artisanal mining.

Where ASGM intersects with criminal networks, state capacity must be strengthened. The World Gold Council is seeking to promote dialogues between producing country

governments, financial intelligence units, and law enforcement bodies to share typologies, improve coordination, and build the institutional backbone required to disrupt illicit flows. This work is particularly critical in regions affected by conflict, where the gold trade has been exploited by armed groups and trafficking syndicates. Formalisation efforts must be backed by strong governance, and this includes support for enforcement, border control, and beneficial ownership transparency.

ASGM is no longer a fringe activity. It is a system of production, employment, and exchange that impacts over 100 million lives, and it is now a strategic dimension of the global gold market.

What happens in ASGM will shape the future of gold supply, influence price dynamics, and determine how markets respond to evolving expectations around responsibility, sustainability, and legitimacy. The status quo – marked by informality, exploitation, and opacity – is unsustainable, but a better outcome is within reach. By aligning public, private, and multilateral actors around practical interventions and shared objectives, ASGM can be transformed into a more inclusive, transparent, and resilient part of the gold ecosystem. This is a strategic imperative which, if successful, will offer benefits felt across the value chain – from mine sites in rural Africa and Latin America to trading desks in London, Zurich, and Shanghai.

Angie Vlasaty-Peterson,

Director

of Marketing and Communications at Komatsu Global Mining, USA, outlines how a people-first approach to automation will continue to transform mining for the better.

In the relentless march toward increased automation, the mining industry stands at a crossroads. While much of the conversation has been focused on the technical capabilities – robots, data, AI, sensor-driven equipment, remote control, among others – the true story about autonomous operations may be richer and more compelling.

To reframe the narrative is to recognise that mining automation – at its core – is about people: the workers on-site; the data scientists behind the screens; the communities that are shaped by mining’s presence; the investors seeking sustainable value; and the generations who are yet to join the field.

By shifting the lens from machines to human experience, we can unlock not only safer, smarter, and better work environments, but also more resilient economies and sustainable progress.

Automation is not replacing people – it is redesigning work to be safer, smarter, and more rewarding. The spectre of job loss has long haunted the advance of automation, but this is an outdated narrative.

In reality, technology is opening up new horizons for those within the sector, particularly when guided by the principles of human factors engineering. This discipline ensures that the design of mining systems considers a cognitive workload, ergonomic safety, and user experience, which squarely places people at the centre, including:

Reduced exposure to harm: Automated vehicles and drones can now traverse complex terrain, meaning fewer workers must operate near unstable walls, handle high-temperature machinery, or endure the risks of high-altitude or underground sites. Remote operation rooms – far from blasting zones – translate into lives saved and injuries avoided.

Improved interfaces: Modern mining equipment integrates intuitive controls and real-time feedback, making the leap from manual to automated tasks less daunting. Augmented and virtual reality training platforms allow workers to learn on digital twins of real sites, dramatically reducing both the learning curve and the risk of mistakes. The result is a workforce empowered to master complex systems with confidence and competence.

Elevated roles: As repetitive, physically taxing jobs are absorbed by machines, humans step into higher-value positions – remote oversight, predictive maintenance, advanced data analysis – where critical thinking, creativity, and expertise come to the fore. These are careers with greater room for growth, satisfaction, and recognition, attracting a new cohort of talent to mining.

The shift is not from people to machines – but rather from perilous labour to purposeful work, extracting material that is critical to everyday life.

The real power of automation is the data it generates – and how people use it to make decisions and drive results.

Data ‘mining’ is the new ore, rich with insights that can transform every facet of the mining industry. Its value, however, is realised only when it is made accessible, actionable, and in service to human decision-makers, at every level, which includes:

Data equity: Advanced mining systems can now collect, process, and visualise vast streams of information – operational metrics, environmental readings, equipment status – in dashboards readable not just by engineers, but also by dispatchers, safety coordinators, and even external stakeholders like community planners. This broad accessibility fosters a culture where everyone can contribute to smarter, safer, and more efficient operations.

Proactive operations: That is to say that predictive analytics anticipate equipment failures before they happen, allowing teams to intervene early; reduce costly downtimes; and extend asset life. Similarly, real-time monitoring enables energy optimisation, emission cuts, and adaptive resource management. Free from fire-fighting mode, teams can focus their attention on strategic improvements, innovation, and continuous learning.

Transparency and trust: With robust data sharing, mining companies can provide regulators, local communities, and investors with transparent views of operational performance, environmental impact, and safety metrics. This transparency is more than just compliance – it is the cornerstone of the social license to operate, building trust, and setting the stage for long-term sustainability and shared value.

Data-driven mining is not about replacing human instincts, but rather it is about enhancing them, and ensuring that every decision made is better informed and more inclusive.

The significance of engaging with customers early in the development process to understand their needs and wants cannot be underestimated. This approach involves interacting with the actual users of the products to gather insights and feedback, including:

A focus on the users: Automation product engineers and developers alike emphasise the importance of early-stage engagement with customers and with a focus on the actual humans using the products.

Co-creative: Mining companies are adopting the co-creation approach, whereby early-stage solutions are taken back to customers for feedback and usability testing.

Human factors and innovation: All too often the emphasis is on technical subjects. The focus should be on the importance of understanding human problems and not just technical ones. Technology should inherently be designed around helping human beings function in their work environment more effectively.

Automation has become a catalyst for a mining culture that is attracting the next generation – and building resilient communities. Mining’s future lies not just in deeper mining or richer lodes, but in the people and places shaped by its evolution. Automation, when thoughtfully implemented, is the force that can elevate both the workforce and communities to greater heights through:

Attracting top talent: Today’s digital-native generations seek workplaces that embrace AI, robotics, cloud computing, and advanced analytics. They are drawn to the promise of solving complex problems, using cutting-edge technology, and making a meaningful impact. Mining companies that lean into automation signal that they are not relics of the past, but pioneers of the future – drawing top talent with diverse skillsets. According to Quartz.com, mining engineering is positioned third among STEM careers.

Remote and hybrid work: Automation releases many roles from the mine site itself. Remote operation centres, digital monitoring, and virtual collaboration tools allow professionals to contribute from urban headquarters, regional hubs, or even their own homes. This flexibility opens the door to a broader, more inclusive workforce – women, a diverse workforce, and those from regions far from traditional mining centres –can all find new opportunities to join and thrive.

Resilient local economies: Mining towns should not decline when ore runs out. With autonomous systems,

digital infrastructure, and ongoing training initiatives, these communities can pivot into tech-enabled hubs. Local workers can gain skills transferable beyond mining, from IT to logistics to renewable energy. Remote operations centres spark demand for everything from computer support to hospitality, providing a foundation for diversified, future-proof local economies.

Therefore, automation is not an existential threat to mining communities, but a springboard to their renewal and long-term prosperity.

Today’s mining sector faces a convergence of urgent pressures: the imperative for safety; the need to lower emissions and operating costs; and a desire to make work more meaningful for the next generation. Automation is addressing these challenges through:

Immediate safety improvements: Removing people from hazardous environments; automating risky tasks; and using real-time monitoring reduces the risk of accidents and saves lives.

Lower operating costs and emissions: Precision machinery, energy optimisation, and predictive maintenance translate into fewer breakdowns, less waste, and a smaller carbon footprint.

More meaningful, data-driven work for frontline teams: Workers transition from manual labour to roles where critical thinking, creativity, and strategic decision-making take centre stage.

Looking further ahead, the impact of people-first automation compounds:

Sustainable supply chains for critical minerals: Responsibly automated mines will be central to the world’s shift to clean energy, providing lithium, copper, and rare earths for batteries, turbines, and solar panels.

A more diverse, digitally fluent workforce: By embracing digital transformation, mining companies become magnets for the next generation of problem-solvers, innovators, and leaders from backgrounds previously underrepresented in the sector.

Stronger trust with communities and stakeholders: Transparency, inclusivity, and shared value build the durable relationships necessary for mining’s social license – and its long-term success.

To realise this vision, mining leaders, investors, and technology partners must rethink automation, not as a mere upgrade of machines, but as a people-first transformation. This is a moment to invest in human factors engineering, inclusive data strategies, and robust community engagement. It is time to unlock the full potential of everyone involved in mining – onsite workers, analysts, communities, and the innovators of tomorrow. The future of mining is not just about automation. It is authentically human – being reshaped by the very people it serves.

Jen Ence, Dyno Nobel, USA,

explores the importance of the mining and explosive industries for a sustainable future.

Mining is an essential part of life. From the roads we drive on, to life-saving medical devices, to the phones sitting in our pockets, much of our modern way of living is crafted with materials that can only be obtained through mining. The safest, most efficient way to extract them from the earth is through the use of commercial explosives.

As society moves toward a more sustainable future, mining – and explosives – will play a key role in securing the resources that will make it possible. How does the mining industry continue to obtain the essential materials the world needs while embracing sustainability as a core practice? For Dyno Nobel, a global leader in commercial explosives, it is not a single approach, but a multifaceted one.

Innovations in explosives technology have made them safer and more productive than ever before. Now, they can also help reduce carbon emissions, fumes, and flyrock.

Explosive products that support variable densities to match explosive energy to the rock characteristics can improve not only fragmentation, but sustainability. Since hard and soft rock seams are often dispersed throughout the borehole, single-density explosive loading technology can be inefficient.

Variable density loading, such as Dyno Nobel’s DIFFERENTIAL ENERGY® technology, improves upon traditional loading techniques by allowing for up to six different density segments of emulsion within a single

borehole to adapt to an operation’s unique geology. This places the explosive energy exactly where it is needed to break the rock most efficiently, reducing hazards such as flyrock, potential for harmful nitrous oxide (NOx) fumes, and groundwater contamination.

A large gold mine in Australia, which had historically used an ammonium nitrate/emulsion blend, was facing challenges with fragmentation, productivity, and NOx fumes. They also wanted to reduce their carbon emissions. They trialled using DIFFERENTIAL ENERGY to address these challenges.

Once DIFFERENTIAL ENERGY was introduced, emissions dropped by 7% and NOx incidents were eliminated during the trial. And because the emulsion performed at a higher level than the product that was previously used, fragmentation and productivity improved as well.

Looking to the future, the raw materials used in the manufacture of the explosives themselves offer areas for improved sustainability. Dyno Nobel has successfully trialled renewable diesel in their DIFFERENTIAL ENERGY emulsion. Unlike traditional diesel components, renewable diesel has a significantly lower lifecycle emissions profile that results in customers reducing their scope 1 emissions from blasting. Emulsions manufactured from renewable diesel also perform at the same level of high performance as

Dyno Nobel’s other emulsions, showing the potential for operations to reduce their scope 1 emissions without impacting the site’s productivity.

For makers of explosives, embracing more environmentally friendly practices in manufacturing processes is another opportunity to improve sustainability.

Several of Dyno Nobel’s manufacturing plants have made significant investments in sustainability initiatives. At their site in Wolf Lake, Illinois, a US$1.7 million ground-mounted solar array is expected to generate more than 1 million kWh of renewable energy every year, accounting for nearly 45% of the plant’s current electric demand. Emissions will also be reduced by 320 tpy of CO2.

At their Moranbah plant in Australia, Dyno Nobel opened a AUS$20 million nitrous oxide abatement project that will abate approximately 200 000 tpy of carbon dioxide equivalent emissions. At their Louisiana, Missouri plant, an US$8 million tertiary abatement project will actively abate 520 000 tpy of carbon dioxide emissions, the equivalent of taking 125 000 vehicles off the road or planting more than 9 million trees.

By improving sustainability in the manufacturing process, explosives manufacturers can help reduce the mining industry’s environmental impact before the products even get to the blast pattern.

Blast practices play a crucial role in an operation’s sustainability efforts. Making even minor adjustments can lead to significant improvements throughout the entire production stream. While many operations have traditionally looked at drilling, blasting, loading, hauling, crushing, and milling as separate processes with no overlap, Dyno Nobel’s Drill to Mill® approach focuses on optimising drilling and blasting for results that cascade through downstream processes.

From a production standpoint, this approach can optimise fragmentation for increased value and improved processing efficiency. The benefits do not end there, however. By examining and improving every aspect of blasting, environmental impacts can also be reduced.

State of the art design software can make it easier to predict, manage, and analyse vibration, reducing negative impacts on the environment and nearby communities. Flyrock incidents that would otherwise pose safety risks to mine personnel, nearby structures, and the environment can be mitigated. With the right design and products, NOx generation, which can cause not just air pollution but significant dangers to humans and wildlife in the area, can also be reduced.

Beyond the effects of the blast itself, breaking the rock more efficiently and optimising fragmentation can reduce the environmental impacts of downstream processes. Loading and hauling times can improve, and truck-fill factors can increase, allowing for more tonnes to be moved per shift. Wear on ground-engaging tools can also be reduced, prolonging the life of the equipment.

At the crusher, the fragmentation improvements made by optimising blast designs reduce power costs and extend the life of wear items such as liners and mantles. Power requirements per tonne can also be reduced during the milling process as throughput is increased. By optimising blast designs and practices, sustainability can be improved through the entire production stream.

Highly accurate initiation technology goes hand-in-hand with improved blast designs. The millisecond timing accuracy of electronic detonators provides more precise control over fragmentation and vibration, reducing negative impacts on the environment and nearby communities. These detonators also make it possible to separate waste rock from high-quality ore, which decreases ore loss and dilution.

For precise detonation in underground operations and ore bodies that are difficult to access, wireless detonators such as Dyno Nobel’s CyberDet® technology can safely and sustainably allow blasting without requiring wired connections. With essential resources increasingly found in challenging environments, wireless detonator technology provides a safer and more efficient way to mine them.

Sustainability in mining can go beyond explosives and blast designs. Delivery methods are also a major opportunity to reduce environmental impact, such as greenhouse gas (GHG) emissions.

In April 2025, Dyno Nobel unveiled what is believed to be the world’s first mine-ready electric mobile processing unit (MPU). With a fast-charging battery station that is compatible with renewable energy sources including solar, wind, and hydropower, the DYNOBULK® Electric MPU provides a 300 km range on a single charge for sustained operations throughout an entire shift in most mining conditions. A regenerative braking system that captures and stores energy during descents also reduces overall power consumption and extends battery life to minimise energy waste. The DYNOBULK Electric MPU is soon to be trialled in Australia, and generated a significant amount of interest at the 2025 Electric Mine Show held in Chile and GRX25 held in Brisbane, Australia.

Compared to emissions-intensive diesel engines, electric MPUs can reduce noise levels and exhaust fumes to improve working conditions for operators while supporting GHG emission reduction goals. With operational efficiency that performs at a level equivalent to traditional diesel engines and advanced safety systems to protect mine personnel, electric MPUs stand to represent the new frontier in explosive delivery technology.

Explosives can also be used in more surprising sustainability projects for the mining industry.

In Canada, Dyno Nobel’s DynoConsult® team had the opportunity to take on a unique quarry closure project with the aim of creating new habitats for an endangered species of bat. With other bats roosting in the area, it was essential that vibration and air overpressure were kept to a minimum. Dyno Nobel’s team of experts crafted a blast design to minimise these risks, and electronic detonators were used to create two artificial bat caves, providing homes to Little Brown Bats that may have otherwise fallen victim to disease.

This is not even close to being a typical project for an explosives company, however, it is one that reflects the variety of ways that explosives can be used in sustainability initiatives. As mines and quarries close and undergo reclamation efforts, explosives can play a major role in safely repurposing the land.

Mining has implications for sustainability not just in the present, but in the future. As society increasingly looks to utilise alternative energy sources such as solar, wind, and electric power, mining will play a critical role in the transition. Solar panels, wind turbines, electric batteries, and other components of sustainable energy sources all require resources that can only be acquired through mining.

As we look to the future, it is clear that mining is not going anywhere, but will make any future transitions to more sustainable power sources possible. By embracing sustainable practices, innovating and improving explosive technologies, and reducing negative environmental impacts, the mining and explosives industries can lead society into a safer, more sustainable future.

Pablo Manfredi, Austin Powder, considers the transition of blasting services at Veladero Mine in Argentina.

Located over 4000 m above sea level in San Juan Province, Argentina, Veladero Mine is one of the most significant gold operations in South America. A joint venture between Barrick Mining and Shandong Gold, the mine presents a technically demanding environment due to

its high altitude, extreme weather conditions, and complex logistics. In this context, the transition of the blasting services and explosives supply contractor was a critical process requiring rigorous planning, precise execution, and strategic alignment among all stakeholders.

On 1 November 2024, Austin Powder Argentina officially assumed responsibility for blasting services at Veladero, replacing the previous provider. The transition followed several months of planning, including weekly coordination meetings, regulatory engagement with the National Agency for Controlled Materials (ANMaC), and active involvement of local authorities and technical teams from both companies. The objective was to ensure uninterrupted operations while fully complying with regulatory and technical requirements.

During the transition phase, four magazines, an ammonium nitrate storage facility, and a silo yard were commissioned.

Four mobile manufacturing units (MMUs) were also introduced, inspected, and authorised by regulatory authorities. A key success factor was the integration of technical and operational personnel from the outgoing contractor, ensuring knowledge retention and minimising the learning curve.

Austin Powder introduced the Paradigm® blast design software at Veladero, enabling precise simulation of energy distribution, seismic effects, and expected fragmentation. Four engineers were trained in its use, allowing for optimised drill patterns and reduced overbreak. The company also implemented E*STAR® electronic detonators, offering high timing precision and advanced programming capabilities to improve energy efficiency and minimise vibrations.

The operation is supplied with locally formulated bulk emulsions designed for demanding geotechnical conditions. These emulsions exhibit high water resistance, excellent stability, and controlled energy output, improving fragmentation and reducing downstream energy consumption. MMUs enable on-site mixing and loading, ensuring product freshness, full traceability, and operational safety. Field QA/QC controls verify density, viscosity, and delay times.

The transition was facilitated by a strong cultural alignment between Austin Powder and Veladero, founded on shared values of safety, integrity, environmental stewardship, and teamwork. Weekly operational meetings, joint safety protocols, and collaborative problem-solving reinforced this alignment. The inclusion of women as equipment operators and continuous training for technical staff reflects the commitment to diversity and local talent development.

In the first months of operation, the transition was completed without safety incidents, maintaining a continuous explosives supply. Drill patterns were optimised, operational costs were reduced, and fragmentation quality improved. Innovation projects were also initiated, including seismic monitoring with geophones and the recovery of used oils for ANFO production, currently under evaluation by the ANMAC.

Austin Powder has a solid footprint in Latin America, with operations in Argentina, Chile, Brazil, Costa Rica, Panama, and Mexico. In Argentina, the company operates ammonium nitrate plants, bulk and packaged emulsion facilities, non-electric and electronic detonator assembly plants, primary explosives (PETN/RDX) and booster plants, logistics centres, and quality control laboratories. The company serves gold, silver, and copper mines, delivering integrated

With decades of expertise in large-scale mining, we deliver tailored blasting solutions that maximize productivity. Combining technical mastery with a safety-first approach, we act as true collaborators in customer success. Our precision, innovation, and commitment to environmental stewardship set us apart.

— Safety First: Unwavering commitment to safety, with cutting-edge protocols and above-and-beyond industry compliance.

Industry-leading Expertise: Proven track record in complex mining operations, using advanced technologies like drone surveying and precision initiation systems.

— Innovative Solutions: Customized blasting and proprietary tools like E STAR Diamond and Paradigm Software provide cost-effective results.

— Sustainability: Support Mining companies to achieve their sustainability goals by developing innovative products and making a positive impact on local communities.

— Trusted Partnerships: Responsive support, strong customer focus, and leadership in mining safety and innovation.

solutions that combine products, technology, and specialised technical support. Sustainability, safety, and community development initiatives are embedded in its operational model, supported by a regional network enabling efficient logistics, technical support, and technology transfer.

The blasting services transition at Veladero Mine stands as a benchmark in strategic planning, technical execution, and inter-institutional collaboration. Austin Powder successfully integrated advanced technology, site-adapted products, and an operational culture aligned with large-scale mining standards. This case underscores the importance of specialised suppliers capable of adapting to demanding environments while contributing to efficiency, safety, and sustainability in mining operations across Latin America.

Veladero Mine, in San Juan Province, Argentina, is a high-sulfidation epithermal deposit with gold and silver mineralisation, mined via opencast methods. Extreme geographic conditions, including high altitude,

low temperatures, and complex logistics pose significant challenges for blast design and execution. The operation features a valley-leach plant and has produced over 8 million oz of gold since commissioning in 2005.

ANMaC – which oversaw the regulation, licensing, and inspection of firearms, ammunition, and explosives in Argentina – was restructured in July 2025 under Decree 445/2025. It was replaced by the National Firearms Registry (RENAR), now operating as a dependent body of the Ministry of Security. The RENAR regulates blasting services in Argentina, which oversees licensing of magazines, explosives depots, and MMUs. Austin Powder met all technical and safety requirements, including pre-authorisation inspections of MMUs, ammonium nitrate depots, and traceability systems. Additional audits were coordinated with fire departments, provincial authorities, and mining safety agencies to ensure comprehensive compliance.

At Veladero, Austin Powder deployed Paradigm software to simulate blasts with high precision, integrating geotechnical and topographical data to design efficient patterns, minimise overbreak, and enhance fragmentation. E*STAR detonators provide precise timing, remote programming, and improved operational safety, enabling detailed control of firing sequences and reducing unwanted vibrations.

A comprehensive risk management plan addressed logistical, labour, technical, and regulatory aspects. Monitoring committees, contingency protocols, and communication channels with all stakeholders ensured uninterrupted operations. The retention of outgoing contractor personnel, early commissioning of critical infrastructure, and coordination with regulatory agencies ensured a smooth, incident-free transition.

Austin Powder promotes sustainable practices across its operations. At Veladero, a project is under evaluation to recover used oils for reuse in ANFO formulation, aligned with circular economy principles. Environmental controls are applied to emulsion handling, waste management, and resource efficiency, in line with international sustainability standards and the mining industry’s environmental commitments.

Veladero serves as a platform for introducing new technologies, such as seismic monitoring with geophones, automation of loading processes, and real-time data analysis. Austin Powder aims to expand its presence in the Andean region, strengthening its role as a strategic supplier for large-scale mining. The lessons learned from this transition will serve as a model for future projects in complex, high-demand environments.

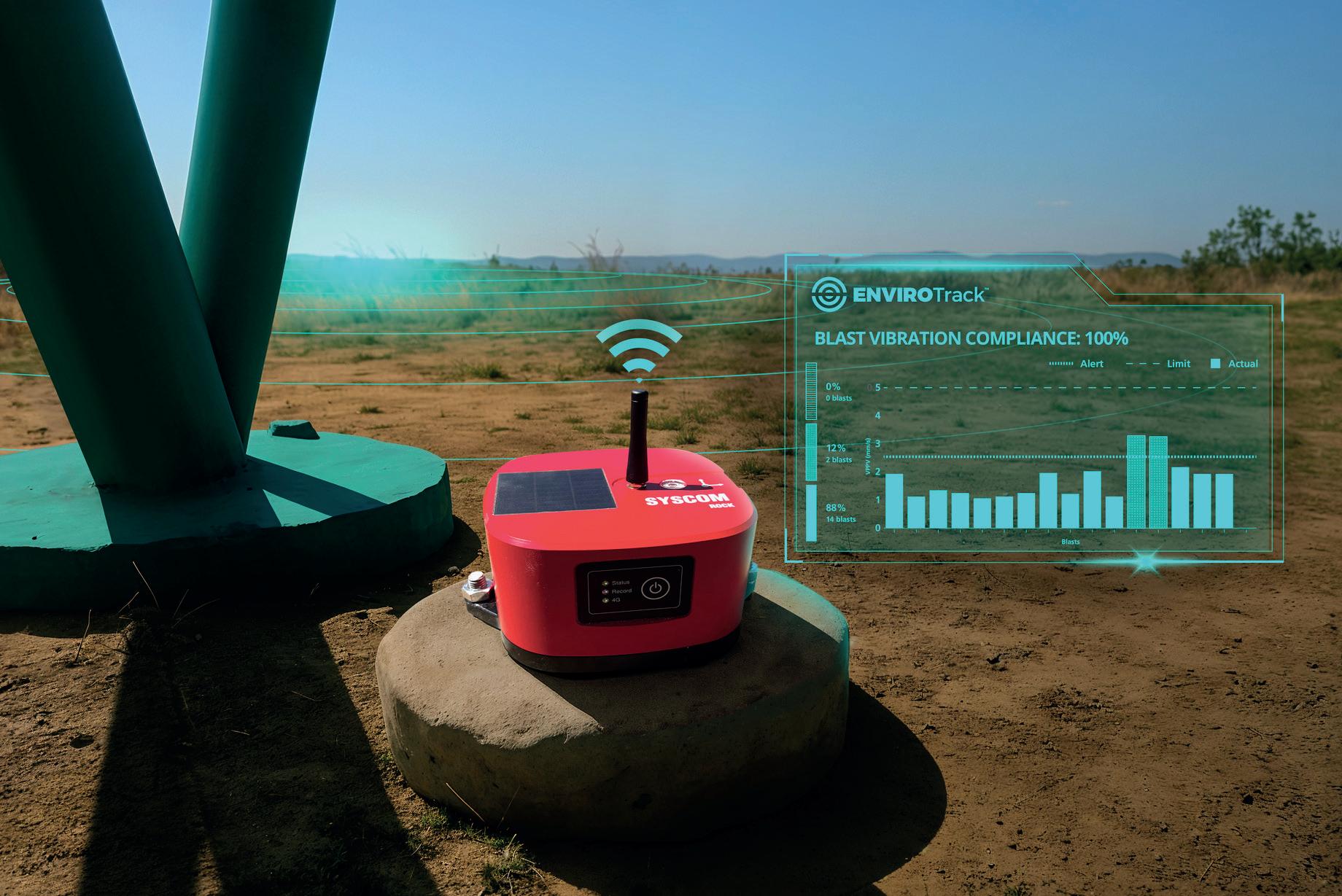

Ola Al Hassani, Vice President – Blast Design and Execution,

Orica Digital Solutions, demonstrates how technology is able to protect critical mining infrastructure and nearby communities.

In today’s mining landscape, the drive for operational efficiency and scale has transformed blasting practices. From expanding minable areas, to executing high-volume blasts, mines are striving to recover more resources with fewer interruptions. Yet, as blast size increases and pit walls become steeper, so too does the risk to critical infrastructure, underground stability, and surrounding communities.

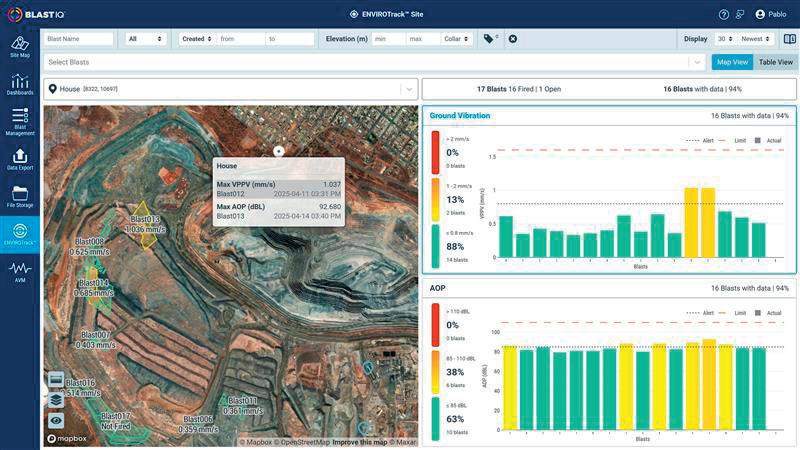

This is where vibration monitoring becomes essential, not just for compliance and maximising mine productivity, but for safety and community trust. Orica Digital Solutions’ ENVIROTrack™ is built to meet this need.

Why vibration matters in modern blasting

Blasting is fundamental to mining, but its effects ripple far beyond the blast site. Ground vibrations and air overpressure can compromise slope stability,

threaten nearby structures, and disturb local communities. As mining operations expand closer to public infrastructure and environmentally sensitive zones, maintaining compliance with vibration limits and safety standards becomes both a legal necessity and a social imperative.

Failure to monitor and manage these vibrations can lead to costly consequences – mine shutdowns, equipment damage, or even structural failures. But with effective vibration monitoring, mines can design larger, more efficient blasts while staying within safe thresholds, enabling better yield without compromising safety.

ENVIROTrack is a fully integrated vibration monitoring system designed to provide mining operations with real-time, data-driven control over blast impacts. It combines cutting-edge

Syscom sensors with Orica Digital Solutions’ BlastIQ™ platform, providing crucial insight into vibration and environmental performance.

ENVIROTrack plays a crucial role in blast design and execution by capturing detailed vibration data from every blast. This information enables engineers to refine their blast designs, optimising energy distribution, and minimising issues. As a result, mines can confidently carry out larger blasts with improved fragmentation and reduced interruptions to operations.

In terms of environmental and compliance monitoring, ENVIROTrack helps sites maintain adherence to national and international vibration standards. This ensures that blast activities do not negatively impact nearby communities, sensitive infrastructure, or the surrounding environment.

At the core of ENVIROTrack’s capabilities are Orica Digital Solutions’ Syscom Instruments vibration measurement devices. These instruments are purpose-built for the challenging conditions of mining environments and are equipped with high precision velocity or acceleration sensors. These sensors are capable of accurately capturing far-field vibrations, allowing for comprehensive monitoring across various blast scenarios. While initially designed for far-field monitoring, recent underground trials suggest they may also be suitable for certain near-field applications.

The devices are designed for 24/7 autonomous operation, using robust batteries and solar panels to remain active in remote locations without the need for constant maintenance. Integrated edge computing capabilities and 4G connectivity ensure that data is captured and transmitted to cloud-based platforms in near real-time, eliminating the need for manual data retrieval or on-site intervention.

To ensure accuracy and long-term reliability, each sensor is installed following strict industry best practices, with mounting methods tailored to the specific environment. Depending on the monitoring objective, sensors may be positioned as close as 30 m from the blast source in underground operations, or several kilometres away for compliance monitoring in nearby communities. Mounting techniques vary and include securing the devices to concrete bases anchored into in-situ rock, as well as direct attachment to tunnel walls or other stable surfaces. This flexible and standardised approach enables stable, unmanned monitoring over extended periods of time.

One of the key features of the ENVIROTrack is its digital dashboard, which integrates into Orica Digital Solutions’ BlastIQ platform. The dashboard provides users with a clear and accessible interface through which they can visualise both near real-time and historical data on ground vibrations and air overpressure.

Vibration events are clearly presented using a colour-coded interface to indicate compliance status. Green signifies that the blast was within the allowable limits, orange indicates that thresholds were approached, and red signals that the limits were exceeded. This visualisation helps teams quickly assess risk and performance at a glance.

Achieve control requirements

Facilitate regulatory compliance

Reduce environmental impacts Seamless data integration

ENVIROTrack™ is used around the world in surface and underground mining, quarry and construction applications; delivering safer blasting practices which minimise the environmental impacts of ground vibration and air overpressure.

State-of-the-art instruments are deployed at key points of interest across the mine, then connected to a powerful data visualisation tool This enables customers to receive automated reporting and near real-time alerts to help manage environmental risks and compliance requirements of their operations

To learn more about ENVIROTrack™ and how it can support your operations, please contact your local Orica Digital Solutions representative or visit orica com/envirotrack

In addition to visual insights, ENVIROTrack also supports the generation of detailed event reports, which can be exported for internal review, regulatory compliance, or communication with stakeholders. To support fast decision-making, the system also includes a flexible application programming interface (API) that enables data integration with third-party systems. Automated notifications can be configured to alert users immediately when vibration limits are exceeded, ensuring that action can be taken to promptly address potential risks.

ENVIROTrack is a key part of Orica’s broader digital vision, which aims to deliver a fully integrated suite of digital workflows that support the sustainable and efficient mobilisation of the earth’s

resources. By embedding vibration monitoring into everyday operations, ENVIROTrack empowers mining companies to make better decisions, respond more quickly to potential issues, and build more resilient and accountable operations.

In today’s mining landscape, where license to operate, environmental responsibility, and data transparency are critical, shifting from reactive to proactive blast management is no longer optional – it is essential. With ENVIROTrack, mining operations can proactively avoid structural damage and reduce long-term maintenance costs. They can also foster stronger community relations by minimising disruption and addressing concerns with concrete data.

Furthermore, the system helps ensure compliance with stringent environmental regulations, reducing the risk of penalties or operational delays. By enabling greater precision in blast design and execution, ENVIROTrack also allows sites to unlock more value from each blast, improving both productivity and sustainability across the board.

As mining operations go deeper, steeper, and increase in complexity, the importance of precision vibration monitoring cannot be overstated. ENVIROTrack, with its integration of Syscom sensors and BlastIQ’s data ecosystem, offers an end-to-end solution that not only aids in safer blasting practices which minimise environmental impacts and protects infrastructure, but permits operators to blast with confidence.

Whether it is ensuring compliance, optimising designs, or verifying underground blasts, ENVIROTrack helps mining operations achieve safer, smarter, and more sustainable outcomes.

Glenn Kerkhoff, AVEVA, USA, describes how AI and data analytics are connecting modern mines, driving down costs, and revolutionising uptime.

As the global energy transition accelerates, demand for critical minerals like lithium, cobalt, and nickel is surging. At the same time, mining operators face mounting costs, stricter environmental regulations, and a shrinking labour pool.

The pressures are real – and growing. So, how can companies do more with less? The answer lies in harnessing

the right technologies to turn volatility and uncertainty into strategic advantage.

According to management consultants McKinsey, advanced analytics and digital tools could generate up to US$290 billion in added value across the mining and metals sector by 2035, through higher productivity, predictive maintenance, and better operational decision-making.

Today’s digitally led companies are harnessing real-time operations data. They are using live insights to enable supervisors to respond to performance issues as they happen – across mobile mining equipment, process plant, asset health, energy consumption, and sustainability.

By leveraging digital tools, companies can gain a complete view of enterprise operations data at multiple sites. They can access pit-to-port visibility of material movements, inventory balances, ore grade, and equipment availability across the entire mining value chain, while integrating data sources such as pump and conveyor data to improve operational visibility.

For example, operators can optimise the supply of bulk commodities – such as iron ore or coal – by blending materials from multiple sites to meet final customer specifications. They could also refine blending strategies and coordinate the timing of shipments at port facilities to ensure production aligns with delivery schedules.

These types of changes are even more transformative in large, geographically dispersed operations, where even minor inefficiencies can lead to significant losses.

Mining operations are energy-intensive but the good news is that digital tools can now optimise power usage while dramatically driving down costs.

It is possible to pull live data from systems to identify where power is being used inefficiently and which assets are consuming more than their baseline. Companies can then respond in real-time – whether it is by shutting down idle conveyors, optimising ventilation fans, or tweaking operations.

AI, machine learning, and data analytics can be leveraged to recommend optimal settings for equipment – such as mill speeds, pump pressures, or ventilation setpoints – that minimise energy use without compromising output.

A case in point is the world’s largest gold mining company Newmont. To enhance production at its Papua New Guinea site, Newmont integrated a data management and analytics platform with equipment telematics, fleet management, and ERP systems. This initiative has reduced fuel usage by 1%, improved equipment availability by 3%, and identified a 5% opportunity to reduce diesel consumption – equivalent to US$1.5 million annually – while lowering CO₂ emissions.

In the past, heavy equipment maintenance has been either reactive – fixing problems after failure – or preventive, based on manufacturer schedules.

Modern predictive maintenance changes the game. By continuously monitoring real-time sensor data – such as vibration and temperature – mining companies can detect early warning signs of mechanical issues before they occur.

This allows them to schedule interventions precisely when needed, rather than stocking costly components like

haul truck tyres on site ‘just in case’. In remote operations where downtime is costly and supply chains are long, predictive maintenance helps strike the balance between reliability and cost-efficiency.

This capability, powered by AI and machine learning, demonstrably extends the lifespan of machinery, reduces unscheduled downtime, and improves plant safety.

According to data from the US Department of Energy, predictive maintenance can reduce mining equipment maintenance costs by up to 30% and unplanned downtime by as much as 50%.

Moreover, a centralised, digitally integrated maintenance approach enhances consistency across multiple sites, while improving spare-parts inventory planning and optimisation.

Operators are also turning to digital tools to optimise mine planning and design. 3D modelling and simulation allow engineers to visualise and plan infrastructure, such as plants, mills, and crushers, with far greater accuracy. Digital twins can replicate real-world conditions, enabling scenario testing before ground is even broken – minimising risk and enhancing returns.

For example, global mining firm Rio Tinto has deployed a suite of digital tools to drive greater efficiency, transparency, and control across major resource development projects.

A secure, cloud-hosted environment provides real-time visibility into cost and schedule performance – transforming uncertainty into predictability and enabling more agile decision-making.

One of the most significant advancements has been the shift toward design reuse. For the first time, an entire crushing facility, including conveyor systems, was replicated from one project to another. This approach moves beyond modularity, enabling the reuse of entire facilities and significantly reducing engineering time and capital expenditure.

A broader push toward standardisation is also underway. By preconfiguring project environments and enabling the early integration of engineering service providers, what once required up to six months of preparation can now be executed in weeks.

The ability to access this information globally via a secure cloud infrastructure is reshaping how large-scale projects are managed. Remote visibility and collaboration are now operational realities.

Mines of the future will be powered by real-time data and supported by predictive analytics, remote operations, and AI.

Digitalisation is key to producing the critical minerals and metals for the energy transition, while helping mining companies meet their sustainability goals and thrive in increasingly competitive environments.

Industrial organisations that invest in these capabilities today are positioning themselves for future resilience, operational success, and global leadership.

LOW COST OF PRODUCTION

SUSTAINABLE OPERATIONS

Can mining satisfy the world’s hunger for raw materials – and meet environmental targets too?

With Cummins’ help, it can. Our range of mining engines, made even cleaner and more e icient through technologies like alternative fuels and advanced monitoring, are helping mining explore a future that can be both sustainable and profi table. It’s power: balanced.

The first edition of Global Mining Review’s ‘The Digital Mine’ conference is taking place on 25 September 2025.

This virtual conference is dedicated to exploring the use of digitalisation, automation, and AI technologies to enhance mining operations around the world.

Join us for a series of informative presentations from industry experts, focusing on innovative technology and solutions that are helping to create the mines of the future, today.

Expert-led technical presentations

‘On Demand’ presentation access

Chat & networking features

Live Q&A sessions

Actionable business insights

Interactive exhibition booths

https://bit.ly/3EfqZ7A?r=qr

Andres Losada, Motorola Solutions, USA, details how advanced safety and security technologies are transforming threat detection and efficiency for mining operations.

For centuries, caged canaries were used to detect the presence of lethal gases deep underground in mining expeditions. If the tiny birds weakened or stopped chirping, miners knew to evacuate – and to get out quickly. Fast forward to the robust global mining operations of today, and while mining remains one of the most hazardous industries in the world, modern mines are increasingly relying on integrated video security, advanced radios, and environmental sensor technologies to help protect their people, property, and environments.

Mining sites are laden with inherent dangers throughout their remote locations and sheer scale, typically encompassing miles of subterranean tunnels and vast open pits – not to mention makeshift

communities with amenities and living accommodations for teams of site workers. The ever-present risks for occurrences such as gas leaks, ground collapses, underground fires, and more – coupled with the looming threat of theft given the plethora of high-value extracted resources and expensive heavy machinery – present a host of challenges when it comes to protecting and securing mining’s many facets.

In such high-stakes settings, the importance of robust, reliable, and advanced video security, two-way radio communication and environmental sensing technologies cannot be overstated. These are not just convenient tools – they are essential safeguards, silently working to help protect lives, secure valuable assets, and drive efficiency across a mining operation’s complex industrial facilities.

A cornerstone of a modern mining operation’s physical safety infrastructure is the extensive deployment of varied types of specialised video security cameras. These are not just any run-of-the-mill, off-the-shelf video cameras; they are purposefully engineered, highly specialised devices that are designed and built for continuous performance amid specific use cases of extreme conditions.

High-resolution video security cameras provide visible scene capture under rough conditions. From abrasive dust to near-total darkness, these specialised video security cameras offer remote viewing capabilities that can dramatically reduce the need to have miners and

other workers in dangerous areas. Strategic placement of these high-resolution, long-range devices throughout mines, quarries, and living areas affords real-time visual information allowing security operators to observe conditions, detect potential risks, and identify anomalies from safe distances.

Ruggedised video security cameras are engineered to withstand and perform during emergency events. Under the most difficult conditions, such as prolonged exposure to corrosive elements, these devices offer continuous operation and reliable data capture – even against explosions.

Thermal video security cameras are built to perform effectively in extremely hazy to pitch-black conditions, which is paramount in subterranean tunnels that are often obscurely lit. Thermal cameras can also detect heat signatures, which becomes indispensable in murky, dusty environments where visual cameras struggle. This capability helps to identify potential fires, overheating machinery, and can even detect the presence of people in smoke-filled areas.

For sprawling mining sites, it is also critically important that video security cameras provide continuous, real-time monitoring of key areas, including entry and exit points, quarries, equipment yards, and subterranean tunnels. In addition to rapid incident

assessment, such continuous visual intelligence is vital for detecting unauthorised access and preventing theft.

A transformative progression, representing a fundamental and lasting shift in how mining operations are managed, is the growing use of personal protective equipment (PPE) analytics. This software enhancement can be deployed and integrated into video management systems (VMS) from the cloud. Using computer vision and artificial intelligence (AI), a VMS could analyse video feeds to identify whether workers are wearing key protective gear like specified hard hats, safety vests, eye protection, and more. Managers receive a notification when a worker is out of compliance.

Beyond checking for a hard hat, advanced PPE analytics can leverage AI to recognise the specific type of PPE being worn, which helps ensure it is the correct gear for a particular hazardous zone or task. This enhancement allows VMS’ to detect things like specialised fire-resistant clothing, flagging an alert to a manager if a worker enters a high-heat area without the appropriate thermal protection. This intelligence can also analyse worker posture and movement to identify unsafe behaviours, such as a worker bending or lifting incorrectly in a way that could lead to injury, adding an additional layer of proactive risk mitigation, moving beyond compliance to accident prevention.

The benefits extend to real-time alerts for confined space entry violations, ensuring that only authorised personnel with the correct training and equipment enter high-risk areas. In the event of an emergency, the system can even detect if a worker has fallen or is immobile, automatically triggering an alarm and directing rescue teams to their precise location, greatly improving response times and potentially saving lives. This comprehensive, intelligent monitoring transforms raw video data into actionable insights, making mining environments safer and more efficient.

In the expansive and often challenging world of mining, reliable radio communication systems are truly the lifeline for workers. Instant and clear communication is not just convenient; it is a critical safety imperative. Strong digital radio systems help ensure that personnel can communicate effectively across vast distances, through geological barriers, and in noisy operational environments.

These systems are vital for coordinating daily tasks like material transport and blasting, but their most crucial role emerges during emergencies. The ability to instantly relay distress calls, issue evacuation orders, or guide rescue teams is invaluable in rapidly evolving situations such as cave-ins, fires, or gas leaks. This robust communication backbone helps ensure every worker can be reached and accounted for.

Komatsu’s FrontRunner Autonomous Haulage System (AHS) is designed to improve operational efficiency while lowering fuel use and emissions per ton, driving sustainable, consistent productivity.

Global mining operations are realising significant benefits from advanced radio platforms. These platforms can be leveraged to connect with other security devices, reducing the need for redundant communication networks. For instance, a specialised edge computing device, such as Motorola Solutions’ MC Edge®, can seamlessly integrate with an existing radio network. This powerful addition allows for the incorporation of Internet of Things (IoT) devices and a myriad of smart sensors without the need for an entirely new communication infrastructure.