In the fast-paced world of foodservice, keeping your walk-in coolers and freezers at perfect conditions is non-negotiable From ensuring top-notch food

kitchen can’t go without. Say goodbye to manual logs and constant worry over storage conditions – this innovative touchscreen monitor delivers real-

time precision, transforming how you manage food safety.

Why the CFCM-240 Stands Out in Foodservice

1. Real-Time Alerts: Instant Action, Zero Compromise

Imagine never missing a beat on food storage conditions. The CFCM-240 continuously monitors temperature and

spoilage surprises or compliance hiccups – just prompt notifications that help prevent food waste, protect inventory and keep your kitchen run-

always a step ahead

2. Easy, Intuitive Touchscreen for All Skill Levels No need for complex training sessions or confusing controls.

Continued on Page 37

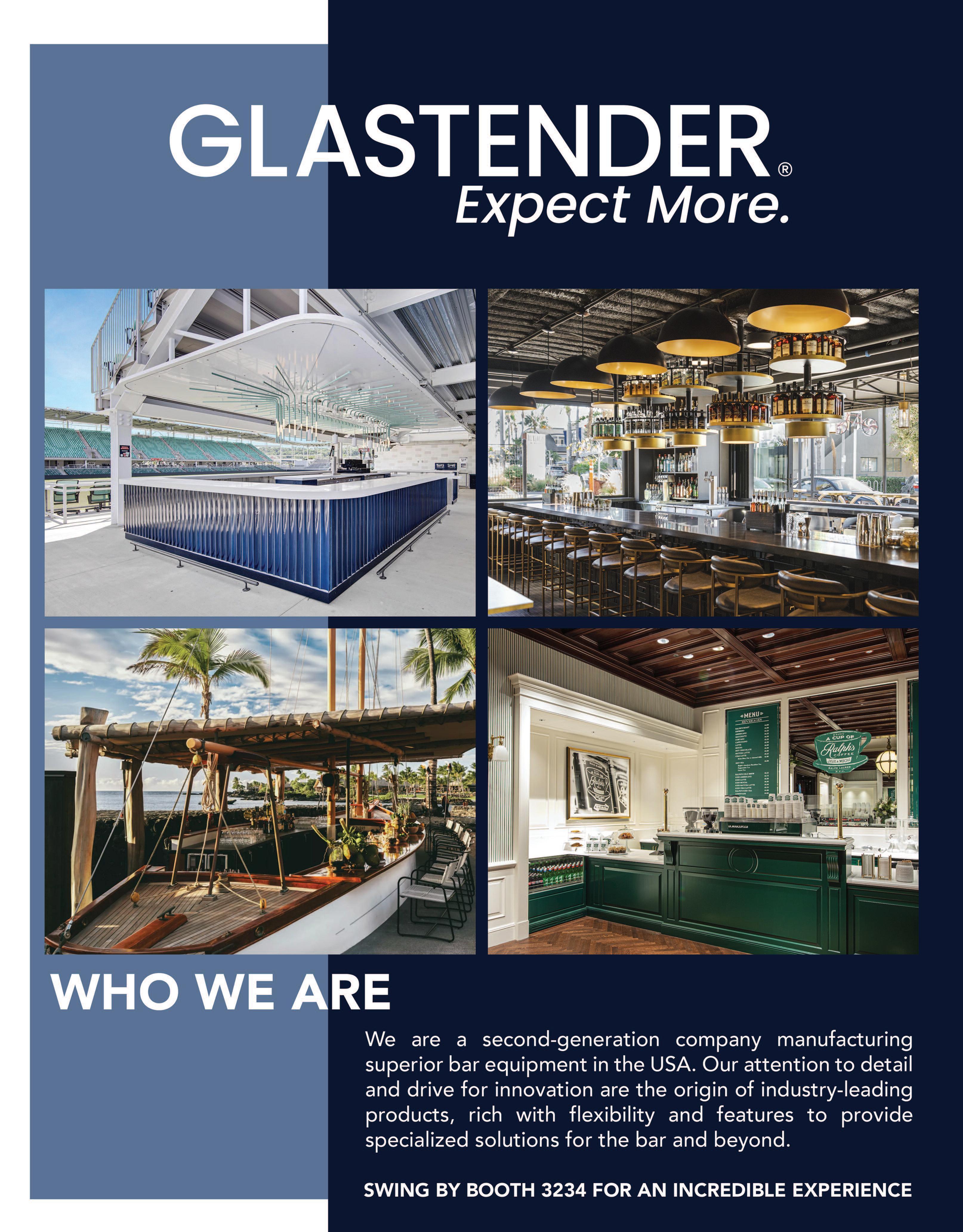

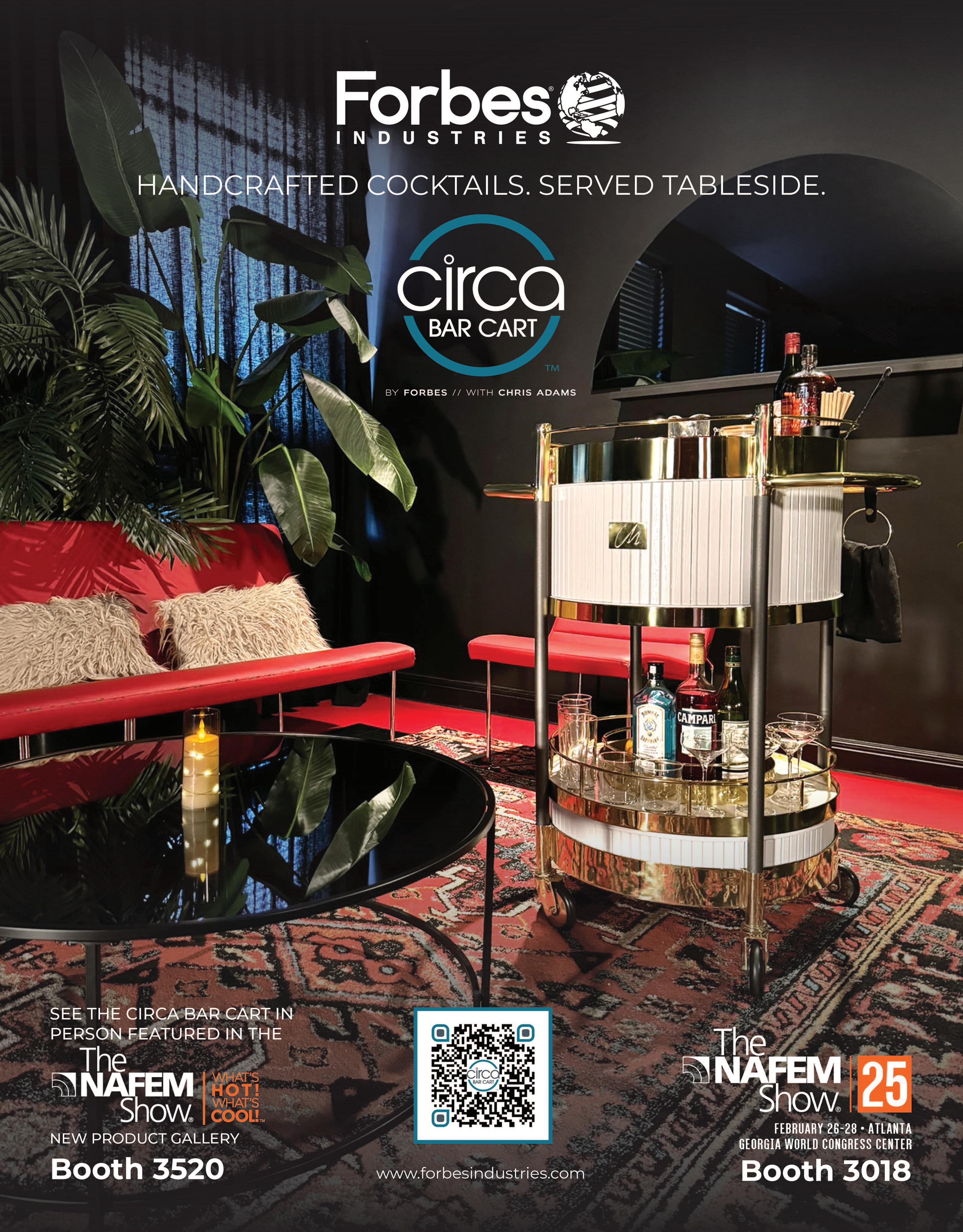

As defined in Glastender Inc Cocktail Life Cycle, crafting cocktails is a process which, in most cases, requires seven tasks to serve to the customer and another three tasks to cycle used glassware back into rotation. In an efficient bar design, dedicated pieces of equipment are arranged so each task is performed with as few body movements

Continued on Page 37

At this year’s show, Panasonic showcases the High-Speed Oven, an innovat i v e s o l u t i o n d e s i g n e d f o

d e r n commercial kitchens Combining highspeed performance with unparalleled efficiency, the SonicChef is an investment that brings exceptional value to foodservice professionals

Compact Size, Big Impact

Space is a premium in busy kitchens, and the SonicChef delivers maximum functionality in a minimal footprint

W i t h i t s c o m -

p a c t , v e n t l e s s design, this oven is the perfect fit f o r o p e r a t i o n s w h e r e e v

Despite its small

i n g c a p a b i l i t i e s , offering versatility without compromising quali-

workspace, making it ideal for operations with fluctuating customer volumes

B e y o n

SonicChef stands out for its durability, efficiency and cutting-edge cooking technologies. By integrating inverter microwave, radiant broil and convection heating, it ensures even cooking and top-tier food quality every time Its

t y . W h e t h e r you’re operating in a café, food truck or a bustling restaurant, the SonicChef adapts seamlessly to your workspace

Stackable for Greater Efficiency

The ability to stack up to two SonicChef ovens allows operators to scale their production efficiently while maintaining a compact footprint Whether you need a single oven for daily tasks or t w o h i g

needs This modular design doubles your cooking capabilities while pre-

B y N i k H e i m a c h , S e n i o r C o p y w r i t e r , TundraFMP

Food is more than just nourishment –

i t ’ s a n e x p e r i e n c e . A m e m o r y . I t i s

r o m a n t i c , f u n , e x c i t i n g , c o m f o r t i n g

and, to some, deathly serious Food is so many things, and so many restaurants exist to capture a vision of what food can be

There’s magic in food and it is anything but exclusionary There is no bad blood spilled between a foie gras and the perfect cheeseburger. You can find your bliss at a roadside diner as easily as at any Michelin-star restaurant But t h e i n g r e d i e n t s t h a t f e e d A m e r i c a aren’t stored in a walk-in alone They’re found on the countertop In the dishwasher On tabletops and in janitorial

c l o s e t s . T o s u c c e e d i n h o s p i t a l i t y , restaurants need supplies.

T h e m o s t s u c c e s s f u l f o o d s e r v i c e

o p e r a t i o n s r e l y o n s u p p l i e r s w i t h f a s t ,

d e p e n d a b l e a n d f l e x i b l e s o l u t i o n s

T h a t ’ s w h a t T u n d r a F M P d e l i v e r s t o

m u l t i - c h a i n a n d s i n g l e - s t o r e r e s t a u -

side, cold side, apparel, disposables –we’ll even custom source supplies just for you We care about restaurants the same way restaurants care about their patrons At the end of the day, it all comes down to one word: service.

T u n d r a F M P b r i n g s m o r e t o t h e table. Whether it’s feeding to fulfill a necessity or embracing the simple luxury of flavor, restaurants of every size count on us to spin their supply plates so they don’t have to We believe in the power of food

reduces operational costs, adding even more value to your investment

Visit Panasonic in booth #3118 to explore how the SonicChef High-Speed Convection Multi-Oven can revolutionize your kitchen. Experience the perfect combination of value, space efficiency

SonicChef help you do more with less, so you can focus on delivering outstanding meals to your customers

p.panasonic.com or stop by booth #3118.

r a n t s a c r o s s t h e c o u n t r y S a m e - d a y

s h i p p i n g , r a p i d p r o d u c t r o l l o u t s , T h e

L a u n c h p a d N R O p r o g r a m a n d c u s -

t o m e r - s p e c i f i c o r d e r i n g w e b s i t e s a r e

j u s t t h e b e g i n n i n g o f w h a t y o u s h o u l d

e x p e c t f r o m y o u r s u p p l y e x p e r i e n c e

TundraFMP is a company created by former chefs, managers, servers and technicians who understand the many hurdles of running a successful restaurant. We understand the unique needs of your world because it’s our world, too

Back-of-house, front-of-house, hot

Our goal is to prove ourselves as the ultimate foodservice supplier by turning any restaurant’s vision into a reality. W i t h m u l t i p l e d i s t r i b u t i

thousands of in-stock products and d

n g America’s favorite chains, TundraFMP is ready to provide everything but the f

ment. From there, the magic you make is up to you. F o

tundrafmp com

F

stops for busy customers looking for a quick, quality cup of coffee. Yet, maintaining an efficient and consistent coffee service can be a significant chal-

impact operational efficiency and customer satisfaction.

Infinibrew: A Game-Changer for Foodservice Locations

Infinibrew is designed to address these common challenges with innovative features that simplify

machines often come with drawbacks that make the process time-consumi n g , i n e f f i c i e n t a n d c o s t l y E n t e r

Infinibrew, a cutting-edge coffee brewing solution that eliminates these pain points, enabling cafés, restaurants and hotels to elevate their coffee service effortlessly and through automation

Common Challenges with Traditional Coffee Machines

Traditional coffee equipment requires staff to oversee every aspect of brewing, from monitoring freshness to managing coffee volume. This is often done w h i l e s i m u l t a n e o u s l y h a n d l i n g c u stomer interactions and other operational responsibilities At the end of each day, the machine and dispensers must undergo thorough cleaning to ensure safety and maintain beverage quality, as well as to prepare for the next shift. These daily tasks demand significant time and effort from staff, impacting overall efficiency and consistency In addition, expensive servers are often damaged or destroyed during the cleaning process since they are t r a n s p o r t e d f r o m t h e m a c h i n e t o a cleaning area.

Anticipating the right coffee volu m e i s a p e r s i s t e n t c h a l l e n g e . H o s p i t a l i t y o p e r a t o r s o f t e n c o

g slower periods, which leads to waste and higher costs Conversely, brewing too little during peak times results in dissatisfied customers and missed sales opportunities. These difficulties in balancing supply with demand directly

service.

Infinibrew’s automat-

for constant monitoring and manual brewing. The machine can brew coffee in small

ensuring a fresh cup every time This system reduces the risk of running out of coffee or brewing excessive amounts, improv-

y and customer experience

With Infinibrew’s Clean-In-Place feature, cleaning is as simple as pressing a button. The machine performs a full cleaning cycle without requiring parts to be removed or operations to be halte

time, minimizes downtime and eliminates the need to handle heavy servers, improving safety and reducing the risk of damage

Infinibrew’s intelligent brewing technology adjusts output to match realtime customer demand Whether it’s peak or off-peak hours, the machine ensures the right amount of coffee is always available This not only reduces waste but also cuts costs and ensures customers consistently enjoy a fresh cup of coffee

By Francesco Marra, President and Chief Executive Officer, Marra Forni

A s t h e r e s t a u r a n t i n d u s t r y e v o l v e s ,

Marra Forni continues to set the standard for innovation We’re proud to i n t r o d u c e t h e M a r r a F o r n i E l e c t r i c Rotator, the first commercial electric r o t a t i n g o v e n m a d e i n t h e U n i t e d States. This groundbreaking oven comb i n e s a d v a n c e d t e c h n o l o g y w i t h thoughtful design, providing operators with unmatched efficiency, cost savi n g s a n d s u s t a i n a b i l i t y – a l l w h i l e ensuring the high-quality results Marra Forni is known for

Why Choose the Marra Forni Electric Rotator?

1. Lower Maintenance Costs

One of the most significant advantages of the Electric Rotator is its low maintenance requirements With fewer moving parts and no need for gas line i n s p e c t i o n s , b u s i n e s s e s c a n s a v e between $1,000 and $2,000 annually on maintenance. This translates into fewer disruptions, reduced downtime and increased operational efficiency

2. Enhanced Energy Efficiency and Equipment Longevity

E l e c t r i c o v e n s a r e

y m o

e energy-efficient, consuming less power than traditional gas ovens while maintaining precise temperature control. A

efficiency and durability offers substantial long-term value for any operation.

3. Future-Proofing Your Kitchen

As the world shifts toward electrification and regulations on carbon emissions tighten, investing in an electric rotator oven positions your business ahead of the curve By choosing the Electric Rotator, you’re not just adapting to change – you’re leading it, demonstrating a commitment to sustainability and forward-thinking kitchen design

The rotating mechanism in the Electric Rotator reduces the need for manual intervention, ensuring consistent cooking and lowering labor demands. This innovation can save businesses an estimated $2,000 to $3,000 annually by streamlining operations and allowing staff to focus on other tasks The result? Increased efficiency, reduced labor costs and consistently perfect results with every bake

At Marra Forni, we’ve built our reputation on creating world-class ovens that blend craftsmanship with cutting-edge technology The Electric Rotator is no exception It’s a testament to our dedication to empowering chefs and operators with tools that meet the demands of modern kitchens while staying rooted in the tradition of exceptional cooking

.newcocoffee.com, call

or email sales@newcocoffee.com.

longer lifespan, providing years of reliable performance This combination of

Sustainability is becoming a priority in the HORECA industry, and restaurants embracing a “green” approach appeal to eco-conscious customers and give owners peace of mind, knowing they’re m a k i n g a p o s i t i v e e n v i r o n m e n t a l impact For many, going green can increase operational costs – fortunately, that’s not the case with effective frying oil management. With proper han-

d l i n g a n d m a i n

a n t s can significantly extend the lifespan of their oil, which makes operations both more profitable and sustainable

Using VITO, businesses can double the life of their oil, instantly reducing the need for frequent oil orders, which cuts down on delivery and disposal

t r i p s T h i s i n t u r n l o w e r s f u e l u s e , decreases CO₂ emissions, and reduces the waste associated with oil packaging Less oil consumption also means

less demand on agricultural resources – restaurants cutting their oil usage by h

field’s worth of plant life each year!

A high-efficiency filtration system like VITO’s can save up to 50% in oil

c o s t s ,

a m

d e buildup in food, and ultimately improve food quality in taste and appearance. When frying oil is cleaner and lasts longer, customers notice a difference –

Satisfied customers are loyal customers!

Incorporating VITO’s filtration system not only boosts profits but also enhances customer satisfaction while positively impacting the environment.

www vitofryfilter com, call 847 859 0398, email info@vitofryfilter com or stop by booth #200

BAK Food Equipment announced that Zack Olson has joined the team as Sales and Marketing Specialist In this new r o l e , O l s o

with Thomas Bako, Director of Business

Dito Sama, a brand synonymous with high quality, innovative food preparation equipment, has a long-standing presence in the professional kitchen industry Founded with a commitment to creating reliable, ergonomic and efficient tools, Dito Sama produces a range o f p r o d u c t s d e s i g n e d t o m e e t t h e demands of foodservice environments Renowned for their durability, ease of use and strict adherence to hygiene standards, Dito Sama's products – such as food processors, slicers and mixers –are designed to optimize kitchen operations while supporting food safety.

At the core of Dito Sama’s philosophy is the pursuit of efficiency through t h o u g h t f u l d e s i g n E v e r y p i e c e o f equipment is meticulously crafted to reduce manual effort while maintaining exceptional standards of quality and safety By simplifying processes and boosting productivity, Dito Sama empowers professional chefs with relia b l e t o o l s t o a c h i e v e o u t s t a n d i n g results The brand’s commitment to innovation ensures its products continue to evolve, meeting the ever-changing needs of the foodservice industry

In addition to product quality, Dito Sama is committed to maintaining sustainable business practices and supporting local communities The compa-

ny's commitment to sustainability is evident in its environmentally friendly production processes and the longevity of its products Dito Sama strives to minimize its environmental footprint and ensure that its solutions are not only effective but also responsible. E u r o

t h D

p w

o Sama guarantees that North American customers have access to local support and service for Dito Sama products

T h i s

improve their kitchen operations with equipment that has been thoroughly tested to meet the demanding needs of commercial kitchens. Designed for reliability and consistent performance, these products excel in high-volume restaurants, catering services and food processing facilities, delivering great results in diverse professional kitchen environments

Visit Dito Sama at booth #4927 to discover how its solutions can enhance efficiency, safety and overall perform-

achieve excellence in any commercial foodservice setting

.ditosama.com/us, call

or stop by booth

Food Equipment’s existing client

tionships O

C a p i t a l D i v i s i o n w i t h a f o c u s o n c o mp a n i e s i n t h e a e r o s p a c e a n d d e f e n s e i n d u s t r i e s I n t h i s r o l e , O l s o n w o r k e d w i t h t o p - l e v e l e x e c u t i v e s a n d C - s u i t e m a n a g e m e n t f r o m c o m p a n i e s o f a l l s i z e s F o r m o r e i n f o r m a t i o n , g o t o w w w .bakfoodequipment.com.

In professional kitchens, the perception that gas surpasses electric is difficult to overcome. Few images are more iconic

t

w h e t h e r h e a t i n g

white-hot flames or keeping a stockpot at an almost indiscernible simmer over gentle orange-blue flickers With various advantages to consider, though, it may be time to shift the paradigm in favor of the all-electric kitchen, and Waring is here to help that transition with everything from induction burners and countertop ovens to griddles and sandwich grills

Dan DeBari, Waring’s GM, cites the brand’s mission and core values as the f r a m e w o

Waring’s vision for the future

“Waring’s purpose has helped us employ strategies in our product devel-

opment, sustainability initiatives and messaging in hopes of making a positive impact in the industry we serve,” says DeBari “There is a ton of momen-

kitchens

how they can contribute to reversing

can supply restau-

ment that is much faster, has better recovery rates, emits no carbon dioxide or methane, promotes a cooler, cleaner environment, and ultimately increases operational efficiency ”

Rich Rosendale, a Waring Collective member, notes a key advantage of the electric kitchen: potentially eliminating the need for a hood, depending on state and local codes. Gas-powered appliances require expensive venting, but electric kitchens may not require hoods Rosendale lists two of his locations, Forklift and pop-up restaurant R3,

launching the sites

“If we had to use gas,” he says, “we

would have spent a lot more money, had a lot more inspections and waited several more months for the openings ”

Rosendale outfits these kitchens with griddles, pizza ovens, induction burners and convection ovens. To maximize use of the space, induction-ready pans are hung on kitchen walls with magnets

“Electric shows that you can really put a fully functional restaurant anywhere,” Rosendale adds Waring Collective member Jeremy Umansky is a fan of the electric kitchen for its steps toward sustainability. All electric is good, he says, because that

friendly kitchen He also likes the modular aspect of an electric kitchen “

health of our staff and customers is

portability as well are hugely beneficial for our business,” Umansky says

Working with limited space and budget, Umansky assembled an electric kitchen with no hood or walk-in fridge but with undercounter refrigeration, induction cooktops, countertop ovens, an immersion blender and a thermal holder, among other gear.

Another Waring Collective mem-

kitchen advantages His electric-appli-

With an assortment of specialty appliances, including waffle makers, pasta cookers, grills and griddles, not

Waring Xpress™ crêpe maker and multipurpose cooktop, Waring has a lineup of gear to outfit or augment your allelectric kitchen – the kitchen of the future, today F

waring com or stop by booth #1300

Marketing, Wood Stone

If there’s one booth you can’t afford to m i s s a t t h i s y e a r ’ s s h o w , i t ’ s W o o d

Stone With over 35 years of expertise i n d e s i g n i n g h i g h - q u a l i t y c o o k i n g

e q u i p m e n t , W o o d S t o n e i s s y n o n ym o u s w i t h r e l i a b i l i t y a n d c u l i n a r y

excellence This year, we’re thrilled to u n v e i l P e r f e c t H e a t T e c h n o l o g y , a n integrated heating system that r e d e f i n e s w h a t ’ s p o s s i b l e i n

commercial kitchens

Perfect Heat Technology is not just a feature – it’s the heartbeat of what makes Wood Stone equipment extraordinary This revolutionary integrated heating system delivers consistent and reliable heat across every cooking surface, ensuring that operat o r s a c h i e v e o p t i m a l r e s u l t s whether they’re searing, roasting, baking or rotisserie roasting

F o r c h e f s , t h e v a l u e o f

Perfect Heat Technology is clear

I t e m p o w e r s t h e m t o c r e a t e unforgettable culinary masterpieces; imagine perfectly roasted vegetables, artisanal pizza with a flamekissed crust with bubbling toppings, perfectly seared steak or tender, juicy rotisserie meats – all thanks to the u n m a t c h e d p e r f o r m a n c e o f W o o d Stone’s integrated heating system.

solutions, operators can focus on what t

tomers.

Our dedication to excellence has earned us the trust of countless chefs and foodservice professionals worldwide Backed by decades of industry experience, we’re committed to helping operators succeed, whether they run a neighborhood pizzeria, a high-

end restaurant or a bustling food hall

At Wood Stone, we understand the demands of busy commercial kitchens, where speed and dependability are non-negotiable That’s why we design equipment that not only elevates flavors but also streamlines operations

At the show, Wood Stone invites you to experience the power of Perfect Heat Technology firsthand Stop by our booth #1808 to see how our innovative equipment can transform your kitchen a n d e l e v a t e y o u r f l a v o r s t o n e w heights.

F o r m o r e i n f o r m a t i o n , g o t o w w w woodstone-corp com, call 360 650 1111, email hello@woodstone net or stop by booth #1808

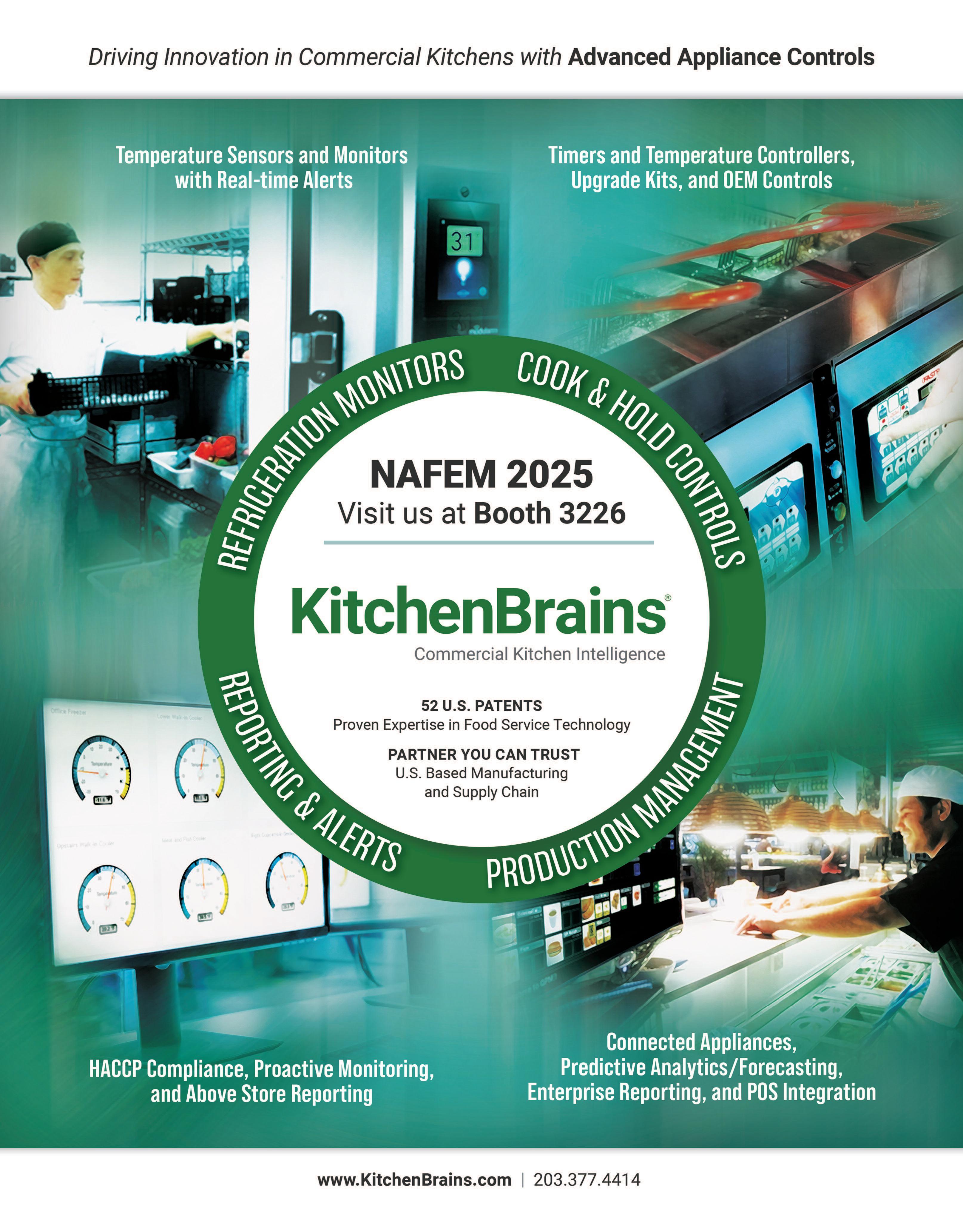

By Christine Senkiewicz, Vice President of Marketing, Kitchen Brains®, Inc.

In the fast-paced foodservice industry, balancing the needs of operators with the evolving challenges faced by both commercial refrigeration and cooking

sacrificing profitability. This collaborative approach offers OEMs and operators scalable solutions that maintain a competitive edge and nurture longterm partnerships O

equipment manufacturers (OEMs) is no easy task Kitchen Brains stands apart b y c o m b

s e d expertise with OEM-driven solutions With 55 years of innovation – averagi n g o n e p a t e n

c h e n Brains has developed 52 U.S. patents, 36 of which are specifically designed to a d d

d b y kitchen operators These patents represent our deep understanding of the kitchen's unique demands, providing engineered solutions to simplify complexity

Operators often need immediate solutions to urgent cooking, holding and refrigeration issues, but communic a t i o n b a r r i e r s b e t w e e n O E M s a n d operators can create frustration and delays Kitchen Brains bridges this gap with its extensive operator experience and deep knowledge base Our proven configurable control platforms dramati c a l l y s h o r t e n p r o d u c t d e v e l o p m e n t cycles, while our U S -based manufact u r i n g a n d i n t e g r a t e d o p e r a t i o n s ensure quick, responsive service from design to delivery By translating operator needs into turnkey solutions, we help both OEMs and operators stay ahead of the competition.

Cost management is another challenge in the industry. OEMs face rising supplier costs and operator resistance to price hikes, squeezing margins and limiting innovation Kitchen Brains bala n c e s t h e s e c o m p e t i n g p r e s s u

e s through flexible intellectual property (IP) options that share both risks and r e w a r d s . O u r e f f i c i e n

n methods, built on decades of operator

, SalesMaker Carts

e o f reacting to operational

direct operator service offers a unique understanding of kitchen real-

enables us to deliver forward-thinking solutions

stay ahead of the curve

tors to lead with innovation instead of simply reacting to challenges.

Kitchen Brains’ deep understanding of both operator and OEM needs makes us an invaluable partner in the commercial kitchen middle-of-house™ ecosystem With unmatched expertise and cost management options, from custom control solutions to upgrade kits, we turn complex problems into opportunities for growth OEMs and operators alike can rely on us for innovation, profitability and long-term success

For more information, go to www kitchenbrains com, call 800 243 9271 and 203.377.4414 or stop by booth #3226.

Transporting foodservice equipment for sales and service can be a lot of work, why not let SalesMaker Carts do the heavy lifting for you? Utilize our range of compact folding carts and s t a i r - c l

machine pick-ups and deliveries easier.

Since 1992, SalesMaker Carts has been providing its one-of-akind, single-person operation

to customers looking to safe-

ambulance gurney transport-

Carts has developed a product line of folding carts feat u r i n g r o c k - s o l i d r e l i a b i l i t y and time-tested simplicity to c a t e r t o t h e n e e d s o f t h e f o o d s e r v i c e e q u i p m e n t industry.

S a f e l y t r a n s p o r t y o u r c o u n t e r t o p m a c h i n e s w i t h

o u r h e i g h t a d j u s t a b l e

Demtruk folding cart options

tackle tasks that traditionally required a full crew, minimizing risks associated with handling bulky loads on precarious stairs With a robust 1200-pound l o a

options, Escalera is engineered to meet y

The roll-off platform feature allows the operator to safely load and unload up to 500 pounds in and out of work vans, trucks and passenger vehicles. With platform options of 27 5 inches to 48 inches long and load capacities up to 500 pounds, we have the right fit so one man can do the job of two in a compact folding cart form

Our motorized stair climbing hand trucks empower a single operator to

your Escalera into a mini forklift with our manual or electric hand winch, facilitating smooth equipment unloading from vans, trucks and trailers Ready for action, our inventory is stocked and primed for shipping from o

Reach out to us to request a quote, verify stock availability or receive expert advice on configuring the perfect solution for your needs We're eager to collaborate with you! For

c h a n g i n g , a n d y o u h a v e t o m a k e adjustments to keep it moving forward When you have really good people working for you, it makes it a lot easier to do. We are bringing innovation to the industry and technology to our manufacturing. We are providing quality products that we feel proud of and the customer feels satisfied with

F E N : T a l k i n g a b o u t i n n o v a t i o n a n d technology – what value are you bringing to this industry?

CL: I know the product solutions that we’ve designed are providing a lot of value to the industry We do that with materials, our engineering expertise and

with the technology that we have implemented during the manufacturing process We get all of that to blend together to create a product that solves a customer’s problem, and once they get it, they’re happy, satisfied and they keep coming back to us. That tells us that what we’re doing, we’re doing right.

FEN: In terms of manufacturing, what are your standards of finished pieces that leave the factory? What do you want to deliver to your customer?

CL: Our manufacturing team understands how to make these products. It is their craft Our engineers and manufacturing team work closely together to ensure things are fabricated and assembled correctly When it gets down to shipping that Choice Equipment Company (Cont’d from p 1)

• C o n s i s t e n t T a s t e a n d T e x t u r e :

final product, I say, “Ask yourself, would you take money out of your wallet and buy that rack? Are you proud of that?” They understand that And I think they take that to heart when they’re producing that final product We all have a sense of pride in the products we manufacture.

FEN: Choice Equipment manufactures here in the United States, and you actually see it as critical to the food industry Why is that?

CL: There are a lot of reasons why Made in the USA is important to us. I mentioned the art and the craft that our people use to produce our products, but this also keeps us flexible in helping the customer Yes, we could go overseas, we could buy product, we could bring in components

and so on And we do that some But we do it in a way that helps support what we do here If you stray away from that too far, then you're not responsive to the customer Our customers know that when they have a problem, they can come to us for a solution. Keeping manufacturing here in the United States means that they will have their product in a couple of weeks, whereas imports will take four to five months Our customers are thrilled with our response time We keep our customers first and that is what keeps them coming back

f o o d s e r v i c e o p e r a t i o n o n m u l t i p l e common foodservice issues

• P r e v e n t s F o o d b o r n e I l l n e s s e s :

Ensuring food is cooked and stored at the right temperatures is essential for k i l l i n g h a r m f u l b a c t e r i a l i k e S a l m o n e l l a , E . c o l i a n d L i s t e r i a .

U n d e r c o o k e d f o o d o r f o o d s t o r e d improperly can lead to the growth of these pathogens, increasing the risk of foodborne illnesses

• C o m p l i a n c e w i t h H e a l t h

Regulations: Restaurants are required to adhere to local health codes that mandate specific temperature ranges for cooking, storing and holding food. By regularly checking food temperatures, restaurants can ensure compliance with these regulations and avoid violations, fines or even shutdowns

T h e C F S B r a n d s f a m i l y n o w i

F o o d s e r v i c e P r o d u c t s , S a n J a m a r , Dinex, Sparta, Snap Drape, WipesPlus, Piper, Jofel, AyrKing, El Castor, Elite

G l o b a l S o l u t i o n s , G E T , W i n c o a n d , most recently, Araven The company’s 14 brands offer a comprehensive suite of solutions that encompass any frontof-house, back-of-house, foodservice equipment, healthcare meal preparation and delivery, and hygiene needs.

L a s t y e a r ’ s a c q u i s i t i o n o f T F G , known for its front-of-the-house and back-of-the-house solutions, brought industry brands G E T and Winco into the CFS Brands family Similarly, the recent acquisition of Araven added cutting-edge food storage and prepara-

Cooking food to the right temperature ensures that it is prepared properly, preserving its flavor, texture and overall appeal Overcooking or undercooking can compromise the quality of the dish, making it unappetizing or unsafe to eat

• Safe Holding and Storage: Foods held or stored at incorrect temperatures can become breeding grounds for bacteria, leading to cross-contamination and spoilage Regular temperat u r e c h e c k s h e l p e n s u r e t h a t f o o d remains within the safe “temperature zone” (hot food above 140 degrees Fahrenheit and cold food below 40 degrees Fahrenheit), thus minimizing the risk of contamination.

Kitchen Operations

• S t r e a m l i n e d F o o d P r e p a r a t i o n :

Checking temperatures regularly helps

tion solutions, enhancing CFS Brands’ ability to meet the diverse needs of its c u s t o m e r s T h e s e m o v

f l e c t t h e company’s commitment to providing a growing range of solutions under one roof.

In addition to growing via acquisitions, CFS Brands has continued to push the boundaries of product innovation The company unveiled a flurry of new entries toward the end of 2024, t h e T i m

e s s ™ l i n

n i v e r s a l d i spensers that are ideal for high-traffic e n v i r o n m e n t s , t h e 3 5 - Q u a r t Commercial Mop Bucket from Sparta engineered to maximize productivity and additions to the San Jamar ecologic™ Classic line of dispensers that make it easier – and cost effective – to operate in a planet-friendly manner

Other key product 2024 product

kitchen staff manage cooking times and ensure consistency This reduces the chances of overcooking or underc o o k i n g d i s h e s a n d h e l p s m i n i m

waste

• Managing Buffets or Large Events: I

s o r c a

e d events, where large quantities of food are served at once, temperature checks are essential They ensure that food remains safe to eat throughout service, preventing health hazards and ensuring that food stays at the right temperature for guests

Training and Staff Awareness

• Ensuring Best Practices: Consistent temperature checks also reinforce food safety practices among staff. Regular monitoring helps educate employees on the importance of temperature control and encourages them to follow p r o p e r f o o d h a n d l i n g p r o c e d u r e s , which improves overall hygiene and safety in the restaurant

launches include upgraded versions of t h e S m a r t - T h e r m ® a n d D u r a T h e r m ® induction units from Dinex, offering superior performance and reliability for demanding healthcare environments w h e r e p a t i e n t s a t i s f a c t i o n i s p a r amount; San Jamar EZ-KLEEN® bottles, d e s i g n e d f o r e a s y p o r t i o n i n g a n d c l e a n i n g ; a n d A l i b i ™ S t e m l e s s drinkware, which combines durability and style

This growth brings significant bene f i t s t o t h e f o o d s e r v i c e e q u i p m e n t industry. A larger, more diverse CFS B r a n d s s t r e a m l i n e s p u r c h a s i n g processes by enabling distributors and operators to source a wide array of p r o d u c t s f r o m a s i n g l e s u p p l i e r Consolidation also reduces operational c o m p l e x i t i e s , s i m p l i f i e s v e n d o r r e l ationships and lowers overall costs by

Taking food temperatures is vital for e n s u r i n g f o o d

high-quality standards, reducing waste a n d d e l

experience By adhering to temperature guidelines, restaurants can operate efficiently, comply with health regulations, and protect both their customers and their reputation

DayMark Safety Systems is here to help. The new MenuChex software – paired w i t h y o u r t a b l e t a n d a R E V 7 1 6 Thermocouple – can be a powerful tool in your kitchen Expand the suite to DayMark’s other back-of-house software solutions – MenuCommand® and MenuPilot® – and pair with a MATT85™ or MATT77™ printer to automate and print custom rotation labels.

F o r m o r e i n f o r m a t i o n , g o t o w w w daymarksafety com, call 800 847 0101, email info@daymarksafety com or stop by booth #2235

creating efficiencies at every level With its focus on strategic growth and groundbreaking product development, CFS Brands is setting a new standard in the foodservice supply industry. Its ability to deliver innovation, reliability and convenience positions the company as a trusted partner to help o p e r a t o r s t h r i v e i n a n i n c r e a s i n g l y competitive marketplace while keeping their operations efficient and effective

E x p e r i e n c e t h e w o r l d o f C F S Brands at this year’s show. For the first time, the company’s entire suite of solutions can be found in one place: booth #6412 located on Level 1 of Hall C4 F

w cfsbrands com or stop by booth #6412

Hatco (Cont’d from p 1) f o r g e d s t r a t e g i c p a r t n e r s h i p s , a r e a t e s t a m e n t t o h i s c a p a b i l i t i e s D u s s e r t ’ s c o m p r e h e n s i v e e x p e r t i s e i n m a r k e t a n a l y s i s , t e a m l e a d e r s h i p a n d c l i e n t r e l a t i o n s h i p m a n a g e m e n t w i l l b e i n v a l u a b l e i n h i s n e w p o s it i o n F o r m o r e i n f o r m a t i o n , g o t o w w w .hatcocorp.com.

i v e s a n d p r e s e n c e a c r o s s t h e r e g i o n H i s s u cc e s s f u l t e n u r e s a t P a r t s T o w n – R E P A , F i l t r o x , R e v o l a n d W e l b i l t , w h e r e h e c o n s i s t e n t l y d r o v e g r o w t h a n d

eight pounds of fresh, customizable plant-based proteins in 24 hours, has been the talk of the foodservice industry

Engineered with safety and reliability at its core, this turnkey technolog y f o r f l a v o r - p a c k e d f e r m e n t a t i o n empowers chefs to explore new horizons of culinary creativity and meet the e v e r - g r o w i n g d e m a n d f o r m e n u options that are nutritious, delicious and sustainable

“The PlanitPOD exists to empower chefs with new proteins, not as finished foods but as flexible, innovative ingredients that free them to bring their magic and create new food experiences,” said Chef Jeremy Umansky, one of the world's foremost experts on ferm e n t a t i o n a n d C o - A u t h o r o f “ K o j i Alchemy: Rediscovering the Magic of M o l d - B a s e d F e r m e n t a t i o n . ” “ I t ’ s t h e first machine of its kind that can safely handle the fermentation process on

h e l p i n g f o o d p r o d u c t i o n f a c i l i t i e s s t r

m

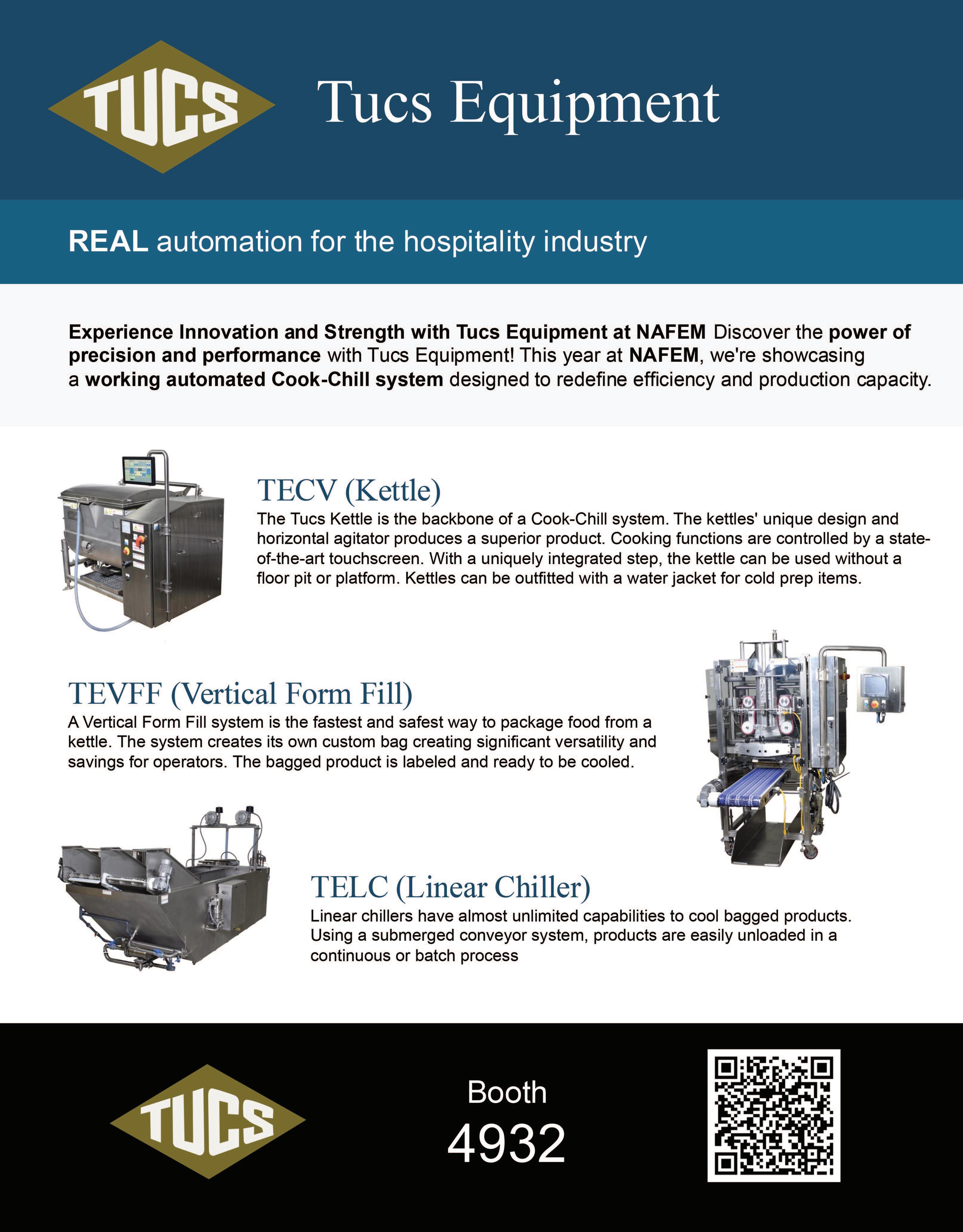

i n e o p e r a

, e n s u

o d safety and maximize efficiency. At this year’s trade show, attendees have the rare opportunity to witness automat i o n a t i t s p e a k b y v i s i t i n g T u c s Equipment at booth #4932

Automation: the Key to Efficiency

I n t o d a y ’ s f a s t - p a c e d f o o d i n d u s t r y , automation is no longer a luxury – it’s a necessity. Automated systems not only reduce labor costs but also increase consistency, improve food safety and o p t i m i z e p r o d u c t i o n t i m e l i n e s T u c s Equipment is at the forefront of this a u t o m a t i o n r e v o l u t i o n , o f f e r i n g turnkey solutions that empower food processors to meet growing demands without compromising quality.

waste, whether it is from preparation or leftovers Food waste has always been an issue, but with an increase in population, the volume of food waste has grown dramatically every year. When food waste goes to a landfill, it rots and releases methane, which is a climate super pollutant and 87 times worse than carbon dioxide for the environment

FEN: What is Power Knot and the LFC® biodigester?

IM: Power Knot developed the LFC biodigester in response to customer demand to reduce smells from outdoor compactor bins and to make a significant impact on the customer’s carbon f o o t p r i n t . P o w e r K n o t d e s i g n s a n d manufactures the LFC biodigester in Silicon Valley, California

location These security measures are key as the POD allows you to ferment extremely safely for your guests and for your health department If you want to grow tempeh or koji, follow a few easy steps to prepare your substrate, and press a button – simple as that!"

A New World of Flavor Awaits

m b e r ,

PlanitPOD features carefully curated software that comes preprogrammed to take the guesswork out of fermentat i o n a n d e n s u r e c o n s i s t e n t c o o k i n g every time No fermentation experience or training is required. The stepby-step preparation process makes it easy to create the canvas for new culinary masterpieces

n g

Developed in partnership with Planit Protein, PlanitPOD unleashes endless plant-protein possibilities with an innov a t i v e e c o - f r i e n d l y p l a

Planit Protein’s clean, shelf-stable, soyfree substrates like Roasted Chickpeas, I

n blend with its proprietary organic culture, PlanitPOD makes it easy to craft a diverse range of fresh fermented menu items

M e n u i n s p i r a t i o n i n c l u d e s P O D protein tikka masala, Middle Eastern P O D p r o t

based burgers, crispy “chicken” sandwiches and much more.

Designed to be the world’s most

At booth #4932, Tucs is showcasing a fully operational, automated Cook-Chill l i n e . T h i s s t a

includes:

• A P r e c i s i o n K e t t l e : D

t

ensure even cooking and precise temperature control for a wide variety of recipes

• An Automatic Bagger: Seamlessly packages finished products with minimal human intervention, maintaining hygiene and efficiency.

• A 14-Foot Linear Chiller: Rapidly cools cooked products to safe storage temperatures, preserving quality and extending shelf life A d d i t i o n a l l y , T u c s m a n u f a c t u r e s sous vide tanks capable of cooking between 500 and 3,000 pounds of protein in a fully automated process. These tanks ensure consistent results while

digester that disposes of most food waste within 24 hours It uses a natural

which microorganisms eat the food waste and turn it into water There are nine different sizes that digest from 10 kg (20 lb) per day to 6000 kg (13200 lb) per day of food waste

FEN: How does Power Knot envision the LFC biodigester changing the face of waste management?

IM: Traditional waste management is smelly, expensive and time consuming

charge waste hauling and transport costs based on weight of the waste and the distance to the waste facility

middleman and offers

Protecting the Planet, Nourishing the Bottom Line In keeping with planet-friendly consumer values, the PlanitPOD fermentation process eliminates the environmental toll the production of traditional sources of protein takes on the plane t , l i k e c o s t l y r e f r i g e r a t e d s u p p l y chains

“Giving commercial kitchens, and even home users, a way to create their own protein is absolutely essential,” said Tal Ronnen, Author of the New York Times bestseller “The Conscious Cook” and Founder and Chef at the C

based restaurants “We know that traditional animal protein is bad for the planet and our health, so giving this access to professional chefs and home cooks is going to be a game changer ”

Waring envisions PlanitPOD as the ultimate industry solution, with protein and fermentation reimagined for plantbased menu items made on-site with clean ingredients that are good for the people, the planet and your bottom line

A

will give chefs around the world a canvas to create a wide and ever-expanding variety of plant proteins right in their own kitchens

“Unlimited potential is what it has,” Chef Umansky summed up “The POD is a fantastic innovation, and I am proud to be a part of this groundbreaking release ” F

waring com or stop by booth #1300

asset for high-volume food production

Real Results: 20,000 Meals, Two Employees, Two Hours Imagine producing 20,000 ready-to-eat meals with just two employees in a mere two hours That’s the kind of efficiency that Tucs Equipment delivers with its advanced Cook-Chill systems

T h e d e m o n s t r a t e d s e t u p a t b o o t h #4932 is a close replica of this high-output, low-labor operation, showing how a u t o m a t i o n c a n r e v o l u t i o n i z e f o o d production

Why Choose Tucs Equipment?

T u c s E q u i p m e n t ’ s c o m m i t m e n t t o excellence goes beyond its high-quality machinery. As an American manufacturer, it takes pride in supporting d o m e s t i c i n d u s t r i e s ,

tion that is simple and effective The m a c h i n e s i m p r o v e o p e r a t i o n s b y removing smelly bins outside that can attract pests and the need for personnel to carry that waste from the kitchen or galley to that bin.

FEN: Why should we care about waste data analytics?

IM: You can’t control what you can’t measure All LFC biodigesters automatically connect to the LFC Cloud, Power Knot’s revolutionary continuous data a n a l y t i c s s y s t e m . T h r o u g h t h e L F C Cloud, customers can track how much waste is being digested and how much carbon dioxide equivalent is diverted from the landfill The LFC weighing mechanism is NTEP certified, meaning that an organization can rely on the d a t a a n d u s e i t i n i t s s u s t a i n a b i l i t y reports.

The machines can also account for

every piece of equipment is built with

craftsmanship. This dedication to superior materials and precision manufacturing ensures that Tucs’ equipment not only performs efficiently, but also stands the test of time

Don’t Miss the Action Visit Tucs Equipment at booth #4932 to see innovation in action. Watch the complete Cook-Chill line in operation a n

productivity Speak with Tucs’ knowledgeable team to learn more about its solutions and how it can tailor systems to meet your unique needs

For more information, go to www.tucs equipment.com or stop by booth #4932.

the type of waste or the source of the waste to fully categorize the waste With the LFC biodigester, any commercial kitchen or business is able to get a b e t t e r u n d e r s t a n d i n g o f w h e r e improvements can be made with a result of wasting less and improving profitability

FEN: Who is currently using the LFC biodigester?

IM: Power Knot helps any organization that has a commercial kitchen or generates large amounts of organic waste. We have machines installed on six continents and all of the world’s oceans C u s t o m

n c l u d e r e s t a u r a n t s , a l l major hotel lines, stadia, military bases, universities and cruise ships

For more information, go to www.power knot.com, email info@powerknot.com or stop by booth #2100

restaurants waste daily, I was determined to find a solution that could make a real impact That’s when the VITO oil filter system was born Designed with efficiency in mind, VITO allows restaurants to filter their frying oil directly in the fryer. In just 4.5 minutes, the VITO filter removes fine particles that degrade oil quality, ultimately helping it last longer and stay fresher This leads to cleaner oil, better-tasting food and significant savings on oil costs

FEN: What makes the VITO brand so successful, especially as sustainability gains traction?

to right, and a top riser for urns that makes pouring quick and easy Say goodbye to drips – the countertop and top riser are sealed and equipped with a drip tray in front of the top riser

With the Forbes Industries Coffee Station, you can:

• Serve freshly brewed coffee, thanks to the dedicated top riser specifically designed for displaying and accessing coffee urns No more reaching over or bending down – your brewing masterpieces are always within easy reach.

CFCM-240 simplifies monitoring to a quick glance or tap From new hires to seasoned chefs, anyone on your team can effortlessly check storage conditions or view temperature trends in r e a l - t i m e . T h e i n t u i t i v e i n t e r f a c e reduces training time, allowing staff to f o c u s o n d e l i v e r i n g q u a l i t y s e r v i c e while the monitor does the heavy lifting

3. Hassle-Free Data Logging & Reporting

When health inspectors come around, you’ll be ready. The CFCM-240 automatically logs temperature and humidity data, creating a seamless record t h a t ’ s a l w a y s i n s p e c t i o n - r e a d y N o

as possible Beyond equipment layout, the design of the equipment itself provides next-level advantages to the bartender and their efficiency.

In the underbar, Glastender’s catal o g o f e q u i p m e n t s o l u t i o n s i s unmatched in terms of features and flexibility For instance, the Cocktail Prep Cooler’s (CPC24) combination of refrigerated bottle well, garnish station and lower bottle storage, with cutting board work surface uses 27 inches less space than a comparable lineup without a CPC24 To make the most of this space, a 12-inch liquor step could be

AS: Sustainability is increasingly important, but VITO’s success goes further By extending oil life, VITO helps operators cut oil consumption and save money With fewer oil changes, kitchen staff can focus on other tasks, reducing fryer-related workload. Cleaner oil also means betterquality fried food, which customers notice. R e s t a u r a n t s c h o o s e V I

simple, safe design We considered the challenges faced by food service operators – cost savings, operational efficiency, safety and environmental impact VITO was engineered to address all of these, offering a highly efficient, costsaving and user-friendly solution.

FEN: VITO filters are used in over 150

• Keep everything organized with the spacious enclosed bottom cabinet that features three doors Sugar, creamers, mugs and other essentials find their perfect home, hidden yet readily accessible

• Minimize spills and maintain cleanliness with drip trays under the urns on t h e m a i n s h e l f . M e s s y m o r n i n g s become a thing of the past, keeping your countertop pristine

• Add a touch of sophistication to your space with the station’s appealing aesthetic, sleek painted metal handles and subtle one-inch-high solid surface risers found in each drip tray.

paper logs or manual entries – just complete, reliable data that’s easy to access and review Need insights on long-term trends? The CFCM-240 provides a goldmine of information that helps reveal equipment performance a n d g u i d e s m a i n t e n a n c e , s o y o u ’ r e always on top of potential issues.

4. Built to Last in High-Demand Kitchens

The CFCM-240 isn’t just advanced; it’s tough Built to withstand extreme cold, moisture and the everyday demands of commercial foodservice environments, this monitor is a long-lasting addition to your kitchen. It minimizes downtime and replacement costs, giving you peace of mind in knowing your inventory and investments are well protected!

added doubling the available liquor s t o

enclosed dry waste cabinet

The patented Fusion Sink (FS12) is a n o t h e r i n g e n i o u s s p a c e - o

model. Combining a hand sink and dump sink into one compact unit, the FS12 saves a full 12 inches of space sufficient for housing a dry waste container Arguably the simplest manner to maximize space in any bar is with addon cabinet bases, as they make use of

below bar equipment.

countries How does VITO make this happen?

AS: In addition to our headquarters and production facilities in Germany, we have four subsidiaries in key global locations, supporting our dealer and distributor network. This ensures efficient service across regions With distributors in 46 countries and local dealers, VITO products are accessible worldwide Many distributors have partnered with us for nearly 20 years, receiving regular training, marketing support and competitive terms to bring VITO to market successfully. This long-term collaboration has built a steady customer base and thriving after-sales business, crucial to our success

5575 Coffee Station is more than just furniture: it’s an opportunity to elevate your coffee experience

Now that you’ve got your coffee, it’s time to explore the rest of Forbes’ offerings Forbes Industries prides itself on being a mobile innovator, manufacturing furniture and equipment in the United States For over 100 years, it has provided customers with the quality mobile products they need to keep their businesses moving forward From b

and bellman carts to mobile service carts, action stations, bars and back

5. IoT-Enabled for Next-Level Control

Want to keep tabs on multiple locations? The CFCM-240 is ready With o p t i o n a l I o T c o n n e c t i v i t y , y o u c a n remotely monitor and manage condit i o n s a c r o s s s e v e r a l s i t e s t h r o u g h Renau’s cloud services. Real-time data, c e n t r a l i z e d d a s h b o a r d s a n d m o b i l e alerts let you take control wherever you are, empowering you with insights and notifications to respond instantly to changes Whether you’re managing a single kitchen or a multi-location o p e r a t i o n , t h e C F C M - 2 4 0 s c a l e s t o meet your needs.

6. Retrofittable

W h e t h e r i n s t a l l e d a t t h e f a c t o r y o r retrofitting an existing installation, the

s i m i l a r e q u i p m e n t i n a t r a d i t i o n a l u n d e r b a r l i n e u p F o r e x a m p l e , a 4 2i n c h a s s e m b l y s t a t i o n w i t h d o u b l e o v e r s h e l v e s h a s t h e f u n c t i o n a l i t y o f a

n i n e - f o o t s e c t i o n o f e q u i p m e n t i n a

n o n - p a s s - t h r u d e s i g n . P a s s - t h r u s t a -

t i o n l i n e u p s f u r t h e r o p t i m i z e s p a c e b y

p r o m o t i n g t e a m w o r k e f f e c t i v e l y d o u -

b l i n g t h e b a r t e n d e r ’ s p o t e n t i a l o u t -

p u t

VITO Fryfilter is proud to serve the United States from our Orlando headquarters We’re here to help kitchens save on oil costs, simplify fryer upkeep and serve up the best fried foods From small cafés to bustling chains, our Orlando team is ready to make a difference.

FEN: Where can readers find you at the show?

AS: Catch us at our black and yellow booth #200 to see a demo and learn more

, email info@vitofryfilter.com or stop by booth #200

bars, it is known for innovations that m

experiences effortless

See all of Forbes’ innovative products at the show Forbes is showcasing water bubblers/stations, its award-winning mixology carts designed in collaboration with Master Mixologist Chris Adams, linen-less nesting and catering tables, live-action and buffet stations, amazing mobile bars and back bars, and much more

booth #3018.

CFCM-240 unlocks the full potential of your equipment

h e C F C

- 2

C

o l e r / F r e

T o u c h s c r e e n W a l k - I n M o n i t o r i s m o r e t h a n a m o n i t o r i n

i t ’

c h a n g e r i n f o o d s a f e t y a n d k i t c h e n e f f i c i e n c y . B y c

While modular bar die may not optimize space by definition, it is the accuracy of the die wall in which space is optimized. Round and curved bars benefit most as site-built walls lack the necessary technology to produce complex geometry to the precision of die walls

designers to completely fill an underbar so no inch of space goes underutilized. Whether a drainboard needs to shrink or stretch a few inches, or custom degree corners are required to fulfill the exact curve desired, processes f

standard equipment – no additional lead time necessary When it is time to optimize your bar design, contact the Glastender team to help create your ideal solution.