MEGA TRENDS

EDITORIAL NOTE WELCOME FROM THE CEO INSIGHTS FROM NEXUS COMMUNITY ABOUT NEXUS

INSIDE EDITION 31 • MARCH 2023

SIDE 31

FREEK BLEKXTOON (ALLPARTS) JOINS

NEXUS AUTOMOTIVE INTERNATIONAL AS NEXUS WORKSHOPS NETWORK DEVELOPMENT EXPERT.

Freek Blekxtoon, NEXUS Workshops Network Development Expert

NEXUS AUTOMOTIVE INTERNATIONAL WILL ACCELERATE ITS GROWTH IN AFRICA THROUGH A DEDICATED ENTITY, IAMAGA.

WHY THE AUTOMOBILE INDUSTRY SHOULD BE DIGITALIZED.

Qiu Liqiang, General Manager, G-Parts

BREMBO BEYOND EV KIT: RESISTANCE TO CORROSION, LESS NOISE AND DURABILITY DIFFERENTIATE THIS RANGE OF THE AFTERMARKET PRODUCTS DEDICATED TO ELECTRIC CARS Matteo Busnelli, Head of Aftermarket Marketing, Global Business Unit Aftermarket Brembo S.p.A.

22 26

32

38

SIDE 2 INSIDE EDITION 31

NTN INNOVATION ADDRESSES YOUR CHALLENGES.

Christophe Idelon, Vice President Automotive

Aftermarket,

NTN Europe

THE NEW GENERATION FORCES US TO QUESTION OURSELVES.

Claudie Cahart, CEO, ID Rechange

Claudie Cahart, CEO, ID Rechange

VALEO SERVICE – A SUSTAINABLE APPROACH FOR A MORE SUSTAINABLE AFTERMARKET.

INSIDE 31 | MARCH 2023

NEXUS IN ! SIDE MAGAZINE is published by NEXUS Automotive International, Geneva, Switzerland.

NEXUS Automotive International SA

Chemin du Château-Bloch 11

1219 Le Lignon | Geneva | Switzerland

T +41 22 306 49 50

www.nexusautomotiveinternational.eu

FINDING THE RIGHT KIT FOR DIGITALIZATION IN THE AUTOMOTIVE AFTERMARKET.

Jens Schüler, CEO Schaeffler

Automotive Aftermarket

72

44 92 80

ON-SITE ENGINEERING

STATE-OF-THE-ART PRODUCTION TECHNOLOGY

QUALITY COMPONENTS

APPLICATION-SPECIFIC DESIGN

EXTENSIVELY TESTED

AIRSPRINGS | STRUTS | SHOCKS | COMPRESSORS | COILCONVERSIONKITS

SUMMARY

WELCOME FROM THE CEO

Gaël Escribe, CEO

NEXUS Automotive International

NEWS FROM N!

• NEXUS Automotive International creates an Ecommerce business unit & appoints Robbie Stevens as Head of Ecommerce Business Unit

• A first for the US: NEXUS Automotive International launches its N! Academy training session during the AVI Annual Technician Conference

• NEXUS Automotive International will accelerate its growth in Africa through a dedicated entity, IAMAGA

• Freek Blekxtoon (AllParts) joins NEXUS Automotive International as NEXUS Workshops Network Development Expert

INSIGHTS FROM THE AFTERMARKET WORLD AND BEYOND

09 14 14

• New from BorgWarner: DualTronicTM Dual Clutch Modules now available for the Aftermarket, BorgWarner • Brembo beyond EV kit - Resistance to corrosion, less noise and durability differentiate this range of the Aftermarket products dedicated to electric cars, Matteo Busnelli, Head of Aftermarket Marketing Global Business Unit Aftermarket Brembo S.p.A. • Why the automobile industry should be digitalized, Qiu Liqiang, General Manager G Parts • The new generation forces us to question ourselves, Claudie Cahart, CEO ID Rechange

• Sustainable Mobility, Idan Katz & Danielle Walsh Partner & CTO Mobilion, CEO of Clearly • How to keep our Customers mobile in the coming years? N! Service Team, NEXUS Automotive International • Digitalization, Electrification, Sustainability, Consolidation, in Africa, Martin Hendriksen, Strategic Planning & Customer Experience Director NEXUS Automotive International • Digitalization, Technology, Brand Value & pricing: 4 major factors are becoming significant, Robbie Stevens, Head of Ecommerce Business Unit NEXUS Automotive International • NTN innovation addresses your challenges, Christophe Idelon, Vice-President Aftermarket

NTN Europe • The North American mega trends, Robert Roos, President of The ProntoNetworkAPSG and President of NEXUS North America • The premature death knell of the internal combustion engine, Barry Neal, Senior Partner & Neury Freitas, Partner Roland Berger • Finding the right kit for digitalization in the automotive aftermarket, Jens Schüler, CEO Schaeffler Automotive Aftermarket • Sparker & Novazure: accelerating the green revolution in mobility, Marco Bevilacqua, Co-Founder & Executive Officer of Reefilla, Alex Kosyakov, CEO of Natrion • Valeo Service - A sustainable approach for a more sustainable aftermarket • The race to the end customer has begun! Jean-Marc Pierret, Journalist ZePros • How digitalization influences the future service experience, Philippe Colpron, Head of ZF Aftermarket and Executive Vice President

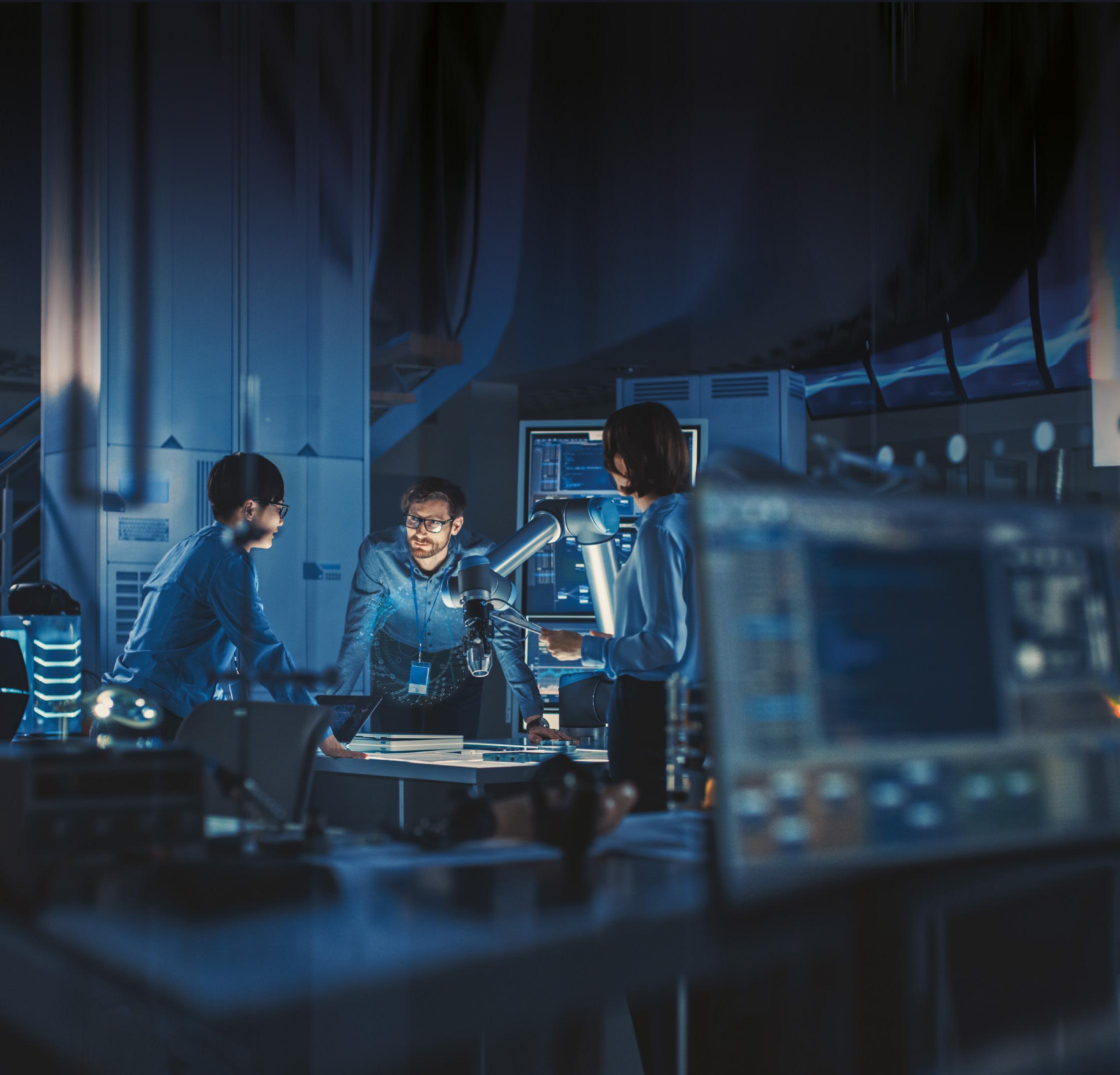

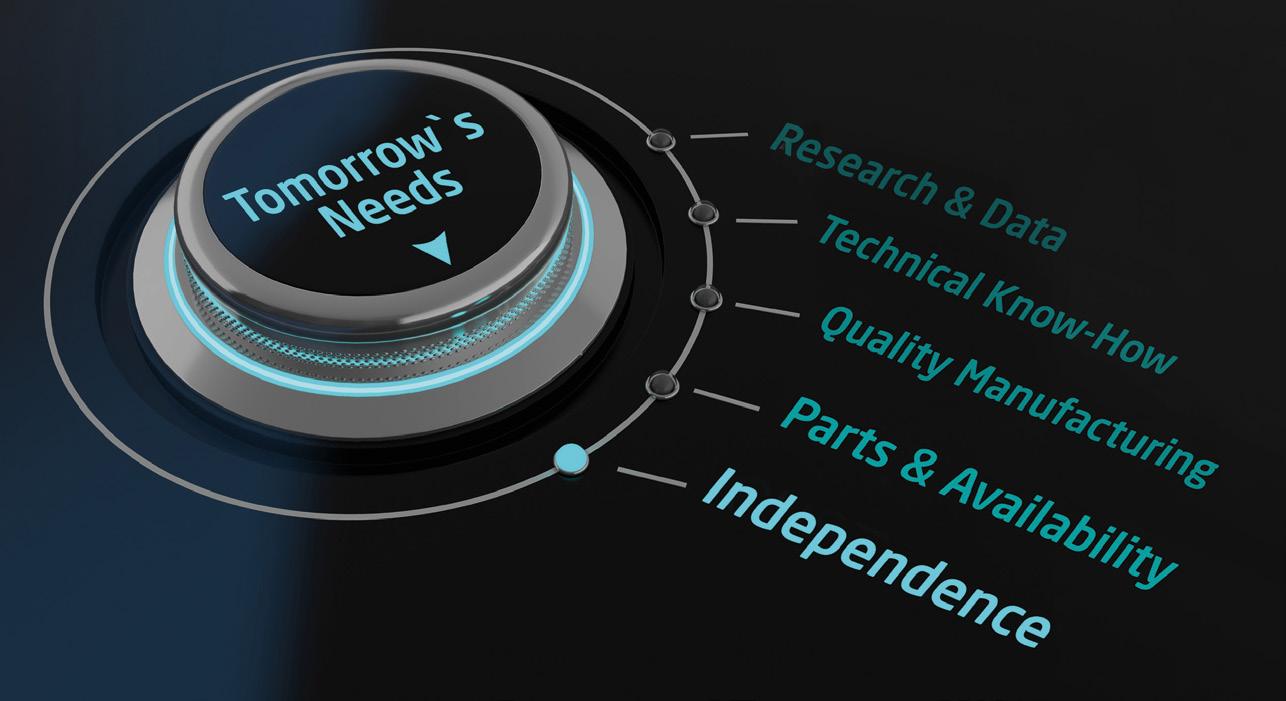

Tackling Future Challenges Today

How the bilstein group Creates Digital Solutions

The automotive aftermarket is becoming more and more digital, and so is the bilstein group. An internal department is focusing solely on digital commerce to support our customers in the online world - online retailers and the stationary trade alike. We support these customers with targeted content and solutions, such as 360-degree product images and videos, or with direct system connections to help them experience our products digitally.

In the long run the bilstein group has the same ambitious thinking online as it does offline, meaning we want to be just as customer-oriented. We want to offer our customers more than just automotive parts. To do this, it is important to listen to every customer and recognise their needs.

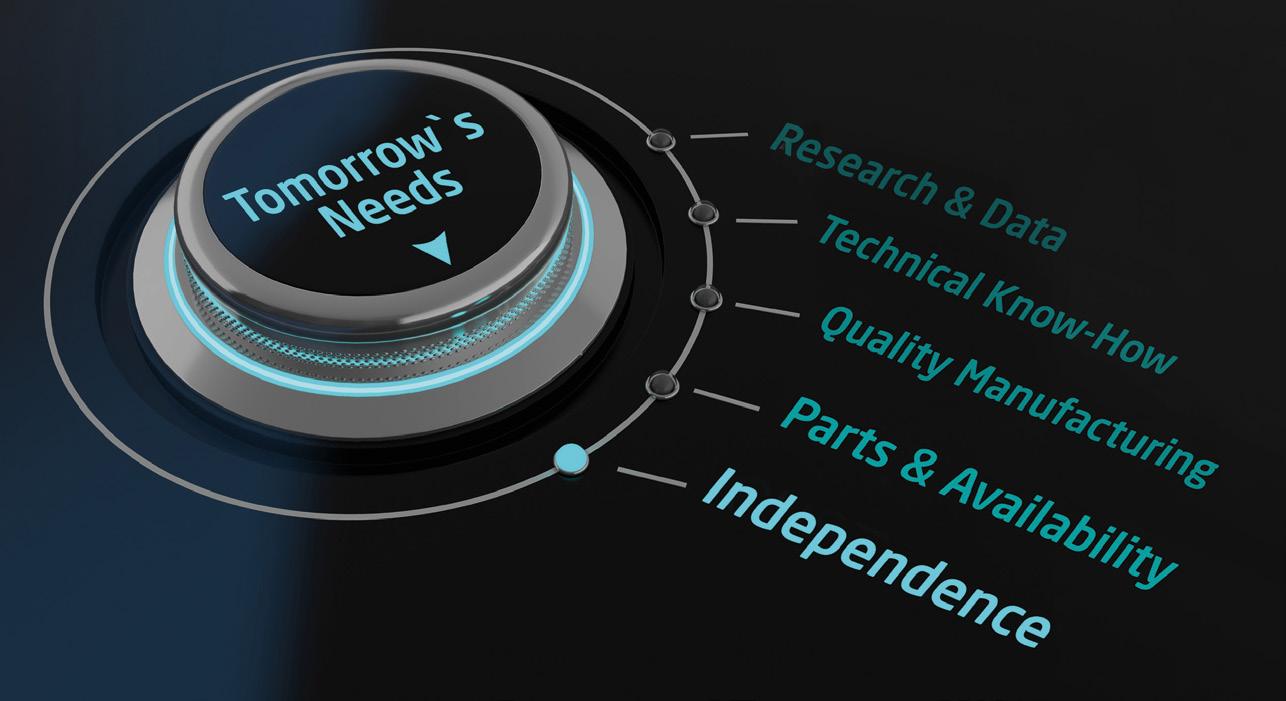

Research & Data

Data helps us to deliver predictable business. However, we do not rely on third parties for vehicle data; instead, the bilstein group employs an in-house team of specialists dedicated to vehicle research and data accuracy. They are constantly collecting data to verify that we have the correct parts in range. We are also creating our own solutions - developing new software to fulfil our customers’ future needs and anticipating upcoming trends at an early stage.

The data we collect is more than just vehicle data. Having the correct data plays a crucial role in every aspect of business - from competitive intelligence and sourcing, to pricing and sales. For us, data analytics is one path to success: by collecting, analyzing and utilizing data, we establish controlling processes and stimulate business development.

Sharing is Caring

Our goal is to show you unlocked market potential. Please feel free to contact us and start a conversation - this way, we can support you as best as possible:

+49 2333 911-0

info@bilsteingroup.com

bilsteingroup.com

The bilstein group has the same ambitious thinking online as it does offline, meaning we want to be just as customer-oriented.

Tomorrow`s Needs are Our Drive

With our three strong brands febi, SWAG and Blue Print, we are consistently oriented to the current and future needs of our customers.

As a result, we maintain an ongoing focus and commitment throughout our organisation to…

• Create solutions which support sustainable progress and future opportunities for each level of the supply chain

• Remain agile and know today what our customers need for their business development tomorrow

• Produce what is needed without the range restrictions of first or second tier mono-suppliers: we are Independent

• Provide The Right Product in The Right Place at The Right Time

Individually

www.bilsteingroup.com

Strong, Unbeatable as a Team

WELCOME FROM THE CEO

SIDE INSIDE EDITION 31 • MARCH 2023 8

Dear Reader,

NEXUS, as a leading player, is connecting the leaders of the AA and investing in innovative and sustainable models to lead the revolution of the industry including digitalization, transformation and sustainable mobility. Since 2014, our purpose has been to move the sector forward, to innovate, invest, to be able to support these major priorities as well as accelerate the growth of our community. Our aim is to offer you the big picture and identify the challenges of tomorrow.

So, in this new edition of INSIDE, we share some thoughts, inputs and solutions deployed by our community - prior to the NEXUS Business Forum, which will take place 21 - 23 March, in Montreal.

For the very first time, we are organizing the NEXUS Climate Day with the key players of sustainability in order to draw together the concrete actions that the community could deploy to be more sustainable.

Addressing the evolution of the market will give us the opportunity to reach new heights together. We hope you will find it inspiring! Now enjoy reading IN!SIDE magazine.

For this, the first 2023 edition of INSIDE magazine, we would like to focus on the mega trends that our industry is facing.

Gaël Escribe CEO of NEXUS Automotive International

Driving your business Now and in the future

Our value propositions, reliable, sustainable, ready for tomorrow

from BorgWarner.

up a gear in sales!

Shift

Front Pipes & Flexibles

The absolute number 1 in sustainability

Contributing to a cleaner world by consistently innovating in mobility & energy.

I reduce exhaust fumes and noise.

What’s your superpower?

Catalytic Converters & Diesel Particulate Filters

Intermediate Silencers

Rear Silencers

Mounting and Repair Parts

Towbars

Bicycle Carriers

DPF Additive

Be ready 4 ... the next generation

• based on organometallic components (liquid cerium and/or iron)

• 4 generations with own specific concentration

• NOT an universal solution

• Full kit package, including all needed accessories to empty and refill

Did you know that BOSAL is also determined to take a leading position in the emerging renewable energy markets and is expanding fast into advanced sustainable products. We are already a key player in heat exchanger solutions for all emerging technologies. It is our ambition in achieving a leading market offering and high market success in this sector.

: aftermarket

ENERGY

www.bosal.com

BOSAL GEN

NEW

Take part in more sustainability

Conserving resources through reuse: With its exchange program, Bosch is focusing on the circular economy. By effectively reusing the returned parts, raw materials are used sustainably. Join in and make your contribution to sustainability by value-based vehicle repairs with a Bosch eXchange part.

boschaftermarket.com

It’stimetogo

beyond

theordinary

work harmoniously together, to prevent corrosion and reduce noise.

Assembled to Brembo’s unparalleled OE quality specifications, you have peace of mind knowing your brakes are performing, and protected, from rust in every condition, and every drive, up to and beyond 100,000km.

Specially designed for leading global car manufacturers, and drivers, who always go beyond the ordinary.

BREMBO OE QUALITY

LESS NOISE

ANTI-CORROSION

EV SPECIFIC

bremboparts.com

N! NEWS SIDE INSIDE EDITION 31 • MARCH 2023 14

NEXUS AUTOMOTIVE INTERNATIONAL CREATES AN ECOMMERCE BUSINESS UNIT & APPOINTS ROBBIE STEVENS AS HEAD OF ECOMMERCE BUSINESS UNIT

NEXUS Automotive International, the Automotive Aftermarket Company, is delighted to announce the launch of a new business unit dedicated to Ecommerce. Robbie Stevens is appointed Head of Ecommerce Business Unit starting in January. His appointment will allow NEXUS to answer to the needs and priorities of its community and in fine, support growth and the upcoming transformation.

A new business to better fit the priorities of the N! community

The launch of the Ecommerce Business Unit - such as the launch of the Heavy Duty one - is the perfect illustration of how N! supports its community to accelerate and generate growth and move from “Parts” to “Parts and Services” through the diversification of its activities.

On one hand, the creation of this dedicated Ecommerce Business Unit is answering the needs of the Ecommerce players – which are part of N! community since its creation in 2014 – to create value. This department will, on the other hand, create tools and services for the traditional players to support the upcoming transformation. Ultimately, this new Business Unit could generate new entrepreneurial initiatives that could become future start-ups incubated by NEXUS. For 20 years, Robbie Stevens career path has developed within the automotive aftermarket.

First, he founded his own successful automotive online company before joining Mister-Auto, as Head of Marketplace Business Development to expand their global marketplace footprint. Then, Robbie was promoted to Country Manager (UK & Ireland) in 2017, before becoming ‘sales-focused’ as a freelance. Robbie then launched Ford Motor Company’s first ever B2C ecommerce Strategy with webshops and marketplaces in the big 5 EU markets along with North America as Head of Global Sales Growth & Marketing for Autonative. “We are very happy to welcome Robbie, who perfectly knows the industry - and start the new year with such a major project for N!. Indeed, innovation is part of N! DNA since its creation, our motto is to focus on keep supporting our community and provide some tools to lead the transformation; as we did the previous years and we will for the coming ones!” said Gael Escribe, CEO of NEXUS Automotive International.

clas.com BODY REPAIR HYBRID & ELECTRIC MECHANICS

TOOLS

TOOLS

HAND

GENERAL

WORKSHOP EQUIPMENT

Support for the stressful tire change season

New Continental tire service tools for fast TPMS service and simple tire management – with smartphone feeling thanks to touchscreen and intuitive operation. Top model Autodiagnos Tire 300 with integrated RFID module and camera.

For many workshops, tire business means one thing above all: rush. To make this stressful seasonal business work easier and faster, Continental presents three new tire service devices: Autodiagnos Tire 100, Autodiagnos Tire 200 and Autodiagnos Tire 300. The Autodiagnos Tire range stands out with its intuitive operation and a high degree of user-friendliness. Almost all European vehicles are covered.

As intuitive as a smartphone

The new tire service tools grant quick access to key system data, and thanks to their touchscreens with a very simple manual navigation, they are as easy to use as smartphones. The new Autodiagnos Tire devices support workshops not only in activation, programming and relearning of sensors, but also in downstream processes such as documentation, storage and ordering of new tires. The integrated OBD II relearning routines simplify relearning of new TPMS sensors to the ECUs in the vehicle as much as activation of sensors in seasonal tire changes.

Autodiagnos Tire 300 – flagship with a RFID module

The flagship Autodiagnos Tire 300 has everything that workshops and fleets need for efficient tire service: The large 8-inch display shows all relevant TPMS and tire data at a glance. In addition, the new tools are already fit for future applications, such as direct communication with the RFID tags in the tires via the integrated RFID module. These tags contain all of the important data from the tire manufacturer. After the assignment to a vehicle, Autodiagnos 300 transfers the TPMS sensor’s entire data package to the on-board electronics.

Autodiagnos Tire 200 –smart communication between tire and workshop

Autodiagnos Tire 200 comes with a 5-inch touchscreen, synchronizes jobs wirelessly with the workshop’s order system via Wi-Fi and has them printed out. It can acquire TPMS sensor data via an integrated OBD II module and initiate relearning. An especially attractive feature is the “ID Match” function, allowing workshops to identify individual sensors via the OBD II interface and fix the issue afterwards.

Autodiagnos Tire 100 – TPMS service with OBD II module

The low-cost entry-level model of the range is based on the proven system used in all of the tire service tools for sensor activation, programming and relearning at Continental. In addition, it includes a number of user-friendly applications. It is connected to the vehicle’s OBD II interface via a network cable on an external OBD II module. The 3.5-inch touchscreen shows all TPMS data on one screen for easy control of the functions.

Everything inside: OBD II module, RJ45 interface, RFID chip and WLAN connection. Thanks to the integrated camera, the Autodiagnos Tire 300 can also take pictures of the tyres or the vehicle and assign them directly to a job. It is equipped with an 8-inch display and the flagship of the new TPMS service tool family.

Touchscreen and super-fast activation, relearning included –the three new TPMS service tools from Continental (from left): Autodiagnos Tire 100, 300 and 200.

N! NEWS SIDE INSIDE EDITION 31 • MARCH 2023 18

A FIRST FOR THE US: NEXUS AUTOMOTIVE INTERNATIONAL LAUNCHES ITS N! ACADEMY TRAINING SESSION DURING THE AVI ANNUAL TECHNICIAN CONFERENCE

NEXUS Automotive International, the Automotive Aftermarket Company, launched its first N! Academy for North America January 12-15, 2023 during the AVI Annual Technician in-person Training Conference sponsored by NEXUS North America shareholders (APA, APSG and VIPAR Heavy Duty).

More than 250 technicians attended classes on Friday 13th and Saturday 14th January - along with local vocational school students - eager to learn and sharpen their automotive technical knowledge. The courses on offer were dedicated to passenger cars and heavy duty; and covered a broad range of subjects including: hybrid electric, EV technology, Heavy Duty air brake boosters, air conditioning and HD emissions systems. These were taught by high level professional trainers. This event also enabled a dozen suppliers to introduce their product experts & branded product solutions and educate the technicians about the materials. This session was in addition to the training itself and designed to create links between the NEXUS North America community.

“APSG and our NEXUS North America Shareholder partners – APA and VIPAR - are thrilled to be a primary sponsor of the AVI training confe-

rence,” said Robert Roos – President of NEXUS North America. “Technologies in our industry are evolving at a faster and faster pace and the need for training these automotive repair experts on advanced technologies is critical to providing car and fleet truck owners with independent repair options for their vehicle.”

“NEXUS Academy is proud to expand its automotive training program for automotive professionals into North America and enhance the ways that Technicians and other automotive personnel can learn”, said Florian Precigout – Garage Concepts and Service Director for NEXUS Automotive.

“As we move forward, we are excited to provide access to our N! Academy website – offering highly technical training to the basics of automotive light vehicle and heavy- duty repair – for automotive professionals of the NEXUS North America community.”

FULL MECHATRONIC RANGE

Your One-Stop-Shop of ALL spare parts from turbo to tailpipe – meaning that we also cover the most popular mechatronic spare parts for exhaust systems placed on your Euro 4-6 and EPA10-17 buses and trucks.

Our Mechatronic parts are:

• Directly replaceable with OE

• Tested at Dinex Test Center

• Wide product range

• High quality part with warranty

• Stock item for fast delivery

• Easy to install

going the extra mile

On Stock Coming Soon

Dinex is ready to support you before, during and after the purchase. Get more technical knowledge about our full mechatronic program here.

Dinex.net

NOX Sensors Temperature Sensors Pressure Sensors AdBlue / DEF Dosers AdBlue / DEF Injectors Fuel Injectors

N! NEWS SIDE INSIDE EDITION 31 • MARCH 2023 22

FREEK BLEKXTOON (ALLPARTS) JOINS

NEXUS AUTOMOTIVE INTERNATIONAL AS NEXUS WORKSHOPS NETWORK DEVELOPMENT EXPERT

Freek Blekxtoon, CEO of NEXUS Automotive Netherlands, (AllParts wholesale network for twenty years), is joining NEXUS Automotive International as NEXUS Workshops Network Development Expert in the Garage Service & Concept department. He takes up his appointment from April 1st 2023.

In this role he will further develop the NEXUS networks of garages (N!Auto and N!Truck), which are already active in more than 20 countries. Freek Blekxtoon’s ambition is to support and enhance the development of the networks to reach a target of 25,000 in 2025.

Gael Escribe, CEO of Nexus Automotive International, adds: “We are very pleased that Freek will be committed to our international group for the very first time. His knowledge and experience, and his network in both the car and truck markets, will be very valuable in supporting our team. We are ambitious and definitely need his

expertise to enhance the professionalism of our networks if we are to hit that target of 25,000 garages!”

Freek Blekxtoon said: “I am full of energy and happy to take on the international challenges within NEXUS Automotive International!”

NEXUS Automotive Netherlands (Eemnes) - previously GroupAuto Nederland - now has 32 AllParts wholesaler members and recently became a shareholder of NEXUS International for the automotive segment. Wijlhuizen (with Beneparts) is the truck and trailer partner for NEXUS in the Benelux.

ContiTech Air Spring Systems. Technology On Your Side. ContiTech Luftfedersysteme GmbH airsprings_replacement@as.contitech.de www.airspringreplacement.com The Original! Made by ContiTech.

DENSO brings its remanufacturing programme into the limelight

Emphasising its credentials as an environmentally conscious manufacturer with sustainability at its core, DENSO’s comprehensive programme includes diesel injectors and pumps, starters and alternators and nickel hybrid vehicle batteries

DENSO is widely recognised as one of the world’s largest original equipment (OE) component manufacturers and system suppliers, with an extensive aftermarket portfolio. Its remanufacturing programme however, is less well known, despite being active in the European market for more than 10 years.

To raise aftermarket awareness of the environmentally sustainable components, DENSO Europe, Pan European Strategic Marketing Manager, Fatiha Laauich spoke with Andre Koppenol, manager of the remanufacturing team and his colleagues, who are collectively responsible for the OE quality range.

Fatiha Laauich (FL): “So, what is the main reason that DENSO has a remanufacturing programme?”

Remanufacturing Team (RT) “It’s actually threefold, to deliver high quality products of the same standards as the original component on the vehicle, but manufactured in an environmentally friendly and sustainable way

FL: “So, where do DENSO remanufactured components fit in the aftermarket?

RT: “Today, if a product like a starter or alternator fails, or the battery in their hybrid vehicle breaks down, European motorists have a choice as to whether they replace it with a brand-new unit or a remanufactured one.

“Each of these components is the same in terms of its quality, in fact in some circumstances, such as when it’s rebuilt according to the latest OE standards compared to a new unit of a four year old design, you could even say it’s better. So, the choice for the consumer is whether they prefer a remanufactured unit that is more environmentally friendly and cheaper to purchase, or a completely new one

“However, we’d obviously encourage our customers to highlight the environmental and potential newer technology benefits of the remanufactured unit ”

FL: “A question that often arises is the difference between remanufacture and repair? ”

Feature

N! NEWS SIDE INSIDE EDITION 31 • MARCH 2023 26

NEXUS AUTOMOTIVE INTERNATIONAL WILL ACCELERATE ITS GROWTH IN AFRICA THROUGH A DEDICATED ENTITY, IAMAGA

Nine years after the creation of the automotive aftermarket company, NEXUS Automotive International will further focus on Africa through IAMAGA, a dedicated entity. The aim is to accelerate growth on the continent and continue deploying N! innovative and sustainable initiatives.

• N! Academy Training deployment (garages/ distributors).

• Garages network services structuration.

• Mobility in Africa through innovation screening.

N! will further develop the activities of IAMAGA, a regional entity dedicated to the African Automotive Aftermarket, which includes 34 Africa based members and their affiliates.

IAMAGA will be providing specific services to its community such as:

• Transactional activities, for optimized access and pricing.

• Strategic Partnerships with OEMS, with specific commercial collaborations.

• Financing and coordination of innovative projects.

• Assistance with sustainability related initiatives.

• Data sharing.

• African members representativity (central service center, credit risk scoring, …)

• Sustainability: « Re-man / Re-use / Recycle » activities structuration.

• Replicate the newly created Algerian Academy in other markets.

IAMAGA will also reunite its community through the organization of a dedicated mid-year event, which will take place in Morocco.

“Africa has always been strategic since the launch of NEXUS - it’s part of the DNA. After 9 years, we have developed an impressive network that is looking forward to providing more quality parts, more services, innovation, and of course, a sustainable future!” said Gael Escribe, CEO of NEXUS Automotive International.

NEW FROM BORGWARNER: DUALTRONICTM DUAL CLUTCH MODULES NOW AVAILABLE FOR THE AFTERMARKET

Millions of cars on Europe’s roads are already equipped with pioneering clutch systems from innovation leader BorgWarner.

That is why the automotive supplier is now expanding its aftermarket portfolio with the introduction of dual clutch systems for passenger cars. To be specific: BorgWarner will offer six DualTronicTM Modules for some of the most common and widely used vehicle types. The original spare parts, identical to the pro-

SIDE INSIDE EDITION 31 • MARCH 2023 28

ducts provided for engine manufacturers worldwide, are produced according to the latest OEM requirements and quality standards and are guaranteed to fit accurately.

Advantages for the customer

Drivers benefit from improved fuel economy that rivals single clutch automated gearboxes, less torque interruption, and superior hill hold and creep performance. Shift quality equal to the best conventional automatic transmissions and adaptive performance contribute to overall enhanced comfort. In the long run, car owners profit from improved durability and reliability.

How it works

BorgWarner´s DualTronicTM wet-clutch technology features tunable launch characteristics and scalable torque capacity in a compact, modular design. The clutch module uses two wet clutches to engage the odd and even gears respectively, allowing shifts within fractions of a second with no perceived interruption of powerflow. The DualTronicTM control module employs low-leakage electro-hydraulic solenoids to precisely control the clutch and the transmission’s gearshift actuation system for responsive shifting and dynamic performance.

READY FOR ANYTHING: NEW TIMING BELTS

We are adding a large number of new models to our range of timing belts. This will ensure mechanics are perfectly equipped for carrying out repairs to around 1.5 million vehicles from Hyundai, Kia, Jaguar, Ford, Land Rover, Peugeot and Citroën.

Efficient, attractive and packed with extras: thanks to these qualities, and more besides, models from Hyundai and Kia continue to make inroads into the European market. To make sure mechanics are ideally prepared for all repair jobs on these vehicles too, we have expanded our product range accordingly: new additions include the CT1237 timing belt for the camshaft of new Hyundai Kauai, Kona, Tucson, i30 and i40 models, for example. This belt is also suitable for Kia models with a 1.6 l diesel engine, such as the Ceed, Optima, Proceed, Sportage, Stonic and Xceed, and can be fitted in mild hybrid applications too. The CT1238 belt for the oil pump (belt in oil) in the above models from Hyundai and Kia is likewise new.

–

The lineup of new products is completed by the CT1240 timing belt fitted in 2.0 EcoBlue engines from Ford. It has a slightly different tooth profile compared to the CT1233, making it suitable for the following vehicles from model year 2019 onwards. The engines affected are all 2.0 EcoBlue units including mild hybrid applications, such as in the Focus IV, Galaxy III, Kuga III, Mondeo V, Ranger, S-Max, Tourneo Custom V362 Bus and Transit Custom Bus models as well as the Kuga 2.0 EcoBlue mild hybrid.

As usual, all the key technical specifications can be found in the Product Information Center (PIC).

www.continental-engineparts.com

– Citroën C5 and C6

Peugeot 407 Coupe

ThenewtyregenerationfromContinental. Germanengineeredsafety. Didyouknowthatourtyreshavereceivedtopratingsinindependenttestsonaregularbasisfor morethantenyears?Andthiscontinuoussuccessisreallynotacoincidence,sincewealwaysput maximumeffortandpassionintoeverysingleproduct.Theseresultsmakeusproudandatthesame timemotivateustocontinueworkingsuccessfullyinthenameofdrivingsafety.Sothatyoucanrely onus,whenothersrelyonyou. Allyouneedfornextsummer. www.continental-tyres.com Sporty SportContact ™ 7 Durable UltraContact Comfy PremiumContact ™ 7

SHAPING THE FUTURE OF MOBILITY

SIDE INSIDE EDITION 31 • MARCH 2023 32

MATTEO BUSNELLI

Head of Aftermarket Marketing, Global Business Unit

Aftermarket Brembo S.p.A.

BREMBO BEYOND EV KIT: RESISTANCE TO

LESS NOISE AND DURABILITY DIFFERENTIATE THIS RANGE OF THE AFTERMARKET PRODUCTS DEDICATED TO ELECTRIC CARS

Today, electric and hybrid vehicles use regenerative braking in addition to traditional dissipative braking, resulting in less use of the friction brake than a car with a combustion engine.

However, regenerative braking has its own applicability, dependent on the total battery capacity and the battery capacity available at the time of use. In general, for Mild Hybrid and Full Hybrid cars, regenerative braking has very little influence on the use of conventional brakes due to the reduced battery capacity; whilst it has an important influence on electric cars.

In addition, cars with high regenerative braking, i.e. electric and plug-in cars, can make the most

of their characteristics in driving situations where acceleration and slowing down (city driving), or uphill and downhill (mountain driving), prevail. Moreover, regenerative braking cannot generate the same braking power as dissipative (frictional) braking. Therefore, in emergency braking, as well as in other modes of use, dissipative braking is always necessary for electric cars.

Today, most hybrid and electric cars use carry-over braking systems derived from conventional vehi-

CORROSION,

cle applications. This means that, particularly for electric cars, these braking systems are oversized for normal car use and, therefore, the actuation components will wear very little.

Manufacturers are reacting to this by trying to develop technological solutions suitable for this type of vehicle. In particular, the most important solutions concern: lightness, reduction of noise and residual torque, protection against corrosion and silent friction material.

As far as maintenance is concerned, it is very important in the new generation of electric cars to check for corrosion and possible deterioration of the components. The proper functioning of the brake caliper, and the possible replacement of deteriorated components, must be carried out promptly so as not to compromise the operation and safety of the system.

The Brembo Beyond EV kit is the right answer and consists of a special combination of coated brake discs and pads, enhancing Brembo’s Aftermarket offer for electric cars. This solution, derived directly from OE expertise, has been specifically designed to combine low environmental impact with the best possible performance and safety.

Safety and durability were central to the design of this solution. Electric cars use regenerative braking in addition to traditional dissipative braking, resulting in reduced use of friction brakes. Over time, this can result in the formation of rust on brake system components that are not used, ero-

ding the safety of the brake system, and increasing maintenance costs.

Thanks to the Brembo Beyond EV kit, Brembo’s goal was to create a disc and pad package that is quiet and resistant to corrosion, but which also minimizes residual drag and lasts longer, hence contributing to sustainability. The double-layer treatment of the disc helps to protect the entire kit from corrosion up to and beyond 100.000 km in any driving conditions. The special copper-free friction material reduces both dust and braking noise, and the galvanized backing plate protects the pad from corrosion.

Braking systems play a key role in shaping the future of mobility and Brembo, as a Solution Provider, is developing new products that will improve the driving dynamics of these new generations of vehicles.

SIDE INSIDE EDITION 31 • MARCH 2023 34

PREPARED FOR AN ELECTRIC FUTURE

Tenneco’s DRiV Business Committed to Helping Customers Capture

EV Service Opportunities

DRiV’s Monroe brand illustrates the importance of a manufacturer’s OE portfolio to success in the future EV aftermarket. Monroe OE Solutions passive dampers – used by leading EV manufacturers – and Monroe Intelligent Suspension electronic suspension technologies will ultimately redefine the aftermarket shock absorber service experience.

Conversations about electric vehicles used to begin with “If”. Now they are centered around “how fast”. While the shift to EVs has immediate implications for consumers and vehicle dealers, it will also soon affect the way in which the aftermarket serves its customers.

“Every major change in automotive technology was initially viewed as a threat to the aftermarket, only to become a new source of growth”, said Audrey Harling, Group Vice President and General Manager, EMEA Aftermarket for Tenneco’s DRiV group. “There is a similar opportunity in the shift to EVs.”

What We Know.

Although electrification dominates the headlines, ICE vehicles continue to dominate European roads. These vehicles are also longer lasting than any earlier generation of passenger vehicles, so parts and service opportunities tied to the ICE car parc will remain strong for years to come.

One interesting fact about EVs is that the weight and positioning of their EV battery packs can exert added stress on many components. DRiV already offers more than 2,000 steering and suspension parts engineered specifically for hybrid and battery-electric vehicles.

Braking Remains Strong.

EVs place severe demands on brake system components. Additionally, brake squeal and other noises can be more apparent on EVs. DRiV is one of the world’s largest manufacturers of brake pads for passenger vehicles. This unique OE insight ultimately benefits workshops that rely on FERODO replacement pads.

Also key to servicing EVs is using the proper brake fluid. FERODO has already introduced a first-to-market DOT 5.1 fluid – FERODO FBE050 – for EVs and HEVs to help workshops provide top-quality repairs of these vehicles.

Bringing

it All Home.

No matter how big or small the EV service opportunity might soon become, it represents a fundamental change for every workshop owner and mechanic. This makes technical training more important than ever.

These include better-than-OE MOOG track control arms manufactured from high-strength aluminium materials and featuring specialized surface treatments that further enhance strength and durability.

Many MOOG parts also now feature an advanced, “hybrid core” bearing technology that increases socket durability while providing smoother, quieter, more precise articulation.

Garage Gurus has already developed training modules covering best practices for servicing alternative fuel vehicles and the team continues to monitor emerging service requirements and other issues specific to these vehicles.

“We are well aware of the challenges and emerging technologies in the automotive aftermarket and it is our mission to help workshops succeed in this new future”, said Marijn Staal, senior manager, training and technical services, EMEA, Tenneco, and head of the Garage Gurus team.

C RE

HYBRID TECHNOLOGY

Elring – Das Original Experience breeds innovation

As an automotive supplier, ElringKlinger has become a trusted partner to its customers – with a firm commitment to shaping the future of mobility. With 10,000 employees at 45 locations worldwide, ElringKlinger has a global presence and is always close to its customers.

The Elring aftermarket brand offers an all-embracing package: original equipment quality, functional reliability, and premium, end-to-end service. This includes, for example, sales and technical training, service information, explodedview drawings, monthly newsletters focusing on engine sealing solutions, an online sealing compound wizard, professional installation videos, the Elring Academy, the training truck, and much more besides.

YouTube Website Instagram Facebook

YOUR PARTNER FOR SUCCES

Eurol is the biggest independent lubricant manufacturer from The Netherlands, our products are available in over 90 countries. We produce and supply approved and OEM-specified lubricants. Our importers can rely on a partnership, where flexible and custom-made support in Marketing & Sales immediately results in profitable distribution of Eurol Lubricants. Interested? Please contact us by email intersales@eurol.com

EUROL.COM

DRIVEN BY THE WAVE OF DIGITALIZATION

SIDE INSIDE EDITION 31 • MARCH 2023 38

General Manager, G-Parts

WHY THE AUTOMOBILE INDUSTRY SHOULD BE DIGITALIZED

1. Automobile and industry: driven by the wave of digitalization. The automobile has changed from an original means of transportation to an intelligent mobile terminal connected with various ecologies. The new “four modernizations” of automobiles is the accelerated development of intellectualization and networking, and the future of electrification and sharing can be expected, which puts forward higher requirements for the digitalization and safety of automobiles.

2. Market and commerce: M2B2b2c value chain model. Vertical integration mode of traffic intermediary. B2B auto parts e-commerce model. S2c value chain model.

3. The upgrading advantages of a digital business model. It reduces the communication and transaction costs of both parties and coordination failure. The analysis and judgment generated by big data model calculation are more accurate. The industry is undergoing digital transformation to

meet the preference trend of increasingly young auto consumers. The upgrading of digital intelligent driving capability in the automobile industry is the general trend.

The policy is changing - the digital supervision of transport services is to make full use of modern information technology to build a digital transport management and service system; and to reconstruct the transport business management chain, the transport industry production chain and the transport service supply chain. This is achieved by connecting up and down, linking up front and back, integrating inside and outside, and building and using all kinds of information systems. It focuses on the digitalization of business management, the coordination of organization and operation and the precision of industry supervision. Building a modern transportation service system with allfield coverage, all-chain coordination, all-around supervision, all-weather service, and all-factor aggregation.

QIU LIQIANG

SUSTAINABLE DEVELOPMENT TREND OF CHINESE AUTOMOBILE INDUSTRY ENTERPRISES

1. Automobile Industry Association actively promotes the construction of a social responsibility system. China Association of Automobile Manufacturers (CAAM) continues to drive industry enterprises to fulfill their social responsibilities and promote the sustainable development of China’s automobile industry. They have successively released the Industry Sustainable Development Report and held the Forum on Sustainable Development of the Automobile Industry.

2. The number of sustainable development reports/social responsibility reports/ESG reports will continue to increase. According to the “Golden Bee Corporate Social Responsibility Report Evaluation System”, the number of automobile enterprises that issued social responsibility reports is relatively low compared with the listing scale of automobile enterprises. The importance of social responsibility information disclosure is insufficient. With the continuous improvement of regu-

latory requirements, more enterprises will take the initiative to prepare sustainable development reports/social responsibility reports/ESG reports to disclose the performance of their responsibilities.

3. Sustainable management of suppliers has become the consensus to realize the stable operation of the supply chain. In the face of many problems brought by the current industrial chain and supply chain, the automobile industry enterprises continue to refine the sustainable standards and supplier code of conduct for the management of environmental, social and governance risks in the supply chain. In the Supplier Code of Conduct, it has repeatedly emphasized the aspects of supplier selection, including human rights, environmental management system, occupational health and safety system, responsible procurement, etc. The sustainable management of suppliers has become the consensus to realize the stable operation of the supply chain.

SIDE INSIDE EDITION 31 • MARCH 2023 40

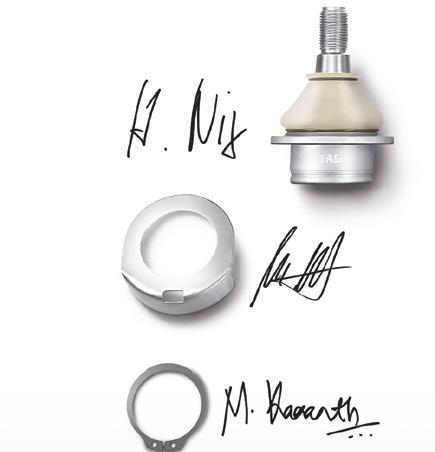

We are part of every part

As a leading developer of technical innovations with 130 years of chassis expertise, Schae ler prides itself on an uncompromising approach to quality: Every element of our chassis components and intelligent repair solutions is developed and tested by Schae ler engineers in line with the most stringent quality standards. Signature quality to be proud of.

http://a ermarket.schae ler.com/chassis-parts

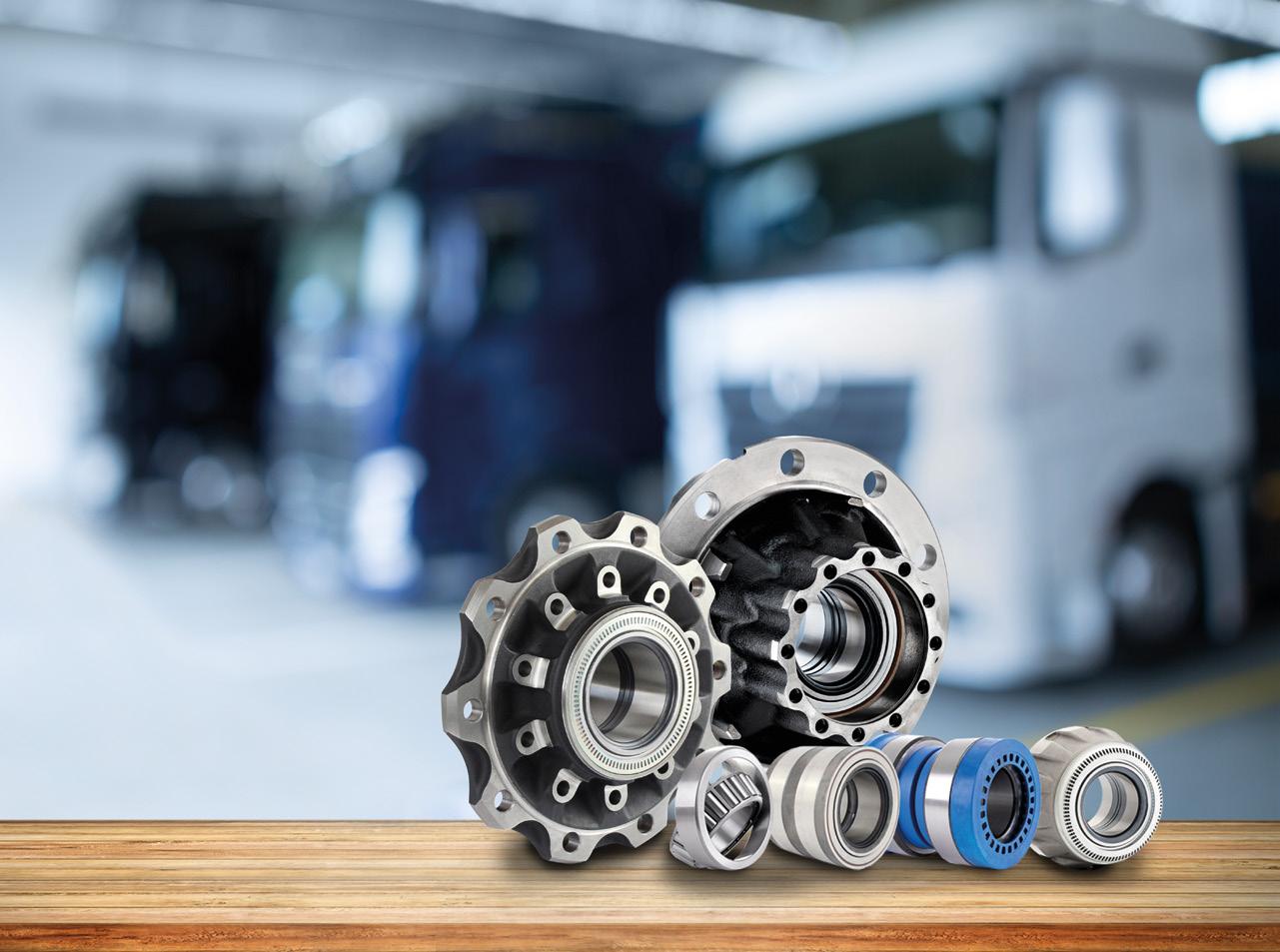

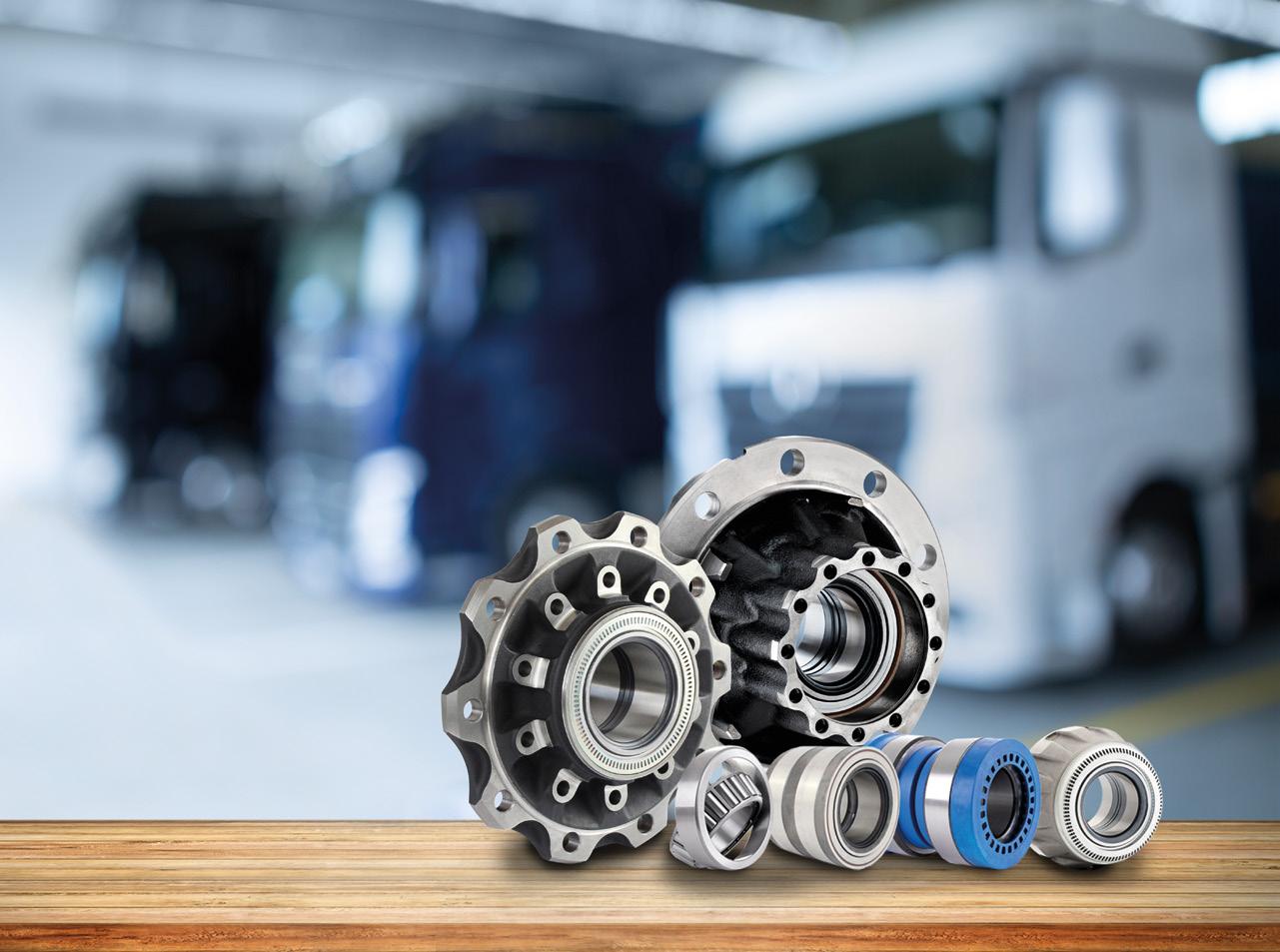

RELIABLE UNDER TOUGH CONDITIONS

WHEEL BEARINGS FOR ALL KINDS OF COMMERCIAL VEHICLES

Wheel bearings as a part of the wheelend are exposed to extreme loads in day-to-day operation. With a wide range of different types of wheel bearings from Fersa Bearings, Knorr-Bremse TruckServices now has the right solution available. The product portfolio for trucks, buses and trailers comprises various bearing types and is complemented by the corresponding tools.

| truckservices.knorr-bremse.com |

Let’s keep riding our wave of success together!

Only the best quality is good enough when it comes to replacing propshafts in cars, SUVs and light commercial vehicles. Manufacturing these high-tech components calls for a wealth of expertise and high-precision production facilities. You can rely on propshafts from GKN Automotive because they meet these stringent demands and exactly match the products supplied to OEMs.

High-tech shafts for safety and comfort:

Propshafts from GKN Automotive meet the toughest safety standards from vehicle manufacturers

Ultra-modern technologies make smaller, lighter and extremely heat-resistant joints possible

Highly advanced tube materials, filled tubes for vibration and noise optimisation, variable tube diameters and lightweight, thin-walled tubes

Crash-optimised compositions

Precision-balanced shafts to OEM specifications minimise vibrations and maximise ride comfort

We have the right product for every application:

Complete, OEM-quality propshafts

Applications for all renowned manufacturers

Propshafts for all vehicle categories from mini SUVs to light commercial vehicles

22 million vehicle links in TecDoc

Sole supplier of the latest joint technologies on the spare parts market

Premium Propshafts from GKN Automotive www.gknautomotive.com Our propshafts offer you three benefits: Premium OE quality Pre-assembled and balanced for a fast installation Available from your IAM parts dealer Unmatched power transmission technology:

Manufactured precisely to OEM specifications: Propshaft from GKN Automotive for the Audi Q5

Safety as standard: The Ballspline plunge unit from GKN Automotive, shown here as a sectional view in the lower half of the shaft, enables the component to become shorter in a crash (example from the VW Amarok).

CLAUDIE CAHART CEO, ID Rechange

THE NEW GENERATION FORCES US TO QUESTION OURSELVES PAY AS WE USE

The 40–60-year-olds generation has gone through the biggest societal and technological changes following the arrival of the internet and smartphones into their lives.

SIDE INSIDE EDITION 31 • MARCH 2023 44

The new generation wishes for a slowdown – a return to simple things, to a more responsible consumption.

This generation is more pragmatic, and more concerned about the environment: it is sensitive to this and, for example, finding such solutions ecofriendly packaging (or no packaging at all) and to the carbon footprint that is created. Much less materialistic, they give less importance to possessions and are very sensitive to giving a second life to products. Their idyllic world is: “Pay as you use”

This adage goes beyond possible financial reasons for doing so. This new mode of consumption has facilitated e-commerce sites to be born and to become part of our daily lives in all sectors including: textile, food and automotive.

ID RECHANGE has over 200 members and 8 platforms in France. Its role is to study the impact of all these behaviours and new modes of consumption in the short/medium and long-term by drawing on the expertise of N! INTERNATIONAL and

its equipment partners. This expertise encompasses the provision of services, training (technical and tertiary) and digital solutions to the current 200 NEXUSAUTO repairers through its distributors remains the priority for ID RECHANGE.

In addition to behavioural changes, there are technological ONES. The end of combustion engines announced in Europe for 2035 already requires us to question ourselves. The choice of a radical electrification of the car park suggests a significant impact on maintenance and repair.

With an average age for the French car park of about 12 years and non-adapted infrastructures, ID RECHANGE still has time to consider and propose other services to its members and garages.

From 10 to 12 March, ID RECHANGE will bring together all its distributors and NEXUSAUTO garages on the Castellet circuit. The garage equipment supplier partners will have the opportunity to explain to professionals the challenges of training and equipment for today’s and tomorrow’s vehicles.

The original & only complete battery training solution

GS Yuasa Academy is a cutting edge online learning platform, purpose built to deliver professional battery training and certification.

• Over 20 detailed training courses

• More than 100 dynamic videos

• Downloadable certificates

• Tailored learning for your job role

Learn at your own pace. Wherever. Whenever.

Start learning online at academy.gs-yuasa.eu

UPS

Haldex steel air tanks for Trucks

Your choice in vehicle servicing. Because it’s from Haldex, every air tank is tested to the most rigorous standards.

Haldex Parts

DECARBONISING, A GLOBAL CHALLENGE FOR HUMANITY

SIDE INSIDE EDITION 31 • MARCH 2023 48

IDAN KATZ & DANIELLE WALSH Partner & CTO Mobilion; CEO of Clearly

SUSTAINABLE MOBILITY

1. Why should we address mobility when addressing sustainability?

The movement of goods and people are mandatory for ordinary life and societal stability. Economic growth worldwide is premised upon various forms of mobility, including the movement of materials to worksites, the distribution of finished products to markets, the daily travel of workers, and the emergency travel of those in need of medical assistance.

Economic globalisation, higher living standards and the boom in tourism have spurred on an increase in passenger and freight volumes worldwide and are expected to triple by 2050 if current demands continue. With nearly all forms of transportation relying on petroleum products, it is no surprise then that the transportation sector is responsible for the fastest growth in CO2 emissions.

In order to limit, control and associate responsibility over carbon emissions, governments and businesses worldwide have committed to the

Paris Agreement objectives, but reaching these objectives is not easy. For years, technology has focused on operational efficiency, but achieving emissions efficiency is not a trivial task.

Road transportation of passengers and goods (by car, truck, bus or two-wheeler) account for between 20% and 25% of world energy consumption and carbon emissions1. These systems are complex, and decarbonisation will require companies to collaborate on: collecting and sharing data, implementing and adopting solutions and access to funding.

Mobility touches us all, and whilst it is hard to decarbonise, it is not impossible. With the aid of advanced technology, we can achieve the needed collaboration and fusion of data across supply chains. Once achieved, new business models can be implemented and generate new values of monetary and planetary - to each and every one of the stakeholders involved.

1. Global Logistics Emissions Council (2019). “Global Logistics Emissions Council Framework for Logistics Emissions Accounting and Reporting v2.0”. GLEC

2. The problem - Why is it challenging to decarbonise transportation?

The challenge with decarbonising road transportation is that a shift needs to occur whereby fleets not only pursue operational efficiency, but also pursue emissions efficiency. And not only that, but they need to ensure their transition to net-zero is viable. Companies need to be able to measure a fleet’s existing emissions, before understanding how to reduce these. Then they need to consider how reduction initiatives will be funded, especially when there are multiple beneficiaries in place.

Many fleets have no visibility over their carbon emissions, let alone their emission hotspots. Current methods used to calculate carbon footprints can be very rudimentary, and therefore inaccurate such as making use of ‘spend data’ gathered from bills and invoices, along with default emission factors created from high-level industry averages and external data sets. These methods provide a simple average and reference point but are insufficient to make any meaningful improvements. In order to execute a reduction policy, organisations must obtain insights of much higher accuracy. The use of primary usage data and intelligent simula-

tions are essential for supporting the execution of reduction initiatives.

Companies already have access to primary data from across a variety of siloes such as mobility data, organisational data, external pollution and energy data. The challenge lies in blending these very different data sets in addition to many others across their entire supply chain, periodically and in an automated way to generate meaningful insights that organisations need to guide their sustainability efforts.

Consider a retailer who has packed the truck, and a fleet manager who has plotted the route. One knows the weight of each load but does not keep track of how far it goes, or what type of fuel the vehicle uses, or how much it has used. The other knows the distance of their routes, their demand, and what is being spent on fuel, but doesn’t know the details of each load. In reality, both should be in constant communication with each other in order to obtain the current emission status of the fleet. To reduce emissions by electrifying the fleet means this combined data is essential. Assessing the electrification of a fleet requires taking addi-

SIDE INSIDE EDITION 31 • MARCH 2023 50

tional factors into account, such as the potential need to invest in charging infrastructure or improving the grid capacity. Manually simulating emissions reductions and cost from such initiatives can be complex, time consuming and inaccurate.

Moreso, funding such reduction projects require additional assessment of local, national and international regulations, to also understand what government assistance exists (e.g. regulations, tax breaks, or carbon credits). These can be difficult to understand, collate and apply to the project correctly. And, when multiple beneficiaries are involved, deciding on the optimal way to finance a project between them can become quite complex.

3. The Solution – introducing on-going visibility via data fusion

“It is no secret that there are large gaps in sustainable mobility surrounding observability of emissions and funding requirements. At ‘Clearly’ we know what companies need to identify, price and fund carbon reduction projects. Harnessing Big Data and Artificial Intelligence ‘Clearly’ is the first of its kind to offer trip-level tracking. This means we can accurately simulate and quantify emission

reductions to optimally select reduction projects, understand their true cost by pricing grants, tax rebates and carbon credits, and facilitate collaborative financing.”- Danielle Walsh,

CEO.

4. Ending Remarks

Decarbonising mobility is a widely recognised global challenge for humanity. There is an increasing expectation of companies to become leaders in sustainability, the importance of which cannot be underestimated. Consumers highly associate matters of sustainability with brands, which can significantly influence decisions around purchasing from partnering with specific companies. This has already led to many companies taking their first steps towards Net-Zero by announcing carbon reduction targets set in line with frameworks like the Science Based Targets initiative (e.g. aiming to be Net-Zero by 2030).

‘Clearly’ is a data-led mobility emissions platform, offering net-zero solutions for road transportation decarbonisation and access to sustainability-linked finance for retailers and logistics providers.

WHEN FICTION BECOMES REALITY.

HELLA – THE ELECTRONICS EXPERT FOR INTELLIGENT DRIVER ASSISTANCE SYSTEMS.

The Blue.on filter concept: Less waste thanks to long-life components

The Hengst Blue.on system consists of three components: housing, filter element and valve adapter. During servicing only the filter element has to be replaced – the other components are long-life parts. During replacement the oil in the filter can be collected via the drain plug and disposed of separately from the filter element. The system can be used for passenger cars, utility vehicles, farming and construction machinery and marine applications and generates 92 % less waste than conventional spin-on filters.

The benefits at a glance:

100 % recyclable filter element

50 % weight advantage compared to spin-on filters

Can be applied on all popular engine interfaces

Choice of different filter media

Components made of recycled plastic

Filter unit with customizable coding prevents the use of unsuitable or unsafe filter elements

hengst.com/blue.on

Service part

Long-life part Cap Long-life part Adapter with valves

Filter element

LET’S EMBRACE THE CHANGE

HOW TO KEEP OUR CUSTOMERS MOBILE IN THE YEARS AHEAD?

The Automotive Aftermarket has, over many years, worked hard to provide its customers with quality parts and ensure a swift delivery of them.

The Customers’ needs are evolving and the new 20’s are bringing many more challenges for both customers to face, as well as the companies that are distributing parts across the world.

Now, it is no longer only a case of providing good parts, in due time, at a convenient price. New trends are more than ever linked to how the industry can support the customers mobility, thanks to tailor-made services.

The impacts of this on the workshops has been a strong evolution of the CUSTOMER PORTFOLIO REPARTITION. The usual Private motorists and Fleet Managers (for private or corporate

EMBRACE

CUSTOMERS MOBILE.

SIDE INSIDE EDITION 31 • MARCH 2023 54

LET’S

THE CHANGES AHEAD, BE AGILE AND COLLECTIVELY KEEP OUR

The Automotive Aftersales market megatrends are divided into 2 MAIN CATEGORIES with 2 TOPICS for each*.

SUSTAINABLITY

ELECTRIFICATION

The EV market share should go up to 57 % by 2030 instead of 4,4 % in 2020, pushed-up by oil peak, climate change, regulation, incentives and technologies.

CARE SHARING

The customers’ demand, incentives, cost effectiveness could drive the market share to 38% in 2030, instead of 4,4 % in 2020

DIGITALIZATION

CONNECTIVITY

The global revenue generated by connected services could reach $420 bn in 2030, instead of $67 bn in 2020.

AUTONOMOUS DRIVE

No longer science-fiction, autonomous vehicles could reach 4.5 % due to customer demand and almost ready technologies leading to new customers’ needs.

vehicles) are no longer the only ones - the garages have to deal with insurers, OEM (new VMs) and other forces impacting on the market and the decision making.

The NEW VEHICLE TYPES AND SYSTEMS are impacting considerably on the daily activity of the workshops. The EV battery, ADAS, embed software… all these new topics are impacting on the knowledge & skills that every mechanic needs to master.

Customers are also looking for NEW DIGITAL TOUCHPOINTS (online and offline) and the market needs to ensure that a proper integration is made into to the drivers’ eco-system.

Parts distribution can lead these changes by offering their customers new products, concepts and services.

Nexus garage Network concepts can help and support the adaptation of the workshops to meet the evolving market needs.

Many topics covered by the N! Service offer can help create a new history within our industry. This includes: connected warehouses, new delivery models (for example EV, autonomous), a strong Workshop operating platform, an online training experience with N!Academy Cloud, and an Online Presence Management tool.

For more information about N! Services, drop us an email @ service@nexusautomotive.eu.

*Study from IAC Partners

» HIGH-QUALITY HYDRAULIC FILTERS FROM HERTH+BUSS

Herth+Buss on YouTube Technical expertise and practical tips

Available in various designs!

The range of filters used in automobiles is diverse. In our Jakoparts range we offer a wide range of filters for Asian vehicle models. In excellent quality and with a perfect fit!

Not all filters are the same. Durability, efficiency and an exact fit are the guarantees for long-lasting filter functions. Added to this are proven, high-quality materials such as special filter paper and corrosion-treated metals. The Jakoparts range includes a wide spectrum of oil, fuel, air and cabin filters for Asian vehicles and has now also been extended to include hydraulic filters.

A hydraulic filter, also called a transmission oil filter, is needed in every hydraulic system. The task of the hydraulic filter is to clean the oil that is needed to operate the vehicle‘s hydraulic components. To achieve this, the fluid is passed through the filter and the filter element separates all particles above a defined size. Without the use of the hydraulic filter, the particles would collect in certain places and could lead to malfunctions. The filter only has a limited service life and must therefore be replaced at regular intervals. Every car manufacturer specifies how often a hydraulic filter should be changed. This information should be strictly adhered to in order to prevent damage.

With our new range of hydraulic filters, we offer the right spare part for different vehicles with automatic transmissions! Furthermore, our filters meet the highest quality requirements. They filter abrasion from the transmission oil and protect against wear. The filters are available in the following three different versions: filter insert, sieve filter or screw-on filter. At the moment we offer more than 30 hydraulic filters. The range is continuously being expanded.

Hydraulic filter, automatic transmission Article number: J135*

Even the best experts in the workshop sometimes reach their limits. This is where our YouTube channel comes into play. With our tutorials and BuddyTalks, we not only pass on our knowledge to workshops, but also to specialist retailers or amateur mechanics. With the help of the Workshop-Buddies and our technicians, we have extensive expertise in vehicle parts and vehicle electrics. Of course, there are also useful tips and tricks for the workshop. herthundbuss.com/

JAKOPARTS – Das Stärkste für Asiaten!

channel

Break through to the future of mobility

The automotive and motorcycle industries are currently facing a once-in-a-century transformation, and mobility solutions are required that reduce environmental damage, decrease traffic accidents, and improve comfort. At the same time, competition is intensifying in fields such as electrification, autonomous driving, and connectivity, which will form the future core of automotive and motorcycle systems.

As a result of this, Hitachi Astemo with it`s TOKICO suspension brand is dedicated in providing cutting edge technologies. Shock absorbers and struts are an important part of the overall suspension and steering system. With increasing weight of the vehicles such as in new Electric Vehicles (EV) the suspension systems are gaining importance for the right body weight management of the vehicle. A prime example are our solutions for semiactive and active suspension, for which Hitachi Astemo has already been awarded several OE Projects for EV´s, thus proving that Hitachi Astemo is one of the global leaders for EV components.

Hitachi Astemo with its Tokico and Showa suspension brands is one of the leading manufacturers for passenger cars and motorcycle suspension. Respectively Hitachi Astemo and it`s Tokico brand is dedicated to supply the same OE quality to the Independent Automotive Aftermarket. Tokico supplies over 1.000 part numbers for Japanese vehicles and covers over 2.800 different vehicles models. Our goal is to develop and provide a full product coverage for Asian vehicles including Korean applications. Tokico shock absorbers restore OE damping forces ensuring consistent tire/road contact and a safe handling of the vehicle, which results in Improved driving dynamics and increased control for body and tire movement.

Hitachi Astemo a global leader for suspension systems

OE shock absorbers on 1 out of 5 new cars are manufactured by Hitachi Astemo.

Hitachi Astemo a global leader for suspension systems

OE shock absorbers on 1 out of 5 new cars are manufactured by Hitachi Astemo.

IAM deliveries through our central warehouse in Europe. DID YOU KNOW?

13 shock absorber factories in 7 different countries.

Visit our website

AFRICA IS NO EXCEPTION

SIDE INSIDE EDITION 31 • MARCH 2023 58

MARTIN HENDRIKSEN Strategic Planning & Customer Experience Director, NEXUS Automotive International

DIGITALIZATION, ELECTRIFICATION, SUSTAINABILITY, CONSOLIDATION IN AFRICA

The automotive aftermarket industry in Africa does not escape change driven by trends in digitalization, electrification, sustainability, and consolidation.

These trends will also help shape the future of the industry, affecting both consumers and businesses in Africa. How will these trends play out in the region, considering factors such as GDP growth, exchange rate fluctuations, and the difficulty of securing foreign currency? How quickly will the Chinese electric vehicle industry have an impact in Africa and what about education and training as drivers of economic growth?

Digitalization is transforming the automotive aftermarket industry globally, and Africa is no exception. With more vehicles equipped with advanced technologies, the demand for skilled technicians and mechanics has risen, leading to a

shortage of qualified personnel. Digital tools and platforms are being developed to help bridge this gap, enabling technicians to diagnose and repair complex vehicles with greater speed and accuracy. In Africa, markets lag their Western counterparts with the skills shortage being one of the major stumbling blocks.

Sustainability is also a trend that is gaining traction in the automotive aftermarket industry. With growing concerns about climate change and the impact of fossil fuels on the environment, there is an increasing demand for greener and more sustainable vehicles. In response, automotive manufacturers are investing in developing and

AFRICA IS NO EXCEPTION

marketing more sustainable vehicles, and businesses in the aftermarket industry are following suit. Sustainability is not the first priority in many African situations and global players have a leadership role in this respect. In terms of energy however, some African markets face electricity shortages due to the failure of traditional generation methods. It is expected the private sector will become more involved in the generation of electricity and much of the new power will be generated in a more sustainable way as a result.

Electrification is another trend that is shaping the future of the automotive aftermarket industry. As electric vehicles gain popularity, there is a growing need for charging infrastructure and repair and maintenance services. However, many African countries are struggling to keep up with the pace of change, and there is a shortage of trained technicians who are capable of servicing these vehicles. In Ethiopia for example, the latest technology vehicles are available but there are no people qualified enough to service and repair them and parts are in short supply. Some owners fly in the necessary skills and parts, whilst others ship their vehicles overseas for the necessary service and repair work to be done. This highlights again the need for education and training in this field to support the growth of electric vehicles in Africa.

It is most likely that Chinese manufacturers will lead the electrification game in Africa with lowcost models. Potentially one could see a growing

SIDE INSIDE EDITION 31 • MARCH 2023 60

electric fleet in Africa powered by sustainable energy sources such as solar and wind.

Consolidation is another trend that is shaping the future of the automotive aftermarket industry in Africa. With the market becoming increasingly competitive, businesses are seeking to merge or acquire other companies to achieve greater scale and efficiency. This trend is expected to continue in the coming years and will have a significant impact on the structure of the industry in Africa. Many African businesses in the automotive aftermarket sector are traditional family run enterprises and these families start to question their futures in a fast-changing industry.

Furthermore, the Africa Continental Free Trade Agreement (AfCFTA) is a trade pact signed by African countries to boost intra-African trade by eliminating tariffs on goods traded within the continent. The agreement covers a market of 1.3 billion people and a combined GDP of $3 trillion and has been signed by 54 of the 55 African Union member states, with only Eritrea not yet having joined. The signatories represent a diverse group of countries in terms of size, geography, and level of development, including large economies like Nigeria and South Africa, and smaller ones like Rwanda and Senegal.

The AfCFTA officially came into force on January 1, 2021. The agreement aims to create a single market for goods and services, increase investment

flows, and enhance economic growth and development across Africa. The full implementation of the AfCFTA is an ongoing process and there is no set deadline for when it will be fully implemented. The implementation will be phased in over time, with certain sensitive sectors and products excluded initially, and tariffs gradually being eliminated. The objective is to create a fully integrated African market, which would provide a major boost to the continent’s economic growth and competitiveness.

In conclusion, the automotive aftermarket industry in Africa will undergo major changes, driven by trends in digitalization, electrification, sustainability, and consolidation. The impact of these trends will be shaped by factors such as GDP growth, exchange rate fluctuations, and the difficulty of securing foreign currency. As electric vehicles gain popularity, education and training will play a critical role in driving economic growth and ensuring that the industry is able to keep up with the pace of change. Change in big steps is no stranger to Africa, for example most Africans never had fixed line telephones but almost everyone has a mobile phone today!

Nexus will focus its African efforts through the IAMaga structure, taking cognisance of the major trends to help build better aftermarket business on the continent.

Take part in more sustainability

Conserving resources through reuse: With its exchange program, Bosch is focusing on the circular economy. By effectively reusing the returned parts, raw materials are used sustainably. Join in and make your contribution to sustainability by value-based vehicle repairs with a Bosch eXchange part.

boschaftermarket.com

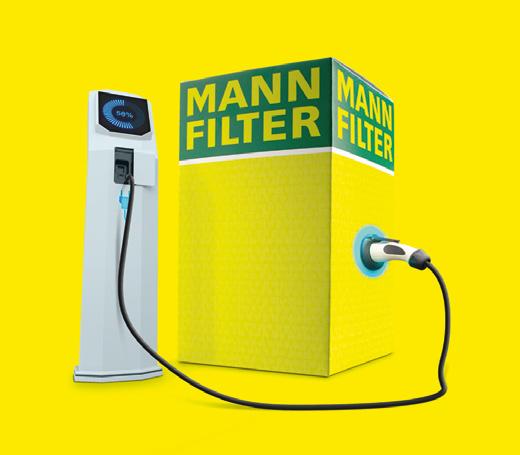

Meeting challenging trends of the automotive industry

The premium filtration brand MANN-FILTER is well prepared for future market needs such as zero-emission mobility as well as protection of vehicle occupants from air pollution and provides the solutions which its partners require.

Climate change is one of the biggest dangers facing mankind and requires urgent action. To meet the climate goals of the Paris Agreement, CO2 emissions from passenger car traffic – among other things – need to be significantly reduced. As global brand of MANN+HUMMEL, one of the worldwide market leaders for filtration with over 80 sites worldwide, MANN-FILTER pursues a technology-open approach to provide customers with the best filtration solutions towards zero-emission mobility. In this regard, alternative drives play a major role and e-fuels can contribute their part as well. The mobility of the future will certainly consist of a mix of different drive technologies, and liquid fuels will be required for a long time, such for passenger car fleets. Here, synthetic fuels can make an additional contribution to effective climate protection in transport. Respective solutions to meet the next filtration challenges are already an integral part of the MANN-FILTER portfolio. Already today, customers can choose from more than 1,200 filters for cars and vans with electric powertrains from MANN-FILTER.

Another big challenge is air pollution which endangers the health of people worldwide. To protect vehicle occupants MANN-FILTER offers a large portfolio of different cabin air filters. As a pioneer of the bio functional cabin air filter, they are naturally also creating further innovative products and new technologies in this area. This is the only way to meet the growing demands for protection against harmful gases and health-threatening particles such as particulate matter and effectively protect vehicle occupants.

Despite being able to offer a wide range of filtration solutions to the customers, MANN-FILTER is determined to further grow innovation skills and improve their products. To meet the challenges ahead, MANN+HUMMEL experts are developing the filters of tomorrow in the vehicles of today. After all, customers should also be able to rely in the future on: MANN-FILTER – Perfect parts. Perfect service.

MEYLE eSolutions. Your partner for repair solutions for electric vehicles.

Electric vehicles will continue to become significantly more important for independent workshops and dealers in the coming years. Current studies indicate that more than 80 million electric vehicles will be on the roads in 2035 (data includes European Commission study on well-to-wheel considerations for a variety of fuel and power-train combinations). With its MEYLE eSolutions product portfolio, MEYLE is already well positioned, with more than 1,100

electric-vehicle parts on offer. When developing the spare parts of the future, we depend on our MEYLE engineers who have been coming up with innovative solutions for more than 20 years with MEYLE HD –parts that are more durable and reliable than their OE counterparts. Always at your side, we’re your partner and DRIVER’S BEST FRIEND. Competent in all matters – including electric mobility. Just give us a call!

After Tesla drivers all over the world reported annoying squeaking sounds in Model 3 and Model Y series vehicles, our MEYLE engineers analysed the problem and are now, after intensive development work, introducing the MEYLE HD control arm for Tesla models 3 and Y. MEYLE

is thus offering a technically superior alternative to the original part to up to 700,000 Tesla drivers and stakeholders around the globe who could encounter the defect, thus ensuring the fun driving experience that people expect from Tesla. With a four-year guarantee*.

More information at www.meyle.com

* Further information about the guarantee: www.meyle.com/guarantee-certificate

With the HD control arm for Tesla, MEYLE underscores its expertise in the field of electric mobility.

EXCITING TIMES ARE AHEAD OF US

SIDE INSIDE EDITION 31 • MARCH 2023 66

ROBBIE STEVENS Head of Ecommerce Business Unit, NEXUS Automotive International

TECHNOLOGY, BRAND VALUE & PRICING: 4 MAJOR FACTORS ARE BECOMING SIGNIFICANT

DIGITALIZATION,

eCommerce has become a critical aspect of retail’s post-pandemic life and with Nexus creating a new eCommerce business unit to support the upcoming and ever expanding established digital community with tools and services, plenty of exciting times are ahead of us!.

In this issue of INSIDE, I will be focusing on the 4 major factors that are becoming significant:

1. Customers Buying Behaviour / Expectations:

Digitization is transforming the auto parts aftermarket in several ways. One of the most significant is the increasing use of ecommerce platforms for buying and selling parts (Amazon, eBay etc..). This allows end customers, be it the “Do It Yourself” or the “Semi-Pro” to easily find and purchase the parts they need, while also providing manufacturers and distributors with a convenient and accelerated means to reach a larger customer base.

The automotive aftermarket industry has been experiencing significant growth in recent years, thanks in large part to the rise of these ecommerce platforms. The global ecommerce automotive aftermarket is projected to reach a market size of 78 billion US dollars by 2030 *. As more and more customers turn to online channels for their automotive aftermarket needs, their expectations are also evolving, prompting traditional businesses to adapt to new trends and preferences.

Convenience is the key for the growth we see in eCommerce. By shopping online, customers can compare prices, view product/vehicle compati-

bility, and read reviews from other customers all from the comfort of their own homes. This has become especially important during the COVID-19 pandemic, as many people have been reluctant to visit physical stores. As a result, traditional businesses looked to eCommerce to maintain and grow their customer base.

In addition to convenience, customers are also demanding a more personalized and interactive online shopping experience. This means that businesses need to invest in technology that can provide customers with recommendations based on their browsing and purchasing history. Websites need to be easy to navigate and provide ample product information and visual aids like photos and videos.

Another key trend in the automotive aftermarket is the rise of DIY customers. The increasing number of DIY customers is driving the growth of the eCcommerce automotive aftermarket. These customers are looking for parts and accessories that they can install themselves or by a semi-pro friend, and they often prefer to buy these products online. To cater to this segment, there is a need to provide detailed fitting guides and videos, as well as more technical customer support to help answer any questions that may arise.

2. Technology:

Technology is playing a significant role in enabling the growth of aftermarket automotive ecommerce, making it easier and more convenient for customers to shop for car parts and accessories online. Some ways in which technology has enabled aftermarket automotive ecommerce include:

Omnichannel Software: Many eCommerce plat-

forms have made it easier to list and sell their products online. Omnichannel software provides a ‘middleware’ solution that enables you to ‘plug into’ multiple platforms such Shopify, eBay, Amazon, Walmart with one connection and a centralized management interface.

Search and Navigation: Automotive ecommerce sites use bespoke search and navigation tools that enable customers to quickly and easily find the products they need. Advanced search features allow customers to search by make, model, year, and part number. Navigation tools like menus and filters help customers narrow down their search results by category, price, and brand.

Mobile Optimisation: With the increasing popularity of mobile devices and with the majority of first user visitors coming via mobile, many aftermarket automotive eCcommerce sites have optimized their websites for mobile devices. This allows customers to shop for parts and accessories from anywhere, at any time, using their mobile devices. Augmented Reality: With the help of augmented reality (AR) technology, customers can visualize how a product will look on their vehicle before making a purchase. For example, AR technology can allow customers to see how a new set of wheels or a body kit will look on their car by overlaying digital images on top of real-world images captured by their mobile device’s camera.AR was the future but it is now the present day expectation from the end customer.

Analytics and Personalisation: Many aftermarket automotive ecommerce sites use analytics and personalisation tools to track customer behaviour and make personalized product recommendati-