A DutyHeavy Community

Gaël Escribe, CEO & Janusz Zielinksi, VP Global HD Business Development

06 NEWS FROM N!

• N! Business Forum, Abu Dhabi April 8-10: A global stage for sharing insights and inspiration on complex industry subjects

• DR!VE+ targets the Heavy Duty market with OE-matching Quality, value-for-money offer

• NEXUS Automotive International unveils Global strategic Tire partnerships

Joining the N! Community

• Welcome to Telos, Big7, Scapir, AC Autos-Camions, Prime, Zero Corp and Al-Gous International as new members

• Welcome to Cummins Meritor, Shell, Welte EDS and Solera as new suppliers

24

INSIDERS SUSTAINABILITY SOLUTIONS FOR FLEETS

• Interview Davide Ghioni, CEO Telos

• Feedback on The Train The Trainer in Poland

• NEXUS Automotive International represented in the European Truck Racing Championship in 2025

• Resilience and Growth Take Center Stage at the VIPAR Heavy Duty 2025 IMPACT Conference

• 30 years of Nelas Auto Parts

40 INSIGHTS FROM NEXUS COMMUNITY

• Excellence reborn: BorgWarner reman Turbochargers for Commercial Vehicle

• Sustainable solutions for truck fleets: Cojali’s cross-cutting commitment

• How circularity in tires and digital insights turn pressure into performance, Continental

• DPF reconditioning: a smarter, greener way to keep fleets moving, Dinex

• Exide Technologies streamlines Commercial Vehicle battery ranges with new product line-up, smart label design and easier fitment

• SKF fuel saving wheel bearings: a smart response to fleet cost pressures

• TIP NEXUS Lyon 2025

• TMD Friction reduces CO2 emissions by 46%

• Why choose remanufactured parts for Trucks? Valeo

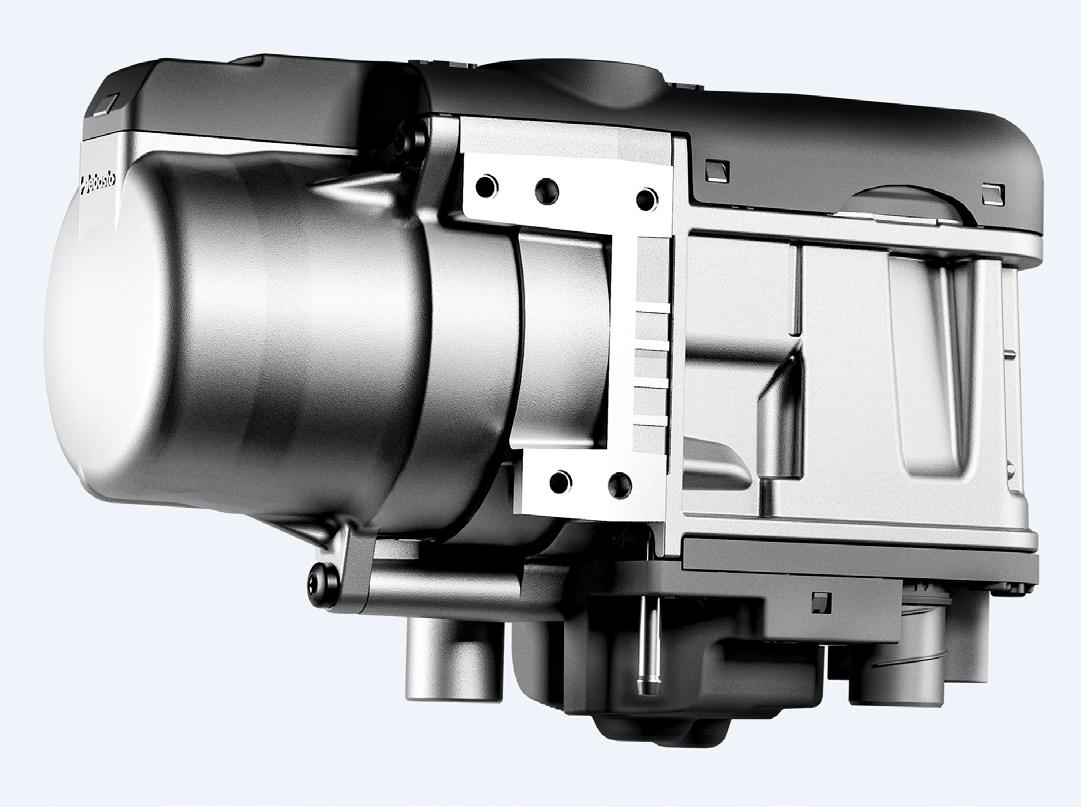

• Sustainable heating solutions for diesel and electrical trucks, Webasto

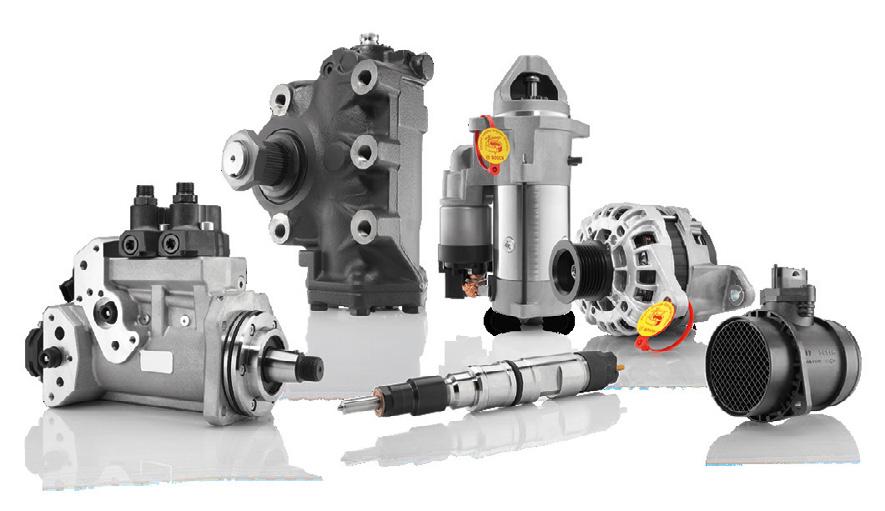

• ZF Aftermarket remains the one-stop source for smart, safe and sustainable transport technologies

88 INSIGHTS FROM SUPPLIERS

INSIDE TRUCK 11 | NOVEMBER 2025 IN ! SIDE TRUCK Newsletter is published by NEXUS Automotive International, Geneva, Switzerland.

NEXUS Automotive International SA Chemin du Château-Bloch 11 1219 Le Lignon | Geneva | Switzerland

T +41 22 306 49 50 www.nexusautomotiveinternational.eu

WELCOME

Gaël Escribe CEO of NEXUS Automotive International

Janusz Zielinski VP Global HD Business Development

Dear reader,

I am happy to present you our 11th edition of the IN!SIDE Truck magazine which is precedes the 5 th edition of the Global N! HD Summit in Lyon.

The global NEXUS Heavy-Duty Community is continuously growing. In 2025 we have welcomed new suppliers and members with activities dedicated to the CV parts segment, some of which you will be able to see in the NEW Members & Suppliers section.

2025 is a very challenging year for the transportation and heavyduty Aftermarket businesses. The main disruptions of our sector primarily come from tariffs, increased costs, e-commerce growth, AI-driven diagnostics, and predictive maintenance.

We are also seeing increased demand for sustainable aftermarket solutions from fleets. The automotive aftermarket industry needs to develop and deliver sustainable parts, secure green maintenance & repair processes, and stay in line with the circular economy rules.

We invite you to participate our next HD Summit event which will take place on November 18th, 2025, in Lyon, where NEXUS members, suppliers and external experts will discuss all relevant topics around the “sustainable fleet solutions”.

Gaël Escribe

N! NEWS INS !

A GLOBAL STAGE FOR SHARING INSIGHTS

AND INSPIRATION ON COMPLEX INDUSTRY SUBJECTS

NEXUS Automotive International’s most significant event of the year - The NEXUS Business Forum 2025 - is currently taking place in Abu Dhabi from April 8 to 10. This prestigious gathering has brought together over 700 aftermarket professionals, including more than 85 suppliers and some 215 member companies.

The event opened with the “Momentum” Plenary Session, in collaboration with INSEAD, a leading international business school.

Attendees gained insights on education, data, artificial intelligence, and business strategy in the US from industry experts. The session also addressed future challenges and opportunities for the aftermarket industry, with speakers from

the N! Community sharing their perspectives with the support of Premium partners: Bilstein, Brembo, KYB, Mahle, NRF, Phinia/ Delphi, Schaeffler, SKF, TotalEnergies, Valeo, ZF & Mecafilter as regional partner.

The 3rd NEXUS Climate Day

A highlight of the forum is the third NEXUS Climate Day, which attracted around 200 participants. This event

brought together sustainability experts with members of the N! community, representing the entire supply chain.

The NEXUS Climate Day focused on developing practical solutions, initiatives and best practices. Several Proof of Concepts (POCs) with key suppliers like Bosch, TotalEnergies, and Valeo, lead to the establishment of new NEXUS standards as the Green Garage.

These included Premium partners Astemo, Bosch, Delphi/Phinia, Mann+Hummel, NTN, SKF, TotalEnergies & Valeo with the support of Bilstein, Elring, KYB, Mecafilter, Mobilion, NRF & Smartparts.

Focus on Heavy Commercial Vehicles

This year’s NEXUS Business Forum has a special focus on the Heavy Commercial Vehicle (HD) sector. More than 50 NEXUS members from the HD sector are participating in Speed Date meetings with top suppliers.

For the first time, HD parts suppliers such as Cummins - Meritor, Dinex, Cojali/Jaltest, Knorr Bremse, Webasto, and Welte/EDS are showcased in a dedicated HD Village.

TRUCK

The event also features special activities related to HD parts and solutions. On Thursday April 10, the HD Strategic Committee held an exclusive meeting, bringing together NEXUS members from various regions to discuss strategic initiatives and trends shaping the future of the HD segment.

In a nutshell

More than 3,000 “speed date” meetings were organized to foster growth within the community and unlock new business opportunities, addressing key topics and facilitating discussions among members of the N! Community.

The White Beach Party took place at the St. Regis, Abu Dhabi, on the evening of Wednesday, April 9th. Bosch was named PC Supplier of the Year and Hengst HD Supplier of the Year. The Growth Champion awards were won by PHINIA (formerly Delphi) as Strategic Supplier and Dayco as Preferred Supplier.

Tavo was awarded HD Member of the Year, while Dinamik was awarded PC Member of the Year. Jeff Koviak – CEO APSG – from Federated Auto Parts received recognition for its 40th anniversary.

NEXUS IS DELIGHTED TO ANNOUNCE THAT THE NEXT N! BUSINESS FORUM 2026 WILL TAKE PLACE IN LAUSANNE, SWITZERLAND, FROM MARCH 31st TO APRIL 2nd, 2026.

STEVEN ZIMMER, COO of SmartParts

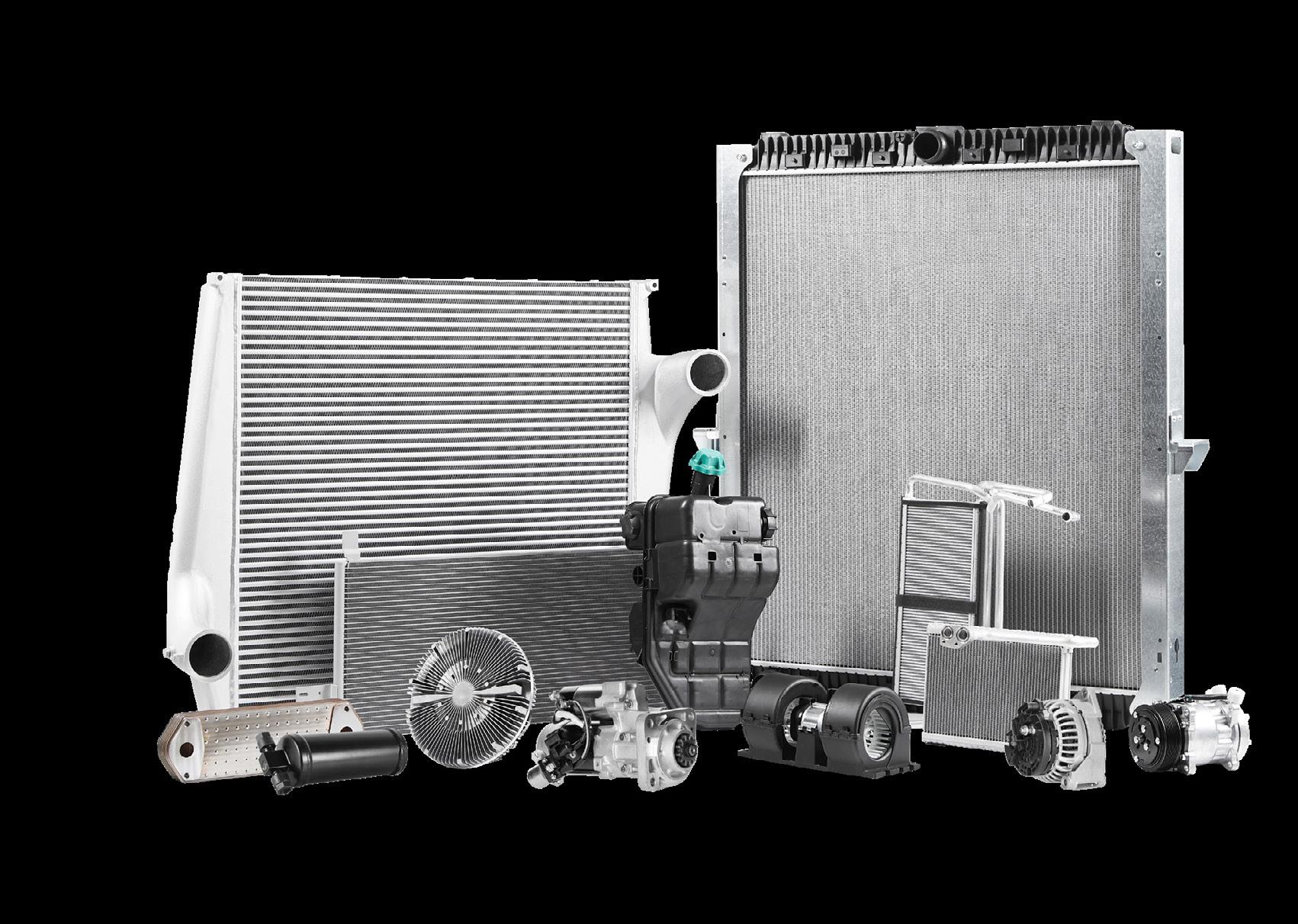

DR!VE+ TARGETS THE HEAVY DUTY MARKET WITH OE-MATCHING QUALITY, VALUE-FOR-MONEY OFFER

At the HD Summit in Lyon, DR!VE+ unveils its Heavy Duty solutions for the NEXUS Community, delivering OE-matching quality, valuefor-money products. Steven Zimmer, COO of SmartParts, explains the reasons behind this initiative.

Why is SmartParts present at the Heavy Duty Summit in Lyon this year?

Steven Zimmer : We’re here to connect with the entire Heavy Duty NEXUS Community. The Summit is the perfect place to gauge interest in our DR!VE+ HD range and gather direct feedback from members.

Is this your first time presenting at the Summit?

Steven Zimmer: Yes, it is. We’re bringing ranges in 4 product lines: filtration, braking, lubricants and batteries. Similar to our Passenger Car strategy, we are focusing on the fast movers in workshops. In addition, we’re highlighting our wide coverage of light commercial vehicles, over 90%.

Why is DR!VE+ launching a Heavy Duty range now?

Steven Zimmer: The demand came directly from our customers. As a ser-

vice provider to the NEXUS Community, we listen closely to their needs. They expressed a clear desire for value-formoney products in the Heavy Duty segment, and we responded, delivering OE-quality solutions, as no compromise on quality is acceptable in HD. The Summit, along with individual meetings with members, will help us validate the strategy and ensure it fully meets their expectations.

What’s your main goal at this Summit?

Steven Zimmer: To understand in detail what the HD NEXUS Community wants, ensure DR!VE+ HD meets those needs, and build confidence among members. Our ultimate aim is to complement premium brands with reliable, cost-effective solutions that support the full fleet, just as we do successfully in Passenger Cars.

ENGINEERED FOR RELIABILITY AND VALUE

DR!VE+ is the global aftermarket brand exclusive to NEXUS members. Present in over 50 countries and offering more than 11,000 fast-moving part numbers, DR!VE+ delivers OE-matching quality and exceptional value for money, now extended to the Heavy Duty sector.

Available for trucks, trailers, buses, and Light Commercial Vehicles, DR!VE+ supports the complete fleet needs of NEXUS members and their customers, strengthening the NEXUS offer by complementing premium brands with reliable, high-performing solutions built for every Heavy Duty challenge.

NEXUS AUTOMOTIVE INTERNATIONAL UNVEILS

GLOBAL STRATEGIC TIRE

PARTNERSHIPS

NEXUS Automotive International has launched its Global Tire Strategic Program, marking a significant shift in focus toward the tire business. This ambitious initiative builds the largest global connected tire ecosystem, leveraging strategic partnerships, innovative agreements and cutting-edge digital platforms.

Focused on aftermarket spare parts since its creation in 2014, NEXUS Automotive International decided in early 2024 to invest strategically in the tire business. NEXUS is now building a connected ecosystem around tires that can be industrialized and scaled across multiple countries.

NEXUS Automotive International has secured global partnerships with three world-class tire manufacturers—Continental, Linglong, and ZC Rubber—and a global agreement with WYZ Group, a tire digital solutions specialist. These partnerships are built around three-key principles: ease of doing business, availability of products, a wide

offering, and a combination of stock and drop-shipping solutions.

• Continental: NEXUS is strengthening its global strategic agreement by positioning Continental as its strategic supplier for the premium tire segment. By leveraging Continental’s high-quality products and extensive expertise, NEXUS will give its members top-tier tire solutions that ensure reliability and performance.

• Linglong: The new global agreement in the quality segment leverages Linglong’s recent investments in OE advanced technologies, brand activities, and its ultra-modern factory in Serbia. In Europe, this agreement will

be powered by Dipropneu, a leading European tire wholesaler providing products and support for the Linglong partnership.

• ZC Rubber: The new global agreement provides an exclusive global brand— “RISEN”—for NEXUS members. With the tagline “Ready to go further” the brand combines advanced technology and innovation to boost driver confidence on the road. This agreement is supported by Districash, Europe’s #4 tire wholesaler, which will provide products and support for the ZC Rubber partnership.

• WYZ Group: NEXUS has chosen WYZ Group as global strategic partner for its digital platform. WYZ Group brings 16 years of experience in tire digital solutions by connecting multiple stocks, managing business rules, handling complex catalogues, and devising pricing strategies. This collaboration will give NEXUS distributors and their clients the confidence to sell tires with the right product choice, optimal availability and competitive pricing.

Building on an existing business of roughly 15 million tires per year, the Global Tire Strategic Program will represent:

• A well-understood product category within the NEXUS community

• A double-digit total volume increase, establishing NEXUS as one of the largest tire distributors worldwide

• A strong community of NEXUS Tire Specialists exchanging best practices and collaborating on joint procurement initiatives

TRUCK

• Solid strategic supplier agreements favoring progressive supplier convergence

• An exclusive brand that gives NEXUS members the confidence to grow their tire business

• A robust tire garage program, supported by a unique and flexible digital platform for NEXUS members, which will be fully integrated with the Service Next WOP garage platform

• 100% of the tire volume tracked through the digital platform, allowing for effective monitoring and steering of purchases

• Tire volumes distributed through a combination of direct wholesaling and drop-shipping arrangements.

Bruno Perchec, Global Suppliers & Tires Manager, NEXUS Automotive International, said: “Tires are the primary reason for cars entering workshops, so it is essential for distributors to strengthen their relationships with customers, especially as they navigate an increasingly competitive market. By offering a onestop-shop service for parts and tires, NEXUS will help its members maintain a strong competitive presence in their marketplace.”

NEXUS Automotive International’s investment in tires aligns with its commitment to sustainability, innovation, and growth. By strategically embracing the tire industry, NEXUS remains at the forefront of shaping the future of the automotive aftermarket.

NEW MEMBERS

ITALIA

Telos was founded with the aim of being the main global partner for the best workshops in the market in northern Italy. It handles most of the leading spare parts brands and is able to offer numerous products at favorable conditions, a comprehensive training programme and a wide range of equipment for workshops and body shops. Telos has become a market reference in just a few years thanks to constant investment in strategic divisions, and with its 49 sales outlets it covers its target market extensively.

Telos

SPA

Telos was a member of Groupauto Italy until December 31st, 2023 and joined NEXUS Automotive Italy on January 1st, 2024.

NEW MEMBERS

BIG 7 is a distribution company selling spare parts for commercial vehicles (trucks, buses and trailers).

The company began its activity in 2001. Since 2007, it has worked under the name EUROMOTOR. In 2018, the company was rebranded and 2 companies were formed: TruckMotors and BIG 7. The main company for working with Suppliers was TruckMotors. BIG 7 was used for internal business operations. Since 2024, there was a division of business between the founders of TruckMotors into two independent

Big7 has joined NEXUS Eurasia as of August 1st, 2024.

companies TruckMotors and BIG 7. All assets of TruckMotors were divided into two equal parts between TruckMotors and BIG 7.

BIG 7 sells spare parts to retail customers, service stations, corporate clients, organizations, and markets.

SCAPIR

Scapir has joined IAmaga as of January 1st, 2025.

Scapir, based in Casablanca, Morocco, has been specializing in the supply of automotive spare parts since 1987. Our range includes braking, cooling, electrical, lubricants, and suspension systems, all complying with international quality standards.

AC Autos-Camions

Autos-Camion has joined NEXUS Automotive International through the IAMaga structure on January 1st, 2025

Autos-Camions was founded in 1993 and has over 30 years of experience in the Malagasy market for passenger cars, Japanese vehicles, and heavy goods vehicles. The company currently employs over one hundred people.

Autos-Camions is now part of a group of companies, with subsidiaries in the hotel industry and pharmaceutical distribution in Madagascar.

We currently represent brands such as Kolbenschmidt, Euroricambi, Hengst, Elring, Diesel Technic, Howo, Sampa, Vaden, Fras-Le, DPIA Colaert, and many others.

We are seeking partnerships with companies like ZF, Sachs, Mahle, Schumacher, and Jost.

Our current import volume for European brands is approximately €5 million.

We began our operations as a B2B company. Since 2021, we have opened B2C outlets in the capital. Today, we have two stores specializing in the sale of spare parts for heavy goods vehicles, one created in 1995 and the second in 2021 - a third being in the process of completion - and two stores specializing in the sale of spare parts for light cars, Japanese, French, German and Korean.

NEW MEMBERS

Prime

Prime has joined IAMaga as of March 1st, 2025.

Prime is based in Tunis, the company specializes in the distribution of spare parts for trucks, buses, and heavy equipment. The company is currently experiencing significant growth, and they are expanding their distribution network to encompass all types of automotive vehicles.

Zero Corp

ZERO Corporation has joined NEXUS Automotive International as of August 1st, 2025.

Since its founding in 1994, ZERO Corp. has become a leading auto parts import and export company. It is involved in the sales and distribution of aftermarket parts for Commercial Vehicles, European Passenger Vehicles, and car care accessories involving wiper blades, scratch

remover, engine oil, engine oil treatment and other products. The company counts 200 sales partners and workshops and exports in more than 100 companies over Asia, Europe, Africa, Australia and South America.

AL-Gous International Company

Al-Gous International has joined NEXUS Automotive International through the IAMaga structure as of November 1st, 2025.

Al-Gous International Company is a family-owned company specialized in supplying and trading truck spare parts, lubricants and greases. Al-Gous International Company has many exclusive distribution and/or authorized distribution agreements with several major and leading manufacturers of original spare parts from the European Union countries, Turkey and China.

NEW SUPPLIERS

TRUCK

We are pleased to introduce to you the latest suppliers that joined our progressive worldwide community:

Cummins Meritor, is a USA-based global market leader, offering a wide range of industry-leading drivetrain systems, including axles, brakes, suspensions, drivelines and aftermarket parts, for the commercial vehicle and industrial markets. Cummins’ extensive drivetrain solutions include axles, brakes, carriers, drivelines, gearboxes and power take-offs, gears, suspensions, tire inflation systems, transfer cases and transmissions for Truck, Bus and Trailer applications.

Cummins has been in the industry since 1919 and is known for its high-quality components and robust catalogue.

Cummins Meritor

cummins.com

Main contact person: Terry Livingston, Sr Sales Dir, Nat’l Accounts

Email: terry.livingston@cummins.coms.com

Cummins Meritor has joined NEXUS Automotive as from 1st of January 2025.

NEW SUPPLIERS

Shell is an international energy company with expertise in the exploration, production, refining and marketing of oil and natural gas, and the manufacturing and marketing of chemicals. They use advanced technologies and take an innovative approach to help build a sustainable energy future.

Shell Lubricants

shell.com

Main contact person: Pol Christophory, Regional Key Account Manager

Email: Pol.Christophory@shell.com Shell Lubricants has joined NEXUS Automotive as from 1st of January 2025.

Welte Cardan-Service

welte-group.com

Main contact person: Stefano Ananasso, Team Leader Driveshaft Sales International

Email: stefano.ananasso@welte-group.com

Welte Cardan-Service has joined NEXUS Automotive as from 1st of January 2025.

Welte Cardan-Service is a leader in the field of cardan shaft technology with several locations in Europe. The company goal is to offer our customers high-quality cardan shafts and components that are focused on reliability, durability and efficiency.

We are pleased to announce that Solera has joined NEXUS as a Listed Supplier with global scope. This partnership marks a significant step in further developing our innovative capabilities and bringing unique solutions to our member network worldwide.

Solera, a Texas-based global leader in risk management, asset protection, and datadriven solutions for the automotive and insurance industries, operates in 88 coun-

Solera

Solera has joined NEXUS Automotive as from 1st of January 2025.

tries across six continents. Their expertise in digital identity management, re-underwriting, and advanced analytics will provide our members with cutting-edge tools to optimize their operations and enhance decision-making. By integrating Solera’s industry-leading solutions into our network, we are strengthening our commitment to innovation, efficiency, and value creation for our members. We look forward to unlocking new opportunities together.

INS ! DE TRUCK INSIDERS SUSTAINABILITY SOLUTIONS FOR FLEETS

WELCOME TO TELOS AS NEW MEMBER

Davide Ghioni, CEO Telos

How do you see the future of the automotive aftermarket in a short term, in a long term in a challenged context (electrification, AI,…)?

The automotive aftermarket is constantly evolving, making it challenging to predict long-term impacts. It’s essential to monitor market trends and be prepared to respond, not by moving too early, but by seizing the right moment to support our clients and guide them through these changes.

What are you expecting from N! community?

What are your reasons to be proud to join NEXUS?

We are proud to be part of Nexus, as we see it as the most valuable international partner today. It plays a key role in supporting our supplier relationships and provides us with valuable insights

for both commercial growth and brand development.

Moreover, having recently entered the truck sector, the expertise and resources available through Nexus will be a tremendous asset for us.

What are you willing to bring to N! Community?

We would be glad to offer our experience and support, if needed, in the two-step spare parts distribution market. Over the years, we have built strong expertise in garages networks, marketing, and logistics. In particular, over the past year, we have focused on enhancing our distribution and operational structure, launching our first hub with an automated Autostore warehouse.

Could you tell us more about Autostore?

Of course, AutoStore is an innovative automated warehouse system designed to maximize space, speed, and precision in logistics. With this solution, we can further boost our logistics performance and deliver an even faster, more efficient, and high-quality service to all our customers.

TRUCK

Telos S.p.A. was founded in January 2025 from the merger of Telos Lombardia and Telos Gs. Telos S.p.A. is the reference partner for workshops across Northern Italy. Centralized offices to be mor e efficient and synergistic in the development of strategic activities; training rooms and operational showrooms. In 2025, the company also introduced the Truck division, further expanding its range of products and services.

122.7 Mln turnover

Over 500 employees 46 branches

60 Area sales representatives

8 regions covered https://www.telosspa.it/

All of this is fully available to garages that want to join the Telos world. September 2025 marked another important milestone: the opening of Telos Spa’s logistics hub, equipped with an automated warehouse powered by AutoStore technology. An investment that enables faster and more efficient goods management, benefiting the entire distribution system and workshop services.

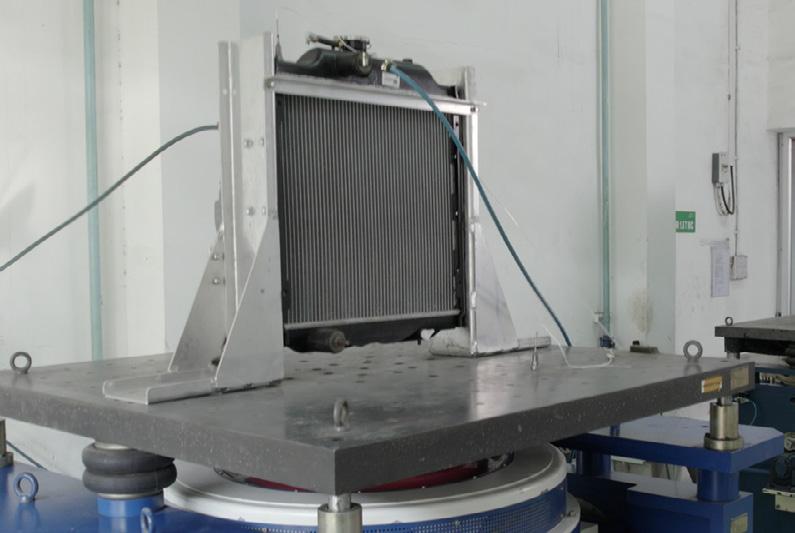

N!ACADEMY HEAVY-DUTY TRAIN THE TRAINER WEEK 2025

Empowering Technical Excellence Across Europe

The N!Academy Heavy-Duty Train the Trainer Week, held in Solec Kujawski, Poland, from 15–19 September 2025, brought together leading suppliers, trainers, and workshop professionals for five days of intense technical knowledge-sharing. Hosted by Autos Sp. z o.o., the week highlighted cutting-edge technologies, practical repair insights,

and the collaborative spirit driving the NEXUS community forward.

Day 1 – Powering Fleets with Lubricants and Batteries

The week began with two dynamic sessions led by industry leaders. TotalEnergies. Trainer Andrzej Husiatyński introduced the new RUBIA OPTIMA range, specifically designed for heavy-duty truck manufacturers, and

TRUCK

presented LubANAC, the advanced oil analysis solution that helps workshops and fleets optimize maintenance schedules and boost performance.

In the afternoon, Exide Group. Trainers Krzysztof Najder and Maja Tylkowska, addressed a fundamental challenge: ensuring “Right battery, right fit.” Their new Commercial Vehicle range structure was presented alongside practical fitment guidance, giving participants tools to guarantee reliability and efficiency in every installation.

Day 2 – Diesel Expertise and Diagnostic Depth

Tuesday shifted the spotlight to Delphi Technologies. Trainers Tomasz Hurt, Mihai Eugen Popa, and Andrzej Bojakowski delivered comprehensive sessions covering the diesel repair

program, including test equipment, starters & alternators, and advanced diagnostics.

With modern diesel systems becoming increasingly complex, Delphi’s training provided participants with hands-on knowledge and diagnostic strategies that can be directly applied in workshops, ensuring faster, more accurate repairs.

Day 3 – Braking Systems and Transmission Technologies

Midweek saw technical deep dives into vehicle safety and drivetrain innovation. In the morning, Knorr-Bremse. Trainers Virginijus Pranckevicius and Rafał Andraka presented the iTEBS X modulator OCT and showcased the KB Diagnostics online configuration tool. This new digital platform equips technicians

with streamlined diagnostic capabilities for modern braking systems.

The afternoon session was led by ZF Group, where Grzegorz Arbajter explored clutch technology in the context of automated transmissions, including the renowned TRAXON gearbox and upcoming ZF innovations. The training reinforced the critical link between precision clutch systems and optimal transmission performance.

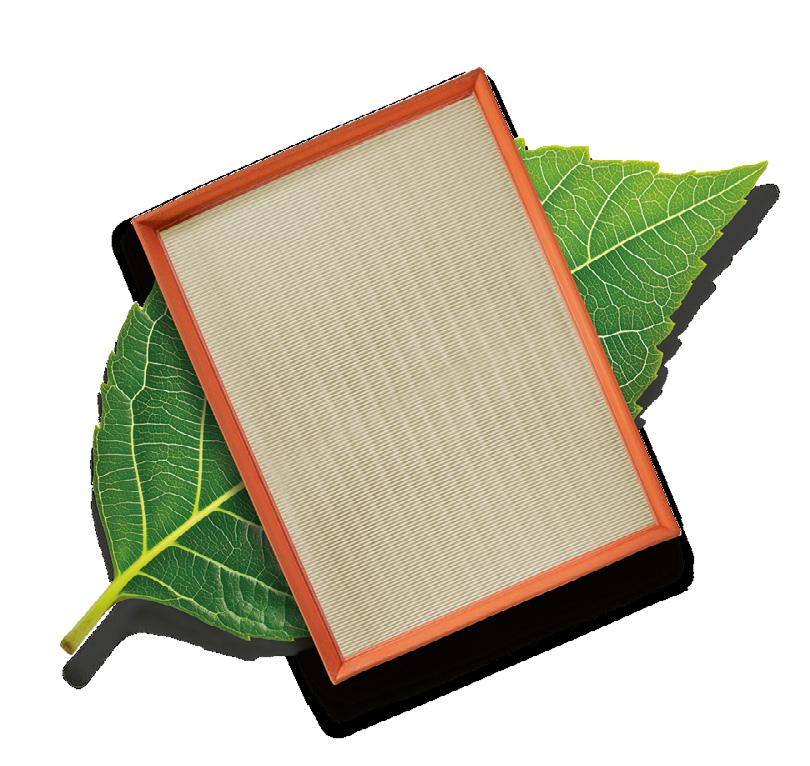

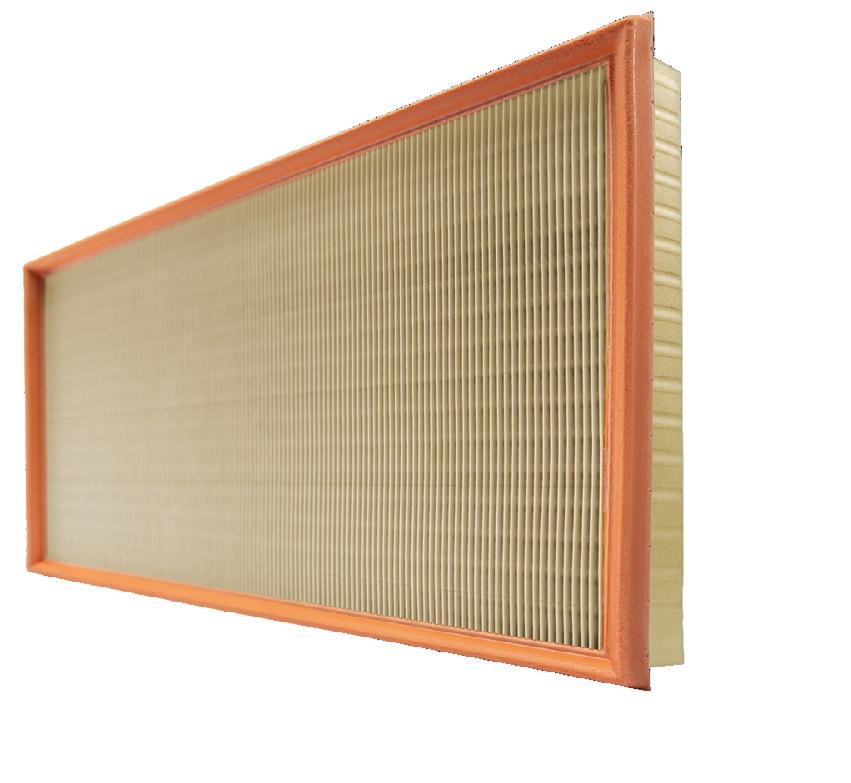

Day 4 – Filtration and Emission Solutions for Sustainable Mobility

Thursday emphasized environmental performance and sustainability. MAN-

N+HUMMEL experts Andreas Schirra and Arkadiusz Szafrański presented the MANN-FILTER CV range, underlining best practices in commercial vehicle filtration.

Participants also toured Autos Sp. z o.o. facilities with Karol Filarski, including an exclusive look at the NEXUSTRUCK mobile concept in action.

In the afternoon, Dinex Group specialists Karlis Banis and Janusz Kryskowiak guided participants through emission system maintenance, covering NOx sensors, AdBlue pumps, injectors, and DPF reconditioning. Their session high-

lighted the crucial role of proper exhaust system management in extending vehicle lifespan and reducing environmental impact.

Day 5 – Advanced Diagnostics to Drive Workshop Excellence

The final day was dedicated to advanced diagnostics with Cojali S.L. Trainer Juan Ignacio Garcia Navarrete delivered an impactful program covering diagnostic fundamentals, hands-on vehicle diagnostics, and special repair tools.

This session tied together the week’s focus: equipping trainers with not only theoretical knowledge but also the practical skills needed to transfer expertise across the NEXUS network.

Shaping the Future of Heavy-Duty Training

The 2025 N!Academy Train the Trainer Week in Poland was more than a training

program—it was a knowledge accelerator. Each session reinforced the NEXUS commitment to empowering workshops with cutting-edge expertise, innovative tools, and practical solutions that drive efficiency, sustainability, and excellence in the heavy-duty sector.

As our industry evolves, N!Academy will continue to stand at the forefront, preparing trainers and technicians to master the technologies, shaping tomorrow’s mobility.

Thank you to all trainers, partners, and participants for making this week an outstanding success. Together, we are building stronger expertise and a more sustainable future for heavyduty mobility.

NEXUS AUTOMOTIVE INTERNATIONAL REPRESENTED

IN THE EUROPEAN TRUCK RACING CHAMPIONSHIP IN 2025

For years, NEXUS Automotive International has been active in the European Truck Racing Championship (ETRC) – one of the most thrilling motorsport competitions on the continent. The 2025 ETRC season will feature eight adrenaline-packed racing weekends hosted at some of Europe’s most iconic racing circuits, including venues in Italy, Germany, Slovakia, Belgium, the Czech Republic, France, and Spain.

More than just a motorsport championship, the ETRC is a powerful networking platform for the entire truck industry. It brings together key players from across the sector and serves as an excellent meeting point for Independent Aftermarket distributors and suppliers, particularly those operating in the Heavy-Duty segment.

For the 2025 season, NEXUS is excited to support the young and ambitious German racing team – Kursch Kurtscheid Racing. The team has stepped up to compete in the ETRC’s top-tier cham-

pionship for the very first time. Behind the wheel is Stefan Kursch, a determined and talented driver who earned valuable racing experience in the Dutch Truck Racing Championship over the last few years. Known for his aggressive yet calculated driving style, Stefan is ready to take on Europe’s best.

The team entered the season with a newly built MAN racing truck, engineered specifically for 2025. It has been equipped with high-performance, high-durability spare parts provided by proud NEXUS Suppliers – a testament

to the quality and resilience of parts available through the NEXUS network.

The NEXUS-backed Kursch Kurtscheid Racing Team is grateful to all sponsors and partners for making this project possible. Their unwavering support and commitment to quality continues to drive innovation and excellence both on and off the racetrack.

As the team powers through an exciting 2025 season, NEXUS is already looking forward to what 2026 has in store. Stay tuned and see you at the races!

RESILIENCE AND GROWTH TAKE

CENTER STAGE AT THE VIPAR HEAVY DUTY 2025 IMPACT CONFERENCE

From the opening remarks by VIPAR Heavy Duty President & CEO Chris Baer to the closing message from keynote speaker Tony Hawk, the 2025 IMPACT Conference delivered a powerful and recurring theme — Resilience.

The independent heavy duty aftermarket has navigated a period of significant challenges since the network last gathered, including uncertainty surrounding tariffs, freight, regulations, and supply chain pressures, as well as the accelerating need to adopt advanced technology tools such as artificial intelligence and enterprise resource planning sys-

tems. Despite these headwinds, VIPAR Heavy Duty reports continued growth in both its distributor network and business initiatives.

“The IMPACT Conference is a powerful reminder of the strength and adaptability of our network. Coming together in person allows us to deepen rela-

TRUCK

tionships, share insights, and align on strategies that ensure we are all better equipped to face challenges and seize opportunities,” said Baer.

This year’s strong attendance showed that the network is engaged and looking to the future. An impressive combination of attendees, 1:1 Meetings, and trade show booths provided ample opportunity to explore new business channels and plan for the future.

Baer set the stage on opening day with an update on the current state of the VIPAR Heavy Duty network.

Conference Highlights Expansion Across the Americas: Distributor growth is apparent in the number of companies and points of sale, and in the success of those distributors who are excelling with just one location. In addition, VIPAR Heavy Duty continues to expand its presence in Central and South America, adding new stockholders in Guatemala, El Salvador, Venezuela, and Colombia. These distributors are helping to build the network in new regions, bringing market expertise and vision to new areas.

Operational Excellence and Innovation:

The conference showcased major initiatives, including the implementation

of an Oracle NetSuite ERP system, the launch of PARTSPHERE RMS 2.0, automation in the Global Parts Network reman brake process, and enhancements to PARTSPHERE PIM & DAM product data systems. These innovations are improving efficiency, competitiveness, and service.

Supplier Partnerships:

VIPAR Heavy Duty highlighted collaboration with suppliers, encouraging them to expand and contribute to growth in new markets. Several suppliers were recognized for their engagement and support, aligning with VIPAR across the Americas in both strong existing programs and creative new offerings.

Training and Development: Through initiatives like the Nucleus Knowledge Center, VIPAR Heavy Duty continues to prioritize training and professional development, addressing critical workforce needs and supporting the next generation of industry leaders.

Strengthening Leadership for the Future:

Baer announced that in a special motion, the VIPAR Heavy Duty Board of Directors voted to appoint current Vice President of Marketing, Jeff Paul, to Executive Vice President as of Jan. 1, 2026. “Jeff sets a high bar for commitment, drive, and integrity, and our organization is fortu-

nate to have him to guide the ship in future years,” said Baer.

Baer also announced that Jim Pennig, who retired from his position as Vice President of Business Development this past summer, will return to the company to redesign its national accounts program.

VIPAR Heavy Duty leadership was joined by guest speakers from the industry to provide a well-rounded agenda.

Jeff Paul, Vice President of Marketing

• Shannon O’Brien, Commercial Vehicle Lead for MEMA Aftermarket Suppliers presented “Suppliers Respond: Insight from the Front Lines.” Her research, conducted exclusively for VIPAR Heavy Duty, combined a detailed supplier survey and in-depth interviews to provide meaningful feedback to distributors on shared challenges and opportunities with suppliers.

• John Kairys, Executive Director of the Automotive Aftermarket Charitable Foundation shared the AACF story with IMPACT Conference attendees at various sessions and a trade show booth. The AACF is a 501(c)(3) organization that supports people employed in the heavy duty aftermarket industry and their families during times of hardship. They were the beneficiary of this year’s IMPACT Memorial Golf Outing. VIPAR Heavy Duty was proud to enter into a new partnership with AACF earlier this year to support their fundraising efforts and raise awareness.

• Thierry Mugnier, Founding Partner and CFIO of NEXUS Automotive International SA, spoke to suppliers about the Latin American expansion opportunities available to them through VIPAR Heavy Duty’s partnership NEXUS. He emphasized NEXUS’ goal to create

TRUCK

stronger alignment between its North American and European organizations, noting that collaboration and shared responsibility among distributors and partners are essential to the network’s success. He also highlighted that by the end of 2025, VIPAR Heavy Duty will represent the largest and strongest group of heavy duty distributors within the NEXUS community.

The conference concluded on a high note with a keynote presentation from legendary skateboarder and entrepreneur Tony Hawk. From his first shaky ride on his brother’s skateboard (and a handful of splinters!) to becoming a global icon, Hawk’s story was one of resilience, creativity, and relentless determination. Every fall became fuel to rise higher — on the ramp, in business, and in life. He’s helped make skateboarding a legit cool sport — one kids now choose the same way they choose baseball or soccer.

“Skating is an individual endeavor with a huge sense of community,” Hawk shared. “If I’ve helped make skateboarding more acceptable, that’s my greatest legacy.” His message reminded the heavy duty audience that passion, perseverance, and purpose can build lasting impact — no matter the field.

The 2026 VIPAR Heavy Duty Family of Companies IMPACT Conference is scheduled for Oct. 18-23 at the JW Marriott Marco Island in Marco Island, Fla.

30 YEARS OF NELAS AUTO PARTS

In early October, Nelas Auto Parts celebrated its 30th anniversary. The gala dinner was attended by representatives of leading auto parts manufacturers in Europe, as well as the company’s largest customers in Bulgaria. We cele-

brated the past 30 years, but with an eye on the future.

The story begins in 1995, when the company was founded with the clear goal of providing spare parts, lubricants

and consumables for trucks and trailers, with a guarantee of reliability and quality.

Today, Nelas Auto Parts is a leading importer and distributor of spare parts, consumables and lubricants and a leader in the commercial vehicle segment in Bulgaria.

With 9 own branches in 8 of the largest cities in Bulgaria. Over 12,000 sq. m. of warehouse space all over the country and over 60,000 active positions available in stock.

Currently the company works with 150 suppliers, of which 65 are leading OE manufacturers.

More than 5,000 customers in Bulgaria. Our customers are mainly HD workshops, fleets and construction companies that rely on Nelas Auto Parts professionalism.

Our aim is to provide the best service, with high-quality auto parts, and to remain a fair partner to all our customers and suppliers.

INS ! DE TRUCK INSIGHTS FROM THE AFTERMARKET WORLD AND BEYOND

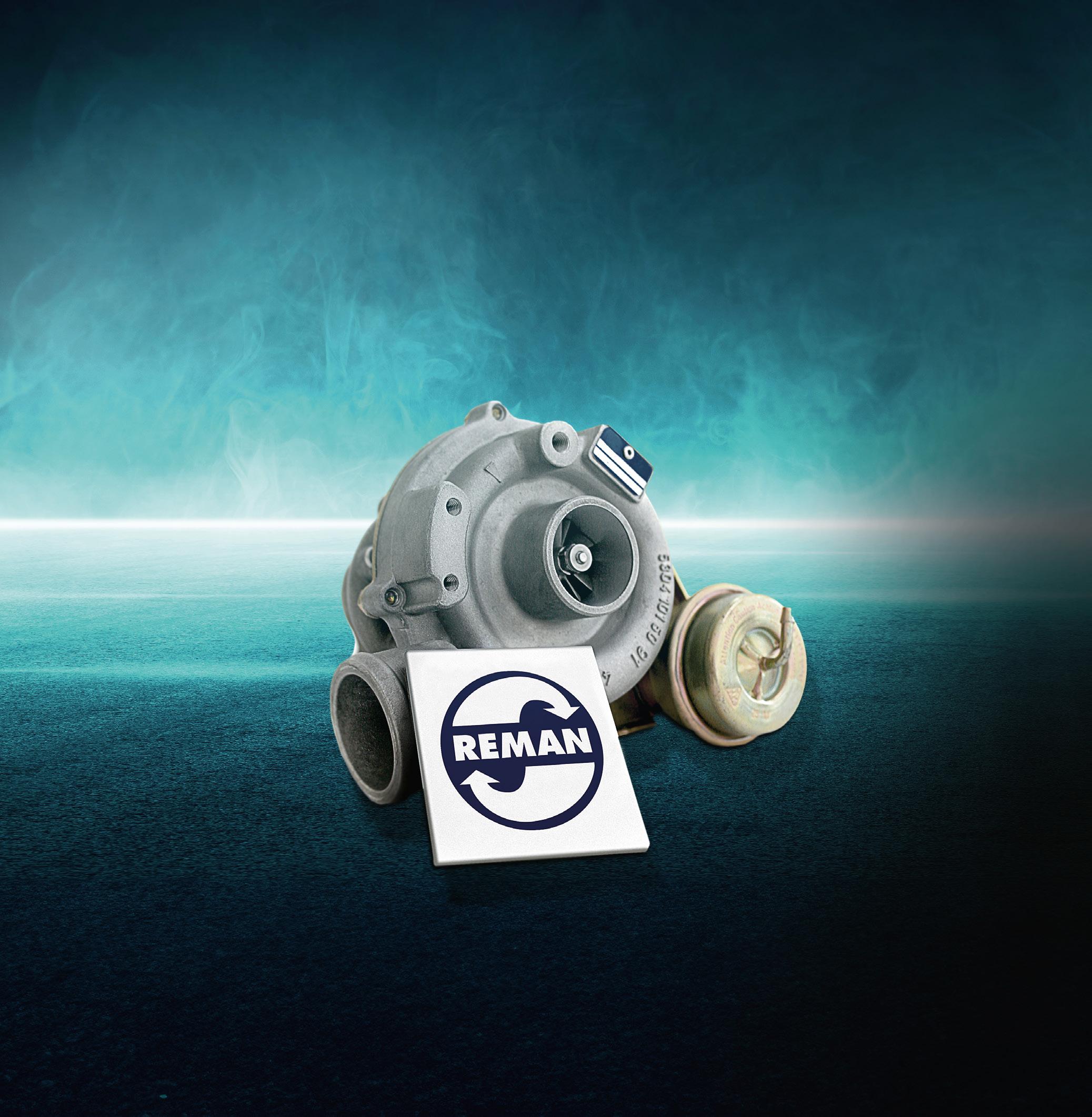

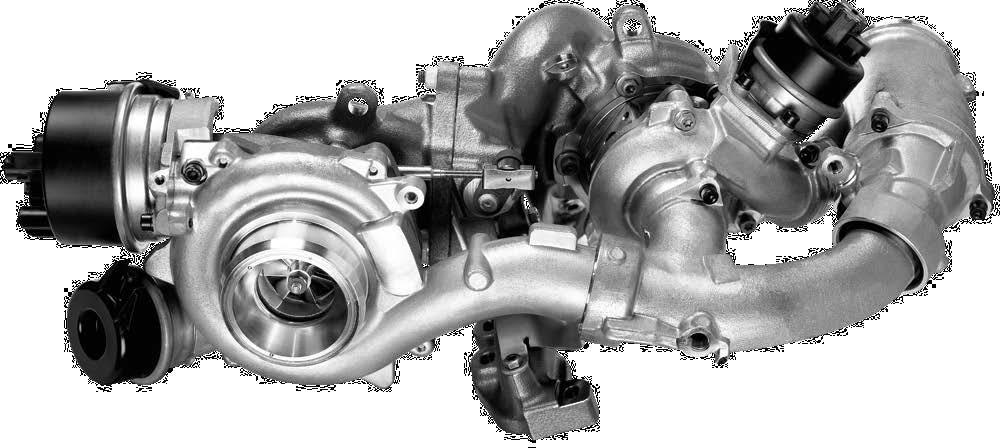

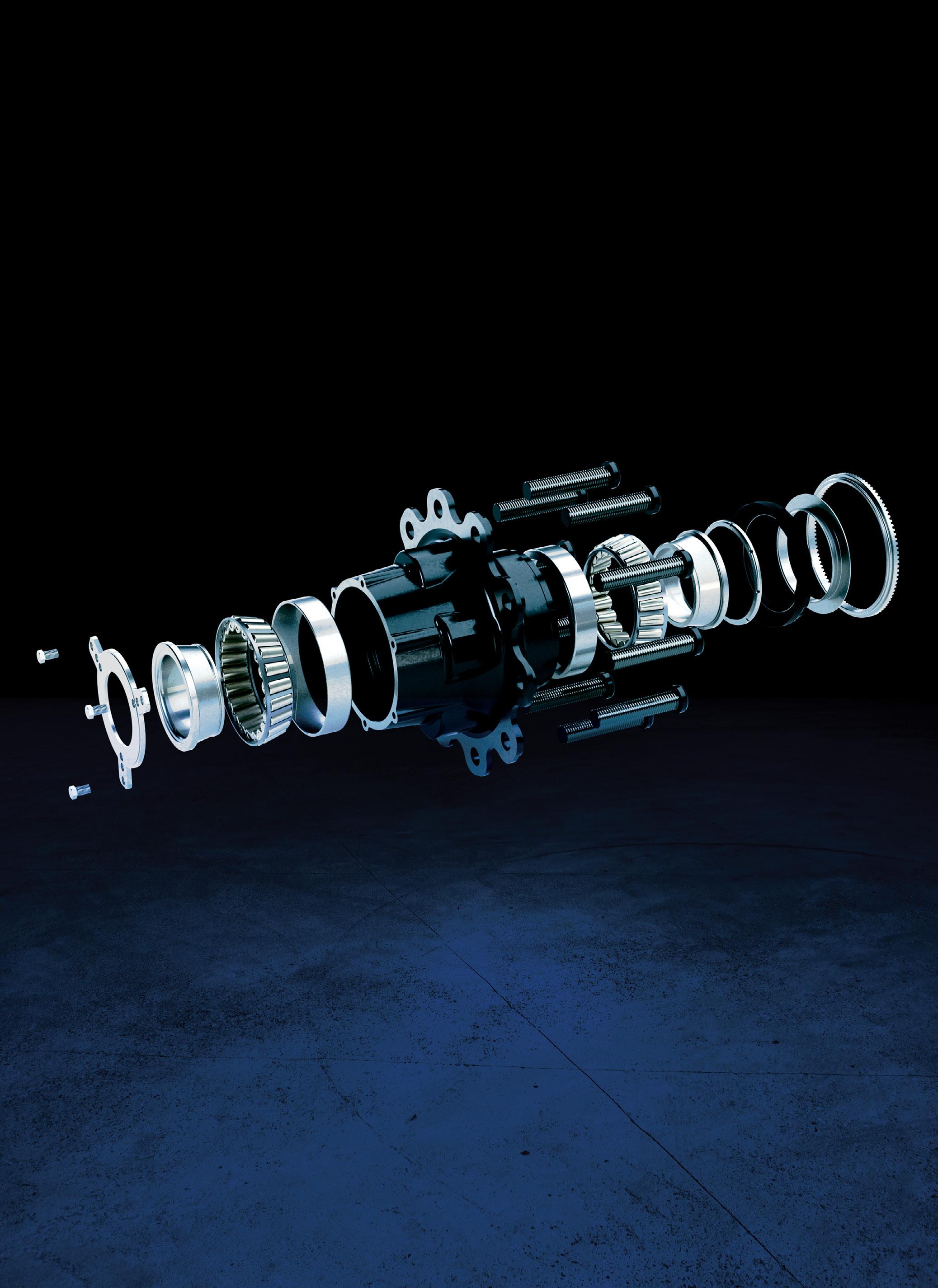

EXCELLENCE REBORN: BORGWARNER REMAN TURBOCHARGERS FOR COMMERCIAL VEHICLES

BorgWarner REMAN turbochargers represent excellence reborn— remanufactured from original components to deliver a sustainable, cost-effective, and high-performance solution tailored to the demanding needs of commercial vehicles and fleet operations. Each REMAN turbocharger undergoes a meticulous process of dismantling, cleaning, reprocessing, and rigorous testing to ensure it meets the same high standards of quality and reliability as new OE components.

A Smart Choice for Fleets

For fleet operators, vehicle uptime, fuel efficiency, and long-term cost control are essential. BorgWarner REMAN turbochargers offer a practical solution by combining the performance and reliability of a new turbocharger with the economic and environmental advantages of remanufacturing. With decades of experience, BorgWarner provides a wide range of REMAN turbochargers that cover numerous applications across commercial vehicles, buses, agricultural, and construction machinery.

These turbochargers are engineered to perform under tough operating conditions, helping fleets stay on the road longer while minimizing maintenance-related downtime.

Cost-Effective Without Compromise

REMAN turbochargers are a smart investment for fleet managers looking to reduce operating costs without compromising on quality. By reusing core components and applying advanced remanufacturing techniques, BorgWarner delivers a product that

meets OE standards while offering significant savings compared to new parts. Many fleet operators also appreciate the availability of warranty coverage, which adds an extra layer of confidence.

Sustainability That Works for Business

Built for the Long Haul

BorgWarner’s strong corporate culture— centered on safety, teamwork, and environmental responsibility—ensures that every REMAN turbocharger meets rigorous industry standards. For commercial vehicle operators, this means dependable performance, lower total cost of ownership, and a reduced environmental footprint—all without compromising on quality.

Sustainability is increasingly important in the commercial vehicle sector. BorgWarner REMAN turbochargers support a circular economy by reducing waste, conserving raw materials, and lowering the environmental impact of component production. For fleets aiming to meet environmental goals or enhance their sustainability credentials, REMAN turbochargers offer a responsible and effective solution.

OE Competence for the Aftermarket

Driving your business. Now and in future.

As good as new

Our broad REMAN turbocharger portfolio provides sustainble, cost-effective, highquality solutions for vehicles in the later stages of their life cycles.

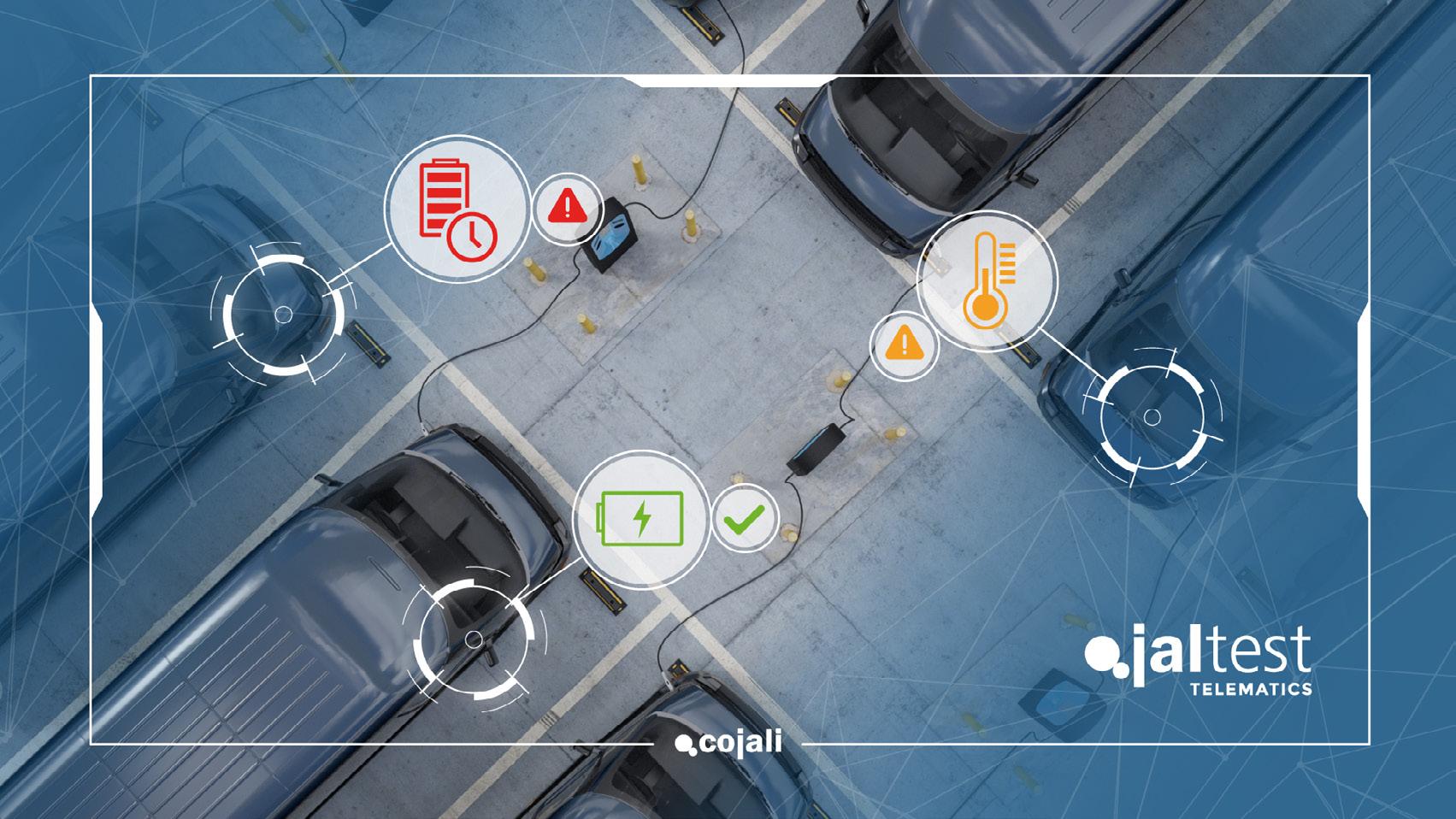

SUSTAINABLE SOLUTIONS FOR TRUCK FLEETS: COJALI’S CROSS-CUTTING COMMITMENT

In an era where sustainability is no longer an option, but an urgent need, the transport and logistics sector faces increasing pressure to reduce emissions, improve efficiency and adopt smart technologies. The Spanish multinational Cojali, manufacturer of leading technological solutions in the commercial automotive sector, has taken up this challenge by offering integrated and sustainable solutions for fleets worldwide.

Its focus covers key areas such as components for commercial vehicles, reconditioned electronics, advanced diagnostics and telematics for fleet management. Through its brands Cojali Parts, Cojali Reman, Jaltest Diagnostics and Jaltest Telematics, it provides operators with a complete ecosystem that combines operational efficiency, technical reliability and environmental commitment.

TRUCK

Parts that ensure long-term performance and sustainability

To move towards cleaner and more efficient mobility, it is essential to start with a solid foundation: durable and reliable components. In this sense, Cojali Parts offers a wide range of mechanical, pneumatic, electrical and electronic parts designed under the highest quality standards to extend their useful life. This durability reduces the frequency of replacement, which reduces waste generation and the associated environmental impact. In addition, high-quality components minimise breakdowns, reduce downtime and improve on-road efficiency. In short, the quality of spare parts is not only a technical guarantee: it is a strategic cornerstone for moving towards a cleaner and more sustainable transport model.

Giving electronics a second life: a commitment to circular economy

Added to this robust foundation is a responsible approach to reuse. Through Cojali Reman, Cojali is committed to the reconditioning of electronic components, recovering control units, actuators and other key devices to give them a new life with full guarantees. This process reduces the volume of electronic waste, avoids the unnecessary manufacture of new parts and conserves raw materials. It is a solution that combines sustainability and cost-effectiveness, as it gives fleets access to reconditioned components with warranty and at a lower cost. With this solution, encompassed under the name of Green Cojali, the company reinforces its commitment to circular economy, making recondi-

tioning a strategy of high environmental and economic value.

Intelligent diagnostics to

anticipate

problems

and improve performance

Prevention is key to sustainability. Jaltest Diagnostics, Cojali’s multi-brand diagnostics solution, allows workshops and fleets to maintain their vehicles accurately and proactively. Their ability to detect faults before they become serious failures is crucial, especially in systems that directly affect emission control, such as EGR, DPF or SCR.

Detecting these problems early helps to keep the engine calibrated, ensure fuel efficiency and significantly reduce pollutant emissions. An engine running in optimal conditions not only pollutes less, but also extends its service life and optimises its performance.

In addition, Jaltest Diagnostics relies on a complete ecosystem that includes specialised training for technicians and solid after-sales support, ensuring that the human factor is always aligned with technological requirements. Fewer failures, optimised operations and better maintained vehicles are key pillars in building a truly sustainable fleet.

Connectivity

as an accelerator of sustainable decisions

Completing this technical and preventive vision, Jaltest Telematics introduces a connectivity layer that transforms fleet management. This solution enables real-time monitoring, geolocation, driver behaviour analysis and,

crucially, remote diagnostics, facilitating continuous and effective vehicle health monitoring.

Predictive maintenance and remote diagnostics help anticipate failures, reduce unplanned downtime and avoid unnecessary travel, improving operational efficiency and reducing the environmental footprint. This is in addition to advanced eco-driving tools that analyse driving style —braking, acceleration, RPM usage— and offer specific recommendations to reduce fuel consumption and optimise routes. Thus, every technical decision becomes a real opportunity to build more intelligent, efficient and sustainable logistics.

A global vision for sustainable mobility

In short, Cojali’s strength lies in its ability to offer an interconnected technological ecosystem where each solution empowers the others. Jaltest Diagnostics provides accurate and critical information that feeds Jaltest Telematics platforms, enabling predictive and connected fleet management. These intelligent decisions translate into more efficient interventions, supported by the use of reconditioned components from Cojali Reman, with a clear commitment to circular economy. All this is underpinned by the technical reliability of Cojali Parts, which ensures maximum performance with the lowest environmental impact.

EMBEDDED TECHNOLOGICAL SOLUTIONS FOR SUSTAINABLE FLEETS

SUSTAINABLE SOLUTIONS FOR FLEETS

HOW CIRCULARITY IN TIRES AND DIGITAL INSIGHTS TURN PRESSURE INTO PERFORMANCE

Fleet managers today face a complex landscape of rising costs, evolving regulations, and increasing pressure to reduce emissions. Yet, within these challenges lie opportunities to transform operations and achieve unprecedented levels of efficiency. According to a 2024 survey of 850 fleet managers across the US, UK, France, and Germany, a significant majority identified cost pressure and sustainability as top concerns. More than half of respondents expressed concern about their fleet’s competitiveness over the next five years if substantial changes are not made.

TRUCK

The tire paradox

While tires represent a small fraction of direct fleet costs—approximately two percent—they exert a disproportionate influence on overall expenses. From fuel consumption and maintenance to downtime and safety, tires affect nearly half of a fleet’s operating costs. This makes them a strategic lever for cost optimization. Continental’s Lowest Overall Driving Cost (LODC) approach recognizes this and begins with tire selection and management, extending into retreading, casing programs, and digital tire monitoring.

Contilifecycle: circular economy in action

Continental’s ContiLifeCycle program embodies a holistic approach to tire sustainability. It integrates premium new tires, casing management, retreading, and recycling into a closed-loop system. The foundation of this model is the durable casing, engineered to withstand multiple life cycles. Through the ContiCasingAccount, fleets gain transparency and flexibility in managing their casings rom inspection and storage to crediting and disposal. Recycled rubber from end-of-life tires is reintegrated into new compounds, reinforcing the circular economy.

Retreading in focus

Retreading is a cornerstone of sustainable fleet management. In the EMEA region, approximately 20% of replacement truck tires are retreaded. Continental offers two retreading solutions: ContiRe and ContiTread. ContiRe

employs hot vulcanization to renew tires bead-to-bead, using the same technology and safety standards as new tires. ContiTread applies pre-cured tread patterns delivering reliable performance with reduced environmental impact. These solutions are available across a wide range of applications, from longhaul and urban transport to construction and winter conditions.

The benefits of retreading are substantial. Internal studies show that retreaded tires can reduce CO₂ emissions by up to 85%, save up to 55 kg of material per tire, and cut tire costs by up to 50%. Moreover, retreaded tires offer comparable mileage to new tires without compromising safety, making them a smart choice for fleets aiming to balance performance with sustainability.

Digital + circular: amplifying gains

Digital tire management solutions like ContiConnect enhance the value of circular tire strategies. By providing realtime data on pressure, temperature, and mileage, these systems enable proactive maintenance and reduce the risk of breakdowns. Case studies from Klaus Baum Logistik, Bus Company SRL, and Turner Transport Ltd illustrate the impact: improved fuel efficiency, reduced manual checks, and enhanced safety. With digital tire management, fleets can maintain efficient tire conditions, extend tire life, and minimize environmental impact.

A roadmap to sustainable fleet management

Implementing sustainable tire strategies requires a structured approach. It begins with an LODC audit to identify cost drivers and inefficiencies. Protecting casing value through proper inflation and timely maintenance ensures retreadability. Defining a retreading policy aligned with operational needs helps standardize practices. Digital tools like ContiConnect should be embedded into daily workflows, enabling data-driven decisions. Finally, tracking key performance indicators such as CO₂ savings, material usage, and cost per kilometer provides measurable outcomes and supports continuous improvement.

Overcoming adoption barriers

Despite the clear benefits, adoption of new technologies like Digital Tire Monitoring can be hindered by high upfront costs, unclear return on investment, and lack of strategic direction. Fleet managers cite ease of implementation, user-friendly interfaces, and compatibility with existing systems as critical enablers. Flexibility to meet specific fleet needs is also essential. Early adopters tend to experience fewer cost pressures and greater operational resilience, underscoring the value of proactive transformation.

Looking ahead: the connected, circular fleet

Continental envisions a future where fleets are fully connected and circular. Intelligent tires equipped with sensors will communicate their status in real time, enabling seamless servicing without yard downtime. Retreaded tires will be tracked and reintegrated into inventory, supporting sustainability goals. Predictive maintenance will replace reactive repairs, and data will drive every decision. This vision is not just aspirational it is achievable with today’s technology and a commitment to change.

ROGIER VAN DER OUDERAA, Product & Supply Chain Director, Aftermarket

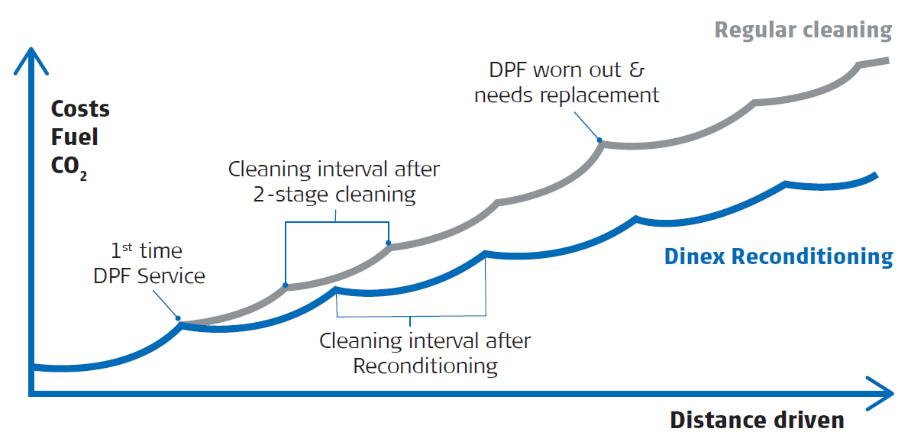

DPF RECONDITIONING: A SMARTER, GREENER WAY TO KEEP FLEETS MOVING

If there’s one word fleet owners dread more than “costs,” it’s “downtime.” Trucks are built to deliver — not sit idle for frequent DPF cleaning or premature replacements. The good news? There’s a smarter solution that cuts delays, saves money, and is more sustainable.

The Diesel Particulate Filter (DPF) removes over 99.9% of ultra-fine soot particles from exhaust gases, virtually eliminating exhaust particulate pollution from trucks and buses. To keep the flow open, it regularly burns soot into ash — but sooner or later, that ash must be removed. The question is: settle for routine cleaning, or choose a solution that restores near-new performance, extends service intervals, and lowers total ownership costs?

Why “Cleaned” Isn’t Always Clean Enough

Regular cleaning (“Bake’n’Blow”) is simple: heat the DPF to loosen ash, then blow it out with air or water. In 24–48 hours the truck is back on the road — with what looks like a clean filter. But studies show up to 50% of ash remains, often hardened after months of service and regenerations.

Think of it like vacuuming the cab: the loose dirt disappears, but the grit ground into the mat stays put. In a filter, that buildup shortens cleaning intervals by up to 30% and blocks the catalytic coating, triggering more fuel-hungry, mechanically stressful “Active Regeneration” cycles. You’re not starting fresh — you’re patching a worn filter and bringing replacement closer.

That’s why Dinex recommends an approach that restores near-new performance, keeps longer service intervals, and lowers costs.

A Better Process, and a Smarter Service

TRUCK

The Dinex Reconditioning Program solves three major DPF cleaning challenges:

1. Residual ash removal – Our OE-endorsed, 3-stage process removes on average twice as much ash — even hardened deposits — restoring catalytic properties, extending service intervals, and improving passive regeneration.

2. Downtime reduction – With our vast distribution network, there’s no 24–48 hour wait. Swap your used filter for a Dinex reconditioned unit — complete with clamps and gaskets — and be back on the road in under an hour.

3. Peace of mind – All filters come with a 2-year warranty and full Type Approval. Return your used filter in the original packaging for a refund once it passes our market-leading acceptance criteria, enabled by our ability to repair minor dimensional and mechanical damage.

ARTICLE HIGHLIGHTS

By choosing Dinex DPF reconditioning over traditional cleaning, fleets not only benefit from 2 years warranty and full Type Approval, but can also achieve:

• Up to 30% longer DPF service intervals

• Lower costs for fuel and replacements

• Up to 1,8 kg less CO₂ per 1,000 km

From Downtime to Drive Time

In trucking, every hour of uptime counts. Regular cleaning only buys time — reconditioning restores near-new performance, extends service intervals, and cuts fuel-wasting active regenerations. By removing hardened ash, we

DID YOU KNOW?

Producing a DPF emits about 500 kg of CO₂. Reconditioning extends durability, saves fuel, and can cut up to 3,2 ton CO₂ over its expected life.

extend filter life, lower CO₂ in the value chain, and back it with Type Approval and a 2-year warranty.

Less downtime and more stability aren’t just convenient — they’re a competitive edge. Dinex reconditioning keeps you moving, day after day.

More Drive Time. Less Footprint.

Dinex DPF Reconditioning is an alternative to traditional cleaning, that keeps you on the road longer, cuts costs, and builds more circularity into your business — a smarter choice, for smarter fleets.

OE-Endorsed Process

Removes up to 2x more ash, including hardened deposits.

Learn more in this short 5 minute video, or check out our website for the full range.

Reduces Down-Time

Extended cleaning intervals and less than 1 hour swapping.

Full confidence 2-years warranty and all Type Approved.

EXIDE TECHNOLOGIES STREAMLINES COMMERCIAL VEHICLE BATTERY RANGES WITH NEW PRODUCT LINE-UP, SMART LABEL DESIGN AND EASIER FITMENT

• Exide restructures its Commercial Vehicle portfolio for easier battery selection: GEL PRO, EFB PRO, SHD PRO and HD PRO

• Enhanced performance through design and manufacturing improvements

• New label design with easy product identification and clear color-coding by technology

• CV changes apply to all of Exide Technologies’ premium battery brands: Exide, Tudor, Fulmen, Centra and Sonnak

Exide Technologies, a leading provider of innovative and sustainable battery storage solutions for automotive and industrial applications, has streamlined its Commercial Vehicle (CV) battery

range with a simplified new battery line-up and a fresh new label design.

Starting in September, these CV updates are designed to strengthen product performance, clarify brand identity and bolster sustainability across Exide’s portfolio – while also making battery selection easier for customers.

Streamlined range structure

By restructuring its CV portfolio – new range line-up, intuitive naming and color-coded labelling by technology –Exide is offering customers consistency, clarification and compliance, plus a modern design that is easy to read. This ensures fleet managers and installers alike can find the battery they need first time, every time.

Exide Technologies simplifies its Commercial Vehicle battery range with a new line-up, smart labels, and easier fitment

TRUCK

• New CV portfolio: GEL PRO, EFB PRO, SHD PRO, HD PRO

• Improved performance through design and manufacturing upgrades

The new CV range consists of four product lines:

• Clear label design with color-coded technology identification

• Changes apply across Exide’s premium brands: Exide, Tudor, Fulmen, Centra, Sonnak

Exide Technologies has streamlined its CV battery offering with a simplified product structure and refreshed label design to improve performance, brand clarity, and sustainability.

GEL PRO: Made for extreme cycling. This VRLA battery with its original gel technology comes with OE pedigree and is highly robust, with best-in-class deep cycle properties. It allows unmatched safe depth of discharge of 90%, which improves Total Cost of Ownership (TCO) and minimizes the risk of breakdowns.

Simplified Range Structure

life and minimized risk of unexpected or premature battery failure. This battery is designed for long-haul modern and standard trucks with rear-chassis installations and/or hotel functions and has proven its performance and robustness in many OEM truck installations across Europe.

Improved Selection & Fitment

Exide has refined its Online Battery Finder to reduce confusion and speed up accurate replacements.

Technical & Sustainability Enhancements

The new line-up and intuitive naming help fleet managers and installers quickly identify the right battery. The four product lines include:

GEL PRO is ideal for express delivery trucks and city buses with power-hungry equipment and deep cycling needs. Its “T” version is dedicated to standard and long-haul trucks (with and without dual systems) thanks to its reinforced design and hotel function.

• GEL PRO – For extreme cycling and deep discharge, ideal for delivery trucks and city buses.

• EFB PRO – High durability and vibration resistance, suited for long-haul trucks with hotel functions.

• SHD PRO – Maximum cranking power for cold starts and heavy-duty vehicles.

• HD PRO – Reliable power for standard applications, covering nearly all vehicle types.

EFB PRO: Engineered for extreme durability. Exide EFB PRO comes with enhanced rechargeability and charge acceptance while offering the highest resistance to vibration due to its HVR technology. A tougher and longer-lasting battery means reduced TCO for fleet owners and truck drivers – fewer replacements over the vehicle’s service

SHD PRO: Maximum power at every start. This battery type is designed with more plates and active material to maximize grid surface, providing enhanced cycling and exceptional cranking power with every start. SHD PRO stands for Super Heavy Duty and is ideal for cold temperatures and for trucks, buses, or agricultural and construction vehicles with big engines. Its design is strong and reliable thanks to hotmelt fixation plate groups, making it a suitable choice for uneven roads.

Investments in European manufacturing have boosted product consistency and lifespan. New black plastic lids and boxes support circular production and increased use of recycled materials.

Guido Scanagatta, Director of Product Management, noted:

This update brings performance, efficiency, and environmental benefits, while making battery selection and replacement easier.”

HD PRO: Reliable power for standard use. This Heavy-Duty battery is the go-to battery for trucks without special requirements for vibration resistance, cycling capacity or extra cranking power.

The range covers nearly 100% of the vehicle parc, including special types.

Easier battery selection and fitment

As part of the update, Exide has also revised its Online Battery Finder recommendations. In the past, workshops could often see multiple options listed for the same truck or CV model –technically correct, but not always the most user-friendly. By streamlining and focusing the recommended choices, Exide has made fitment faster, clearer and more dependable. This refinement allows customers to save time and ensure accurate battery replacement.

Technical enhancements and circular design

Demonstrating its OE pedigree, Exide Technologies continues to invest in its European manufacturing sites, increasing automation and process controls for consistent premium products across its CV production. The company has also enhanced CV battery performance and lifespan, particularly for modern

long-haul applications, thanks to an advanced chemical composition of its batteries.

Furthermore, Exide’s complete CV range will feature black plastic lids and boxes in the future – enabling the increase of recycled plastics and circular production. This supports the company’s sustainability goals as it continues to reduce its environmental impact and Energize a new world.

Guido Scanagatta, Director Product Management and Application at Exide Technologies, said: “Implementing this refreshed and improved CV range has been a significant undertaking, and it is one that will bring performance, efficiency, simplicity and environmental benefits to the customer. It is part of our overall commitment to simplifying battery selection, enhancing fitment accuracy and making replacement even easier.

Made to keep you on the road.

The new and simplified range structure with a modern label design for easier product identification.

JÜERGEN EYRICH, Engineering Manager Vehicle Aftermarket

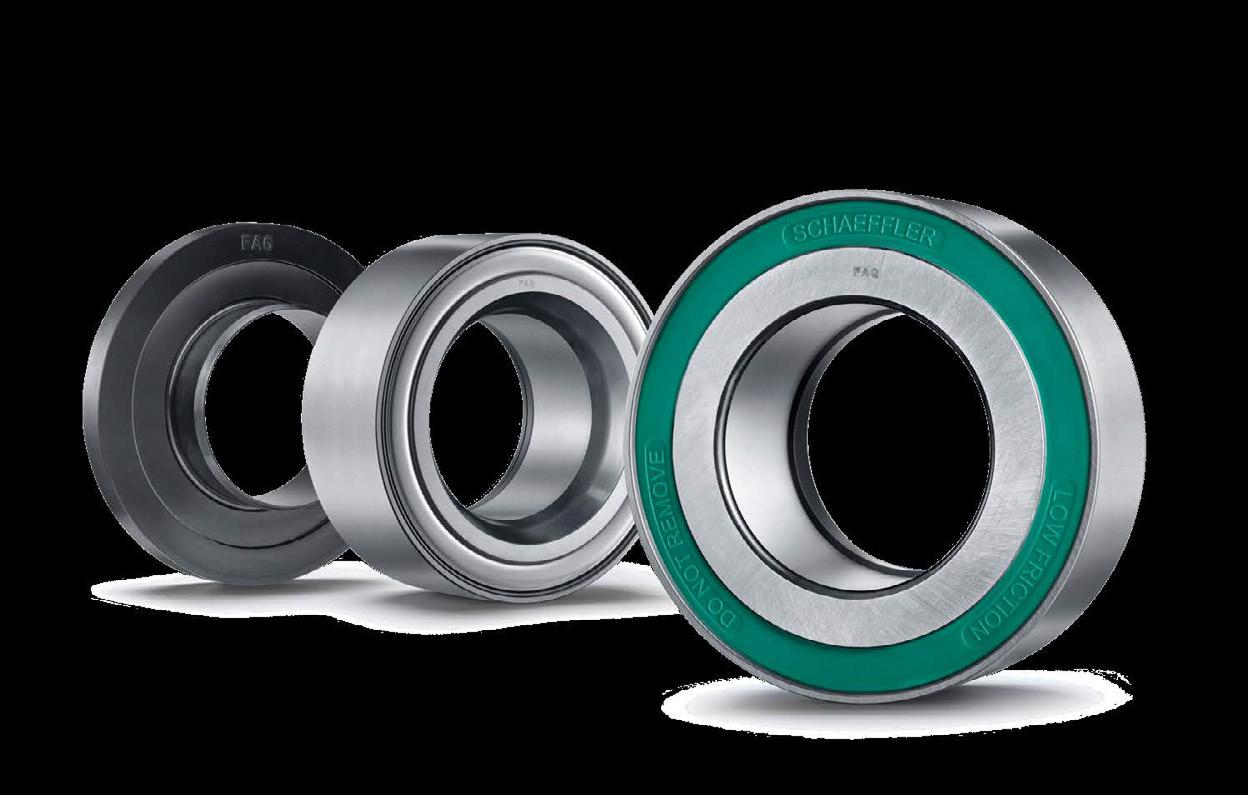

SKF FUEL SAVING WHEEL

BEARINGS: A SMART RESPONSE TO FLEET COST PRESSURES

Wheel bearings keep the truck rolling. For more than 100 years, SKF has led innovation in the Commercial Vehicle wheel end market. Today, SKF Fuel Saving Wheel Bearing Kits offer fleet operators a powerful cost-saving solution. Engineered for maximum reliability and fuel efficiency, these advanced bearings reduce fuel consumption and lower maintenance costs, helping truck fleets operate more sustainably and profitably.

This performance is made possible by optimized raceway profiles, improved surface finishes, specially formulated greases and low-friction seals. To validate these innovations, SKF developed a dedicated test rig that measures friction torque under radial load. The results confirm the effectiveness of SKF’s engineering efforts to improve bearing efficiency.

In a comprehensive testing campaign using this rig, SKF compared its Fuel Saving Wheel Bearings with other aftermarket kits. The findings were impressive. SKF consistently showed the lowest friction levels, often less than half the torque of competing products. The tests included bearings from

several well-known suppliers, reinforcing SKF’s position as the most efficient choice in the market.

Truck wheel bearings account for approximately 4–5% of the total power required to keep a vehicle rolling. Replacing just one wheel bearing with an SKF solution can reduce power loss by up to 355 W, translating into a fuel saving of around 0.1 liters per 100 km. While this may seem minor at first glance, over an average annual mileage of 120,000 km, it adds up to a confirmed saving of around 110 liters per truck per year, equivalent to €176 in fuel savings, based on the average EU diesel price.

Tackling Fleet Challenges with Proven Efficiency

In today’s competitive transport industry, fleet operators face shrinking margins and rising maintenance costs. SKF Fuel Saving Wheel Bearings are designed to directly address these challenges. By improving fuel efficiency and reducing friction, SKF helps fleets cut operating expenses and extend vehicle uptime. It’s a solution designed not just to perform, but to support the success of modern fleet businesses.

TIP NEXUS LYON 2025

Driving Performance and Sustainability Across Europe

Since its creation in 1968, TIP Group has grown into one of Europe’s leading providers of transport equipment leasing, rental and maintenance services. With a fleet of more than 90,000 units— and nearly the same number of customer-owned assets under management — TIP supports logistics and freight operators across 17 countries. Our network spans more than 130 locations and includes 270 mobile service units, enabling us to remain close to

our customers wherever they operate. Behind these figures stand 3,100 dedicated employees, including 1,400 highly skilled mechanics. As part of I Squared Capital, a major global infrastructure investor managing over 50 billion dollars in assets, TIP benefits from strong financial foundations and the ability to invest in innovation and long-term solutions.

Our ambition is simple but powerful: help our customers do more with less. We aim to optimize costs, improve

uptime and reduce CO₂ emissions by rethinking how fleets are managed throughout their lifecycle. Beyond leasing and rental, TIP provides full-service maintenance and repair, digital solutions and used equipment remarketing. Our mission goes beyond managing vehicles; we are building sustainable partnerships that generate measurable value for customers, suppliers and the planet.

The TIP MED Region — Balancing Complexity and Customer Expectations

Within this European network, the TIP MED region — which covers France, Spain and Italy — plays a critical role. We manage a combined fleet of 24,000 vehicles, equally divided between TIPowned assets and customer-owned units. Supporting this operation are 500 employees, including 200 mechanics working across 25 workshops. MED region operates under two distinct service models, which coexist within the same organization. On one side, for TIP-owned leased assets, our priority is maximizing uptime, preserving value and optimizing total cost of ownership. On the other, we serve third-party assets much like an independent workshop network, where speed, service quality and cost efficiency are critical for customer satisfaction.

This dual model brings both complexity and opportunity. It requires flexible strategies, a deep understanding

TRUCK

of customer needs and above all, close collaboration with suppliers to ensure parts availability, optimized stock levels and competitive costs. Success comes from aligning our internal expertise with strong external partnerships, creating solutions that work for every customer profile.

Leading the Change — Daniel Gaspar

As Maintenance Leader for TIP MED Region, I oversee maintenance operations, strategy and partnerships across France, Italy and Spain, supporting a fleet of more than 24,000 vehicles. With over 22 years of experience in transport operations, fleet management and purchasing, my role combines operational leadership, financial responsibility and supplier engagement.

Over the past years, my focus has been on transforming our maintenance model. Together with my teams, we have increased productivity, optimized our parts strategy and reinforced supplier partnerships to improve efficiency and reduce costs. One of the key achievements has been the launch of our planned refurbishment programs, which extend the lifecycle of critical assets, reduce CO₂ emissions by up to 35% and create significant value for both TIP and our customers.

My approach is centered on three pillars: efficiency, reliability and visibility. By improving planning and predictive

maintenance, optimizing parts availability and integrating digital tools across our operations, we have transformed the way we manage uptime, costs and customer expectations.

Key Insights from TIP NEXUS

Lyon 2025

During this TIP NEXUS presentation, we shared how we are reinventing fleet maintenance. The journey starts with better planning and a shift from reactive firefighting to predictive forecasting. By focusing on high-impact tasks, improving incident response, adapting part strategies to asset age and leveraging data from telematics and digital platforms, we have streamlined work-

shop operations and reduced unplanned downtime.

The results are clear. Overdue work orders, which accounted for more than 20% of total jobs in 2021, have been reduced to less than 5% today. Corrective repairs and breakdowns have dropped significantly, while downtime per stop has been shortened thanks to better preparation: kits are ready, parts are delivered in advance and technicians can focus on execution rather than waiting.

We also highlighted how TIP integrates circular economy principles into fleet management. Through our refurbish-

TRUCK

ment programs, we identify the right moment to intervene before the highcost curve hits. Instead of replacing assets prematurely, we extend their lifecycle, optimize TCO and reduce environmental impact — achieving up to 35% fewer CO₂ emissions per refurbished unit.

These improvements are only possible through strong partnerships with our suppliers, who support us in better planning, ensuring part availability and co-developing smart solutions for the future.

The Road Ahead — Building Smarter, Greener Partnerships

If there’s one message to take away from this journey, it’s that we can’t succeed alone. Meeting customer expectations, optimizing costs and achieving sustainability goals will only happen through closer collaboration across the

entire value chain — from manufacturers to distributors to fleet operators. We need fast and connected digital information to identify the right parts in seconds, not minutes. We need predictive intelligence that combines fleet mileage, part lifespan and supplier data to anticipate failures before they happen. We need ready-to-install smart kits, designed for specific jobs, to reduce errors, speed up repairs and improve workshop efficiency. And we need sustainable solutions — certified, traceable and warrantied refurbished parts that reduce waste and emissions without compromising performance.

The path forward is clear. By aligning people, processes and partners, we can create leaner, cleaner, smarter supply chains — delivering better value for our customers, stronger collaboration with suppliers and meaningful contributions to our industry’s sustainability goals. “Leaner. Cleaner. Smarter. Together.”

TMD FRICTION REDUCES CO2 EMISSIONS BY 46%

Driving Performance and Sustainability Across Europe

Leverkusen, 26th August 2025 – TMD Friction, the leading global manufacturer of brake friction solutions, has published its latest ESG Report summarising its environmental, social and governance progress for 2024. In the report, the manufacturer reveals it has achieved a 46% reduction in tonnes of CO2 for Scopes 1 and 2 relative to its 2021 baseline. This has been achieved

through various initiatives across the manufacturer’s operations, from greener energy and more efficient processes to better waste management and product development.

The global manufacturer has also surpassed its ambitious 2040 target for removing volatile organic compounds (VOCs) from its products, achieving a 31% reduction in 2024, significantly exceeding its goal of 20% reduction by

TRUCK

2040. This has been achieved in part by investing in new technologies and developing a VOC-free adhesive.

With a starting base from 2021, TMD Friction’s Sustainability Roadmap 2040 sets clear environmental goals to reduce emissions across Scope* 1, 2 and 3, focusing on a robust strategy for the short, medium and long-term.

Lynn Edwards, Vice President of HSE and Sustainability at TMD Friction, said: “As a global leader in brake friction manufacturing, we are committed to driving change and pioneering a more sustainable brake industry. Every day we work towards making these smaller improvements to achieve our bigger goals, but it’s only by seeing it all together in our yearly ESG Report that we can truly appreciate how far we have come.”

Increasing green energy

In 2024, TMD Friction utilised 52% green energy from its suppliers, edging closer to its goal of accessing 100% renewable energy by 2030. The manufacturer was also able to reduce energy usage by 3% through initiatives such as upgrading or replacing older equipment, improvements to compressed air leakage management, and optimisation of heat recovery at the regenerative thermal oxidizer (RTO).

The investment in specialised energy management software has enabled TMD Friction to analyse energy consumption

Global brake friction manufacturer releases progress on its Sustainability Roadmap 2040, which includes:

● 46% reduction in tonnes of CO2 for Scopes 1 and 2

● 31% reduction in volatile organic compounds (VOCs)

● 52% green energy usage

data online and achieve transparency in the breakdown of energy costs according to their source.

People, packaging and purpose TMD Friction encourages employees to be part of its sustainability journey, actively encouraging them to identify, propose and lead initiatives that create a positive impact via its Kaizen Programme. In 2024, there were 162 global projects led by employees, nine of which were sustainability focused. The nine projects delivered combined savings of more than €631,000 across its operations.

One key Kaizen project focused on making the company’s packaging more sustainable. The objective was to find alternatives that reduced environmental impact but maintained functionality. Various options were considered but the clear winner was a honeycomb structure made entirely from recycled paper. During testing, it performed well in all applications. The new innovation will replace 19 different types of foam, marking a crucial milestone in TMD Friction’s sustainable packaging improvements.

David Baines, CEO and President of TMD Friction, said: “We couldn’t achieve such ambitious goals without the commitment and passion from our employees. Through initiatives like our Kaizen Programme, they are making a real difference to our operations, proving that meaningful change happens when everyone is empowered to contribute to our sustainability journey.”

Improving waste management

TMD Friction has big targets to reduce landfill waste by 20% in 2025, 50% in 2030 and finally by 70% in 2040. By employing its 5Rs strategy (refuse, reduce, reuse, repurpose and recycle), it is enabling targets to be met. In 2024, TMD Friction increased onsite recycling by 14%. Individual regions also implement their own locally focused sustainability initiatives to improve operations.

TMD Mexico, for example, donates its waste wood to a local company specialising in designing and crafting furniture from reclaimed wood. At the Mexico facility in 2024, 16 tonnes of wood was recycled into sustainable furniture, preventing its final disposal in landfill.

2025: A pivotal year Following a successful 2024, 2025 is a target year for TMD Friction as part of its Sustainability Roadmap 2040. In 2022, specific improvement goals using 2021 as the baseline were set. The targets are ambitious but achievable. In 2025, TMD Friction will be working on exploring further renewable energy sources, eliminating critical substances, and increasing the use of recyclable packaging.

THE FULL ESG REPORT CAN BE DOWNLOADED HERE: https://tmdfriction.com/wp-content/uploads/2025/08/TMD-ESG-report-2025.pdf

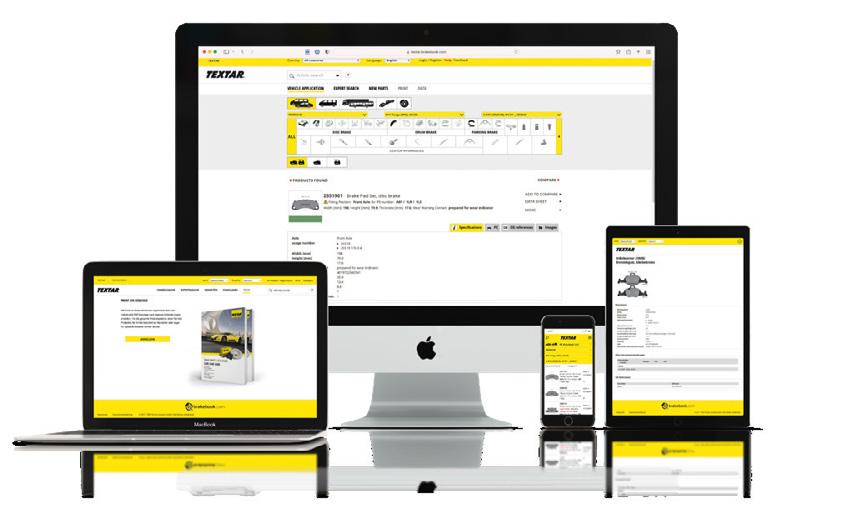

BRAKE CHAMPION!

Up-to-date catalogue data

User-friendly search options

Barcode scanner and photo pad identification tool

Create your own catalogue – based on your requirements

Specifically designed to facilitate customer identification of brake parts

WHY CHOOSE REMANUFACTURED PARTS FOR TRUCKS?

Take Part in the Circular Economy

In a world where resource scarcity and environmental responsibility are increasingly in focus, Valeo is deepen-

ing its commitment to a circular economy through its “I Care 4 the Planet” initiative—placing remanufacturing and more responsible practices at the heart of its aftermarket strategy.

TRUCK

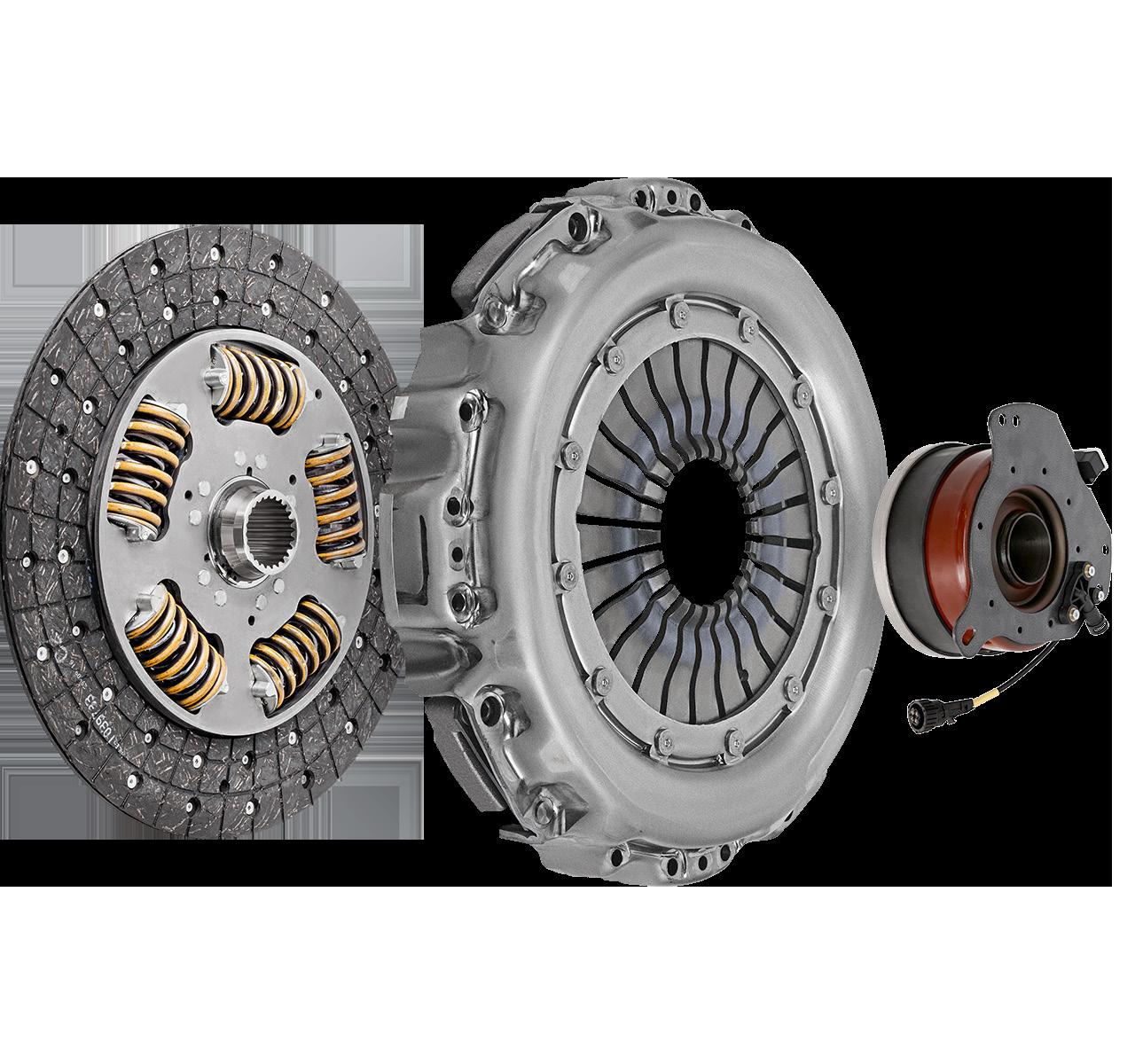

With over 40 years of remanufacturing expertise, Valeo’s offer for commercial vehicles has grown well beyond clutches. It also includes reman solutions of starters & alternators, and most recently, a remanufactured Clutch Pneumatic Concentric Actuator (PCA), broadening the options available to the market.

Benefit from Remanufacturing

Remanufacturing is a meticulous process that restores used components to like-new condition. For Valeo’s truck clutches, the remanufacturing offer was launched over 40 years ago, in 1982 in Amiens, France. Collected components are disassembled, cleaned, repaired or replaced, tested, and reassembled. Each remanufactured clutch matches the same func-

tional characteristics as its brand-new counterpart while being composed of up to 80% recycled materials.

Have an Impact on your Budget

Remanufactured parts cost less than new ones, making them a smart, budget-friendly option for both workshops and final customers. Through a simple core deposit system, workshops pay a surcharge that’s refunded once the used part is returned, ensuring an ongoing supply of components and supporting the remanufacturing cycle.

Trust in Performance, Backed by Warranty

Every Valeo remanufactured product is engineered to deliver reliability and value, supported by a two-year warranty with unlimited mileage—on par with new parts. This commitment to quality ensures that workshops and fleet operators benefit from more responsible solutions without compromising performance.

Choose Less Plastic in Packaging and Reduced Transport Emissions

Packaging is being reimagined to reduce plastic use. 100% cardboard packaging is a Valeo standard for clutches, starters and alternators, OptiPack pads, wiper motors and blades.

Transportation is another lever for impact. With a preference for European production, Valeo contributes to reduce transport-related emissions: 98% of clutches are manufactured in France and Türkiye. 99% of wiper blades and 100% of brake pads are made in Europe.

Support a More Responsible Aftermarket