SUSTAINABILITY

INSIDE EDITION 30 • DECEMBER 2022

EDITORIAL NOTE WELCOME FROM THE CEO INSIGHTS FROM NEXUS COMMUNITY ABOUT NEXUS SIDE 30

SUSTAINABLY REMANUFACTURING ELECTRONICS – MAKING THE PROCESS EVEN GREENER. Marcus Hecht Team Lead Project Management Remanufacturing & Resale at Knorr-Bremse TruckServices

BREMBO AND SUSTAINABILITY: THINKING RESPONSIBLY. ACTING CONCRETELY. Matteo Busnelli Head of Aftermarket Marketing, Global Business Unit Aftermarket Brembo S.p.A.

MEYLE UNVEILS ITS FIRST CLIMATE-NEUTRAL PRODUCT RANGE.

WHAT DOES SUSTAINABILITY MEAN FOR MANN+HUMMEL? Simon Frick Senior Vice President Sales IAM Europe at MANN+HUMMEL

14 26 34

40

SIDE 2 INSIDE EDITION 29

A UNIQUE E-AXLE SOLUTION. Maik Evers Head of Product Management, Schaeffler Automotive Aftermarket COMMITTED TO A MORE SUSTAINABLE DISTRIBUTION AND SOCIAL AND ECONOMIC PROGRESS. Aranca Negru International Department Coordinator INSIDE 30 | DECEMBER 2022 NEXUS IN ! SIDE MAGAZINE is published by NEXUS Automotive International, Geneva, Switzerland. NEXUS Automotive International SA Chemin du Château-Bloch 11 1219 Le Lignon | Geneva | Switzerland T +41 22 306 49 50 www.nexusautomotiveinternational.eu 50 40 60 74 NRF SUSTAINABLE PROJECTS. THERMAL MANAGEMENT SOLUTIONS FOR ELECTRIC MOTORS AND SUSTAINABLE NEXT-GEN MOBILITY.

In a context of electrification, digitalization and consolidation, NEXUS is investing in innovative and sustainable models that will lead the upcoming transformation of this industry, to become THE AUTOMOTIVE AFTERMARKET

COMPANY

THE AUTOMOTIVE AFTERMARKET COMPANY

SUMMARY

WELCOME FROM THE CEO

Gaël Escribe, CEO NEXUS

Automotive International NEWS FROM N!

• Automechanika Frankfurt: NEXUS Automotive International revealed its new signature and shared its vision for the future of the aftermarket

• Equip Auto Paris 2022: NEXUS Automotive International accelerates its innovation strategy to integrate and expand its service offering

INSIGHTS FROM THE AFTERMARKET WORLD AND BEYOND

09 11 14

• 3 questions about sustainability to Emmanuel

Voguet • Brembo and sustainability: Thinking responsibly. Acting concretely. Matteo Busnelli, Head of Aftermarket Marketing - Global Business Unit Aftermarket Brembo S.p.A. • SINDRI digs out vehicle data in a blink, Continental • Sustainably remanufacturing electronics –

making remanufacturing even greener. Marcus Hecht, Team Lead Project Management Remanufacturing & Resale at Knorr-Bremse TruckServices • What does sustainability mean for MANN+HUMMEL? Simon Frick, Senior Vice President Sales IAM Europe at MANN+HUMMEL • MEYLE unveils its first climate-neutral product range • NRF Sustainable projects • Sustainability also in repair. A unique e-axle solution. Maik Evers, Head of Product Management, Schaeffler Automotive Aftermarket • SKF is a responsible business partner. We see sustainability as a moral obligation. Blanca Martin, International Trading Groups Manager at SKF • Thermal Management Solutions For Electric Motors And Sustainable Next-Gen Mobility. TotalEnergies • Sustainability is Valeo’s responsibility • Paving the path for a green and sustainable aftermarket. Philippe Colpron, Head of ZF Aftermarket and Executive Vice President • Committed to a more sustainable distribution and social and economic progress. Aranca Negru, International Department Coordinator at SERCA •

WELCOME

WE OWE YOU MORE THAN BUSINESS AS USUAL SIDE INSIDE EDITION 30 • DECEMBER 2022 6

Sustainability is more than just a priority amongst us all and, it goes without saying, that our industry has to engage and act now. Over the past 4 years, NEXUS has taken multiple initiatives in the sustainability domain and, in the immediate future, NEXUS will continue to pursue its efforts in this area. Indeed, one of the three main pillars of the future roadmap includes sustainability as an emergency.

So, in this new edition of INSIDE, we share some thoughts, inputs and solutions deployed by our community - prior to the NEXUS Climate Day, which will take place during our Business Forum in Montreal in 2023. We hope you will find it inspiring! Now enjoy reading IN!SIDE magazine.

Gaël Escribe CEO of NEXUS Automotive International

Dear Reader,

Since its creation in 2014, NEXUS is constantly adapting to the needs and expectations of our industry in accordance with our stated aim of:

“We owe you more than business as usual”.

DEFINE SUSTAINABILITY STANDARDS FOR TOMORROW

SIDE INSIDE EDITION 30 • DECEMBER 2022 8

EMMANUEL VOGUET Nexus Corporate Communication & Sustainability Director

4 QUESTIONS TO EMMANUEL VOGUET

What do you see as the next challenges for sustainability in the aftermarket?

Stronger together! This is the challenge. Addressing sustainability in the Aftermarket cannot be done efficiently if every player is working on his side in silo. There cannot be the suppliers on one side, the distributors on another, and the workshops at the end.

We need to work on the entire supply chain, to define a common vision, common usages, a common language, based on a collaborative approach. The aftermarket has to define its sustainability standards for tomorrow, because pick of production of thermic cars will be reached around 2035. Right after this, the automotive aftermarket will hold, on its own shoulders, the future of the thermic car park. The maintenance of those cars will be at the center of a sustainable automotive aftermarket.

Reman is also a major challenge we need to address. Because this is the entry gate of a circular economy. It is not only one answer to the climate change issue, but also an answer to the scarcity of raw materials, and at the end, strategic independence.

What is N!’s roadmap in this area?

It is 3 years now that we have been working on these questions.

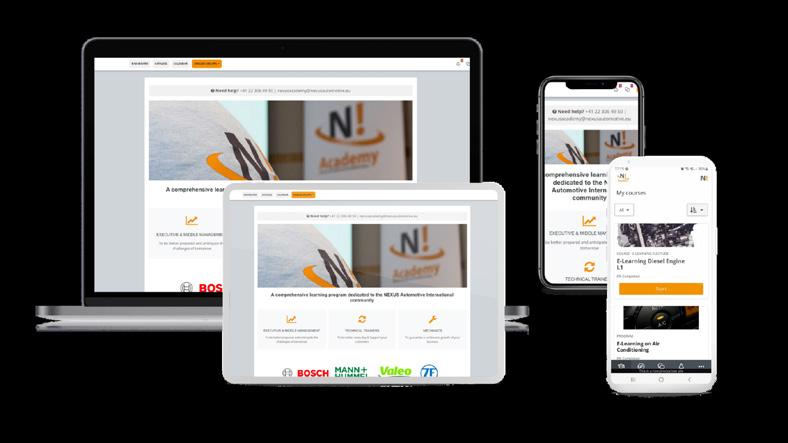

We have designed and deployed a Nexus CSR policy, with a concrete objective of CO2 reduction. We have initiated working groups on the Green garage label, the green products identification; and we have integrated a sustainability module in our Nexus Academy platform. And, of course, we are totally committed on the rating question: we actively participated in the creation of Inteliam, an independent ESG rating company.

We therefore took 2 decisions:

1/ No more candidates will enter Nexus without an Inteliam rating: it is now mandatory to achieve this before entering Nexus.

2/ We have decided to ask Inteliam to rate Nexus: it is a real change in paradigm as none of our competitors have done this before. For us, being rated will strengthen the position of our members and reinforce the collaboration forged with our suppliers, who are concerned to have a sustainable downstream, which is technically called the scope 3.

By being rated, we are offering a real ‘added value’ to both our members and suppliers. In the future, suppliers will reward those who are rated. Anticipating such things is in the Nexus DNA. Last but not least, we decided to organize a Nexus Climate Day every year.

What are the latest innovations that have caught your attention?

I’m impressed and inspired by 2 of them lately: the Austria Distribution Federation, and the North America Sustainable Committee.

Walter Birner, the chairman of the Austria Distribution Federation, has issued a recommendation to limit 3 daily deliveries to the workshops.

Thanks to this, the carbon footprint has been reduced, without asking the workshops to create an inventory. They are just pushing them to anticipate their daily activities and to better plan their needs.

This is a major shift, and will also put on the table the question of the last mile delivery. But this success shows that where there is a will, there is a way.

The second initiative is the sustainable committee created by Continental, Parts Authority, Delphi Technologies and Nexus; approved by Autocare. They are so advanced that they have even reached a point where they will disclose a sustainability charter - approved by the US Association AutoCare - that will become the standard in the US. These initiatives are definitely not greenwashing moves, it is problem solving!

Why did you organise the N! Climate Day?

Nexus Climate Day is much more than another conference among others. It is the launching of a yearly on-going process.

Our objective is to build a conference where only doers and problem solvers will share their best practices, and discuss what could be tomorrow’s standards.

It will also be the place to align the entire Nexus supply chain on common processes: from the suppliers to distributors, to workshops.

We will identify what makes a consensus to make it a standard, and what needs to be further discussed to reach a consensus. (May I suggest if it doesn’t alter the sense/ meaning change to this: Through discussion we will identify a common ‘standard’ in order to reach a consensus.

But at the end, this Nexus Climate Day is definitely one answer to the main stake of the entire industry I mentioned at the beginning: to succeed, we are stronger together!

Nexus Climate Day is an anti-silo weapon!

SIDE INSIDE EDITION 30 • DECEMBER 2022 10

you know that

is also determined to take a leading position in the emerging renewable energy markets and is

sustainable products.

player

heat exchanger solutions

emerging technologies,

Solid Oxide Fuel

Solid Oxide Electrolysers

sector.

absolute number 1 in sustainability Front Pipes Catalytic Converters & Diesel Particulate Filters I reduce exhaust fumes and noise. What’s your superpower? Intermediate Silencers Rear Silencers Contributing to a cleaner world by consistently innovating in mobility & energy. : aftermarket Towbars Bicycle Carriers Mounting and Repair Parts N° of NEW Bosal ref (2022) PG description Emission level Complete car applications & OE references Carpark coverage 28 Catalytic converters Euro IV to VI 1071 car applications & 190 OE references >16M cars 18 Diesel Particulate Filters Euro V 2 Exhaust mounting material 4 Pipes 26 Silencers 78 NEW REFERENCES At BOSAL Research and Development department, more than 120 engineers are involved in developing new technologies, focusing on more durable and environment-friendly products. Our outmost efforts are being put into making an exhaust system the least polluting as possible, resulting in products meeting EURO5 & EURO6 standards. All these products are fully homologated and satisfy all legal requirements in Europe. *2022/01 – 2022/09 ENERGY www.bosal.com

Did

BOSAL

expanding fast into advanced

We are already a key

in

for all

such as

Cell Technology (SOFC) or

(SOEC) and more investments are done in other sustainability projects. It is our ambition in achieving a leading market offering and high market success in this

The

SECURITY & QUALITY ORIENTED

hengst.com/blue.ion

This one has it all.

NEW ANSWERS TO THE CHALLENGES FACING THE INDUSTRY

SIDE INSIDE EDITION 30 • DECEMBER 2022 14

MATTEO BUSNELLI

Head of Aftermarket Marketing, Global Business Unit Aftermarket Brembo S.p.A.

BREMBO AND SUSTAINABILITY: THINKING RESPONSIBLY. ACTING CONCRETELY

The automotive sector is facing a period of major transformations, driven by macro trends such as electrification, autonomous driving, digitalization, where sustainability is a key priority for all manufacturers.

New mobility paradigms require new answers to the challenges facing the entire industry. This is why, in September 2020, Brembo announced a new strategic vision and embarked on a journey to become a solution provider, with the ultimate aim of contributing, together with its customers, to the best driving experience.

Part of this strategic vision is the goal of developing increasingly green products and processes, in line with Brembo’s approach to sustainability - thinking responsibly and acting concretely, in adherence to the UN 2030 Agenda and its 17 Sustainable Development Goals (SDGs). Brembo has been committed for years to improving its production processes with the aim to increase sustainability.

Compared to 2019, the company has reduced emissions from its production plants and offices by around 29%. On the resource side, it also promotes the reduction of water consumption in production processes and the development of water reuse solutions. In 2021, Brembo received the Platinum Sustainability Rating from EcoVadis, a rating attributed to only 1% of the companies evaluated, improving on the already excellent results of previous years. To recognise Brembo’s commitment to responsible management of water resources and reducing CO2 emissions, the non-profit organisation CDP (ex Carbon Disclosure Project), confirmed the Group was among global A-List companies both for the ‘Water Security’ and ‘Climate Change’ categories for the fourth consecutive year.

In terms of products, thanks to its technological know-how and continuous research and development, Brembo introduced the Beyond Greenance Kit Concept, a kit of pads and discs that has been developed together as a whole system to guarantee the highest Brembo quality standards and, at the same time, a much lower environmental impact with a significant reduction in emissions: -83% in PM10 and -80% in PM2.5.

Furthermore, the Greenance Kit concept, which merges the words ‘GREEN’ and ‘PERFORMANCE’, guarantees extended mileage and a significant improvement in terms of the total cost of ownership of vehicles. It ensures better durability of the brake discs, up to 3 times. This leads to an optimisation of maintenance costs, a top priority for professionals and high mileage drivers. It is a solution anticipating low environmental impact requirements and it has already achieved the ECE-R90 homologation tests, as well as the most severe benchmark parameters conducted by the company’s road tests technicians, according to Brembo’s stringent requirements. Brembo Beyond Greenance products will be available as a kit solution (discs and pads) in the second quarter of 2023.

At the same time, light commercial vehicles, fleets and taxis will be able to benefit from the Brembo Beyond Enesys - Energy Saving System® - Brembo’s solution to reducing the residual torque of the brakes and therefore also fuel consumption and C02 emissions, hence bringing tangible benefits in terms of a lower environmental impact for this kind of vehicles.

Another example of an innovative and greener Brembo solution is the Beyond EV kit, consisting of specially coated discs and innovative brake pads, designed to work together, and substantially enhancing Brembo’s Aftermarket offer for electric cars. The Kit is tailor-made for the most popular electric cars on the market. A double-protective treatment helps to prevent corrosion of the entire kit up to and beyond 100.000 km and adds brilliance and appealing aesthetics to the discs itself. Furthermore, the special copper-free friction material reduces both dust and road noise when braking, whereas the galvanized backing plate ensures maximum protection against corrosion on the whole system.

Safety and durability are central to the design of this new braking solution. Electric cars use regenerative braking in addition to traditional dissipative braking, resulting in reduced use of friction brakes. Over time, this can trigger the formation of rust on brake system components that are used less, endangering the safety of the brake system, and increasing maintenance costs.

SIDE INSIDE EDITION 30 • DECEMBER 2022 16

Choose the aftermarket partner who’s here to help keep you ahead, today and tomorrow. Whether it’s parts, tools, support or training we’ve got your back!

Visit the Masters of Motion hub for more information delphiaftermarket.com

Delphi Technologies is a brand of BorgWarner Inc.

Partner with Delphi Technologies

going the extra mile Find your local sales office at Dinex.net Filter service shouldn’t be Trucking is costly and complicated Use Dinex Recon RX Safe Type-approved and 2 year warranty, after 3-step cleaning and reconditioning Sustainable Up to 95% less carbon footprint than new filters Economic Cheaper than OE, and cash-back deposits for return of used filters Read more here:

COMPREHENSIVE PICTURE

THE VEHICLE’S

CONDITION SIDE INSIDE EDITION 30 • DECEMBER 2022 20

A MUCH MORE

OF

OVERALL

SINDRI DIGS OUT VEHICLE DATA IN A BLINK

Lightning-fast access to vehicle data, straight to your device via an app – this is SINDRI. Continental’s new tool brings the direct vehicle acceptance to a new level – by digizing it all the way. Learn more about how the tool helps to leverage business potentials.

SINDRI gives workshops and car re-marketers super-fast access to vehicle data, supports the monitoring of vehicle conditions and paves the way to leverage business potentials. The simple to use SINDRI app is designed by Continental and can be used with tablets. Whilst only a visual inspection with paper and pen was carried out previously, from now on SINDRI digitizes the entire vehicle acceptance and evaluation process and enables a deep dive into the vehicle’s data condition.

VCI in – data out SINDRI makes the data available in less than five minutes – much faster than conventional methods with complex diagnosis devices. It can be used simultaneously whilst carrying out a visual inspection. Therefore, users are quickly accessing a much more comprehensive picture of the vehicle’s overall condition, partly thanks to individually configurable checklists. The SINDRI app receives data from a compact Vehicle Communication Interface (VCI), which accesses the ECUs via the OBD-II interface. Due to the data and metrics know-how at Continental, SINDRI covers more than 80 percent of European vehicle fleets.

Reading – decrypting – understanding

SINDRI can be easily operated: plug in the VCI, start the app – and a clear, understandable description of the vehicle’s condition appears on the tablet display after a few minutes. SINDRI reads out the control units, decrypts error codes and displays service-relevant information such as the oil level, battery voltage and upcoming inspections. Using already integrated interfaces, checklists can be created on the tablet from the collected data and can later be exported as a PDF. Increase customer trust – leverage business potential The advantage: users can view all the data immediately on-site, and upcoming repairs can be discussed and agreed upon, or the vehicle in-depth condition can be analyzed and validated in the field of remarketing. This strengthens customer trust in the workshop and car dealer. And, it also opens up business potentials for workshops to carry out necessary work on the vehicle, that would not have been recorded in a conventional check. “Digitalization not only makes life easier for workshops and dealers, but also take their services to a whole new level. SINDRI continues our policy of creating digital solutions that make our partners’ everyday tasks easier, more efficient and more customer-friendly,” says Peter Wagner, Head of the Automotive Aftermarket business segment in the Smart Mobility business area.

New packaging concept:

smaller, lighter, more climate-friendly

Continental will introduce a new packaging concept for its timing belt kits with water pump.

Previously, the individual components of these kits (belts, water pump, tensioner pulleys, etc.) have been packed into individual boxes, which are then stacked together in a large outer box.

In future, however, a specially folded cardboard insert will ensure that all components are held securely in place with good protection inside the box without the need for individual packaging. This means only half the amount of cardboard has to be produced, significantly reducing CO2 emissions.

“There are also other climate-relevant advantages when it comes to transportation,” adds Anna Bentlage from Projects and Standards at Continental Power Transmission Group Automotive: “Since the new packaging is lighter and smaller, haulage companies will be able to transport just under 70 percent more belt drive kits with water pump on a pallet. This significantly reduces the number of trucks on the road. By our calculations, this cuts our CO2 emissions by around 390 tons annually.”

Added to which, the cardboard used for the new kit packaging is made from recycled material and is itself recyclable. Dealers gain from having significantly more space on their shelves, while workshops can enjoy easier handling when unpacking, greater clarity in their workplaces and a lot less cardboard packaging waste.

www.continental-engineparts.com

ThenewsummertyregenerationfromContinental. Germanengineeredsafety. Didyouknowthatourtyreshavereceivedtopratingsinindependenttestsonaregularbasisfor morethantenyears?Andthiscontinuoussuccessisreallynotacoincidence,sincewealwaysput maximumeffortandpassionintoeverysingleproduct.Theseresultsmakeusproudandatthesame timemotivateustocontinueworkingsuccessfullyinthenameofdrivingsafety.Sothatyoucanrely onus,whenothersrelyonyou. Allyouneedfornextsummer. www.continental-tyres.com Sporty SportContact ™ 7 Durable UltraContact Comfy PremiumContact ™ 7

More Service. More Expertise.

Elring – Das Original your reliable Gasket Partner

Elring – Das Original is your partner for spare parts when it comes to OE-quality products with functional reliability and premium end-toend service. This includes not only an interactive online catalogue, exploded-view drawing for truck and vans online and in the print catalogue, an online sealing compound wizard, which helps you to find the sealant you need, but also Sales and Technical Service information. Furthermore, our team is specialised to support you concerning storage suggestions based on vehicle fleet and sales figures as well as Sales gap analyses. Besides we offer storage systems for optimised space utilisation and rapid identification of products.

Our technical training offer for workshop and engine specialists in the passenger car and commercial vehicle segment ranges from flexible online seminars to on-site hands-on training with the Elring Training Truck. Sales staff is also trained on our products in the areas of catalogue, cross-selling and basic technical knowledge. To support our training offering, assembly videos and tutorials can be found on the Elring - Das Original YouTube channel. The Elring Online Academy complements the range of training options and gives participants the chance to become a certified Elring expert.

Stay up to date subscribing to our monthly newsletter

Check out our Elring Academy and become a Certified Expert!

Find all installation videos and tutorials on our YT channel

www.elring.com Follow us on Instagram

YOUR PARTNER FOR SUCCES

Eurol is the biggest independent lubricant manufacturer from The Netherlands, our products are available in over 90 countries. We produce and supply approved and OEM-specified lubricants. Our importers can rely on a partnership, where flexible and custom-made support in Marketing & Sales immediately results in profitable distribution of Eurol Lubricants. Interested? Please contact us by email intersales@eurol.com

EUROL.COM

AN ENVIRONMENTALLY FRIENDLY CLEANING PROCESS

SIDE INSIDE EDITION 30 • DECEMBER 2022 26

MARCUS HECHT

Team Lead Project Management Remanufacturing & Resale at Knorr-Bremse TruckServices

SUSTAINABLY REMANUFACTURING ELECTRONICS – MAKING THE PROCESS EVEN GREENER

Working with Fraunhofer institutes, Knorr-Bremse has developed an environmentally friendly cleaning process for electronic components that significantly reduces the scrap rate in the industrial remanufacturing of control units – making the whole process even more sustainable.

The industrial remanufacturing of used truck parts is a pretty tough job on the whole. Caked-on dirt, rust film and oil residues from hundreds of thousands of kilometers on the road have to be removed. Rough treatment is dealt out to brake calipers, compressor cylinder heads and crankcases, clutch actuators and the like. Industrial washing systems operating at high temperatures, sometimes even wire brushes and impact wrenches work on the used components until they can only be distinguished from new parts for original equipment by their distinct marking. Then, they are ready for use as EconX® parts, helping to get trucks, trailers or buses back on the road again.

“This is all highly unsuitable for our electronic components,” says Marcus Hecht, Team Lead Project Management Remanufacturing & Resale at Knorr-Bremse TruckServices. Inside the sturdy, dust-proof casings that make the various control units fit for use in such a rugged daily operating environment lie soft, sensitive cores: electronic components such as microchips or pressure sensors, soldered onto printed circuit boards. “If just one of the many solder joints breaks, or one of the components is damaged by a static discharge, the entire unit becomes unusable,” says Hecht. Contact with corrosive cleaning fluids and ultrasonic cleaning are to be avoided at all costs. A

AN ENVIRONMENTALLY FRIENDLY CLEANING PROCESS

largely dust-free, anti-static working environment is therefore standard when working with the circuit boards. “At the same time, the control units are among the most valuable components in the entire braking system,” says Hecht.

Critical point: the pressure sensor

Aside from software updates, which have to be performed regularly, the control units are extremely low-maintenance and robust. They are able to withstand the usual vehicle vibrations and even major temperature fluctuations. The pressure sensor is especially crucial to everyday operation. Hecht comments: “The sensors are part of the compressed air circuit in the truck. There, they determine the pressure applied to each brake and pass the values on to the electronic systems. “Although the quality of the compressed air is closely managed and the filter cartridge takes out the worst impurities, the compressed air is not clinically clean,” says Hecht. “Tiny dust particles, water and oil droplets are brought in with the compressed air and can settle on the pinhead-sized sensor cell over time. Dirt can also be introduced during coupling and uncoupling or during maintenance in the workshop.” Hecht and his team were therefore faced with the challenge of gently, yet effectively cleaning the pressure sensors when disassembling the control units – without damaging the rest of the unit.

Project with Fraunhofer institutes and Bavarian Research Foundation

Knorr-Bremse brought the topic of pressure sensors into the ASPIRE research project that the IGCV (Institute for Casting, Composite

SIDE INSIDE EDITION 30 • DECEMBER 2022 28

and Processing Technology) and IPA (Institute for Manufacturing Engineering and Automation IPA) Fraunhofer institutes were conducting with partners from industry and funding from the Bavarian Research Foundation. The aim of ASPIRE is to close gaps in remanufacturing process chains, thereby increasing overall regeneration rates and further reducing CO2 emissions and material consumption. The research project involved comparing a variety of cleaning agents and processes. It led to the creation of a pilot system that, according to Hecht, “not only rinses, but also reliably removes water residues. Due to the risk of frost, water residues can be just as damaging as any actual contamination of the tiny sensor cell.”

Series-ready cleaning

The series-ready system has been in operation at Knorr-Bremse’s remanufacturing plant in Liberec,

Czech Republic, since November 2021. Rinsing with the biodegradable cleaning agent, which dissolves dirt particles and oil film from the sensor at lukewarm temperatures, takes just a few seconds. A narrow cannula is inserted into the so-called chimney of the sensor to precisely apply the cleaning agent to the sensor cell. The rest of the circuit board remains untouched. Next, the cleaning agent is rinsed off with water and the sensor is dried using compressed air, also via the cannula. This residue-free rinsing and drying is absolutely crucial to the quality of the whole process. And that’s it – done and dusted. Remanufacturing expert Hecht adds: “With this system, we are very likely to reduce the scrap rate in our pressor sensor remanufacturing to below one percent. That is an exceptional figure and good news in terms of sustainability – not to mention the relief it brings during the current shortage of newly produced microchips.”

Ferodo® is a registered trademark of Tenneco Inc. or one or more of its subsidiaries in one or more countries. www.ferodo.com POWERFUL BRAKING FOR ELECTRIC AND HYBRID CARS CHOOSE THE POWER OF PERFORMANCE. 1st • TO MARKET • TOMARKET EKRAMOT• T TEKRAMOT• • TO M A TEKR FBE050: DOT 5.1 EHV BRAKE FLUID FERODO introduced the World’s 1st dedicated Brake Fluid for Electric and Hybrid cars

TECHNICAL

© GATES 2022 - All rights reserved.

TechZone is the online technical resource for installers of drive systems and cooling systems. Make it your

choice to find: ■ Fitting tips and guidelines ■ Diagnostic solutions ■ Technical videos ■ The tools to do the job ■ Live webinars

Avoid the mistakes that other garages have made. You can also sign up to receive the latest tech tips by email.

GATES AUTOMOTIVE CATALOGUE APP AVAILABLE IN THE AVAILABLE FOR GATESTECHZONE.COM

SUPPORT FROM GATES TECHZONE Gates

first

FEWER COMEBACKS

Gates TechZone. Right, first time.

Stay connected www.sogefigroup.com The art of filtration OE expertise and innovations Dedicated aftermarket solutions Comprehensive filtration range

clas.com COOLING SYSTEM FILLING/ DRAINING DEVICE + FAST INTERVENTION NO POLLUTION OF THE GROUND EFFECTIVE TIME ON THE DEVICE ECOLOGICAL SIMPLE FAST COST EFFECTIVE

3 DIMENSIONS: THE ECOLOGICAL, THE ECONOMIC AND THE SOCIAL

SIMON FRICK Senior Vice President Sales IAM Europe at MANN+HUMMEL

WHAT DOES SUSTAINABILITY MEAN FOR

MANN+HUMMEL?

Sustainability is more than just a “green coat”. Sustainability encompasses three dimensions: the ecological, the economic and the social. At MANN+HUMMEL, we see ourselves as pioneers and add a fourth dimension to these existing concepts.

SIDE INSIDE EDITION 30 • DECEMBER 2022 34

As a technology-driven company, we have been developing innovative solutions for over eight decades now. We firmly believe that the dimension of technology is an essential component of sustainability. In the case of MANN+HUMMEL, the dimension of technology is the dimension of filtration. With our MANN-FILTER premium brand aimed at the independent automotive spare parts market, we not only offer innovative solutions for clean mobility, but also provide sustainable filters and packaging manufactured with resource-saving methods.

MANN-FILTER air filters made from recycled plastics Our improved MANN-FILTER air filters made from recycled plastics make a significant contribution towards the conservation of resources. One square metre of the improved C 24 005 filter medium now contains recycled plastic from up to six 1.5-litre PET bottles, which means that the proportion of recycled fibers has been increased threefold. Moreover, thanks to its high dirt-holding capacity the air filter only requires 30% of the filter media surface area of traditional air filters with cellulose

media. The fibers of the enhanced medium are Oeko-Tex Standard 100 certified, and have therefore been tested for harmful substances and declared harmless.

MANN-FILTER packaging made from recycled fibres

We also place an emphasis on sustainability with our MANN-FILTER packaging: Each green-yellow box consists of about 80% to 95% recycled fibres. For the European market, more than 4,800 filter elements are available for over 48,000 vehicles and machines, including more than 12,000 cars and transporters, more than 9,100 lorries and buses, nearly 1,000 motorcycles and 25,500 applications in off-highway vehicles and industry.

CO2 savings

By using modern lighting (LED) and intelligent lighting control, switching compressors and other measures, we were able to reduce our CO2 emissions by around 3,300 tonnes in 2018. All these measures aim to continually reduce our CO2 footprint and all aspects of the value chain and to ensure that natural resources are used responsibly.

You can find further information about our MANN-FILTER products in original equipment quality here: https://www.mann-filter.com

HELLA and Faurecia operate under the umbrella brand “FORVIA”; as a factual group, they form the world’s seventh largest automotive supplier and one of the global market leaders in high-growth technology fields.

FORVIA comprises the complementary technology and industrial strengths of Faurecia and HELLA. With over 300 industrial sites and 77 R&D centers, 150,000 people, including more than 35,000 engineers across more than 40 countries, FORVIA provides a unique and comprehensive approach to the automotive challenges of today and tomorrow.

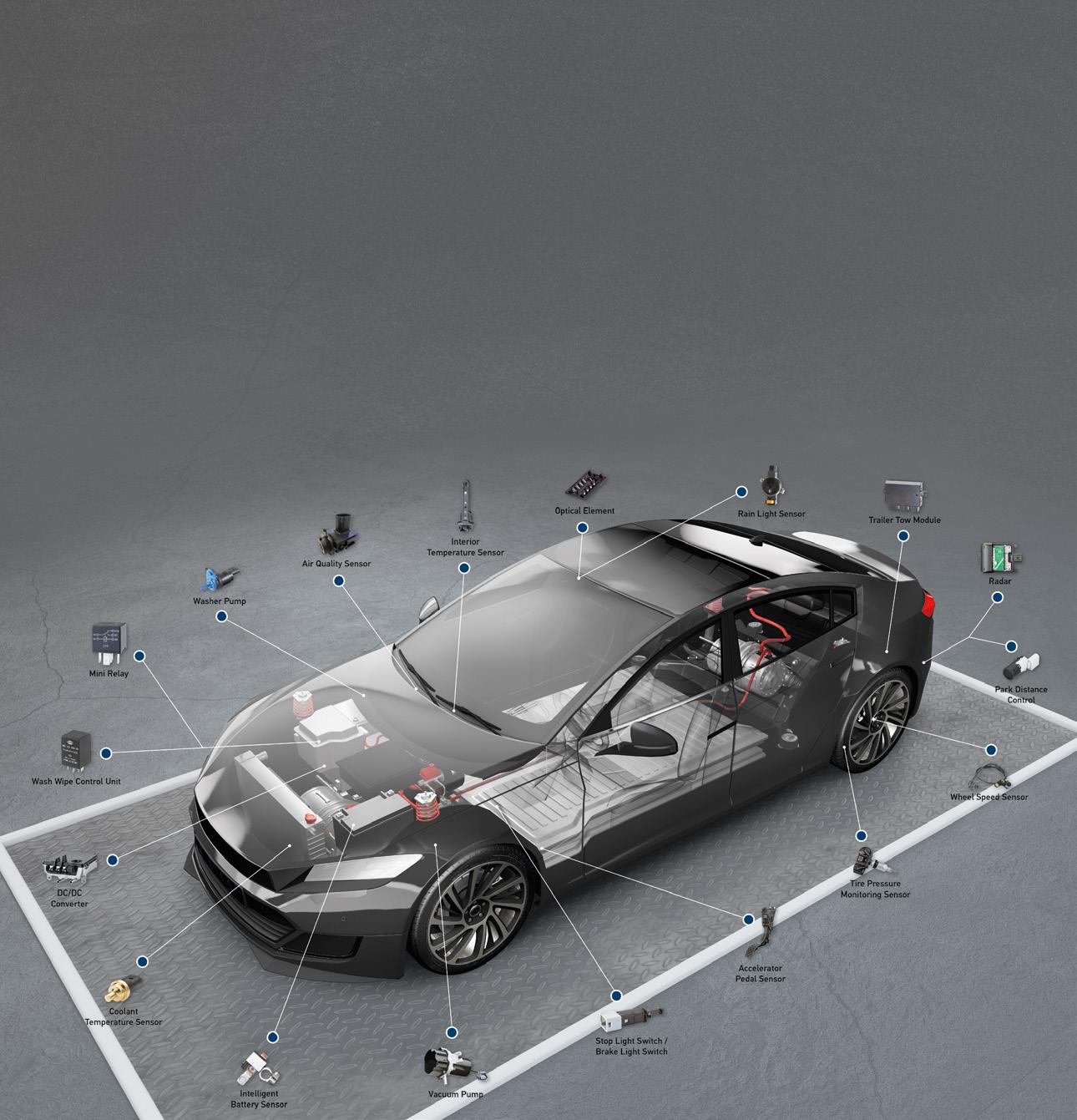

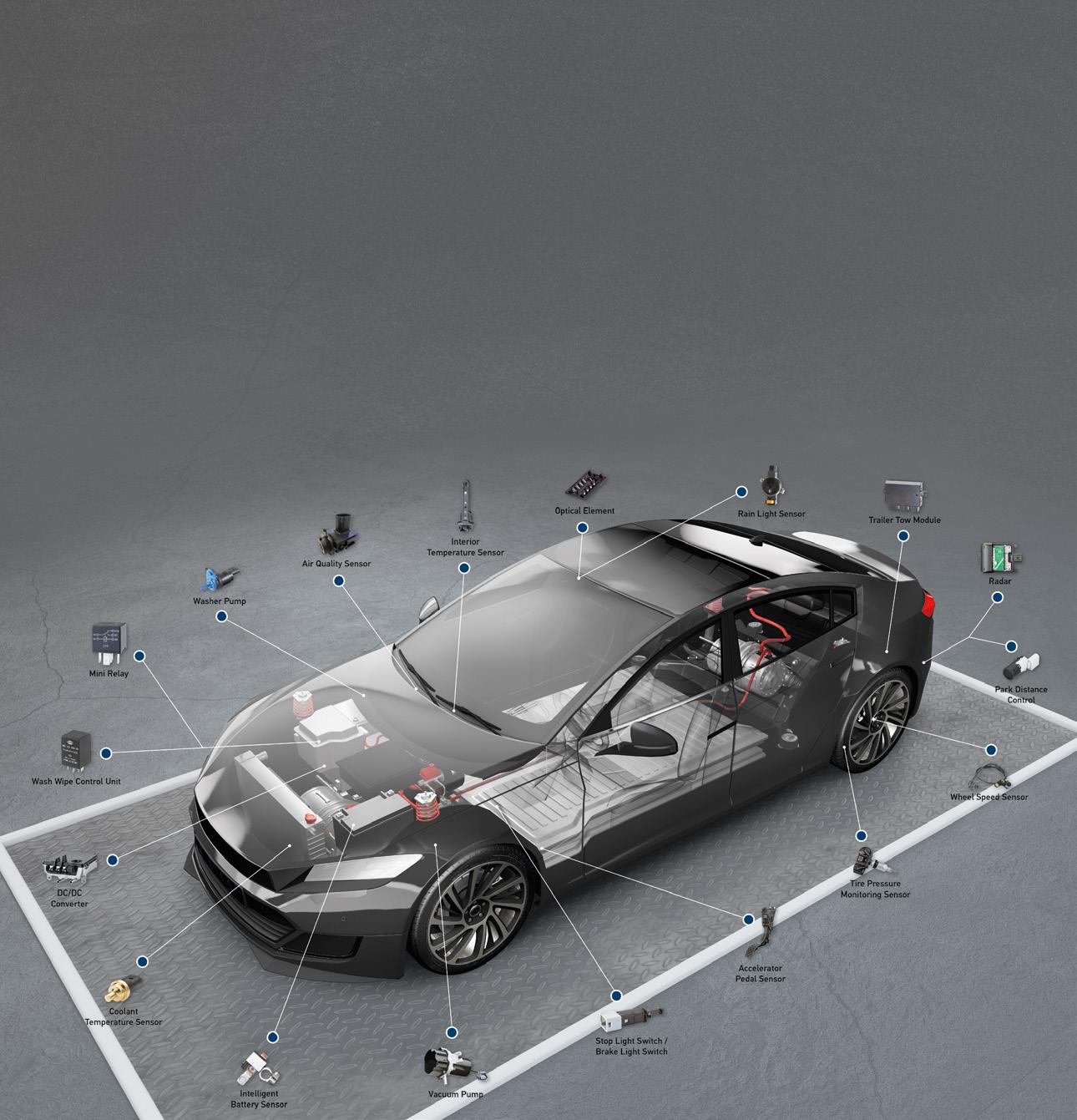

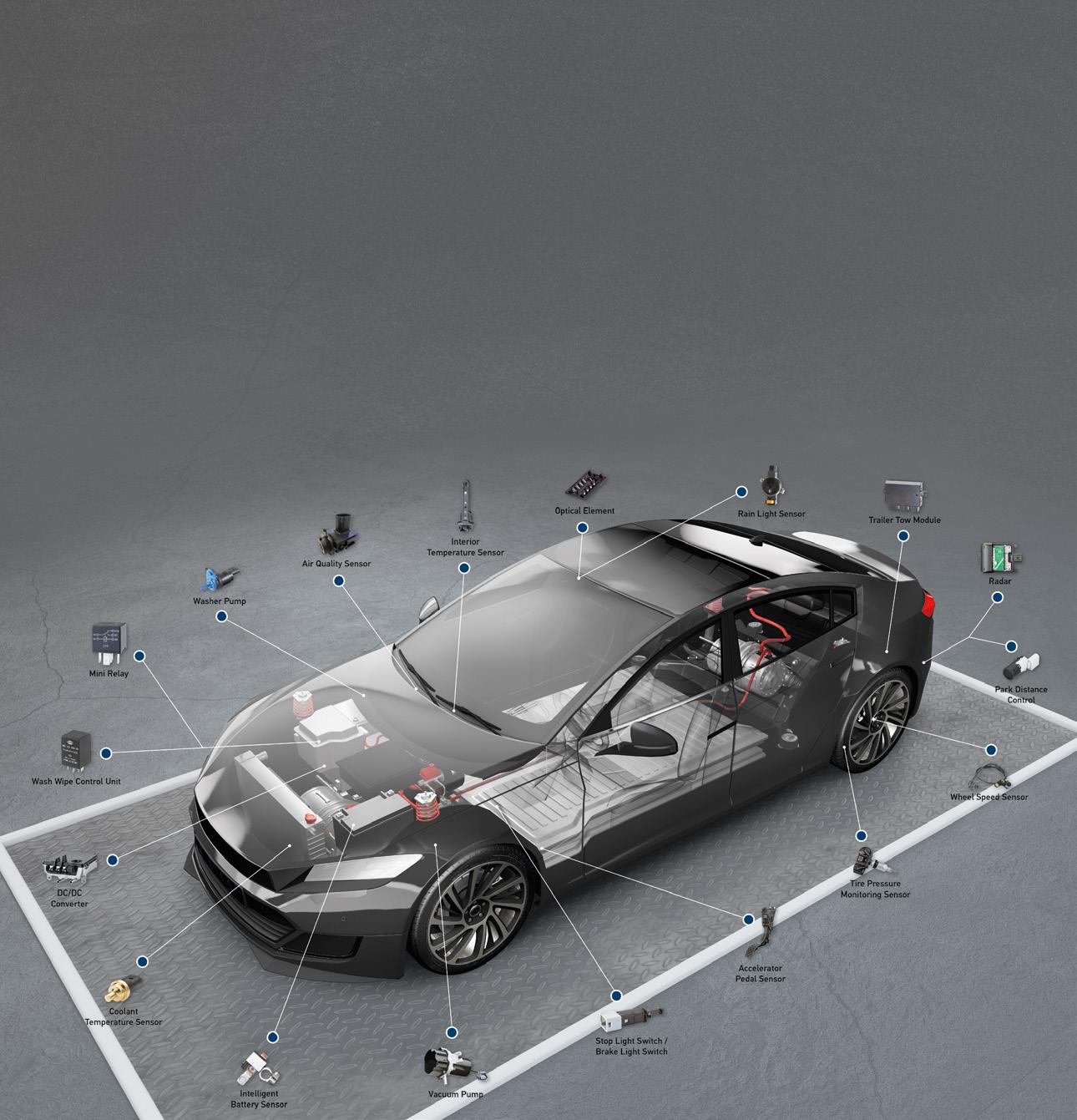

Growing range of parts for electric vehicles

HELLA is responding to the growing share of electric and hybrid vehicles in the fleet with an equally growing spare parts portfolio. The range currently includes around 100 items for the electric drive and energy management. New additions are user-friendly Mode 3’ charging cables for single-phase and three-phase charging in the private and public sector. In the coming months, the product portfolio for high-voltage vehicles will be expanded by more than 250 items.

www.hella.com

For more information:

E-MOBILITY: A new global leader uniquely positioned to grow and accelerate innovation creating the 7th largest automotive supplier

ENABLING

As a partner of independent parts distributors and workshops, we are fully familiar with the daily challenges you face. That’s why it is particularly important to us to give you active support, so that you can respond quickly and remain profitable. As a leading manufacturer of OE driveline components, we supply aftermarket parts that fit perfectly and repair solutions for all the major vehicle models. In addition, with our new, ultramodern warehouse logistics system we can make our products available quickly.

better www.gknautomotive.com

Experience

Always by your side – yesterday, today and in the future.

Recognised by the Agency for Natural Resources and Energy of the Ministry of Economy, Trade and Industry of Japan as a company that excels at saving energy, KYB is commited to manufacturing products that are friendly to people and the Earth, as well as actively adopting environmental conservation activites.

KYBSuspension @KYBEurope KYB-Europe KYBEurope kyb-europe.com recycling9 ofmanufacturimaterials solarpanels installed atgifunorth - theworld’s largestshock absorberfactory $4.7 million spent on environmental conservation in 2019 o e s u p pl i ertotheworld’s f i r s t massproduced e l e c t r i chybridvehiclet h e t oyotaprius OESuppliertothe top3selling electricvehicles ineurope ecommittedtoreducing nergy consumptionby 1% everyyear

Innovation and sustainable mobility

You can rely on it

The internal combustion engine will keep us busy for quite a while. But the future belongs to e-mobility and other emission-free drives. On the street and in the workshop.

That is why we take care of one thing without leaving the other: MAHLE develops and offers the right products and solutions as well as a comprehensive service for sustainable mobility, whether with an internal combustion engine, electric drive or alternative technologies and fuels. Our range extends from engine cooling and air conditioning to engine parts and filters, to workshop equipment and diagnostics.

At a time when mobility is changing rapidly, we need an experienced, trustworthy and innovative partner. Someone who

not only guarantees quality, reliability and expertise, but also knows the ways that no one has “driven” before.

With MAHLE, your workshop delivers 100% performance –today and tomorrow.

mahle-aftermarket.com

BE CLIMATENEUTRAL WITH ITS FULL LINE OF PRODUCTS BY 2030 SIDE INSIDE EDITION 30 • DECEMBER 2022 40

MEYLE UNVEILS ITS FIRST CLIMATE-NEUTRAL PRODUCT RANGE

• MEYLE HD steering and suspension parts have been the first climate-neutral product range available in the independent aftermarket since June 2022.

• MEYLE plans to be climate-neutral with its full line of products by 2030 as reiterated during the last edition of the COP27 in Sharm El Sheik.

Having launched the first MEYLE HD part 20 years ago, the Hamburg-based manufacturer is now transforming its MEYLE HD steering and suspension parts into the first climate-neutral product range in the independent aftermarket. The company aims to be climate-neutral by 2030.

MEYLE has been working to improve the carbon footprint of MEYLE HD steering and suspension parts since 2019 and has managed to significantly reduce production emissions through energy efficiency measures and the use of wind power. MEYLE is now taking the next decisive step and working with ClimatePartner to compensate for the CO2 emissions associated with MEYLE HD parts in the steering and suspension category. These parts are largely manufactured at the company’s own plant in Turkey, which like the MEYLE headquarters in Hamburg, has been certified car-

bon-neutral since 2021 (Scope 1 and 2 in accordance with the GHG Protocol). The concept behind MEYLE HD parts has always been sustainable: repairing rather than replacing the entire unit – with spare parts more durable than the original. “That’s good. But for us, it’s not enough. We want to be a driving force in a very heterogeneous and international sector,” says Florian Gaertner, MEYLE Corporate Responsibility Manager. “That’s why we committed ourselves to the UN Global Compact in 2021, are systematically accelerating our sustainability activities and expanding them step by step.”

Sustainability management now comprises a whole host of projects across all company departments. Our most important aim is to offer a product range that is entirely climate-neutral by 2030, with a key focus on avoiding CO2 emissions.

“We’re doing everything in our power to make this happen and will only compensate for remaining emissions with investments in sustainable projects”, says Gaertner.

The company’s headquarters and SIO production facility for steering and suspension parts are already certified carbon-neutral. The next step is to make all the other sites carbon-neutral. MEYLE is also making an effort to reduce its suppliers’ CO2.

By using CO2-reduced materials - such as “green aluminium and steel” - the company is planning to further reduce CO2 levels in the future. Thanks to a switch in packaging and shipping materials in logistics, MEYLE has already reduced its use of plastic by around four tonnes a year, with further reductions still to come.

Sustainability and the ongoing mobility transformation are very important to MEYLE. This is why, in 2016, the company invested in the infrastructure necessary to allow employees and guests to charge their electric vehicles.

Motorsport also generates important information about how the parts perform, allowing MEYLE to further develop them and make the products even more durable. MEYLE has set its sights firmly on new drive technologies and, since last season, has sponsored the first ADAC Opel e-Rally. The current progress report on human rights and the environment is available on the MEYLE CR website.

SIDE INSIDE EDITION 30 • DECEMBER 2022 42

BE CLIMATENEUTRAL WITH ITS FULL LINE OF PRODUCTS BY 2030

Sustainability at MEYLE

MEYLE works with its partners to increase efficiency throughout its value chain and make it more sustainable. With climate change and the energy revolution, the scarcity of resources, increased awareness of sustainability and green vehicles, the need to act has never been as great as it is today. Sustainability management at MEYLE is based on the three pillars of the sustainability triangle: cost efficiency, people and the environment. Our goal is to be climate neutral by 2030.

THREE STRATEGIC CR GOALS:

1. ENVIRONMENT

Reducing CO 2 until carbon neutrality is achieved – in an effort to decelerate climate change.

2. COST EFFICIENCY

We want to offer the best, and most sustainable, automotive spare parts.

WHAT HAS BEEN ACHIEVED TO DATE. SOME MILESTONES:

MEYLE’s headquarters in Hamburg has been certified as CO2-neutral. The same applies to the MEYLE AG website.

By using 100 per cent green electricity, we saved 860 tonnes of CO2 in 2021.

3. PEOPLE

Empowering employees and improving the greater good.

We have offset unavoidable emissions by investing in climate protection projects. Emissions are measured according to the Greenhouse Gas Protocol (GHG).

By digitising our employee magazine, we have saved 35,000 sheets of paper per year. We have also reduced the number of printed product catalogues and promotional materials, which has saved further resources.

We promote electric mobility and provide electric vehicles and charging infrastructure.

By switching to LED lighting in our warehouse, we have reduced our previous electricity consumption by around 30%.

In 2021, we signed up to the UN Global Compact initiative.

Our company restaurant ‘SchlemmerMEYLE’ has had organic certification since 2020.

The award-winning green roof on the company building is good for the environment and is popular with our employees.

MEYLE strives to create technically enhanced products that offer drivers more sustainable solutions for vehicle repairs and maintenance. Our MEYLE HD parts, in particular, last longer thanks to their optimised design.

As of June 2022, MEYLE HD steering and suspension parts are the first climate-neutral product range in the independent aftermarket. We use green electricity in our own production facilities and have reduced our CO2 emissions considerably. To offset previously unavoidable CO2 emissions from our steering and suspension parts, we have invested in a hydroelectric power plant in Turkey through our partner ClimatePartner.

For more information about all activities, see: Corporate Responsibility (meyle.com)

We have reduced the amount of plastic in logistics and packaging by 4 tonnes per year.

CONTACT:

MEYLE AG, Sarah Quinn

Tel.: +49 40 67506 7234

E-Mail: press@meyle.com

MEYLE AG, Benita Beissel Tel.: +49 40 67506 7418

E-Mail: press@meyle.com

FACTSHEET

4t

100%

Mando’s new series hybrid drive system, the Mando Pedalrite, gives electric vehicles and e-cargo bikes a technological edge.

The demand for e-commerce delivery will result in more delivery vehicles in inner cities, leading to a rise in both emissions and traffic congestion without effective intervention. This is one of several reasons why Mando Corporation made its grand entry into the bicycle industry 10 years ago.

After the Mando Footloose, the world’s first chainless e-bike, the company now presents a revolutionary technology that addresses what is essential for reducing pollution in cities: a system that increases the functionality of heavy duty e-cargo bikes and people carriers. This makes emission-free deliveries even more attractive for both companies and consumers.

Pedalrite:

The Mando Pedalrite is a powerful chainless drive system designed primarily for electric cargo vehicles. It provides manufacturers with an integrated e-Mobility Module platform that consists of ePedal (alternator), electric motor, battery, wire harness and HMI+HBC.

Mando’s series hybrid drive system, the Mando Pedalrite, made its official debut at Eurobike this year. Five test vehicles were introduced: CitKar, BAYK, B&P engineering, Hopper and ECCOV and with great success. Visitors were able to test drive the vehicles at the outdoor booth, and everyone was impressed by the natural, intuitive pedal feeling and simplicity. That was before they even found out that the drive system was chainless.

hlmandoaftermarket.com

Less raw material consumption Low energy to manufacture Clean environment production (Gray Room) Easily recyclable

GREEN

Filtration preserves the environment by filtering atmospheric emissions through suitable materials (e.g. polyester media) THINK

THINK

SMALLER PRODUCT BOXES RESULTS IN LESS CARDBOARD USE

NRF SUSTAINABLE PROJECTS

NEW PRODUCT BOX SIZES

NRF started up an internal project to reduce their packaging sizes. If a box is too large, you are shipping a lot of air, which is of course not the ideal situation. The box sizes of 1,250 fast movers were checked carefully. The outcome was interesting. We found with 43% of the products, the box size could have been reduced. With some boxes, it will be only be a matter of a few centimeters, but with others the savings would be much more. NRF is now implementing these box changes.

The reduced box sizes will save a lot in terms of transport movements and costs. And, given that the sales numbers of these items are high, it will even save the use of some complete containers. Moreover, it considerably reduces the amount of cardboard needed and this will save the customer racking space in their warehouse.

NEW EDGE PROTECTION

Quality is more than just the reliability of our parts. NRF wants to ensure that our products are optimally protected during transport and storage. Therefore, new edge protection has been introduced, which prevents products from being damaged and then returned. These cardboard corners are lightweight, strong and up to two meters long. They also help to stabilize the load during shipping and storage. Simple and highly effective!

REDUCED TRANSPORT THROUGH LOCAL DISTRIBUTION

NRF has 7 warehouses strategically located throughout Europe. The main aim of this approach is to be

SIDE INSIDE EDITION 30 • DECEMBER 2022 46

close to our customers. Each location has its own local customer service and sales team. Furthermore, each location has its own warehouse. These local warehouses are supplied by the European Distribution Centre in Gdansk, Poland. The main advantages of local warehouses are that deliveries to customers are quick and the transport distance is as short as possible.

DEVELOPING AN AFTERMARKET RANGE FOR ELECTRIC VEHICLES

The global electric and hybrid vehicle market has taken a huge leap forward in the past decade. Looking at the global electric car parc, the development is enormous. And, of course, this number is only growing. Although electric vehicles do not have a combustion engine, they still require cooling parts to cool the battery and power electronics. And since they are all equipped with an

air conditioning system, they all need the required A/C parts. The aftermarket for these vehicles is also growing. NRF also proves to be a leading supplier in this specific segment.

Currently, NRF offers the largest aftermarket cooling range for electric vehicles. NRF is supplying a range of 715 references. The range includes a Tesla Model 3 condenser (NRF no. 350517) and pressure switches for a Tesla Model 3 and Model S (NRF no. 38971 / 38972 / 38973).

To promote their electric range, NRF has an orange Tesla Model S, named #nrforangelightning. This show car is used during technical trainings. The NRF TECHsupport team has developed a special training course for electric vehicles. Key topics include safety rules, A/C maintenance and battery (dis)connection.

Live demonstration of NRF’s Tesla Model S (#nrforangelightning) at Automechanika Frankfurt 2022.

Live demonstration of NRF’s Tesla Model S (#nrforangelightning) at Automechanika Frankfurt 2022.

LIQUI MOLY speaks electric mobility, too

The mobility of the future and all solutions from our full range.

LIQUI MOLY offers a full range of automotive chemicals for every type of vehicle. Of course, for fully electric cars, too. There are two new products for them: Top Tec Gear EV 510 is a gear oil especially for Tesla models and the Fuel Cell Coolant FCF20, which is designed for Polymer Exchange Membrane Fuel Cells.

For a complete overview of the range, see www.liqui-moly.com

2

1 Sparkling finish

Oil-driven

An electric vehicle does not run completely without oil. Here, too, is a transmission system that needs lubrication and cooling. LIQUI MOLY carries the right gear oil for every electric vehicle, for example the new Top Tec Gear EV 510 for Tesla models.

4 Service products

As with hybrids, gasoline engines or diesel engines, you can rely on LIQUI MOLY service products for electric vehicles.

Only electric on the label? Only electric inside. An electric vehicle does not need liquid fuel. 5

6

Paint, chrome, glass, plastic: LIQUI MOLY ensures the perfect appearance. Regardless of the drive. This applies not only to the outside, but also to the passenger compartment. An e-vehicle is futuristic and minimalist. Dirt and dust do not fit into this “clean” world. Fortunately, there is a complete care series for the interior from LIQUI MOLY. Leather, upholstery, plastic, metal – these products clean everything.

3 Gluing, sealing, repairing Daily business for LIQUI MOLY: Plastics, metals … whatever. Their products repair everything. Even on electric cars!

Tires and brakes

Although purely electric vehicles may have special tires that are designed for the extremely high torque, they are basically “only” tires requiring the usual service.

LIQUI MOLY delivers everything for changing wheels and the brakes.

Keeping you cool

An electric vehicle has a cooling system for which we offer fluids in accordance with the manufacturer approvals. In order to meet future requirements, modern batteries require special non-conductive coolants. And LIQUI MOLY offers cooling fluids even for fuel cells.

3 5 6 1 1 2 2 4

Driving your business

Thanks to our REMAN program, we have been able to recycle more than 24,000 metric tons of aluminum, steel and cast iron over the past 30 years. aftermarket.borgwarner.com

Providing sustainable solutions

Now and in the future Our value propositions, reliable, sustainable, ready for tomorrow

MAIK EVERS

Head

A UNIQUE E-AXLE SOLUTION

Mr. Evers, the Schaeffler Group was named one of the 50 Sustainability & Climate Leaders by the United Nations. What does this mean?

For us, the appointment of the Schaeffler Group by the UN as one of the Sustainability & Climate Leaders is not just recognition of the work we have done to date, but as an incentive and an obligation to continue implementing our sustainability strategy with the utmost consistency. That´s why, the United Nations’ 17 Sustainable Development Goals (SDGs) form the foundation of our sustainability engagement today and in the future.

In more detail, what is the timeframe and concrete targets you are working on?

Schaeffler has set itself ambitious goals: All production within the Schaeffler Group is to become

BECOME CLIMATE-NEUTRAL BY 2030

SIDE INSIDE EDITION 30 • DECEMBER 2022 50

of Product Management, Schaeffler Automotive Aftermarket

climate-neutral by 2030, with the supply chain scheduled to be decarbonized by 2040. As early as 2024, Schaeffler plans to only obtain electricity from renewable energy sources at all its locations around the world. And, because sustainability is not limited to climate protection, Schaeffler will also reduce its freshwater consumption by 20 percent by 2030 and address safety at work.

How does the Schaeffler Automotive Aftermarket Division support these overarching goals?

Within our division we are contributing to the set targets of the Schaeffler Group. Additionally, our repair solutions are extending the lifetime of vehicles. In close cooperation with Schaeffler’s Automotive Technologies division, we are further bringing the topic of e-mobility into the independent aftermarket. Specific focus is here on expanding and extending our product range for full & plug-in hybrids. As of today, we cover more than 85% of chassis and engine components for hybrid vehicles. Moreover, we are also already considering full electric vehicles. A recent example of this is our new Schaeffler E-Axle RepSystem-G, a unique solution for repairing e-axles. Further, new digital tools are helping us to maintain, sell and distribute our 20,000 repair solutions in a sustainable way. Intelligent, virtual warehouse functions are connecting our customers’ distribution systems in the spare parts market to ensure that we only produce, store and ship what is actually in demand. And, by bundling the assembly and logistics activities in our Aftermarket Kitting Operation (AKO), we are saving more than 2,500 tons of CO2. Year in, year out. The result: far lower resource consumption

and greenhouse gas emissions, less waste and a reduction of space requirements.

Can you please give some more details about the new repair solution for e-axles?

The Schaeffler E-Axle RepSystem-G is a first-tomarket repair system for the gearbox application of the Volkswagen e-Golf VII. It allows garage experts to repair the e-axle instead of replacing it. Thus, this dedicated repair is not only cheaper for the car driver, but also much more sustainable. Thanks to our dedicated know-how, the Schaeffler E-Axle RepSystem-G includes all the relevant components for a professional gearbox repair in one box. This makes it specifically easy, convenient and safe for garages when ordering our parts. We have officially launched this unique repair system at Automechanika Frankfurt 2022 and are looking forward to bringing it to the market by early next year.

https://aftermarket.schaeffler.com

POINTS FOR PROS

A CUSTOMER LOYALTY PROGRAMME WITH MULTIPLE BENEFITS

One customer loyalty programme, four companies, ten brands. The proPoints programme is the perfect win-win, where workshops and parts dealers purchasing Aftermarket products are rewarded with high quality consumer goods.

NGK SPARK PLUG, working together with CLARIOS, HELLA and ZF, has a very attractive and successful customer loyalty programme. ‘proPoints’ gives participants the opportunity to collect bonus points when purchasing the premium brands NGK Ignition Parts, NTK Vehicle Electronics, HELLA, Hella Pagid, Hella Gutmann, ZF, LEMFÖRDER, SACHS, TRW and VARTA. That is more than 70% of the Aftermarket products garages purchase.

Covering such an impressive range of brands, it is no wonder that proPoints has already achieved significant success. Up until now, the programme has been available to workshops in Austria and Germany, and many have signed up to take advantage of its wide range of offers. That success has encouraged the companies involved to expand the programme to Poland, where workshops now also have the opportunity to collect bonus points. The programme will be extended to further European countries in the near future.

One of the appeals of the programme is its simplicity. All a garage needs to do to take part is register at www.propoints.com. It’s easy, completely free and non-binding. Once they are registered, they immediately start collecting 25 points for every 100 euros/500 Polish Zloty spent at participating distributors. Those points can be exchanged for high quality consumer goods ranging from tools, sport equipment and consumer electronics, to office and kitchen accessories.

istockphoto.com

© Vasyl Dolmatov

NEW ENERGY VEHICLES COMPONENT PROGRAM

The newest technology vehicles’ car park grows fast, and we are ready to support you with a competitive offering of replacement parts and technical expertise within thermal management systems. Explore the difference in our constantly expanding component program for Hybrid and Electrical Vehicles.

ONE-STOP SHOPPING FOR KEY SYSTEM PARTS CLIMATE, ENGINE COOLING EFFICIENCY & EMISSIONS SYSTEMS THE DIFFERENCE WIDE COVERAGE OF THE MARKET POPULAR APPLICATIONS CONSTANTLY DEVELOPING PRODUCT RANGE GENUINE NISSENS QUALITY SPECIAL FEATURES SECURING LONG LIFESPAN

nissens.com/nev

THERMAL & EFFICIENCY SYSTEMS Be part of the future aftermarket

THE SMALLEST POSSIBLE ENVIRONMENTAL FOOTPRINT

SIDE INSIDE EDITION 30 • DECEMBER 2022 54

BLANCA MARTIN International Trading Groups Manager, SKF

SKF IS A RESPONSIBLE BUSINESS PARTNER. WE SEE SUSTAINABILITY AS A MORAL OBLIGATION.

We want the world to move away from fossil fuel dependency and go into clean technology. In the automotive aftermarket SKF is striving for a smarter and better industry.

Our contribution is to make and design our products lighter, with lower friction, longer lasting and more efficient, as well as to be able to produce and supply with the smallest possible environmental footprint.

Around the world, a growing number of countries are set to phase out the production of combustible engine vehicles over the next two decades. As part of their commitments to the Paris agreement on climate change, the global automotive industry faces its most significant transformation ever.

SKF has been helping the automotive industry meet different challenges since the beginning of the electrical vehicle (EV) revolution. For EVs

to work efficiently, the motors that drive them must run at very high speeds. This places enormous strain on the bearings. We are developing designs for bearings – and their associated polymer cages and lubricants – that ensure they can withstand the higher speeds, acceleration, temperatures, and electric currents generated by these motors. Today, we are partnering with key OEM and Tier 1 pioneers for the launch of full EVs. We have the technical, manufacturing and supply chain capabilities needed to support the sector’s accelerating growth. Our leading low friction solutions for EV motors, drivetrains, and wheel bearings are key enablers to increase vehicle range, a technology transformation towards a carbon neutral vehicle market.

THE SMALLEST POSSIBLE ENVIRONMENTAL FOOTPRINT

All in all, SKF Group has set the target to reach net zero greenhouse gas emissions in our own facilities by 2030. We have achieved the target in 4 factories already, for example by increased energy efficiency, and reduced emissions from purchased energy. And, at the same time, we have also improved safety, reduced water use, increased lifetime of applications, increased material efficiency, reduced noise levels, etc.

In July 2021, SKF signed on to the Science Based Targets initiative (SBTi) and committed that all its climate targets shall be in line with the Paris Agreement, to limit global warming to 1.5C. SKF will reach net zero emissions by 2050 (from raw material to finished product). As part of this updated approach and to engage with other stakeholders to drive change, SKF joined the SteelZero and ResponsibleSteel multi-stakeholder initiatives in 2021. SKF Group uses the Sustainable Development Goals (SDGs) from the United Nations to collaborate more closely with customers, to create customer sustainability performance, and to deliver even more sustainable solutions.

SIDE INSIDE EDITION 28 • JUNE 2022 56

The perfect motion is the one you can stop

New SKF Brake Pads

For technical support and insights visit: vehicleaftermarket.skf.com or scan the QR code to know more about the SKF products..

® SKF is a registered trademark of the SKF Group. ©SKF Group 2022

*Retains up to 99,97% of particles up to 0,3 microns. Capable of capturing very small particles such as some viruses, bacteria and pollens. Time to take care of your health: keep purified air inside your car!

NEW INNOVATIVE CABIN FILTER

NEW INNOVATIVE CABIN FILTER

Strong partner for e-commerce

For success in the automotive aftermarket, reaction times, timeliness and accurate product data are crucial. The importance of online commerce is growing rapidly around the world, and so is the need for high-quality data that enables accurate product identification and correct ordering.

TecDoc is increasing customer confidence in online purchasing with its large-scale data quality initiative. Excellent data quality leads to more orders, fewer returns and better service. The customised catalogue and web shop solutions using TecDoc data support aftermarket community members in setting up and optimising their e-commerce activities.

At Automechanika, TecAlliance presented the new data management solution DMM Online. With this intuitive online tool, parts manufacturers can manage their product offerings in the TecDoc standard and make them available at points of sale.

Data is sent via the innovative TecDoc Instant Data Processing (IDP) interface: this shortens the time to market because updates can be transmitted almost in real time. All data sent via IDP is immediately integrated and published worldwide in the TecDoc Catalogue and in catalogue solutions based on TecDoc data.

Optimal processes from availability request to return

TecCom solutions cover all processes related to order processing in the automotive aftermarket ‒ from availability requests and parts ordering to electronic invoices and returns.

The basis for automating these processes is optimum message quality from parts suppliers, combined with the highest possible standardisation and data consistency. With the “TecCom Excellence Program”, TecAlliance offers wholesalers an efficient tool to compare suppliers. The rating system acts as a business catalyst, allowing buyers to evaluate new partnerships and strengthen existing business relationships.

Complaints and returns are a big issue ‒ also in the automotive aftermarket. Professional and transparent processes provide the chance to minimise the time and costs required for these tasks while at the same time increasing long-term customer satisfaction and loyalty. TecCom Returns enables standardised and transparent processing of returns and warranty claims. Via the online portal, wholesalers can immediately create warranty and returns claims free of charge and transmit them to all their suppliers worldwide. Workshops can enter returns claims quickly and easily via the Garage Link, even without access to the TecCom Portal.

For more information visit: www.tecalliance.net

OFFERING INNOVATIVE RANGES OF FLUIDS

SIDE INSIDE EDITION 30 • DECEMBER 2022 60

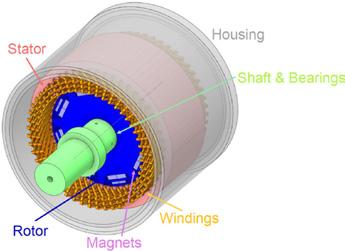

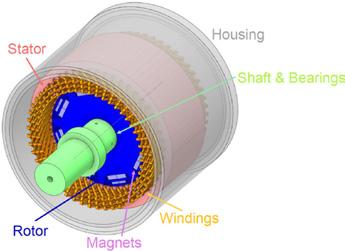

THERMAL MANAGEMENT SOLUTIONS FOR ELECTRIC MOTORS AND SUSTAINABLE

As various EV architectures compete for the leadership position, all players are facing fast-moving challenges for electric fluids formulation. Fluid marketers are looking to take advantage of this unique opportunity by diversifying into EV fluids markets. Among them, TotalEnergies is considering this technological trend as the most important driver change to meet market developments and customer needs, with cutting-edge technologies.

As power densities increase, standard e-motor cooling methods (based on air or external water-jackets) fail to deliver the necessary heat removal performances. Moreover, for compact and weight-efficient drive solutions, e-motors are increasingly coupled in e-axles with transmissions, forming a unique gearbox. The same oil used for lubrication is also deployed, with pumping systems, in the e-motor cooling circuit. Thus, having a new approach enables us to cover both the e-motor cooling and the lubrication of the gears and rolling bearings, which can be very advantageous.

The architecture of next-generation electric vehicles will require the development of a single type

of fluid for their electric drive units (EDUs), combining high-performance lubrication of the transmission and efficient motor cooling. First-generation electric motors were entirely air-cooled, but the low specific heat capacity of air in relation to its volume required a different strategy. Thus, water cooling systems began to appear, soon challenged by dielectric cooling fluids, a much-needed step that was also pushed by TotalEnergies. The so-called innovative direct-oil-cooling strategy allows serial production of EDUs with higher torque and power density at a lower weight.

TotalEnergies, in collaboration with EnginSoft, compared two cooling strategies for a state-ofthe-art Permanent Magnet Synchronous Motor: - an indirect water jacket embedded in the stator, - direct oil jets from a hollow rotor shaft hitting the coils and other critical areas.

Although the housing and stator are slightly cooler, it was clearly observed that the rotor and winding regions reach higher temperatures in the water-jacket system. Particularly critical in this is the rotor, which houses the permanent magnets whose performance can be affected by temperature variati-

The fast electrification of the automotive industry creates a new demand for a variety of electric fluids including thermal management fluids for battery, electric machines, and associated power electronics.

NEXT-GEN MOBILITY

cooling circuit. Thus, having a common approach enables us to cover both the e-motor cooling and the lubrication of the gears and rolling bearings, which can be very advantageous.

cooling circuit. Thus, having a common approach enables us to cover both the e-motor cooling and the lubrication of the gears and rolling bearings, which can be very advantageous.

The architecture of next-generation electric vehicles will require the development of a single type of fluid for their electric drive units (EDUs), combining high-performance lubrication of the transmission and efficient motor cooling. Firstgeneration electric motors were entirely aircooled, but the low specific heat capacity of air in relation to its volume required a different approach. Thus, water cooling systems began to appear, soon challenged by dielectric cooling fluids, a much-needed step that was also pushed by TotalEnergies The so-called innovative directoil-cooling strategy allows serial production of EDUs with higher torque and power density at a lower weight.

The architecture of next-generation electric vehicles will require the development of a single type of fluid for their electric drive units (EDUs), combining high-performance lubrication of the transmission and efficient motor cooling. Firstgeneration electric motors were entirely aircooled, but the low specific heat capacity of air in relation to its volume required a different approach. Thus, water cooling systems began to appear, soon challenged by dielectric cooling fluids, a much-needed step that was also pushed by TotalEnergies The so-called innovative directoil-cooling strategy allows serial production of EDUs with higher torque and power density at a lower weight.

TotalEnergies, in collaboration with EnginSoft, compared two cooling strategies for a state-of-the-art Permanent Magnet Synchronous Motor: - an indirect water jacket embedded in the stator, - direct oil jets from a hollow rotor shaft hitting the coils and other critical areas

TotalEnergies, in collaboration with EnginSoft, compared two cooling strategies for a state-of-the-art Permanent Magnet Synchronous Motor: - an indirect water jacket embedded in the stator, - direct oil jets from a hollow rotor shaft hitting the coils and other critical areas

ons over time. Overall, the average temperature for direct cooling is 10°C lower with detailed mapping given in the following graphs and illustrations.

Although the housing and stator are slightly cooler, it was clearly observed that the rotor and winding regions reach higher temperatures in the water-jacket system. Particularly critical in this is the rotor, which houses the permanent magnets whose performance can be affected by temperature variations over time Overall, the average temperature for direct cooling is 10°C lower with detailed mapping given in the following graphs and illustrations

Although the housing and stator are slightly cooler, it was clearly observed that the rotor and winding regions reach higher temperatures in the water-jacket system. Particularly critical in this is the rotor, which houses the permanent magnets whose performance can be affected by temperature variations over time Overall, the average temperature for direct cooling is 10°C lower with detailed mapping given in the following graphs and illustrations

3L/min – 6,000rpm 3L/min – 6,000rpm 3L/min – 6,000rpm 3L/min – 6,000rpm Water-Jacket Direct Oil-Cooling Water-Jacket Direct Oil-Cooling Average Temp. [°C] Maximum Temp. [°C]

3L/min – 6,000rpm 3L/min – 6,000rpm 3L/min – 6,000rpm 3L/min – 6,000rpm Water-Jacket Direct Oil-Cooling Water-Jacket Direct Oil-Cooling Average Temp. [°C] Maximum Temp. [°C]

Housing 96 98 (+2) 102 102 (+0)

Housing 96 98 (+2) 102 102 (+0)

Stator 107 103 (-4) 120 111 (-9)

Stator 107 103 (-4) 120 111 (-9)

Windings 125 104 (-20) 132 110 (-21) Rotor 125 116 (-9) 133 125 (-8)

Windings 125 104 (-20) 132 110 (-21)

Rotor 125 116 (-9) 133 125 (-8)

Magnets 129 120 (-9) 133 125 (-8) Shaft 107 99 (-8) 123 114 (-9)

Magnets 129 120 (-9) 133 125 (-8) Shaft 107 99 (-8) 123 114 (-9)

ses significantly when the temperature rises. For decades, the lubricant industry has sought to optimize friction and fuel economy, but today it focuses on improving the thermal properties of the fluids it offers, with thermal management replacing fuel economy as the new leitmotif. With its high dielectric properties, oil can be sprayed or splashed directly wherever heat is generated, resulting in significantly lower average and maximum temperatures of crucial components such as magnets and coils. Direct oil cooling thus opens the way to higher power densities for the future generations of e-motors and optimized cooling control strategies.

3L/min – 6,000rpm Water-Jacket

3L/min – 6,000rpm Water-Jacket

3L/min – 6,000rpm Direct Oil-Cooling

3L/min – 6,000rpm Direct Oil-Cooling

Several flow rate configurations were tested to study the behaviour of the e-motor for the oil jet in the worst case and for indirect cooling in the best-case scenarios (2 l/min versus 20 l/ min). The average temperature of the windings for oil cooling is at least 14°C lower. This trend is also confirmed at a higher speed condition (10,000rpm), where the temperature can reach higher values. For this operating point, it has been reported a higher temperature difference (above 40°C) for the two cooling strategies.

Key take-away

The thermal properties of electric vehicle fluids are of paramount importance because the efficiency of electro-mechanical conversion decrea-

TotalEnergies Lubricants is stepping up its position as a global and integrated player in electric mobility, by offering innovative ranges of fluids for electric and hybrid vehicles: Quartz EV Fluids, dedicated to light vehicles, Rubia EV Fluids for industrial and utility vehicles, as well as electric buses and Hi-Perf EV Fluids for two-wheelers. Resulting from extensive work led by R&D teams, these new ranges of fluids have been especially designed to meet the needs and technical requirements of electric and hybrid vehicles. Designing the thermal management system in an electric vehicle properly is key to improving driving ranges, which is a big challenge not only for the battery pack but also for other components such as the electric motor and/or power electronics. Strong efforts have been made in optimizing cooling performances of dedicated solutions towards Electric Drive Units, identified as EV-Drive MP and EV-Motor families.

SIDE INSIDE EDITION 30 • DECEMBER 2022

62

Quartz EV fluids are developed through extensive R&D efforts and tailor-made technical solutions to meet the new electrical, thermal and friction constraints of hybrid and electric vehicles. As a trusted partner of car manufacturers, TotalEnergies Lubrifiants aims to become the responsible energy company that offers technical and people-oriented solutions, and sustainable performance. Our goal is to promote cleaner mobility, better for people and the environment.

LEADING THE WAY IN ITS REMANUFACTURING PROCESS

SIDE INSIDE EDITION 30 • DECEMBER 2022 64

SUSTAINABILITY IS VALEO’S RESPONSIBILITY

Valeo has set the non-negotiable goal of being carbon neutral by 2050 and will achieve 45% of that target by 2030. As Christophe Périllat, Valeo’s CEO, states, “This commitment is our contribution to a major societal issue – the fight against global warming.” Valeo regards its position at the forefront of the automotive industry as a grave responsibility and has set the foundations to make sure that all of their future technologies are as clean and environmentally-friendly as possible.

Reman(ufactured)

As part of historic sustainable initiatives, Valeo already has thirty-five years’ experience of remanufacturing parts for cars, which has been a key part of going sustainable. From collecting worn parts, dismantling and cleaning them, to finally replacing and reassembling them, Valeo leads the way in its remanufacturing process. Products have great repairability, a robust aftermarket design, and are easily recycled.

Today, Valeo remanufactures one million products every year. As an example, a remanufactured Valeo alternator re-uses more than 90% of the original product. It allows an 80% reduction in carbon footprint, compared to a similar new product, with the guarantee of similar performance and quality. By 2030, Valeo will simply double this volume of remanufactured products.

Switching on to the Future

As of 2022, Valeo is the world leader in the electrification of vehicles, providing millions of cars with electric power each year; and already equipping 1 car in 3 with a Valeo solution. This addresses both

environmental and legislative issues on a global scale. To give an example of how fast the auto industry is being electrified, global electric car sales surged by 140% in the first quarter of 2021, according to the International Energy Agency, and that has only continued to grow in 2022. In the aftermarket, there has also been a huge shift towards electrification and, as a result, Valeo has continued to expand its electric portfolio. Whether it’s a new range of brake pads for electric and hybrid cars, or an Integrated Belt Starter Generator (IBSG 48V), which makes electrification more widely accessible; Valeo is truly rising to the challenge of creating a sustainable car parc.

Valeo Supports Reforestation

On top of many other sustainable initiatives, another key aspect of Valeo’s drive towards a carbon neutral future is the support of global reforestation. Since 2017, Valeo has supported Reforest’Action, a French company with the mission of protecting, restoring and re-establishing forests worldwide as a genuine answer to climate change and the subsequent loss of biodiversity. Reforest’Action has now planted and protected over 17 million trees across 39 countries since its creation in 2010.

The World is What You Make It

Valeo firmly believes that only by working together can we overcome the current crisis we all face. Sustainability is vital to our future and there is no other way but to take personal and corporate responsibility for making our future a greener one. Valeo has every intention of doing that.

INNOVATING FORTHE FUTURE

A History of Changing Gears

Dual Clutches, be them wet or dry, represent exactly what Valeo stands for: history, innovation, reliability, and expertise. Nothing is left on the worktop when trying to find ways to continually improve upon 90 years of progress. The first clutch Valeo ever made was in 1932, and now, almost one hundred years later, Valeo has factories in China, France, Italy and South Korea that produce dual clutches which are currently fitted in 4.9 million vehicles around the world.

Clutches for Everyone

While there are many arguments for the benefits of wet or dry dual clutches, Valeo aims to deliver to the needs of both. Valeo is now in the unique position of selling the exact same range of wet and dry dual clutches to the IAM as those fitted as original equipment on major international brands.

With twenty-five dry dual clutch references and fifteen dual wet clutch references in their range, Valeo has something for everyone. Dual clutches are an integral part of the driving experience. In an automatic transmission car, and although the future of the clutch pedal is in doubt due to automatic cars becoming more prevalent in the marketplace, the dual clutch, itself, is here to stay.

The Difference is in the Name

Dual wet clutches are termed “wet” because of a constant oil supply that keeps the moving parts lubricated, and as a result, cool. Wet clutches are also fitted on a multi-plate design that compensates for the lack of friction, which results from the use of lubricants. Dual wet clutches improve driving comfort by eliminating torque interruption.

Dual dry clutches, unlike wet clutches, have no problem producing friction. They are simpler in nature and use a single plate design, which

doesn’t need a pump to provide liquid coolants.

Always aiming for the best

Valeo’s aim—as always—is to deliver the best for both types of clutch, and by doing so, continually match the modern consumer’s expectations of a driving experience that is smoother, quieter, and more environmentally friendly than ever before.

Valeo’s new dual-clutch transmission—with an electro-hydraulic clutch and electromechanical shift actuation—was developed to ensure high fuel efficiency, low weight, low inertia, and excellent drivability.

In technical terms, Valeo’s innovations over the last two years include:

Excellent acceleration performance through continuous power delivery, with a minimum loss of driving torque.

First class driving performance due to precise electromechanically controlled gear changes.

Smooth gear shifts and good fuel economy resulting from independent control of the clutch actuator.

Electrohydraulic actuation with very low power consumption.

Driving comfort in high torque engines, due to a fast system response and efficient control strategies, which eliminate torque interruption during gear shifts.