PARTIAL DISCHARGE TESTS FOR MEDIUM-VOLTAGE POWER CABLE SYSTEMS

PD SECRETS, TIPS, AND TRICKS PAGE 48

ACCEPTANCE AND MAINTENANCE

TESTING PAGE 56 USING VLF AND PD TESTING PAGE 64

ISSN 2167-3594 NETA WORLD JOURNAL PRINT ISSN 2167-3586 NETA WORLD JOURNAL ONLINE FALL 2020

With the Megger MRCT and MVCT, 2 MINUTES is all the time you need for single ratio combined testing of your current transformers.

This includes winding resistance, excitation, demag, ratio, and phase error testing across all CT classes.

All it takes are 2 minutes and the Megger MRCT or MVCT Current Transformer Test Sets.

MRCT

Relay and current transformer tester

MVCT

VT and CT analyzer

1-800-723-2861 us.megger.com

Electrical Power Systems Industry Resource on Technical and Professional Training FALL 2020: VOL. 5. NO. 2

NE W

LIVE VIRTUAL ONLINE TRAINING

TRAIN LIVE WHILE REMOTE IN ORDER T O STAY SAFE & UP T O DATE

TRAINING INSTITUTE

VIRTUAL TRAINING OPTIONS

-NFPA 70E 2018

-NFPA 70E 2021*

-BASIC ELECTRICITY

-ELECTRIC PRINT READING

-SUBSTATION: COMPONENTS, TESTING & INTERPRETATION

-INTRODUCTION TO LOW VOLTAGE BREAKERS

-INTRODUCTION TO PROTECTIVE RELAY MAINTENANCE

Courses can be attended via Open Enrollment or by requesting dates for your personnel

For questions or to enroll, visit us at avotraining.com/virtual or call us at 877-594-3156

OMICRON Academy: An Engineer’s Playground

-ELECTRICAL SAFETY FOR INDUSTRAIL FACILITIES

-ELECTRICAL SAFETY FOR UTILITIES

-NATIONAL ELECTRICAL CODE 2020

OMICRON invites you to join our classes on Protection Testing, Digital Substations, Transformer Testing, Circuit Breakers, and more in our new on-line interactive trainings or in-person at the OMICRON Academy in Houston.

* available October 2020

Find additional training at omicronenergy.com/na-training

Benefit from professional courses with expert trainers, full-scale training equipment, e ective methodology and excellent customer care. Then, try what you have learned in the classroom with some practical testing at our indoor substation, and hands-on relay test lab.

Eugenio Carvalheira Engineering Manager, Protection and Control

A NETA World Journal

Special Publication

A publication dedicated to disseminating information on technical and professional training for the advancement of the electrical power systems industry

THE RACE TO VIRTUAL TRAINING

By Ralph Parrett, AVO Training Institute

RESPONDING TO COVID-19 WITH ONLINE EDUCATION AND TRAINING

By Dinesh Chhajer and Greg Valdez, Megger

TRAINING TECHNICIANS IN A PANDEMIC

By James R. White, Shermco Industries

FREE monthly webinars

*Earn 1 NETA CTD and 1 PDH or 0.1 CEU

Learn valuable testing tips and tricks

Can’t attend? View video recordings

Testing Tactics Webinar Series

Megger has partnered with NETA (International Electrical Testing Association) to present Testing Tactics, a special monthly webinar series that allows registrants to receive NETA CTDs (Continuing Technical Development Credits)* for attending the live webinar.

The Megger Testing Tactics Webinar Series provides valuable educational electrical testing knowledge in areas including theory and applications, best practices, industry standards / procedures, and safety. These FREE webinars are presented by Megger’s expert Applications Engineers and Product Managers, who utilize their experiences in the field and industry to give you greater insight into electrical testing so you can test with confidence.

Upcoming Webinars

Sep 18

Protection

MV and HV Circuit Breaker

Testing beyond Timing and Travel Measurements

Oct 23

Cable State-of-the-art diagnostics technologies for proactive cable condition assessment

us.megger.com/webinars

Nov 20

Rotating Machines

Fundamentals of motor protection

Dec 18

Protection

LV circuit breaker ground fault protection utilizing primary injection test method

04

FALL 2020

06 10

THE RACE TO VIRTUAL TRAINING

BY RALPH PARRETT, AVO Training Institute

Ihave worked in the electrical industry for nearly 15 years, and I never could have imagined being in the position we have all been thrown into. During my time in the electrical industry, I have worked in many capacities: maintenance and repair technician, project manager for critical system upgrades, technical instructor, curriculum developer, and now playing a key role in a private training company whose business foundation was based on face-to-face safety and hands-on training.

With the honor of a promotion in February, I had a big agenda of my own that I was excited to start on. Bringing our lab equipment up to par with industry standards, refreshing our curriculum, updating our delivery methods, creating classroom environments that are interactive from floor to ceiling — the list goes on and on. I did have plans to develop a learning delivery offering where the instructor would be remote from the learners and training would be provided through a virtual training platform. I had no idea that offering would have to be streamlined to also maintain a presence for our customers. The world’s population has faced adversity in many different ways, and the current situation has done quite the number on how every person has had to make some form of adaptation

to how they conduct their daily lives both professionally and personally. This article focuses on what to expect while attending virtual training courses delivered online as well as the benefits and challenges of virtual learning.

TECHNOLOGY

Virtual online training has grown rapidly to deliver learning opportunities to attendees from pre-K to university — and technical trades are no exception. Virtual online training permits the learner to have nearly the same experience they would in a physical classroom. Most of the information is delivered live by an instructor rather than in a prerecorded session. Attendees can ask questions to gain greater understanding of the topic or to clarify an area they may not feel they have fully grasped. To do this, virtual training platforms offer chat windows and the ability to turn on microphones and webcams that allow students to interact with the instructor and even other attendees. Sounds good right? The sales pitch is easy until you get into an environment you have never been exposed to.

INTERACTION

We are accustomed to and generally thrive on face-to-face interaction inside a classroom, but while attending a virtual online class, the learner is commonly alone, and that can dampen the learning experience. How can we fix this? The instructor is responsible for driving interaction while delivering the content, and the learners are responsible for interacting. The instructor has various methods available to encourage interaction with learners, but it is truly up to the attendee to invest in the interaction.

Understanding that remote learning differs from in-person learning is the best first step; the second step is to dive in. The first time I taught a virtual online course, there were just over 20 attendees. I explained the importance of interaction for their and my own experience and told them that without their interaction, I wouldn’t be able to identify adjustments that needed to be made to achieve learning. Because of their willingness, the objectives were accomplished, and we even had fun while covering the information. If you find yourself attending a virtual online session, I encourage you to open yourself up to this new

4 | TRAINING TALK | A NETA WORLD JOURNAL SPECIAL PUBLICATION

opportunity of learning. You may be surprised with the results.

SAFETY

With everything, there are always benefits and challenges. One major, and obvious, benefit to virtual training is the reduction in health exposure for participants, their families, and their co-workers. One challenge in the virtual training environment is the loss of physical presence. Attendees and the instructor can feel isolated at times, and everyone plays a vital role in breaking through that by participating. Another major benefit for the customer is that the training is delivered remotely. This further reduces health exposure during travel to a training location and reduces the costs of travel to the training location. Even though the information is delivered remotely, it is still possible to receive industry-leading training to increase their knowledge and skills.

Safety is the most vital element in providing the environment the learner needs to be successful. When a learner feels safe, the foundation for learning has been accomplished. Training environments

Understanding that remote learning differs from in-person learning is the best first step; the second step is to dive in.

must think with safety in the forefront, and thanks to entities such as OSHA and NFPA, we have always had great guidelines on how to do so. The integrity of an attendee’s health has always truly been a reflection on the safety of the learning environment. Prior to a global pandemic, there never was much thought about potential exposure to a virus. As a training professional, I can assure you that the health and safety of every individual participating in online learning has, and always will be, the number-one priority.

RALPH PARRETT is a United States Navy veteran with over 13 years of professional experience relating to electrical safety and maintenance training. During his time at AVO Training Institute, his proven dedication to training led to his position as Manager of Content & Delivery. His passion has always been to provide a topnotch training experience to ensure his students are more effective and safer when they return to the workplace. Ralph has extensive knowledge of maintenance, repair, and troubleshooting on control and instrumentation, relay logic systems, ABB control systems, central control station programs, power system equipment testing and maintenance, and other various types of equipment. He has developed and taught theory, operation, maintenance, and safety of various engineering systems.

A NETA WORLD JOURNAL SPECIAL PUBLICATION | TRAINING TALK | 5

RESPONDING TO COVID-19 WITH ONLINE EDUCATION AND TRAINING

BY DINESH CHHAJER and GREG VALDEZ, Megger

The global coronavirus outbreak and related social distancing, remote working, and employee health concerns have drastically altered the way business and training are conducted in a progressively changing landscape. The limitations put in place to prevent the spread of the virus directly affect the ability to adequately train employees in traditional face-to-face settings and call for implementing new digital tactics and educational procedures.

This article provides a picture of possible post-COVID training tools and content that enable technicians and engineers to continue their educational journey.

Our in-person Best Practices Seminars, the monthly Testing Tactics Webinar series, on-site customer training, the Technical Library on our website, and phone support from our technical support group worked well when travel and face-to-face meetings were the norm.

But as the coronavirus took hold, new ways of maintaining contact with our customers required converting from face-to-face to virtual meetings, increasing our digital content, and creating new ways to reach out online.

BEST PRACTICES SEMINARS

Our Best Practices Seminar series has been offered for more than 10 years to share testing concepts, advanced testing techniques, industry standards, and experiences from application engineers. Traditionally, these day-long, in-person seminars were split into two sections:

1. Testing and maintenance discussions related to transformers, batteries, relays, cables, and low-, medium-, and high-voltage circuit breakers

2. Educational hands-on sessions using equipment related to the topic at hand

Still free to all, the 2-day seminars are now comprised of two 1-hour technical presentations and a 30-minute question and answer session each day. The hands-on session has been replaced with a 15-minute description of the test instrument relative to the applications and techniques being discussed. Attendees ask questions and get answers during the Q&A session.

These webinars are held every four weeks and cover topics including battery maintenance, transformer winding condition assessment, partial discharge for assessing insulation condition, power factor and dielectric frequency response for insulation assessment, and cable diagnostics and fault location. Previous Best Practice Seminars remain available to watch online.

TESTING TACTICS WEBINARS

Testing Tactics Webinars provide valuable educational knowledge across several areas, including testing theory and applications, best practices, industry standards and procedures, and safety. These free webinars are presented by expert application engineers and product managers who use their field and industry experiences to provide insight into electrical testing, help users avoid common mistakes, and accelerate testing without sacrificing efficiency — and most important, safety. Held on the third Friday of every month, each 1-hour live webinar is followed by a 15to 30-minute Q&A session. For this series, we collaborated with NETA in North America to allow attendees to receive NETA Continuing Technical Development Credits (CTDs).

Over the years, we have used online webinars to share knowledge and industry experience with our

6 | TRAINING TALK | A NETA WORLD JOURNAL SPECIAL PUBLICATION

customers. The monthly Testing Tactics webinars have proven to be extremely successful, so as the virus shut down our ability to visit customers onsite, the decision was made to focus on broadening the assortment of webinars. From that initiative, several new webinar series addressing testing tactics, special applications, and case studies — and even one called You Ask, We Answer — have been added to meet our users’ educational needs.

Special Applications

The Special Application webinar series was conceived to answer the need to continue product operation trainings amid the coronavirus restrictions. The focus shifted to instrument operation, step-by-step procedures, safety recommendations, and best field practices, as well as the basics of results analysis. The sessions show users how specific instrument features are direct answers to industry-standard requirements and recommendations and/or to typical situations a user will encounter in the field while testing. The 1-hour broadcasts are followed by a live Q&A. Recordings of previous Special Application webinars continue to be accessible online.

You Ask, We Answer

The topical range of our webinars is expanding beyond traditional offerings with a series of webinars based around questions from users. These interactive webinars are all about customers and users and the questions and issues they run into in the field. Webinar attendees can ask questions in real time, and technical experts answer them live during the webinar. The webinar presentations are recorded, so attendees can refer back to the recordings as needed.

Case Studies

The power industry thrives on learning from each other’s experiences. Industry events and technical conferences are some of the best places to share field knowledge and real-world experiences, but most current and future conferences have been either cancelled or are going virtual.

The Case Studies webinars feature application engineers who share their field experiences and the test data that was collected. They walk through how the results were analyzed, outline the troubleshooting steps that were performed, and illustrate the process

of narrowing down the root cause of the problem. The series includes real-world examples collected from various sources, including consultations with utilities and service companies to help them troubleshoot asset problems and get back online safely and efficiently.

The Case Studies webinars cover topics on transformer testing such as winding resistance, turns ratio, power factor, and sweep frequency response analysis. Other assets such as circuit breakers and batteries are also covered.

Ultimately, our new solutions allow us to maintain contact with our customers, and that is the key component.

ONLINE MEDIA

Online media has come to the forefront, as people found themselves unable to travel or work in the field. We knew we had to make more use of online media channels to add content that educated and enhanced our current customers’ use of our equipment.

How-To YouTube Videos

We understand the nature of electrical maintenance activities where a technician might have a good understanding of the technique but does not possess total recall of the operating details of an instrument. These instances generate situations where a quick response from an expert becomes a partner in the job. Gaining easy access to the answers to common issues that arise in the field is imperative. To facilitate this, we created a series of how-to videos related to the frequently asked questions our technical support group (TSG) receives on a daily basis.

The TSG is a team of application engineers and specialists who help electric utilities and testing service companies understand how instruments operate and how to analyze the results from a variety

A NETA WORLD JOURNAL SPECIAL PUBLICATION | TRAINING TALK | 7

of electrical tests. We compiled commonly asked questions to create a series of 3- to 8-minute videos that walk through test procedures and software demonstrations to refresh a technician on operating details or instrument features.

Posted on YouTube, these videos are organized on playlists or can be added to user playlists for quick access while testing as if they were interacting with an applications specialist. The videos cover relay, transformer, instrument transformer, cable, and battery products and can be used as small training capsules on top of being a quick way to find answers to common questions.

Remote Customer Training

In-depth training has traditionally been conducted onsite with sessions conducted by applications engineers who cover the theoretical and practical aspects of the application in question. The need for in-depth training has not stopped, so we adapted to provide this type of training under the current circumstances. The use of platforms like Microsoft Teams has been instrumental, as it allows the same applications engineers to conduct remote sessions with customers, first by enabling remote, webinar-like presentations to cover theory, best practices, procedures, and testing recommendations, and then using audio- and video-enabled devices to conduct controlled-environment demonstrations and explanations using the instruments. The sessions are followed simultaneously on the customer side using their own instruments and test specimens or using demonstration boxes. This allows trainees to acquire knowledge of the application and the procedures, while still getting the experience required for field tests.

Technical Podcasts

Technical Podcasts are 15- to 25-minute discussions related to electrical testing theories, ideas, and practices that provide insight and educational information in an easy-to-digest format. Technical experts including product managers and applications engineers engage in lively discussions that focus on a single subject, or they might answer a series of questions that have been collected from customer interactions.

Technical Library

Our website’s technical library is the repository for the numerous application notes, articles, papers, and technical pieces we produce on an ongoing basis.

Application Notes

The library contains numerous documents related to products, testing, and education that include application notes. An application note addresses a technical topic and condenses the information into a relatively small number of easily digested pages. To date, more than 180 application notes have been released on topics ranging from explaining technology basics to performing a particular test on an apparatus to interpreting results.

Application notes save customers time researching complex technologies or scouring through a product user guide. While some application notes are longer, many are only 1–2 pages in length, making them convenient to provide to field personnel. Some customers print and laminate them for repetitive use.

Transformer Life Management Bulletin

Even during a pandemic, power must be delivered to consumers with a high degree of reliability. Transformers are an important asset for power delivery, and the transformers in our aging fleet need special attention through preventive and predictive maintenance. The Transformer Life Management (TLM) Bulletin goes into the details of diagnostic test methods as recommended in various international standards. The TLM Bulletin is for customers who need an in-depth understanding of transformer testing techniques in order to review test results and get involved in troubleshooting practices. Important topics such as power factor, excitation current, core demagnetization, OLTC dynamic resistance, and moisture in insulation are covered. The TLM series is a great learning resource for transformer operators and asset owners to gain the insight required to make informed decisions to optimize the life of a transformer.

VIRTUAL LEARNING PROGRAM

Our training arm was hit especially hard by the virus as training courses have always been held in person to provide individual attention to students. The inability to teach in that manner meant transitioning to online learning and assessment while maintaining the high level of education we have provided for more than 50 years. This necessity led to our Virtual Learning Program.

In March, we began providing safety and coderelated courses virtually via online platforms. Since

8 | TRAINING TALK | A NETA WORLD JOURNAL SPECIAL PUBLICATION

then, virtual offerings have been expanded to include maintenance-based training for protective relays, breakers, and substations. This platform allows attendees to receive the training required to maintain their qualifications and keeps them up to date on new industry standards. Attendees can interact with each other and the instructor through text, video, and audio chats to provide a learning environment as close to in person as possible.

Case Study

Georgia Power, which owns and operates over 12K miles of transmission and 75K miles of distribution lines, provides electric service to more than 2.5M customers in 155 Georgia counties. A key component to Georgia Power’s implementation of over 100 of our relay tests was a train-the-trainer program for education on the software component. The idea was for our technical and product management staff to train approximately 20 Georgia Power trainers and test engineers.

The original plan to begin in-person training in February 2020 was delayed until March. Then the beginning of the coronavirus eliminated the possibility of any in-person training for the near future. Both parties agreed to a revised plan using video conferencing. The first online training session was conducted in April, and subsequent sessions have continued for nine consecutive weeks of progressive training that has proven our ability to transfer knowledge through the use of video conferencing.

One attendee, Kevin Pierce, a Georgia Power senior protection and control test engineer, stated, “Megger custom-tailored their on-line training for GPC such that they go at our speed to train us on all the features of the core RTMS templates. Since our group supports RTMS for all field personnel, we require this foundation in order to meet our goal of being able to create our own test plans. It is obvious that Megger is committing significant time and effort to ensure we learn what we need to know to be successful.”

CONCLUSION

As we navigated this “new normal” and implemented these new forms of contact, we found we still needed to maintain personal contact with our customers in addition to offering materials online or on media channels. Individual conversations and interactions between people can never be replaced by impersonal media, so many of our daily interactions with clients occur via video conferencing, which has proven to be extremely successful and productive.

Ultimately, our new solutions allow us to maintain contact with our customers, and that is the key component that opens the door for us to share our knowledge and experience in support of the electrical testing industry. As we travel down this unforeseen road, we will continue to research and implement new and exciting ways to maintain a strong training regimen and educational program for our users.

DINESH CHHAJER is the Manager of the Technical Support Group at Megger USA. His responsibilities include providing engineering consultation and recommendations in relation to testing of transformers, batteries, circuit breakers, and other substation assets. Dinesh has presented numerous white papers related to asset maintenance and testing at various conferences within power industry. Dinesh previously worked as an Application Engineer at Megger and a substation and design Engineer at Power Engineers Inc. He is an IEEE member and a licensed Professional Engineer in Texas. Dinesh received his MS in electrical engineering from the University of Texas at Arlington.

GREG VALDEZ has been the Marketing Manager, NAFTA at Megger USA for six years. He previously was the Marketing Specialist at the AVO Training Institute, a Megger Subsidiary. Greg has been in marketing/advertising for over 20 year. He has a BA in advertising from Southern Methodist University and an MBA with a concentration in marketing and product/ brand management from SMU Cox School of Business.

A NETA WORLD JOURNAL SPECIAL PUBLICATION | TRAINING TALK | 9

TRAINING TECHNICIANS IN A PANDEMIC

BY JAMES R. WHITE, Shermco Industries

I’m like most everyone at this point. I’d like to go to a beach, pop a beer, and relax in the sun. Instead, I’m stuck at home writing articles like this because of COVID-19. While most of us are sick of this whole thing, the fact of the matter is that social distancing and masks in public seem to be necessary to keep the numbers reasonable. That’s why I just stay at home, cranking out articles and columns. I look bad in a mask, but wear one anyway.

The question now is how do we train our technicians when we have huge problems getting them to a class? Flying is an issue because, from what I’ve seen on TV, people are packed in because the airlines have to make a profit. Once your technicians get to the training site, will your vendor maintain social distancing by limiting class size, or do they put as many as they can into a class? A good question to ask the technicians you plan to send: Will you maintain social distancing including during breaks and lunch? We don’t want them to be carriers when they return, and younger people generally are not as worried about COVID-19 as older workers. These issues make it difficult to get the needed training in a safe and timely manner.

NFPA 70E’s 2021 edition has not been approved by the Standards Council yet, but I have no doubt it will be in June. All training has been moved to Section 110.6 in this new edition. A new Informational Note to Section 110.6(A)(4) includes provisions for interactive web-based and interactive electronic training. The key word in both of these types of training is “interactive.” The Committee wants such training to allow for immediate responses to questions — not training where questions are written down and answered sometime later. OSHA demands immediate answers and stated the requirement in their Letter of Interpretation dated November 22, 1994, which was published in the Summer issue of this Training Talk supplement to NETA World on page 11.

Our company faces the same problems as everyone else. Our Training Institute will open soon to provide the hands-on training needed so badly by new technicians, but they will be required to comply with a number of rules to keep students safe from the COVID-19 danger. We have also published a detailed operations guideline to keep all our employees safe. That takes care of the in-person hands-on training, but what about refresher and other types of training?

We are addressing this problem on a number of levels. When hands-on training is required for new technicians, we use web-based interactive training plus an environmental health and safety (EHS) or other suitable trainer to start conversations that can provide immediate answers to questions. This has shown to be as effective — possibly even more effective — than having a stand-up instructor fly to each location to present a course. The down side is the need to develop a web-based training program that includes the level of information to make this methodology practical. We have an entire department that does nothing but develop this type of program, so it involves definite cost. I’m not certain how valuable this is for smaller companies, but it is one option.

Another option is a revised program I first witnessed at Dallas County Community College (DCCC) years ago. I was part of a team exploring different options within the DCCC system to expand and more effectively use technology to present training

10 | TRAINING TALK | A NETA WORLD JOURNAL SPECIAL PUBLICATION

programs without live instructors. At the time, an instructor conducted hands-on training on a satellite, and students followed along by having the same type of equipment to work on during the lab sessions as the instructor. At the time, it was considered too expensive to install satellite dishes at all their locations.

Today, with web-based programs such as Microsoft Teams and Zoom, expense is no longer an issue. The idea of having an instructor conduct handson training over an interactive program is very doable. Such training can be delivered at low cost and still meet 70E and OSHA requirements for immediate answers to questions. As an example, a class on safety apparel could feature an instructor with a set of arc-rated and rubber-insulated PPE being transmitted to as many attendees as required. Those attendees would have the same PPE in front of them. The instructor would demonstrate the process of inspecting the PPE and ask for questions or concerns. Using the software, students would be able to ask their questions, and the instructor could provide immediate responses to the questions.

Training can be delivered at low cost and still meet 70E and OSHA requirements for immediat answers to questions.

CONCLUSION

Web-based interactive training is an inexpensive way to provide training to technicians who are not in the office, keeping them separated from each other in a time of virus control, and meeting all requirements to ensure the training is up to the required level. I’m certain this is not for everyone, and there is the issue of keeping the attendees focused on the training, but with a good instructor and proper preparation, it presents a practical way for even smaller NETAmember companies to present needed training to their employees.

JAMES (JIM) R. WHITE, Vice President of Training Services, has worked for Shermco Industries Inc. since 2001. He is a NFPA Certified Electrical Safety Compliance Professional and a NETA Level 4 Senior Technician. Jim is NETA’s principal member on NFPA Technical Committee NFPA 70E®, Standard for Electrical Safety in the Workplace®, NETA’s principal representative on National Electrical Code® Code-Making Panel (CMP) 13, and represents NETA on ASTM International Technical Committee F18, Electrical Protective Equipment for Workers. Jim is Shermco Industries’ principal member on NFPA Technical Committee for NFPA 70B, Recommended Practice for Electrical Equipment Maintenance and represents AWEA on the ANSI/ISEA Standard 203 Secondary Single-Use Flame Resistant Protective Clothing for Use Over Primary Flame Resistant Protective Clothing. An IEEE Senior Member, Jim received the IEEE/IAS/PCIC Electrical Safety Excellence Award in 2011 and NETA’s Outstanding Achievement Award in 2013. Jim was Chairman of the IEEE Electrical Safety Workshop in 2008 and is currently Vice-Chair for the IEEE IAS/PCIC Safety Subcommittee.

A NETA WORLD JOURNAL SPECIAL PUBLICATION | TRAINING TALK | 11

te

AVO Training Institute: The One Stop for Electrical Safety and Maintenance Training

If it’s electrical, AVO Training is focused on it. Electrical safety and maintenance training is not just part of our offering, it’s our sole focus. That’s why we offer more electrical training courses than any other training facility. Our training is available as hands-on at any one of our 12 training facilities throughout the U.S. or online through live virtual instructor-led training or self-paced learning.

Live Virtual Online Training Courses: www.avotraining.com/virtual

• NFPA 70E 2018 – 2-Day

• National Electrical Code Changes 2020 – 2-Day

• Electrical Safety for Industrial Facilities – 4-Day

• Electrical Safety for Utilities – 4-Day

Self-paced Online Training Courses: www.avotraining.com/online

• Arc Flash Online Safety Awareness Training

• Changes to the National Electrical Code

Hands-on Training Courses: www.avotraining.com/handson

Electrical Maintenance

• Substation 1 & 2

• Protective Relay (Basic & Advanced)

• Cable (Splicing & Terminating, Fault Location & Tracing, Testing & Diagnostics)

• Circuit Breaker (Low-Voltage, Medium-Voltage, Molded & Insulated Case, SF6)

• Transformer (Basic & Advanced)

• Motors (Motor Maintenance & Testing, Motor Controls & Starters)

• Microprocessor-Based Relay Testing (Generation, Feeder, Transformer)

• Battery Maintenance & Testing

Electrical Maintenance, cont.

• Power Factor Testing

• Grounding & Bonding

• Power Quality & Harmonics

• Programmable Logic Controllers, Maintenance & Troubleshooting

• Protective Device (For Industry & For Utilities)

• Short Circuit Analysis

• Protective Relay Maintenance (Generation & Solid-State)

• Infrared Thermography 1 & 2

• Advanced Visual Testing Software

• Energized Overhead Contact System Line Safety

Electrical Safety

• NFPA 70E 2018

• Electrical Safety for Industrial Facilities

• Electrical Safety for Utilities

• Electrical Safety for Inspectors

• Electrical Safety for Mining

• Electrical Safety for Overhead Contact Systems

• National Electrical Code 2020

• National Electrical Code Changes 2020

• OSHA Electrical Safety-Related Work Practices

• OHSA Generation, Transmission and Distribution

• Maritime Electrical Safety

Electrical Fundamentals

• Basic Electrical Troubleshooting

• Basic Electricity

• Electronics for Electricians

• Electrical Print Reading – ANSI

• Electronics Troubleshooting

WWW.AVOTRAINING.COM • 877-594-3156 *NETA continuing technical development (CTDs) units are required of NETA Certified Technicians. AVO Training Institute is accredited by the International Association for Continuing Education and Training (IACET) and is accredited to issue the IACET CEU.

DIRECTORY OF TECHNICAL AND PROFESSIONAL TRAINING

An Engineer’s Playground

“Icameinwithlittleexposuretoindustrypracticesandnow feelverycomfortable/competentwiththe standardproceduresaswellasrecommendedsafety measuresduringmaintenance.”

-N.

Mitchell, Electrical Diagnostic Testing of Power Transformers class participant

Excellence Through Education

Many people refer to the OMICRON Academy in Houston as “An Engineer’s Playground.” This is because in addition to classrooms, we also have a state-of-the art indoor substation with a variety of apparatus to perform hands-on testing including transformers, circuit breakers, protective relays, indoor circuit, PD testing area and our recently installed distribution automation wall.

Training Topics

•Protection Relays and Meters Testing

•Circuit Breaker/Switchgear Testing

•Instrument Transformer Testing

•Power Transformer Testing & Diagnostics

•Partial Discharge Testing

•Protection Theory

•End-to-End Testing

•Reclosers and Distribution Automation

See our full list of courses at omicronenergy.com/na-training

Megger’s Testing Tactics Webinar Series 2020

Learn valuable testing tips and tricks from Megger application engineers and product managers. In this webinar series, our experienced staff will show you how to make your testing more efficient by sharing their lessons learned in the field. You will find answers to frequently asked questions, learn how to avoid the most common mistakes, and accelerate your testing.

Upcoming Webinars

• MV and HV Circuit Breaker Testing beyond Timing and Travel Measurements

September 18, 2020 | Presenter: Volney Naranjo

• State-of-the-art Diagnostics Technologies for Proactive Cable Condition Assessment

October 23, 2020 | Presenter: Robert Probst

• Fundamentals of Motor Protection

November 20, 2020 | Presenter: David Beard

• LV Circuit Breaker Ground Fault Protection Utilizing Primary Injection Test Method

December 18, 2020 | Presenter: Daniel Carreno

Previous Webinars

• Best Field Practices for Testing Instrument Transformers: CTs, VTs, CVTs

November 15, 2019 | Presenter: Daniel Carreno

• Tan Delta Testing on Medium Voltage Cables

December 20, 2019 | Presenter: Javier Ruiz

• Fundamentals of Partial Discharge Measurements

January 24, 2020 | Presenter: Charles Nybeck

• DC Insulation Resistance Testing: Effective Use of Guard Terminal

February 21, 2020 | Presenter: Nick Rees

• Understanding Sweep Frequency Response Analysis and Best Field Practices

March 20, 2020 | Presenter: Sanket Bolar

• MV and HV Cable Fault Location Utilizing ARM Method

April 17, 2020 | Presenter: Javier Ruiz

• An Insight Into End to End Testing Philosophy

May 22, 2020 | Presenter: Sughosh Kuber

• Off-line Partial Discharge Testing of Rotating Machines

June 19, 2020 | Presenter: Charles Nybeck

• Feeder Protection in Power Distribution Systems

July 17, 2020 | Presenter: Abel Gonzalez

• Narrow Band Dielectric Frequency Response –Application on HV and EHV OIP Bushings

August 21, 2020 | Presenter: Diego Robalino

How to Join Megger Webinar Series

• Megger Webinars are held on the 3rd Friday of every month.

• Time: 10:00 AM Central Time

• Sessions are FREE

• Earn 1 NETA CTD and 1 PDH or 0.1 CEU

• us.megger.com/webinars

Earn Credits

Megger has partnered with NETA (International Electrical Testing Association) in North America to present the special monthly webinar series Testing Tactics that allows webinar registrants to receive NETA CTDs (Continuing Technical Development Credits) for attending the live webinar.

• Only attendees of the live Testing Tactics webinar sessions are eligible to receive 1 NETA CTD (Continuing Technical Development Credit) and 0.1 CEU (Continuing Education Units) or 1 PDH (Professional Development Hour) for each webinar attended.

• Live attendees of the webinar will also receive a PDF copy of the PowerPoint presentation.

Webinar Registration:

us.megger.com/webinars

Megger designs and manufactures portable electrical test equipment. Megger products help you install, improve efficiency, reduce cost, and extend the life of your or your customers’ electrical assets or your own. For more information, visit us.megger.com

DIRECTORY OF TECHNICAL AND PROFESSIONAL TRAINING

Shermco Industries: Your Electrical Safety Experts

Shermco is a leader in electrical power systems maintenance, repair, and testing, and for years, we have trained others in those skills. Offering onsite, classroom, and hands-on training, Shermco conducts a wide variety of courses covering Electrical Systems Maintenance, Electrical Safety, and Electrical Technical Skills. Some of the most influential leaders in electrical safety work at Shermco Industries, and now you have direct access to that experience and expertise! Shermco offers technical and electrical safety programs year-round and at multiple locations in the U.S. and Canada. NETA CTDs and CEUs through IEEE are available for most courses where applicable. Train with the experts. Train with Shermco.

Shermco University

Distance Learning Courses

• Electrical Safety Refresher

• Electrical Safety for Qualified Electrical Workers

• Electrical Safety for Managers

• Electrical Safety for Non-Electrical Personnel

• Electrical Safety for Utilities

• National Electrical Code

• Company Custom Courses

How Does Distance Learning Work?

Teleconference courses are taught face-to-face and allow live interaction between instructor and students even though they may be in different geographic locations. Synchronous tools such as text chat, audio chat, or video chat will provide students with real-time access to the instructor while the class is in session.

Class size limited to twenty (20) participants.

Call and reserve your seat today.

Enroll today by visiting www.shermco.com/training or call 888-Shermco.

For more information, to download our current course catalog, or to register online, go to www.shermco.com/training or email trainingservices@shermco.com SHERMCO.COM • 888-SHERMCO

DIRECTORY OF TECHNICAL AND PROFESSIONAL TRAINING

CEUs available from

www.shermco.com/training

To be the best in your field, train with the best in the field. Shermco Real-World Training.

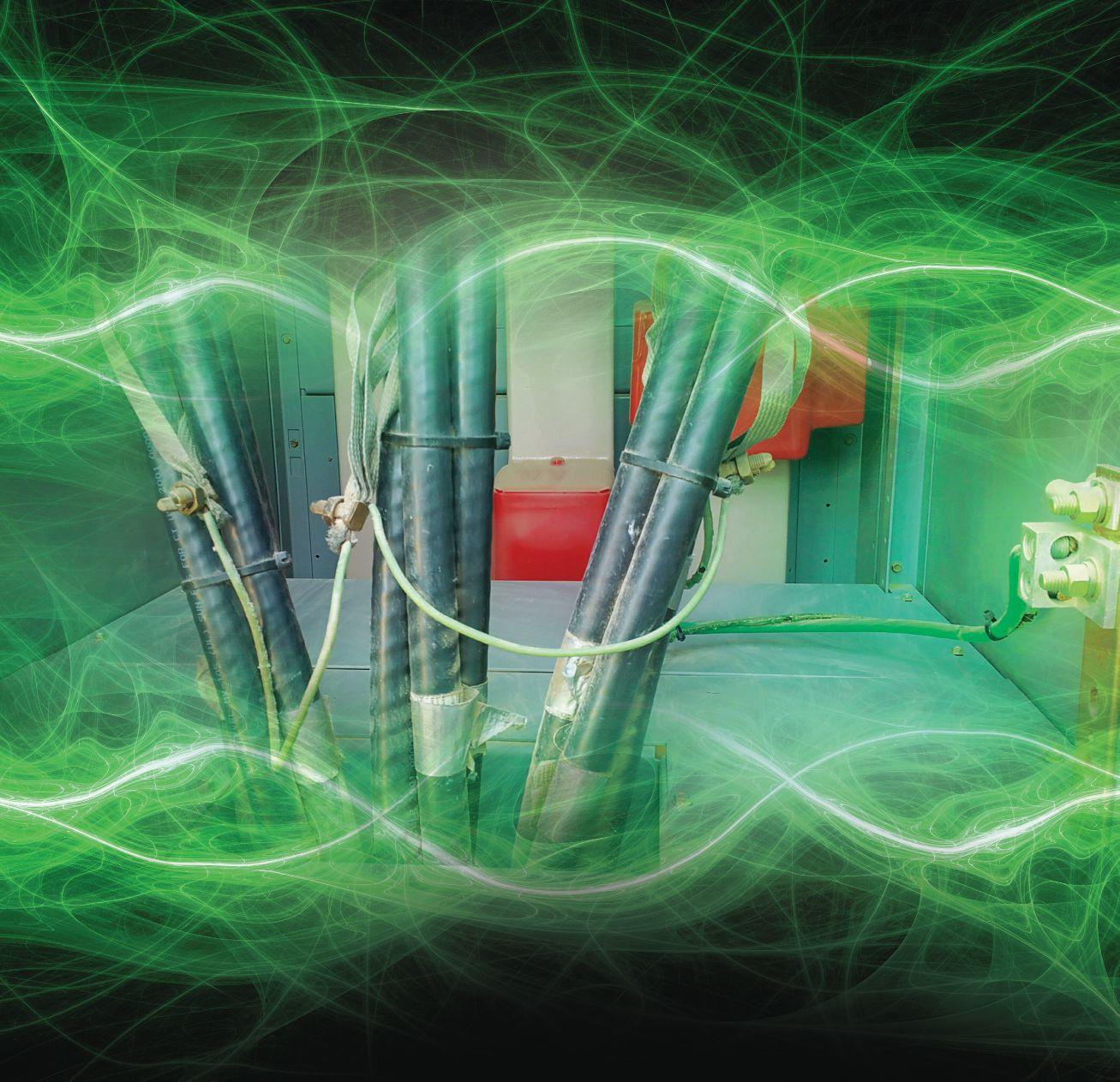

COVER STORY

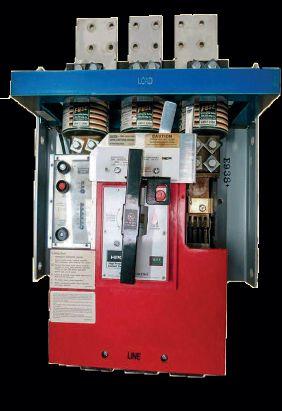

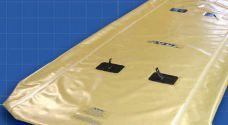

Partial Discharge Tests for MediumVoltage Power Cable Systems

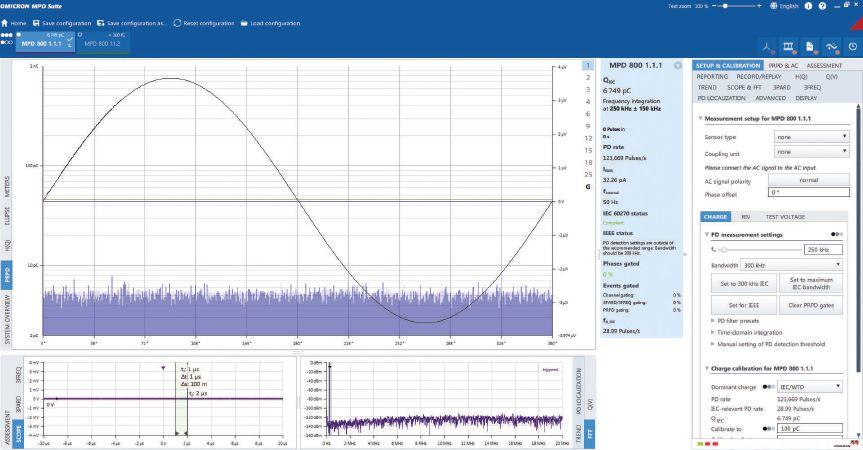

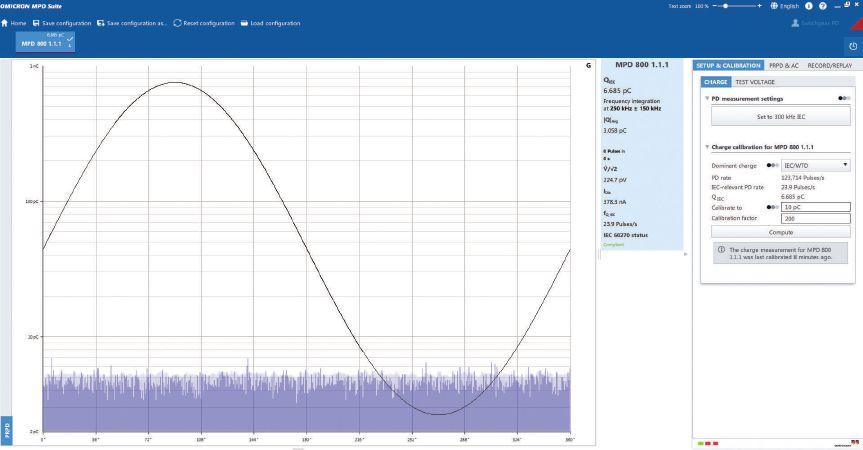

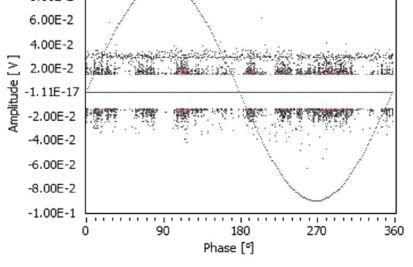

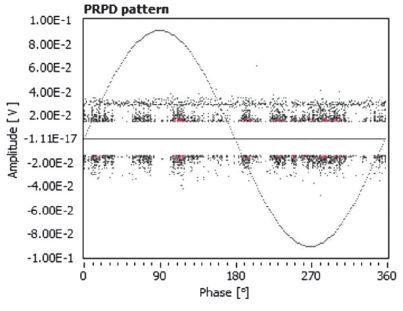

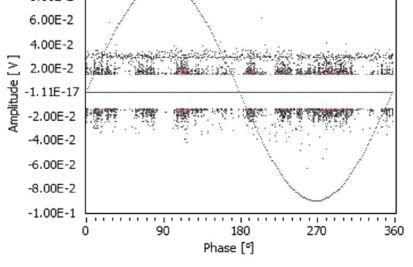

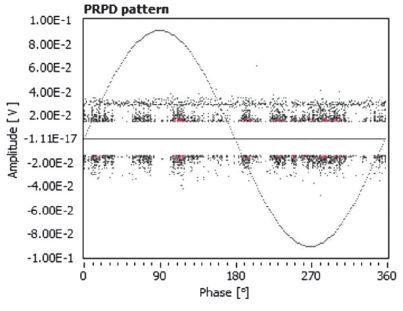

Although the benefits of diagnostic testing in MV cable systems are widely applied during commissioning and maintenance, the main competition is the run-to-failure practice. Fortunately, more and more cable owners now accept diagnostic testing technologies to improve MV cable system reliability and to reduce lifetime asset management costs.

The partial discharge test has the unique advantages of distinguishing various types of defects and localizing the sites of those defects. But while performing a PD test is simple, using the PD data to diagnose the system that requires a wealth of knowledge and experiences. Hopefully, PD data interpretation will be simplified by rapid development of computer engineering and artificial intelligence.

Jim Guo, PhD, and Zhong Zheng, TechImp US Corp

FEATURES

7 President’s Desk

Scott Blizard, American Electrical Testing Co., LLC

NETA President

48

56

Partial Discharge Secrets, Tips, and Tricks

William G. Higinbotham, EA Technology LLC

Acceptance and Maintenance Testing

Medium-Voltage Electrical Power Cables

Thomas D. Sandri, Shermco Industries

64 Using VLF and PD Testing to Improve Commissioning Reliability

Javier Ruiz, Megger

TABLE OF CONTENTS TABLE OF CONTENTS NETAWORLD • 3

36

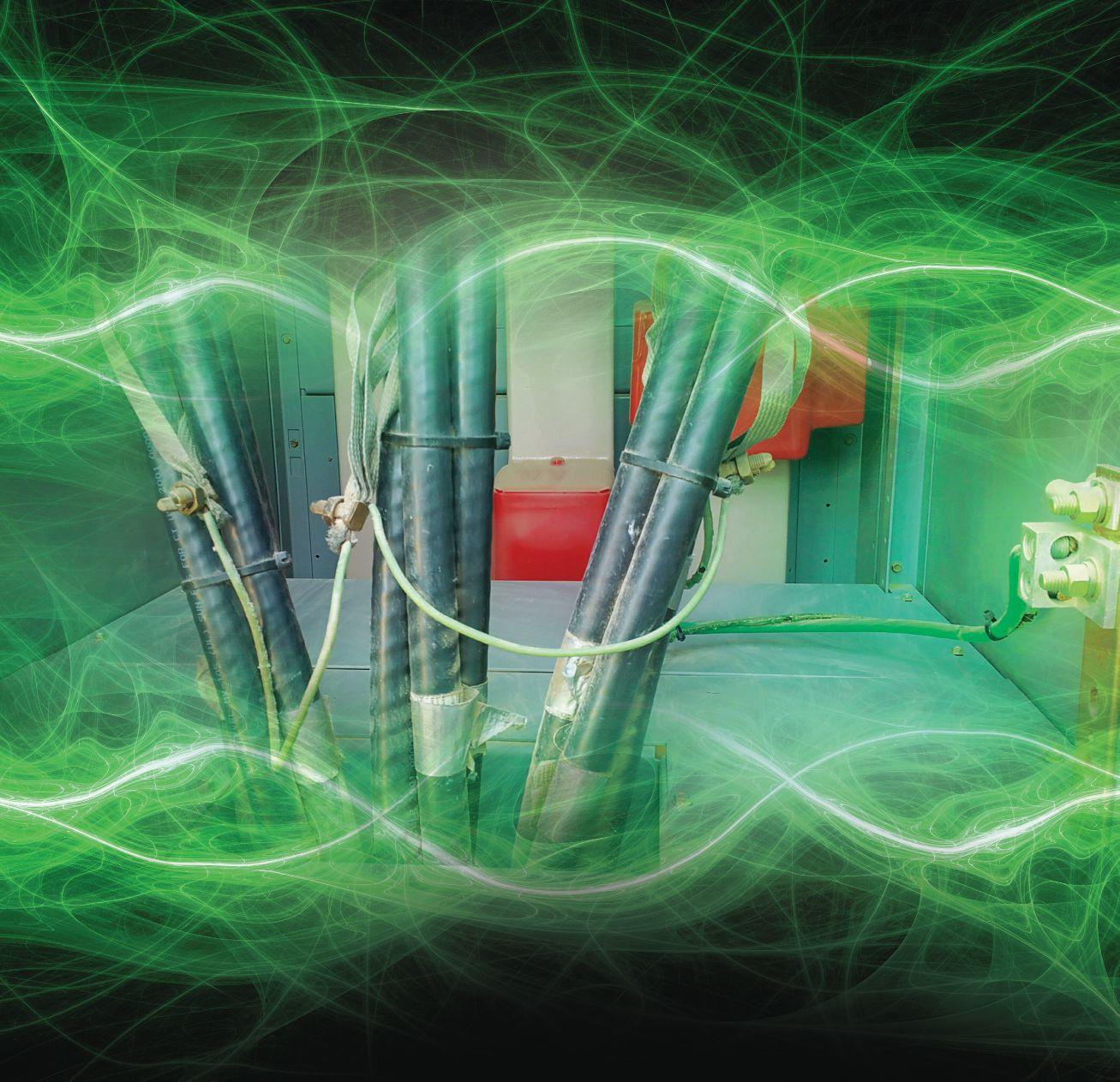

FALL 2020 · VOLUME 42, NO. 3 COVER

OF SHERMCO INDUSTRIES 56

IMAGE COURTESY

10 NFPA 70E and NETA

NFPA 70E–2021 is Here — How Did That Happen?

Ron Widup and James R. White, Shermco Industries

14 Relay Column

Archiving Protective Relay Settings

Steve Turner, Arizona Public Service Company

18 In the Field

Drones & Spaghetti Dinner

Don Genutis, Halco Testing Services

23 Safety Corner

Programs, Policies, Manuals, Procedures, and Training

Paul Chamberlain, American Electrical Testing Co., LLC

28 Tech Quiz

Cable Testing

James R. White and Thomas D. Sandri, Shermco Industries

31 Tech Tips

Medium-Voltage Grounding

Jeff Jowett, Megger

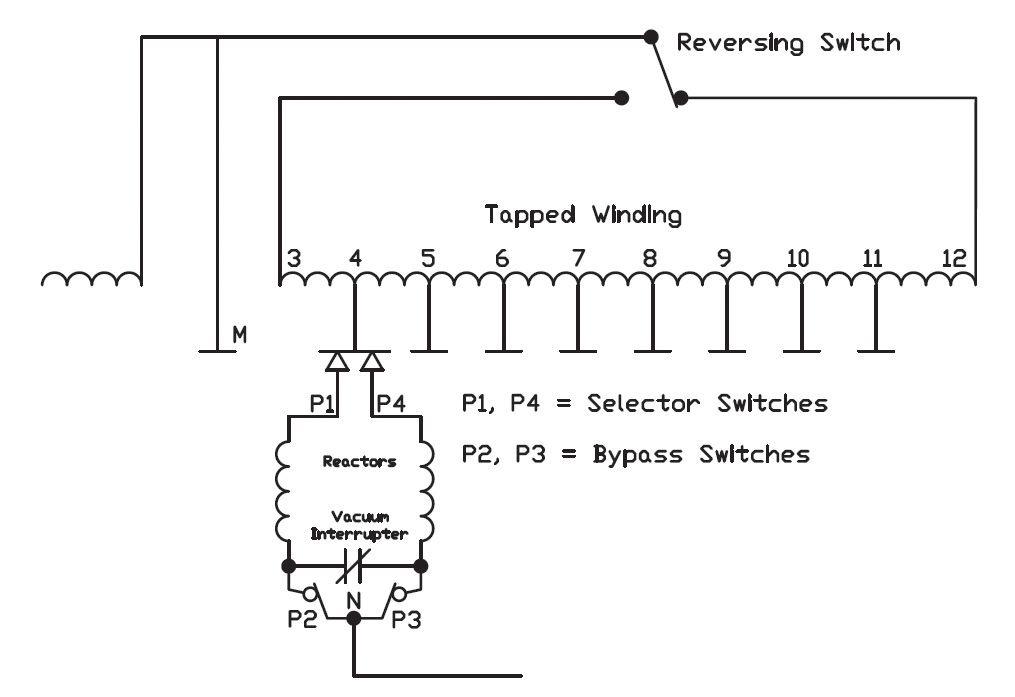

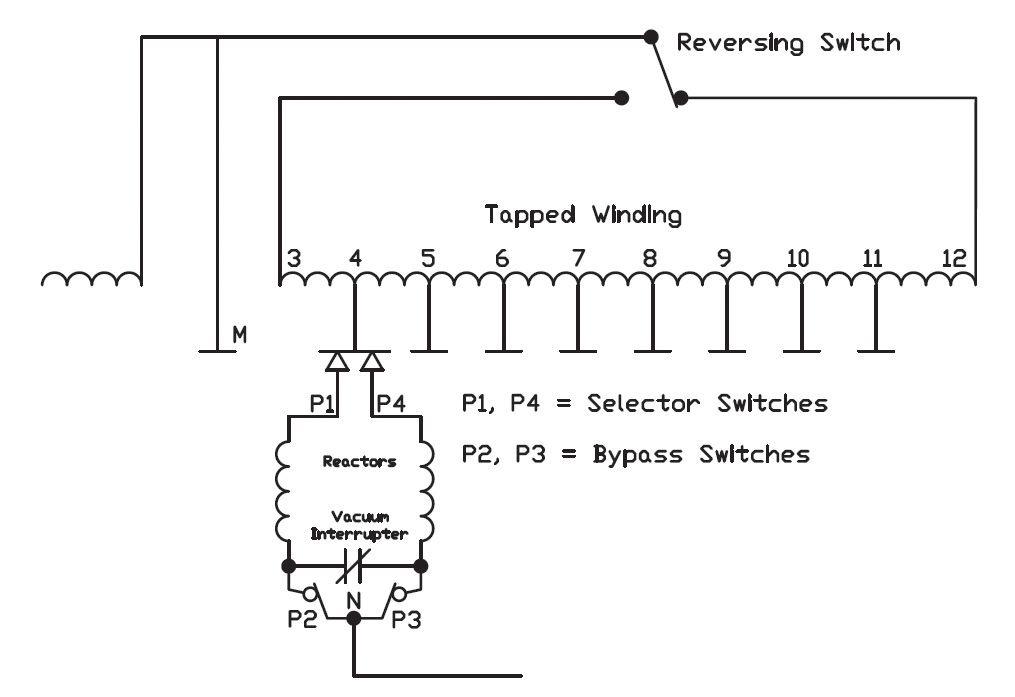

74 Protection Considerations for an Improperly Installed On-Load Tap Changer

Alex Rangel, Saber Power Services, LLC

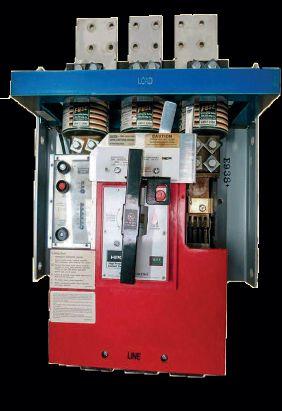

84 Improved Safety Method for Measuring Dead Tank Circuit Breaker Operation Radenko Ostojić and Adnan Šečić, DV Power — Sweden

92 Power Quality, Reliability, and Sophisticated Automated Systems

Alan Ross, Electric Power Reliability Alliance

ADVANCEMENTS IN THE INDUSTRY

98 Onsite PD Measurement during Commissioning: Safe…Right from the Start Mathieu Lachance, OMICRON electronics Canada, and Tim Gannon, Advanced Electrical Services

INSIGHTS & OBSERVATIONS — NETA CAP SPOTLIGHT

104 Weidmann Electrical Technology: 143 Years of Global Impact

SPECIFICATIONS AND STANDARDS 108 ANSI/NETA Standards Update

110 ASTM F18 Committee Report

James R. White, Shermco Industries

111 NFPA 70B Committee Report

David Huffman, Power Systems Testing Company

114 In Memoriam — John Hauck

Accredited Companies

Advertiser List

4 • FALL 2020 TABLE OF CONTENTS TABLE OF CONTENTS IN EVERY ISSUE

INDUSTRY TOPICS

NEWS

IMPORTANT LISTS 117 NETA

122

NETA

Rental and Sales

Protec is your source for electrical test equipment rental and sales, working with leading manufacturers to offer flexible daily, weekly, and monthly lease rates. If you are not sure what equipment best fits for your needs, call us for a consultation and quote. Our support line is open 24 hours and we can deliver equipment immediately in case of emergency.

Calibration Services

Our calibration labs Dallas and Chicago offer NISTtraceable calibration services for all makes and models of electrical test and measurement equipment. Our qualified technicians will ensure that your electrical test instruments are working at peak performance and meet all manufacturer standards. Quick turnaround is standard, with most equipment completed in 5 business days or less.

Asset Management

Eliminate your overhead and minimize equipment downtime with Protec’s asset management services. We customize a unique solution for your business to store, calibrate and maintain your equipment for whenever you need it. Receive analytics for ROI, yield and utilization to drive educated business decisions.

Nobody Works Harder For You Than Protec

We understand that you need experienced people to align you with the proper electrical test and measurement equipment, in the right place at the right time.

That’s why we are the number one choice for mission critical equipment, where time, quality and service are vital.

Electrical test equipment is our specialtyyour satisfaction is our passion.

1517 W Carrier Pkwy, Ste 116 Grand Prairie, TX 75050

Angeles 2935 E Ricker Way Anaheim, CA 92806 Reno-Tahoe 924 Greg Street Sparks, NV 89431

E 45th Ave, Ste 400 Denver, CO 80239

Large Enough To Serve Your Needs, Small Enough to Care protecequip.com For a Quote Call 866-352-5550 Atlanta 880 Veterans Memorial Hwy Mableton, GA 30126 National Headquarters

New York City 70 Triangle Boulevard Carlstadt, NJ 07072 Denver 12050

Houston 14251 Gulfstream Park Drive Webster, TX 77598 Chicago 1501 Wright Blvd Schaumburg, IL 60193 The Electrical Test and Measurement Equipment Rental Experts

Los

3050 Old Centre Road, Suite 101

Portage, MI 49024

Toll free: 888.300.NETA (6382)

Phone: 269.488.NETA (6382)

Fax: 269.488.6383

neta@netaworld.org

www.netaworld.org

executive director: Missy Richard

NETA Officers

president: Scott Blizard, American Electrical Testing Co., Inc.

first vice president: Eric Beckman, National Field Services

second vice president: Scott Dude, Dude Electrical Testing, LLC

secretary: Dan Hook, Western Electrical Services, Inc.

treasurer: John White, Sigma Six Solutions, Inc.

NETA Board of Directors

Ken Bassett (Potomac Testing, Inc.)

Eric Beckman (National Field Services)

Scott Blizard (American Electrical Testing Co., Inc.)

Jim Cialdea (CE Power Engineered Services, LLC)

Scott Dude (Dude Electrical Testing LLC)

Dan Hook (Western Electrical Services, Inc.)

David Huffman (Power Systems Testing)

Alan Peterson (Utility Service Corporation)

Chasen Tedder, Hampton Tedder Technical Services

John White (Sigma Six Solutions)

Ron Widup (Shermco Industries)

non-voting board member

Lorne Gara (Shermco Industries)

NETA World Staff

technical editors: Roderic L. Hageman, Tim Cotter

assistant technical editors: Jim Cialdea, Dan Hook, Dave Huffman, Bob Sheppard

associate editor: Resa Pickel

managing editor: Carla Kalogeridis

copy editor: Beverly Sturtevant

advertising manager: Laura McDonald

design and production: Moon Design

NETA Committee Chairs

conference: Ron Widup; membership: Ken Bassett; promotions/marketing: Scott Blizard; safety: Scott Blizard and Jim White; technical: Alan Peterson; technical exam: Dan Hook; continuing technical development: David Huffman; training: Eric Beckman; finance: John White; nominations: Alan Peterson; alliance program: Jim Cialdea; association development: Ken Bassett and John White

© Copyright 2020, NETA

NOTICE AND DISCLAIMER

NETA World is published quarterly by the InterNational Electrical Testing Association. Opinions, views and conclusions expressed in articles herein are those of the authors and not necessarily those of NETA. Publication herein does not constitute or imply endorsement of any opinion, product, or service by NETA, its directors, officers, members, employees or agents (herein “NETA”).

All technical data in this publication reflects the experience of individuals using specific tools, products, equipment and components under specific conditions and circumstances which may or may not be fully reported and over which NETA has neither exercised nor reserved control. Such data has not been independently tested or otherwise verified by NETA.

NETA MAKES NO ENDORSEMENT, REPRESENTATION OR WARRANTY AS TO ANY OPINION, PRODUCT OR SERVICE REFERENCED OR ADVERTISED IN THIS PUBLICATION. NETA EXPRESSLY DISCLAIMS ANY AND ALL LIABILITY TO ANY CONSUMER, PURCHASER OR ANY OTHER PERSON USING ANY PRODUCT OR SERVICE REFERENCED OR ADVERTISED HEREIN FOR ANY INJURIES OR DAMAGES OF ANY KIND WHATSOEVER, INCLUDING, BUT NOT LIMITED TO ANY CONSEQUENTIAL, PUNITIVE, SPECIAL, INCIDENTAL, DIRECT OR INDIRECT DAMAGES. NETA FURTHER DISCLAIMS ANY AND ALL WARRANTIES, EXPRESS OF IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

ELECTRICAL TESTING SHALL BE PERFORMED ONLY BY TRAINED ELECTRICAL PERSONNEL AND SHALL BE SUPERVISED BY NETA CERTIFIED TECHNICIANS/ LEVEL III OR IV OR BY NICET CERTIFIED TECHNICIANS IN ELECTRICAL TESTING TECHNOLOGY/LEVEL III OR IV. FAILURE TO ADHERE TO ADEQUATE TRAINING, SAFETY REQUIREMENTS, AND APPLICABLE PROCEDURES MAY RESULT IN LOSS OF PRODUCTION, CATASTROPHIC EQUIPMENT FAILURE, SERIOUS INJURY OR DEATH.

MEDIUM-VOLTAGE CABLES

Welcome to the fall edition of NETA World. In this issue, our authors cover the various methods for performing testing on mediumvoltage cables. I recommend you start with the article by Tom Sandri of Shermco Industries, which lays out the current test methods for acceptance and maintenance testing of medium-voltage cables. Next, dive into the articles on specific testing methods including partial discharge, dissipation factor (tan delta), and VLF.

Fall is typically one of our busiest times of the year. Many of our customers are performing scheduled maintenance outages, and the workdays can be longer as well as more stressful than normal. Even if your days throughout the fall season are not that much different, one thing we must constantly do is evaluate and mitigate exposures to risk. This helps make the work environment safer for all. When working with medium-voltage cables, be sure the technician has all the documentation as well as a clear understanding of the testing method and the test equipment being used to perform the testing. Review the safety precautions needed to operate the equipment or device and ensure all recommended safety precautions are followed.

Today is July 16, 2020, and the country is in the middle of a COVID-19 resurgence. NETA Member Companies and their technicians throughout the United States and in Canada have been identified as essential workers as they support and maintain the critical infrastructure of our nations. Follow the COVID-19 policies of your company as well as your customers’ companies. The preventative measures to limit the spread of the COVID-19 virus that have been communicated by the CDC in the United States and the Public Health Agency of Canada should be included. Be safe, and err on the side of caution.

Mark your calendars! PowerTest 2021, the premier electrical maintenance and safety conference, will take place March 8–12, 2021, at the Rosen Shingle Creek in Orlando, Florida. We look forward to seeing you there.

Coach safe behavior…Living injury and disease free every day!

Scott A. Blizard, President International Electrical Testing Association

Scott A. Blizard, President International Electrical Testing Association

PRESIDENT’S DESK PRESIDENT’S DESK

• Cables

• LV/MV Circuit Breakers

• Rotating Machiner y

• Meters

• Automatic Transfer Switches

• Switchgear and Switchboard Assemblies

• Load Studies

• LV/MV Switches

• Relays - All Types

• Motor Control Centers

• Grounding Systems

• Transformers

• Insulating Fluids

• Thermographic Surveys

• Reclosers

• Surge Arresters

• Capacitors

• Batteries

• Ground Fault Systems

• Equipotential Ground Testing

CoNSulTING AND ENGINEERING SERvICES

• Transient Voltage Recording and Analysis

• Electromagnetic Field (EMF) Testing

• Harmonic Investigation

• Replacement of Insulating Fluids

• Power Factor Studies

Electric Testing, Inc. EC13004105 • 24 Hour Emergency Service

Industrial

ACCEPTANCE AND MAINTENANCE TESTING AND REPAIR

11321 West Distribution Avenue • Jacksonville, Florida 32256 • (904) 260-8378 201 NW 1st Avenue • Hallandale, Florida 33009 • (954) 456-7020

We Buy, Sell, Trade, Calibrate, Repair

Featuring quality, reliable, on-time service and support for all brands and types of solid state power electronics.

Power electronics are our business

Let us suppoort you with our quality repair, calibration and servicing of your solid state equipment. We also buy, sell and trade:

•Communications devices for power equipment

•Protective relays

•Circuit breaker trip devices

•Motor overload relays

•Rating plugs

4701 Spartan Drive • Denton, TX 76207 (877-874-7349) • Phone: 940-243-3731 • Fax: 940-387-8277 Email: info@solidstaterepair.com • Web: www.solidstaterepair.com

“SOLID STATE” INDUSTRIAL ELECTRONICS “SOLID STATE” INDUSTRIAL ELECTRONICS Toll Free 877-TRIP-FIX NOWRENTING TESTEQUIPMENT

NFPA 70E–2021 IS HERE — HOW DID THAT HAPPEN?

BY RON WIDUP and JAMES R. WHITE, Shermco Industries

In September 2020, the newest (2021) edition of NFPA 70E, Standard for Electrical Safety in the Workplace® will be available to the industry. So how is it that such an important safety standard, put forth as a national consensus document, is reviewed, revised, and improved every three years? We’ll look at the process a little later in this article.

But first, let’s talk about this very important safety document, which on issuance becomes immediately active and enforceable…including any changes that have taken place. Unlike a code, this is a work practices document; therefore, any new requirements are now in effect, and there are no grandfathered rules and regulations.

For background on 70E, the NFPA website (www.nfpa.org) states the following:

While the number of workplace electrical injuries has declined in recent years, the risks of shock, electrocution, arc flash, and arc blast remain a significant health and safety concern. Each week nearly three workers die, and annually thousands are injured by electrical hazards. Many of these incidents could have been prevented through compliance with the latest safety codes and standards.

NFPA 70E, Standard for Electrical Safety in the Workplace is the quintessential resource for helping companies and employees reduce exposure to risks and reduce occupational injuries and fatalities. It was created to provide a document that meets the need of the Occupational Safety and Health Administration (OSHA) and is entirely consistent with the NEC and other applicable publications.

NFPA 70E provides provisions that help comply with OSHA 1910 Subpart S and OSHA 1926 Subpart K. This essential standard for anyone with interest in ending electrical-related accidents, liability, and loss offers expert information on subjects ranging from safety-related work practices to special equipment and maintenance requirements. Informative Annexes provide indepth coverage of personal protective equipment (PPE), developments in electrical design, risk assessment and control, human performance and electrical safety, and many other critical topics.

10 • FALL 2020 NFPA 70E-2021 IS HERE — HOW DID THAT HAPPEN?

NFPA 70E AND NETA n e

After months of work by the NFPA 70E Technical Committee, the new 2021 edition features extensive changes, including:

• Revisions to Article 110 to incorporate the general requirements for electrical safety-related work programs, practices, and procedures from other articles

• References to arc-resistant switchgear in Tables 130.5(C) and 130.7(C)(15)(a) changed to arc-resistant equipment to address the use of other types of arcresistant equipment

• Addition of Article 360, Safety-Related Requirements for Capacitors, and Annex R, Working with Capacitors, to address specific electrical safety requirements unique to capacitors

• Edits to Annex D, Incident Energy and Arc Flash Boundary Calculation Methods, to reference IEEE-1584-2018 as a method of calculation

WHAT’S THE PROCESS TO GET HERE?

For the 70E and other consensus-based standards to go from a current edition to “new and improved” is quite an involved process, involving many people and many hours of focused and passionate contribution to the change. (Shout-out to all those who contribute!)

In the current cycle, 344 Public Inputs resulted in 85 First Revisions, and 155 Public Comments resulted in 46 Second Revisions. Compared to previous cycles, the workload was quite a bit less, so NFPA 70E may be approaching a “tweaking-the-words” maintenance cycle where major changes are increasingly rare, and it is principally revised to improve its clarity and usability.

In 2015, NFPA introduced a new process that was used for the 2021 edition. Under the old process, proposals for change were referred to as Proposals. Under the new process, Proposals are

referred to as Public Inputs (PIs); Comments are now Public Comments (PCs); and the Report on Proposals (ROP) is now the First Draft (FD).

FIRST REVISION

Revisions made during the First Draft Meeting are balloted for acceptance in a First Revision (FR). The First Draft is circulated to committee members and posted on the NFPA website for public comments. It only takes a majority vote (51%) for an FR to be accepted by the committee during the meeting. However, a 66% majority vote is required to approve an FR when it is formally balloted by the committee. The First Draft is published on the NFPA website and is available at no charge to anyone who wants to submit a comment on a committee action. It is available for several months to ensure everyone has an opportunity to submit comments.

SECOND DRAFT

The Second Draft Meeting is different in that the committee is bound by any First Revisions and Public Comments (PCs) received. Any changes made at this meeting are Second Revisions (SRs). The Second Draft (SD), previously known as the Report on Comments, consists of committee actions that are balloted on and accepted from the Second Draft Meeting. These actions, known as Second Revisions (SRs), are used to create the Second Draft. Any First Revisions accepted by the committee at the First Draft Meeting that did not receive Public Comments are considered First Revisions, and no further action can be taken on them. People who wish to discuss PIs during the First Draft Meeting or PCs at the Second Draft Meeting can do so if they schedule a meeting in advance with the committee chairperson. Once the Second Draft Meeting has been completed, the standard is balloted. It takes a 66% majority vote to approve the Second Draft.

THE HOME STRETCH

The NFPA consensus process is very thorough, allowing full public input and comment on committee actions. Many people consider

NETAWORLD • 11 NFPA 70E-2021 IS HERE — HOW DID THAT HAPPEN?

AND NETA

NFPA 70E

NFPA 70E AND NETA

it to be the best methodology for standards publication currently used by any organization. Public input is critical to the consensus process, and public input is solicited by NFPA using open announcements in news releases and in publications such as print and online magazines and trade journals. Any person can submit a PI online at the NFPA website (www.nfpa.org).

NFPA’s electrical oversight committee, the Correlating Committee, reviews the actions of the NFPA 70E Committee to ensure there are no major issues or inadvertent conflicts with earlier actions or other NFPA standards. When a Second Draft has been published and committee members or proposers still have differences of opinion, a Notice of Intent to Make a Motion (NITMAM) can be submitted to NFPA. NITMAMs are published on the NFPA website for public review and are discussed at the annual NFPA World Safety Conference and Exhibition.

Even after the revision cycle closes, another avenue to change the stardard is a Tentative Interim Amendment (TIA). A TIA can be

submitted any time an error is found in the committee’s actions. For a TIA to be accepted, two conditions must be met: The change must correct an error, and the change must be an emergency in nature. For the 2021 cycle, no NITMAMs or TIAs have been submitted.

One final action that can be taken by the public is a Notice to Appeal. This does not occur often, as there is very-low probability that a Notice to Appeal will be considered once a NITMAM on the same committee action has already been considered. No Notice to Appeal actions were taken for the 2021 cycle.

SUMMARY

The new edition of the 70E is out — so purchase a copy, familiarize yourself with the changes, understand the content and the very important work practice rules, and go through the day in a safe and planful way while working on or near electrical energy…whether at work or at home.

Be safe out there — and test before touch!

Ron Widup and Jim White are NETA’s representatives to NFPA Technical Committee 70E, Electrical Safety Requirements for Employee Workplaces. Both gentlemen are employed by Shermco Industries in Dallas, Texas, a NETA Accredited Company.

Ron Widup, Senior Advisor, Technical Services and Vice Chairman of the Board of Directors, has been with Shermco Industries since 1983. He is a member of Technical Committee on NFPA 70E, Electrical Safety in the Workplace; a Principal Member of National Electrical Code (NFPA 70) Code Panel 11; a Principal Member of the Technical Committee on NFPA 790, Standard for Competency of Third-Party Evaluation Bodies; a Principal Member of the Technical Committee on NFPA 791, Recommended Practice and Procedures for Unlabeled Electrical Equipment Evaluation; a member of the Technical Committee on NFPA 70B, Recommended Practice for Electrical Equipment Maintenance, and Vice Chair for IEEE Std. 3007.3, Recommended Practice for Electrical Safety in Industrial and Commercial Power Systems. Ron also serves on NETA’s board of directors and Standards Review Council. He is a NETA Certified Level 4 Senior Test Technician, a State of Texas Journeyman Electrician, an IEEE Standards Association member, an Inspector Member of the International Association of Electrical Inspectors, and an NFPA Certified Electrical Safety Compliance Professional (CESCP).

James (Jim) R. White, Vice President of Training Services, has worked for Shermco Industries since 2001. He is a NFPA Certified Electrical Safety Compliance Professional and a NETA Level 4 Senior Technician. Jim is NETA’s principal member on NFPA Technical Committee NFPA 70E®, Electrical Safety in the Workplace; NETA’s principal representative on National Electrical Code® Code-Making Panel (CMP) 13; and represents NETA on ASTM International Technical Committee F18, Electrical Protective Equipment for Workers. Jim is Shermco Industries’ principal member on NFPA Technical Committee for NFPA 70B, Recommended Practice for Electrical Equipment Maintenance and represents AWEA on the ANSI/ISEA Standard 203, Secondary Single-Use Flame Resistant Protective Clothing for Use Over Primary Flame Resistant Protective Clothing. An IEEE Senior Member, Jim was Chairman of the IEEE Electrical Safety Workshop in 2008 and is currently Vice Chair for the IEEE IAS/PCIC Safety Subcommittee.

12 • FALL 2020

NFPA 70E-2021 IS HERE — HOW DID THAT HAPPEN?

Relay and Protective Devices

Batteries and UPS

Low Voltage Circuit Breakers

Medium/High Voltage Circuit Breakers

SF6 Analysis

Transformer Testing

Cable Testing

Cable Fault Location

Location

Power

Power Monitoring

Data and Recorders

Data Acquisition and Recorders

Online and Offline Partial

Online and Offline Partial Discharge

Low Resistance Ohmmeters

Low

Insulation

Insulation Resistance/Megohmmeters

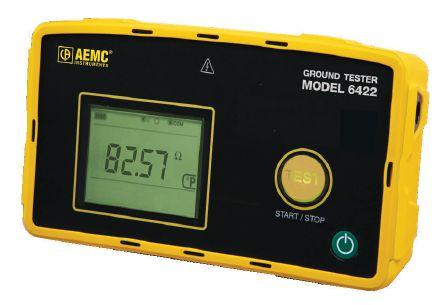

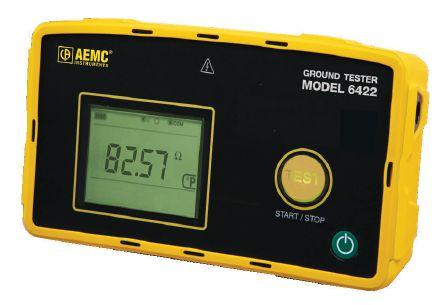

Ground Test Equipment

Ground Test Equipment Test

Photovoltaic Test

Infrared Cameras

Cameras

Ultrasound and TEV

Online/Offline Motor

Online/Offline Motor Testing

AC and DC Load Banks

AC DC

AC and DC Hipots

AC and DC

VLF and Tan

VLF and Tan Delta

888.902.6111 info@intellirentco.com intellirentco.com

We rent equipment

support

rental |

| logistics

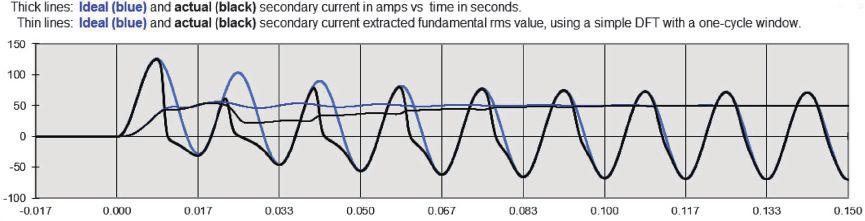

EFFECT OF CT SATURATION ON TRANSFORMER DIFFERENTIAL PROTECTION

BY STEVE TURNER, Arizona Public Service Company

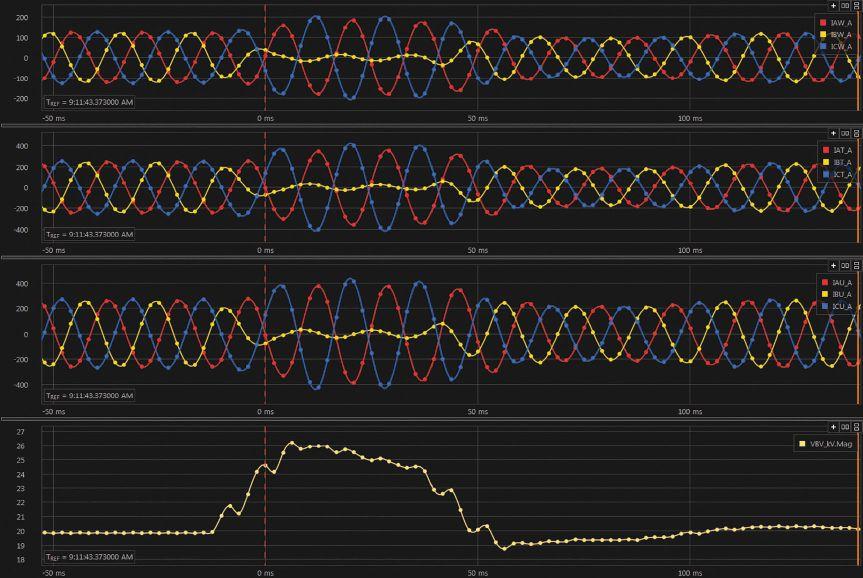

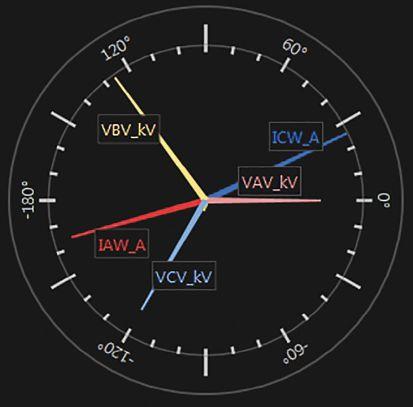

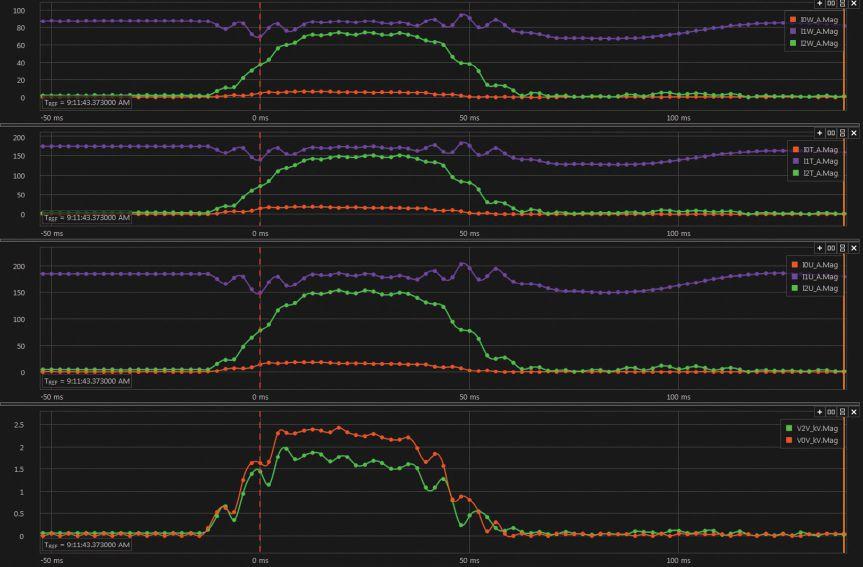

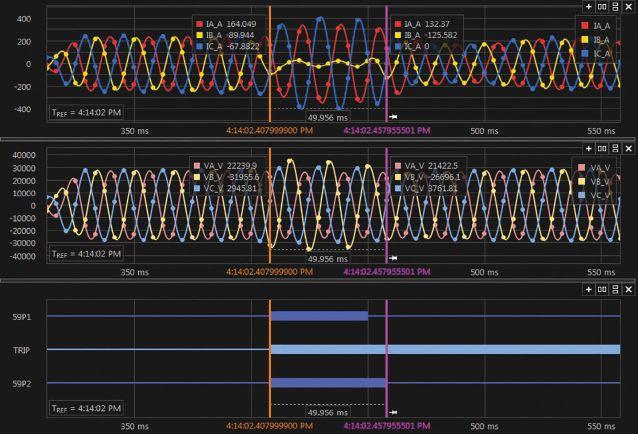

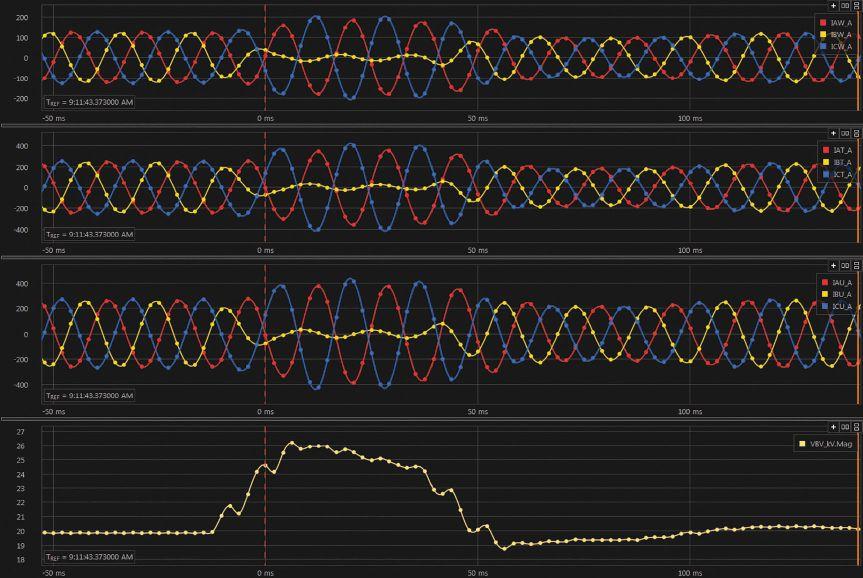

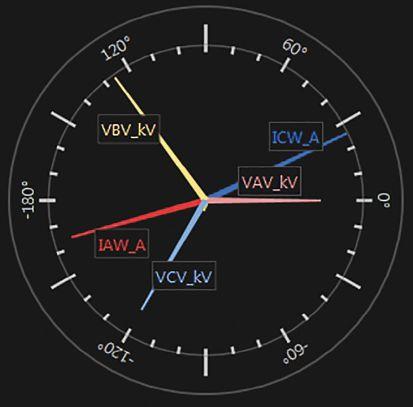

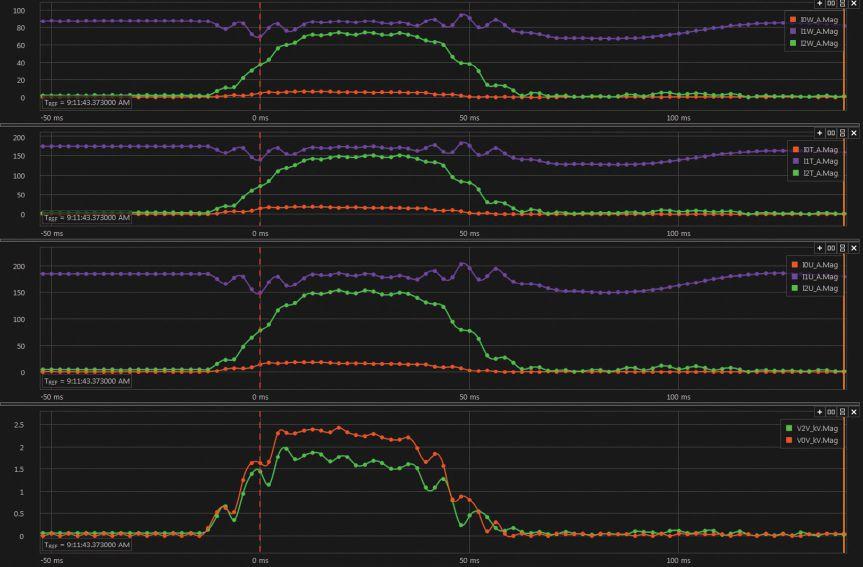

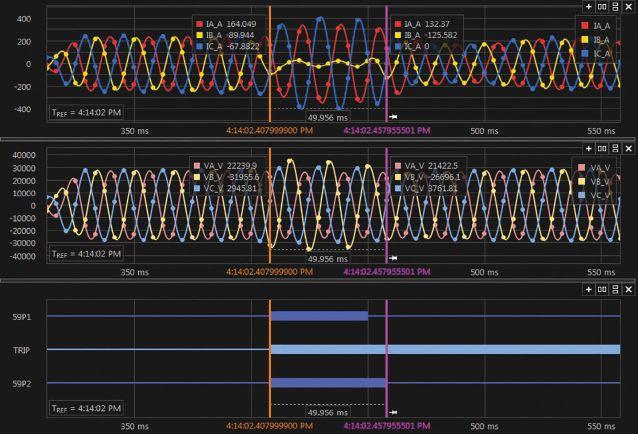

This article demonstrates how CT saturation can adversely affect transformer differential protection and how to easily mitigate its effects via inbuilt relay functions. The solution is to provide calculations and simulation for a three-phase fault on the low side of the transformer just external to the CTs.

APPLICATION

The application is for a three-phase delta-wye connected transformer serving station load at a power plant.

Transformer Name Plate Data

Size = 1.5 MVA

XT = 6.77% on transformer base

kVwdg1 = 12.47 kV

kVwdg2 = 480 V

CTR1 = 500:5

CTR2 = 4,000:5

CT2 Data from manufacturer data sheets

RCT = 1.861 ohms (0.002326 ohms per turn)

VS = 190 V (saturation voltage at excitation current equal to 10 amps)

System Data

X/R = 6.777

14 • FALL 2020 EFFECT OF CT SATURATION ON TRANSFORMER DIFFERENTIAL PROTECTION

RELAY COLUMN

FAULT CURRENT CALCULATIONS

Calculate the low side fault current as follows (ignoring system impedance for worst case scenario):

Vnom ≔ 480 V

X��1 ≔ 0.0677 per unit on transformer base (actual value) per unit on 100 MVA base

Ibase = 1.203 x 10⁵A

Inom = 1.804 x 10³A

full load current wrt 480 V winding

three phase fault current at transformer low side bushings (ignoring system impedence), per unit on 100 MVA base

secondary fault current measured by relay (non-saturated)

primary fault current measured by relay

Figure 1: Low-Side Fault Current Calculations

SIMULATION

Obtain the corresponding secondary current using a CT saturation simulation.

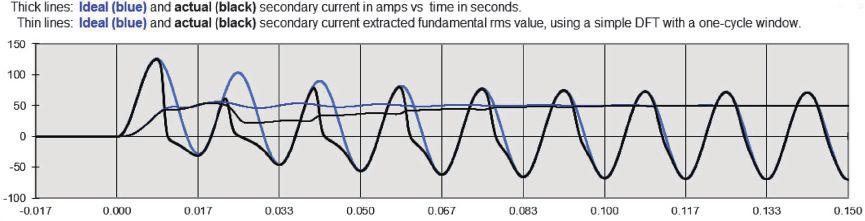

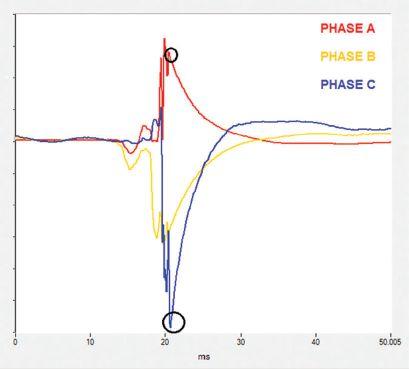

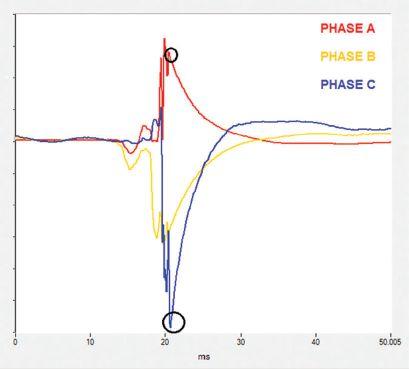

Figure 2: CT Simulation Results for Full DC Offset

OBSERVATIONS

The secondary current is most distorted during the first cycle of the fault. To help mitigate unwanted tripping during the external fault condition, enable harmonic restraint for the transformer differential protection.

Figure 3: Harmonic Restraint

NETAWORLD • 15 EFFECT OF CT SATURATION ON TRANSFORMER DIFFERENTIAL PROTECTION

RELAY COLUMN

MVA

≔

MW MVA

��1

1.5

��1

Ibase ≔ –––––––––– Inom ≔ ––––––––––

Ibase CTR CTR ≔ X��01 ≔ X��1·–––––––––X��01 TAP ≔ TAP = 2.255 A CTR 4000 100 MW 100 MW MVA��1 X��01 = 4.513 I� ≔ 5 1 I� = 0.222 I� ·––––––– = 33.313

I� ·

base

Inom

A

I

= 2.665 x 10⁴ · A

RELAY COLUMN

Harmonic blocking is not enabled since it can delay tripping during internal faults. Note: The relay vendor’s specifications for this particular relay indicate the transformer differential protection operates slower when harmonically restrained, which can also help ride through the period of saturation.

Restrained Element (With Harmonic Blocking) Pickup Time: 1.5/1.6/2.2 cycles (Min/Typ/Max)

Restrained Element (With Harmonic Restraint)

cycles (Min/Typ/Max)

Figure 4: Transformer Differential Protection Operating Times

CONCLUSION

CT saturation can occur during faults external to transformer differential protection.

Use harmonic restraint to help mitigate unwanted tripping during such events. Test the transformer protection relay to ensure the harmonic restraint works properly.

Steve Turner is in charge of system protection for the Fossil Generation Department at Arizona Public Service Company in Phoenix. After working with Beckwith Electric Company, Inc. for 10 years, Steve spent two years as a consultant in San Diego. His previous experience includes positions as an Application Engineer at GEC Alstom and in the international market for SEL focusing on transmission line protection applications. Steve also worked for Duke Energy (formerly Progress Energy), where he developed the first patent for double-ended fault location on overhead high-voltage transmission lines and was in charge of all maintenance standards in the transmission department for protective relaying. Steve has BSEE and MSEE degrees from Virginia Tech University. He has presented at numerous conferences including Georgia Tech Protective Relay Conference, Western Protective Relay Conference, ECNE, and Doble User Groups, as well as various international conferences. Steve is a senior member of IEEE and a member of the IEEE PSRC.

An extensive inventory of over 200,000 sq. ft. across the southeast means the Southland Group has the products you need most in stock and ready to ship! Our team of experienced technicians provide on-site field service support and engineering services to ensure that your products are safe, reliable and service ready. Contact us today and let us create the solutions you need most!

Pickup Time:

2.62/2.72/2.86

THE PREMIER ELECTRICALMAINTENANCEAND SAFETYCONFERENCE SAVE THE DATE MARCH 8 - 12,2021 ROSENSHINGLECREEK ORLANDO,FLORIDA POWERTEST.ORG 888.300.6382

DRONES & SPAGHETTI DINNER

BY DON GENUTIS, Halco Testing Services

BY DON GENUTIS, Halco Testing Services

May 2020 was a difficult month for our nation, and 2020 is certainly shaping up to be a difficult year. As essential service providers, many in our industry were called upon to maintain or continue building the nation’s infrastructure. We all understand and appreciate that hospitals, emergency services, government facilities, manufacturing, and even residences could not function without power, and NETA technicians across the country stepped up to ensure reliable power was, as usual, taken for granted. Thank you, NETA Technicians!

This article explores a few technologies that are useful for commissioning utility-scale renewable generation plants that were successfully used during the midst of the pandemic.

Six dedicated technicians scattered throughout the United States found themselves driving to a job site as airlines shut down or site-specific rules required a 14-day isolation period if mass travel transportation was used. Technicians from Dallas, Houston, Atlanta, Los Angeles, and Washington DC converged on a remote

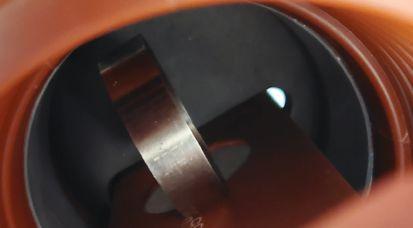

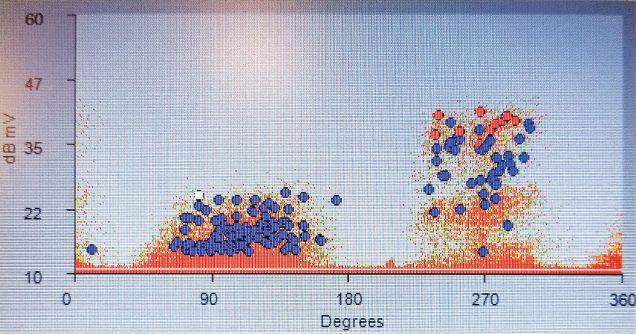

area in West Texas that recently became more remote due to mandatory or voluntary business closures. Their task was to use infrared and partial discharge technologies to detect conductor and insulation defects that could lead to future unwanted failures at a 200 MW solar facility.

PARTIAL DISCHARGE

On-line partial discharge testing has been the focus of many previous NETA World articles

18 • FALL 2020 DRONES & SPAGHETTI DINNER

IN THE FIELD

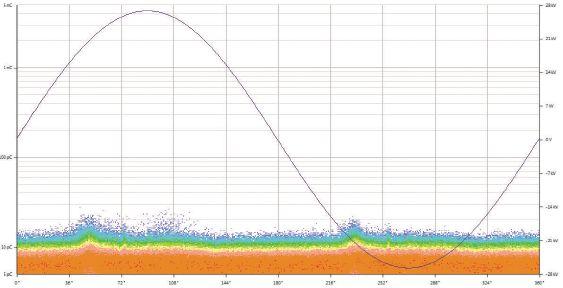

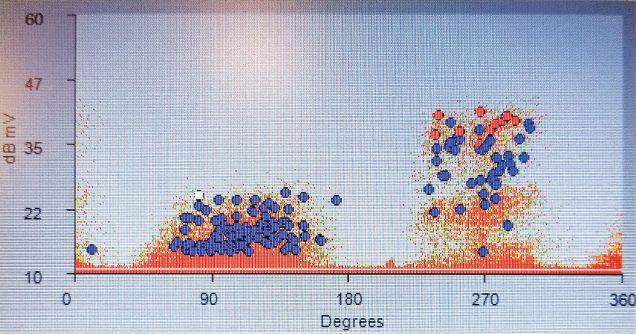

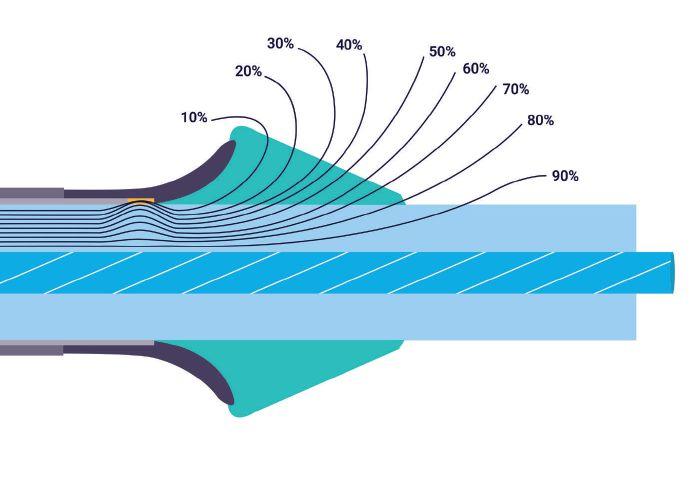

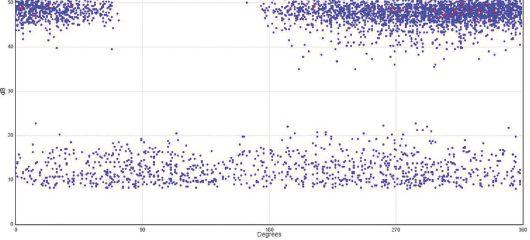

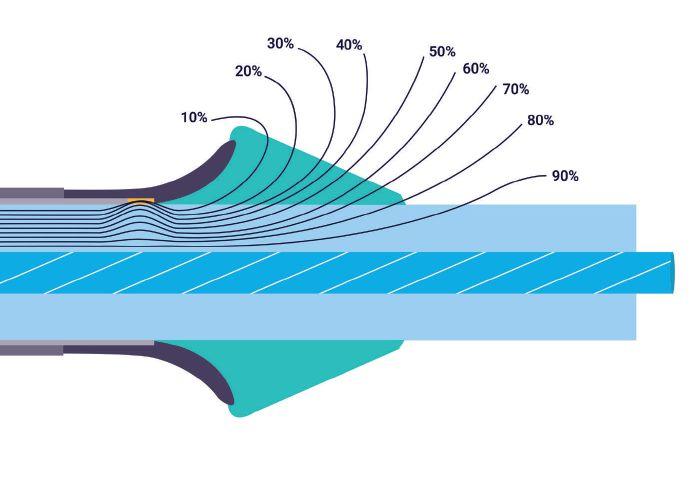

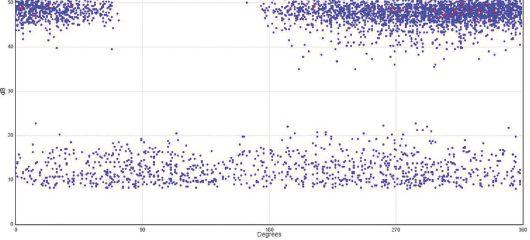

and has proven to be a very good technique for detecting insulation defects in medium-voltage cable systems, switchgear, transformers, and other apparatus while the equipment remains in service. Specialized sensors are temporarily connected safely to grounded components to decouple the electromagnetic signals associated with the discharges, and sophisticated software is used to process the raw signals and remove noise using complex algorithms to assess insulation condition.

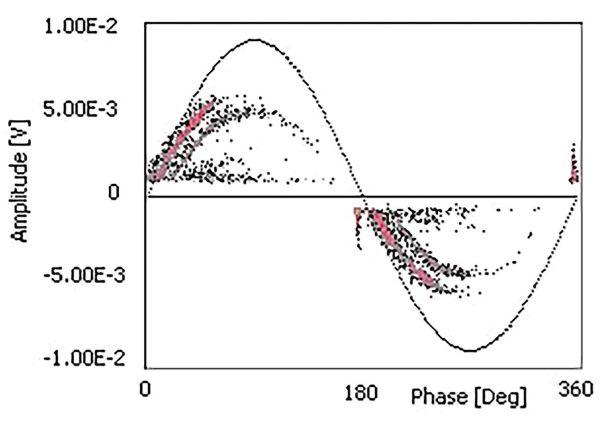

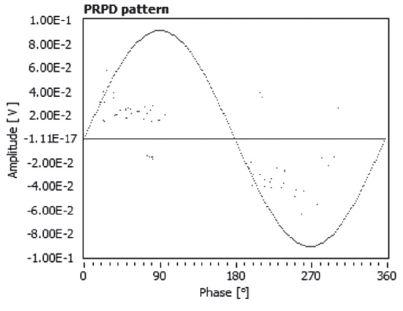

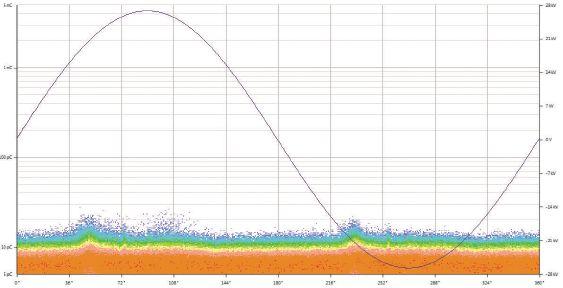

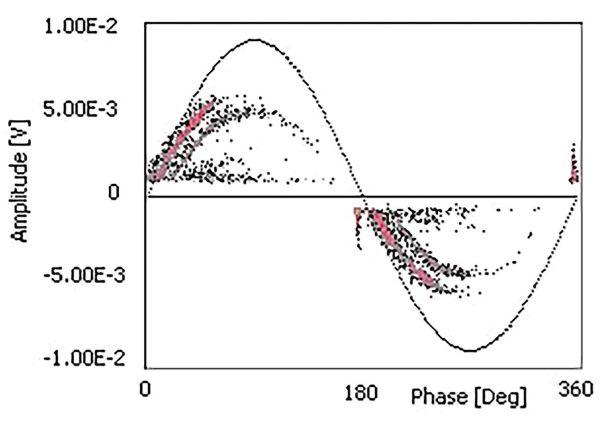

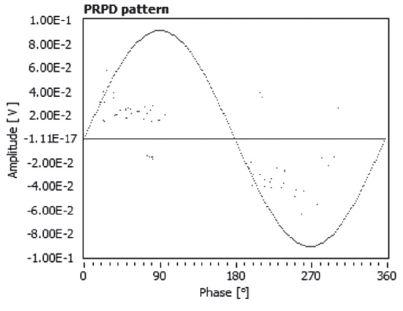

At renewable installations, this technology is capable of detecting insulation defects in cable, cable terminations, and apparatus connected to the cables including switches, circuit breakers, and transformers. One additional bonus for using online partial discharge technology is that it can readily discover loose medium-voltage connections, as the minor arcing that results creates readily detectable high-magnitude electromagnetic signals long before the problem can escalate to become distinguishable as a thermal defect that infrared technology can detect. Figure 1 displays the signal associated with this initially minor arcing phenomenon. For these reasons, online partial discharge testing can be an excellent tool for commissioning medium voltage renewable installations and should be considered for commissioning any type of medium-voltage systems.

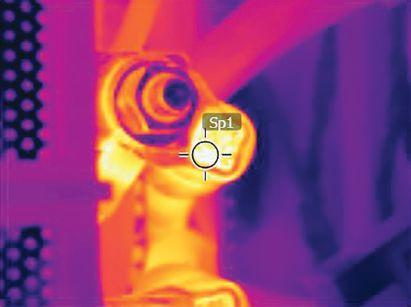

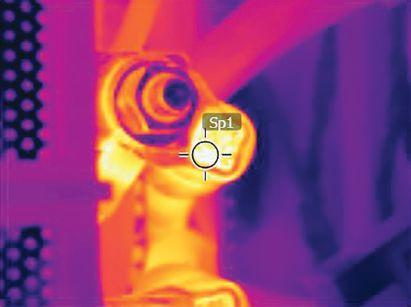

INFRARED

Infrared thermography has been regularly used for decades to detect conductor overheating and is the most widely used online tool second only to voltage and current indicating or sensing instruments. This technology provides thermal images of connections so that elevated temperatures are readily apparent. Actions can then be taken to rectify the problem before complete failure occurs. Figure 2 displays a typical connection problem.

At renewable installations, infrared techniques have proven valuable to detect conductor problems at the hundreds or even thousands

of DC wire and cable connections and inverter bus connections. Another valuable application for infrared imaging at solar facilities is to inspect the PV panels themselves for functionality. Nonfunctional panels will not generate power, and defects can range from open conductors, open connectors, or damage to the panel itself. Although solar panel thermal imaging can be performed on foot, using specialized drones equipped with infrared cameras has proven to be much more efficient at large installations.

DRONES

Unmanned aircraft systems (UAS) or drone usage has grown astronomically in recent years since it proved advantageous in a broad range of applications from construction to defense to social distancing. Combining infrared

NETAWORLD • 19 DRONES & SPAGHETTI DINNER

IN THE FIELD

Figure 1: Electromagnetic Signal from Minor 34.5 kV Arcing

Figure 2: Infrared Detects Loose Low-Voltage Connection

IN THE FIELD

technologies with drone use is a relatively new application that has already provided significant cost savings and safety benefits over conventional inspection techniques. Studies have shown that as much as 50% cost savings can be achieved by using drone technologies for PV panel inspections.

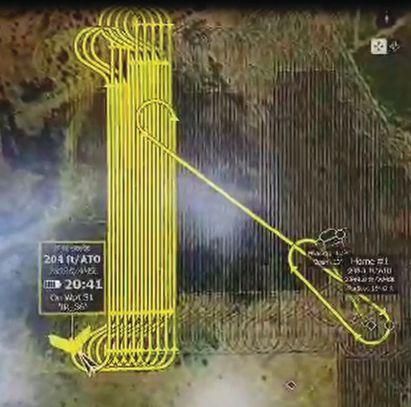

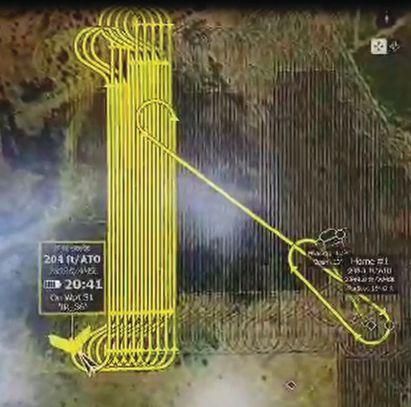

Utility-scale solar sites typically required veryfast, fixed-wing aerial hardware to efficiently weave back and forth along the countless rows of panels to collect infrared data (Figure 3). To maximize field efficiency, flight plans are preprogrammed and loaded into the hardware.

Drones fly at high altitudes to map large areas by taking hundreds of infrared images that are

then analyzed and compiled into a cloud-based report of deficiencies that consists of anomalies such as those displayed in Figure 4. The report includes GPS coordinates and the physical description and location of the anomalies so the problem can be expeditiously remediated.

SPAGHETTI DINNER

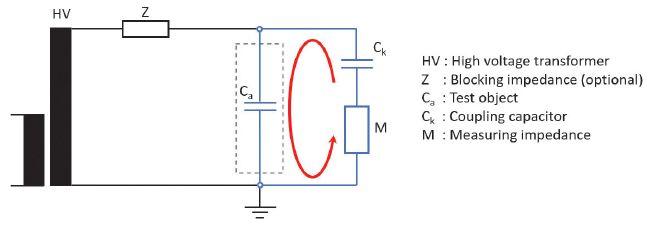

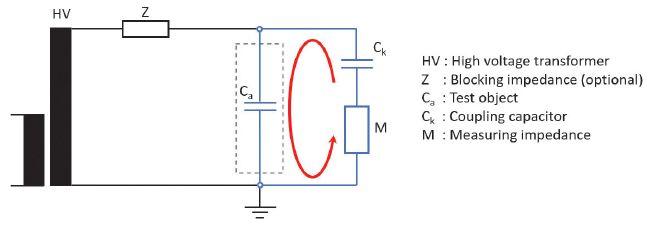

On one particularly comfortable May evening in West Texas, an unlikely group of a halfdozen technicians were pleasantly surprised by a thoughtful senior technician who took it upon himself to prepare a full-on spaghetti dinner. The team sat together on green picnic tables at the rear of the motel property but spaced themselves properly to abide by social distancing guidelines. The sky was silent — no aircraft flew above — reminding them of the weeks after the 9/11 crisis and making them all wonder which way the world will turn tomorrow. Soon, the air was filled with colorful and perhaps slightly exaggerated war stories plus the sweet smell of garlic. A few cans of beers were cracked open leading to peaceful comradery and a welcome escape from these stressful times. That evening, the faint sound of the Marshall Tucker Band playing “This Old Cowboy” could be heard in the distance from some cheap radio as the group ate the “best” spaghetti dinner they ever had.