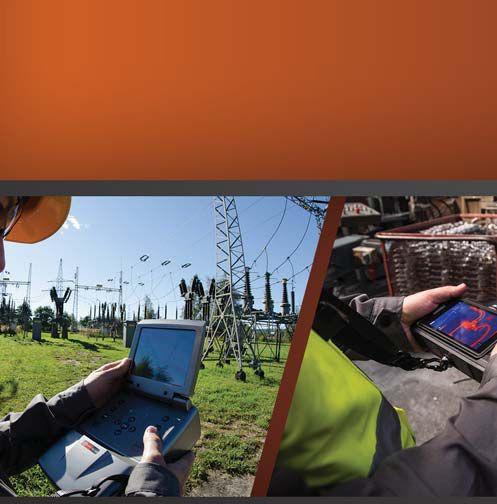

Cable testing and diagnostics are key to maintaining power line reliability and longevity.

Megger’s industry leading cable test and diagnostic solutions are built to quickly and accurately locate cable issues that others cannot, so you can Power on.

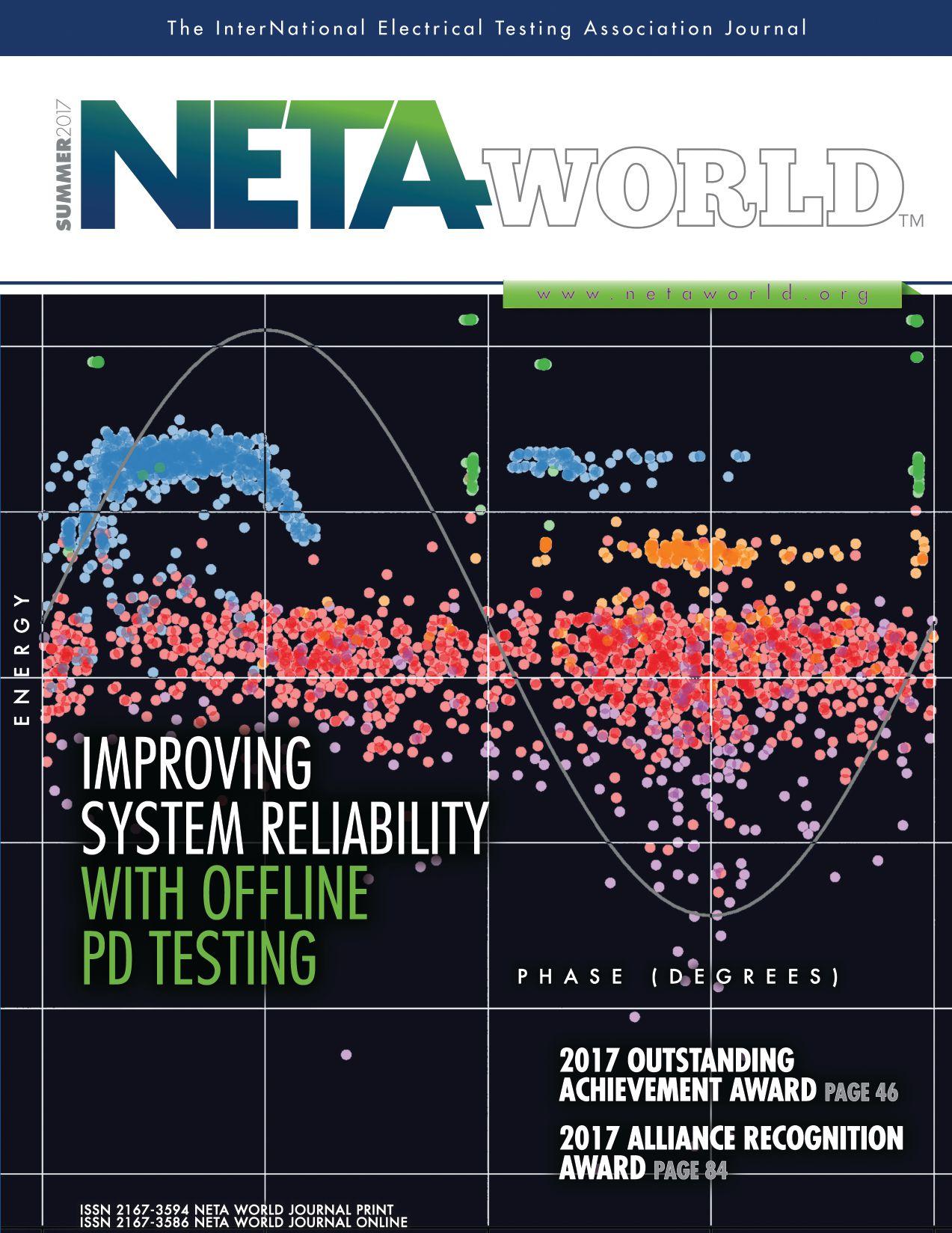

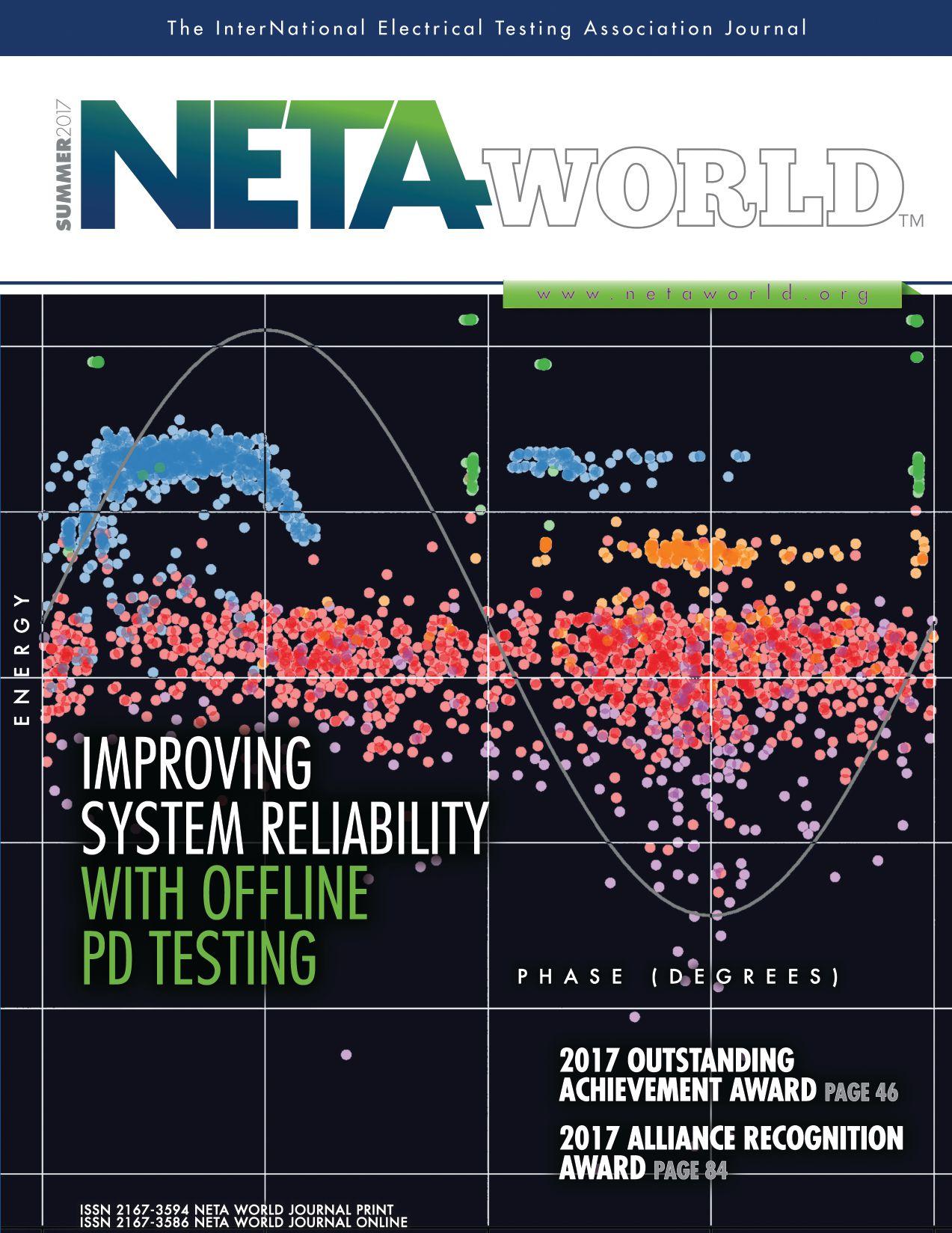

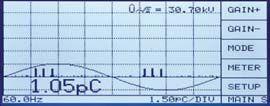

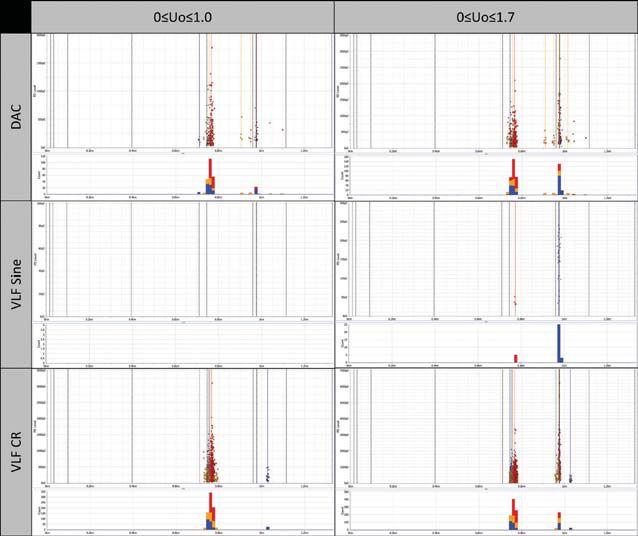

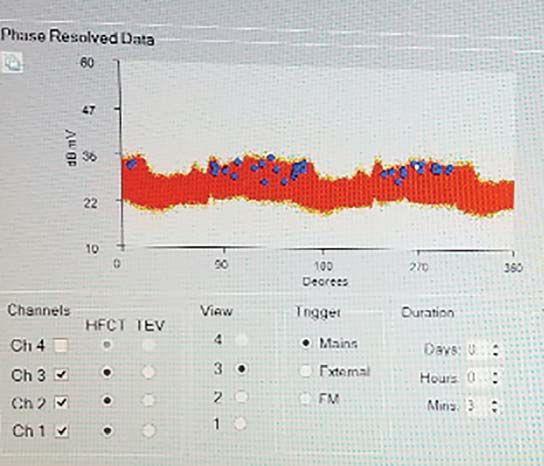

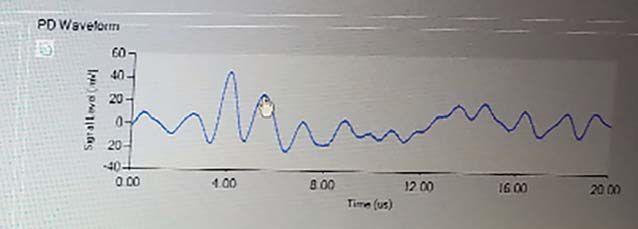

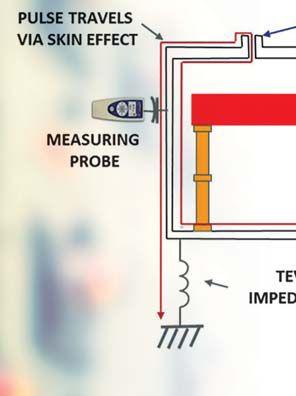

Partial discharge (PD) testing, a new generation of diagnostic testing for medium- and highvoltage underground power cable systems, offers a powerful diagnostic technique capable of identifying problem spots in cables long before they cause an in-service outage or, if used during commissioning testing, detecting problems before the cable is placed into service. This knowledge can then be used to improve system reliability, reduce unplanned outages, reduce emergency call-outs, and help target the most vulnerable cables for replacement while allowing good cables to remain in service.

Jason Souchak, Megger

Cover image provided courtesy of O. Perpiñán, M.A. Sánchez-Urán, F. Álvarez, J. Ortego, F. Garnacho, authors of Signal analysis and feature generation for pattern identification of partial discharges in high-voltage equipment, Electric Power Systems Research, Volume 95, February 2013, Pages 56-65, ISSN 0378-7796, https://doi.org/10.1016/j.epsr.2012.08.016.

7 President’s Desk

Ron Widup, Shermco Industries

NETA President

68 Cable Insulation Assessment of a Small M-V Distribution System Using Online Partial Discharge Techniques

Don Genutis, Halco Testing Services, Inc.

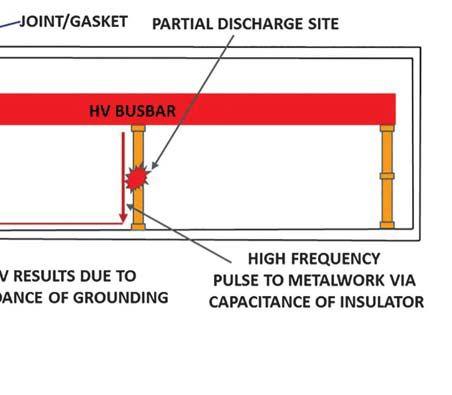

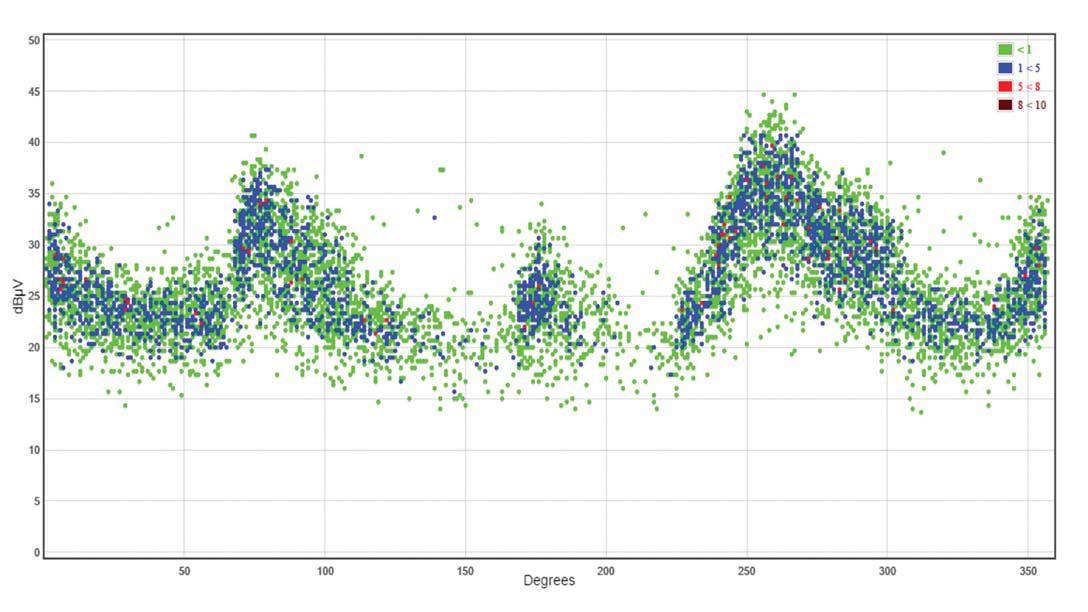

76 Non-Invasive PD Testing of Switchgear: Does It Really Work?

William G. Higinbotham, EA Technology, LLC

11 NFPA 70E and NETA

Big Changes to 2018 70E Tables

Ron Widup and Jim White, Shermco Industries

18 No-Outage Corner

Using Ultrasonic Instruments in Outdoor Substations

Don A. Genutis, Halco Testing Services, Inc.

22 Tech Quiz

Partial Discharge

Jim White, Shermco Industries

28 Tech Tips

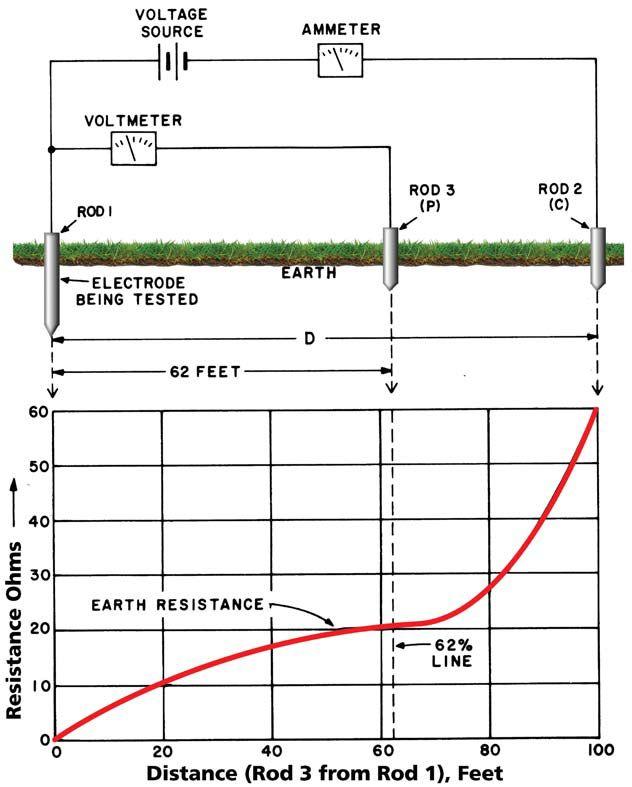

Ground Testing FAQs

Jeff Jowett, Megger

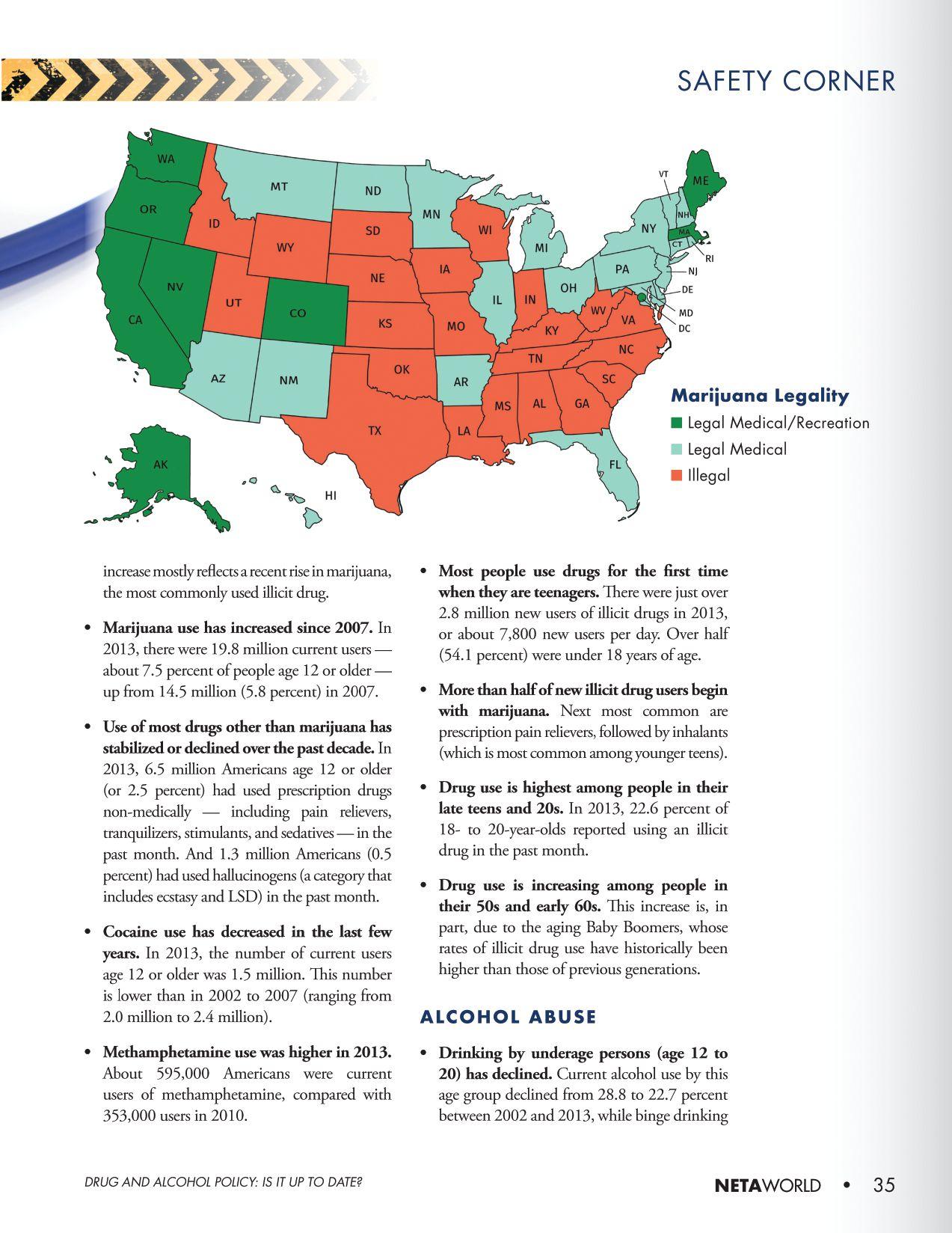

34 Safety Corner

Drug and Alcohol Policy: Is It Up to Date?

Paul Chamberlain, American Electrical Testing Co., Inc.

40 Relay Column

Safety and Its Importance in Protective Relaying

Steve Turner, Electrical Consultants, Inc.

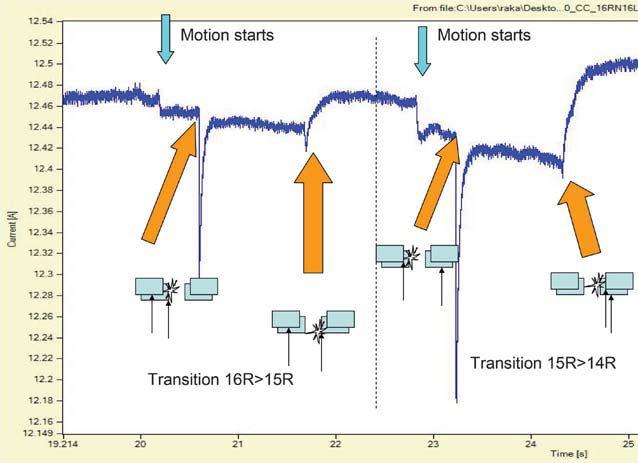

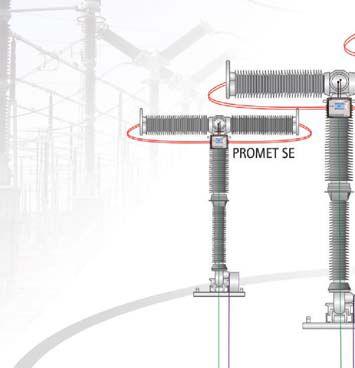

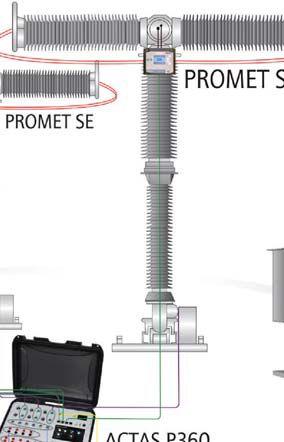

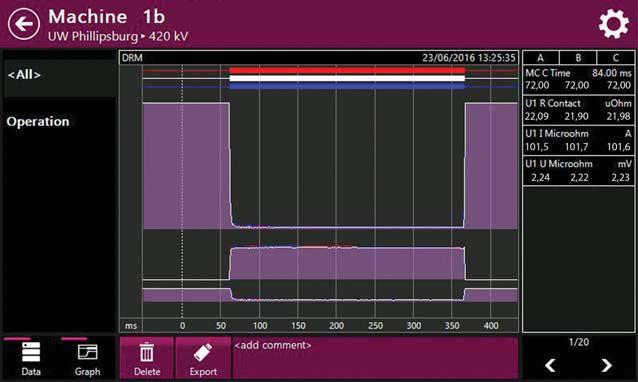

89 On Load Tap Changer Testing —

Dynamic Recording

Raka Levi, Ph.D., AMforum

99 Requirements for Testing Switchgear

Quickly and Economically

Christian Studen, KoCoS Messtechnik AG

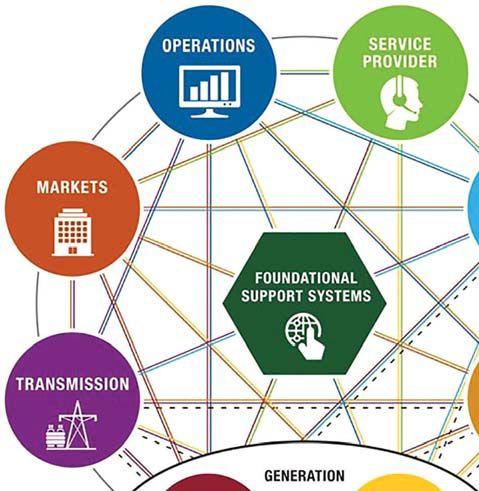

116 Fundamental Changes to the Electric Power System Post-2018

Mark Siira, ComRent International

96 ASTM F18, NEC CMP-13, and NFPA 70E Committee Report

Jim White, Shermco Industries

106 ANSI/NETA Standards Update

110 NFPA 70 Code-Making Panel 10 Committee Report

Scott Blizard, American Electrical Testing Company, Inc.

111 NFPA 70B – 2019 Committee Report

David Huffman, Power Systems Testing Company

24 NETA and LBCC Launch New Education Program for Electrical Testing Technicians

26 NETA Welcomes Newest Accredited Company — Electrical Engineering & Service Co., Inc.

46Outstanding Achievement Award – John White

51 PowerTest 2017 Attracts Record Attendance as Industry Gathers for Premier Electrical Maintenance and Safety Conference

84 Alliance Recognition Award – Will Knapek

112 NETA Members and Alliance Partners

Enjoy Peer Discussion and NETA Updates

124 NETA Accredited Companies

130 Advertiser List

Your source for high voltage and electrical

| CALIBRATION | RENTALS

Working with the biggest names in the industry:

A NETA World Journal

Special Publication

SUMMER 2017 04 07 15 17 20 22

A publication dedicated to disseminating information on technical and professional training for the advancement of the electrical power systems industry.

NETA CERTIFICATION: IN PURSUIT OF EXCELLENCE IN ELECTRICAL TESTING

By Dan Hook, Western Electrical Services, and Kristen Wicks, NETAPOWER CABLE OUTAGES AND THE TRAINING CONNECTION

By Alan Mark Franks, AVO TrainingCOUNT THE NUMBER OF Fs

By David Sowers, Knowledge Vine

SAFETY TRAINING IN COMPLIANCE WITH OSHA AND NFPA 70E

By Jim White, Shermco Industries

DON’T FILL IN THE BLANKS

By David Sowers, Knowledge Vine

DIRECTORY OF TECHNICAL AND PROFESSIONAL TRAINING

NETA was established by a group of individuals who collaborated because they realized that quality assurance requires a team of people working toward the same goal, with a shared vision, and a well-defined outcome. These people believed that the best way to provide safe, reliable power was to bring a third-party, independent perspective to the table along with the architects, engineers, manufacturers, installers, and facility management to help assure that all facets of the system work together as designed. The individuals responsible for providing that perspective must be fluent in all these spheres of responsibility, but also must be knowledgeable in very specific technical areas across all manner of equipment and systems, individually and as a whole. This realization was eventually quantified in the ANSI/NETA ETT, Standard for Certification of Electrical Testing Technicians

Diversity in collaboration helps assure that stakeholder voices are heard and represented in the final product.

While the role of these uniquely qualified individuals was not officially codified by NETA until 2000 when the ANSI/NETA ETT Standard for Electrical Testing Technicians was first published as an American National Standard, NETA had been certifying electrical testing technicians for many years prior. The most current edition of the ANSI/NETA ETT is the 2015 edition, slated to be released as a revised American National Standard in 2018. It will consider the work achieved over the past two years during the certification exam restructuring, but will stay true to the core tenants of the document. To learn more about the specific requirements for NETA Certification and to download a complimentary copy of the current ANSI/NETA ETT, please visit NETA’s website at www.netaworld.org

standard to which all NETA Certified Technicians are held.

Like most things, NETA’s certification program has evolved and expanded as certification-industry best practices were established and revised. One thing that has remained constant throughout the history of the program is a commitment to safety, public protection, and assuring that the content is technically relevant. Each Technical Exam Committee Chair and the Exam Committee they lead has raised the bar in pursuit of that moving target: excellence.

The road to excellence never truly ends. Loftier heights are achieved, new goals are set, but the path to each is paved with routine. Routine preventive maintenance and improvement is critical to the health and safety of every system, whether it is an electrical power

Excellence is a moving target; never stop climbing.

system or a certification exam designed to establish minimum competency requirements for electrical testing technicians. NETA has established an ongoing maintenance program for certification exams to assure that resources are allocated to this program on an ongoing basis in support of the growing population of individuals seeking certification.

The most recent round of maintenance to NETA’s certification program began in 2015, with the launch of a project aimed at elevating the quality of NETA’s certification exams for Level 2, Level 3, and Level 4 Certified Electrical Testing Technicians. NETA contracted with a third-party exam development and administration company, Schroeder Measurement Technologies, Inc., to provide an assessment of the existing certification program and make recommendations for improving it through a job analysis survey, exam item (question) writing, form development, and standard setting. This project marked the largest initiative in the history of the association in terms of fiscal and human resources.

Proactive planning assures a solid certification program now, and into the future.

The result of this collaboration is a psychometrically sound set of certification exams that are in alignment with current industry standards and practices. Psychometrics is the field of science associated with the development of instruments (such as examinations) that measure knowledge, skills, and attributes (KSAs) — essentially measuring what is in someone’s mind. This measurement is a critical component of a strong

certification program, which also includes components like relevant pre-requisites for training, education, and experience, as well a recertification mechanism to assure that certified individuals are keeping pace with emerging technologies and revised or new industry standards and best practices.

NETA Accredited Companies are tasked with helping their technicians prepare for these certification exams over the course of their careers. Many NETA Accredited Companies have internal training programs designed to assure that their technicians meet the prerequisites and have the necessary field experience to succeed on the exams. Industry partners offering training are also heavily relied upon to provide the technical expertise in certain subject areas where practical and book-based knowledge is required. One of the most important tools for preparation is the detailed content outline that functions as the blueprint for the certification exams. This document is available on NETA’s website and should be used in conjunction with ANSI/NETA ETT when designing an exam preparation program.

Overall, what NETA’s Certification Program means for NETA, NETA’s Accredited Companies, and the industry at large is that now, more than ever, specifying NETA means specifying quality, safety, and reliability. When electrical components and systems are tested as specified in the ANSI/NETA standards by a Certified Electrical Testing Technician, that work is being performed by a specialist who has demonstrated that they have the knowledge, skills, and attributes needed to perform that work accurately, safely, and in accordance with industry standards.

No matter who you are, or what your responsibility is in the electrical testing industry, remember this helpful hint: If you are pursuing excellence, keep NETA in the equation.

DAN HOOK is the Executive Vice President in charge of Business Development at Western Electrical Services, where he previously held Field Service Engineer, Sales Engineer, and Chief Operating Officer positions. He has been in the industrial electrical industry for over 20 years and has U.S. Navy and civilian experience. Currently, he focuses on strategies to grow three company divisions and manages employee development, trade association affiliations, and corporate-level sales efforts. Dan holds a Master’s degree in Electric Power Engineering from Rensselaer Polytechnic Institute and maintains his professional engineer’s license in Washington, Utah, Arizona, and Oregon. He earned an MBA in 2012 from Pacific Lutheran University with a concentration in Entrepreneurship and Closely Held Businesses. Dan is a certified NETA Level IV Technician as well as a NICET Level IV in Electrical Testing Engineering Technology. He is also a member of the NETA Board of Directors, a member of the NETA Standards Review Council, and is the NETA Certification Exam Committee Chair.

KRISTEN K. WICKS is the Technical Services Director for NETA, the InterNational Electrical Testing Association, and has been supporting NETA’s technical efforts since 2006. A summa cum laude graduate of the Honors College at Florida State University, Kristen serves as the liaison to NETA’s Standards Review Council and collaborates with NETA’s Board of Directors, committees, and subject matter experts to assure that NETA’s programs, products, and services are aligned with its mission and vision, are technically substantiated, are in accordance with other industry standards, and are stylistically and grammatically correct. Kristen manages the association’s technical portfolio, which encompasses programs and projects such as the Technical Certification Examination program, Continuing Technical Development program, NETA Approved Military Organization (NAMO) program, and NETA’s American National Standards. Kristen also contributes to NETA’s marketing and outreach initiatives, training program development, NETA World Journal, and supports NETA Accredited Companies in leveraging and implementing the ANSI/NETA standards in service to their electrical power systems clients.

Much has been said about the aging condition of power cable installations in the United States. Cables can be categorized as service-aged solid dielectric, service-aged laminated (PILC), or cables of more recent design and installation. Much has been learned about the causes of cable outages, and recent studies indicate that even with design issues in early cables, the major cause of these outages can be related to poor quality during the installation process, either in cable installation, termination, or splicing.

The National Electric Energy Testing Research & Applications Center (NEETRAC) documents that approximately 50 percent of cable outages can be directly attributed to poor workmanship during cable installation, splicing, and terminating. As a result of the failure analysis studies conducted by NEETRAC, it can be concluded that there is a significant connection between cable outages and a lack of training in cable installation, splicing, and terminating of medium-voltage cables. As well-stated in “Cable Accessory Failure Analysis,” presented at the NEETRAC Fall 2010 ICC Educational Session: “All evidence points to improved training

as the single most cost-effective means of improving system reliability.” Figure 1 represents the process of improving system reliability through failure analysis, training, and skill certification.

First, consider the issue of failure analysis. A process of root cause should be employed to all cable outages to determine the primary cause of failure. If the failure is due to a product quality issue, the manufacturer is likely involved, and these types of issues normally include a significant timeline. Redirection in purchasing and product approvals may be necessary to offset any further outages due to the use of the product.

More often, the root cause can be identified as a workmanship issue, either in cable installation, splicing, or termination. Often, imminent cable failure is due to tracking caused by inadequate preparation and cleaning during the splicing process. This is one of the many common modes of failure experienced by utilities today.

Tracking leads to imminent cable failure and is caused by inadequate preparation and cleaning during the splicing process.

Improper cable preparation leaves semi-conductive insulation shield material that will result in cable failure.

Another example of improper cable preparation is where tool settings are not adequate for the semicon stripping process, which will certainly result in failure.

In many cases, the results of improper cable installation make it somewhat difficult to get to the bottom of what actually caused the initial failure. With these issues in mind, it is imperative that a comprehensive cable failure analysis program be in place to determine root cause, thus ensuring that costly failures can be eliminated.

Improper cable installation caused cable failure in a manhole installation.

Failure analysis certainly will identify poor workmanship that leads to failure. Identifying these types of issues can provide invaluable insight concerning the training of workers involved in installation, splicing, and termination of cable systems.

Training certainly will have an impact on system reliability, provided that the proper skills in cable

handling, preparation, splicing, and terminating are imparted to the worker. This is a craftsmanship issue that requires a detailed understanding of medium-voltage cable construction as well as the use of proper procedures and tools. Historically, these craft skills were taught in an on-the-job (OJT) fashion with apprentices working under the watchful eyes of skilled craftsmen who had years of cable experience. These mentors grew up in the early stages of the cable industry and acquired their skills over a significant timeline that coincided with the boom of the power cable industry. As Baby Boomers are leaving the workplace, so are most of these mentors and, along with them, many years of cable splicing and terminating craft skills.

OJT training philosophies need to be supplemented with more formal training with finite objectives and proctored labs where workers not only learn the technologies, but also the craft skills necessary to perform medium-voltage cable work. The implementation of formal cable training greatly reduces the time it would take to gain this experience on the job. By implementing formal training, the quality of instruction can be monitored to ensure that all trainees get the same information and apply the knowledge in controlled lab exercises proctored by experienced instructors; this ensures that the mentorship is complete. The impact of high-quality training where workers demonstrate the learned skills has a definite impact on the future quality of maintenance and new installation work.

Training can be outlined in four basic areas of craftsmanship:

■ Cable installation and handling

■ Cable preparation and tools

■ Cable splicing

■ Cable termination

Many cable failures occur because of mishandling the cable during installation. Issues such as exceeding the bending radius, excessive tension, excessive side-wall pressure, cuts, abrasion, and damage to the jacket can lead to cable failure. Much of this damage goes unrecognized, as many current acceptance testing methods will not identify the damage unless it is catastrophic in nature. In short,

It often takes a significant amount of equipment and rigging to install power cables.

these damages go unnoticed — sometimes for years — and ultimately lead to failure and a premature shortening of cable life.

Cable handling, specifications, rigging, application of lubricants, conduit fill, etc., are necessary components of training that installers need to ensure proper installation of medium-voltage cables. It often takes a significant amount of equipment and rigging to install power cables.

A cable failure in a medium-voltage cable installation like this one could potentially cause catastrophic damage to other feeders in the same vault.

Cable handling and installation take on significant meaning when considering an installation that requires a high level of craftsmanship. A cable failure in this type of installation could potentially cause catastrophic damage to other feeders in the same vault. Every aspect of the need for a quality cable installation is apparent.

A large number of cable outages can readily be attributed to how the cables were prepared for splicing or terminating. Most cable manufacturers

do not provide explicit instructions on how to prepare the cable; rather, the instructions specify the dimensions required in the preparation. Most manufacturers have a disclaimer that reads as follows: “Prepare cables according to acceptable industry practices.” Therein lies the ambiguity, as no specific guidelines are provided as to methods or tooling other than tool manufacturers’ instructions on how to use their specific tools.

Procedures vary widely in the U.S. and, in many cases, there are no specific requirements. Most splices and terminations come in kit form today, and the assumption is that all the instructions needed are in the kit. This is a fallacy, as there are no specific instructions on cable prepping procedures and techniques, not to mention appropriate tools. Everyone would agree that the tool illustrated on the left in Figure 2 would not be appropriate for cable preparation. On the other hand, some may believe that the tool on the right in Figure 2 would be an appropriate tool for preparing a cable. Box cutters and other razor-blade knives have contributed significantly to cable failures in the U.S. One could argue that in the hands of a well-trained splicer, the box cutter would work. The better argument is that the appropriate tool is one manufactured for cable prepping, and that is the tool that should be in the hands of a welltrained splicer.

There are many tools available for any cable splicing or terminating project. Cable tool selection is a responsibility of the end user and should be based on reliability, ease of use, and repeatability of the task being performed. Adjustment and maintenance of the tool is as important as the tool itself. Keep in mind that improper use of the tool or a maladjusted tool could prove detrimental.

The use of appropriate tools alone does not ensure quality. Training in cable construction, dimensions, materials, care, and use of appropriate tools, along with environmental controls, are needed to equip the worker with the the skills to complete a quality splice or termination.

Let’s consider the technologies available today to splice medium-voltage cables. The major technologies employ products of tape, heat-shrink, molded, cold-shrink, resin, and a specialized group of products for paper-insulated lead cable splicing. Technologies are also available where the outside diameter of cable is a significant issue or where flexibility is needed, such as cables for dredge or mining operations. All of these products require special skills for the splice to meet the quality standards required for the installation.

There are literally hundreds of individual products and kits that cover the scope of medium-voltage cable splicing. Mastering the technologies required to move efficiently within the medium-voltage cable field requires a solid base of cable understanding. The use of specialized tools, attention to detail, preciseness, and other skills are required to perform quality splicing with the array of cable and ancillary products available today. The following introduces examples of several technologies used in industrial and utility cable systems with comments identifying certain skills needed to perform quality work.

Tape splices can be completed in various levels of voltage and configurations. Instructions are normally very detailed, and several different types of tapes are used to complete the splice. Tapes can be ordered in kit or bulk quanities depending on the end user’s needs. These types of splices define the craft skills needed to perform medium-voltage cable splicing. Properly completed, this type of splicing will perform well for many years.

Some of the critical points that must be employed by the splicer include:

■ Cable prepping dimensions are critical.

■ Cable must be kept extremely clean and splicer cannot handle insulation surfaces.

■ Proper tape must be used to replace cable construction.

■ Thickness of materials is critical, especially the insulation layers.

■ All tapes are assembled in a half-lapping process that has to be learned.

■ Tension and tape elongation is critical for proper performance of the splice.

■ Moisture proofing, grounding, shielding, rejacketing are all part of the technology.

■ The variables in maintaining tension, precise intepretation of instructions, and the time it takes to assemble this type of splice make this technology somewhat difficult to master.

Modern material science should be credited for the development of various types of heat-shrink materials. These products are available in multiple voltage levels and numerous cable configurations. Since these products use heat from a torch for assembly, a multitude of precautions and safety procedures must be implemented by the splicer. Work in confined spaces, flames, hazardous location work, and the general requirements for using flames are skills required of the splicer.

Since heat-shrink splice products use heat from a torch for assembly, a multitude of precautions and safety procedures must be implemented by the splicer.

Cold-shrink splice products have entered the product market and are being extensively used in the wind power sector. These splices are normally used on large conductor, jacketed concentric cables and can present some difficulty in installation in direct-bury trench installations due to the environment. As mentioned previously, prepping, dimensions, assembly, and clean insulation surfaces are critical to the reliability of all splices. Since many of these splices are at the 35 kV level, environmental issues during construction are main contributors to failure.

Molded products have increased in use due to the ease in assembly these products provide; they are the product of choice for underground residential cable installation. These products come in all mediumvoltage ranges and can be slip on, bolt on, or a combination of technologies to accommodate the splicing configuration desired. The cable prepping and adherence to specific dimensions are critical for this type of product. The tracking surfaces provided by these splices are usually short, requiring the surface to be extremely clean during installation.

Resin splices are not the most common type of splice used in the U.S., but do have an application. Assembly, prepping, sealing, and mixing the compounds become critical issues for the assembly of this type of splice. Many failures occur when voids are left in the filling process, producing partial discharges that ultimately lead to failure.

Splicing PILC cable should only be undertaken by techs with significant training and experience with this technology, which is cable splicing in a totally different dimension. Probably the oldest splicing technology in the U.S., it is considered a craft of its own. The largest myth today is that lead cable is gone; there are many miles of lead cable in large metro installations. The main issue today is finding techs who have the experience to splice the cable in the numerous configurations required. With companies transitioning from lead to other cable insulations such as poly or EPR, additional technical issues present themselves. All manner of mistakes can be made that would affect the integrity of the splice, not to mention the safety issues with handling molten lead. Significant tooling and knowledge are required.

Terminating medium-voltage cables presents similar technical issues as performing cable splicing. The same cable prepping, cleaning, assembly, and

connecting technologies are present and require a skilled tech. As can be expected, there are fewer cable termination failures in the U.S. than failures in cable splices. This is due to the environmental issues, difficulty in assembly, and numerous opportunities for error that present themselves during the splicing operation. With that said, a termination being installed outdoors in inclement weather may also present the same difficulties.

What follows are examples of similar products for terminating medium-voltage cables. The most common failure point in cable terminations is the failure to control the electrical stresses created by terminating the insulation shielding. Moisture seals are necessary for terminations installed in outdoor applications or in environments where contaminants might enter the termination.

Taped terminations require a significant amount of time like hand-taped splices. A taped termination, thought of as half of a splice, requires specific dimensions for tape thicknesses to form a stressrelief cone. The electrical stress must be controlled to ensure there is no excessive electrical stress on the insulation at the point of termination of the insulation shielding. This construction results in the creation of a geometric stress cone as illustrated in Figure 3.

Terminations made of high-performance heatshrink materials (Figure 4) are currently available for all medium-voltage cables. As in heat-shrink splices, care in the use of torches must be exercised. One of the significant issues using a torch is that the

technician must ensure the entire termination body has been sufficiently shrunk, and there are no voids in the termination.

The advent of cold-shrink products that can withstand severe environmental and electrical conditions along with ease of construction have enhanced their use in the utility market. As with all previously described methods, the cold-shrink terminations must be installed with precision and adherence to approved cable preparation techniques.

Molded and modular terminations are used in a variety of applications including utility, industrial, and commercial. The terminations are designed to address a host of installation configurations

A three-phase cable installation using cold-shrink terminations requires great precision in installation.

and equipment specific termination requirements. Most of the failure issues with molded products are a result of prepping mistakes and a lack of clean assembly coupled with issues in torque and connector crimping. Cable alignment and external physical stress also contribute to failure.

Molded and modular terminations are used in a variety of applications including utility, industrial, and commercial.

Figure 5: Paper-insulated lead cable terminations can use heat-shrink or cold-shrink technology.

Previous methods of terminating PILC cables consisted primarily of the porcelain-insulated type (Figure 5). Today, PILC cables can be terminated by using modern technologies of heat-shrink or cold-shrink technology. Only well-experienced technicians should undertake the termination of PILC type cables.

There are literally hundreds of examples of mediumvoltage cable splicing and terminating that could illustrate different challenges to the cable splicer. The examples in this article promote the understanding of

the different skills a technician must have to perform reliable cable splices and terminations using an array of technologies. Key to the current status of cable splicing in the U.S. is the migration of experienced technicians away from the workforce, either by retirement or being promoted to supervisory-level positions of leadership that take them away from the everyday, on-the-job mentoring necessary to transfer the splicing and terminating skills needed in today’s cable environment.

Employers must consider either more formal apprentice programs with documented mentorship or formal training with clear objectives and proctored activities ensuring trainees demonstrate their skill. Either of these methods should lead to certifying of the employee’s skills and should include documented demonstration of successful splicing and terminating craftsmanship.

Further certifications or re-certification may be necessary based on evidence obtained through failure analysis as indicated in the model in Figure 1. Remember, you can only expect what you inspect. Many of the cable outages today could have been averted by simply having a quality inspection program in place to ensure installations were being completed within guidelines.

Project manning and time constraints on many installations create the “get in, get it done, and get out” philosophy, and cable terminations and splices are usually the last part of the installation. The sense of urgency of project completion can easily be directed

at the cable splicer. A skilled, certified cable splicer understands that the quality of the cable installation is in his/her hands and will take all necessary steps to provide reliable terminations and splices that will last the duration of the cable’s life span.

To ensure a reliable cable installation, have competent personnel who are trained, have demonstrated splicing skills, and have attained a level of certification that will ensure a quality installation is achieved.

Cable prepping is the basis for all medium-voltage cable terminations and splices. Significant training in the use of special tools and materials with emphasis on following instructions is necessary.

Unlike the assembly of various products that require a more specialized understanding of the process, splices and terminations require the same basic skill in prepping medium-voltage cables. Failures in cable splices contribute to a large portion of cable outages in the U.S.

Validation of a cable splicer’s skill is necessary to ensure quality installations and a reliable cable future. Certification and recertification ensure that the splicer has demonstrated the requisite skills and is maintaining that skill level.

With the high-quality cable products on the market today, we must conclude that the future of cable reliability is in the hands of the cable splicer.

ALAN MARK FRANKS is a Senior Safety Specialist at AVO Training Institute. He has over 48 years in the electrical utility industry with an extensive background in electrical safety and power distribution. Mark was instrumental in developing the pre-OSHA Electrical Safety Audit for the industry and the conducting of on-site audits of facilities, installation of electrical equipment and systems, safety procedures, and training records and programs, all based on OSHA and NFPA regulations and other industry consensus standards. He has been an authorized OSHA Instructor for all general industry and construction regulations. Mark is a certified fiber optic technician, certified fiber optic instructor (#839), and a member-in-good-standing of the Fiber Optic Association. He participates in numerous associations including NFPA 70E 2000 alternate committee member, International Association of Electrical Inspectors, American Society of Safety Engineers, National Cable Splicer Certification Board, and American Society for Testing and Materials. Mark has provided electrical safety training and performed electrical safety audits for general industry, utilities, and mines both underground and surface. He has instructed all aspects of power cable splicing, termination, testing, and fault location for 25 years and has been instrumental in developing the AVO Training Institute Cable Technician Certification Program.

Self-checking test: Quick! Count the number of times the letter “F” appears in the following sentence. Take your time but only count once.

“Finished files are the result of years of scientific study combined with the experience of years.”

What answer did you get? The most common responses are 3 or 6. If you answered 3, you have probably re-read the sentence looking for those three missing letters. If you answered 6, you may be feeling a little self-satisfied, but you are also wrong. Technically, the answer is zero. Don’t worry, I’ll explain.

Did you answer three? Here’s why you got it wrong. Your brain typically does not recognize the letter F in the word “of”. This could be for one of two reasons. First, the letter F generally sounds as you would expect, like in the words “fox” or “fast” or “finished files.” However, in the word “of,” it has a “v” sound as in “ov”. This pronunciation causes the brain to fail to immediately recognize the

letter because it doesn’t correspond with the sound we are accustomed to hearing form the letter F.

Second, since “of” is a common preposition and not a lexical word, we may just skip right over the word as we read in our heads. For years we have seen prepositions, conjunctions, and other grammatical words and have conditioned ourselves to give them little thought as we move quickly to the lexical words, which reveal meaning or intent. We tend to read in shorthand to get straight to the point, having little time for bothersome little words like “of”.

So, even though you assumed there was some sort of gimmick, and you were asked to self-check, you still probably missed three of the letter Fs in that sentence. Don’t feel bad. The high and mighty folks that answered six are about to get their comeuppance.

Did you answer six? OK, let’s assume for the sake of argument that you read the sentence only one time and came up with six for an answer. There are also several explanations as to how you came to that answer, ranked in order of least to most plausible.

■ You are a super genius who should rightly direct your scorn toward the masses of disappointing wastes of perfectly good oxygen — everyone else.

■ You read the sentence twice and really slowed down the second time because three seemed like too easy of an answer.

■ You have seen this little mental gymnastic exercise before, so you were keyed in to the potential trap already.

■ You slowed down and focused on reading each word.

■ You’re lying.

So, if you answered six, you are probably feeling superior to the people who answered three while simultaneously wondering what I meant earlier when I stated that technically the answer is zero. Here are the directions again:

Self-checking test: Quick! Count the number of times the letter “F” appears in the following sentence. Take your time but only count once.

When it’s time to selfcheck, take the time to do it right. When you’re given vague or interpretive guidance, ask for clarification.

Be focused and methodical. Second, look at the structure of the directions. The structure led you to think, “He’s talking about the sentence which is in bold or standing alone.” The structure encourages you to move past the instructions to the bold face type and thereby fail to read the instructions critically. My vague or interpretive guidance set you up for error.

Here’s the takeaway. When it’s time to self-check, take the time to do it right. When you’re given vague or interpretive guidance, ask for clarification. When you recognize an error trap, get it fixed. Now that we are growing as an organization, here are your instructions for the next self-checking test:

Technically, the “following sentence” referred to by the directions is “Take your time but only count once.”— not the sentence that begins with “Finished files…”. As you can see, the “Take your time…” sentence has zero Fs in it. If you caught that one, then try this out on your friends at your next Mensa meeting. Don’t feel bad if you didn’t catch the nuance because you were set up to make that mistake by vague guidance.

Look at the directions again. First, I frame it as a self-checking exercise, then I immediately put time pressure on you by saying “Quick!” and then I tell you to “Take your time.” So which is it? Are you supposed to hurry or be more methodical? Just to clarify, we are a human performance company. Always take a moment to self-check.

■ Step 1: Count the number of times the letter F appears in the sentence in Step 2. Caution: Operating experience has revealed that the letter F is often overlooked in the word “of”. Be aware of each occurrence of the word “of” and the potential to miss the letter “f” in it.

■ Step 2: “Finished files are the result of years of scientific study combined with the experience of years.”

■ Step 3: Record your answer with a newfound sense of confidence achieved by only those who have been given clear, understandable guidance.

How many of you could come up with the intended correct answer of six? We can all apply for Mensa membership now.

DAVE SOWERS is Director of Performance Improvement at Knowledge Vine LLC, a human performance training and consulting organization. A veteran of the U.S. Navy’s nuclear power program, he has more than 25 years of industrial experience gained through his work in the military, semiconductor manufacturing, commercial nuclear power, and hydro-electric generation. Dave holds both B.S. and M.S. degrees in Management from Troy University and a M.S. in Emergency Management and Homeland Security from George Washington University.

Providing employee training can be a very expensive proposition. It includes cost of the service, travel expenses, and shipping course materials, as well as employee time, benefits, and possibly overtime — all of which add up quickly. However, training must be provided, as both OSHA and NFPA 70E mandate demonstration of certain skills and knowledge. As an example, the definition of a qualified person in 29CFR1910.399 states:

“Qualified Person. One who has demonstrated skills and knowledge related to the construction and operation of electrical equipment and installations and has received safety training to identify and avoid the hazards involved.”

With the costs so great and the scheduling of employee time often complex, it is not difficult to understand why some companies take a check-the-box approach to training. These are the companies that will conduct training just to show that it was done, the old “looks good on paper” thing…or does it?

To understand the requirements for training and auditing, responsible training managers and

company leaders who have the authority to enforce training policies should read and understand 29CFR1910.332 and .333, as well as NFPA 70E Sections 110.1, 110.2, and 120.2. The requirements of training qualified persons are substantial. My experience is that most workers who initially attend safety programs are not qualified persons. They have the technical expertise (technicians, Master Electricians, electrical engineers) but lack the skills and knowledge to properly conduct a risk assessment, select the correct PPE, or interpret arc-flash hazard warning labels. Meeting the mandated training requirements requires a multistep process; it is not a one-and-done thing.

To be a qualified person, that person must have the technical skills and knowledge related to their job. Journeyman, Master Electrician, and NETA Certified Technician all demonstrate technical skills and knowledge, and many people consider them to be qualified because of those skills and knowledge. However, OSHA and the 70E require more. There must also be demonstrated safety skills and knowledge.

A qualified person must be trained on how to apply the OSHA and NFPA 70E requirements in their job on a practical level. That means being able to accurately perform a shock and arc-flash risk assessment; select, inspect, wear, and care for arc-rated clothing and PPE; and understand the limitations and indications of the test instruments being used, as well as how to inspect them before use to determine if they are safe to use. This is by no means a complete list. The requirements are lengthy. Read NFPA 70E Section 110.2 to get a better grasp of why qualified electrical worker training is not a one-day or even a one-time training proposition.

Qualified person training also requires learning while on the job (OJT). This training is essential because it covers safe operation and any changes in the equipment, procedures, or safe work practices related to their job-specific work environment. When performing OJT, be as straightforward as possible so there are no misunderstandings.

If you’re a box-checker, stop reading; your feelings are going to be hurt. A Louisiana facility hired a contract instructor for NFPA 70E training. For eight hours, the NFPA 70E contract instructor read the 70E to the attendees, straight out of the book, word for word. Box checked! Maybe not. As a follow-up to the training, the facility safety manager had conversations with the attendees; when he realized the recent NFPA 70E training was inadequate, Shermco Training was called in to do proper 70E-mandated training. It took more than two days, but the facility attendees gained the safety skills and knowledge to perform their work tasks safely. Neither OSHA nor the 70E require a contractor to be hired to conduct training, nor is classroom training alone always effective. The combination of classroom and field training is often the best option.

Initial safety training for qualified persons also requires a demonstration of skills. This means documented, hands-on lab sessions that specifically target mandated safety-training skills. NFPA 70E and OSHA call for these three lab sessions:

1. Determining Nominal Voltage

2. Selection of Appropriate PPE

3. Determining the Absence of Voltage

However, there’s more to it than that. To determine nominal voltage, that person must first understand how to select and use each type of test instrument; know how to inspect it for safe use (including how it might provide false indications); understand the limitations and specific risks that type of instrument might pose, and know how to use it in a safe manner; and be able to accurately interpret nameplate information or single-line diagrams to determine the nominal voltage.

The other two labs include more extensive training requirements beyond the obvious. A quick look at the 29CFR1910.399 definition of a qualified person states this clearly. It is also required in 1910.332 and 1910.333. Bringing in a well-qualified instructor to conduct the training can provide insights that someone in-house may not have.

Providing “blah-blah” training — especially as initial training to qualified persons — is almost worse than no training at all. It conveys a message that employees have no real value, that no one really expects them to follow the training given, and that it is a waste of time. They are absolutely correct. Save your time and money because, if an incident occurs and OSHA investigates, check-the-box training won’t help your case at all. Review OSHA’s Letter of Interpretation dated November 24, 1994 (see http://bit.ly/2paotF1). In this letter, OSHA clearly states that computer-based training is valuable — but not sufficient — to meet OSHA’s training requirements. The letter adds, “Equally important is the use of hands-on training and exercises to provide trainees with an opportunity to become familiar with equipment and safe practices in a nonhazardous setting.”

Companies with a good safety culture look for effective safety training. This safety culture is generated from the top down with real commitments to safe work practices and a desire to protect their workers.

NFPA 70E does not mention refresher training, but it requires retraining every three years. That retraining should cover any changes in the company’s electrical safety program, work procedures, work practices, policies, NFPA 70E requirements, and any OSHA regulatory requirements that pertain to their jobs. It does not require a repeat of the initial training that they should have received. There is a lot of misunderstanding in the industry about this. The duration of the retraining is determined by the amount of information that employees need to receive. In most cases, a one-day training program is sufficient, but it may take longer, especially if there are new work practices or procedures to cover. Retraining is also required when new equipment with different operating procedures is installed, when audits disclose that employees are not following procedures or policies, and if the employee must perform an unfamiliar task.

For initial training of qualified persons, OSHA and NFPA 70E both require a demonstration of skills and knowledge. The knowledge component can be partially satisfied by a test at the completion of

the training program. Demonstrating skills requires a hands-on lab session. Some training companies advocate that their customers can confirm the required skills on a job or at a later date. Don’t drink that Kool-Aid. In 99 percent of the cases, that never happens. It sounds good and people may have the best intentions, but do the hands-on demonstration of skills when the instructor is at the worksite. The lab sessions must be documented. Joe Pipkin, OSHA’s former representative to the NFPA 70E Committee, once stated, “If you don’t document it, you can’t prove you did it.”

Lab sessions must be documented and must be pertinent to the demonstration of skills required. Looking at NFPA 70E 110.2:

(D) Employee Training.

(1) Qualified Person. A qualified person shall be trained and knowledgeable in the construction and operation of equipment or a specific work method and be trained to identify and avoid the electrical hazards that might be present with respect to that equipment or work method.

(a) Such persons shall also be familiar with the proper use of the special precautionary techniques, applicable electrical policies and procedures, PPE, insulating and shielding materials, and insulated tools and test equipment. A person can be considered qualified with respect to certain equipment and methods but still be unqualified for others.

(b) Such persons permitted to work within the limited approach boundary shall, at a minimum, be additionally trained in all of the following:

(1) Skills and techniques necessary to distinguish exposed energized electrical conductors and circuit parts from other parts of electrical equipment

(2) Skills and techniques necessary to determine the nominal voltage of exposed energized electrical conductors and circuit parts

(3) Approach distances specified in Table 130.4(D)(a) and Table 130.4(D)(b) and the corresponding voltages to which the qualified person will be exposed

(4) Decision-making process necessary to be able to do the following:

a. Perform the job safety planning

b. Identify electrical hazards

c. Assess the associated risk

d. Select the appropriate risk control methods from the hierarchy of controls identified in 110.1(G), including personal protective equipment.

And yes, all this is needed to be a qualified person. OSHA refers to single-point responsibility — that is, the employer will be at fault, period. If the employer can show that the injured person was properly trained, was provided with the proper PPE, and demonstrated the skills and knowledge to be considered qualified, OSHA may determine the employer did all it could do. However, that’s a high bar to leap over.

If OSHA cites companies when an employee is injured regardless, then what good is it to provide the training and PPE? The short answer is that it could be the difference between a willful citation and a serious citation. A willful citation is evidence of negligent behavior, which leaves the company open to legal action and could void their Workman’s Compensation protection. This is never a good situation. It is always best to show good-faith effort, reduce the potential consequences of an incident and, most important, assure that your employees and co-workers are as safe as possible while performing potentially dangerous tasks.

JIM WHITE is the Training Director for Shermco Industries. He is the Principal Member of the ASTM F18 Electrical Protective Equipment for Workers Committee and the NFPA Recommended Practice for Electrical Equipment Maintenance Committee (NFPA 70B). He represents NETA as the Principal member of NFPA 70E and is NETA’s Principal member on NEC CMP13. Jim is an IEEE Senior Member and was Chairman of the IEEE Electrical Safety Workshop in 2008.

As a supervisor, do you send messages that are open to interpretation? Do you allow others to fill in the blanks with their definition of what good looks like? Can you be upset when someone fails to read your mind and performs a task differently than you imagined? You have a wealth of experience, much of it paid for in bumps, bruises, and blood. You’ve learned lessons the hard way. Your workers don’t have the benefit of that experience and aren’t likely to make the same choices without specific guidance.

Early in our marriage, my wife gave me the vague guidance to “pick up some groceries” on my way home. This seemed like an easy enough task; after all, I had been feeding myself for years. We need food, and the grocery store has food for sale. The path for success seemed pretty well laid out.

I put great thought into what made its way into the cart. I got the basics such as bread, milk, and eggs, and rounded out the cart with other reasonable options. Oreos? I’ve seen her eat Oreos before — but wait! Generic Oreos are half as much; grab two bags. I am crushing this grocery shopping thing. When we unloaded bags of bachelor staples like chicken wings, nachos, and Capt’n Crunch, my wife realized further trips to the grocery store required specific guidance or supervisor engagement. Her idea of “mission accomplished” was vastly different from mine.

How did a task that seemed so simple go so wrong? Why didn’t her expectations align with my understanding? Was this a failing on my part or was poor communication to blame? Could she really be mad when I filled in the blanks with my best guesses?

There’s a reason you’re in charge. You have the experience and subsequent judgment to choose the safest, most efficient option for getting a job done. It’s your job to narrow the number of options for your team so they can avoid the hard lessons you had to learn. In all likelihood, you also had a supervisor who at one time or another muttered “What were you thinking?” How great would it have been if they had been specific in their expectations and saved you from having to fill in the blanks with your best judgment?

Nobody comes to work thinking, “I’m gonna mess stuff up today.” Workers try their best to perform the tasks given to them by drawing from the information provided and then filling in the gaps with their best judgment, which does not include the supervisor’s experience. Don’t leave blanks for your workers to fill in. It bears repeating, your workers are not you. They are well-intentioned, independent-thinking people, but without your specific guidance, they are going to look at all the options and choose the one that makes the most sense to them. If you can eliminate most of these options, the chances of them doing the task as you anticipated increases greatly. Be complete and specific on how to do the job successfully and safely. It’s not micro-managing — it’s establishing standards and expectations to set them up for success.

A supervisor told me about instructing a new loading dock worker to clean up an outside dolly so it could be used to move office furniture. He wanted it to have a fresh coat of paint but didn’t want the wheels or plastic handles to get paint on them. He told the worker, “Tape up the dolly and spray paint it red for use in the office building.” When the supervisor returned, the dolly was completely wrapped in tape and the tape was painted red. To this supervisor’s credit, he recognized his role in this

faulty execution. He said, “I couldn’t even be mad. He did exactly what I said. I realized that this guy had spent very little time in the office area of the facility. He had no idea what they did or why they would need a completely taped up and spray painted dolly, but he gave them what they requested.” He filled in the blanks his supervisor left. Of course, workers have a responsibility to ask questions if they are unsure, but recognizing and admitting a lack of understanding is often difficult.

As a worker, do you find yourself trying to fill in the blanks? Are you faced with multiple options on how to complete a task? Do you find yourself using your best judgment to meet your supervisor’s expectations but aren’t 100 percent sure what that is? Effective communication is a two-way street. Your supervisor may assume you know the best course of action, but if you don’t take a moment to question your actions or to fully understand your role, you are setting yourself up for failure. You have to be your own advocate. Speak up and ask for specific guidance or solicit operating experience from your supervisor. Understand that most supervisors would rather answer 100 dumb questions from you than answer one hard question from leadership: “Why did that accident happen?”

When you are given guidance, make sure you completely understand the expectations. It’s not enough to know what to do; you also need to know how to do it. If you find yourself with several options to complete a task, stop and get clarification. Don’t try to fill in the blanks.

If workers are going to do as we ask and seek out further guidance, supervisors have to ensure they create an environment where questions are

welcomed. Workers, especially inexperienced ones, are in a tough position. We are asking them to recognize what they don’t know, and then admit their ignorance. They don’t want to disappoint their supervisor, and they certainly don’t want to seem incompetent. They are motivated to seem capable and effective for the sake of job security and the esteem of their co-workers.

Effective supervisors are easily approached with even the simplest of questions. They recognize that it takes less time to get a worker lined up than it does to do rework or fill out an accident form. Supervisors should be open to dumb questions, and should thank workers for asking them. They may have just saved you time and effort or may have just protected equipment, themselves, or their coworkers.

Think about how you communicate. Ensure you are giving direction that is specific and not open to interpretation. Make sure your people understand what good looks like. Simply saying “be safe” is not enough; give them actionable guidance. “On this job, you need to keep your hands out of the line of fire by…” or “Make sure you use the following PPE for this task…” or “Here are the human performance tools we are going to use on this job…” Be complete and be specific, and don’t leave blanks for your workers to fill in.

My wife and I learned this lesson with my ill-fated “get some groceries” outing. Trips to the grocery store these days involve a detailed list and, generally, some direct supervisor engagement. Her next move may be to require procedure usage and place-keeping with circle/slash, since there is still the occasional box of Capt’n Crunch that finds its way into the cart (a clear Foreign Material Exclusion violation).

DAVE SOWERS is Director of Performance Improvement at Knowledge Vine LLC, a human performance training and consulting organization. A veteran of the U.S. Navy’s nuclear power program, he has more than 25 years of industrial experience gained through his work in the military, semiconductor manufacturing, commercial nuclear power, and hydro-electric generation. Dave holds both B.S. and M.S. degrees in Management from Troy University and a M.S. in Emergency Management and Homeland Security from George Washington University.

Many AVO courses are eligible for NETA CTDs.*

If it’s electrical, AVO Training is focused on it. Electrical safety training, electrical maintenance training, and electrical consulting is not just a part of our offering, it’s our total focus. That’s why we offer more electrical safety and electrical maintenance training courses than any other training facility. With over 52 different courses, we offer the widest selection of courses available. To complement our training courses, we have a stand-alone Engineering Division that offers Arc Flash Studies, Risk Assessment Analysis, and a full menu of electrical engineering services.

Available Courses:

Protective Relay

• Protective Relay Maintenance - Basic

• Protective Relay Maintenance - Advanced

• Protective Relay Maintenance - Generation

• Protective Relay Maintenance - Solid State

• Microprocessor Based Relay Testing - Generation

• Microprocessor Based Relay Testing - Distribution/ Industrial

• Advanced Visual Testing Software

Circuit Breaker

• Circuit Breaker Maintenance, SF6

• Circuit Breaker Maintenance, Molded- and Insulated-Case

• Circuit Breaker Maintenance, Medium-Voltage

• Circuit Breaker Maintenance, Low-Voltage

Cable U

• Cable Splicing and Terminating, Medium-Voltage

• Cable Fault Location and Tracing, Medium-Voltage

• Cable Testing and Diagnostics, Medium-Voltage

Substation

• Battery Maintenance and Testing

• Transformer Maintenance and Testing

• Advanced Transformer Maintenance and Testing

• Substation Maintenance I

• Substation Maintenance II

• Power Factor Testing

Safety

• NFPA 70E 2015 Electrical Safety

• Electrical Safety for Utilities

• Electrical Safety for Mining

• Electrical Safety for Industrial Facilities

• Electrical Safety for Inspectors

• Electrical Safety for Overhead Contact Systems

• 2017 National Electrical Code

• OSHA Electrical Safety Related Work Practices

• Maritime Electrical Safety

Basics

• Basic Electricity

• Basic Electrical Troubleshooting

• Electronics Troubleshooting

• Electronics for Electricians

• Electrical Print Reading

• Grounding & Bonding

Engineering

• Short Circuit Analysis

• Protective Device Coordination Utilities

• Protective Device Coordination Industry

• Power Quality & Harmonics

Motors/Controls

• Programmable Logic Controllers

• Maintenance & Trouble Shooting

• Motor Maintenance and Testing

• Motor Controls and Starters, Low-Voltage

Throughout the year, Doble hosts accredited technical trainings on a variety of topics to help engineers and technicians of all levels be more efficient, effective, and safe in the field. Learn from the industry’s top experts, receive real-world training that you can immediately apply, and build your professional network.

• Protection Engineers & Technicians Summit

June 12-15, 2017 | Fort Worth, TX

Training on test plan/routine building for generator protection, transformer protection, and more featuring live demonstrations and protection asset management plus case studies, conference papers, and software training.

• Circuit Breaker Seminar

October 2-6, 2017 | Pittsburgh, PA

Brush up on fundamentals, get practical hands-on training, and learn from the experts at the industry’s best circuit breaker educational seminar.

• Life of a Transformer Seminar

February 19-23, 2018 | National Harbor, MD

Practical training on all aspects of transformers, including sessions focused on transformer differential protection, transformer maintenance, and asset and maintenance strategies.

• Rotating Machinery & Electrical Plant

Reliability Tutorial

April 11-12, 2018 | Boston, MA

Learn everything you need to know to reliably maintain the electrical side of a generation or industrial plant.

• Laboratory Seminars

Offered throughout the year

Learn how to review data to assess transformer condition from instructors presenting theory and practical examples that illustrate common problems found in the field.

• Protection Training Courses

Offered throughout the year

Choose from a range of protection courses that will prepare you for testing a modern grid, power plant, and industrial facility.

Many Doble training courses are eligible for NETA Continuing Technical Development Credits (CTDs) as well as IACET certified Continuing Education Units (CEUs). Visit: www.doble.com/earning-ceus

For more information, Visit: www.doble.com/training Email: events@doble.com Call: 617.926.4900

Effective transformer management requires special skills acquired from years of hands-on experience. The diminishing number of experts is causing a growing need for specialized training to ensure these skills are not lost. SDMyers offers your team the opportunity to benefit from our 50 years of transformer maintenance expertise. We offer a variety of training options including enhanced e-learning courses; seminars; and onsite, online, and customized courses.

• Principles of Transformer Maintenance

Basics of transformers: electric concepts, solid and liquid insulation, oil testing and analysis, basic electrical testing, and maintenance.

• Principios de Mantenimiento de Transformadores

Este curso introduce al alumno en una serie de temas que resumen los fundamentos básicos de los transformadores y de mantenimiento del transformador.

• In-Service Inspection & Sampling of Fluid-Filled Transformers

Learn safe procedures needed to obtain a representative sample of dielectric fluid. Features a sampling demonstration and practical exercises to obtain accurate oil samples for use in lab analysis.

• Half-Century Transformer

Foundational understanding of transformers: operation, maintenance implementation, and related industry standards.

• Half-Century Transformer - Applied Maintenance

Foundational understanding of transformers: operation, maintenance implementation, and related industry standards. Includes lab and equipment tours, rewind facility tour, case studies, and expert panel discussion.

• Advanced DGA Diagnostics

Learn to identify fault gases and what causes their formation, evaluate the condition of cellulose insulation, examine the role DGA plays in new oil testing, and discuss obtaining samples from transformers.

• Load Tap Changer Principles & Maintenance

Load tap changing, styles of tap changers and their operation, and how to develop a preventative load tap changer (LTC) maintenance program.

• Electrical Testing - Power Factor Testing for Transformers, Bushings, and Breakers

The Power Factor is a measurement of the efficiency of the transformer’s insulation system and a reliable electrical test to detect deterioration.

• Transformer 360 Course is 3 days — take any or all. Day 1: Re-energized Half-Century course as part of a transformer reliability program. Day 2: Risk & Reliability and DGA. Day 3: LTC Testing & Maintenance and Electrical Testing.

• Transformer Lifecycle Management

Manage the lifecycle of the transformer including specification and purchasing, transportation, assembly and start-up, field and shop repair, overall risk and asset management, and end-of-life options. Learn to develop and manage a reliability-based maintenance program.

• Advanced Transformer Maintenance and Planning

Reactive, predictive, and preventative maintenance of transformers, and building a cost-effective testing and maintenance plan to prolong the reliable life of transformers. Includes substation equipment, transformer design and construction, and how to make critical maintenance and planning decisions.

SD Myers courses are eligible for NETA CTDs.*

*NETA continuing technical development (CTDs) units are required of NETA Certified Technicians

Shermco is a leader in electrical power systems maintenance, repair, and testing and, for years, we have trained others in those skills. Offering onsite, classroom and hands-on training, Shermco conducts a wide variety of courses covering Electrical Systems Maintenance, Electrical Safety, and Electrical Technical Skills. Some of the most influential leaders in electrical safety work at Shermco Industries and now you have direct access to that experience and expertise! Shermco offers technical and electrical safety programs year-round and at multiple locations in the U.S. and Canada. NETA CTDs and CEUs through IEEE are available for most courses where applicable. Train with the experts. Train with Shermco.

• Workers

Irving, TX

Jun 6-8, Jul 11-13, Aug 8-10, Sep 12-14, Oct 10-12, Nov 7-9, Dec 12-14

Austin, TX

Aug 15-17, Nov 14-16

Houston, TX

Sep 19-21, Dec 5-7

Tulsa, OK

Jul 18-20, Oct 17-19

Des Moines, IA

Jun 13-15, Oct 3-5

St. Paul, MN

Aug 22-24, Dec 12-14

New Orleans, LA

Jun 20-22, Aug 29-31, Nov 14-16

Sewell, NJ

Jun 6-8, Aug 1-3, Nov 7-9

• Electrical Workers

Irving, TX

Jun 9, Jul 14, Aug 11, Sep 15, Oct 13, Nov 10, Dec 15

• Electrical Safety Refresher

Irving, TX

Jun 5, Oct 9

Austin, TX

Aug 18

Houston, TX

Sep 22

Tulsa, OK

Oct 20

Des Moines, IA

Jun 16, Oct 6

St. Paul, MN

Aug 25, Dec 15

New Orleans, LA

Sep 1

Sewell, NJ

Aug 4

• Understanding the NFPA 70E & 2018 Changes

Irving, TX

Jul 21

Austin, TX

Aug 14

Des Moines, IA

Nov 3

St. Paul, MN

Sep 18

Tulsa, OK

Jul 21, Nov 30

• Low-Medium Voltage Circuit Breaker Maintenance & Testing

Irving, TX

Jun 19, Oct 2

• Circuit Breaker Maintenance Operations & Controls

Irving, TX

Jul 10, Oct 23

Enroll today by visiting www.shermco.com/training or call 888-Shermco and mention your promotional code.

For more information, to download our current course catalog, or to register online go to www.shermco.com/training or email training@shermco.com Shermco.com • 888-shermco

Learn valuable testing tips and tricks from Megger application engineers and product managers. In this webinar series, our experienced staff will show you how to make your testing more efficient by sharing their lessons learned in the field. You will find answers to frequently asked questions, learn how to avoid the most common mistakes and accelerate your testing.

• Best Practices for Performing Dielectric Breakdown Test on Insulating Liquids

May 19, 2017 | Presenter: Daniel Carreno

• A Step by Step Process to Troubleshoot Power Quality Problems

Jun 16, 2017 | Presenter: Andy Sagl/Sanket Bolar

• Do’s and Don’ts of Insulation Power Factor Testing

Jul 21, 2017 | Presenter: Jill Duplessis

• Practical Applications of Cable Testing & Diagnostics Techniques

Aug 18, 2017 | Presenter: Jason Souchak

• The Evolution of Insulation Resistance Testing

Sep 15, 2017 | Presenter: Jeff Jowett

•

Oct 20, 2017 | Presenter: Vijay Sundaram

• Alternate Testing Techniques for Instrument Transformers

Nov 17, 2017 | Presenter: Diego Robalino

• Discharge Results on Medium Voltage Cables

Dec 15, 2017 | Presenter: Jason Souchak

• Best Practices for Performing Travel Measurements on HV Circuit Breakers

Feb 17, 2017 | Presenter: Robert Foster

• Battery Testing and Maintenance as per NERC PRC005 Guidelines

Mar 17, 2017 | Presenter: Volney Naranjo

• Cable Fault Location 202: Advanced Techniques

Apr 21, 2017 | Presenter: Robert Probst

• Megger Webinars are held on the 3rd or 4th Friday every month

• Time: 10:00 AM Central Time.

• Sessions are FREE

Webinar Registration: http://us.megger.com/webinars

Megger designs and manufactures portable electrical test equipment. Megger products help you install, improve efficiency, reduce cost, and extend the life of your or your customers’ electrical assets or your own. For more information, visit http://us.megger.com/.

NETA Self-Paced Technical Seminars (SPTS) are training materials created for distance learning. Every year, PowerTest offers in-depth seminars covering a wide variety of topics. Two seminars are selected by the Conference Committee each year to be recorded and produced into an SPTS.

NETA’s online training courses cover specific sections of the ANSI/NETA, Standard for Acceptance Testing Specifications for Electrical Power Equipment and Systems (ANSI/NETA ATS-2013). This training material assists the field service technician in understanding and acquiring the knowledge to properly test, assess, and validate various systems and electrical power equipment as required by the ANSI/NETA ATS.

SPTS HIGHLIGHTS:

• Four-hour run time

• DVD or USB of the recorded technical seminar and printed hard copy of the presentation

• One access to the proficiency exam

• Earn four NETA CTD Credits (NETA Certified Technicians) or submit for CEUs

AVAILABLE COURSES:

• Power Transformer Testing and Maintenance

Jim White, Shermco Industries

• Critical Maintenance for Circuit Breakers

Jim White, Shermco Industries

• Electrical Testing Basics: What You Need to Know to Succeed — Part 1

Jim White, Shermco Industries

• Electrical Testing Basics: What You Need to Know to Succeed — Part 2

Jim White, Shermco Industries

• A Primer on MCC Maintenance and Testing

Malcom Frederick, Shermco Industries

• Primer on Transformer Diagnostics

Charles Sweetser, OMICRON electronics Corp. USA

• Transformer Dielectric Fluids: Use of DGA and Furans

Melvin Wright, LICA Consulting, LLC

• Using Partial Discharge Detection

Don Genutis and Neil Davies, No-Outage Electrical Testing, Inc.

• Hazards of Electricity, Shock, Arc, and Blast: An Educational Journey Through Case Studies

Jim White, Shermco Industries

• Electrical Testing Medium-Voltage Stator Windings

Tom Sandri, Shermco Industries, and Vicki Warren, Iris Power – A Qualitrol Company

• How Do They Do It? Electrical Power Measurement Methods, Practices, and Standards

Ross Ignall, Dranetz Technologies

• The Practical Application of NFPA 70E in Routine Work Tasks

Jim White, Shermco Industries

• Condition of Maintenance: A Practical Approach to Compliance within the Industry

Jim White, Shermco Industries

• Acceptance and Maintenance Testing for Medium-Voltage Electrical Power

Cables: Exploring Technology Developments Over the Past 20 Years

Tom Sandri, Shermco Industries

• Risk Assessment Techniques Using NFPA 70E: A Primer

Jim White, Shermco Industries

• Maintenance and Testing of Battery Systems

Tom Sandri, Shermco Industries

• Understanding Generator Protection

Scott Cooper, OMICRON electronics Corp. USA

• What Does a Partial Discharge Tell Me and How Do I Perform the Test?

Tom Sandri, Shermco Industries

Developed by the NETA Training Committee Approved by the NETA Standards Review Council

EACH PURCHASE INCLUDES:

• An individual account with access to NETA’s Online Training Center

• One access to the proficiency exam (additional attempts may be purchased separately)

• Earn NETA CTD Credits (NETA Certified Technicians) or submit for CEUs

AVAILABLE COURSES:

• Grounding Systems Acceptance Testing

• Cable Systems Acceptance Testing

• Instrument Transformer Acceptance Testing

Electrical Safety Training Systems

3050 Old Centre Avenue, Suite 102

Portage, MI 49024

Toll free: 888.300.NETA (6382)

Phone: 269.488.NETA (6382)

Fax: 269.488.6383

neta@netaworld.org

www.netaworld.org

EXECUTIVEDIRECTOR: Missy Richard

PRESIDENT: Ron Widup, Shermco Industries

FIRSTVICEPRESIDENT: Jim Cialdea, Three-C Electrical Co., Inc.

SECONDVICEPRESIDENT: Scott Blizard, American Electrical Testing Co., Inc.

SECRETARY: Eric Beckman, National Field Services

TREASURER: John White, Sigma Six Solutions

Ken Bassett (Potomac Testing, Inc.)

Eric Beckman (National Field Services)

Scott Blizard (American Electrical Testing Co., Inc.)

Jim Cialdea (Three-C Electrical Co., Inc.)

Lorne Gara (Orbis Engineering Field Services, Ltd.)

Dan Hook (Western Electrical Services, Inc.)

David Huffman (Power Systems Testing)

Alan Peterson (Utility Service Corporation)

John White (Sigma Six Solutions)

Ron Widup (Shermco Industries)

TECHNICALEDITORS: Roderic L. Hageman, Tim Cotter

ASSISTANTTECHNICALEDITORS: Jim Caldea, Dan Hook, Dave Huffman, Bob Sheppard

ASSOCIATEEDITOR: Resa Pickel

MANAGINGEDITOR: Carla Kalogeridis

COPYEDITOR: Beverly Sturtevant

ADVERTISINGMANAGER: Laura McDonald

DESIGNANDPRODUCTION: Moon Design

CONFERENCE: Ron Widup; MEMBERSHIP: Ken Bassett; PROMOTIONS/MARKETING: Scott Blizard; SAFETY: Scott Blizard and Jim White; TECHNICAL: Alan Peterson; TECHNICALEXAM: Ron Widup; CONTINUINGTECHNICALDEVELOPMENT: David Huffman; TRAINING: Bob Sheppard; FINANCE: John White; NOMINATIONS: Alan Peterson; ALLIANCEPROGRAM: Jim Cialdea; ASSOCIATIONDEVELOPMENT: Ken Bassett and John White

© Copyright 2017, NETA

NOTICE AND DISCLAIMER

NETA World is published quarterly by the InterNational Electrical Testing Association. Opinions, views and conclusions expressed in articles herein are those of the authors and not necessarily those of NETA. Publication herein does not constitute or imply endorsement of any opinion, product, or service by NETA, its directors, officers, members, employees or agents (herein “NETA”).

All technical data in this publication reflects the experience of individuals using specific tools, products, equipment and components under specific conditions and circumstances which may or may not be fully reported and over which NETA has neither exercised nor reserved control. Such data has not been independently tested or otherwise verified by NETA.

NETA MAKES NO ENDORSEMENT, REPRESENTATION OR WARRANTY AS TO ANY OPINION, PRODUCT OR SERVICE REFERENCED OR ADVERTISED IN THIS PUBLICATION. NETA EXPRESSLY DISCLAIMS ANY AND ALL LIABILITY TO ANY CONSUMER, PURCHASER OR ANY OTHER PERSON USING ANY PRODUCT OR SERVICE REFERENCED OR ADVERTISED HEREIN FOR ANY INJURIES OR DAMAGES OF ANY KIND WHATSOEVER, INCLUDING, BUT NOT LIMITED TO ANY CONSEQUENTIAL, PUNITIVE, SPECIAL, INCIDENTAL, DIRECT OR INDIRECT DAMAGES. NETA FURTHER DISCLAIMS ANY AND ALL WARRANTIES, EXPRESS OF IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

ELECTRICAL TESTING SHALL BE PERFORMED ONLY BY TRAINED ELECTRICAL PERSONNEL AND SHALL BE SUPERVISED BY NETA CERTIFIED TECHNICIANS/ LEVEL III OR IV OR BY NICET CERTIFIED TECHNICIANS IN ELECTRICAL TESTING TECHNOLOGY/LEVEL III OR IV. FAILURE TO ADHERE TO ADEQUATE TRAINING, SAFETY

AND

OR

We have to do something about this. Please keep reading.

This is my last President’s Message as my term as NETA President comes to an end and Jim Cialdea of CE Power takes over. Jim is a great contributor to the Association and we look forward to his continued contributions!

The adage, “The harder you work, the luckier you are,” holds true when it comes to involvement in trade and technical associations. I encourage you to get involved with NETA at any level you can. You will find that the more you put in, the more you get out — and the luckier you will be because of it.

At PowerTest this year, I asked the NETA Board members if they would allow me 10 minutes to get on a soapbox, and they graciously agreed. The reason for the soapbox was to speak about something that kills at least eight people every day, is on the rise, and affects people in the workplace, at home, on vacation, in just about any place and at any time. The issue?

Distracted driving.

We focus and train our people on the hazards of electricity and how to be a qualified electrical worker, as we should. This is very important to anyone who has a career involving something as toxic as electricity.