OLDER CBs: RETROFIT OR REPLACE? PAGE 52 KNOW WHEN CBs ARE FIT FOR DUTY OR NEED

ISSN 2167-3594 NETA WORLD JOURNAL PRINT ISSN 2167-3586 NETA WORLD JOURNAL ONLINE FALL 2017 MEDIUM-VOLTAGE

64

ATTENTION PAGE

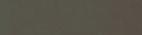

Electrical Power Systems Industry Resource on Technical and Professional Training F A L L 2 0 1 7 : V O L . 2 . N O . 2 FALL 2017: VOL. 2. NO.

Electrical

Electrical

National

NFPA

Infrared

Substation

Electrical

Protective

Circuit

Transformer

• Circuit Breaker Seminar: October 2-6, 2017 | Pittsburgh, PA • Life of a Transformer Seminar: February 19-23, 2018 | National Harbor, MD • Rotating Machinery & Electrical Plant Reliability Workshop: April 11-12, 2018 | Boston, MA • Laboratory Seminars: offered throughout the year • Protection Training Courses: various topics offered throughout the year • Free Webinars: twice a month learn about testing, theory or industry trends TRAINING OPPORTUNITIES www.doble.com/training Learn from the industry’s top experts, receive real-world training you can immediately apply, and build your professional network with various educational programs offered throughout the year. Make training a priority for you & your team LEARN MORE Take the best hands-on electrical training back to the field with you. www.avotraining.com

Safety for Industrial Facilities

Safety for Utilities

Electrical Code 2017

70E Electrical Safety

Thermography Level I

Maintenance

Safety for Mining

Relay Maintenance

Breaker Maintenance

Maintenance Many AVO Training courses are eligible for NETA ctd’s.

TRAINING QUALIFIED PERSONS TO PERFORM ELECTRICAL WORK CAN REDUCE RISK

By Dennis K. Neitzel, CPE, CESCP, AVO Training Institute

PREVENT ELECTRICAL HAZARDS WITH CSA Z462-2015 CLAUSE 4.1.6 TRAINING

By Terry Becker, ESPS

MANAGING THE RISK OF TRANSFORMER FAILURES

By Alan M. Ross, SD Myers, Inc.

ELECTRICAL SAFETY PROGRAM: KEEPING US SAFE

By Anthony

Solutions,

Electrical Safety Program

Inc.

TECHNICAL

TRAINING FALL 2017 04 07 10 13 17 A NETA World Journal Special Publication A publication dedicated to disseminating information on technical

professional training for the advancement of the electrical power systems industry.

Demaria, Dennis Green, and Nenad Pasic, Tony Demaria Electric

DIRECTORY OF

AND PROFESSIONAL

and

TRAINING

TO PERFORM ELECTRICAL WORK CAN REDUCE RISK

BY DENNIS K. NEITZEL, CPE, CESCP, AVO Training Institute

The Occupational Safety and Health Administration (OSHA) and the National Fire Protection Association (NFPA) require employers to protect their employees from electrical hazards in the workplace. To accomplish this, there must be a strong emphasis on “qualified persons only” performing work on or near exposed energized and de-energized electrical systems and equipment. This article will define who a qualified person is and identify the training requirements for the required skills and knowledge.

Proper training and qualification of personnel is extremely important because maintenance of electrical protective devices, particularly circuit breakers and relays, is vital not only to the reliability of electrical systems and equipment, but also to the safety of employees working on, near, or interacting with these systems and equipment. What are the requirements for training qualified personnel?

QUALIFIED PERSON REQUIREMENTS

OSHA 29 CFR 1910.399 defines a qualified person as “one who has received training in and

has demonstrated skills and knowledge in the construction and operation of electric equipment and installations and the hazards involved.” OSHA provides additional information on what constitutes a qualified person in the following notes to this definition:

Note 1 to the definition of ‘‘qualified person”: Whether an employee is considered to be a ‘‘qualified person’’ will depend upon various circumstances in the workplace. For example, it is possible and, in fact, likely for an individual to be considered ‘‘qualified’’ with regard to certain equipment in the workplace, but ‘‘unqualified’’ as to other equipment. (See 1910.332(b) (3) for training requirements that specifically apply to qualified persons.)

Note 2 to the definition of ‘‘qualified person”: An employee who is undergoing on-the-job training and who, in the course of such training, has demonstrated an ability to perform duties safely at his or her level of training and who is under the direct supervision of a qualified person is considered to be a qualified person for the performance of those duties.

OSHA and NFPA 70E, Standard for Electrical Safety in the Workplace, provides strict requirements for safety training that go hand-in-hand with the qualification of an employee. The following information clarifies the mandates for training employees in the electrical field:

OSHA 1910.332, Training, requires a qualified person to be trained in “the safety-related work practices that are required by 1910.331 through 1910.335 that pertain to their respective job assignments.”

Qualified Persons (i.e. those permitted to work on or near exposed energized parts) shall, at a minimum, be trained in and familiar with the following:

■ The skills and techniques necessary to distinguish exposed live parts from other parts of electric equipment,

■ The skills and techniques necessary to determine the nominal voltage of exposed live parts, and

■ The clearance distances specified in 1910.333(c) and the corresponding voltages to which the qualified person will be exposed.

4 | TRAINING TALK | A NETA WORLD JOURNAL SPECIAL PUBLICATION

Note 1: For the purposes of 1910.331 through 1910.335, a person must have the training required by paragraph (b)(3) of this section in order to be considered a qualified person.

Note 2: Qualified persons whose work on energized equipment involves either direct contact or contact by means of tools or materials must also have the training needed to meet 1910.333(C)(2).

The training requirements contained in this section [1910.332] apply to employees who face a risk of electric shock…

Note: Employees in occupations listed in Table S-4 face such a risk and are required to be trained. Other employees who also may reasonably be expected to face comparable risk of injury due to electric shock or other electrical hazards must also be trained.

Table S-4 Typical Occupational Categories of Employees Facing a Higher than Normal Risk of Electrical Accident

Occupation

Blue collar supervisors.(1)

Electrical and electronic engineers.(1)

Electrical and electronic equipment assemblers.(1)

Electrical and electronic technicians.(1)

Electricians

Industrial machine operators.(1)

Material handling equipment operators.(1)

Mechanics and repairers.(1)

Painters.(1)

Riggers and roustabouts.(1)

Stationary engineers.(1)

Welders.

Footnote(1): Workers in these groups do not need to be trained if their work or the work of those they supervise does not bring them or the employees they supervise close enough to exposed parts of electric circuits operating at 50 volts or more to ground for a hazard to exist.

Employees are also required to be trained in and familiar with the safety-related work practices, safety procedures, and other safety requirements that pertain to their respective job assignments. This

training encompasses any other safety practices, including applicable emergency procedures that are related to their work and necessary for their safety.

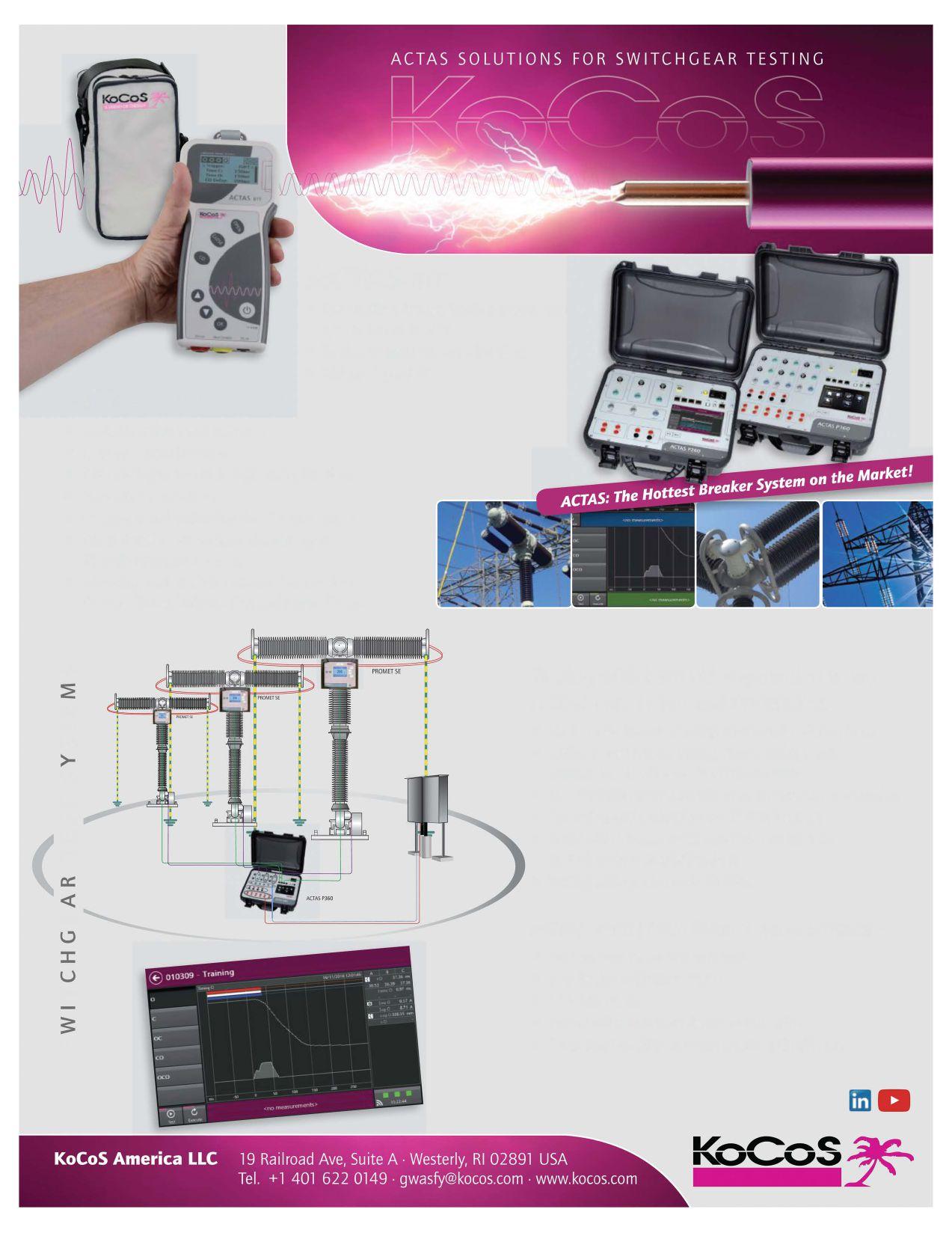

NFPA 70E also requires qualified employees to be trained and competent in:

■ Skills and techniques necessary to distinguish live parts from other parts

■ Skills and techniques necessary to determine the nominal voltage

■ Minimum approach distances to live parts

■ The proper use of:

– Special precautionary techniques

– Insulating and shielding materials

– Insulated tools and test equipment

– Job planning

A person must have this training to be considered a qualified person. The employer, through regular supervision and annual inspections, must verify that employees are complying with the safety-related work practices. Additional training or retraining may be required if:

■ The supervision or annual inspection indicate non-compliance with work practices

■ New technology or new types of equipment are introduced

■ Changes in procedures become necessary

■ Employee is required to use abnormal work practices

OSHA and NFPA consider that tasks performed less than once per year require retraining before the performance of the work practices involved. This retraining may be as simple as a detailed job briefing prior to the commencement of the work, or it may require more in-depth classroom instruction along with on-the-job training. All training is required to establish employee proficiency in the work practices and procedures. Employees are required to demonstrate proficiency in the work practices involved before the employer can certify that the employee has been trained.

OSHA 1910.332 states:

The training required by this section shall be of the classroom or on-the-job type. The degree of training

A NETA WORLD JOURNAL SPECIAL PUBLICATION | TRAINING TALK | 5

provided shall be determined by the risk to the employee.” NFPA 70E goes on to state, “The training shall be classroom, on-the-job, or a combination of both, and that retraining shall be performed at intervals not to exceed three years.

Training and retraining are required to be documented.

In addition to these requirements from OSHA, the NFPA 70E states that employees are required to be trained to understand the specific hazards associated with electrical energy, safety-related work practices, and procedural requirements. These training requirements are necessary to help protect employees from the “electrical hazards associated with their respective job or task assignments” as well as to “identify and understand the relationship between electrical hazards and possible injury.” Training in emergency procedures is also required when employees are working “on or near exposed energized electrical conductors or circuit parts.”

OSHA and NFPA are consistent in their requirements for training and qualifying employees to perform work on electrical equipment and systems. Proper training is a vital part of the

worker’s safety and proficiency, as well as critical to the reduction of electrical hazards.

CONCLUSION

NFPA and OSHA state that to be considered a qualified person, an employee must receive extensive training. The goal of any training program is to develop and maintain an effective and safe workforce.

Electrical power systems today are often very complex. Protective devices, controls, instrumentation, and interlock systems demand that technicians be trained and qualified at a high technical skill level. Safety and operating procedures for working on these systems are equally complex, requiring technicians to be expertly trained in all maintenance and safety practices and procedures. OSHA regulations, as well as NFPA 70E, require employers to document that employees have demonstrated proficiency in electrical tasks and that they are qualified.

Properly training qualified persons to perform electrical work can greatly reduce the risk to employee safety, as well as increase reliability of the electrical system and equipment.

DENNIS K. NEITZEL, CPE, CESCP, is the Director Emeritus of AVO Training Institute, Inc. in Dallas, Texas. He is a Principle Committee Member for NFPA 70E, Standard for Electrical Safety in the Workplace. Dennis has 50 years in electrical power systems and is an active member of the Institute of Electrical and Electronics Engineers (IEEE), the American Society of Safety Engineers (ASSE), the Association for Facilities Engineering (AFE), the International Association of Electrical Inspectors (IAEI), and the National Fire Protection Association (NFPA), and is the co-author of the Electrical Safety Handbook, published by McGraw Hill. He earned his BS in Electrical Engineering Management and his MS in Electrical Engineering Applied Sciences.

6 | TRAINING TALK | A NETA WORLD JOURNAL SPECIAL PUBLICATION

PREVENT ELECTRICAL HAZARDS

training be designed by individuals with appropriate qualifications and subject matter expertise and that delivery of the training be done in a way that is conducive to learning.

Most importantly, CSA Z1001 dictates that the “development of competence through training is an integral part of OHS management,” and that the “goal of training is to help workers and other parties develop and achieve the knowledge, skills, and ability to perform their work in a manner that reduces risk of harm from work-related hazards.”

While the primary goal of regular, compliant training is to ensure workers are capable and knowledgeable in performing their work tasks and recognizing and mitigating hazards that may come with the risk of serious and potentially fatal injury, the possible liability to a company with an inadequate training program and a lack of effective documentation can lead to far-reaching legal and financial consequences.

BY TERRY BECKER, ESPS Electrical Safety Program Solutions INC.

All electrical incidents are preventable. Keep employees safe with an up-todate Electrical Safety Program and appropriate training.

CSA Z462-2015 CLAUSE 4.1.6 TRAINING

What is high-quality, compliant electrical safety, arc flash and shock training? Why and how often do your workers need it? Does your company have an electrical safety, arc flash and shock training specification that outlines corporate training requirements? Are worker training requirements (for example, an Electrical Safety Training Matrix) and other preventive and protective control measures documented in your company’s Electrical Safety Program?

The CSA Z1001 Occupational health and safety training Standard provides guidance in defining compliant, OHS-related training to ensure workers are “suitably trained to perform their work.” The Standard also notes:

Training should meet the needs of the organization as well as those being trained. It is important that

For this reason, the responsibility of reviewing, acquiring, tracking, and documenting ongoing effective and compliant worker training — combined with demonstrating worker competence — rests in the hands of the appropriate electrical safety leaders in the company, not in the hands of the workers, in a top-down collaborative approach that ensures overall success.

But what is high-quality, effective, and compliant electrical safety, arc flash and shock training? Not all training is created equal.

CHARACTERISTICS OF EFFECTIVE TRAINING

Effective training for qualified electrical workers is much more than just basic awareness training. Ask the following questions:

■ Who is providing the training? How long has the training company been in business? What is the education and experience level of the company’s subject matter expert on the CSA Z462 Workplace electrical safety Standard and the instructors delivering the training?

■ Is the training company insured? Does the training company have the appropriate liability insurance to back up its training?

A NETA WORLD JOURNAL SPECIAL PUBLICATION | TRAINING TALK | 7

W I T H C S A Z 4 6 2 - 2 0 1 5 WITH CSA Z462-2015 C L A U S E 4 . 1 . 6 T R A I N I N G CLAUSE 4.1.6 TRAINING

Once your company has selected high-quality, effective, and compliant electrical safety training, how often should you train your workers?

■ Does the training fully align with your company’s Electrical Safety Program? Does it cover all areas and consider your company’s unique situations and training needs?

■ Does the training meet the requirements outlined in both CSA Z462 and CSA Z1001? Are CSA Z462 clauses quoted and reviewed verbatim?

■ Does it clearly define “energized electrical work?”

■ Does the training include a comprehensive review of arc flash and shock hazards? Or does it primarily focus on arc flash?

■ Does the training include an analytical risk assessment procedure? And does the risk assessment procedure allow a qualified person to determine an energized electrical work task’s residual risk level?

■ Is measurement of learning included during the course? Does it specify a thorough evaluation of demonstrated knowledge, skills, and understanding?

■ How long is the training course? Appropriate training time must be considered for in-depth learning and review of the fundamentals, applying the concepts in hands-on exercises, and proper testing to ensure full understanding.

TRAINING PROVIDER RECOMMENDATIONS

When you specify the training developer and training provider, CSA Z1001 offers the following recommendations:

■ Subject matter expertise. Do the provider and instructor(s) have suitable CSA Z462 and

application knowledge, skills, and ability gained through training, education, and experience?

■ Training delivery skills. Are the instructors competent in delivery techniques and methods suitable for adult learners?

■ Continuing education. Have the provider and instructor(s) maintained their training skills by participating in continuing education or development programs?

■ Documentation of training course provider qualifications. Do the provider and instructor(s) have experience sheets and resumes, and are they accredited, or do they have continuing education course certificates or other certificates adhering to accredited standards, licensing, and registration?

Before you bid out the training to vendors, make sure your company has created an electrical safety, arc flash and shock training specification that outlines your corporate training requirements. Additional questions to consider:

■ Did you pre-qualify (by requesting defendable substantiation) that the training developer and training provider you identified could provide compliant arc flash and shock training?

■ Did your evaluation of the training proposal document find evidence that the training is compliant?

TRAINING SCHEDULE

Once your company has selected high-quality, effective, and compliant electrical safety training, how often should you train your workers?

CSA Z462 Clause 4.1.6 Training dictates “employers shall verify at least annually” that required worker training “is current,” and “shall document” that the training “has occurred.”

In terms of retraining, the Clause mandates “a worker shall receive periodic retraining in safety-related work practices and in the applicable changes to this Standard, at intervals not to exceed three years.” It is important to note here that the CSA Z462 Standard is updated every three years.

As an example, Alberta’s OH&S Act, Regulation and Code, Handi-Guide, Chapter 2: OH&S

8 | TRAINING TALK | A NETA WORLD JOURNAL SPECIAL PUBLICATION

Due Diligence, recommends “operators to be ‘recertified’ at periodic intervals, e.g., every three years,” and “when regulatory changes occur and re-training may be required.” It goes on to note that “ongoing or revised training related to PPE is important, particularly where advances in equipment or technologies result in changed practices or better equipment.”

CONCLUSION

For the best due diligence that is defendable to OH&S or OSHA requirements related to arc flash

and shock, ensure that the electrical safety training you procure for your workers is fully compliant training provided by a credible training developer and training provider. The CSA Z1001 Occupational health and training Standard can be used to develop a technical training program specification for your electrical safety, arc flash and shock training, which is only one element of the hierarchy of controls used to reduce risk as a component of a complete Electrical Safety Program.

TERRY BECKER is President and Principal of ESPS Electrical Safety Program Solutions INC., an electrical engineering consulting firm specializing in electrical safety consulting, licensed products, and training solutions. He is the first past Vice-Chair of the CSA Z462 Workplace electrical safety Standard Technical Committee and currently a Voting Member and Working Group 8 Leader, Annexes. Terry is also a Voting Member on the IEEE 1584 Technical Committee and an Associate Member of the CSA Z463 Guideline on maintenance of electrical systems. Terry is a Professional Engineer in the Provinces of British Columbia, Alberta, Saskatchewan, and Ontario.

A NETA WORLD JOURNAL SPECIAL PUBLICATION | TRAINING TALK | 9

MANAGING THE RISK OF TRANSFORMER FAILURES

BY ALAN M. ROSS, SD Myers, Inc.

Despite the fact that transformers have been around for nearly a century with varying opinions on transformer design and maintenance, most experts agree that not all transformer failures are alike. Most also agree that the life of the insulation or paper is the primary limiting factor in the life of the transformer.

Since most industrial companies use power to produce something, the risks associated with loss of that power have been misunderstood and all too often ignored. But risk comes in many different forms. Risk of failure is often quantified by the insurance industry as the cost to replace the transformer. But the loss of productive capacity — business interruption loss — is usually much higher than the cost of transformer replacement.

What is the risk of failure when the condition of the unit has deteriorated and routine preventative maintenance ignored? When asked, “Why do you test the oil in your transformers?” the most common response is, “Our insurance company requires it.” The need for a reliable system must become the reason we test transformers, since every reliable system starts with reliable, uninterrupted power.

CONDITION-BASED RISKS

Why do transformers fail in the first place? Many failures happen after an incident, such as lightening strike or a failure down line from the transformer. These anomalies can be characterized as electrical, mechanical, or thermal, but for the most part, they are separate from the condition of the unit. These may be root-cause failures, but they neglect a significant contributing factor: the condition of the unit. An overloaded transformer with well-maintained dielectric fluid that is not already weakened by poor maintenance is much less likely to fail than an overloaded transformer that has not been maintained.

Can transformer failures be avoided? Can life extension mitigate this risk? Experience proves that it is effective to develop standards, rigorously test and track the condition of the fleet of transformers, and maintain that fleet to those standards. Quite simply, the easiest risk to mitigate is the conditionbased risk.

We maintain productive assets with increasing rigor, yet too often, we confuse chemical or electrical testing of a transformer with the maintenance of a transformer. In one illustrative case, we were asked to develop a standard for testing and maintenance for a customer with multiple transformers and multiple sites. There was a great deal of commonality of the units, and we had done chemical testing for over seven years tracking the condition in the oil of the units. When we asked for the electrical test data to address the complete condition of each unit, we were told: “We only test with you.” That statement changed my perspective on the issue of risk and reliability of electrical systems, with particular emphasis on the heart of the system: the transformer.

And yet, there is so much more to a complete condition assessment than trended oil tests. While that is an important first step, the next steps are equally critical. Is recommended maintenance on oil processing standard throughout the company, or is it left up to each individual responsible for maintaining one plant? Not all oil processing is alike. While some contractors clean the oil, others may process on the unit until they address issues in the paper and the oil.

10 | TRAINING TALK | A NETA WORLD JOURNAL SPECIAL PUBLICATION

What criteria should be used for electrical testing to create a best-practices testing and maintenance protocol? What data is available from the manufacturer at assembly and installation to determine changes over time? A simple Sweep Frequency Response Analysis (SFRA) can serve as the baseline for future condition assessment, yet too often, we do not have that data. It is a matter of developing a reliable system that can address the condition of the unit — without a lot of added costs or downtime — during the life of that unit, not at the end of life. It is all about assessment, planning, and systems.

THE WEAKEST LINK: PAPER

While there are cases when transformers fail without warning, most failures are ones that we can see coming. Deteriorating paper and oil emit gases that can lead to a better diagnosis of the condition of the unit. Moisture content has become a tremendously valuable predictor of failure. Sadly, gassing and high moisture content is not perceived as critically important as it should be. Accelerated deterioration of the paper insulation comes about from moisture, acid, overheating, or oxidation, and it weakens the ability of the unit to perform.

Transformers today are built with much less margin for error than those of the past. If we take the same approach to reliability based on past experiences, we will likely see more unplanned outages and downtime from transformer failures than ever before.

DISSOLVED GAS ANALYSIS

Gases are dissolved in the transformer oil and are formed by both normal operation and aging and by anomalies or abnormal events. Because these gases can reveal the faults of a transformer, they are known as fault gases. Gases are produced by oxidation, vaporization, insulation decomposition, oil breakdown, and electrolytic action. By analyzing the volume, types, proportions, and rate of production of dissolved gases, we can get a very good picture of what has happened or what is happening inside the unit.

While it is becoming increasingly common for primary units within a substation — or, in the case of steel production, the furnace units — to have dissolved gas analysis (DGA) monitors installed on the units, the monitor will likely only detect

that a gas or gases are present. An oil sample with DGA analysis can determine the amount of gas and, in the case of frequent testing, the rate of change in that gas. From that data, knowledge is developed, meaning the cause of the increased gas is determined. In extreme cases, the analysis will indicate a potential catastrophic failure. In most cases, it will indicate a weakening of the overall condition of the unit and the need to avoid overheating and higher loading.

While there are cases when transformers fail without warning, most failures are ones that we can see coming. Deteriorating paper and oil emit gases that can lead to a better diagnosis of the condition of the unit.

DEVELOPING A RELIABLE SYSTEM

So where does that leave us? What should any company dependent on the safe, reliable, and uninterrupted use of electrical power do?

■ Understand the short- and long-term, direct and indirect impact and costs associated with unplanned power outages from the loss of a transformer.

■ Develop and implement a set of standards for determining the operating condition of transformer(s) through the use of intrusive and non-intrusive testing.

■ Develop a preventative maintenance plan to implement company wide, giving reliability professionals the tools they need to monitor and maintain this critical and often overlooked asset class.

■ Develop a reaction plan for every critical transformer in your area of responsibility and control.

A NETA WORLD JOURNAL SPECIAL PUBLICATION | TRAINING TALK | 11

BEST PRACTICES FOR ELIMINATING RISK OF FAILURE

It all boils down to prevention if you want to reduce or eliminate the risk of an unplanned outage of a transformer. Simple adherence to best practices for testing, maintenance, and monitoring will increase the life of the transformer, but will also create a more robust unit that can withstand most kinds of faults. These include:

■ Oil testing on a regular basis with corresponding maintenance assessment reporting. Remember, if we test because the insurance company requires it, we are missing the point of developing a reliable electrical system.

■ Electrical testing. For more critical units — and in the event of an oil testing result that indicates a need for additional testing — standardization is required.

■ Mechanical inspection. Check oil level; check proper functioning of gages, bushings, fans, and radiators; and check quality of connections.

■ Thermography (IR). While most companies provide an annual IR scan of their entire system, there is a great advantage to conducting an

annual routine IR at the time of the oil test. The combined information can lead to specifics about faults, loose connections, or potential bushing failure.

■ Monitoring for gases. Fault gases can lead to catastrophic failure that goes well beyond a simple unplanned outage. Monitoring for these gases creates an early warning system. Since hydrogen is usually present with gases, a costeffective monitoring solution may well be a single-gas monitor with a robust follow-up oil testing program.

■ Why do we test? The reason to test is to determine the condition of the unit and then perform preventive maintenance. A well-maintained and serviced transformer can last over half a century. Test to gain knowledge about the condition of your equipment, and recognize that knowledge leads to the wisdom to provide a low-cost, reliable electric system.

While we may not get every transformer expert to agree on everything, there is universal agreement that a healthy and robust electrical system starts with the heart of that system: the transformer.

ALAN ROSS is Vice President of Reliability at SD Myers, Inc. in Tallmadge, Ohio. He is responsible for developing and executing long-term reliability strategies and next-generation leadership for all operating units, both domestically and internationally. He often presents at industry conferences, has authored several articles on transformer maintenance and reliability, and has written two books: Unconditional Excellence and Beyond World Class. He earned a BS in Mechanical Engineering at Georgia Institute of Technology and an MBA in Marketing from Georgia State University, graduating Magna cum Laude. Alan is a Certified Reliability Leader and a member of the IEEE Reliability Society.

12 | TRAINING TALK | A NETA WORLD JOURNAL SPECIAL PUBLICATION

ELECTRIC AL ELECTRICAL SA F E T Y SAFETY KEEPING US SAFE

BY ANTHONY DEMARIA, DENNIS GREEN, AND NENAD PASIC, Tony Demaria Electric

Having a comprehensive Electrical Safety Program (ESP) and following it is a critical part of keeping electrical workers safe. The path to better safety requires very hard work and total commitment to the values involved. So, what is an ESP, and what are the major stumbling blocks to developing an organization where everyone goes home injury-free every day?

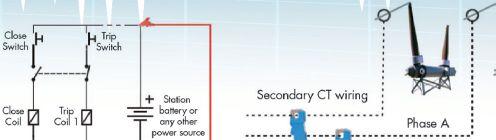

Figure 1 shows how an ESP could be structured. First, the safety policies describe the overall plan. Second, the safety procedures are created for the all-important tasks. A procedure consists of short sequential steps. Each step will have a check box to document that the task has been completed. Third, forms are created with spaces and boxes to fill in the information required.

The following list describes how to model an ESP. The list is not comprehensive; rather, it is meant to cover major points without being confusing.

1. The development and maintenance of an ESP require commitment from upper management to

provide the resources needed. This would include adequate time for the qualified persons responsible and the financial resources to fully develop it (refer to Annex E of NFPA 70E). Involve as many individuals as reasonable. Ownership and buy-in are vital to the program’s success.

2. Then create the policies. These describe what an ESP is and the safety issues covered. It is in text form and needs to be reviewed and accepted by all who are affected by it. As Shermco’s Jim White puts it: “If it isn’t simple, it won’t be used.”

3. Once you have the policies, develop clear, easy-tounderstand, specific safety procedures and forms. Test the procedure under actual field conditions. Any issues with the procedure should be resolved before it is implemented.

4. Perform thorough training for every person on the policies, procedures, and forms, with annual (or more frequent, if necessary) refresher training.

5. Require demonstration of trainee proficiency on the topics taught.

6. Conduct regular, knowledge-building auditing of each person to ensure they understand and follow the policies and procedures. Be certain to document the training and auditing of their proficiency as required by NFPA 70E.

7. Improve the policies and procedures when standards and best practices change or problems are revealed during auditing. Then, retrain to the new improvements. Again, the job is not finished until the paperwork is completed. Document everything.

A NETA WORLD JOURNAL SPECIAL PUBLICATION | TRAINING TALK | 13

POLICIES ELECTRICAL SAFETY PROGRAM (ESP) 3. FORMS 2. PROCEDURES

1.

Figure 1: Electrical Safety Program Components

8. Consider these items to be a continuing cycle of betterment. All of this is done with the spirit that every person is enabling everyone else to be successful at their job. Assume people want to be good at what they do.

9. The people performing the work are the ones who know how to improve what you do. Include your qualified persons at every step.

Do the preceding items sound familiar? There is nothing new in them, and they have been taught many times, in many ways, for the last 40-plus years.

The excellent news is that, as a result of all the ESPs we have and the safety training we perform, there has been a substantial reduction in incidents. In 1994, there was approximately one fatality per day from electrocution, about 365 total. In 2013, that number was down to 139. Considering how the American workforce has increased, this represents a huge drop in electrical shock fatalities.

The bad news is that too many injuries continue to happen. Our reaction is to take another class, create another policy or procedure, and train more. Even though we have achieved good results for our investments in the past, it seems a glass ceiling has been hit.

We reviewed seven serious shock/arc-flash injuries and found several examples of incidents that continue to occur. They happened in our geographical area in the past 10 years. Each incident had substantial similarities. The injuries happened to experienced electrical workers in the major industrial facilities. They all had a minimum of 5 to 10 years journeymen experience, and several of them had over 20 years of experience. All worked for companies with an ESP. All had received electrical safety training for the tasks they were performing when they got hurt. All were preventable.

This is not stated lightly. This is not utopia, and people are not perfect. We are not talking about utopia or perfection in this article. We are talking about people getting hurt, and nobody wants to be injured. So, what went wrong?

PROCEDURES AND FORMS

The ESP described in Figure 1 shows three parts. Large industry, in general, has done a good job

developing comprehensive policies. However, they have not performed well in using procedures and forms. Way too often, we observe no written procedures at job sites, and our peers often tell us they do not use written procedures. Following is an example of a procedure that makes an electrical working condition much safer for all of us.

Establishing an Electrically Safe Work Condition Procedure

NFPA 70E Article 120, if followed correctly, will help achieve an electrically safe work condition:

Determine all possible sources of electrical supply to the specific equipment. Check applicable up-to-date drawings, diagrams, and identification tags.

After properly interrupting the load current, open the disconnecting device(s) for each source.

Whenever possible, visually verify that all blades of the disconnecting devices are fully open or that the drawout-type circuit breakers are withdrawn to the fully disconnected position.

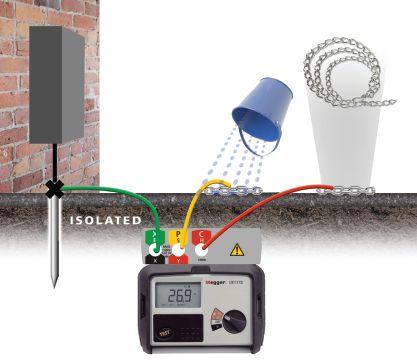

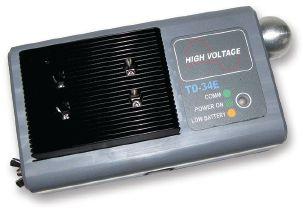

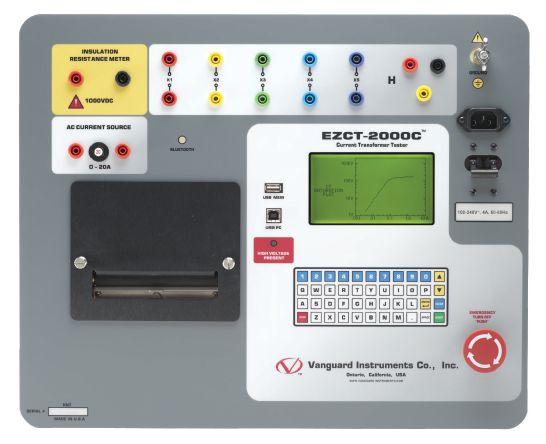

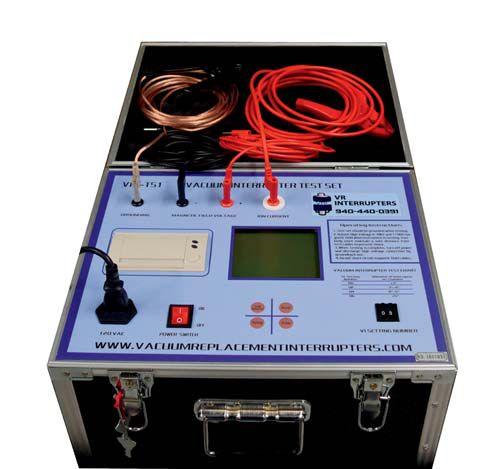

Figure 2: Notice the single voltage setting. It detects ac and dc voltages. This eliminates the possible error of having your voltmeter on the wrong setting.

14 | TRAINING TALK | A NETA WORLD JOURNAL SPECIAL PUBLICATION

Apply lockout/tagout devices in accordance with a documented and established policy.

Use an adequately rated voltage detector to test each phase conductor or circuit part to verify they are de-energized. For circuits less than 1,000 volts, use an instrument such as the Fluke T5-1000 (see Figure 2) and test each phase conductor or circuit part both phase-tophase and phase-to-ground. Before and after each test, determine that the voltage detector is operating satisfactorily.

Do not rely solely on proximity voltage detectors for the absence of voltage testing. If used, always follow that test with a directcontact test instrument to verify the absence of voltage.

Where the possibility of induced voltages or stored electrical energy exists, ground the phase conductor or circuit parts before touching them. Where it could be reasonably anticipated that the conductors or circuit parts being de-energized could contact other exposed electrical conductors or circuit parts, apply ground connecting devices rated for the available fault duty.

There is also a lack of forms, especially quality Job Hazard Analysis (JHA) forms. In 2015, NFPA 70E made a new requirement to include risk analysis to establish the risk of every task as a part of the condition for job safety; however, this has not been well implemented. Refer to Figure 3 for a sample of a JHA with the job hazards and risks considered. Having a procedure with written steps to follow and a form to fill out requires the person(s) performing the work to stop and think first.

THE HUMAN FACTOR

Some of the problems humans have include:

A. We rush people, and people allow themselves to be rushed.

B. Lack of crew harmony — some people just don’t get along. This can lead to poor communications that may result in injuries.

C. People forget, get distracted, get tired, and just make mistakes.

D. People like to take risks. High-voltage electrical workers accept high risk as a regular part of their work. Taking risks is genetic, and people drawn to electrical work tend to be wired for risk.

Items A through D present unique challenges to preventing injuries. By themselves, these behaviors are difficult, if not impossible, to control and eliminate. In the safety community, we now call such barriers human nature or the human factor.

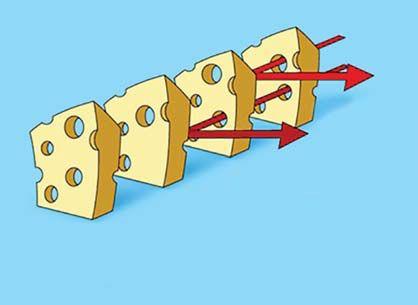

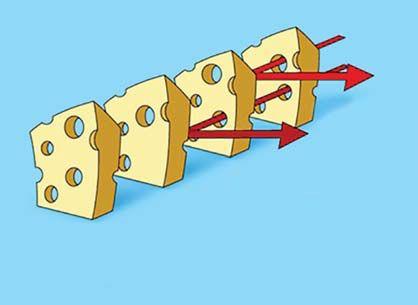

The traditional methods of solving these problems — creating another policy or having more training — will not work. Therefore, a new way of looking at this issue needs to be developed. A good solution to deal with this subject is demonstrated in the Swiss Cheese Model (Figure 4).

This model uses successive layers of defense. It acknowledges that humans get in a rush, may not

Figure 3: Sample JHA with Job Hazards and Risks Considered

A NETA WORLD JOURNAL SPECIAL PUBLICATION | TRAINING TALK | 15

get along, forget, make mistakes, and take too many risks. These are the holes in the Swiss cheese. The layers of cheese show that a mistake may get through on one layer but will be blocked by the next layer. Each layer may represent a written policy, a form to fill out, or a second person witnessing and verifying each step with a check sheet.

CONCLUSION

Companies should develop better procedures and forms, train personnel to understand them, and then audit the work to assure they are being utilized. Account for the human factor by implementing the policies, procedures, and forms in such a way that layers of safety are created, thereby significantly reducing the risk and the injuries.

What is agreed upon in the safety community is that we are on a journey. Knowledge of the ESP is one thing; changing people to follow it is another. The journey will take some time and require our very best efforts.

Hazards

SUCCESSIVE LAYERS OF DEFENSES

Figure 4: For a catastrophic error to occur, the holes need to align at each step in the process, allowing all defenses to be defeated and resulting in error. This would be unlikely.

REFERENCE

Duke University School of Medicine, www.patientsafetyed.duhs.duke.edu

ANTHONY DEMARIA (TONY) served an IBEW electrical apprenticeship while working in the marine electrical industry. He then worked for the Los Angeles Department of Water and Power in substation maintenance and power plant construction prior to starting his own company. He has owned and operated Tony Demaria Electric (TDE) for almost 40 years. TDE’s work includes engineering, technical services, electrical maintenance, troubleshooting, repairs, and testing for large industrials. TDE excels in providing electrical support in the oil industry. Tony served as the NETA Safety Committee Chair for several years.

DENNIS GREEN is a Safety Director, Safety Instructor, Safety Compliance Officer, and Project Manager at Tony Demaria Electric (TDE). He has worked with TDE for over 32 years. Dennis finished his I.B.E.W. Electrical Apprenticeship program in 1988 and since then has been actively involved in numerous electrical projects and training. He is a Member of NFPA 70B Technical Committee on Electrical Equipment Maintenance, an Electrical Section of the NFPA Member, and a Member of the NFPA Electrical Equipment Maintenance Committee. Dennis belongs to the American Association of Safety Engineers as well as IEEE and was a President of the Society of Port Engineers in the Port of Los Angeles/Long Beach.

NENAD PASIC (NENO) is a NETA Accredited Representative and IT Manager for Tony Demaria Electric (TDE). He has worked with TDE for over 15 years. Neno serves on the NETA Training Committee and the NETA Promotions and Marketing Committee. He is an IEEE Member, belonging to IEEE Computer Society, IEEE Communications Society, IEEE Information Theory Society, NFPA, and is an Electrical Section of the NFPA Member. Neno earned a BS in Computer Information Systems, Business Administration from California State University Dominguez Hills along with Project Management and Information Technology Management Certificates from the University of California Los Angeles.

16 | TRAINING TALK | A NETA WORLD JOURNAL SPECIAL PUBLICATION

DIRECTORY

AVO Training Institute: The One Stop for Electrical Safety Training, Electrical Maintenance

Many AVO courses are eligible for NETA CTDs.*

If it’s electrical, AVO Training is focused on it. Electrical safety training, electrical maintenance training, and electrical consulting is not just a part of our offering, it’s our total focus. That’s why we offer more electrical safety and electrical maintenance training courses than any other training facility. With over 52 different courses, we offer the widest selection of courses available. To complement our training courses, we have a stand-alone Engineering Division that offers Arc Flash Studies, Risk Assessment Analysis, and a full menu of electrical engineering services.

Available Courses:

Protective Relay

• Protective Relay Maintenance - Basic

• Protective Relay Maintenance - Advanced

• Protective Relay Maintenance - Generation

• Protective Relay Maintenance - Solid State

• Microprocessor Based Relay Testing - Generation

• Microprocessor Based Relay Testing - Distribution/ Industrial

• Advanced Visual Testing Software

Circuit Breaker

• Circuit Breaker Maintenance, SF6

• Circuit Breaker Maintenance, Molded- and Insulated-Case

• Circuit Breaker Maintenance, Medium-Voltage

• Circuit Breaker Maintenance, Low-Voltage

Cable U

• Cable Splicing and Terminating, Medium-Voltage

• Cable Fault Location and Tracing, Medium-Voltage

• Cable Testing and Diagnostics, Medium-Voltage

Substation

• Battery Maintenance and Testing

• Transformer Maintenance and Testing

• Advanced Transformer Maintenance and Testing

• Substation Maintenance I

• Substation Maintenance II

• Power Factor Testing

Safety

• NFPA 70E 2015 Electrical Safety

• Electrical Safety for Utilities

• Electrical Safety for Mining

• Electrical Safety for Industrial Facilities

• Electrical Safety for Inspectors

• Electrical Safety for Overhead Contact Systems

• 2017 National Electrical Code

• OSHA Electrical Safety Related Work Practices

• Maritime Electrical Safety

Basics

• Basic Electricity

• Basic Electrical Troubleshooting

• Electronics Troubleshooting

• Electronics for Electricians

• Electrical Print Reading

• Grounding & Bonding

Engineering

• Short Circuit Analysis

• Protective Device Coordination Utilities

• Protective Device Coordination Industry

• Power Quality & Harmonics

Motors/Controls

• Programmable Logic Controllers

• Maintenance & Trouble Shooting

• Motor Maintenance and Testing

• Motor Controls and Starters, Low-Voltage

WWW.AVOTRAINING.COM • 877-594-3156 *NETA continuing technical development (CTDs) units are required of NETA Certified Technicians.

OF TECHNICAL AND PROFESSIONAL TRAINING

Doble Engineering Company: Learn from the Industry’s Top Experts

Throughout the year, Doble hosts accredited technical trainings on a variety of topics to help engineers and technicians of all levels be more efficient, effective, and safe in the field. Learn from the industry’s top experts, receive real-world training that you can immediately apply, and build your professional network.

2017-2018 Course Listings

• Circuit Breaker Seminar

October 2-6, 2017 | Pittsburgh, PA

Brush up on fundamentals, get practical hands-on training, and learn from the experts at the industry’s best circuit breaker educational seminar.

• Life of a Transformer Seminar

February 19-23, 2018 | National Harbor, MD

Practical training on all aspects of transformers, including sessions focused on transformer differential protection, transformer maintenance, and asset and maintenance strategies.

• Rotating Machinery & Electrical Plant

Reliability Tutorial

April 11-12, 2018 | Boston, MA

Learn everything you need to know to reliably maintain the electrical side of a generation or industrial plant.

• Laboratory Seminars

Offered throughout the year

Learn how to review data to assess transformer condition from instructors presenting theory and practical examples that illustrate common problems found in the field.

• Protection Training Courses

Offered throughout the year

Choose from a range of protection courses that will prepare you for testing a modern grid, power plant, and industrial facility.

• Free Webinar Series

Stay current on testing techniques, theory, or power industry trends. Webinars are held twice a month and last approximately one hour.

Earn Credits

Many Doble training courses are eligible for NETA Continuing Technical Development Credits (CTDs) as well as IACET certified Continuing Education Units (CEUs). Visit: www.doble.com/earning-ceus

www.doble.com/training events@doble.com 617.926.4900 DIRECTORY OF TECHNICAL AND PROFESSIONAL TRAINING

Megger’s Testing Tactics Webinar Series 2017

Learn valuable testing tips and tricks from Megger application engineers and product managers. In this webinar series, our experienced staff will show you how to make your testing more efficient by sharing their lessons learned in the field. You will find answers to frequently asked questions, learn how to avoid the most common mistakes and accelerate your testing.

Upcoming Webinars

• Practical Applications of Cable Testing & Diagnostics Techniques

Aug 18, 2017 | Presenter: Jason Souchak

• The Evolution of Insulation Resistance Testing

Sep 15, 2017 | Presenter: Jeff Jowett

• Oct 20, 2017 | Presenter: Vijay Sundaram

• Alternate Testing Techniques for Instrument Transformers

Nov 17, 2017 | Presenter: Diego Robalino

• Discharge Results on Medium Voltage Cables

Dec 15, 2017 | Presenter: Jason Souchak

Previous Webinars

• Best Practices for Performing Dielectric Breakdown Test on Insulating Liquids

May 19, 2017 | Presenter: Daniel Carreno

• A Step by Step Process to Troubleshoot Power Quality Problems

Jun 16, 2017 | Presenter: Andy Sagl/Sanket Bolar

• Do’s and Don’ts of Insulation Power Factor Testing

Jul 21, 2017 | Presenter: Jill Duplessis

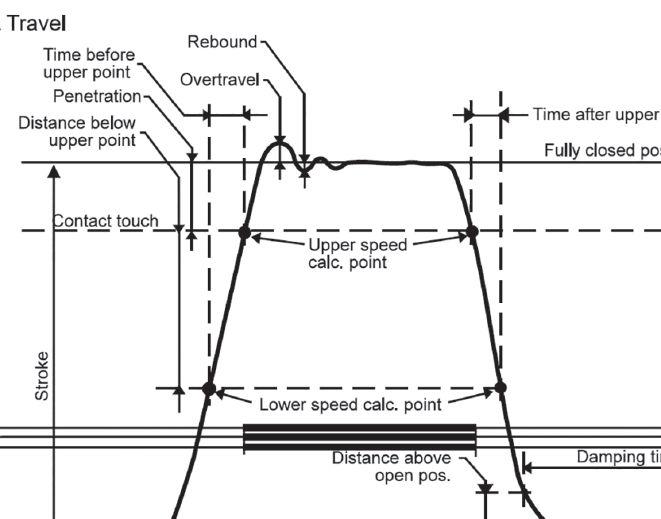

• Best Practices for Performing Travel Measurements on HV Circuit Breakers

Feb 17, 2017 | Presenter: Robert Foster

• Battery Testing and Maintenance as per NERC PRC005 Guidelines

Mar 17, 2017 | Presenter: Volney Naranjo

• Cable Fault Location 202: Advanced Techniques

Apr 21, 2017 | Presenter: Robert Probst

How to Join Megger Webinar Series

• Megger Webinars are held on the 3rd Friday of every month

• Time: 10:00 AM Central Time.

• Sessions are FREE

• us.megger.com/webinars

Webinar Registration: http://us.megger.com/webinars

Megger designs and manufactures portable electrical test equipment. Megger products help you install, improve efficiency, reduce cost, and extend the life of your or your customers’ electrical assets or your own. For more information, visit http://us.megger.com/.

DIRECTORY OF TECHNICAL AND PROFESSIONAL TRAINING

SDMyers: In Electrical System Maintenance and Management, Knowledge Means Power

Effective transformer management requires special skills acquired from years of hands-on experience. The diminishing number of experts is causing a growing need for specialized training to ensure these skills are not lost. SDMyers offers your team the opportunity to benefit from our 50 years of transformer maintenance expertise. We offer a variety of training options including enhanced e-learning courses; seminars; and onsite, online, and customized courses.

Introductory

• Principles of Transformer Maintenance

Basics of transformers: electric concepts, solid and liquid insulation, oil testing and analysis, basic electrical testing, and maintenance.

• Principios de Mantenimiento de Transformadores

Este curso introduce al alumno en una serie de temas que resumen los fundamentos básicos de los transformadores y de mantenimiento del transformador.

• In-Service Inspection & Sampling of Fluid-Filled Transformers

Learn safe procedures needed to obtain a representative sample of dielectric fluid. Features a sampling demonstration and practical exercises to obtain accurate oil samples for use in lab analysis.

Intermediate

• Half-Century Transformer

Foundational understanding of transformers: operation, maintenance implementation, and related industry standards.

• Half-Century Transformer - Applied Maintenance

Foundational understanding of transformers: operation, maintenance implementation, and related industry standards. Includes lab and equipment tours, rewind facility tour, case studies, and expert panel discussion.

• Advanced DGA Diagnostics

Learn to identify fault gases and what causes their formation, evaluate the condition of cellulose insulation, examine the role DGA plays in new oil testing, and discuss obtaining samples from transformers.

• Load Tap Changer Principles & Maintenance

Load tap changing, styles of tap changers and their operation, and how to develop a preventative load tap changer (LTC) maintenance program.

• Electrical Testing - Power Factor Testing for Transformers, Bushings, and Breakers

The Power Factor is a measurement of the efficiency of the transformer’s insulation system and a reliable electrical test to detect deterioration.

• Transformer 360 Course is 3 days — take any or all. Day 1: Re-energized Half-Century course as part of a transformer reliability program. Day 2: Risk & Reliability and DGA. Day 3: LTC Testing & Maintenance and Electrical Testing.

Advanced

• Transformer Lifecycle Management

Manage the lifecycle of the transformer including specification and purchasing, transportation, assembly and start-up, field and shop repair, overall risk and asset management, and end-of-life options. Learn to develop and manage a reliability-based maintenance program.

• Advanced Transformer Maintenance and Planning

Reactive, predictive, and preventative maintenance of transformers, and building a cost-effective testing and maintenance plan to prolong the reliable life of transformers. Includes substation equipment, transformer design and construction, and how to make critical maintenance and planning decisions.

SD Myers courses are eligible for NETA CTDs.*

*NETA continuing technical development (CTDs) units are required of NETA Certified Technicians

DIRECTORY OF TECHNICAL AND PROFESSIONAL TRAINING

Register by phone: 330.630.7000 x.4018 Register online: sdmyers.com/training For class dates and locations, visit sdmyers.com/training/calendar 180 South Avenue, Tallmadge, Ohio 44278, USA

Shermco Industries: Your Electrical Safety Experts

Shermco is a leader in electrical power systems maintenance, repair, and testing and, for years, we have trained others in those skills. Offering onsite, classroom and hands-on training, Shermco conducts a wide variety of courses covering Electrical Systems Maintenance, Electrical Safety, and Electrical Technical Skills. Some of the most influential leaders in electrical safety work at Shermco Industries and now you have direct access to that experience and expertise! Shermco offers technical and electrical safety programs year-round and at multiple locations in the U.S. and Canada. NETA CTDs and CEUs through IEEE are available for most courses where applicable. Train with the experts. Train with Shermco.

Safety Training Course Schedule 2017 / 2018

• Workers

Irving, TX

Sep 12-14, Oct 10-12, Nov 7-9, Dec 12-14, Jan 9-11,

Feb 6-8, Mar 6-8

Austin, TX

Aug 15-17, Nov 14-16, Feb 13-15

Houston, TX

Sep 19-21, Dec 5-7, Mar 13-15

Tulsa, OK

Oct 17-19, Jan 23-25

Des Moines, IA

Oct 3-5, Feb 13-15

St. Paul, MN

Aug 22-24, Dec 12-14

New Orleans, LA

Aug 29-31, Nov 14-16

Sewell, NJ

Nov 7-9

• Electrical Workers

Irving, TX

Sep 15, Oct 13, Nov 10, Dec 15

• Electrical Safety Refresher

Irving, TX

Oct 9, Feb 5

Austin, TX

Aug 18, Feb 16

Houston, TX

Sep 22, Mar 16

Tulsa, OK

Oct 20

Des Moines, IA

Oct 6, Feb 16

St. Paul, MN

Aug 25, Dec 15

New Orleans, LA

Sep 1, Mar 30

Sewell, NJ

Mar 23

• Understanding the NFPA 70E & Changes

Irving, TX

Feb 20

Austin, TX

Apr 5

Des Moines, IA

Nov 3

St. Paul, MN

Sep 18

Tulsa, OK

Nov 30

• Low-Medium Voltage Circuit Breaker Maintenance & Testing

Irving, TX

Oct 2, Feb 12

• Circuit Breaker Maintenance Operations & Controls

Irving, TX

Oct 23, Jan 22

Enroll today by visiting www.shermco.com/training or call 888-Shermco and mention your promotional code.

For more information, to download our current course catalog, or to register online go to www.shermco.com/training or email training@shermco.com Shermco.com • 888-shermco

DIRECTORY OF TECHNICAL AND PROFESSIONAL TRAINING

CEUs available from

Tony Demaria

Electric, Inc.: Our in-house training substation assures that all classes include hands-on training.

Tony Demaria Electric, Inc. (TDE) takes the lead in electrical industry improvements on safety and testing technology and adapts policies and procedures accordingly. TDE is one of the first electrical contractors adopting the use of Arc-Flash Personal Protection and Remote Racking and Switching. TDE is a NETA Accredited Company and participates actively in the NETA organization. TDE employees have published a number of safety and technical articles in NETA World Journal and other publications.

Training Courses Eligible To Earn NETA Continuing Technical Development Credits (CTDCs)

• AC Synchronous Motors – 9 CTDCs

• Batteries and DC Circuits – CTDCs pending

• Electrical Print Reading – 18 CTDCs

• Electrical Troubleshooting – 18 CTDCs

• Lockout / Tagout (LOTO) – 8 CTDCs

• Low Voltage, Air, Power Circuit Breakers Preventative Maintenance – 8 CTDCs

• Medium Voltage, Air, Circuit Breakers Preventative Maintenance – 36 CTDCs

• Motor Bearings and Lubrication – 9 CTDCs

• Motor Control Centers and Switchgear – 18 CTDCs

• Transformers Basics – CTDCs pending

• Transformers, Liquid Filled and Dry Type Preventative Maintenance – 36 CTDCs

Safety and Technical Training Courses

• AC Control Equipment

• AC Induction Motors, Basic

• Arc Flash Hazard Reduction Techniques

• Battery Safety and Maintenance

• Cable Terminating, Splicing, Grounding, and Bonding

• Electrical Inspection, Basic

• Electrical Print Reading

• Electrical Safety for Non-Qualified Workers

• Electrical Safety for Supervisors

• Electrical Skills, Basic

• Electrical Troubleshooting

• Grounding Systems

• Low Voltage Circuit Breaker Fundamentals

• Motor Bearings and Lubrication

• Motor Control Centers (MCC’s)

• NFPA 70E, 1-day

• NFPA 70E, 2-day

• NFPA 70E Refresher

• Synchronous Machines

• Test Meters and Test Equipment

• Transformers and AC Circuits

Custom Training Courses

TDE offers customized training courses that will meet your very specific needs. We will work with you to tailor a course based on your precise requirements to assure you are completely satisfied!

Prices and duration of courses varies. Please call 310.816.3130 or fill out form at http://www.tdeinc.com/contact-us/request-bid-or-information/ for more information.

DIRECTORY OF TECHNICAL AND PROFESSIONAL TRAINING

OPPORTUNITIES for the Electrical Power Systems Industry Learn at Your Own Pace • Online Courses • Self-Paced Technical Seminars (SPTS) • Electrical Safety Training Systems (ESTS) Ask About Continuing Education and NETA CTD Credits. Learn More at: netaworld.org/training or Call 888-300-6382 (NETA) INTELLIGENT TRANSFORMER MANAGEMENT®

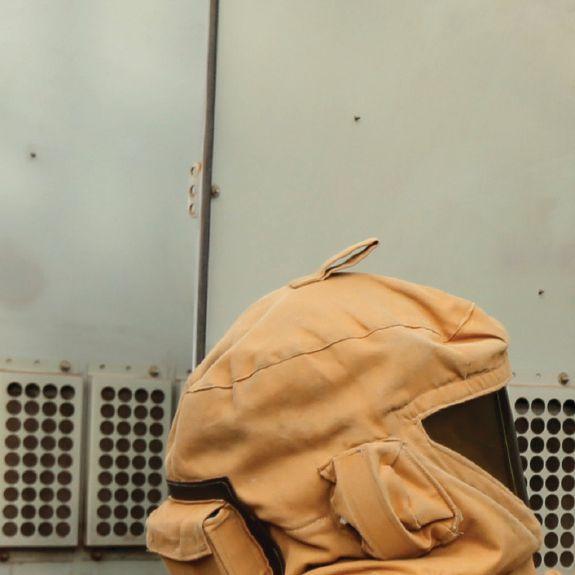

(310) 816-3130 www.tdeinc.com 131 W F St Wilmington, CA 90744 Los Angeles Area Anthony F. Demaria, Sr. Anthony F. Demaria, Jr. MANY COURSES ARE ELIGIBLE TO EARN NETA CONTINUING TECHNICAL DEVELOPMENT CREDITS (CTDC’s) SAFETY | TECHNICAL | CUSTOM TRAINING AVAILABLE Why endanger yourself and others? Let Shermco’s experts teach you the whys and hows of electrical safety! (Meets requirements of OSHA and NFPA 70E) Train with the experts. Train with Shermco. www.shermco.com (Dont_be_this_guy!) (Dont_be_this_guy!)

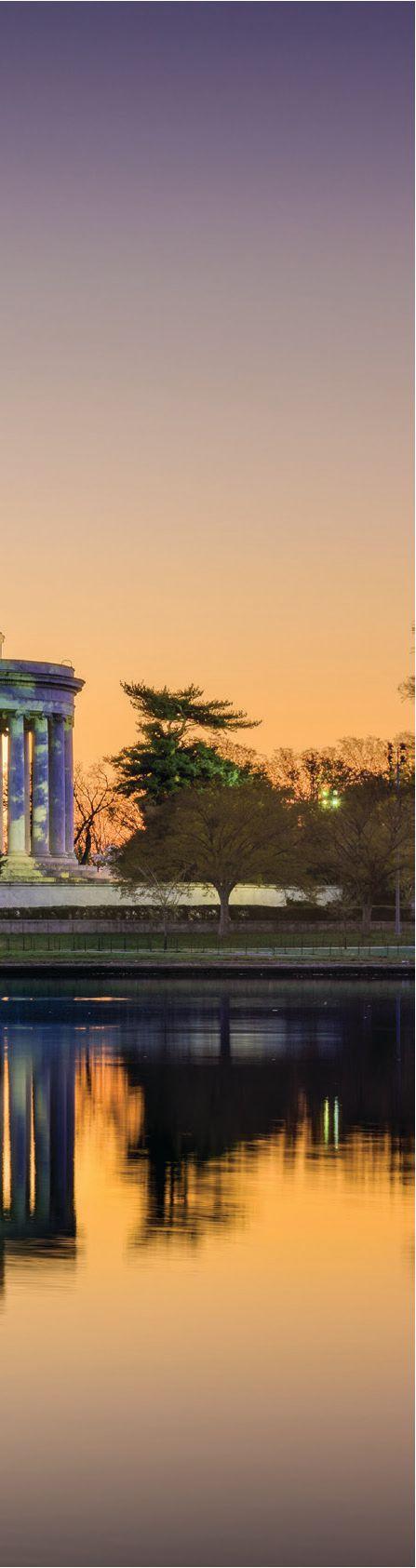

On the Potomac

On the Potomac

Throughout history, Washington, D.C., has been a touchstone for leadership, initiative, and passion — a mecca for those dedicated to the highest ideals and aspirations of both leading and serving a nation. People come to D.C. to share ideas, to communicate, to engage. It’s a perfect environment to energize PowerTest 2018 — in fact, no city represents power more literally and figuratively than Washington, D.C.

With its broad avenues and majestic neoclassical architecture, Washington, D.C., is a city overflowing with history. Monuments and memorials engage you with our nation’s most influential leaders as well as its fallen heroes. The city is a tapestry of all the people and cultures and stories that make our country great.

Though deeply rooted in history, D.C. is always fertile ground for new restaurants, bars, and stores. From the hip neighborhoods of Capitol Hill to U Street to fascinating museums and tree-filled parks, the city has a retreat for everyone.

Washington, D.C., is a place where relationships are formed and plans are made. As the premier event for electrical power systems professionals, PowerTest 2018 will thrive in the highly charged rhythm of this city. Exploring D.C., you can feel the power, the leadership. It’s an electric environment sure to ignite PowerTest 2018 attendees’ desire to connect, learn, explore, and grow in their knowledge of electrical maintenance and safety.

Early Bird Registration is Now Open!

Register on-line at: www.powertest.org or call: 888-300-6382 (NETA)

Non-Members NAC/Alliance

Monday & Tuesday $ 995 $ 895

Monday - Thursday $1895 $1695

Single Day $ 580 $ 550

Doble Seminar $ 445 $ 445

Register Online: To register for PowerTest 2018, save time by registering online. You’ll find a complete brochure and registration form available at www.powertest.org

*Hotel Reservations

Gaylord National Resort Reservation Deadline: & Convention Center February 8, 2018 877–491–0468 Group Name: 201 Waterfront Street PowerTest/NETA

National Harbor, MD Group Rate: $219 20745

*Once you register for PowerTest 2018, you will receive a link via email to secure your hotel reservations at the Gaylord National Resort & Convention Center.

Payment: NETA accepts all major credit cards. Save time and register on-line at www.powertest.org or call 888-300-6382 (NETA)

Extras: PowerTest 2018 Technical Papers – Registered conference attendees will receive all PowerTest technical presentations on a USB drive on site in their registration bag.

Easy Steps for Registration

1. Go to www.powertest.org and review the complete PowerTest 2018 on-line brochure.

2. Decide the number of days you will attend the conference.

3. Tuesday attendees select up to two panels. (Cost of panels included in the registration fees.)

4. Wednesday attendees register for up to two seminars. (Cost of seminars included if registered for Monday –Thursday.)

5. Thursday attendees register for up to two seminars. (Cost of seminars included if registered for Monday –Thursday.)

6. Register for Doble Lab Seminar. (Cost of seminar is in addition to the registration fees.)

7. Sign up for Social Passes. Social pass only needed for guests of attendees who wish to attend the hospitality suites, the Trade Show, and the PowerBash Reception. (Cost of passes is in addition to the registration fees.)

8. Sign up for PowerTest 2018 conference polo shirts and select size. (Cost of polo shirts is in addition to the registration fees.)

F ORINFO RMATIO N visit: power test.org or call: 888-300-6382(NETA)

Monday daay DAY

We’ve gathered leaders in the industry and will stage a full day of engaging 45-minute presentations sure to expand your thinking and generate new ideas. Choose from 27 detailed presentation topics across six tracks.

TECHNICAL PRESENTATIONS

ELECTRICAL SAFETY

• Root Cause Analysis for Electrical Safety

Dennis Neitzel, AVO Training Institute, Inc.

• Identifying Residual Risk from Electrical Hazards: Avoiding Pitfalls to Achieve Risk ALARP

H. Landis Floyd, Electrical Safety Group, Inc.

• Safety Tips for Qualified Persons

Jim White, Shermco Industries

• Risk Assessment in the Design Phase

Mike Doherty, eHazard

• A Program Within a Program

Terry Becker, ESPS Electrical Safety Program Solutions INC.

• Implementation of Human Performance Initiative: A Lessons-Learned Case Study

Rorry Phillips, Shermco Industries

EQUIPMENT

• The Importance of Condenser Type Bushing

Keith Hill, Doble Engineering Company

• Review of Medium-Voltage Asset Failure Investigations

William Higinbotham, EA Technology LLC

• A Customer’s Perspective: Electrical Testing Agencies

Randall Sagan, MBUSI

• Don’t Let a Bad Leak Spoil Your Day – The Latest Solutions for Online Leak Repair of Transformers, Circuit Breakers, and GIS

Lissa Colby, The Colt Group

• Application of OLPD Sensor Technologies

Dustin Ashliegh, Power Monitoring and Diagnostic Technology LTD.

• Proper Grounding to Avoid Disasters

David Brender, Copper Development Association, Inc.

RELIABILITY

• Performing Cable Diagnostics on MV Cables with Special Emphasis on Offline Partial Discharge

TRANSFORMERS

• Transformer Oil Processing and Transformer Field Vacuum Dryout

Gregory Steeves, Baron USA

• A Review of Wye/Delta Transformer Connections and How It Affects Current and Voltage Measured on Both Sides of the Transformer

Todd Martin, Basler Electric

• Diagnostic Testing and Assessing Insulation System Life

Craig Goodwin, HV Diagnostics

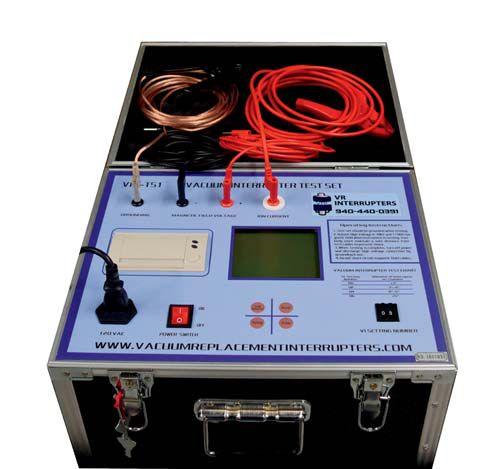

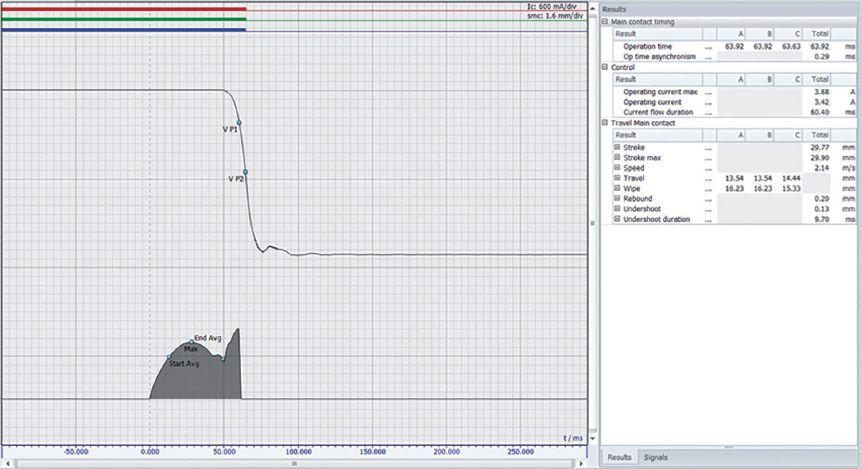

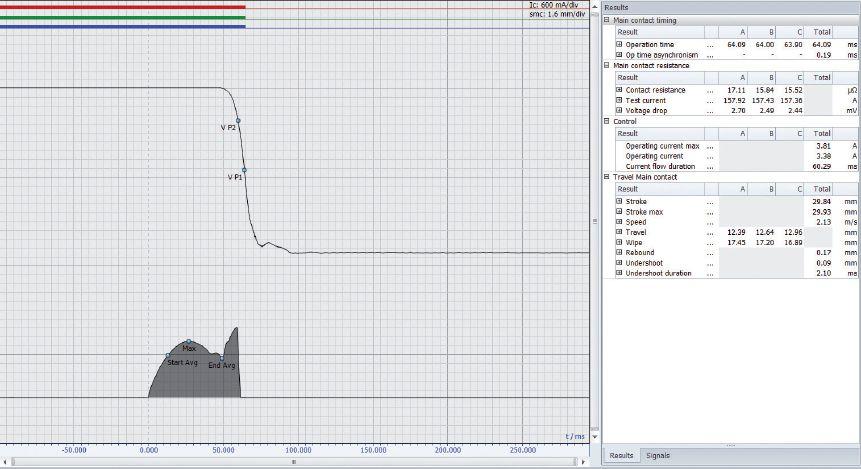

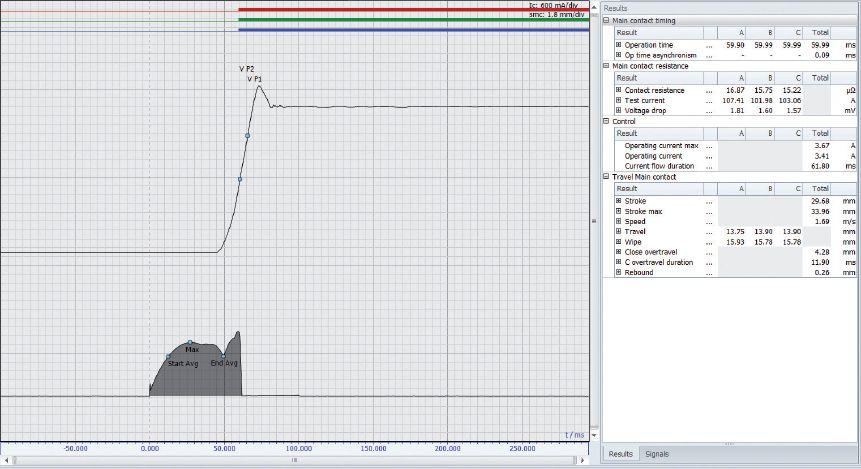

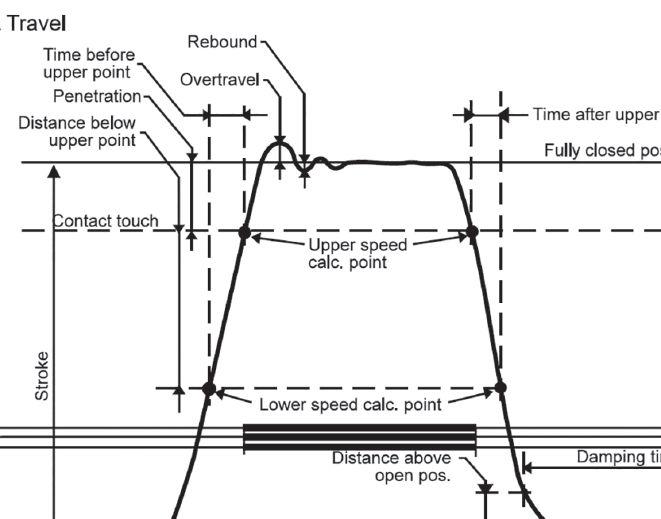

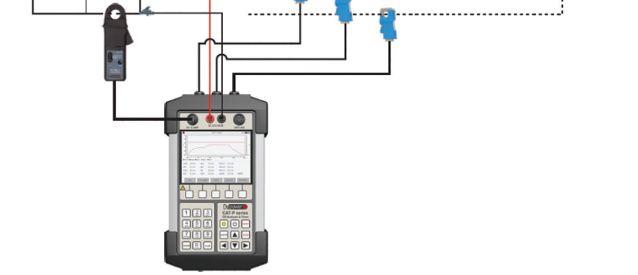

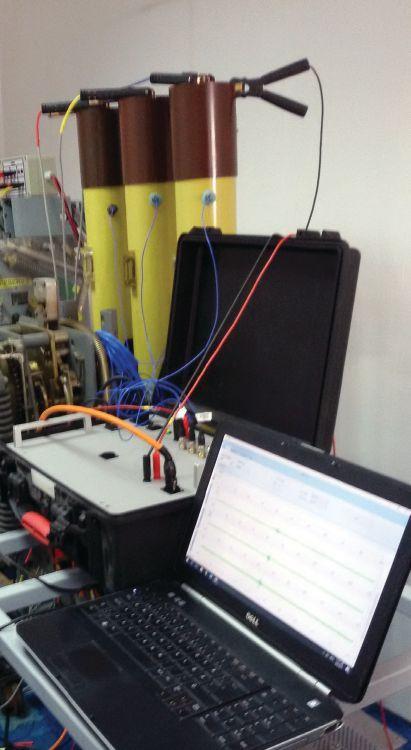

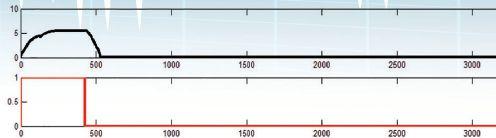

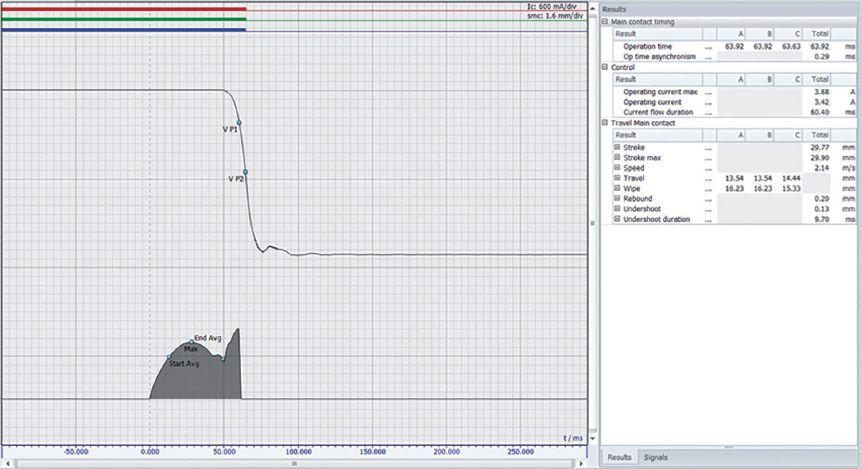

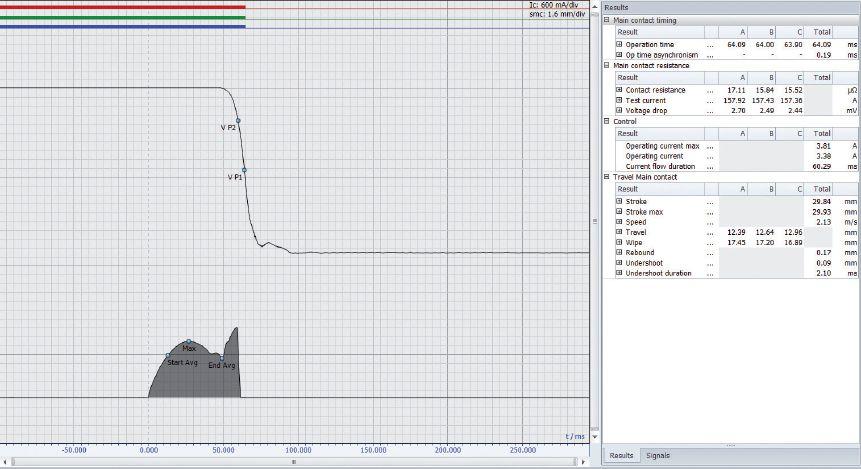

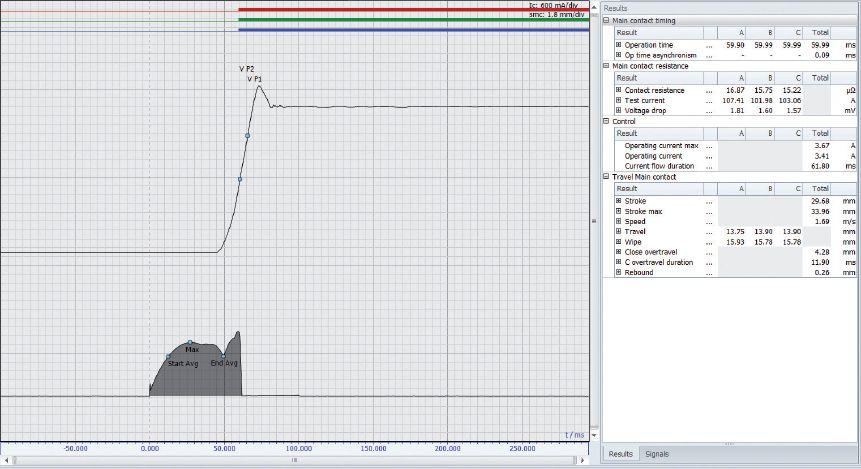

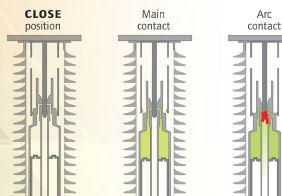

• Timing and Travel Analysis of Medium-Voltage Vacuum Circuit Breakers

Albert Livshitz, CE Power Engineered Services, LLC

• The Importance of Power Factor Testing SF6 Gas Circuit Breakers

Jay Garnett, Doble Engineering Company

• The Art and Science of High-Voltage System Reliability in Industrial Applications

Alan Ross, SD Myers, Inc.

• The Differences Between Acceptance and Maintenance Testing of Medium-Voltage Distribution Power Circuits

Henning Oetjen, Megger

• How to Perform a Power Survey

Ross Ignall, Dranetz

Nicholas Perjanik, Weidmann Diagnostic Solutions, Inc.

• Applying Sweep Frequency Response Analysis and Leakage Reactance to Determine Mechanical Faults in a Power Transformer

Charles Sweetser, OMICRON electronics Corp. USA

• Transformer Insulation Field Diagnostics 1.0

Diego Robalino, Megger

• Narrow Band DFR Transformer Condition Assessment

Robert Breazeal, Southern California Edison Company

RELAYS

• Presentation of IEEE PSRC, WG I-25 Report

Will Knapek, OMICRON electronics Corp. USA

• Transformer Differential Testing & Commissioning John Lane, Doble Engineering Company

• Who Has the 32?

Benjamin Kazimier, Basler Electric SYMPOSIUM

Electrical Incident Reviews and Case Studies Symposium: What Can We Learn?

Moderator: Ron Widup, Shermco Industries

Remember the time you witnessed a 480-volt fault first hand? And if you heard it more than once that “shotgun blast” was likely the same sound each time. Have you seen the effects a medium-voltage electrical arc flash can have on the human body? What can we learn from these incidents?

There are many documented cases of electrical equipment failures or injury from electrical contact or burns. This symposium will present several case studies, provide opinions as to the cause, and more importantly, actions that could have been taken to prevent the incident from occurring in the first place. We can always learn from our life experiences and knowledge… this session will capitalize on this concept with experts in the industry providing insight and analysis to help us in our quest to live an incident-free existence in the world of electrical power. Don’t miss this very informative session!

A full moon over the Washington Memorial.

Tuesday

Join in the discussion during the Tuesday morning Panel Sessions. Select two of the four panel topics and get ready to learn from experts and peers alike.

Panels:

Electrical Safety

Moderator: Jim White, Shermco Industries

Relays

Moderator: Dave Huffman, Power Systems Testing Co.

Cables

Moderator: Tom Sandri, Shermco Industries

Transformers

Moderator: Rob Parton, ABM Electrical Power Services, LLC

Wednesday & Thursday

Two days are dedicated to high-power learning. Choose from 16 in-depth, four-hour seminar presentations. PowerTest 2018 Technical Seminars cover current topics and important industry issues that will broaden your horizons and expand your knowledge, preparing you for challenges ahead.

SEMINAR TITLES

• Reliability vs. Efficiency, Safety vs. Production: Creating Synergy in Quadrants of Dichotomy

Stacey Hefner, Practicing Perfection Institute

• Hands-On Relay Testing (Morning Session)

Tuesday Afternoon

PowerTest 2018 Trade Show

The PowerTest 2018 Trade Show promises more than 100 top-tier electrical power vendors whose mission is electrical safety and reliability. Enjoy a complimentary lunch and beverages as you tour the show and make connections. The PowerTest 2018 Trade Show will take place from 12:00 PM – 5:30 PM.

Tuesday Evening

Don’t miss the PowerTest 2018 PowerBash Reception!

A gathering you don’t want to miss. Enjoy an evening of entertainment, awards, and recognitions, while mixing and mingling. Tuesday evening from 7:00 PM – 10:00 PM.

Ryan McDaniel, Schweitzer Engineering Laboratories, Inc.

• Power Transformer Commissioning

Donald Platts and Brandon Dupuis, OMICRON electronics Corp. USA

• NFPA-70E 2018: Edition Changes, Overview, and Understanding the Impact of the New Standard

Jim White, Shermco Industries

• Medium-Voltage Circuit Breaker Maintenance: A Hands-On Seminar with GE PowerVac Breaker

Finley Ledbetter, Group CBS, Inc.

• Hands-On Relay Testing (Afternoon Session)

Ryan McDaniel, Schweitzer Engineering Laboratories, Inc.

• Power Factor Testing of Instrument Transformers

Keith Hill, Doble Engineering Company

• Best Practices for Battery Testing and Maintenance

Volney Naranjo, Megger

• Cable System Reliability, Testing, and Failure Analysis at Windfarms

Tom Sandri, Shermco Industries

• Grounding and Bonding to Avoid Disasters

David Brender, Copper Development Association, Inc.

• NETA Certification Exam: Useful Information on Preparation and Understanding of the Content

Dan Hook, Western Electrical Services, Inc.

• Transformer Protection and Testing

Vijay Sundaram, Megger

• Power Quality Seminar

Ross Ignall, Dranetz

• Power Factor Testing of Power Transformers

Keith Hill, Doble Engineering Company

• Developing a Cable Fault Locating Strategy – Hands-On Workshop

Tom Sandri, Shermco Industries

• Integration, Protection, and Maintenance of Renewable Power Plants

Ed Khan, Doble Engineering Company

Hospitality Suites

Mingle with colleagues and a host of leaders at Monday night’s hospitality suites. Nine companies will offer their own brand of hospitality with uniquely themed suites. 6:00 PM – 10:00 PM

Friday

The Doble Laboratory Seminar is designed for engineers, chemists, and others responsible for reviewing data to interpret laboratory results to detect and identify problems within electric apparatus. The seminar will be interactive, combining theoretical background with practical experience and hands-on examples including case studies illustrating common problems found in the field.

• Learn about the quality of oils on the market today

• Discover how knowing about the aging characteristics of insulating materials can help you extend the life of your transformer

• Learn how to take oil samples, avoid common pitfalls, and save time and money by sampling only once

• Diagnose apparatus problems with dissolved gas-in-oil analysis

• Find out how to assess the condition of paper insulation

• Detect the presence of incipient fault conditions and categorize them

• Establish the correct method of analyzing moisture-in-oil results

• Study the significance of dissolved and particulate metals and other particle contamination found in electrical apparatus

• Understand how to determine the condition of electric apparatus using laboratory tests

• Diagnostics and condition assessment for LTCs and bulk-oil breakers based on oil test

es e i n o S DAY T J Tr T an ans derra d ed d Two DAYS Mo M We e nee e g rptein to o dgnne DAY ed for r engin n

SPONSORS

Sunday, February 25 9:00 AM – 4:00 PM

Megger Best Practices

Social Pass

Monday, February 26 12:00 PM – 2:00 PM

PowerDB User’s Group

Megger’s Best Practices Seminars are designed to bring you up to speed on new testing techniques and technology as well as offer the opportunity to engage with our expert engineers in discussing best practices for field testing of transformers, circuit breakers, relays, cables, batteries and other substation assets. Megger’s world-class Applications Engineers utilize their vast industry knowledge and experience to craft an in-depth program backed by Megger’s expertise in the market. This full-day of quality education includes technical presentations covering latest update on standards, new developments in testing practices, field observations, analysis and case studies.

The Social Pass includes admission to the Hospitality Suites, Trade Show, Breakfast, and the PowerBash reception. $75 per person. This pass is intended for guests of attendees who are not interested in attending technical presentations. Those attending Mon-Thurs sessions do not need to purchase a social pass, as it is included in full conference registration (with the exception of the PowerBash reception – this is an addtional $25).

Annual User’s Group Meeting open to licensed users of PowerDB Pro Software. Agenda will include presentations by the PowerDB Pro development team as well as utility, industrial, and contractor groups discussing how this product is an integral part of their business operations. Preregistration is required by contacting PowerDB at 979-690-7925 ext. 702 or by registering at www.powerdb.com

5:00 PM – 6:00 PM

New Product Forum

Attendees will have the opportunity to learn about dozens of the latest products and innovations, major expansions, and significant improvements by the leading industry-specific manufacturers and suppliers at the Tuesday Trade Show. Stay until the end for the chance to win an exclusive prize! Must be present to win.

HIGH VOLTAGE SPONSORS MEDIUM VOLTAGE SPONSORS LOW VOLTAGE SPONSORS GENERAL SPONSORS

CONFERENCE View from the Cigar Terrace at the Gaylord National Resort & Convention Center

PREMIUM

Sponsors

FEATURES

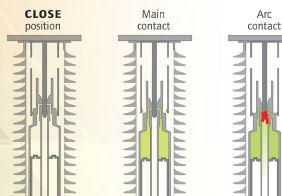

52 When to Consider a Retrofit Replacement Circuit Breaker

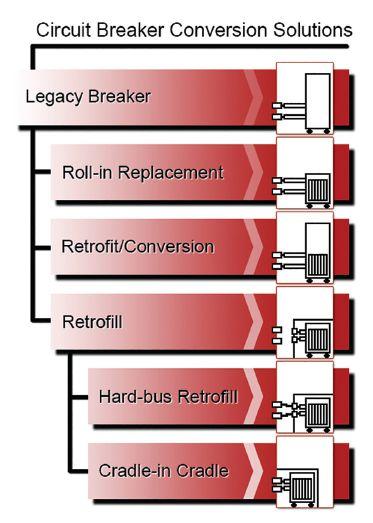

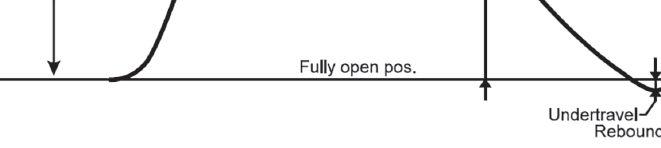

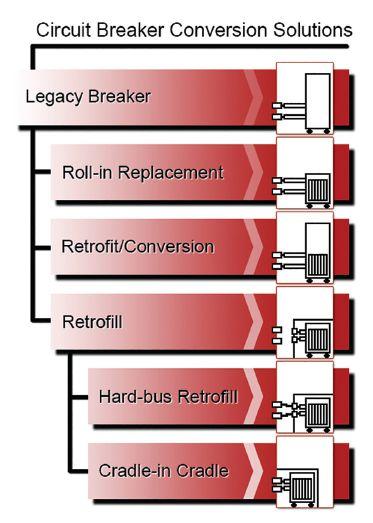

It is no secret that the majority of America’s infrastructure is old, with air-magnetic and even oil circuit breakers commonly in service decades beyond their 20-year design life. The longevity of air-magnetic medium-voltage circuit breakers is a testament to the reliability of the original designs, materials, and manufacturing methods, as well as the performance of those who maintain them today and over the last 30, 40, or even 50 years. But regardless of how well equipment is maintained, time takes its toll. Eventually, maintaining antiquated switchgear becomes impractical, and replacement options look appealing.

When that time comes, should a retrofit replacement breaker be considered against other options? The answer usually comes down to cost and how easily the end user can support the extended outage it will take to replace the gear. This article offers a look at the challenges to be considered when making that decision.

Paul H. Grein, Circuit Breaker Sales Co., Inc.

7 President’s Desk

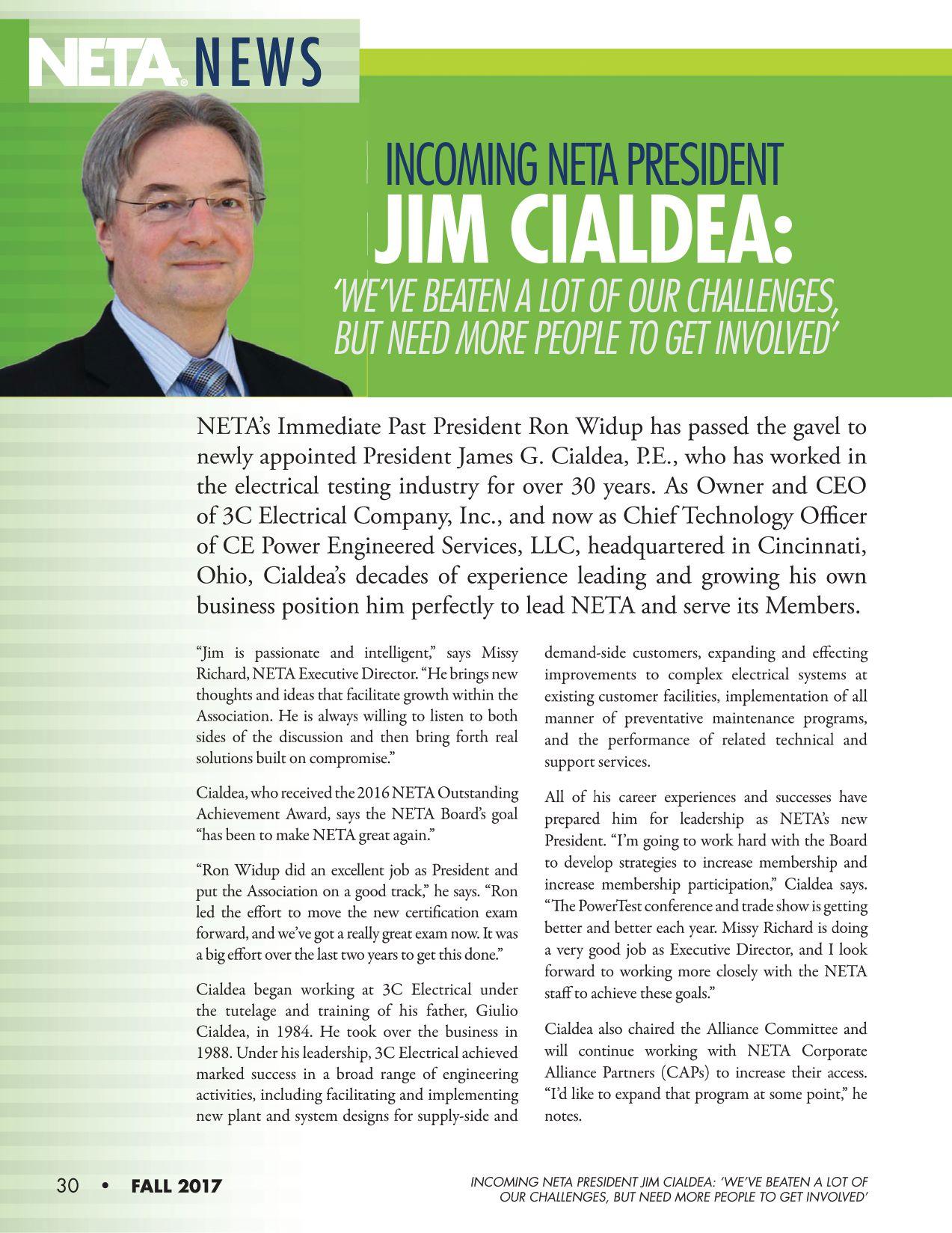

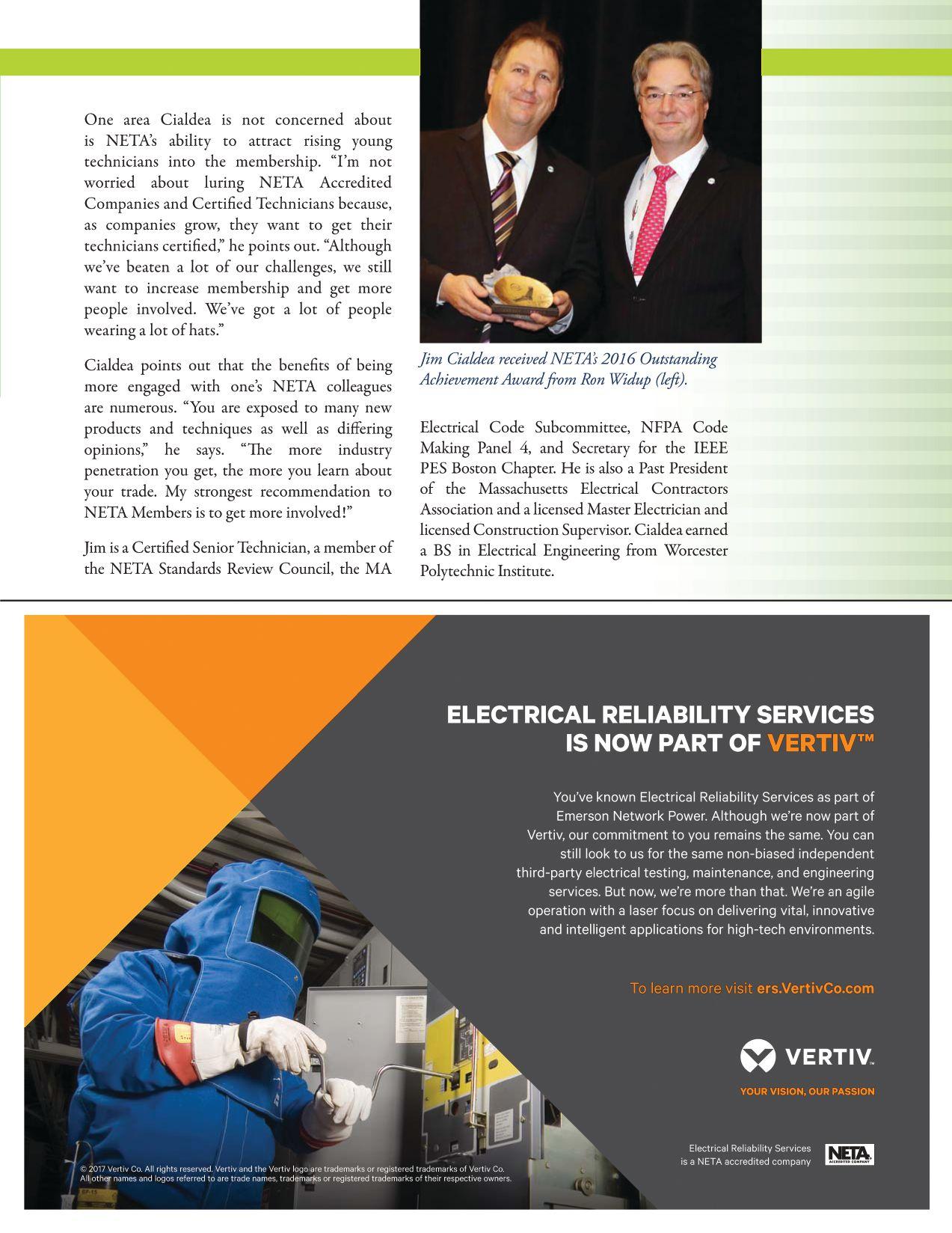

Jim Cialdea, CE Power Engineered Services, LLC

NETA President

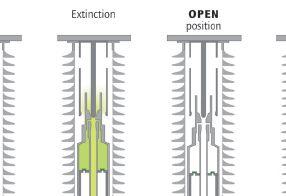

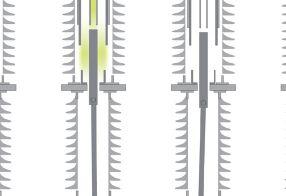

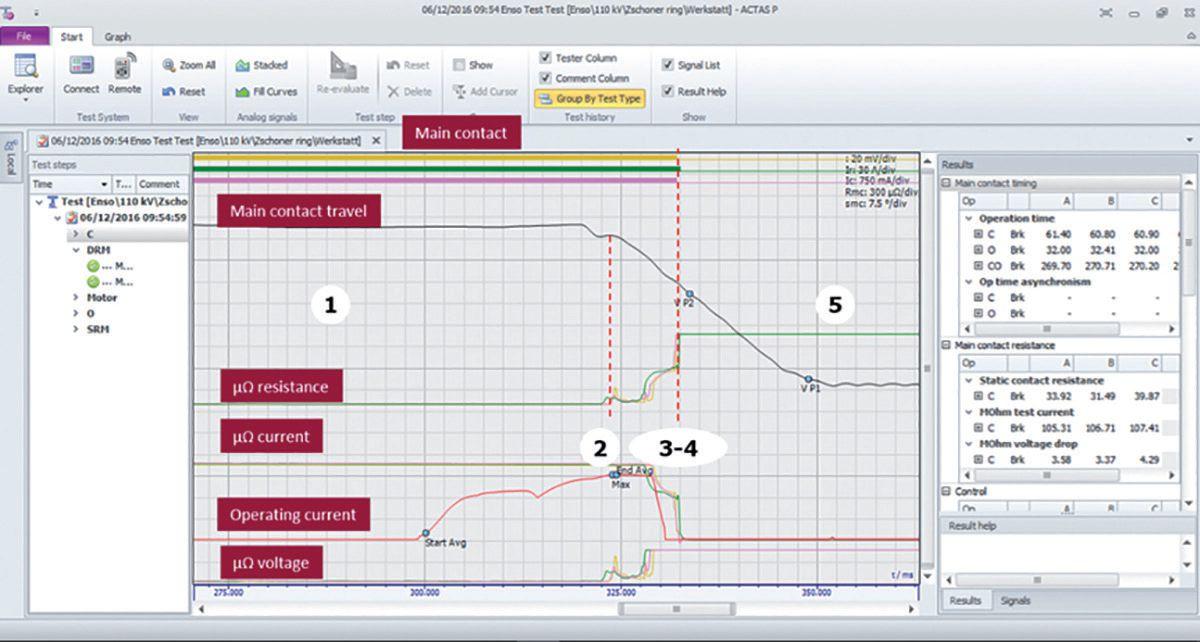

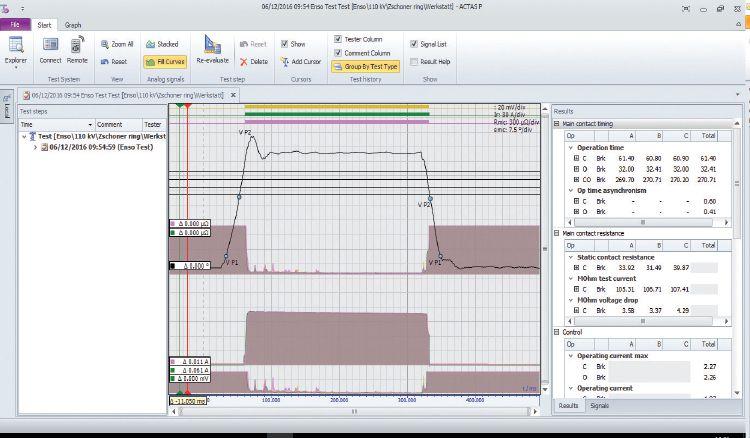

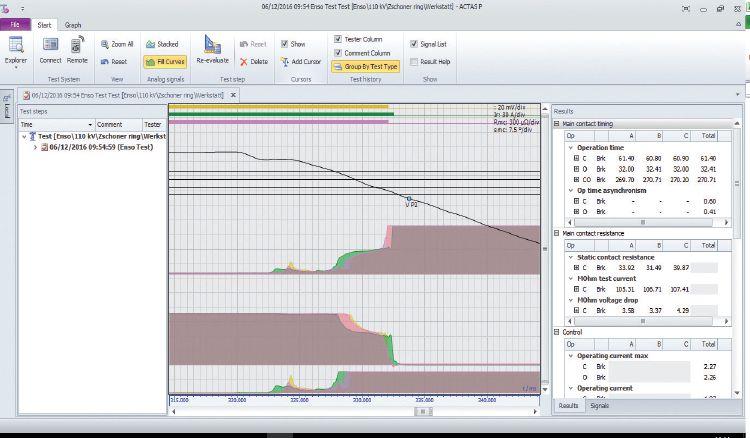

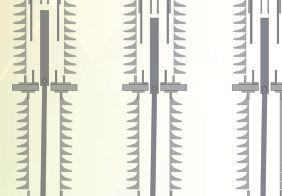

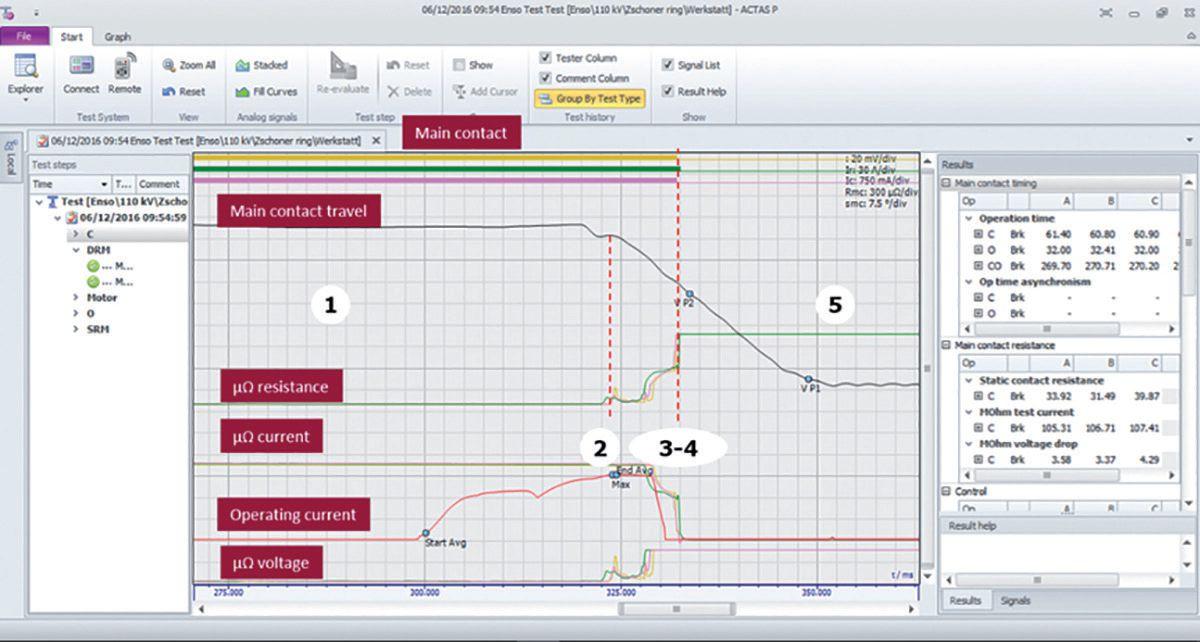

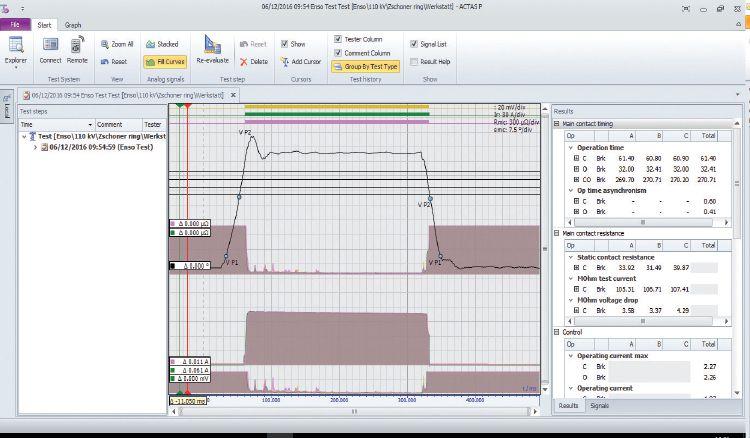

64 Medium-Voltage Circuit Breakers: Fit for Duty or in Need of Attention?

Bret Hammonds, Shermco Industries, and Robert Foster, Megger

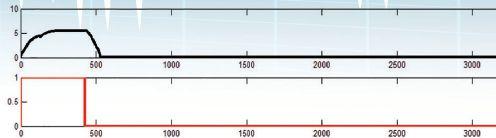

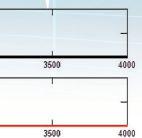

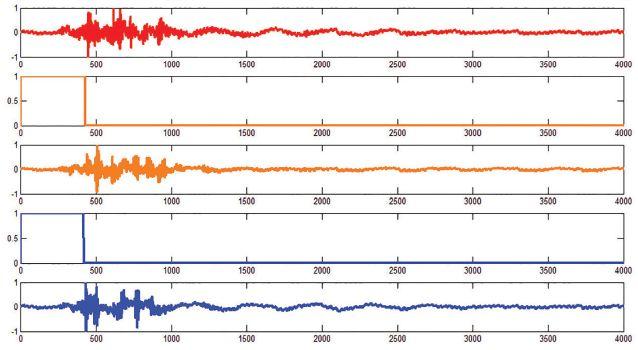

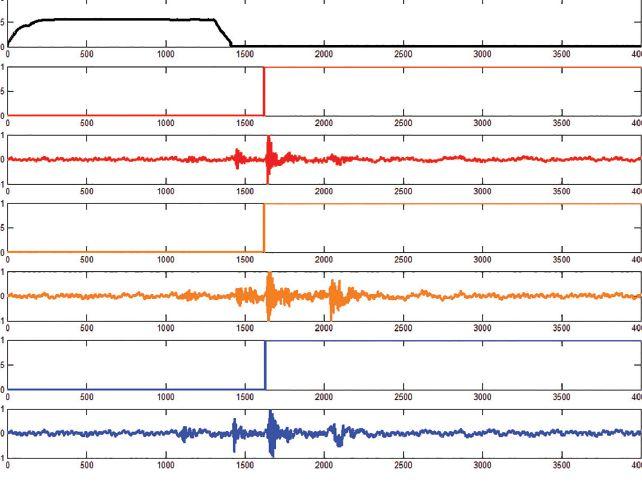

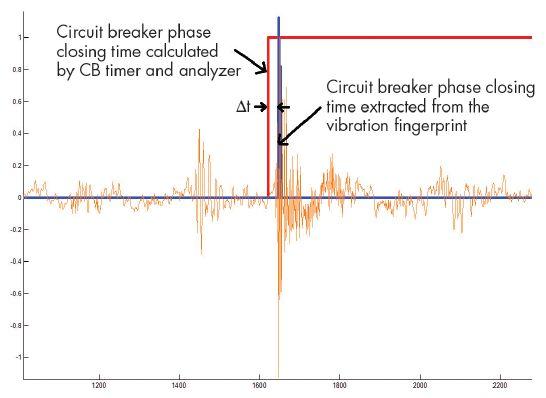

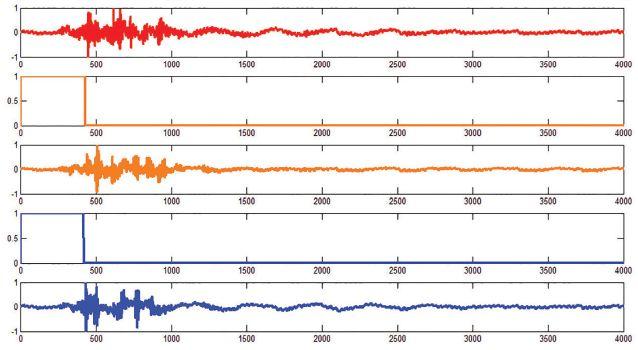

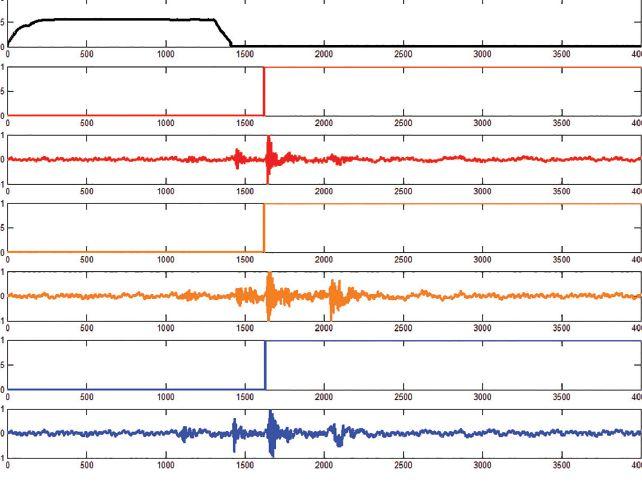

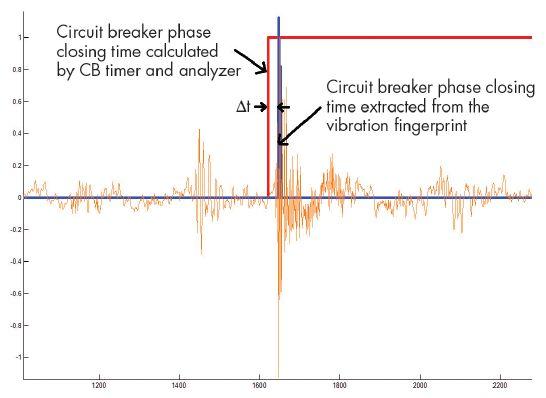

73 Power Circuit Breaker Condition Assessment Based on Vibration Fingerprint Measurement: Why It Can Save Your Day

Adnan Secic and Kerim Obarcanin, DV Power

82 Testing Switchgear: Conventional vs. Both-Sides-Grounded Methods

Guy Wasfy, KoCoS America LLC, and Christian Studen, KoCoS Messtecknik AG

TABLE OF CONTENTS TABLE OF CONTENTS NETAWorld • 3

COVER STORY

52

82

Cover photo courtesy Brian Kaylor, Circuit Breaker Sales Co., Inc.

IN EVERY ISSUE

11 NFPA 70E and NETA

Overhead Power Lines + Unqualified Persons = Tragedy

Ron Widup and Jim White, Shermco Industries

18 No-Outage Corner

Overcoming Five Common Misconceptions About Online Switchgear PD Testing

Don A. Genutis, Halco Testing Services, Inc.

22 Tech Quiz

Medium-Voltage Circuit Breaker Safety

Jim White, Shermco Industries

34 Tech Tips

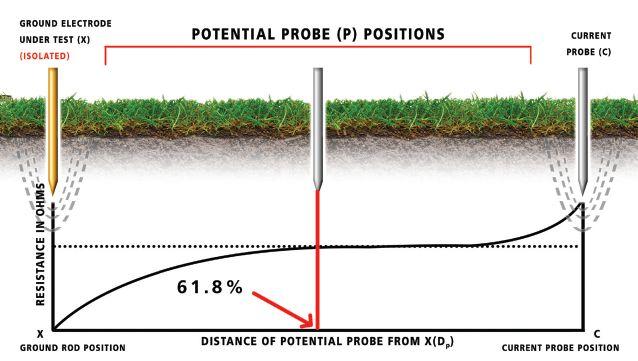

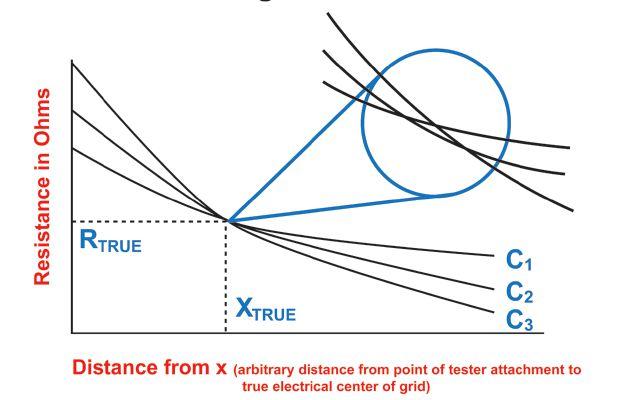

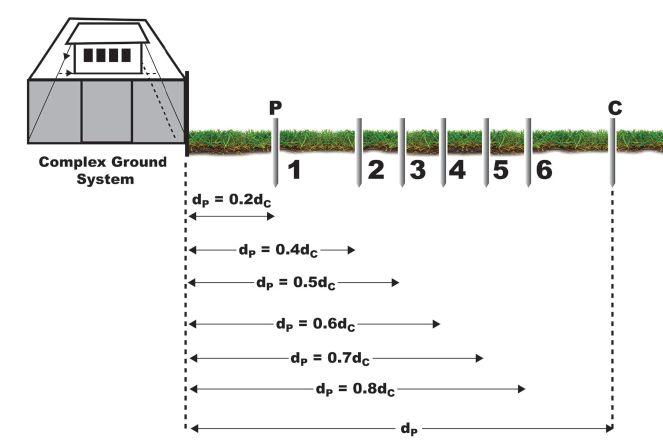

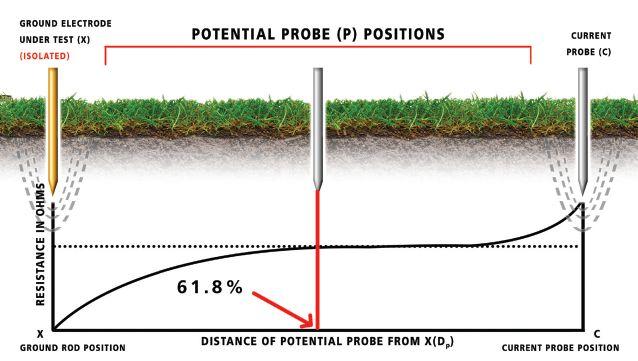

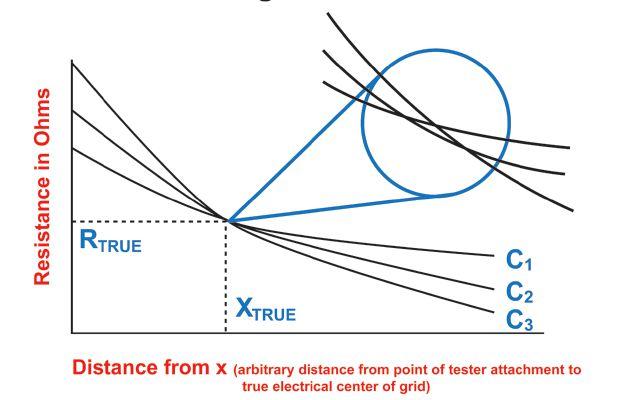

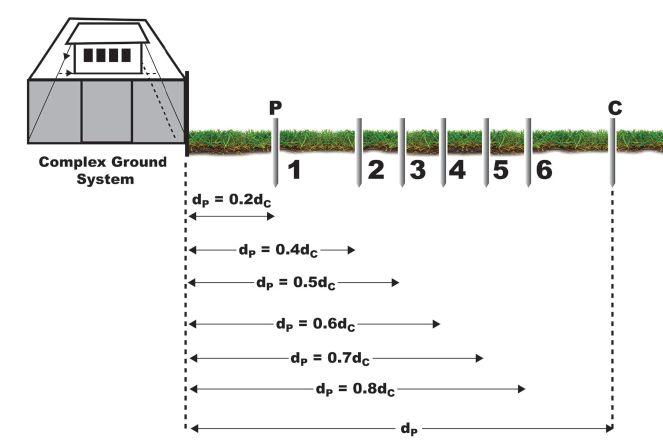

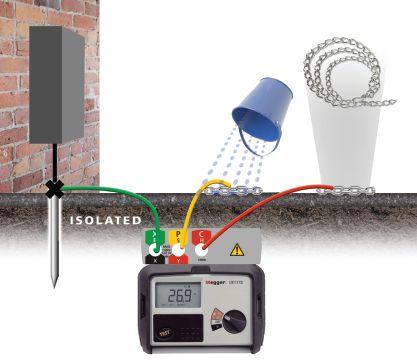

Ground Testing FAQs — Part II

Jeff Jowett, Megger

40 Safety Corner

Medium-Voltage Circuit Breaker Condition

Analysis and Hazard Awareness

Paul Chamberlain and Scott Blizard, American Electrical Testing Co., Inc.

46 Relay Column

Symmetrical Components Review: Base Quantities and Per-Unit

Steve Turner, Electrical Consultants, Inc.

INDUSTRY TOPICS

92 Passing the Torch

Dave Sowers, Knowledge Vine, LLC

ADVANCEMENTS IN TECHNOLOGY

112 Results are Only as Good as the Sample Taken

Nick Perjanik, PhD, Weidmann Electrical Technology Inc.

SPECIFICATIONS AND STANDARDS

106 ASTM F18 Committee Report

Jim White, Shermco Industries

108 ANSI/NETA Standards Update

NEWS NETA SETTING THE STANDARD

98 Changes in the Newly Published ANSI/ NETA ATS-2017, Standard for Acceptance Testing Specifications for Electrical Power Equipment and Systems

Jim Cialdea, CE Power Engineered Services, LLC, and Lorne Gara, Orbis Engineering Field Services, Ltd.

NETA NEWS

24 New NETA Board Member Scott Dude: ‘Impressed with the Integrity and Ethics of NETA’

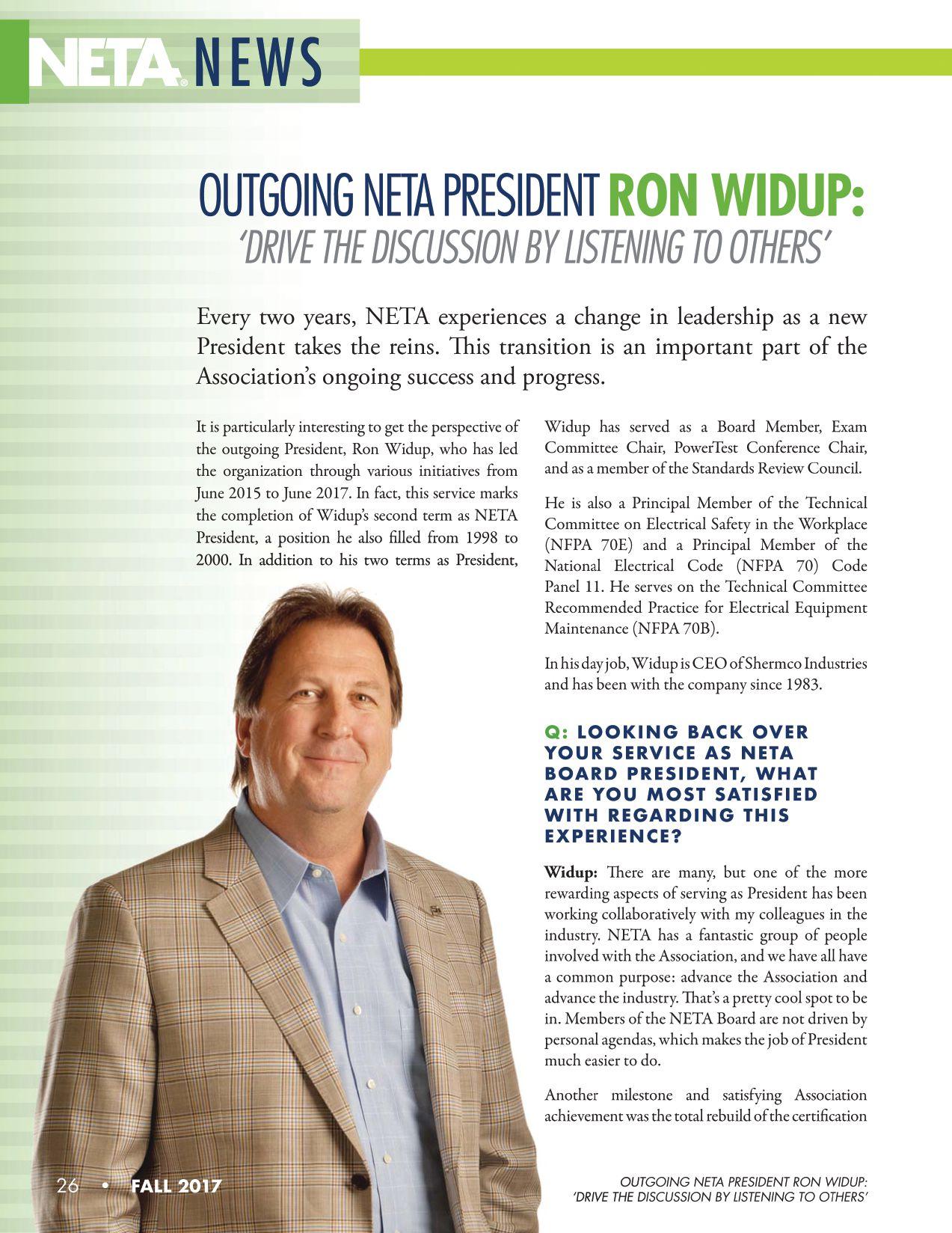

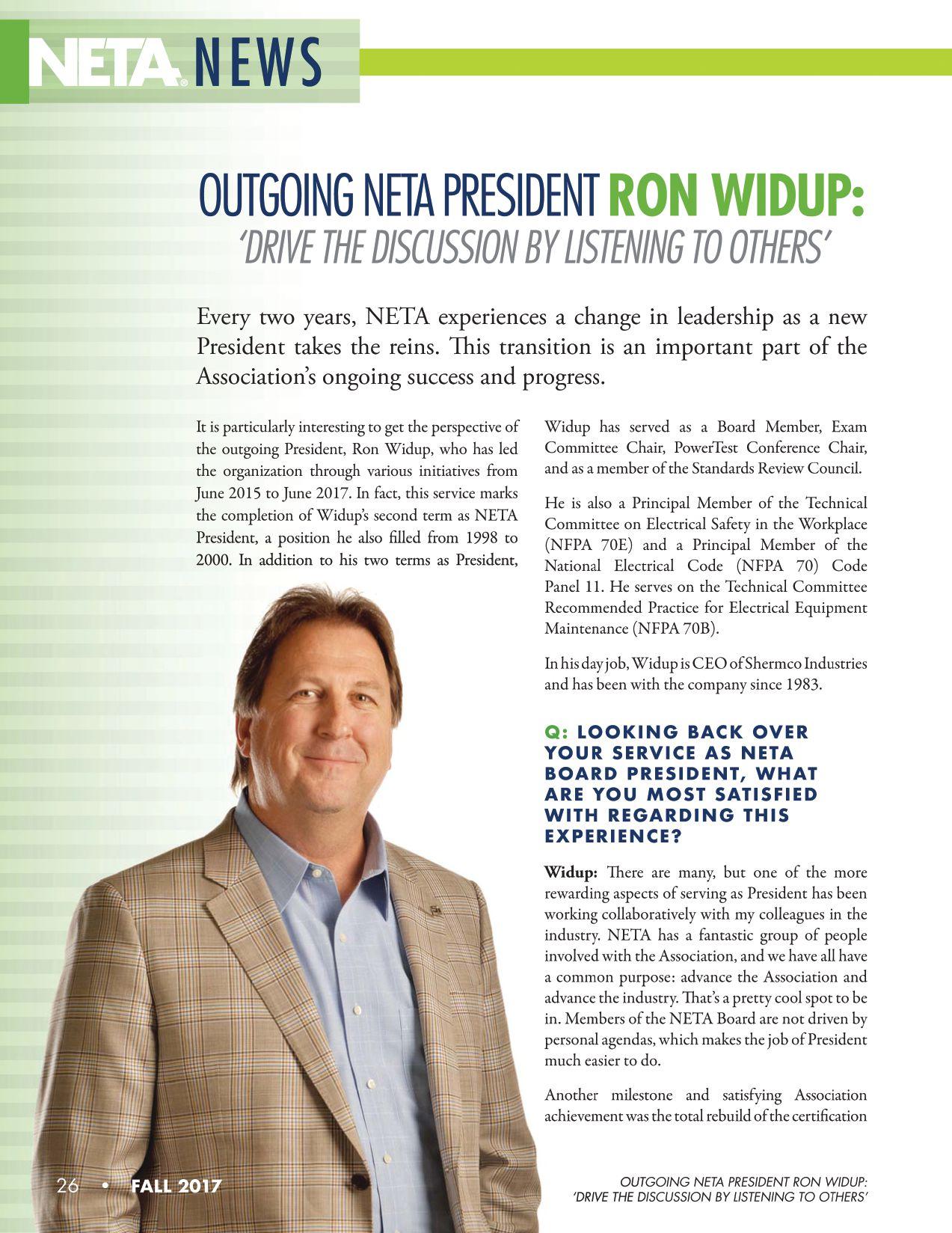

26 Outgoing NETA President Ron Widup: ‘Drive the Discussion by Listening to Others’

30 Incoming NETA President Jim Cialdea: ‘We’ve Beaten a Lot of Our Challenges, but Need More People to Get Involved’

51 NETA Activities Update — January through June 2017

103 Notice of Errata for ANSI/NETA ATS-2017

IMPORTANT LISTS

120 NETA Accredited Companies

126 Advertiser List