If you ask the people of Fort Worth, Texas to talk about their city, they might recount beginnings as a small outpost on a lonely frontier. Unusual, perhaps, in a state where everything is bigger. But, eventually Fort Worth lived up to its state’s big reputation, growing to the fifth-largest city in Texas with about 800,000 people today who are ready to take on modern challenges for expansion and growth. Its cattle and oil beginnings have been interwoven with an array of diverse industries.

PowerTest draws many parallels to Fort Worth. While no one can claim they have been lonely at PowerTest, the premier electrical maintenance and safety event has grown in similar fashion, seizing opportunities to help industry professionals grab the bull by the horns and jump to the top of their game. Fort Worth’s mission to work together to build a strong community describes the PowerTest commitment to build a network of knowledgeable professionals in the electrical safety industry, working together to uphold the standards and improve safety and reliability.

Deep in the heart of Texas, PowerTest 2016 comes to Fort Worth to plug into the city’s vast energy and connect attendees with leading industry experts, high power learning, and networking. Everything’s bigger in Texas, including the opportunities for you at PowerTest 2016.

Gary Norland is a husband, father, electrician, and speaker.

Gary spent several years traveling and working various jobs in construction. He eventually went to work as a union maintenance electrician for his local pulp and paper mill – no more travel, a good income, and stability.

He was a healthy six-foot-three, 240-pound man who loved his work was always about getting the job done. But one day, his life changed electrocuted by a 12,500-volt, 200-amp overhead power line. He ish dy morning to share with you how hard work and dedication to your jobhldb focus, but not your only focus. Gary wants others to understand that if y ’ safety seriously, your life could resemble his in less than a second.

His attitude d when he was s here Monday b should be a you don’t take

ar y Norland

Safety Presentations

We’ve gathered leaders in the industry and will stage a full day of engaging, 45-minute presentations sure to expand your thinking and generate new ideas. Choose from 27 detailed presentation track topics.

• Protective Devices Maintenance and the Potential Impact on Arc-Flash Incident Energy

Dennis Neitzel, AVO Training Institute, Inc.

• Beliefs Drive Behaviors

D. Ray Crow, DRC Consulting Ltd.

• Potential Impact of ISO 55000 on Maintenance Critical to Electrical Safety

H. Landis Floyd, Electrical Safety Group, Inc.

• Electrical Safety Management System Principles and Practices

Mike Doherty, Shermco Industries Canada

• Overview of an Electrical Safety Program Development Guide

Terry Becker, Electrical Safety Program Solutions, Inc.

• Arc-Flash Mitigation by Transformer Differential Relay Protection

Mose Ramieh III, PGTI, and Randall Sagan, MBUSI

• System Testing of Protection Devices and Schemes –What Is It and Why Do We Need It?

Will Knapek, Benton Vandiver, and Alexander Apostolov, OMICRON Corp. USA

• Improving Safety through Partial Discharge Surveying

Tony McGrail, Doble Engineering Company

• Transformer Failures and Case Study

Shuzhen Xu, FM Global

• Protecting Batteries that Protect Your Power System

Brandon Schuler, Electrical Reliability Services

• Power Quality Monitoring and Communications Standards Update

Ross Ignall, Dranetz Technologies

• How Disruptions in DC and Communications Affect Protection

Karl Zimmerman

Schweitzer Engineering Laboratories, Inc.

• Bushing Replacement – It Fits, But Will It Work?

Keith Hill, Doble Engineering Company

• Gaps in Motor Reliability

Lona Mazzeo, PDMA

• Reliability of Electrical Systems: From Testing to Monitoring

Alan Ross, SD Myers

• Understanding and Testing Motor Overload Protection and Thermal Models

Daniel Ransom, Doble Engineering Company

• Electric & Dielectric Condition Assessment of HV Current Transformers

Diego Robalino, Megger

• Understanding Transformer Differential Protection

J Scott Cooper, OMICRON electronics Corp. USA

• Power Factor Testing for SF6 Breakers

Rick Youngblood, Doble Engineering Company

• Vacuum Interrupters: Pressure Vs. Age – A Study of Vacuum Levels in 314 Service Age Vacuum Breakers

John Cadick, Cadick Corporation

• Effects of Low-Resistance Measurement Instruments on Protection and Control Devices

Dinesh Chhajer and Jammie Lee, Megger

• Diagnostic Testing Practices for SF6-Filled Dead Tank Circuit Breakers

Charles Sweetser, OMICRON electronics Corp. USA

• What is TankLoss Index?

Rick Youngblood, Doble Engineering Company

• Circuit Breaker and Transducer: Where Do I Connect?

Robert Foster, Megger

• Application and Commissioning of On-line Partial Discharge Technology to Medium-Voltage Switchgear

Bruce Rockwell, American Electrical Testing Co., Inc.

• Electrical Commissioning Tips and Trends for Advanced Critical Facilities Applications

Corey Dozhier, Oracle

• Electrical Testing and Inspection of Equipment in Questionable Condition

Peter Brosz, Brosz Group of Companies

TUESDAY (CONTINUED)

The PowerTest 2016 Trade Show promises more than 100 toptier electrical power vendors whose mission is electrical safety and reliability. Enjoy a complimentary lunch and beverages as you tour the show and make connections. New this year, we have expanded the hours of the trade show. The PowerTest 2016 Trade Show will take place from 12:00 – 6:00 PM.

Tuesday Evening

DON’T MISS THE POWERTEST 2016 POWERBASH RECEPTION!

A gathering you don’t want to miss. Enjoy the Western charm and music of Texas, celebrate the best of PowerTest, mix and mingle. Tuesday evening from 7:00 – 10:00 PM.

Sunday, March 13 | 9:00 AM – 4:00 PM

Megger’s seminar will address many of the critical and costly aspects of substation maintenance. The interactive session will feature practical presentations on current methods and practices to help ensure the reliability of high-voltage circuit breakers, power transformers, and batteries. You must preregister for this event by contacting Megger: 214-330-3514.

SUNDAY, MARCH 13 | 5:30 PM – 8:30 PM

Join us Sunday evening for traditional Texas hospitality and a wrangling good time. Swagger into the Stockyards Station and experience the storied history of Fort Worth, the best in Southwest BBQ, a few tall cold ones, and a rootin’-tootin’ showdown! $155 per person.

MONDAY, MARCH 14 | 12:00 PM – 2:00 PM

Annual User’s Group Meeting open to licensed users of PowerDB Pro Software. Agenda will include presentations by the PowerDB Pro development team as well as utility, industrial, and contractor groups discussing how this product is an integral part of their business operations.

A special lounge exclusively for spouses and guests of PowerTest attendees, stocked daily with light refreshments and information on local activities. Includes admission to Hospitality Suites Monday evening, Tuesday Trade Show, and Tuesday evening PowerBash reception. $75 per person.

The Social Pass includes admission to the Hospitality Suites, Trade Show, and the PowerBash reception. $50 per person.

& Tuesday$995$895 Monday – Thursday$1895$1695

To register for PowerTest 2016, save time by registering online. You’ll find a complete brochure and registration form available at www.powertest.org

Omni Fort Worth Hotel 888-444-OMNI 1300 Houston Street Fort Worth, TX 76102

Reservation Deadline: February 5, 2016

Group Name: NETA/PowerTest

Group Rate: $209

* Once you register for PowerTest 2016, you will receive a link via email to secure your hotel reservations at the Omni Fort Worth.

NETA accepts all major credit cards. Save time and register on-line at www.powertest.org or call 888-300-6382 (NETA)

PowerTest 2016 Technical Papers – Registered conference attendees will receive all PowerTest technical presentations on a USB drive in their registration bag.

1. Go to www.powertest.org and review the complete PowerTest 2016 on-line brochure.

2. Decide the number of days you will attend the conference.

3. Tuesday attendees select up to two panels. (Cost of panels included in the registration fees.)

4. Wednesday attendees register for up to two seminars.

(Cost of seminars included if registered for Monday – Thursday.)

5. Thursday attendees register for up to two seminars (Cost of seminars included if registered for Monday – Thursday.)

6. Register for Doble Lab Seminar. (Cost of seminar is in addition to the registration fees.)

7. Sign up for Spouse/Guest Passes. (Cost of passes is in addition to the registration fees.)

8. Sign up for PowerTest 2016 conference polo shirts and select size. (Cost of polo shirts is in addition to the registration fees.)

Fort Worth, Texas

66Transformer Maintenance: The Overlooked Items

In my 35 years of involvement with substation transformer maintenance, I have witnessed widely varying perspectives on what maintenance should include. Too often, it is limited to nothing more than inspections. The techs involved might look at the top oil and hot spot indicators, observe the nitrogen pressure or conservator levels, check for leaks — and maybe, if they are thorough — log the load tap changer (LTC) counter. Most technicians comment that the transformer is electrically tested every three to six years by performing the standard regiment of power factor, TTR, excitation, and winding resistance tests; but the majorities are completely unaware of what I call the “overlooked items.”

Rick Youngblood, Doble Engineering Company

7 President’s Desk

Ron Widup, Shermco Industries

NETA President

75Working Safely with Power

Transformers in the Utility Sector

Ray Curry, American Transmission Company

80Transformer Testing Techniques and Standard Development

Diego M. Robalino, PhD, PMP, Megger – AVO Training Institute

See Special Insert PowerTest 2016 Preview Guide

11 NFPA 70E and NETA

First Draft Meeting of the 70E 2018 Cycle

Ron Widup and Jim White, Shermco Industries

18 Niche Market

Transformer Insulation Degradation

Lynn Hamrick, Shermco Industries

28 Tech Quiz

Power Transformers

Jim White, Shermco Industries

30 No-Outage Corner

Case Study: Location of Generator PD Sources

Using Multiple Sensors

Don A. Genutis, Halco Testing Services

42 Tech Tips

Personal Protective Grounding

Jeff Jowett, Megger

48 Safety Corner

Power Transformer Hazard Awareness

Scott Blizard, American Electrical Testing Co., Inc.

55 Relay Column

Modern Advances in Testing Multifunction

Numerical Transformer Protection Relays

Steve Turner, Beckwith Electric Company, Inc. INDUSTRY TOPICS

97 Combined Current and VoltageControlled Source in Arcing Contacts Condition Assessment

Adnan Secic and Radenko Ostojic, DV Power, Sweden

SPECIFICATIONS AND STANDARDS 120 ANSI/NETA Standards Update

Insulated Conductor Committee Meeting Report

Ralph Patterson, Power Products & Solutions LLC 126 IEEE/PES Transformers Committee Meeting Report

Al Peterson, Utility Service Corporation

Sunshine, Sea, and Blue Skies Greet NETA Members in Seattle, Washington Kristen Wicks, NETA

Lorne Gara, Orbis Engineering Ltd.

Top 10 Career-Building Reasons to Attend PowerTest 2016

Join the Spotlight with NETA Corporate Alliance Partners

NETA Alliance Partnership Program – Join and Save at PowerTest 2016

Doble Engineering Seminar Expands Learning to Friday

Ensuring Access to the Right Equipment at the Right Time – And at the Lowest Cost

Herb Ostenberg, Electro Rent Corporation

NETA Accredited Companies

Advertiser List

3050 Old Centre Avenue, Suite 102

Portage, MI 49024

Toll free: 888.300.NETA (6382)

Phone: 269.488.NETA (6382)

Fax: 269.488.6383

neta@netaworld.org

www.netaworld.org

EXECUTIVE DIRECTOR: Jayne Tanz, CMP

NETA Officers

PRESIDENT: Ron Widup, Shermco Industries

FIRST VICE PRESIDENT: Jim Cialdea, Three-C Electrical Co., Inc.

SECOND VICE PRESIDENT: Scott Blizard, American Electrical Testing Co., Inc.

SECRETARY: Mose Ramieh, Power & Generation Testing, Inc.

TREASURER: John White, Sigma Six Solutions

NETA Board of Directors

Ken Bassett (Potomac Testing, Inc.)

Scott Blizard (American Electrical Testing Co., Inc.)

Jim Cialdea (Three-C Electrical Co., Inc.)

Lorne Gara (Orbis Engineering Field Services, Ltd.)

Roderic Hageman (PRIT Service, Inc.)

David Huffman (Power Systems Testing)

Alan Peterson (Utility Service Corporation)

Mose Ramieh (Power & Generation Testing, Inc.)

Bob Sheppard (Southwest Energy Services, LLC)

John White (Sigma Six Solutions)

Ron Widup (Shermco Industries)

NETA World Staff

TECHNICAL EDITORS: Roderic L. Hageman, Tim Cotter

ASSOCIATE EDITOR: Resa Pickel

MANAGING EDITOR: Jayne Tanz, CMP

ADVERTISING MANAGER: Laura McDonald

DESIGN AND PRODUCTION: Hour Custom Publishing

NETA Committee Chairs

CONFERENCE: Ron Widup; MEMBERSHIP: Ken Bassett; PROMOTIONS/MARKETING: Scott Blizard; SAFETY: Scott Blizard and Jim White; TECHNICAL: Alan Peterson; TECHNICAL EXAM: Ron Widup; CONTINUING TECHNICAL DEVELOPMENT: David Huffman; TRAINING: Kerry Heid; FINANCE: John White; NOMINATIONS: Alan Peterson; STRATEGY: Mose Ramieh; ALLIANCE PROGRAM: Jim Cialdea

© Copyright 2015, NETA

NOTICE AND DISCLAIMER

NETA World is published quarterly by the InterNational Electrical Testing Association. Opinions, views and conclusions expressed in articles herein are those of the authors and not necessarily those of NETA. Publication herein does not constitute or imply endorsement of any opinion, product, or service by NETA, its directors, officers, members, employees or agents (herein “NETA”).

All technical data in this publication reflects the experience of individuals using specific tools, products, equipment and components under specific conditions and circumstances which may or may not be fully reported and over which NETA has neither exercised nor reserved control. Such data has not been independently tested or otherwise verified by NETA.

NETA MAKES NO ENDORSEMENT, REPRESENTATION OR WARRANTY AS TO ANY OPINION, PRODUCT OR SERVICE REFERENCED OR ADVERTISED IN THIS PUBLICATION. NETA EXPRESSLY DISCLAIMS ANY AND ALL LIABILITY TO ANY CONSUMER, PURCHASER OR ANY OTHER PERSON USING ANY PRODUCT OR SERVICE REFERENCED OR ADVERTISED HEREIN FOR ANY INJURIES OR DAMAGES OF ANY KIND WHATSOEVER, INCLUDING, BUT NOT LIMITED TO ANY CONSEQUENTIAL, PUNITIVE, SPECIAL, INCIDENTAL, DIRECT OR INDIRECT DAMAGES. NETA FURTHER DISCLAIMS ANY AND ALL WARRANTIES, EXPRESS OF IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

ELECTRICAL TESTING SHALL BE PERFORMED ONLY BY TRAINED ELECTRICAL PERSONNEL AND SHALL BE SUPERVISED BY NETA CERTIFIED TECHNICIANS/ LEVEL III OR IV OR BY NICET CERTIFIED TECHNICIANS IN ELECTRICAL TESTING TECHNOLOGY/LEVEL III OR IV. FAILURE TO ADHERE TO ADEQUATE TRAINING, SAFETY REQUIREMENTS, AND APPLICABLE PROCEDURES MAY RESULT IN LOSS OF PRODUCTION, CATASTROPHIC EQUIPMENT FAILURE, SERIOUS INJURY OR DEATH.

Transforming your world, transforming the industry, transforming the way you think about electrical power system testing and maintenance — that’s an important part of what we try to do here at NETA, and we use the NETA World Journal as a conduit of information for all things electrical.

Have you ever thought of writing an article about the industry? How about a case study from one of your projects? We welcome your submissions and encourage you to expand and communicate what’s going on in our industry.

Entering the winter months, many of you will have a little extra time on your hands as the days get shorter and the nights (that time for writing) get longer. Why not use that time to memorialize our industry — and build your own reputation in the field — with an article submission to the NETA World Journal?

And as we prepare for our annual technical conference, PowerTest, we are especially excited because it will be in Fort Worth, Texas, on March 14-18, 2016. Mark your calendars now and get registered for the conference — it’s sure to be a good one, y’all.

Sincerely,

nce, PowerTest, we are Texas, on March 14-18, or the conference — it’s re end me an email at

I hope this finds you well and in good health. If there is anything you need from NETA or want to see us do for the industry, send me an email at rwidup@shermco.com.

BY RON WIDUP AND JIM WHITE, Shermco Industries

BY RON WIDUP AND JIM WHITE, Shermco Industries

Much as the swallows return to Capistrano (see sidebar), so we returned to the 70E Technical Committee First Draft meeting. With all the approved changes made to the 2015 edition, initially we thought the number of Public Inputs (PIs) might be less for 2018, but that was not the case. The First Draft meeting was from Monday, August 17, through Friday, August 21, with different task groups meeting the weekend before to work out the details of individual sections. The last PI was finished on Friday at about 3:00 PM.

With PIs and a few Committee Inputs, the final count is still unknown. Several somewhat controversial issues are still on the table, including discussion surrounding the arc flash PPE tables [130.7(C)(15)(A)(a) and 130.7(C)(15)(A)(b)]. Table 130.7(C)(15)(A)(a) is moving to section 130.5 and is renamed Estimate of the Likelihood of Occurrence of an Arc Flash Incident for AC and DC Systems. In addition, the last column of the table heading that read Arc Flash PPE Required now reads Likelihood of Occurrence (Table 1). Also, the tasks have been reorganized and combined to make the table easier to use.

Task

Reading a panel meter while operating a meter switch

Perform infrared thermography and other non-contact inspections outside the restricted approach boundary. This activity does not include opening of doors or covers

Work on control circuits with exposed energized electrical conductors and circuit parts, nominal 125 volts ac or dc or below without any other exposed energized equipment over nominal 125 volts ac or dc, including opening of hinged covers to gain access

Insulated cable examination with no manipulation of cable

For dc systems, insertion or removal of individual cells or multi-cell units of a battery system in an open rack

For dc systems, maintenance on a single cell of a battery system or multi-cell units in an open rack

Outdoor disconnect switch operation outside the arc flash boundary (hookstick operated) at 1 kV through 15 kV

Outdoor disconnect switch operation outside the arc flash boundary (gang-operated, from grade) at 1 kV through 15 kV

For ac systems: Work on energized electrical conductors and circuit parts, including voltage testing

For ac systems: Work on energized electrical conductors and circuit parts of seriesconnected battery cells including voltage testing

Removal or installation of CBs or switches

Opening hinged door(s) or removal of bolted covers (to expose bare, energized electrical conductors, and circuit parts). For dc systems, this includes bolted covers, such as battery terminal covers

Equipment

Application of temporary protective grounding equipment, after voltage test

Work on control circuits with exposed energized electrical conductors and circuit parts, greater than 120 V

Insertion or removal of individual starter buckets from MCC

Insertion or removal (racking) of CBs or starters from cubicles, doors open or closed

Insertion or removal of plug-in devices into or from busways

Insulated cable examination with manipulation of cable

Work on exposed energized electrical conductors and circuit parts of equipment directly supplied by a panelboard or motor control center

Insertion or removal of revenue meters (kW-hour, at primary voltage and current)

For dc systems, insertion or removal of individual cells or multi-cell units of a battery system in an enclosure

For dc systems, work on exposed energized electrical conductors and circuit parts of utilization equipment directly supplied by a dc source

Opening voltage transformer or control power transformer compartments

Outdoor disconnect switch operation inside the arc flash boundary (hookstick operated) at 1 kV through 15 kV

Outdoor disconnect switch operation inside the arc flash boundary (gang-operated, from grade) at 1 kV through 15 kV

Source: National Fire Protection Association 70E Committee

Another change is placement of Table H.3(b) into section 130.5. Table 130.3(b) will be Table 130.5(D). It still appears in Annex H, but the committee wanted to bring more attention to this table. It is titled Selection of Arc-Rated Clothing and Other PPE When the Incident Energy Analysis Method is Used. One change made to the table is that the section for less than 1.2 cal/cm2 was removed, as this table only deals with arc-rated clothing; see Table 2 for a partial table.

Table 2: 130.5(D) (Partial)

TABLE 130.5(D) SELECTION OF ARC-RATED CLOTHING AND OTHER PPE WHEN INCIDENT ENERGY ANALYSIS METHOD IS USED

Incident energy exposures equal to 1.2 cal/cm2 up to 12 cal/cm2

Arc-rated clothing with an Arc Rating equal to or greater than the estimated incident energy (Note 1)

• Long-sleeve shirt and pants or coverall or arc flash suit (SR)

Arc-rated face shield and arc-rated balaclava or arc flash suit hood (SR) (Note 2)

Leather gloves or rubber insulating gloves with leather protectors (SR) (Note 3)

Hard hat

Safety glasses or safety goggles (SR)

Hearing protection

Leather footwear

Incident energy exposures greater than 12 cal/cm2

Arc-rated clothing with an Arc Rating equal to or greater than the estimated incident energy (Note 1)

• Long-sleeve shirt and pants or coverall or arc flash suit (SR)

Arc-rated arc flash suit hood

Arc-rated gloves or rubber insulating gloves with leather protectors (SR) (Note 3)

Hard hat

Safety glasses or safety goggles (SR)

Hearing protection

Leather footwear

Source: National Fire Protection Association 70E Committee

The committee had strong opinions concerning the tables, but it reaffirmed the new format and put it into place for the 2015 edition of NFPA 70E. It also reaffirmed the deletion of the Prohibited Approach Boundary, although some committee members strongly wanted it back.

Another issue back from last cycle was changing the dc threshold from 50 V to 100 V. These issues (and a few more) generated some very lively discussions, which is actually good for the committee. These types of discussions made the NFPA 70E the document that it is today. None of us at NETA want a safety standard developed by a rubber stamp committee; rather, important issues should be discussed, and if needed, the merits and opinions debated completely and factually. This is an important safety standard, and all committee members feel strongly about making it the best it can be. And just to prove we were there, check out the photo of the 70E committee at the Schaumburg, Illinois, committee meeting.

2018 NFPA 70E Committee, Schaumburg, Illinois

Sometime around March 2016, the First Draft will be published on the NFPA website (www.nfpa. org/70e) under the Next Edition tab. The committee will vote on its actions, requiring a two-thirds majority to approve it. At this last meeting, votes to approve some actions were pretty close, even though only a 51% majority is needed.

Most of the PIs are from committee members. This is typical, but the committee needs to hear your voice. The next stage of the process is collecting any Public Comments, followed by the Second Draft meeting. The Public Comment period is open from when the First Draft is published on the NFPA website until May 16, 2016. We always hear from people in the industry how the 70E committee should change this or change that, and some of them have some really good ideas, but that is as far as it goes. The more input we have from the people using the 70E — especially from people within the NETA community — the better it will be.

Major changes made to Article 120, sections 130.2, 130.4, 130.5, 130.7, and others are noted in the tables. We also had influence on some key maintenance-related content, and the overall document has been reorganized to give better flow to the standard and make it easier to use. And even though changes were made with good intent, sometimes words have unintended consequences; that’s where our NETA Accredited Companies and Technicians can really help out.

Point out the areas of concern before they become part of this standard; take a few minutes to write public comments and submit them. And test before touch!

The miracle of the Swallows of Capistrano takes place each year at Mission San Juan Capistrano on March 19th, St. Joseph’s Day.

As the faithful little birds wing their way back to the most famous mission in California, the village of San Juan Capistrano takes on a fiesta air, and visitors from all parts of the world and all walks of life gather in great numbers to witness the miracle of the return of the swallows.

At dawn on St. Joseph’s Day, the little birds arrive and begin rebuilding their mud nests, which are clinging to the ruins of the Great Stone Church of San Juan Capistrano. The arches of the two-story, vaulted Great Stone Church were left bare and exposed, as the roof collapsed during the earthquake of 1812.

The Great Stone Church, said to be the largest and most ornate of any of the missions, now has a more humble destiny — that of housing the birds that St. Francis loved so well.

After the summer spent within the sheltered walls of the Old Mission in San Juan Capistrano, the swallows take flight again, and on the Day of San Juan, October 23rd, they leave after circling the Mission, bidding farewell to the Jewel of the Missions.

Source: http://www.missionsjc.com/tours/swallows/

Ron Widup and Jim White are NETA’s representatives to NFPA Technical Committee 70E (Electrical Safety Requirements for Employee Workplaces). Both gentlemen are employees of Shermco Industries in Dallas, Texas, a NETA Accredited Company. Ron Widup is CEO of Shermco and has been with the company since 1983. He is a Principal member of the Technical Committee on “Electrical Safety in the Workplace” (NFPA 70E) and a Principal member of the National Electrical Code (NFPA 70) Code Panel 11. He is also a member of the technical committee “Recommended Practice for Electrical Equipment Maintenance” (NFPA 70B), and a member of the NETA Board of Directors and Standards Review Council. Jim White is nationally recognized for technical skills and safety training in the electrical power systems industry. He is the Training Director for Shermco Industries, and has spent the last twenty years directly involved in technical skills and safety training for electrical power system technicians. Jim is a Principal member of NFPA 70B respresenting Shermco Industries, NETA’s alternate member of NFPA 70E, and a member of ASTM F18 Committee “Electrical Protective Equipment for Workers”.

You can count on us for specialized experience in healthcare, data center, office complex, and commercial acceptance and maintenance testing. Absolutely Power generation, petrochemical, oil & gas, and heavy industries also look to us for high demand services such as start-up commissioning, maintenance testing, shut-down and turnarounds, and breaker shop repair. Get started today.

Email: Alan Postiglione apost@absolutetesting.com

Primary

Hartford Steam Boiler Insurance Company has been collecting information on transformer failures for years and periodically issues reports on the causes of such failures. Table 1 represents a compilation of those study results for 1975, 1983, and 1998. Note that “Deterioration of Insulation” was the second most frequent cause of transformer failure in 1998. This article will focus on internal failures of transformers, with a focus on the chemical processes that can cause insulation deterioration as well as how overloading and moisture accelerate the degradation process.

Basically, insulation within a transformer consists of cellulose (or paper) and insulating oil. A large amount of research has looked at the factors that affect cellulose and mineral oil. Cellulose ages and degrades through three basic chemical processes:

oxidation, acid-hydrolysis, and pyrolysis. These processes are caused by the presence of oxygen, the presence of water, and operating at elevated temperatures. The result is a weakening of the cellulose’s mechanical and electrical integrity, as well as sludging and contamination of the insulating oil.

*Results of Hartford Steam Boiler Insurance Company studies on the causes of transformer failures.

Oxidation is defined as the interaction between oxygen molecules and all the different substances they may contact. Technically, oxidation is the loss of at least one electron when two or more substances interact. Those substances may or may not include oxygen. (Incidentally, the opposite of oxidation is reduction — the addition of at least one electron when substances come into contact with each other.) In a transformer, oil and paper degrade as a result of oxidation.

The most common insulating liquid used in transformers is mineral oil. Some transformer oils, referred to as uninhibited oils, possess a degree of natural protection against oxidation. However, mineral oil, which is known as inhibited oil, requires the addition of an antioxidant to protect against oxidation. For mineral oil, aging and oxidation are synonymous. The aging process begins slowly, as the antioxidants work to neutralize the harmful peroxides and radicals as they are formed. However, with time, the antioxidants decrease in quantity and the aging process increases exponentially. This leads to the formation of acids, aldehydes, ketones, esters, and eventually sludge (a mixture of long insoluble hydrocarbon molecules and particles). The process occurs in the presence of peroxides (unstable oxygen compounds) and free radicals and is accelerated by catalysts such as water and copper.

If allowed to continue, oxidized oil will continue to deteriorate and will transport contamination to the cellulose insulation within the transformer. Here the effects are much more serious. Transformer oil can be changed; unfortunately, cellulose cannot be changed. If the oil is not maintained, the condition of the cellulose will deteriorate to the point where the transformer has reached the end of its working life.

Cellulose degrades (oxidizes) much faster than oil because it contains oxygen within its molecular structure. The degradation process generates water, carbon dioxide, and furfurals, and is accelerated by external sources of oxygen, high temperature, and high levels of oil acidity. The water that is generated combines with dissolved moisture in the oil to further accelerate the degradation process. The end result is broken molecular chains, a lower degree of polymerization (DP), and loss of mechanical strength. In the absence of oxygen, decomposition occurs more slowly through the process of pyrolysis.

Acid-hydrolysis is the breakdown of the cellulose using H+ ions in water as a reactant.

In hydrolysis, a larger molecule, like molecules of cellulose, is broken down into simpler substances by the addition of water molecules. When this process is carried out in the presence of a small amount of acid, like that produced through the oxidation process, it is called acid-hydrolysis. The acid acts as a catalyst by providing H+ ions to facilitate the cellulose’s intake of water (H2O) molecules. To give an idea of the effects of water in the cellulose, it has been suggested that if the moisture content in cellulose doubles, transformer life expectancy is immediately halved.

Pyrolysis is the breakdown of the cellulose at elevated temperatures. Simply stated, the higher the temperature the cellulose operates in, the faster the cellulose will degrade. Operating temperature increases can be the result of operating in overloaded conditions, some type of failure or limitation in the transformer cooling process, or elevated ambient temperature. Any of these situations can result in elevated temperatures of cellulose. It has been suggested that a thermal increase of just 10o C will lead to cellulose lifetime being cut by over 50%.

The best way to combat each of these degrading processes is to monitor transformer health by establishing a transformer maintenance routine and performing periodic oil analysis.

The following should be monitored as part of regular transformer maintenance:

• Physical and mechanical condition. This should include an evaluation of the paint condition and cleanliness of the outside of transformer compartments and radiator cooling fins. Look at the LTC counter log and record the value. This inspection should also include a determination that no hindrance exists in getting air to the radiator cooling fins. Any suspected problem that could result in an oil leak or reduced system cooling should be recorded and brought to the attention of management for corrective action.

• Oil leaks and spills. Oil seepage from within the transformer typically appears as a discoloration of the painted surface around a bushing or penetration. All suspected oil leaks should be recorded and brought to the attention of management for corrective action.

• Correct operation of cooling fans, if applicable. Transformer cooling fans are typically controlled with thermostats, turning on and off based on a temperature setting. If the fans are not running, it should be noted with the as-found thermostat settings recorded. The system should then be exercised by adjusting the thermostat settings to cause the system to operate. With subsequent operation, the thermostat settings should be returned to the original settings with the as-left settings recorded. If the system does not operate, this condition should be recorded and brought to the attention of management for a repair of the system.

Examination of these indicators is also part of transformer maintenance:

• Transformer temperature. For an OA 55/65 Class Transformer, operating temperature limits of the windings are 55o C or 65o C (131o F or 149o F, respectively), dependent on the kVA ratings of the transformer. Determine if the sensor is for top oil or winding temperature. It should be noted that the top oil temperature is probably lower than the winding temperature. Also, note the high temperature indicator and reset with each inspection.

• Transformer pressure. This measures the pressure of the nitrogen blanket above the oil. The gauge usually indicates negative and positive pressure. The pressure can vary from slightly negative to slightly positive due to ambient temperature and operating conditions. For sealed transformers, the

pressure should always be maintained at a slightly positive pressure. This is indicative of a proper seal and also ensures that moisture from the air does not leak into the nitrogen-filled gap at the top of the transformer.

• Transformer oil level. There is usually a mark on the gauge that indicates the 25° C level, which is the proper oil level for the transformer at that temperature. Maintaining the proper oil level is extremely important because if the oil level falls below the level of the radiator inlet, natural circulating flow through the radiator will cease and the transformer will overheat.

The insulation system is typically evaluated by performing the following oil sample tests:

• Dielectric breakdown voltage. The dielectric breakdown voltage is a measurement of electrical stress that an insulating oil can withstand without failure. It is measured by applying a voltage between two electrodes under prescribed conditions under the oil. The dielectric test measures the voltage at which the oil breaks down, which is indicative of the amount of contaminant (usually moisture) in the oil.

• Moisture content. Oil moisture is measured in parts per million (ppm), using the weight of moisture divided by the weight of oil. Water can be present in oil in a dissolved form, as tiny droplets mixed with the oil (emulsion), or in a free state at the bottom of the tank holding the oil. Demulsification occurs when the tiny droplets unite to form larger drops, which sink to the bottom and form free water. When the moisture in oil exceeds the saturation value, there will also be free water precipitated from the oil in suspension or drops.

• Power factor. The power factor of insulating oil equals the cosine of the phase angle between an ac voltage applied and the resulting current. Power factor indicates the dielectric loss of the insulating oil, and thus, its dielectric heating. The powerfactor test is widely used as an acceptance and preventive maintenance test for insulating oil. A high power factor in service-aged oil indicates deterioration, contamination, or both, with moisture, carbon, or deterioration products.

• Interfacial tension. The interfacial tension (IFT) test is employed as an indication of the sludging characteristics of power transformer insulating oil. It is a test of IFT of water against oil, which differs from surface tension in that the surface of the water is in contact with oil instead of air. The attraction between the water molecules at the interface is influenced by the presence of polar molecules in the oil in such a way that the presence of more polar compounds causes lower IFT. The test measures the concentration of polar molecules in suspension and in solution in the oil, giving an accurate measurement of dissolved sludge precursors in the oil long before any sludge is precipitated.

• Acid neutralization number. The acid neutralization number, or acid number, is the amount of potassium hydroxide (KOH in mg) required to neutralize the acid in one gram of oil. It is indicative of the acid content in the oil. With service-aged oils, it is also indicative of the presence of contaminants, like sludge. The acidity test alone determines conditions under which sludge may form but does not necessarily indicate that actual sludging conditions exist. New transformer oils contain practically no acids. The acidity test measures the content of acids formed by oxidation. The oxidation products polymerize to form sludge, which then precipitate out. Acids react with metals on the surfaces inside the tank and form metallic soaps, another form of sludge.

• Color. The color of an insulating oil is determined by means of transmitted light and is expressed by a numerical value based on comparison with a series of color standards. It is recognized that color by itself could be misleading in evaluating oils for service quality. The primary significance of color is to observe a change or darkening of the oil from previous samples of oil from the same transformer. Noticeable darkening in short periods of time indicates either contamination or that arcing is taking place. A darkening color with no significant change in neutralization value or viscosity usually indicates contamination.

furanic acids

As the transformer ages, the sampling program should also include checking for the oxygen inhibitor level. Oxygen inhibitors should be in the oil at acceptable levels, which is typically in the 0.3% to 0.4% range. DBPC, 2,6-ditertrybutyl-paracresol, is the most commonly used antioxidant, but there are many types. As you monitor depletion rates, note the type and level for future reference. Additionally, furanic acids should be monitored when you have other indicators that the cellulose has degraded. When cellulose insulation decomposes due to overheating, chemicals are released and dissolve in the oil.

Transformer insulation is degraded by the presence of oxygen or water , and by operation at elevated temperatures.

er indicators that has ose insulation decomposes due to chemicals are released and dissolve

ical are known as ounds, acids, or furans. In no detectable furans are in the b). As the cellulose the indicate accelerated cellulose evels risk

These chemical compounds are known as furanic compounds, acids, or furans. In healthy transformers, no detectable furans are in the oil (<100 ppb). As the cellulose degrades, the furan levels will increase. Furan levels of 500 ppb to 1,000 ppb indicate accelerated cellulose aging; furan levels >1,500 ppb have a high risk of insulation failure.

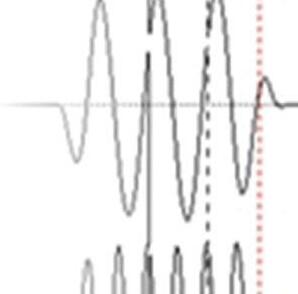

With regard to performing dissolved gas analysis (DGA) and using the results for evaluating

o dissolved analysis using the results for

cellulose and insulating oil degradation, the ratio of CO2/CO can be used as an indicator of the thermal decomposition of cellulose. The rate of generation of CO2 typically runs seven to 20 times higher than CO. Therefore, it is normal if the CO2/CO ratio is above seven. If the CO2/CO ratio is five or less, there is probably a problem. If cellulose degradation is the problem, CO, H2, methane (CH4), and ethane (C2H6) will also be increasing significantly. At this point, additional furan testing should be performed. If the CO2/CO ratio is three or under with increased furans, severe and rapid deterioration of cellulose is occurring, and consideration should be given to taking the transformer out of service for further inspection.

A Guide to Transformer Maintenance, S. Myers, J. Kelly and R Parish (ISBN-13 978-0939320004)

IEC 60076-14 ed 1.0 (September 2013) Power Transformers – Part 14: Liquid-Immersed power transformers using high temperature insulation materials.

Lynn Hamrick brings more than 25 years of working knowledge in design, permitting, construction, and startup of mechanical, electrical, and instrumentation and controls projects as well as experience in the operation and maintenance of facilities. He is a Professional Engineer, Certified Energy Manager, and has a BS in Nuclear Engineering for the University of Tennessee.

DTR® Model 8510 Key Features

• Stores test results in internal memory

• Measures PT/VT and CT turns ratios

• Displays turn ratio, excitation current, winding polarity and % deviation

• Includes DataView® analysis software

Quick Tester Model 8505 Key Features

• Detects open or shorted coils and capacitors

• Automatically identifies device as an inductor or capacitor

• Bright LED indicators and buzzer for L, C, open and short

National Field Services has opened two new locations – in Central Texas and on the Gulf Coast, giving us the power to serve you better. So now we can provide our world-class expertise to even more local markets in Texas. Our 24/7 responsiveness will be at work from our two new offices. So we can keep our customers’ critical systems always on. And it will be easier than ever for our certified technicians and engineers to come to your facility to take care of your needs. National Field Services handles everything from commissioning and start-up to disaster recovery. Ready to connect? Visit natlfield.com today.

Taiwan

+886.2.2835.9738 info@phenixasia.com

Switzerland

+41.61.383.2770 info@phenixsystems.com

35+ Years

Experience

ISO

Ideal for testing thermal, magnetic, and solid state relays, molded case circuit breakers and ground fault

Made for field testing. Models up to 75,000 Amps.

Features: Proven duty cycle Auto-jog and current-hold capabilities.

Mobile units offer: Manual or computer operation with numerous automated modes.

Precise, repeatable current pulses, minimal distortion. Current wave form display with WIN HC.

September brings chillier air, shorter days, and an opportunity for NETA Accredited Company members to gather at one of their regularly scheduled Board of Directors and Member meetings. This fall, meeting attendees gathered in along the Pacific shoreline to discuss the coming months of association business. PowerTest is right around the corner, and there are exciting things in the works when it comes to member services, communications, and the technical exam.

The Board of Directors is constantly assessing the strategic direction of the association, and assuring that the programs, services, and budget are in alignment with the vision for the future while adhering to the foundation of the past. NETA members enjoyed a long

technical exchange in the wake of many code committee meetings that also mark this season. There was also time for additional idea generation with regard to PowerTest and what tweaks can be made there to make it an even more excellent event.

Everyone also made time to share in fellowship over meals, cocktails, and outings around the city. If you have never been to Seattle – go! It is beautiful. If you have never been to a Member meeting, were just at this last one, or haven't been in a while – come! The next one will be in January 2016 in Key West, Florida, and we would love to see you there. Contact the NETA office for more details.

James R. (Jim) White is the Training Director of Shermco Industries, Inc., in Dallas, Texas. He is the principal member on the NFPA technical committee

“Recommended Practice for Electrical Equipment Maintenance” (NFPA 70B). Jim represents NETA as an alternate member of the NFPA Technical Committee “Electrical Safety in the Workplace” (NFPA 70E) and represents NETA on the ASTM F18 Committee “Electrical Protective Equipment For Workers”. Jim is an IEEE Senior Member and in 2011 received the IEEE/PCIC Electrical Safety Excellence award. Jim is a past Chairman (2008) of the IEEE Electrical Safety Workshop (ESW).

Power transformers have no moving parts (except for accessories such as fans, pumps, or LTCs), and yet, they are very complex electrical devices. This month’s Tech Quiz asks questions on general power transformer knowledge — some from the MTS, some not. Let’s see how you do:

1. Power transformer cooling designations underwent changes a few years ago. Match up the old designation with the new:

a. FA ONAF/ODAF

b. FOA ONAN

c. OA/FOA ODAF or OFAF

d. OA ONAF

2. Buchholz relays are used on transformers to detect:

a. Winding over temperature

b. Over pressure of tank

c. Change in oil temperature

d. Internal faults

3. Sudden pressure relays operate on a:

a. Rapid increase in main tank

b. Pressure set point in lbs/in2

c. Difference in pressure between main tank and tap changer tank

d. Rapid increase in conservator pressure

4. What type of sensing element can measure a transformer’s hottest-spot (winding) temperature directly?

a. Fiber optic cable

b. Thermocouples

c. Platinum RTDs

d. Oil well monitor

5. Hydrogen is often the primary gas used for field monitoring of combustible gases. Check all the answers that apply:

a. Hydrogen is the smallest molecule, so it passes through membranes when others won’t.

b. Hydrogen can be tinted to make it more visible, allowing easier detection by optical sensors.

c. Hydrogen is always present when combustible gases are generated.

d. Hydrogen has a distinct odor, allowing the use of olfactory detectors.

BY DON A. GENUTIS, Halco Testing Services

BY DON A. GENUTIS, Halco Testing Services

Generator health is one of the single most critical elements of a power-producing operation's ability to maintain a reliable revenue stream. These generators typically operate at medium voltage levels; thus, a high percentage of overall failures are attributed to insulation defects, as is often the case in any medium voltage equipment.

Statistics from IEEE and EPRI studies indicate that approximately 37% of generator failures can be attributed to stator insulation failure. Stator insulation deterioration can be tracked by regular partial discharge (PD) testing or continuous monitoring methods. The importance of monitoring the generator's insulation for PD activity — along with monitoring other common mode failure components such as bearing condition — is a widely accepted practice in North America. This article will briefly address the general application of multiple generator partial discharge sensors and then discuss a recent event where the sensors predicted an impending failure.

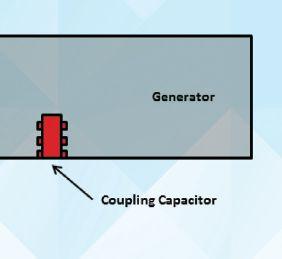

Permanent coupling capacitor sensors can be used to detect generator discharges by connecting a sensor to each bus phase at an accessible location near the generator. The coupling capacitors provide a means of obtaining consistent and calibrated signals. At least one generator monitor manufacturer also uses the generator's existing RTDs to detect PD.

Figure 1: Coupling capacitor shown far left only provides winding coverage to area circled in green, while the RTDs provide coverage to areas circled in blue. Collectively, the use of the coupling capacitor and RTD sensors provide much greater coverage than just the coupling capacitor alone.

Although the RTDs cannot always provide a calibrated signal, they can be useful for detecting PD deeper in the generator windings, as much as 60-70%, whereas the coupling capacitor typically can only see the first 15% of the windings (Figure 1).

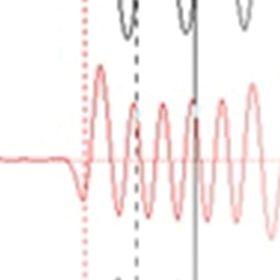

Since the ISO-phase bus can also discharge, an additional set of coupling capacitors should be placed on the bus further away from the first set of sensors to detect the direction of the arriving PD pulses via the time-of-flight method (Figure 2).

A more convenient and cost effective method is to use a set of high frequency CT sensors on the ISO phase ground straps to determine source origination (Figure 3).

Studying individual PD pulse characteristics such as frequency and polarity may assist in determining the likely physical discharge location and the type of discharge occurring.

A customer operating a large steam generator experienced a sudden high increase in Phase A PD magnitude discharge (Figure 4).

The high-frequency characteristics of the pulse indicated that the discharge was occurring near the sensors, and the ringing characteristics indicated a surface or interface discharge (Figure 5).

Figure 5: Typical Signal Pulse Displaying High Frequency Ringing Characteristics Indicative of Local Surface Activity

The polarity indicated that the PD source was originating from the ISO phase bus (Figure 6).

The diagnosis: early stages of surface tracking of Phase A ISO Phase insulator located near the vicinity of the PD couplers.

The engineering department planned an immediate outage, and the inspection revealed excessive moisture occurring in Phase A ISO Phase bus (Figures 7, 8, and 9), resulting in early stage surface insulator tracking. This was precisely the same conclusion as diagnosed by the analysis of the PD pulses. Simple repairs were conducted during the outage, and the generator was brought back on line, thereby averting a potential catastrophic failure.

Figure 8: Moisture Presence on ISO Phase Insulation Component

Figure 9: Insulator Moisture Accumulation and Early Stages of Tracking Damage Due to Discharge Activity and Corrosion Due to Nitric Acid Byproducts

Generator PD monitoring allows tracking of the insulation condition and can provide an early warning of impending failure, thus positively impacting reliability.

Don A. Genutis holds a BSEE from Carnegie-Mellon University. He has over 30 years of electrical testing experience. Don serves as President of Halco Testing Services based in Los Angeles, California.

Figures 1, 2, 6 courtesy of Dynamic Ratings © Dynamic Ratings Inc., all rights reserved.

Help Change the Electrical Safety Culture:

Participate in the Leading International Forum on Electrical Safety

March 7-11, 2016

600+ Attendees

Anticipated

15+ Countries

Learn from presenters that drive the industry standards

25+ Technical Papers

6 In-depth Tutorials

Network w/ committee members from NFPA 70E, CSA Z462, IEEE 1584

3 Receptions

Hospitality Suites

Return to work w/ actionable plans to improve your Electrical Safety Program

NETA has developed a new electrical testing standard called the ANSI/NETA ECS-2015 Standard for Electrical Commissioning Specifications for Electrical Power Equipment and Systems (NETA ECS).

No matter what type of industry sector you are in, when it comes to electrical power equipment, it is important to understand the processes and procedures that take place from a system’s initial concept to final acceptance and energization at your facility. Regardless of the industry — whether it is a steel mill, refinery, paper mill, electrical utility, data center, hospital, commercial building, etc., — all require the individual pieces of electrical equipment to interconnect with each other and work together as a system to assure safety and reliability.

Commissioning is the systematic process of verifying, documenting, and placing into service newly installed or retrofitted electrical power equipment and systems. Commissioning is critical for all new or retrofit installation projects to verify the correct system operation to the design, which contributes to the safe and reliable operation of the system.

NETA recognized that electrical commissioning has not been well defined in the industrial and utility markets, though a greater degree of documentation and guidance exists within the building and health facility sectors. This was one motivation for NETA to develop an electrical commissioning specification that can be applied on a global basis to many industries, and thus the NETA commissioning standard was developed and approved as a consensus-based standard.

A number of commissioning standards have been published to date.

• ASHRAE Guideline 0. Published by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), this standard defines the commissioning process for building systems. It presents best practices for applying whole-building commissioning to facilities.

• ASHRAE Guideline 202. Published by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), this guideline describes how to plan, conduct, and document the commissioning process for buildings and systems.

• NECA 90 – Recommended Practice for Commissioning Building Electrical Systems. Published by the National Electrical Contractors Association, this document describes the procedures for commissioning building electrical systems.

• NIBS Guideline 3 – Building Enclosure Commissioning Process BECx. Published by the National Institute of Building Sciences (NIBS), this standard describes a process that allows an owner to incorporate building enclosure commissioning into a project and is used in conjunction with the ASHRAE Guideline 0.

In addition to the above standards, a number of other commissioning standards can be found in reference to building systems, fire alarm systems, and health facilities. Some of the publishers are ASHRAE, NIBS, NECA, NFPA, ASHE, CSA, and ASTM.

All of the commissioning standards emphasize the importance of commissioning and using an independent third-party testing and commissioning company; however, a considerable difference of opinion exists regarding the definition of commissioning and the processes involved. The commissioning industry is continually evolving, and the commissioning process may involve multiple trades and systems. It is important for the Commissioning Agent to help determine and document the Owner’s Project Requirements (OPR) so they can be used in all stages of the project. The OPR is the focus of the commissioning activities and should include the applicable standards for the project. This could be one standard or multiple standards. The Commissioning Agent should be under direct contract to the owner and have a direct line of communication to the owner.

The commissioning standards currently available are specific either to a business sector or to equipment type. The ANSI/NETA ECS was not developed to replace any of the existing standards. Rather, it was developed for use on any new or retrofit electrical installation projects and can be applied on a global basis to many industries. It describes the commissioning process and the tasks to help the commissioning team develop, execute, and document the commissioning process for electrical power equipment. The ANSI/NETA ECS is a commissioning standard specific to electrical power equipment and systems. It can be used alone or in conjunction with other applicable commissioning standards. In comparison to other available standards, the ANSI/NETA ECS has

unmatched detail of the commissioning process for electrical power equipment.

As today’s systems become more complex, the need for standards, processes, plans, and documentation is increasingly important for commissioning personnel. NETA recognized the need for a commissioning standard specific to electrical power equipment and published the ANSI/NETA ECS Standard for Electrical Commissioning Specifications for Electrical Power Equipment and Systems. NETA is currently working with other standard organizations to define the commissioning process and align the standards. Many of the other standard developers recognize NETA’s efforts and reference the ANSI/NETA documents in their publications.

By defining the commissioning process, the commissioning standards will help guide the owner and the commissioning team to work together to develop and execute the commissioning plan. Note that the commissioning work starts early in the project and continues throughout the project. Fundamental documents such as the OPR are valuable tools that should be the focus of commissioning tests. All applicable commissioning and testing standards should be used together to accomplish the commissioning project.

Regardless of the system complexity or size, create a commissioning team early in the project

(ideally in the pre-design stage) and include the applicable commissioning standards. If the system has electrical equipment, one would certainly want to include the ANSI/NETA ECS Standard for Electrical Commissioning Specifications for Electrical Equipment and Systems, since the systems are complex and require specialized personnel to perform the inspections, tests, and commissioning. Testing and commissioning personnel should be part of an independent third-party organization that is selected based on its certification, experience, knowledge, and specialization. The commissioning agent should be under direct contract to the owner and have a direct line of communication to the owner.

Understanding the full scope of commissioning activities is the first step in obtaining the greatest value of the commissioning process and assuring the safe and reliable performance of your system.

Lorne Gara is a Technical Manager for Orbis Engineering. He provides technical support for the engineering, field services, and automation departments of Orbis and many of its clients. Gara has a wide range of experience in engineering, commissioning, maintenance, fault analysis, and the startup of utility and industrial power systems across North America. He has extensive experience with protective relay setting development, commissioning, and testing of protection and control systems.

National Field Services, a NETA-accredited electrical testing company, is now offering training courses on a range of safety and technical topics at our National Training Center in Lewisville, Texas. Our instructors can also conduct most courses at your facility, on your schedule. Find our Course Catalog and more information at natlfield.com/training or contact Training Program Manager Steve Newton at steve.newton@natfield.com or 469-312-1230. 800-300-0157 natlfield.com/training

Relevant information the electrical power systems industry, from testing procedures and troubleshooting to encountered in the field. It’s real world learning at your fingertips.

Discover page after page of comprehensive, componentspecific, technical resources for both training and reference purposes.

The Handbooks bring together a collection of over of the best articles from past issues of NETA World Journal and the most well received technical presentations from NETA’s PowerTest conferences.

$195* For the 13 volume set $15* For each issue

For more information on the NETA Handbooks or other NETA publications visit the NETA ookstore at www.netaworld.org or 888-300-6382 (NETA)

* Additional cost for shipping and handling

Grounding protection for electrical workers depends on both good practice and proper protective equipment and materials. Fortunately, standards covering both areas have been written and published. Carelessly rigged protective equipment may not carry sufficient current, offer too high a resistance, burn open, or subject a worker to numerous other dangerous conditions. A prime authority in describing and specifying safe grounding equipment is The American Society for Testing and Materials (ASTM), Committee F-18, Electrical Protective Equipment for Workers, which is responsible for ASTM Document F-855, Standard Specifications for Temporary Protective Grounds to Be Used on De-energized Electric Power Lines and Equipment.

A common piece of protective equipment is the grounding jumper, which is designed to safely divert fault current by means of a continuous low-impedance path around the worker. Personal protective grounding jumpers are made up of appropriate lengths of suitable copper grounding cable with mechanically compatible ferrules and clamps at each end. Note that simply applying what is conceived as a dead short across a prospective voltage gradient does not constitute an adequate protective ground. It is instructive to reconsider a protective jumper’s current, which includes the surface contact resistance between the clamp and the conductor being jumpered. (Editor’s note: See the previous article in this series, NETA World Journal, Fall 2015.) Both the clamp and the jumper wire have a resistance, as does the second clamp and surface contact resistance at the other end.

Even though these individual resistances are very small, they can add up to a significant voltage drop at rated short-circuit duty. They do this by creating an equipotential zone, with grounds applied in such a manner that the employee’s hands, feet, and body are at the same potential as the equipment worked upon.

Design, installation, and assembly criteria for equipotential grounding jumpers:

• Must have sufficiently low resistance.

• Be capable of conducting maximum fault current, which could occur from the circuit or equipment becoming energized from any source, and will not burn open under the stress of maximum current flow, thus leaving the worker unprotected.

• Have clamp terminations suitable for conducting maximum fault current as well

as providing a mechanical connection that can withstand the forces generated by electromagnetic induction.

• Use minimum time and preparation for installation.

• Cover a wide range conductor sizes, buss bars, ground wires and ground rods, and structural steel.

• Be easy to apply and amenable to all prospective field conditions.

grounding and what may be considered traditional jumpering is illustrated in Figures 1, 2, and 3. If the worker is separately grounded in parallel with the jumper (Figure 1), the difference between normal body resistance and that of the jumper is substantial. Such an arrangement provides a path for induced voltage dissipation, and the circuit can clear a breaker. But the worker can still develop a potentially fatal voltage across the body, as RG2 — the resistance of the worker’s ground return path — exceeds that of the jumper, RG3 (Figure 2).

During installation, the ground-end clamp is connected first. This assures there is no time during installation, however brief, in which the operator could become the lowest-resistance ground path.

Similarly, the conductor-end clamp should be connected and disconnected with hot-line tools, using sticks of appropriate length for the system voltage, in the event that the conductor becomes live during connection or disconnect. However, in many utilization and low-voltage distribution systems, it is physically impossible to use hotline tools for application of grounds. Therefore, additional shock and arc protective equipment are imperative for worker protection.

An equipotential zone is created when grounds are situated such that the hands and feet of the worker are kept at the same potential. The worker has the same ground return path as the grounding conductor rather than a parallel path of differing potential. The difference between equipotential

The difference in equipotential jumpering is that only one ground return path (RG3) exists (Figure 3). In this case, when the circuit is inadvertently energized, the worker and the grounding jumper are truly in parallel. The return circuit does not employ a separate path through the earth, and therefore, does not include the worker’s body resistance. Rather, the combination of the low resistance of the grounding jumper and the relatively high body resistance of the worker in the same grounding path produces a very low voltage drop across the worker. This technique is commonly referred to as Single Point Grounding. The voltage

drop across the worker becomes a function of fault current through the personal protective jumper and can be determined by the equation:

Vworker = R jumper x I jumper

Typical equipotential grounding techniques are illustrated in Figure 4 and Figure 5.

As mentioned, the successful accommodation of maximum fault current by the grounding jumper is critical in maintaining this protection. Accordingly, personal protective grounding

jumpers must be tested and maintained in adequate working condition. Such jumpers can be subject to considerable electrical stress during fault events, in addition to the usual physical stresses associated with installation and removal. Mere visual inspection and assumptions about internal conditions are not enough to ensure that the jumper is fully protective of the worker’s safety. It should be electrically tested for low impedance to limit voltage drop on the worker. Testing should be done with current injection of the continuous rating of the conductor. Voltage drop of the grounding jumper can be calculated with the formula:

I test /I sca = V test /V sca

I test is the continuous current rating of the grounding conductor jumper. Isca is the maximum available short circuit current of the system where applied. Vtest is the measured voltage drop during the test. V sca is the calculated voltage drop during a fault condition.

It is also recommended that an infra-red (IR) scan of the jumper is performed under rated load current. This will reveal if any “hot spots” or areas of weak bonds or localized high resistance exist that might fail and burn open under the stress of a fault condition. Another valuable test is a low-resistance ohmmeter test with at least 10 amps. The test result is compared to a maximum acceptable value for the rating of the jumper.

Although not all equipment is required to be grounded, it is an industry-accepted recommendation that work on de-energized equipment and circuits is performed with visible protective grounds and jumpers in place at the site. Industry-standard procedures for the placing and removing of such grounds have been devised. Remember that these are generic and not intended to replace specific working practices for particular industries.

Step 1: De-energize the line in accordance with procedures. Use a documented procedure to be certain that the circuit or equipment has been de-energized and isolated from all sources of hazardous energy.

Step 2: Test the circuit for voltage. Don’t assum that the circuit has been de-energized just becau it’s been turned off. Other sources of energy, such as induction from nearby circuits, can produc injurious or lethal shocks.

Step 3: Clean connections. Remember, Singl Point Grounding is effective because the worke body is in parallel with an extremely low resistanc to ground. To maintain that low resistanc extraneous resistances from corrosion and di should be scrupulously eliminated.

Step 4: Apply ground-end clamps first, and remove them last.

Step 5: Conductor-end clamps must be applied and disconnected by hot sticks of adequat rating and length.

atcle thssees.

Step 6: Remove in reverse order from installation. The details of these six steps will be described and elaborated, and various extraneous sources of dangerous voltages — such as induction, static, capacitive and electromagnetic coupling, and other dangers — will be dealt with in the last in this series.

Jeffrey R. Jowett e is a Senior Applications Engineer for Megger in Valley Forge, Pennsylvania, serving the manufacturing lines of Biddle, Megger, and multi-Amp for electrical test and measurement instrumentation He e holds a BS in Biolog y and Chemistrry y from Ursinus College. He was employed for r 22 y years with James G. Biddle Co. which became Biddle Instruumennts and is now Megger.

ource: AVO Training Institute, Dallas, Texas

NETA certified experts at Electrical Reliability Services will keep you in perfect balance. To ensure the reliability of your electrical power, you have to balance the need to reduce maintenance costs with the need to perform regular maintenance. Only the team from Electrical Reliability Services delivers cost-effective services and system expertise to keep you up and running 24/7.

Comprehensive Electrical Testing and Maintenance

Commissioning and Startup Services

Engineering Services

Power System and Coordination Studies

Predictive and Preventive Maintenance

Partial Discharge Testing and Monitoring

24/7 Emergency Service

Ensuring the reliability of your electrical distribution system.

As the leading independent electrical testing, maintenance, and engineering service company, you can rely on Emerson’s High Voltage Maintenance to exceed your electrical equipment performance goals. From testing for problems that could disable your system, to complete turnaround execution, you’ll quickly understand how we are your single source solution for all of your electrical reliability needs. With a service geography across the Midwest and Eastern Seaboards, our service team puts experienced professionals where and when you need them.

BY SCOTT BLIZARD,

BY SCOTT BLIZARD,

Performing a condition analysis or maintenance on a power transformer and auxiliary devices is a hazardous task that requires an experienced individual with a solid ability to identify potential hazards and mitigate risks.

Condition analysis of a power transformer may be performed using methods and products designed to test and diagnose the equipment when it is operating, such as infrared survey, partial discharge detection equipment, and online oil analysis. The Personal Protective Equipment (PPE) required should be appropriate and adequate for all tasks performed.

This article is an overview of some of the potential hazards of a power transformer and various means of safeguarding as well as mitigation of those hazards. This article does not include every potential hazard, but rather, explores some potentially hazardous situations that can occur while performing work on a power transformer and auxiliary equipment. Additional hazards may exist, depending on the type or condition of the equipment. Take all procedures and instructions seriously, and verify that the instruction or equipment operation and maintenance manuals used are for the correct equipment. Check for and identify potential hazards prior to beginning every task by using a Pre-Job Brief worksheet.

Improper Lock Out/Tag Out (LO/TO) is a major contributing factor to injuries caused by power

transformers and auxiliary devices. Controlling hazardous energy is essential, and many forms of energy may be involved. To determine the proper LO/TO procedures, always refer to the appropriate OSHA regulation or required procedure, such as 29 CFR 1910.147 and .333, as well as manufacturer instructions. Electricity is the most obvious hazardous energy source.

Electrically de-energize the power transformer and auxiliary devices from their primary energy source and ensure the equipment is disconnected from all sources of power, both ac and dc, if applicable. Once de-energized, verify that the equipment is at a zero energy state using the manufacturer’s approved method. Verify the accuracy of the detection or voltage measuring device against a known source, check for zero energy on the de-energized equipment, and then test the detection equipment against a known source again. This will verify that the detection meter used was functioning properly during the initial check. Testing for voltage will require its own level of PPE, depending both upon the voltage level and arc-flash hazard level and test procedures per NFPA 70E 2015 — Standard for Electrical Safety in the Workplace or OSHA 29 CFR 1910.269 — Electric Power Generation, Transmission, and Distribution regulation.

Electrical energy isn’t the only energy that requires LO/TO. Devices such as motoroperated switches and circuit breakers and others may contain a large amount of mechanical energy. This energy must be dissipated prior to servicing the equipment or serious injury could occur. Once the energy has been discharged or dissipated, LO/TO the source of the stored energy, if feasible. Ensure that remote operating handles are tagged in a local or manual mode. This will prevent someone from inadvertently operating the equipment.

Certain types of power transformers may also pose a chemical hazard; take caution with gases, chemicals, and liquids. Use proper containment of liquids (e.g. spill containment pads) and address environmental concerns. Ensure compliance with all owner, state, and federal regulations. Beware of units containing Polychlorinated Biphenyls (PCBs) or other hazardous fluids. When working on such units, follow appropriate state and federal guidelines for fluid handling and disposal, and avoid skin contact.

Some cleaners may pose a respiratory and skin irritant if used in enclosed areas or on bare skin. Gain knowledge of the material and check the applicable Safety Data Sheet (SDS) to identify any potential health effects from its use. Once again, proper PPE is necessary for using some cleaners; for example, nitrile gloves, safety glasses, face-shield, and even respiratory protection may be needed.

Transmission, and Distribution regulation, or is it a commercial entity or space regulated under OSHA 1910.146 (permit-required confined spaces regulation)? These OSHA regulations have different requirements, depending on the location of the space and its hazards.

OSHA has created a flow chart to help with that determination, located within OSHA 1910.269 Appendix A. This flow chart is shown in Figure 1 and can also be viewed at http://tinyurl.com/ p329zxo.

Figure 1: Appendix A-5 to §1910.269 — Application of §§1910.146 and 1910.269 to Permit-Required Confined Spaces

When performing the visual inspection, mechanical inspection, maintenance, or repairs on a power transformer, personnel may be required to enter the actual tank. Entering into a confined space requires the entrant to be aware of the conditions within that space. The entrant needs to first ask: Is this confined space located at a facility regulated by the OSHA 1910.269 Electric Power Generation,

To answer the questions on the flow chart, the entrant must know the following from the OSHA regulations.

1. OSHA 1910.146(b) defines a confined space.

a. “Confined space” means a space that:

(1) Is large enough and so configured that an employee can bodily enter and perform assigned work;

(2) Has limited or restricted means for entry or exit (for example, tanks, vessels, silos, storage bins, hoppers, vaults, and pits are spaces that may have limited means of entry.);

(3) Is not designed for continuous employee occupancy.

2. OSHA 1910.146(b) describes when the confined space requires a permit to enter.

a. “Permit-required confined space (permit space)” means a confined space that has one or more of the following characteristics:

(1) Contains or has a potential to contain a hazardous atmosphere;

(2) Contains a material that has the potential for engulfing an entrant;

(3) Has an internal configuration such that an entrant could be trapped or asphyxiated by inwardly converging walls or by a floor which slopes downward and tapers to a smaller cross-section;

(4) Contains any other recognized serious safety or health hazard.

3. The entrant must know if the work to be performed falls under the scope of the 1910.269 regulation — put simply, if that work is conducted during the operation and maintenance of electric power generation, control, transformation, transmission, and distribution lines and equipment. Specific information on that definition may be found in all of 1910.269(a)(1).

4. The entrant must also determine if, under 1910.269, the space is considered an “enclosed space.”

a. Enclosed space: A working space, such as a manhole, vault, tunnel, or shaft, that has a limited means of egress or entry, that is designed for periodic employee entry under normal operating conditions, and that, under normal conditions, does not contain a hazardous atmosphere, but may contain a hazardous atmosphere under abnormal conditions.

b. Note to the definition of “enclosed space”: The Occupational Safety and Health Administration does not consider spaces that are enclosed but not designed for employee entry under normal operating conditions to be enclosed spaces for the