Megger's new SPI225 is the smallest primary injection test system in its class, able to output up to 2,000 A of regulated current to test 225 A circuit breakers. This groundbreaking unit is the first on the market to eliminate variac control for precise digital current regulation. The SPI225 provides a huge library of manufacturer time curves for automated testing of circuit breakers. It complies with NEMA AB-4, NMAC BreakerMaintenanceVol. 3 andNETAtestingguidelines.

'Tm concernedthatweare toofocusedon compliance rather than thinkinganddoingthe right thing. "

Thesearewords spoken byan electric utility executive at the inaugural Modern Solutions PowerSystem Conference sponsored bySchweitzer EngineeringLaboratories, Inc. in Chicago inJune 2012. As one looked across the ballroom, heads nodded in agreement amongthe group ofseveral hundred conferencegoers. Alivelydiscussion led to aconsensus: The oftenweakrelationship between compliance activities andreliabilityis aproblem facing not onlyutilities, butindustryas well, and itdoesnot appear tobe gettingbetter.

KarlZimmerman, SchweitzerEngineering Laboratories, Inc.

7 President's Desk

DavidHuffman, Power Systems Testing Co. NETA President

62 Electrical Safety and Reliability in Substations - Current Transformer Testing Has an Essential Role

Dennis K Neitzel, AVO TrainingInstitute, Inc.

Diego M Robalino, Megger North America

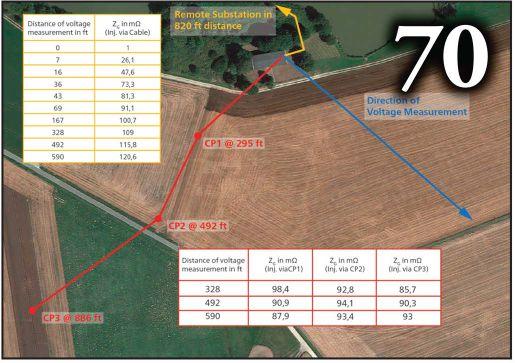

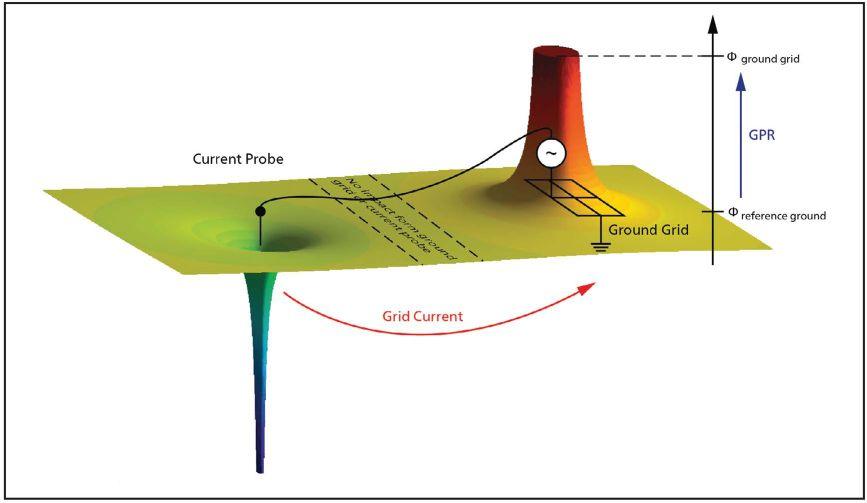

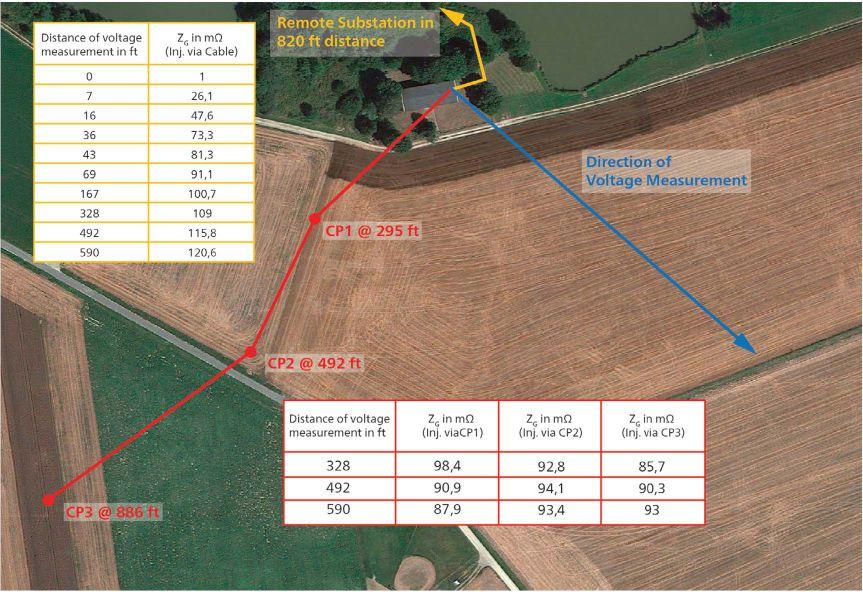

70 Measurements AtLargeGrounding Systems

MoritzPikisch, OMICRONElectronics Corp. USA

Ron

High-Voltage Substations

jim White, Shermco Industries 18 No-Outage Corner

Tracking Down TEV Switchgear Signals

UsingTime ofFlightTechniques

Don A. Genutis, Halco Testing Services

29

Lynn Hamrick, Shermco Industries

Paul

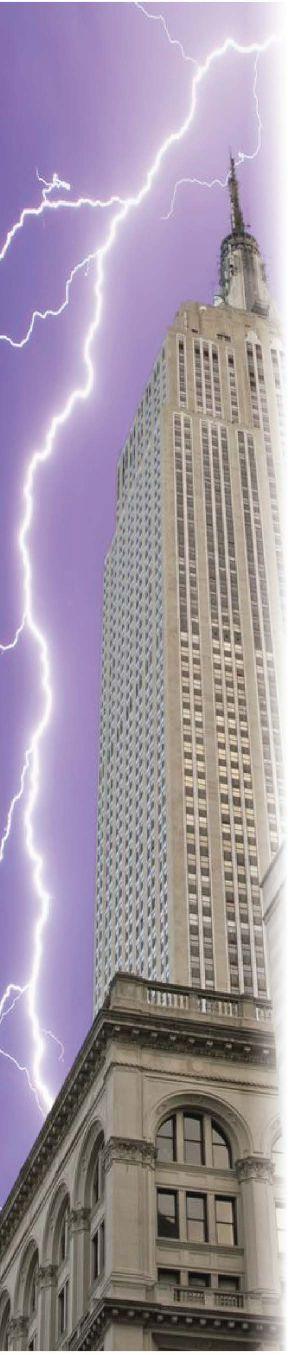

A Look at the Basics ofLightning Protection

jeffjowett, Megger

78 BridgingTheGap: UsingTechnologyTo Capture The Old And Encourage The New joe Barrios andKatie Scarlett Reyes, Tony Demaria Electric, Inc.

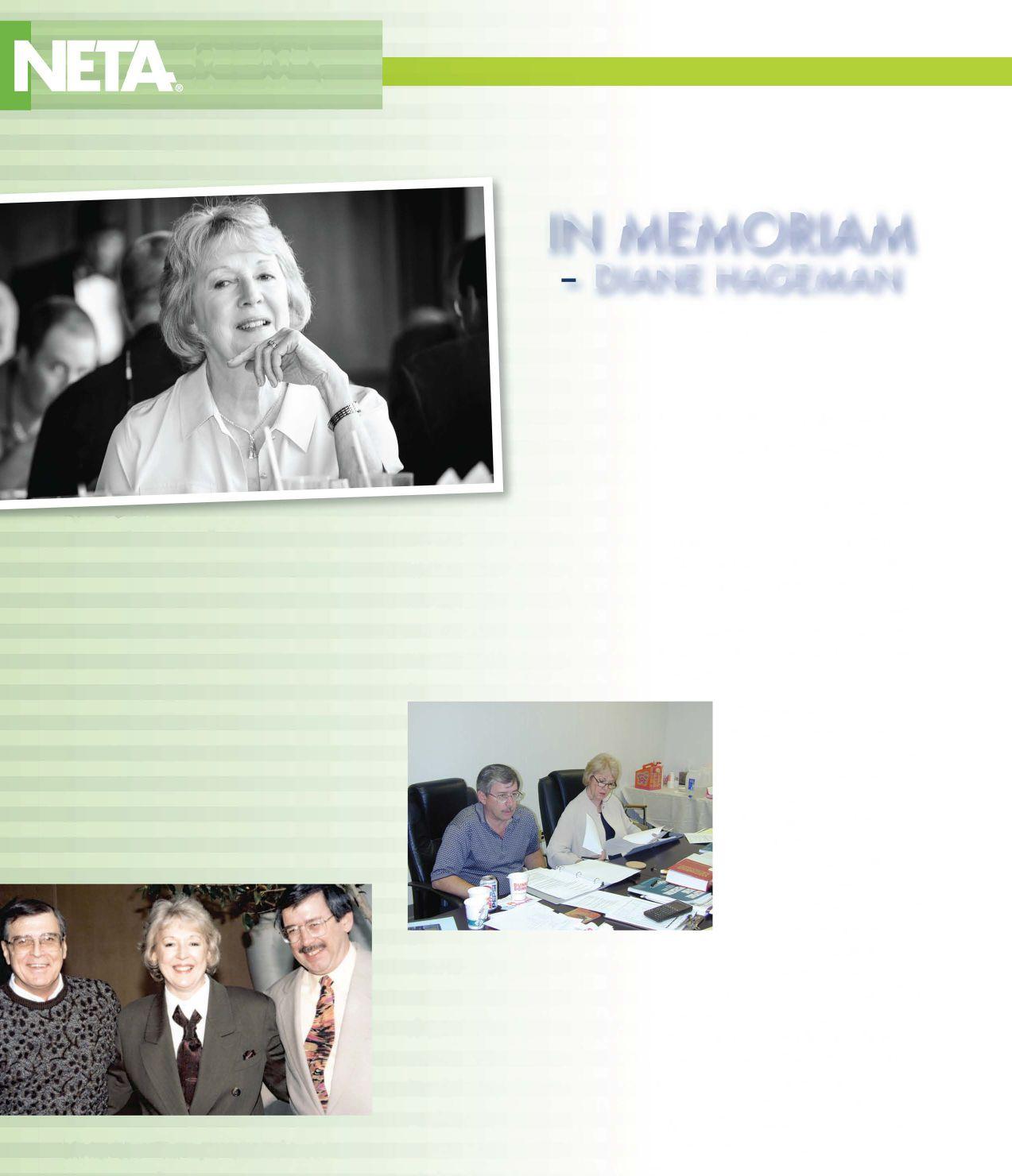

48 In Memoriam- Diane Hageman Resa Pickel, PRITService, Inc.

Kristen Wicks, NETA

Keep Your Eye On the Quiet Ones 2015 NETA OutstandingAchievementAward

Kristen Wicks, NETA

The Zimmerman Theorem: Science + Music + Faith = Happiness 2015 NETAAlliance Recognition Award

Kristen Wicks, NETA

Kristen Wicks, NETA

Sentinel Power Services, Inc. as a

andAlliance Partners Gather in Music City jill Howell, NETA

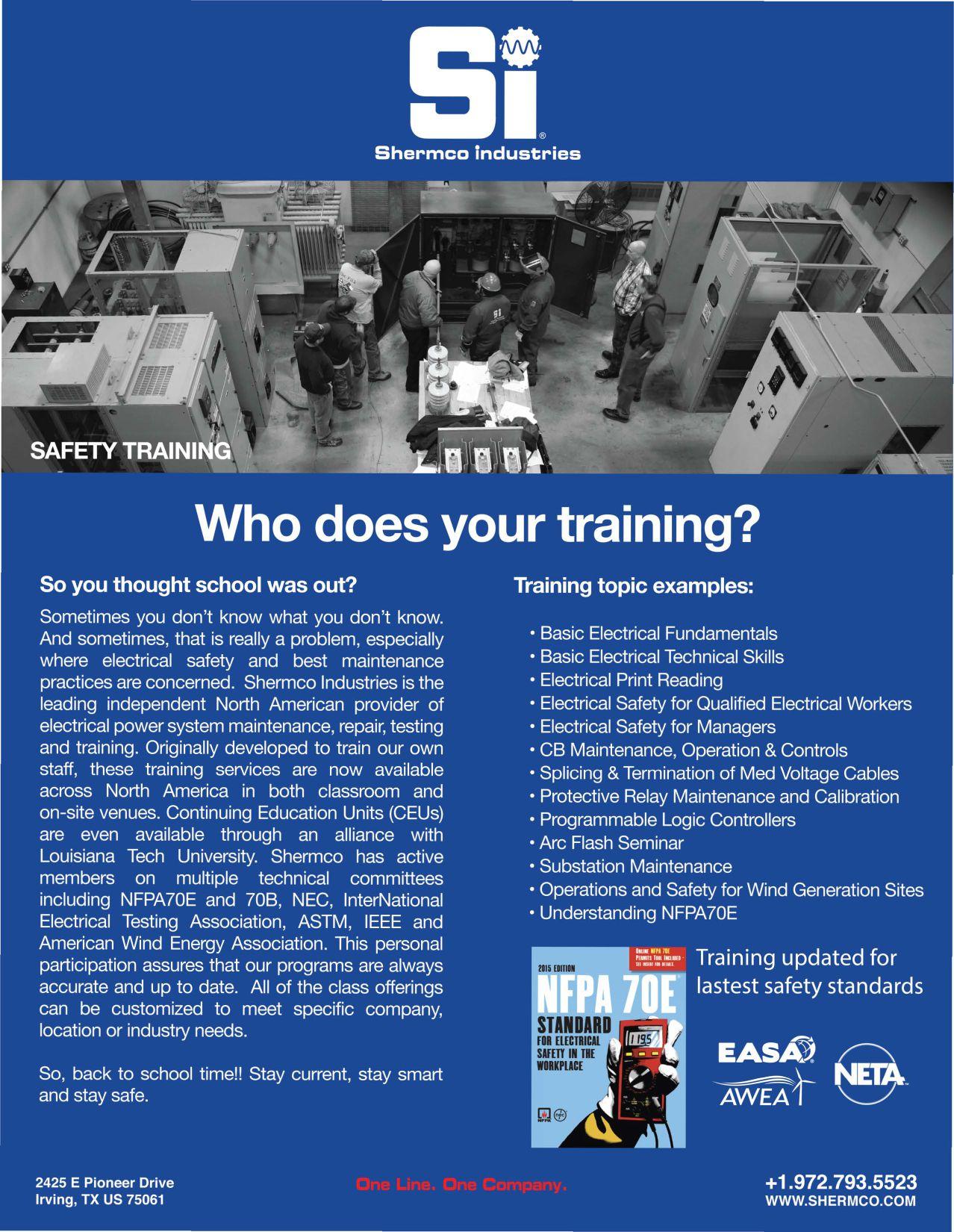

is your Biggest Training Challenge? And WhatAre You DoingAbout It? Ron Widup, Shermco Industries

Handheld PDetector

AilS Sensors in one kit

Phase Resolved PRPS

Analyze PD in real time

Smart PD recognition

RFID tagging

16G On-BoardData

Wireless sensors

Multi-channel

High Resolution

Time of Flight, Waveform

Innovative Software

PD Localization

Specialized apps for:

Cable, Transformers, GIS

Patented Signal Separation

Permanent andTemporary

Internal and External UHF

HFCT, Acoustics

Retro Compatible

Intelligent Diagnostic Server

Economical Cost

Cables, Transformers, MV, GIS, Substations

Engineering Support

PD Commissioning

Cable PD Mapping

Substation PD mapping

In-tank localization

Switchgear, GIS

Cables/terminations

Transformers

OfflineTan Delta/ VLF

Continuous training and support from our factor) in San Jose, CA Case Consulting

25 years of R&D

3050 Old Centre Avenue, Suite 102

Portage, Ml 49024

Toll free: 888.300.NETA (6382) Phone: 269.488.NETA (6382) FAX: 269.488.6383 nera@neraworld.org www.netaworld.org

EXECUTIVE DIRECTOR: jayne Tanz, CMP

NETAOfficers

PRESIDENT: David Huffinan, Power Systems Testing Co.

FIRST VICE PRESIDENT: Ron Widup, Shennco Industries

SECOND VICE PRESIDENT: jim Cia/dea, Three-C Electrical Co., iNC.

SECRETARY: Mose Ramieh, Power & Generation Testing, Inc.

TREASURER: john White, Sigma Six Solutions

NETABoardofDirectors

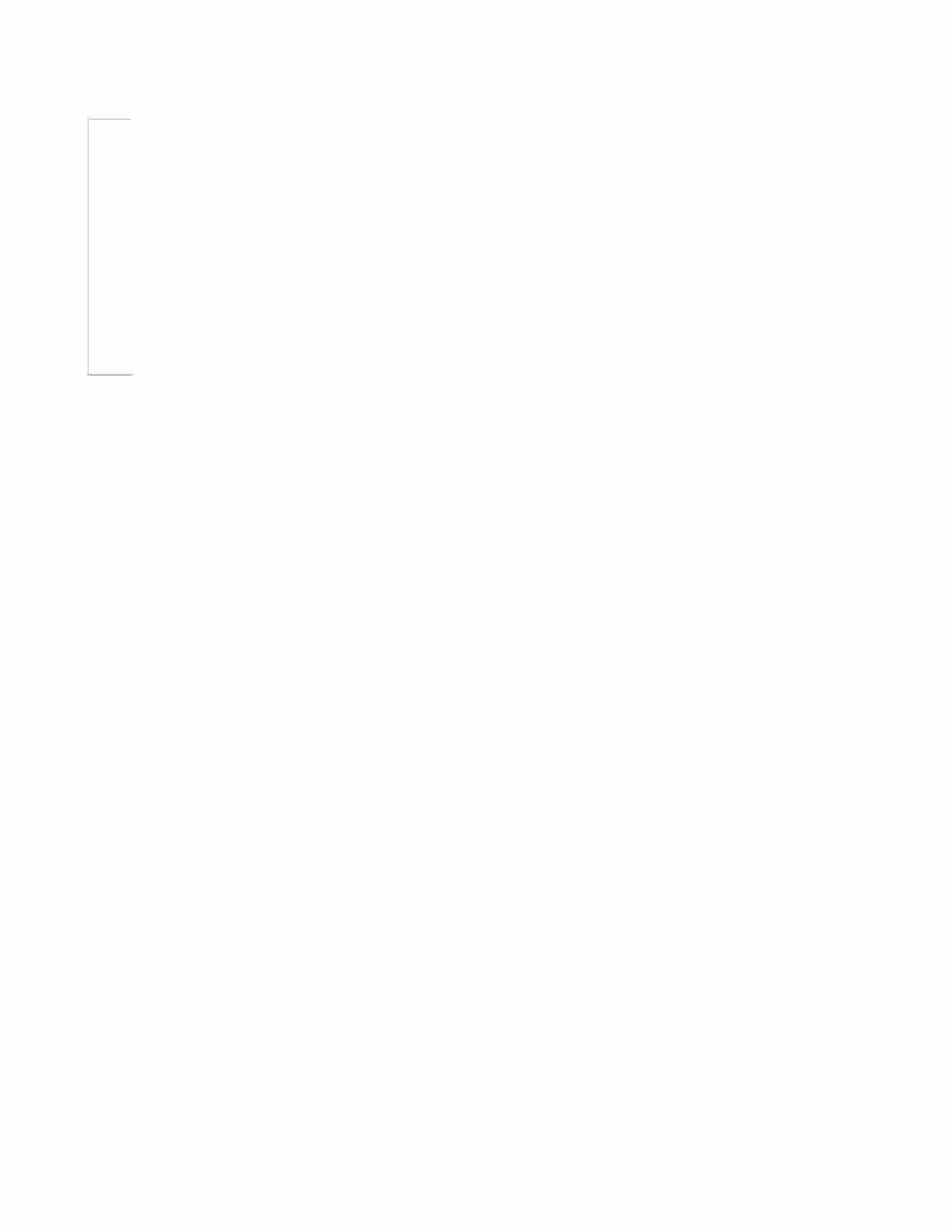

KenBassett {Potomac Testing, Inc.)

ScottBlizard {AmericanElectrical Testing Co., Inc.)

Jim Cialdea {Three-C Electrical Co., Inc.)

Lorne Gara {Orbis Engineering Field Services, Ltd.)

Roderic Hageman (PRIT Service, Inc.)

David Huffinan {Power Systems Testing)

AlanPeterson {UtilityService Corporation)

Mose Ramieh {Power & Generation Testing, Inc.)

Bob Sheppard {Southwest Energy Services, LLC)

john White {Sigma Six Solutions)

Ron Widup {Shermco Industries)

NETAWorldStaff

TECHNICAL EDITOR: Roderic L. Hageman

ASSOCIATEEDITORS: Resa Pickel

MANAGING EDITOR: jayne Tanz, CMP

ADVERTISING MANAGER: Laura McDonald

DESIGN AND PRODUCTION: Hour Custom Publishing

NETACommitteeChairs

CONFERENCE: Ron Widup; MEMBERSHIP: KenBassett; I'ROIIOllONS/MARKETlNG: ScottBlizard; SAFETY: ScottBiizardandjim White; TECHNICAL: Alan Peterson; TECHNICAL EXAM: Ron Widup; CONTINUING TECHNICAL DEVELOPMENT: David Huffinan; TRAINING: Kerry Heid; FINANCE: john White; NOMINATIONS: Alan Peterson; STRATEGY: Mose Ramieh; ALLIANCE PROGRAM: jim Cia/dea

©Copyright 2015, NETA

NETAWorldis published quarterly by the InterNational ElectricalTestingAssociation. Opinions, views and conclusions expressed in articles herein are those ofthe authors and not necessarily those ofNETA. Publication herein docs not constitute or imply endorsement of any opinion, product, or service by NETA.itsdirectors, officers, members, employees or agents {hcrein"NETA").

All technical data in this publication reflects the experience ofindividuals using specific tools, products, equipment and components under specific conditions and circumstances which may or may not be fully reported and o\·cr which NETA has neither exercised nor reserved controL Such data has notbeen independently tested or otherwise verified by NETA.

ENGINEERING:

NETA MAKES NO ENDORSEMENT, REPRESENTATION OR WARRANTYAS TO ANY OPINION, PRODUCT OR SERVICE REFERENCED OR ADVERTISED IN THIS PUBLICATION. NETAEXPRESSLYDISCLAIMS ANYAND ALL LIABILITYTOANY CONSUMER, PURCHASER OR ANY OTHER PERSON USING ANYPRODUCT OR SERVICE REFERENCED OR ADVERTISED HEREIN FOR ANY INJURIES OR DAMAGES OF ANY KIND WHATSOEVER, INCLUDING, BUT NOT LIMITED TO ANYCONSEQyENTIAL,PUNITIVE,SPECIAL,INCIDENTAL,DIRECT OR INDIRECT DAMAGES.NETAFURTHERDISCLAIMSANYAND ALL WARRANTIES, EXPRESS OF IMPLIED, INCLUDING, BUT NOT LIMITEDTO,ANYIMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

ELECTRICAL TESTINGSHALL BE PERFORMED ONLYBYTRAINED ELECTRICAL PERSONNEL AND SHALL BE SUPERVISED BY NETACERTIFIED TECHNICIANS/ LEVEL Ill OR IV OR BYNICET CERTIFIED TECHNICIANSIN ELECTRICAL TESTINGTECHNOLOGY/LEVEL Ill OR IV.FAILURETOADHERE TOADEQyATE TRAINING,SAFETYREQyiREMENTS, AND APPLICABLE PROCEDURESMAY RESULT IN LOSS OF PRODUCTION, CATASTROPHICEQyiPMENT FAILURE, SERIOUS INJURYOR DEATH.

This issue ofthe NETA Worldjournaladdresses challenges related to working in highvoltage substations. Generallydescribed as operatingat 138 kVand above, these stations have uniquetesting, maintenance, and safetyrequirements. I recall being trained in these requirements, and itwas a real eye-opener. Various pieces oftest equipment mayhave problems with the electric fields, the operatingvoltages are higher than manyofus are familiarwith, and the sheer size ofthe equipmentpresents its own challenges. I hopeyou find this issue informative and educational.

I also hopeyourlocal weather has improved. Much ofthe country has had an unpleasantwinter, to saythe least. Perhaps moving forward, things will be a little more normal. Badweather only adds to safety issues faced in the field.

With mytwoyear term coming to an end as ofMay31, 2015, this is myfinal message for the foreseeable future. It's been an honor and a privilege to beyour president. With such agreatpresident serving before me, I hope I metyour expectations. Over the lasttwoyears, we've increased membership, added online training modules, published updated editions oftheANSI/NETAstandardsaswell as a brand new one for electrical commissioning, and held two record-breaking conferences. For my part, it's been an excitingtime.

I wishyouwell, and thankyou for the opportunity to serve. As always, be safe and bevigilant out there.

Sincerely,

David Huffman President InterNational ElectricalTestingAssociation

Oneofthethingselectricalworkersseemtostruggle withisassessing theriskassociatedwithaparticulartask.Wecanidentifyandquantify the hazard well enough, but risk seems to be a vague concept that has no real substance. In actuality, we assess risk constantly. Every time westartupour carto drivesomewhere, crossthestreet, ridein an airplane, shoot a round ofgolf, or ski down the black diamond slope, we assess the risk associated with that task- we just don't perceive it that way.

When NFPA 70E directs us to assess the risk associated with a task, many of us expect our companies to do itforus, as ifwehadno personal responsibilityatall.To somedegree, theemployer does have a duty to assess risk and provide a safe workplace, as well as to supply appropriate training, procedures, and PPE. However, what theemployercannotdoisforeseeeveryconceivable situation and circumstance with which a worker may be faced. As representatives of a NETA Accredited Company, our technicians often report to job sites where there might not be arcflash hazardwarninglabels ora maintenance staff or engineer to discuss the system with. There may not even be an accurate single-line diagram. In these circumstances, and with the absence of valuable electrical power system data, the technician must assess the risk for the particular task at hand.

Having a written electrical safety program (ESP) is important, as this provides technicians

with the basis to evaluate circumstances at the job site against their company's policies and procedures. Without this guidance, technicians are essentially left to their own devices, which may be compromised by erroneous information accumulated over the years. It's akin to using tribal knowledge. Muchlike anAmazonian tribal member, technicians learn from observing others and imitating those observed behaviors. The old saying, "Thestudentcanneverlearnmorethanthe teacher,"isverymuchatplayhere.Learningisoften incomplete and, in many cases, incorrect. This is regularly the case because knowledge acquired by tribal experience is often based on one or two individual's opinions and background. While tribal knowledge isn't inherently problematic - sometimes it is good, sometimes not so good - even the good parts aren't always shared or completely understood byother tribes within the same company.

Along with the ESP, a well-thought-out ]HAl ]SA is important. These document the hazards

that may be encountered and what steps shall be taken to reduce or eliminate the risks. If the task(s) involve exposure to electrical hazards, an energized electrical work permit (EEWP) is part oftheJHNJSAprocess. The EEWP is specifically focused on the electrical hazards and risks that maybe presentwhen there are exposed energized conductors and circuit parts.

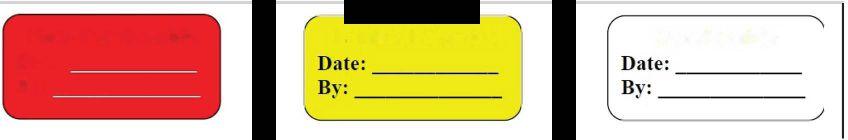

When first approaching electrical equipment, the technician must perform an initial assessment of its condition. Are there unusual noises or smells? Does the equipment appear to be in good condition? What type ofimpact does the environmenthaveontheequipment? Isitindoors or outdoors? Is there a calibration/test sticker on it? Is the dateon the sticker more thanthreeyears old? Is the area dry and clean? We recommend that test or calibration decals become part of everyone's inspection routineandprocedure,such as described in NFPA 70B, 11.27. (SeeFigure 1)

NFPA 70E directs us to perform a shock risk assessmentandan arc-Bash risk assessment. These assessments must determine the nominal phaseto-phasevoltage ofthe equipment or system, the boundaries (arc-Bash, limited, and restricted), the expected incident energy, the required PPE, and other equipment needed to perform the task safely. This would include such items as voltage test instruments, live-line tools, insulated tools, rubbershields and blankets, and so on.

Ifthe technician has to perform a task involving electricalhazards, suchastroubleshooting, further risk assessment is needed. If the equipment requires troubleshooting, it can no longer be considered normally operating; it's in distress and has to be approached as ifit could fail at any moment, including when its circuit breaker is

130.7(C)(l5)(A)(a) Arc Flash Hazard Identification for Alternating Current (ac) and Direct Current (de) Systems

One or more of the following: The equipment is not properly installed ·rhe equipmentisnotproperlymaintained

Equipment covers are offor not secured

There is evidence of imp

Figure2: Article 130, Table 130.7(C)(I5)(A)(a) Partial. From NFPA 70E

opened to deenergize it. Table 130.7(C)(15)(A) (a) provides some assistance in risk assessment. Figure2 is a portion ofthat table.

The task "Normal operation ofa circuit breaker (CB), switch contactor orstarter"indicates that no arc-flash PPE is required ifall ofthe conditions are met. However, the equipment about to be worked on is no longer normally operating, so the "No" changes to a "Yes" - meaning arcflash PPE is required, ifit is necessary to operate the circuit breaker. Secondly, the task "Work on energized electrical conductors and circuit parts, including voltage testing" indicates arc-rated PPE is always required to perform that task, which would include troubleshooting. Part of our risk assessment is now completed. We know that we are exposed to electrical hazards, and we are required to wearprotective clothing and PPE.

Arc-rated clothing and PPE as well as shock PPE must be chosen based on the hazard. If no arc-flash hazardwarning labels are in place, Tables 130.7(C)(15)(A)(a), 130.7(C)(15)(A) (b) and 130.7(C)(16) can be used, as long as the limits for the available short-circuit current or overcurrent protective device operating time stated in Table 130.7(C)(15)(A)(b) are not exceeded. If these limits are exceeded, an incident-energy analysis must be performed. If arc-flash hazard warning labels are in place, the technician should refer to Table H.3(b) in AnnexH todeterminewhicharc-rated clothing and PPE are required.

The risk assessment must also determine what steps maybe needed to protect others from being placed at risk. Signs, barriers, safety barrier tape, or an attendant may be needed to ensure the safety of other personnel as well as the safety of thetechnicianperformingthework. Ifthelimited approach boundary specified in Table 130.4(0) (1), is farther out than the arc-flash boundary, that is where the barriertape should be placed. If the arc-flash boundary is farther out, thenthat is whereit should beplaced.

Non arc-rated PPE may also be required if the task is performed in an area requiring use of a respirator or similar equipment. Is a safety

backup required? The risk assessment must state the requisite PPE, training, and experience for the worker(s), unless these are already covered by the ESP.

There is no such thing as a risk-free task when energized electrical conductors and circuit parts areinvolved. Ifit'senergized, thehazardis present; therefore, so is the risk. Risk can be reduced by operating equipment remotely or by covering adjacent circuits with rubber insulating shields, but the risk canneverbe zero. The remainingrisk is the residual risk.

Once all steps have been taken to reduce risk, the residual risk must be evaluated. If the residual risk is still too great, the work cannot be performed while the equipment is energized. If the technician evaluates the risk and believes it can be done safely, then it can be done energized. In our example task (troubleshooting), it may be that due to the equipment appearance, smell, sounds, etc. - and evaluated in light of the technician's experience - the troubleshooting task is just too risky to proceed. A "Plan B" must be formulated, which would probably include deenergizing the equipment. Ifthe technician believes it can be done safely, then the troubleshooting can proceed. Note that all requirements ofArticle 130 are still in effect.

Assessing risk must also look at other factors related to the work. Are there environmental factors such as rain, ice, lightning, etc.? Is the equipment located in a confined or enclosed space? Is there pedestrian or vehicle traffic nearby? Is other work being performed in the

same area? You may have conducted a niceand-neat electrical risk assessment, but don't get hospitalized by the forklift you didn't prepare for!

Training, of course, is a huge part of the equation. Ifworkers are not following policies or procedures, often it is a lack oftraining that's at fault. Check-the-box training may satisfY a paper trail, but it does little or nothing to promote safety. Employees must be trained to understand the importance ofwhat they do, not just how to do it. This isn't the 1960s, where being told to do something was all thatwas needed. People must understand why tasks need to be done one way instead ofanother, perhapsmoreconvenient,way.

Assessing risk is a vital part of all safety, not just electrical safety. The employer can only do so much, as it is the employee who is at the scene and observing the equipment and conditions. One good truism is, ''Always be responsible for your personal safety." Relying on others could result in a less-than-satisfactory outcome. Listen to your gut feelings Often, accidents could have been avoided if the worker stopped when that little voice in their head said, "I wouldn't do that, if I was you." It never hurts to step back and reevaluate the situation. Maybe something was missed, ormaybe not, buthavingasecondlookis never a bad thing.

At least, that's ourassessment.

Ron Widup and Jim White are NETA's representatives to NFPA Technical Committee lOE (Electrical Safety Requirements for Employee Workplaces). Both gentlemen are employees of Shermco Industries in Dallas, Texas, a NETA Accredited Company. Ron Widup is CEO of Shermcoandhasbeen with thecompany since 1983. HeisaPrincipalmemberof the Technical Committee on "Electrical Safety in the Workplace" (NFPA lOE) andaPrincipalmemberoftheNational Electrical Code (NFPA 10) CodePanel II. Heisalso a memberofthetechnical committee "Recommended Practicefor jim White Electrical Equipment Maintenance" (NFPA lOB), and a member of the NETA Board ofDirectors and Standards Review Council. jim White is nationally recognizedfor technical skills and safety training in the electrical power systems industry. Heis the TrainingDirectorforShermcoIndustries, andhas spentthelasttwentyyearsdirectly involvedin technicalskills and safety training for electricalpower system technicians. jim is a Principal member of NFPA lOB respresenting Shermco Industries, NETA's alternate member of NFPA lOE, and a member ofASTMFIB Committee "Electrical ProtectiveEquipmentfor Workers".

famesR. (Jim) White istheTrainingDirector ojShermcoIndustries, Inc., inDallas, Texas. Heistheprincipal memberon theNFPA technicalcommittee ''RecommendedPractice forElectricalEquipment Maintenance" (NFPA 70B). Jim represents NETA asanalternate memberoftheNFPA TechnicalCommittee "ElectricalSaftty in the Workplace" (NFPA 70E)and representsNETA on the ASTMFIB Committee "Electrical ProtectiveEquipment For Workers': Jim isan IEEESeniorMember andin 2011receivedthe IEEE/PCICElectrical Saftty Excellence award. Jim isapast Chairman (2008)ojthe IEEEElectricalSaftty Workshop (ESW).

Thismonthwewillhavesomequestionsrelatedtohigh-voltagesubstations. Putonyourthinkingcapandseehowwellyoucando.

1. Mediwn-voltageisdefinedas:

a. >1,000 V to35,000 V

b. 2,400v to69,000v

c. >1,000 V to100,000 V

d. Noneoftheabove

2. Whatarefourclassesoflightningarresters?

a.

b. -------------------------

c. d.

3. ANSI/NETAMTSspecifiesamaximumof __ppmmoistureforin-serviceSF6gas.

a. 40 b. 70 c. 110

d. 200

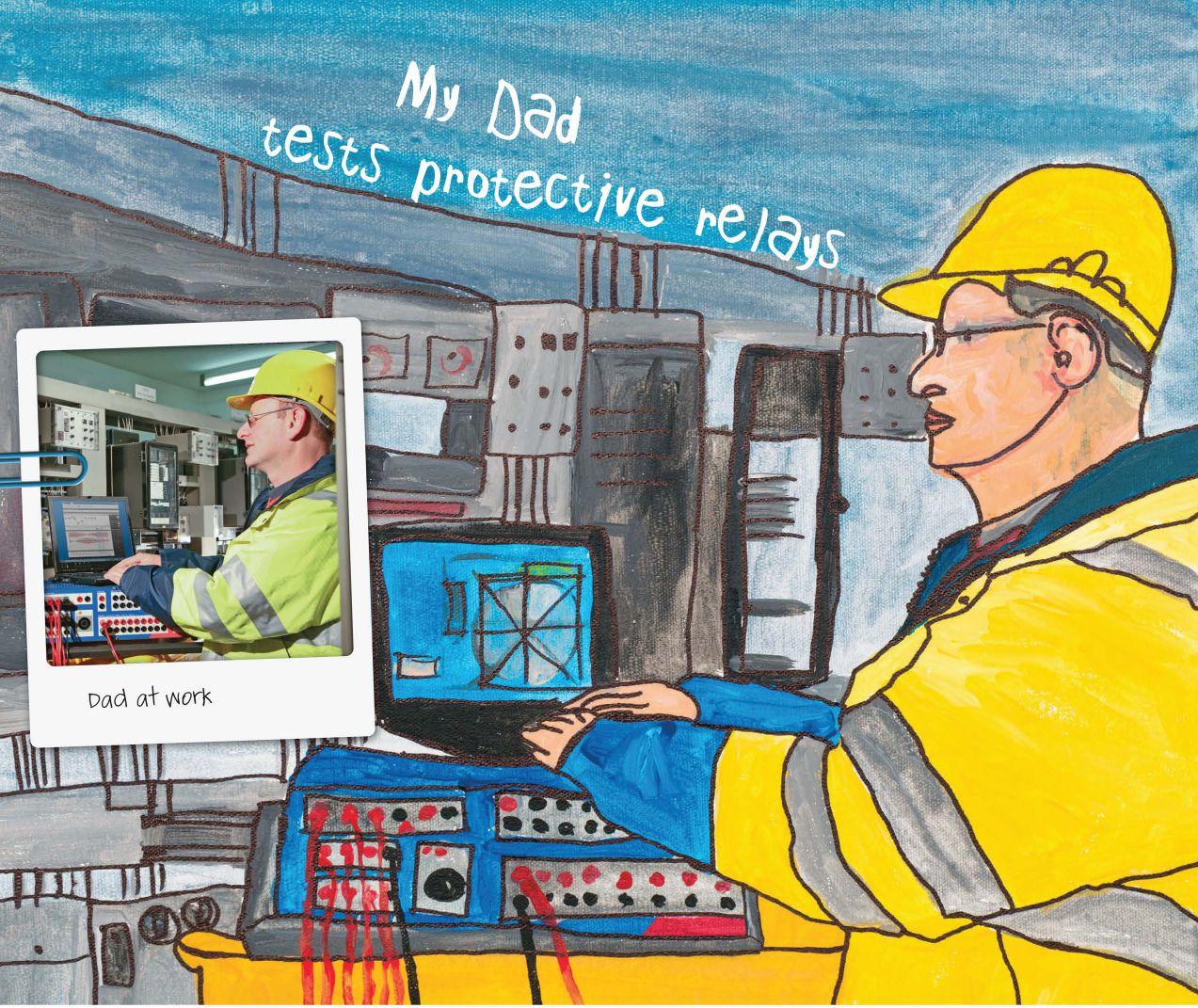

4. Thereis oneoptional testgivenformicroprocessorprotectiverelaysin Section7.9.2 of ANSI/NETAMTS.Whatisit?

a. Insulationresistanceofeachcircuitto ground

b. Functional operationofeachelement

c. Applyvoltageorcurrenttoanaloginputs

d. Controlverification

ElectricalTestingServicesInclude:

Substation Maintenance

Breaker Repair & Modification

Cable Hi-Pot Fault Location

Emergency Transfer Controls

Doble Power Factor Testing

Surge & Transient Protection

Infra-red Scanning

Measurement & Diagnostic Services

Relays & Meter Calibration

Marine Electrical Repairs

Switchgear Service & Testing

Engineering Supervision

North Central Electric, Inc.

Midway Avenue, Hulmeville, PA 19047

(215) 945-7632 Fax: (215) 945-6362

specialist level knowledge of Circuit Breakers, Fuses, and Protective Relays with this convenient take-anywhere eBook.

• Comprehensive Electrical Testing and Maintenance

• Commissioning and Startup Services

• Engineering Services

• Power System and Coordination Studies

HIGHVOLTAGE MAINTENANCE

• Predictive and Preventive Maintenance

• Partial Discharge Testing and Monitoring

• 24/7 Emergency Service

Ensuringthereliabilityofyourelectricaldistributionsystem.

As the leading independent electrical testing, maintenance, and engineering service company, you can rely on Emerson's High Voltage Maintenance to exceed your electrical equipment performance goals. From testing for problems that could disable your system, to complete turnaround execution, you'll quickly understand how we are your single source solution for all of your electrical reliability needs. With a service geography across the Midwest and Eastern Seaboards, our service team puts experienced professionals where and when you need them.

more information:

this shouldn't be the first time you think about

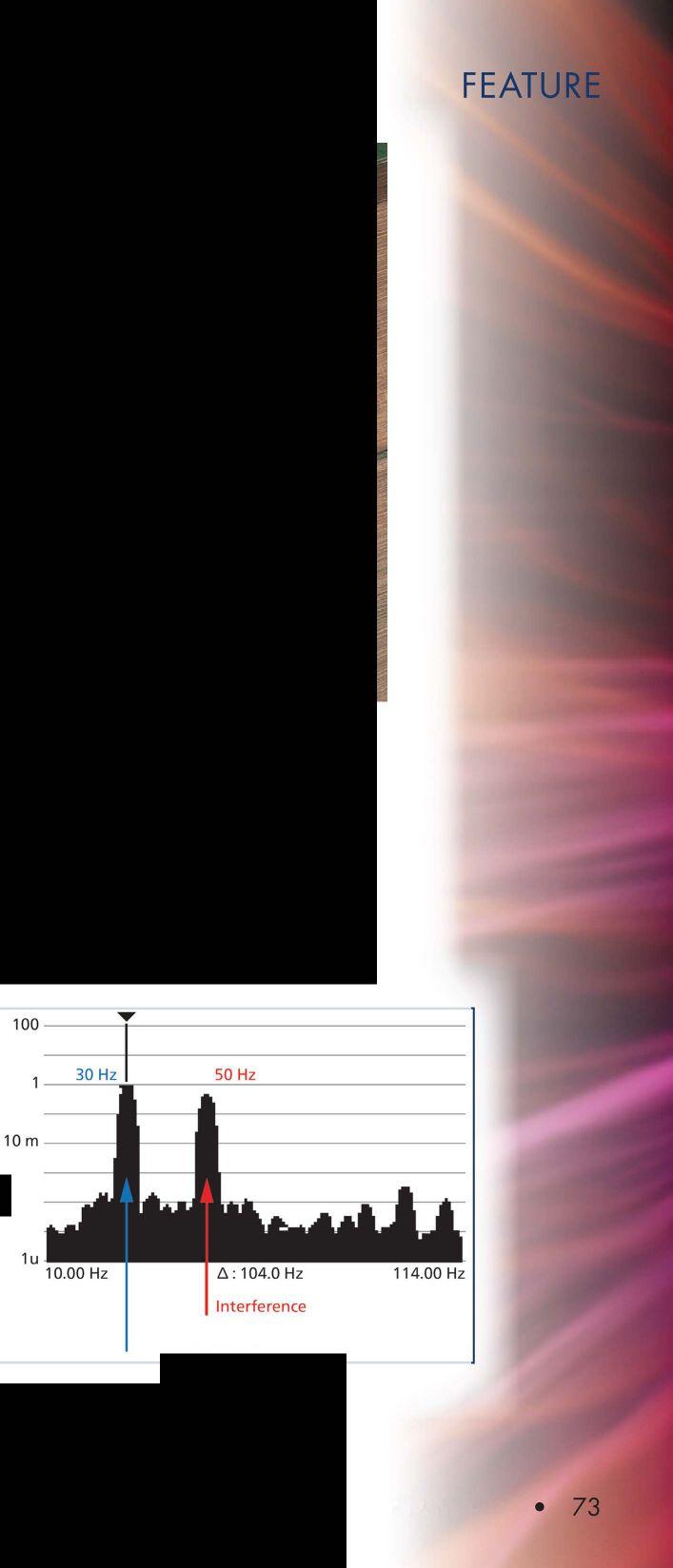

Transient earth voltage orTEVis a term coined by a pioneering British scientist in the 1970s. If the signals it identifies were first discovered in the United States, they would have more likely been called transient ground voltage (TGV) as engineers in Europe typically refer to our ground as earth.

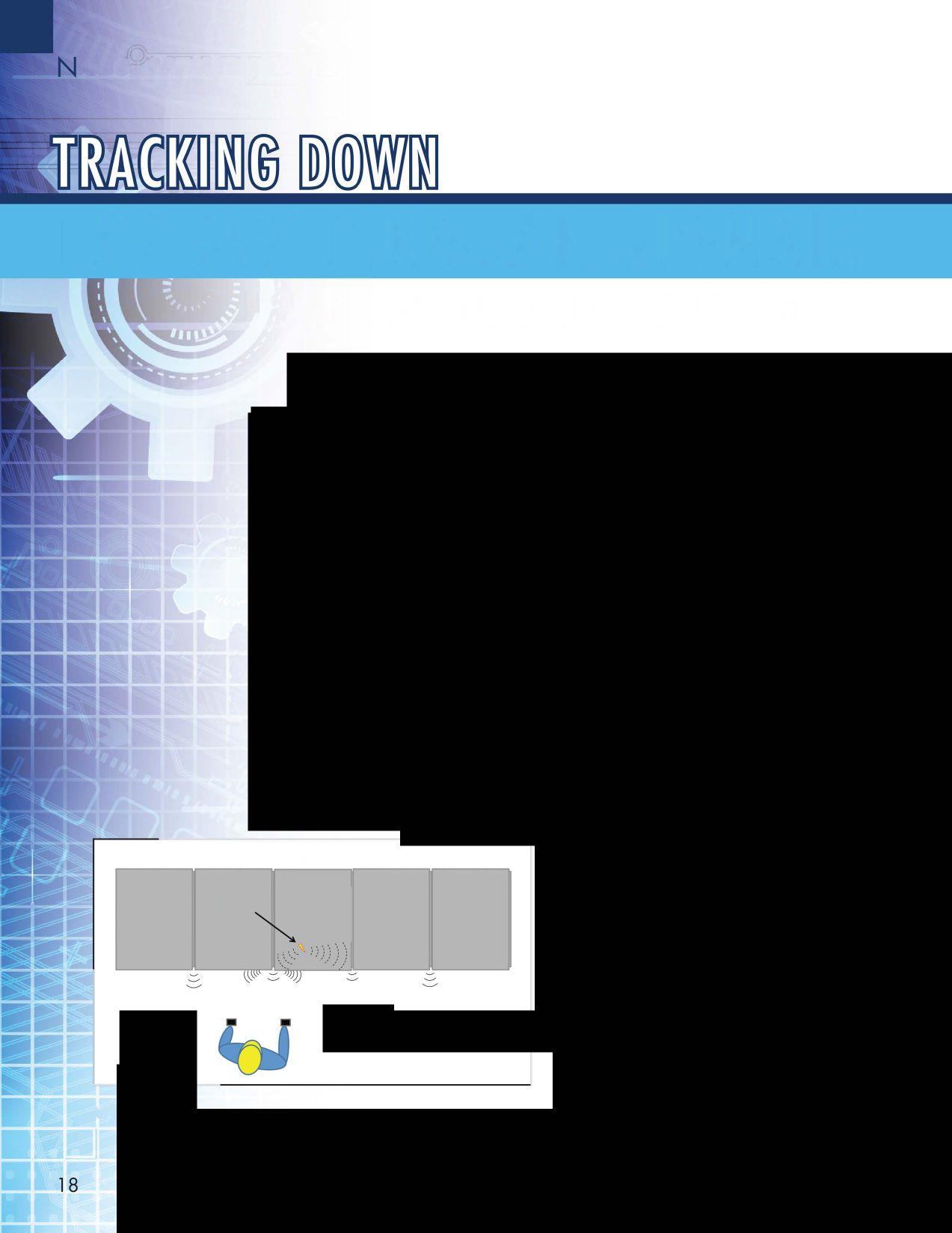

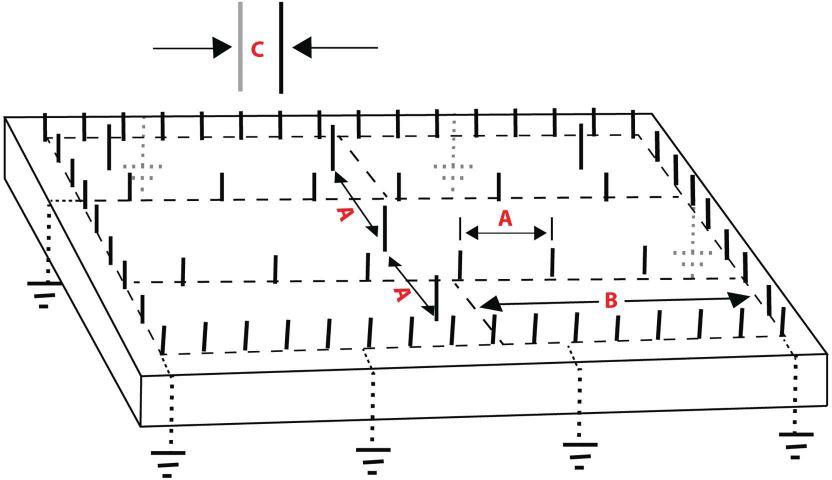

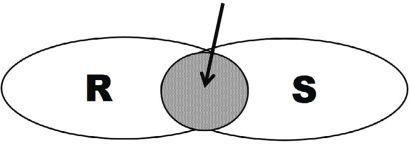

TEV signals are generated by partial discharge activity, which is essentially a partial insulation failure. TEV signals are high-frequency voltage transients or impulses on the ground. They also have the unique feature ofbeing synchronousmore about this later. In the case ofswitchgear assemblies, these signals propagate or ride along the external surface of the grounded switchgear enclosure. As shown in Figure 1, their magnitudes are greater on the enclosure panels that are closest to the discharge source.

Switchgear Plan View

This is how it works: Partial insulation failure creates a spark or partial breakdown that emits a radio frequency signal - think of the flawed insulation area as a small radio transmitter within the switchgear. For outdoor or open structure insulation, these radiated signals can produce signals that interfere with AM radio receivers, sometimes causing that sudden annoying static on a vehicle's radio as it is driven under an overhead distribution line. Partial discharge activity occurring inside of switchgear or other electrical assemblies acts in the same manner. However, the grounded enclosure functions similar to a leaky Faraday cage. It attenuates the signal enough that it is not readily detected with a typical antenna but can still be detected with a TEV sensor. Basically, the TEV signal is trapped inside the enclosure and adheres to its grounded surface but propagates to the outside switchgear enclosure surface though the edges ofthe metal via the skin effect.

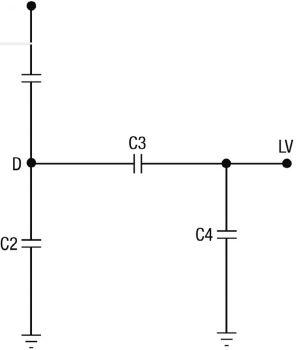

TEV sensors consist of a simple insulated conductive plate that, when placed against the switchgear enclosure, forms a capacitor with the enclosure itself acting as the other plate of

the capacitor The high-frequency TEV signals are captured and then processed and analyzed by the instrument's electronics.

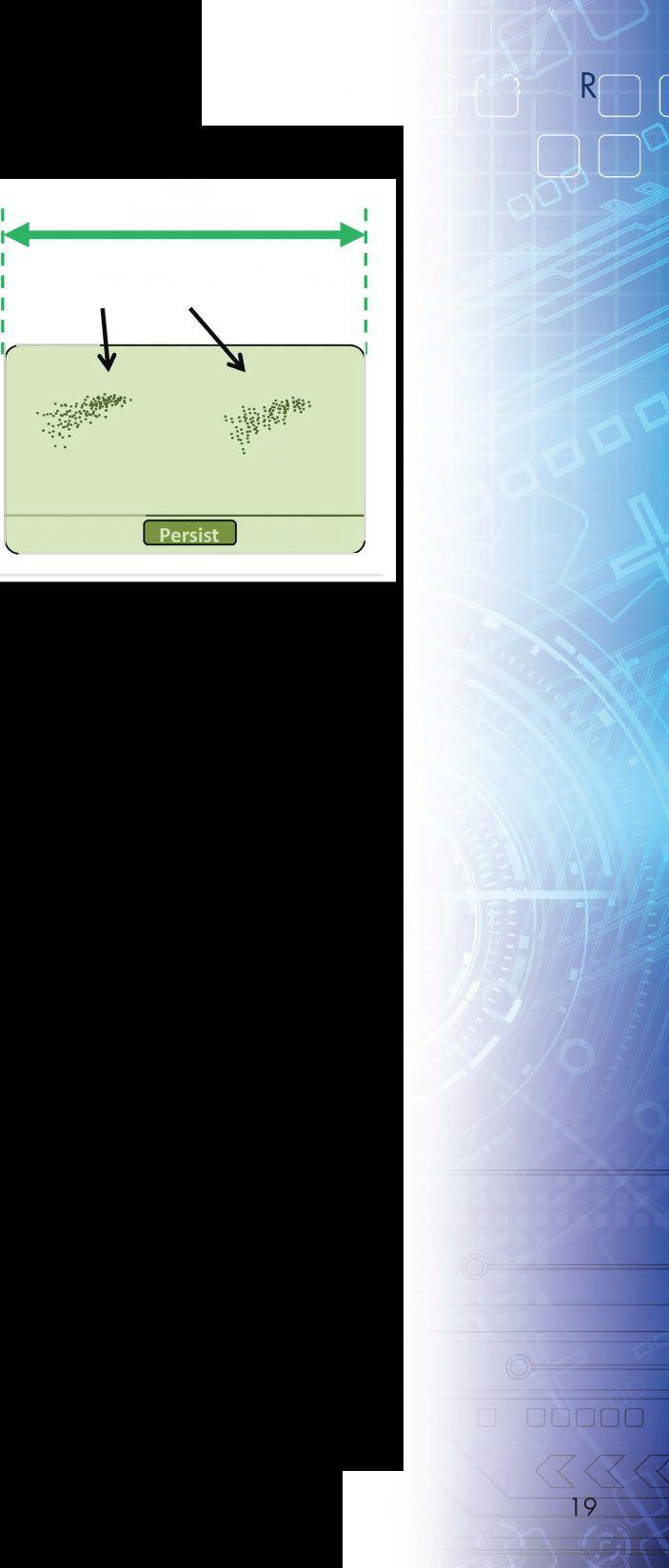

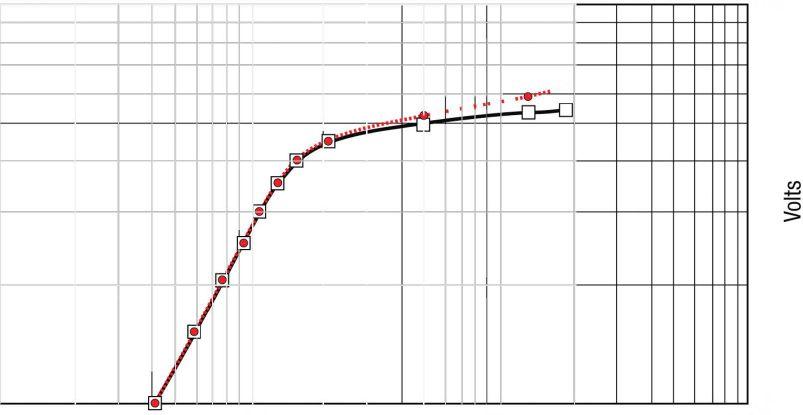

Ok,whatabout the synchronous characteristics referred to earlier? In simple terms, at zero volts there is not enough voltage present for anything to breakdown. But as the ac sine wave rises towards the positive or negative voltage peak, a critical voltage (partial discharge inception voltage) is reached, which creates a localized partial breakdown. This localized partial breakdown or partial discharge is what creates the signals described earlier. Typically, these signals then persist through the sinewave until theyextinguish at a critical voltage known as the partial discharge extinction voltage. The same sequence then repeats itself through the opposite voltage polarity peak, resulting in a pattern of voltage transients that are synchronous or in phase with the ac sine wave Figure 2 shows such a typical PD pattern.

Although one small spark itself only causes negligible insulation damage, thousands of these sparks occurring over days, weeks, and even years will eventually cause cumulative irreversible damage to the insulation until complete catastrophic failure occurs. This process has sometimes been described in literature as electrical rust but perhaps could better be described as death by a thousand razor cuts.

Before jumping into the Time of Flight location method, it is worth of mentioning that just as the TEV signals can reach and travel along the outside of a leaky switchgear enclosure, they cannot escape well-sealed and well-shielded equipment such as oil-filled transformers. For these types of equipment, the PD signals can escape from the inside of the equipment enclosure through an external ground connection, where signal decoupling can be accomplished using split-core, highfrequency current transformers.

The time oftime offlight method for locating TEV signal origination, and thus PD source location, involves using dual capacitive sensors

Cycle

Phase Resolved PD Pattern

as shown in Figure 3. Sophisticated instrumentation is used to time the arrival of the TEV signals at one sensor in comparison to the arrival time at the other sensor. As shown in Figure 4, a bar graph display indicates which sensor is closest

4: Proportion ofTransients

to the discharge. By moving the magnetic capacitive probes around the switchgear at different locations, the PD source can be pinpointed with considerable accuracy.

As technology continues to advance and greater field experience is accumulated, partial discharge techniques and instrumentation will advance accordingly. Present PD instruments can now isolate and ignore undesirable noise from PD signals, and new advancements have led to better methods for pinpointing PD sources. These advancements have also led to the discovery, identification, and repair of insulation defects, which have significantly enhanced reliability for electrical equipment not only in the U.S. butinternationallyas well.

Inc.

This year, ABB celebrates 50 years as the original FT switch manufacturer. With the longest, most successful history, ABB's unmatched quality is the benchmark for the industry. As the test switch manufacturer with the largest installed base, the Flexitest test switch's perfected design offers the highest quality and best lead times, leaving nothing to chance. www.abb.com/substationautomation. Power and productivity for a better world™

Vanguard Instruments has been at the forefront of developing innovative precision sub-station test instruments for over 20 years, and we are continuing our tradition with our latest products such as the CT-7000 53 and CT-8000 53 circuit breaker analyzers with Dual Ground testing feature and our new line of test instruments featuring convenient Bluetooth wireless interfaces. Visit us today at vanguard-instruments.com to find the latest solutions for all of your sub-station testing needs.

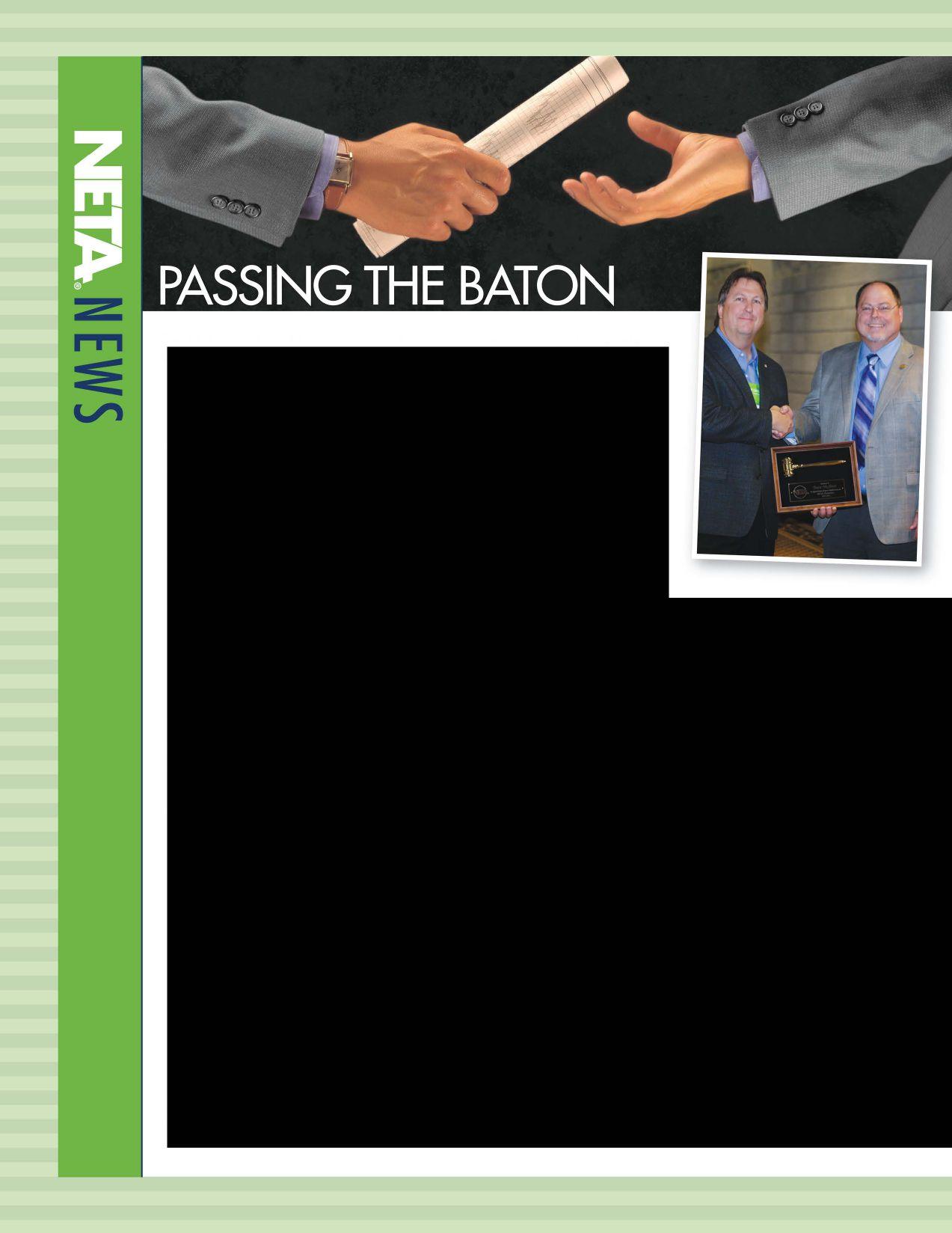

Runningan association is not unlikerunninga relay race. Eachindividualmustdohisparttogettheteamacross the finish line successfully, hopefully ahead ofdeadlines and challenges that are sure to face them on rhe course. Every two years, NETA sees a change in leadership as a new president oftheassociation steps up to thestartinglineto begin theraceanew. Thispassingofthebaton iscriticalto thecontinuityoftheassociation's success.

SinceJune1,2013, DaveHuffman,PowerSystemsTesting Company, has been leading the charge for NETA as its president. During his term, he has seen record years for attendance at PowerTest, growrh in the number of companies attainingNETA Accredited Company status, more electrical testing technicians certified than ever before, and the creation of a brand new ANSI/NETA standard, aswell as thepublication oftworevisedANSI/ NETA standards, and the inception of the Gold and Corporate Alliance Partnership programs. Dave has led exponentialgrowthinawarenessoftheassociation rhrough innovative approaches to outreach and development efforts, in addition to the many other commitments to NETA'sStandardsReviewCouncil,ContinuingTechnical Development Committee, Member Application Review Committee, andExamCommittee, amongorhers.

Dave'ssuccessas aleaderdraws from manysourceswithin hischaracter. Heisatenuredveteranoftheelectricaltesting industry. Hehas loyallyserved the same testing company sincehis collegegraduation-afeat unheard ofin mostof rhecorporateworld today, butnotsurprisinggiven Dave's natural tendencies toward dedication, service, and excellence. In2010, Davereceived rheNETAOutstanding Achievement Award, which was well-deserved for his many contributions to NETA. At that time, he said, "I learned quickly that being apart ofNETA is about a lot morethanjusthavingthelogoandcarryingacertification card. It's about participation andgivingback. Mylife has been so full ofpositive experiences for my family and me becauseofmyinvolvementwithNETA." Sincethen,Dave

Ron Widup (left), incomingpresident as ofjune I, 2015, thanksDaveHuffinan (right), outgoing presidentas ofMay 31, 2015,for leading the associationfor the past twoyears and presents him with the traditional goldengavel.

hascertainlycontinuedtoliveuptothosewordsasNETA's presidentoverthepasttwoyears.

As ofMay 31, 2015, Davewillpass thebaton to NETA's nextpresident, Ron Widup, Shermco Industries. Ron is a pastpresident ofNETA, servingaterm from 1998-2000. Like Dave, he is responsible for furthering the daily business of the association through his contributions on many NETA committees. Ron is NETA's Conference Chair, Exam Chair, a member ofthe Standards Review Council,andmaybebestknownforhecklingtheexhibitors who participate in the New Product Forum eachyear at PowerTest. Both Dave and Ron are prime examples of what it takes to be a top-notch leader within NETA: technical aptitude, commitment to excellence, fearlessness ofuncharted territories, possession ofa generous heart, a sense ofhumor, willing attitude, and no need for more than a fewhours ofsleep every othermonth or so. (That last one is rheonlyway rhe marh makes sense for all rhey accomplish.)

NETAtrulyisblessedwithamultitudeofvolunteerswho arealwayshappyto pickup thebatonwhenitis rheirturn, and who gladly share in the success that comes when the teamcrosses thefinishlineat theendofthe race. Here's to a smoorh transition for the association, from one great leader to the next.

In reviewing §1910.269, it should be noted that it also applies to "equivalent installations of industrial establishments." In this article, the applicability of§1910.269 to the industrial environment will be discussed. Further, this standard was significantly revised with respect to performing arc flash analysis for power generation, transmission, and distribution systems. Therefore, a more focused discussion on these arc-flash analysis requirements will be provided.

Typically, industrial facilities implement requirements from §1910.332 through §1910.335, or Subpart S of the ofthe OSHA standards. In the industrial environment, what would be an equivalent installation referenced in §1910.269? The most obvious examples would be the medium- or high-voltage distribution systemwithin an industrial facility. For our purposes, the definition ofa mediumvoltage (MV) system is a power distribution

BY LYNN HAMRICK, Shermco IndustriesOSHA recently revised and issued the general industry standard associated with the operation and maintenance ofelectric power generation, transmission, and distribution lines and equipment. The standard 29 CFR 1910.269, or §1910.269, is generally associated with electric power generation, transmission, and distribution. This standard is also known as Subpart R of the OSHA standards and is typically applied to the utility industry.

system greater than 1OOOV but no more than 35kV. The definition of a high-voltage (HV) system is a power distribution system of69kV and higher.

Based on the language in §1910.269, it may be appropriate to apply the requirements of §1910.269 in the industrial environmentwhen working on or near MV and HV distribution systems. This would suggest that an employer could choose to define portions of its installations as either utilization or distribution or a combination of both. Unfortunately, the extent of compliance for the application is typically determined on an application-byapplication basis by a compliance safety and health officer (CSHO) when performing an inspection. Therefore, an employer may be cited for violation of the general duty clause under Section 5(a)(l) of the Occupational Safety and Health (OSH) Act whenever any employee would be protected under one standard, when the other, normally applicable standard contains no provisions protecting against the hazard involved.

�

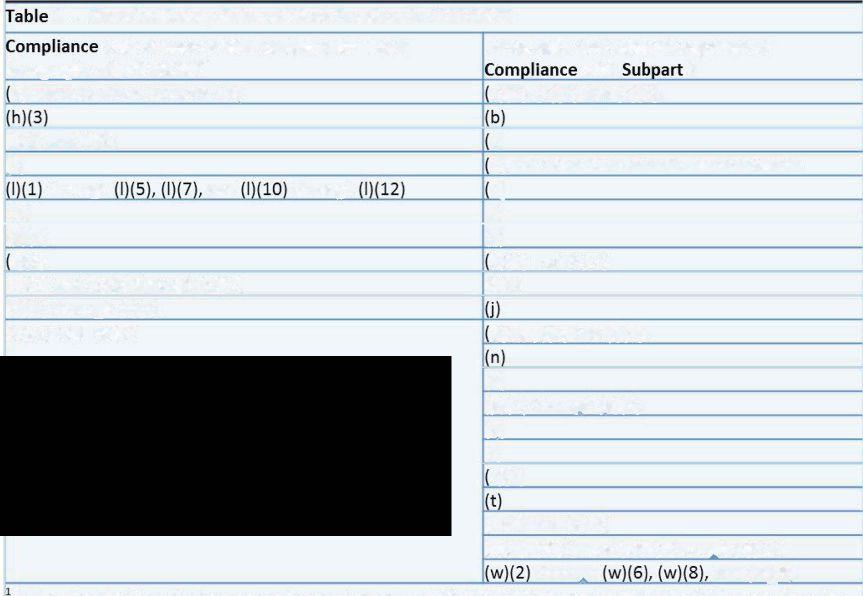

able 1. Electrical Safety-Related Work Practices in §1910.269 �ompliance with Subpart S Will comply with These Paragraphs of §1910.2691

Paragraphs that Apply Regardless of Compliance with Subpart 52 d), electric-shock hazards only a)(2), (a)(3) and (a)(4). h)(3) b) (i)(2) and ( )(3) c) (k) d), for other than electric-shock hazards. 1)(1) through (1)(5), (1)(7), and (1)(10) through (1)(12) e) (m)

(f) (p)(4) (g) s)(2) h)(1) and (h)(2). (u)(1) and (u)(3) through (u)(5) (i)(4) (v)(3) through (v)(5) (j) (w)(1) and (w)(7)

1)(6), ( )(8) and (1)(9). n) (o)

(p)(1) through (p)(3). (q) (r)

s)(1) t)

(u)(2) and (u)(6) (v)(1), (v)(2), and (v)(6) through (v)(12). w)(2) through (w)(6), (w)(8), and (w)(9).

If the electrical installation meets the requirements of §§ 1910 302 through 1910.308 of this part, then the electrical installation and any associated electrical safety-related work practices conforming to §§ 1910.332 hrough 1910.335of this part are considered to comply with these provisions of§ 1910.269ofthis part. These provisions include electrical safety and other requirements that must be met regardless of compliance r,vith subpartS of this part.

OSHA A-2 Table I

Basically, OSHA is concerned that using different work practices could lead to confusion for employees, which could result in serious accidents. In situations such as these, an employer would be expected to determine whether an installation is utilization or distribution and then require employees working on them to meet the work practice requirements of §1910.332 - 335 (Subpart S ofthe standard) or §1910.269, respectively, to maintain consistent and adequate safe work practices. Employers must be cognizant of the requirements of both standards to ensure that the most appropriate work practices are implemented or face the possibility of being cited for violation(s) of §1910.269, 1910 Subpart S or the general duty clause of the OSH Act, ifthe inconsistencies pose hazards to employees. To assist employers in making the right choice, refer to Table 1 in Appendix A-2 of§1910.269 as provided here.

OSHA"considersworkpracticesconformingto §1910.332 through §1910.335 as complying with the electrical safety-related work-practice requirements of§ 1910.269 identified inTable 1 of Appendix A-2 to this section, provided that employers are performing the work on a generation or distribution installation meeting §§ 1910.303 through 1910.308. This table also identifies provisions in §1910.269 that apply to work by qualified persons directly on, or associated with, installations of electric power generation, transmission, and distribution lines or equipment, regardless of compliance with §§ 1910.332 through 1910.335." Further, OSHA "considers work practices performed by qualified persons and conforming to § 1910.269 as complying with §1910.333(c) and §1910.335." Therefore, it is recommended that industrial facilities compare the requirements presented in §1910.269 to the implemented requirementsof§1910.332through§1910.335

to ensure that work practices are appropriately instigated for the applicable safety hazards.

• Securing (with certain exceptions) that employees exposedtohazards fromelectricarcs wear protective clothing and other protective equipment with an arc rating greater than or equal to the estimated heat energy

Appendix E to the standard provides tables listing incident heat energies for common exposures found in electric power transmission and distribution work. Employers may use these tables to estimate incident heat energy under the exposure conditions covered by the tables. In addition, Appendix E provides guidance on:

• Assessing the workplace for flame and electric-arc hazards

As stated previously, industrial facilities implement requirements from §1910.332 through §1910.335, or 1910 Subpart S of the OSHA standards. Unfortunately, 1910 Subpart S does not directly address arcflash hazards. Subsequently, the industrial environment has relied on NFPA 70E Standard for Electrical Safety in the Workplace to provide safety requirements associated with arc-flash hazards. Safety requirements associated with arc flash have been in NFPA 70E since the 2000 edition. Mter 14 years, OSHA has not endorsed NFPA 70E as a requirement standard for the industrial environment, but it has stated that it is an acceptable way of addressing this known hazard. OSHA has essentially utilized the general duty clause under Section 5(a)(l) ofthe Occupational Safety and Health (OSH) Act to implement NFPA 70E. In otherwords, OSHA expects employers to meet NFPA 70E without actually requiring them to meet it.

With regard to arc-flash hazards, §1910.269 is the only OSHA standard that actuallyprovides specific guidance and requirements associated with protection against flames and electric arcs. In general, §1910.269 requirements have the employer:

• Assessing the workplace to identifY where employees are exposed to hazards from flames or from electric arcs

• Making reasonable estimates ofthe incident heat energy of any electric-arc hazard to which an employee would be exposed

• Ensuring that employees exposed to hazards from flames or electric arcs wear clothing that would not melt onto their skin or that could ignite and continue to burn when exposed to flames or the estimated heat energy

• Affirming that the outer layer of clothing worn by an employee is flame resistant under certain conditions

• Selectinga reasonable incident-energy calculation method undervarious conditions

• IdentifYing reasonable parameters for use in calculating incident heat

• Choosing clothing that does not ignite

• SpecifYing protective clothing with an acceptable arc rating

• Requiring arc-rated head and face protection, when the standard requires

With regard to a methodology for determining areasonable incident energy, §1910.269 allows for the use of included tables, which have specific applicable parameters. As a preferred alternative, Appendix E Table 3 is provided for selecting an acceptable methodology for calculating a reasonable incident energy.

Most industrial applications have implemented NFPA 70E in regards to arc-flash analysis and work rules associated with arc-flash hazards. Fortunately, the requirements of §1910.269 and NFPA 70E are mostly in agreement. One difference is associated with the minimum incident energy that would be considered an arc-flash hazard. §1910.269 uses 2.0 call cm2, while NFPA 70E uses 1.2 callcm2. Additionally, §1910.269 provides a calculation methodology for determining reasonable incident energies for circuits that are greater than 15 kV. For some industrial applications, this will enable them to determine a reasonable incident energy for the arc-flash hazard.

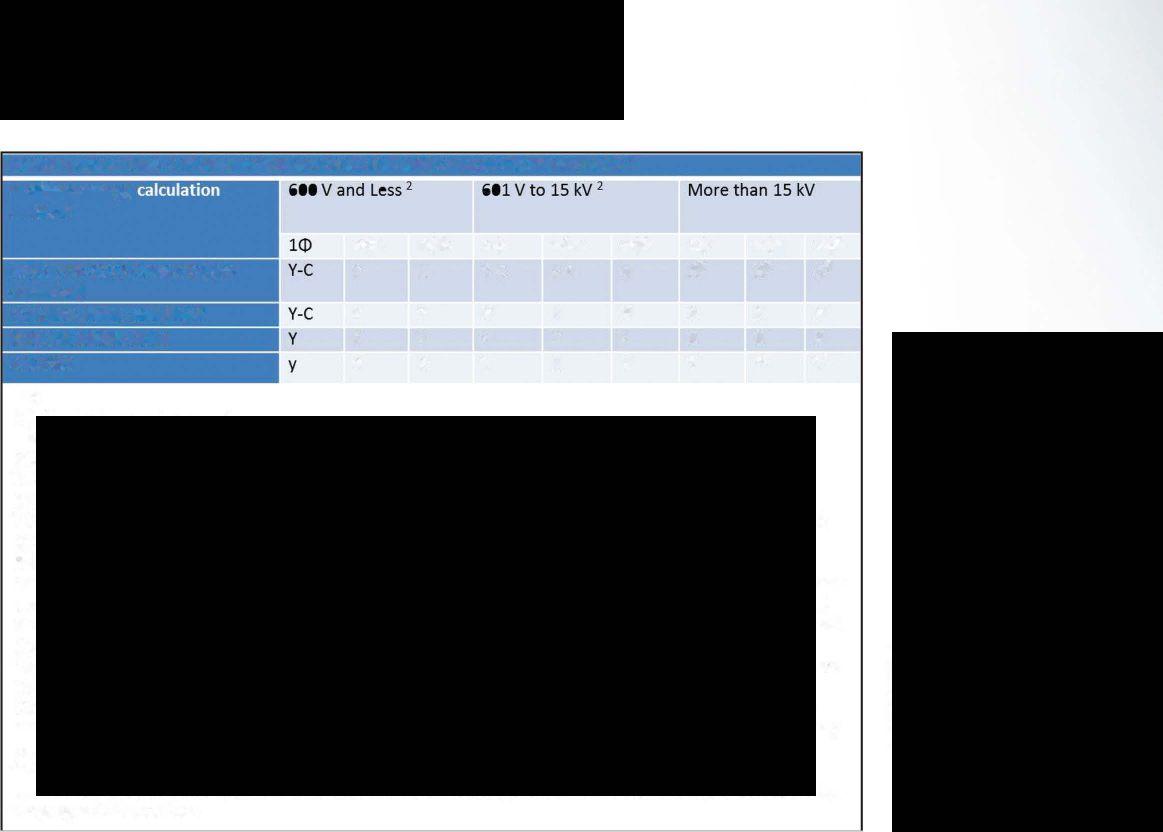

TABLE 3-SELECTING A REASONABLE INCIDENT-ENERGY CALCULATION METHOD 1

Incident-energy calculation method

NFPA 70E-2012 Annex D (lee equation)

Doughty, Neal, and Floyd

IEEE Std 1584b-2011

ARCPRO

Key:

l<D: Single-phase arc in open air.

3<Da : Three-phase arc in open air.

3<Db: Three-phase arc in an enclosure (box).

Y: Acceptable; produces a reasonable estimate of incident heat energy from this type of electric arc.

N: Not acceptable; does not produce a reasonable estimate of incident heat energy from this type of electric arc.

Y-C: Acceptable; produces a reasonable, but conservative, estimate of incident heat energy from this type of electric arc.

Notes:

1 Although the Occupational Safety and Health Administration will consider these methods reasonable for enforcement purposes when employers use the methods in accordance with this table, employers should be aware that the listed methods do not necessarily result in estimates that will provide full protection from internal faults in transformers and similar equipment or from arcs in underground manholes or vaults.

2 Atthese voltages, the presumption is that the arc is three-phase unless the employer can demonstrate that only one phase is present or thatthe spacing of the phases is sufficient to prevent a multiphase arc from occurring.

'Although the Occupational Safety and Health Administration will consider this method acceptable for purposes of assessing whether incident energy exceeds 2.0 ca l/cm2, the results at voltages of more than 15 kilovolts are extremely conservative and unrea listic.

4 The Occupational Safety and Health Administration will deem the results of this method reasonable when the employer adjusts them using the conversion factors for three-phase arcs in open air or in an enclosure, as indicated in the program's instructions.

OSHA Appendix E Table 3

By January 1, 2015, we're required to make reasonable estimates ofincident energy. Finally, the employer must provide protective clothing and other protective equipment meeting the arc-flash protection requirements of the final rule byApril 1, 2015.

OSHA recently revised and issued the general industry standard 29 CFR 1910.269, or §1910.269 Electric Power Generation, Transmission, and Distribution, associated with the operation and maintenance of electric power generation, transmissiOn, and distribution lines and equipment. This standard is also known as Subpart R of the OSHA standards and is typicallyapplied to the utility industry.

Standard §1910.269 also applies to equivalent installations of industrial establishments. Typically, industrial facilities implement

requirements from §1910.332 through §1910.335, or Subpart S of the of the OSHA standards. Based on the language in §1910.269, it may be appropriate to apply the requirements of §1910.269 in the industrial environment when working on or near MV and HV distribution systems. Employers must be cognizant ofthe requirements ofboth standards to ensure that the most appropriate work practices are implemented or face the possibility of being cited for violation(s) of §1910.269, 1910 SubpartS, orthegeneralduty clause of the OSH Act, if the inconsistencies pose hazards to employees.

§1910.269 is the only OSHA standard that actually provides specific guidance and requirements associated with protection against flames and electric arcs. Most industrial applications have implemented NFPA 70E in regards to arc-flash analysis and work rules associated with arc-flash hazards. Fortunately,

the requirements of§1910.269 and NFPA70E are mostly in agreement; however, there are some differences. One difference is associated with the minimum incident energy that would be considered an arc-flash hazard. Standard §1910.269 uses 2.0 callcm2, while NFPA 70E uses 1.2 callcm2. Additionally, §1910.269 provides a calculation methodology for determining reasonable incident energies for circuits that are greater than 15kV.

1. §1910.269 (a)(I)(i)(A)

2. §1910.269 (a((I)(ii)(B)

3. Tables I and3 reprinted withpermission of29 CFR 1910.269

Lynn Hamrick brings over 25years of workingknowledgeindesign,permitting, construction, andstartup ofmechanical, electrical, and instrumentation and controls projects as well as experience in the operation and maintenance offacilities.

Lynn is a ProfessionalEngineer, CertifiedEnergyManager andhas a BS in Nuclear Engineering.from the University ofTennessee.

When production stops or the power goes out...

Powerful ReliabilitySolutions We'realwaysready,24/7!

t/ Power System Acceptance Testing

t/ Commissioning and Start-up

t/ Maintenance fuses gotyou in thedark?

t/ Life-Cycle Extension

t/ Troubleshoot and Repair

Low, Medium and High Voltage Power Fuses

t/ Training and Engineering Services www.monsterfuses.com

Western USToll Free888-444-4335

Eastern USToll Free877-444-1798

t/ Planning and Operations Support

t/ Project Management

It has been 15 years since NETA produced a brand new standard. NETA's most recent addition to the collection of ANSI/NETA standards, the ANSI/ NETA ECS Standardfor Electrical Commissioning Specifications for Electrical Power Equipment and Systems, is a document that reached completion at a critical time fortheindustry.

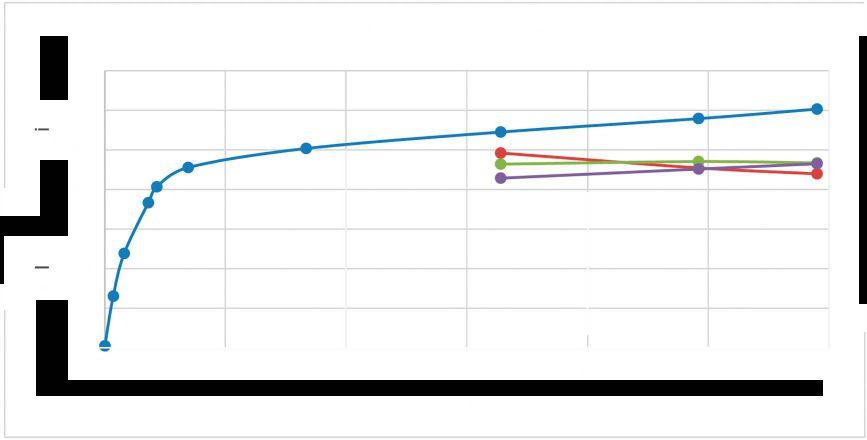

Increasing emphasis is placed on the importance of commissioning in the safe energization of newlyinstalled equipment and systems, as well as their long-term health and reliability. When it carne to the specific tasks required for addressing low-, medium-, and high-voltage electrical power equipment and systems with regard to electrical commissioning, a definite gap existed in industry standards. The NETA Board of Directors determined that it was incumbent upon NETA to create a standard that would work in conjunction with the ANSI/NETA ATS Standard for Acceptance Testing Specifications for Electrical Power Equipment and Systems. NETA's Standards ReviewCouncilwas chargedwith the task, and they in tum, recruited a panel ofsubject matter expertswhoworked together to create the document thatachievedANSI approval on December 3, 2014.

A Cross-section oftheMany Industries 7hat Benefit from Formal, DetailedElectrical Commissioning, Acceptance, andMaintenance Programs

One ofthe first people to receive a copy ofthe new standard, Mechanical and Electrical Instructor L.W Brittian, has a positive initial impression of the document, saying, "All sectors ofthe electrical

industry-from product design engineers, product manufacturers, suppliers, system design engineers, inspectors, contractors, and owners to insurance agenciesandmaintenancepersonnel-allrecognize that a formal, detailed process ofpre-energization, energization, post-energization, acceptance testing, and turnover to the owner/operator provides environmental, economic, and safery benefits from the cradle to grave. Commissioning of electrical systems is an emerging market, and NETA has staked its rightful claim with this long-needed, professionally developedstandard."

TheANSIINETAECS-2015debutedinMarch2015 to an audience of454 PowerTest attendees, many of whom attendedthe Electrical Commissioning track, symposium, and seminars where they got more information about electricalcommissioningandhow this new standard can be applied. Learn more about theANSI/NETA ECS, andorderyourcopytodayat www.netaworld.orgorcall 888-300-6382.

ANSI/NETA ECS WORKING GROUP

NETA extends special thanks to the members of the working group who provided their expertise and time to the creation of the initial draft of the ANSI/NETA ECS.

Lorne Gara, Orbis Engineering, Working Group Leader

Scott Blizard, American Electrical Testing Co., Inc.

Michael Donato, Electrical Reliability Services

Dan Hook, Western Electrical Services, Inc.

AI Peterson, Utility Service Corporation

Mose Ramieh, Ill, Power & Generation Testing, Inc.

Manoj Shah, Southwest Energy Systems, LLC

Ron Widup, Shermco Industries

Chris Zavadlov, POWER Testing and Energization, Inc.

www.doble.com/DelphiPortable

BY PAUL CHAMBERLAIN, American Electrical Testing Co., Inc.

BY PAUL CHAMBERLAIN, American Electrical Testing Co., Inc.

Workers' hands are the most commonly injured part of their bodies. Whether the hazard comes from spinning blades, pinches between two materials, heat, chemicals, or electricity, working hands are under constant attack. In most work environments, utmostcareshouldbetakentoprotectworkers' hands. Thisarticle identifies the common hazards and risks to a worker's hands and the means to mitigate injury and promote safety.

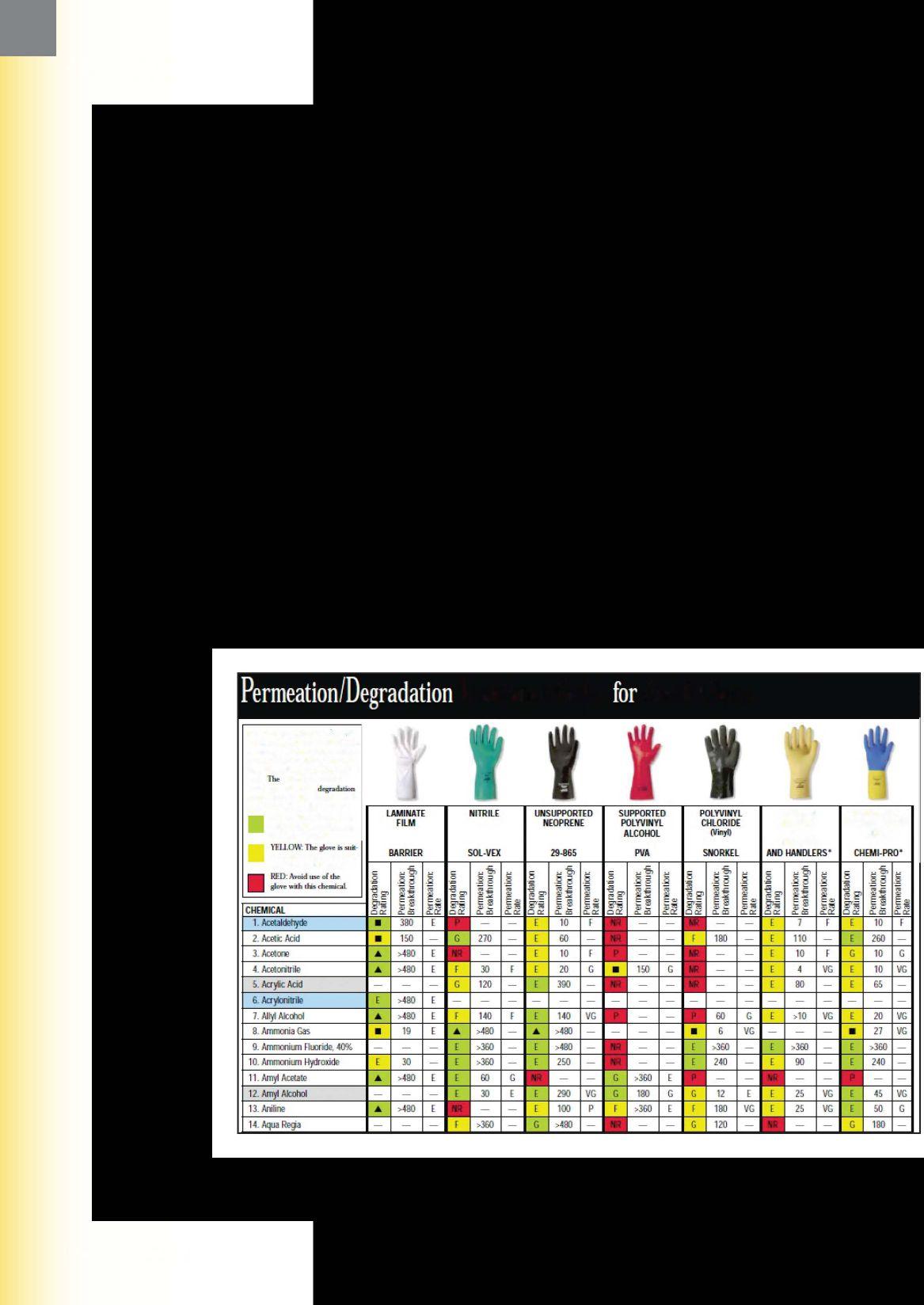

Many commonly used chemicals in the workplace can cause chronic illness through dermal absorption and may go undetected by the worker; as such, direct contact must always be avoided. Some chemicals can cause painful anddebilitatingburns on theskin thatmaytake a long time to heal. Both burns and dermal absorption can potentially result in serious or even fatal injuries. Employers and employees

ThellncsquareRleadlco!UimlfOI' cxhglovel)liCise»iocmdu:LThi. U.;u1195)'10<r9dindiQ,tionolhow -.·e.r:lletListype.ofgioFeinrelation toits;!flpiiabitlt:rrOC'"�chenUGI listed colorr�resenl!'lan cn"CRtlAtil'�fcc-both andpe�DLTheleuo-ined :lqtlatl:is(orlkgracbtiOJI..De: D CREEN:Thegl!weisvtry ..,�usuitedfor�a.ppliallon YiillJtfutc::htmic;a,l.

D YEU. W:Thegl

Figure 1 : AnsellPermeation/Degradation Resistance Guide

NOTE: This actual table is severalpages in length; more information can befoundat.· http:!!www.ansellpro.com/download!Ansell_SthEditionChemica!ResistanceGuide.pdf

must ensure the proper use of gloves that are specific to the type ofchemical being handled.

There are many materials available for glove construction; some are better suited than others for resistance to breakthrough or permeation. Breakthrough time is determined using an ASTM standardized test for the elapsed time between initial contact of the chemical on one side of the glove material and the analytical detection of the chemical on the other side of the glove material. Ifthere is no breakthrough, this is marked as ND (none detected) for the test. These times generally reflect how long a glove can be expected to provide resistance when totally submerged in the chemical. The permeabilityofthe material, orpermeation rate, ishowlongittakesforachemicaltopassthrough the glove on a molecular level. Glove thickness can affect the permeability ofa material. Again, there is an ASTM test for this, and the glove manufacturer must rate the permeability of the glove on its fact sheet. When determining the correct glove for handling a chemical, always referto the manufacturer's fact sheet, such as the one excerpted from Ansell (See Figure 1).

Cutting a finger while removing insulation, scraping a hand on a sharp panel door edge, or slamming a finger with a tool, can be hard to avoid. Human beings are fallible; however, we can minimize the impact of these injuries by using protection like leather, cotton, or rubberized gloves. In extreme circumstances, Kevlar or metal gloves may be necessary. Leather gloves are usually the preferable means ofprotection from all ofthese injuries and are relatively inexpensive. A good rule-of-thumb is that if a tool is necessary to do the job, it is likely that gloves are also needed.

A job hazard analysis, along with good, oldfashionedcommonsense,willalsohelpdetermine if an employee could get lacerated or otherwise injured performinga task. Much like otherforms of personal protective equipment (PPE), gloves

must beinspected forwearand tear and replaced as necessary. Different work methods can also go a long way toward reducing preventable hand injuries. Instead of using a knife to strip insulation, for example, use a wire stripping tool. Use safety knives (Figure 2) to open letters and boxes instead of a razor blade or scissors. Ensuring correct guarding on tools like rotating carpenters saws or right angle grinders will also reduce the likelihood ofinjury. Inspect workers' tools regularlyto ensure that the guarding has not been removed or compromised. Removing the guard may aid in getting a job done quicker or easier, but it could cost a finger- orworse.

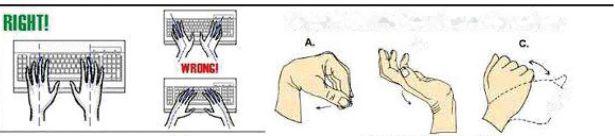

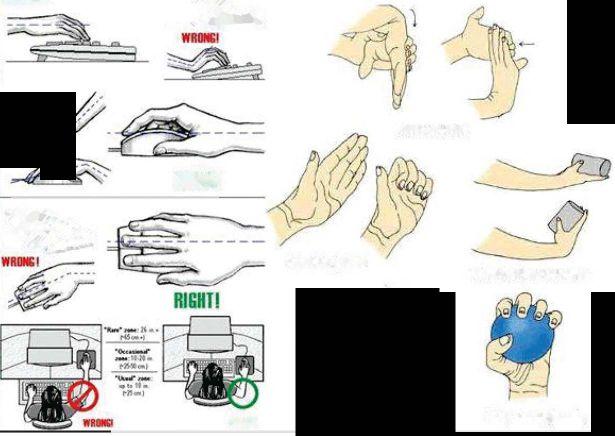

Carpal tunnel syndrome is one of the most common handinjuries in the UnitedStates. It is even harder to prevent when activites outside of theworkplacecontributeto these injuries. Other common types ofrepetitive motion injuries are tendinitis and bursitis, which are injuries to tendons and bursae, respectively. Carpal tunnel syndromeisnotanoccupationalhazardexclusive

to those using a computer; it is also a hazard to anyone who performs repetitive hand motions, mechanical gripping, small part assembly, or encountersvibration in fields such as mechanics, factory work, or an electrical trade. Education is the best method of prevention for repetitive motion injuries. To avoid these injuries, perform frequent range-of-motion exercises (Figure 3) to warm up and alleviate injury. Many tools are available that promote proper ergonomics and posture, such as a wave-style keyboard, or a track-ball mouse. Hand tools such as rightangle power drills and t-handle drivers also help prevent hand and wrist strain and proper hand positioning. Padded palms and fingers can help prevent repetitive motion injury while using vibratory tools such as a hammer drill or jig saw, or while using impact tools such as a hammer.

Additionally, it is suggested that for every hour sittingandworkingon akeyboard, take aminute ortwotogetup,movearound,andstretch. Several

manufacturers ofergonomic mice and keyboards havecompanionsoftwaretoremindtheworkerto stretchandcanevenshowtheworkermoreeffective stretchingexercisesdependingon use (SeeFigure4).

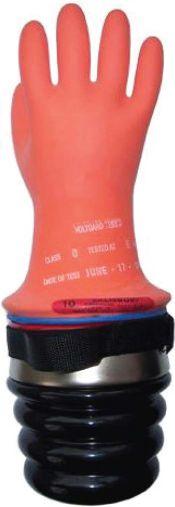

Electrical shock injuries to the hands are common in the electrical testing industry. With regard to PPE, the best prevention for this type ofshock is to wear the correct hand protection. Workers must wear voltage-rated gloves that are correctly rated for the task. The gloves must be tested in accordance with an ASTM standard to ensure they sufficiently protect the worker. See the chart (Figure 5) from Salisbury for the approved voltage levels for each glove design. The cuff length must also be adequate to protect the forearm from electric arc.

Glovesmustbere-testedtotheASTMspecification regularly. There are two OSHA standards that indicate the appropriate test intervals:

• OSHA 1910.137 (Personal Protective Equipment,ElectricalProtectiveDevices). This regulation states that gloves must be electrically tested before first issue and every six months thereafter.

• OSHA 1910.268 (Special Industries, Telecommunications). This regulation states that natural rubber insulating gloves must be electrically tested before first issue, 12 months after first issue and every nine months thereafter.

It is also required that any un-issued glove that has not been tested within 12 months is retested before issued to an employee.

The date of last inspection must be marked on the glove or tracked by another means to confirm that the expiration date has not been exceeded. OSHA regulation 1910.137(b)(2) (xii) states that the employer shall certifY that equipment has been tested in accordance with the requirements ofparagraphs (b)(2)(viii), (b) (2)(ix), and (b)(2)(xi) of this same regulation. The certification shall identifY the equipment that passed the test and the date it was tested. Individualmarkingofthe glove (i.e. equipment

identification numbers) and entering the results ofthe tests and the dates oftesting onto a tracking log is an accepted means ofmeeting this regulatory requirement.

Usersoftheprotectiveequipmentmustalsoinspect them before each use and after any action that may cause damage. This inspection does not need to be tracked, but it does need to be conducted by users to ensure their safety. The user must visuallyinspect the gloves for anyphysicaldamage like punctures, cuts, nicks, cracks, scratches, or abrasions. The user must also inspect the glove for any chemical deterioration ofthe material by looking for swelling, softness, stickiness, or hardness. Owne mayalso cause rapid deterioration of rubber goods. The glove must be inflated to no more than twice its normal size to ensure that the rubber stretches, and the glove must be inspected for breaks in the material by listening and looking forthedefect (SeeFigure6) Ifaportable inflator is not available, then the glove can be manually inflated by rolling the cufftowards the fingers and then spreading the fingers to look and listen for escaping air from holes. To ensure a thorough inspection, this test should also be repeated with the glove turned inside out. More detailed inspection guidelines and procedures can be found underASTM F1236.

With so many bones, ligaments,

Figure 6: Salisbury Rubber Glove lnjlatore tendons, and joints keeping hands and wrists working, there is ample opportunity for injury intheworkplaceandduringeverydayactivities. Correct protection, training, equipment, and techniques go a long way to protect these important assets.

Paul Chamberlain has served as safety manager for American Electrical Testing CompanyInc. since2009. Hehasbeeninthe safetyfieldforthepast 12years, workingfor variouscompaniesandinvariousindustries. Paul received a bachelor ofscience degree fromMassachusettsMaritimeAcademy.

It' s a powe rful stateme nt. Yo umade an inve s tme nt in yo urte s t eq ui pme nt, and yo uwa nt to know that it will be in se r vi ce fo ra lo ng me.

Raytech 's eq uipme nt made fo rthe ha rs h environme nt s of the te s ti ng industry. That' s why 99% of the eq uipme nt sold ove rour18 yea rs in busines s still in se r vi ce today, and how we ca n offe ra 5-year standa rd wa rra ntyat noaddi tio nal charge.

Raytechstands behi nd it s hi ghquali ty meas uri ng and te s ti ng eq ui pme nt, developed and prod uced fo rthe inte rnatio nal powe rindustry.

BY JEFF JOWETT, Megger

BY JEFF JOWETT, Megger

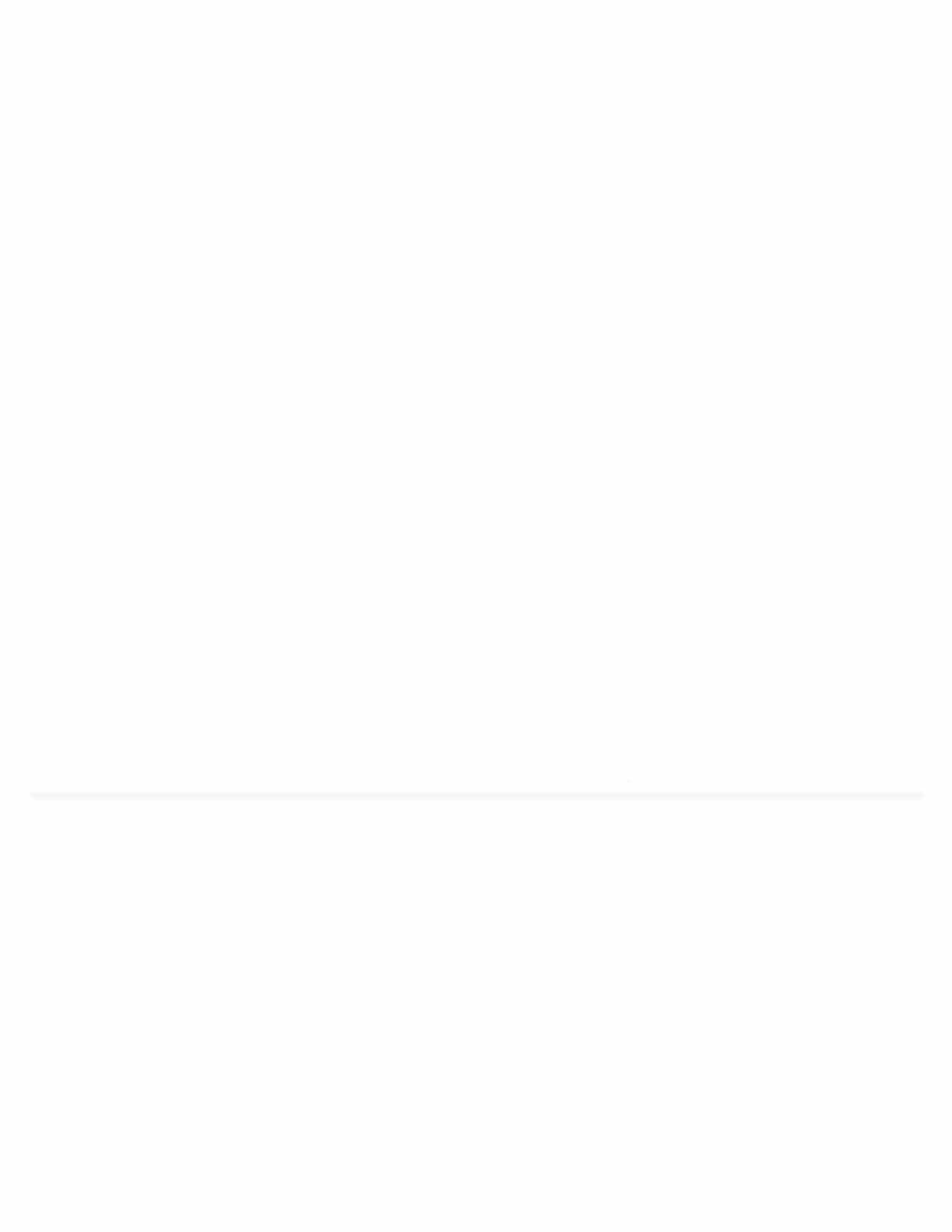

Alightningstrokecanbeconsideredahugeelectricsparktraveling between clouds or cloud to earth. With such an uncontrolled phenomenon, estimates are no more than just that, but 30 to 50 million volts and 18,000 amperes are reliable parameters. The stroke is approximately 90 percent negatively charged. Protection against such an awesome force is a tall order, but nonethelessachievable. Thedemandisrigorous, includingairand ground terminals, grounding conductors and interconnecting conductors, surge suppression devices, and appropriate fittings.

The process oflightning protection consists of intercepting the discharge, safely conducting the lightning currents while minimizing the effects, and dissipating the currents into the earth. Various systems have been devised to address these demanding requirements. Some ofthese involve advanced technologies, such as theearlystreamerairterminalanddissipatingair terminal. Some commentary remains that they are unproven technologies; furthermore, they are not recognized by standards organizations like UL and NFPA. The most widely-accepted protection method continues to be the Franklin air terminal.

Building a protective system begins with risk assessment, including the type ofstructure to be protected and its construction, location, topography, andcontents.Amajorconsideration is the lightning frequency in the area, which varies drastically around the country. These factors are described by six indices and can be

assigned numbers indicating relative degree. Type of structure begins with small singlefamily residences and proceeds through various sizes of commercial buildings, from sensitive structures such as smoke stacks and towers, to hospitals, to buildings housing or manufacturing volatile materials. Construction takes into account both frame and roofwhile assessing them with respect to use of wood, concrete, structural steel, and other materials. Where metallic structure is involved, electrical continuity is a further important consideration.

Location involves surrounding structures and terrain, with both the square footage and the height above surrounding structures and landscape being assessed. The highest riskfactor hereisheightextendingmorethan 50 feetabove adjacent structures and terrain. Topography is assessed in four categories: flat, hillside, hilltop, and mountaintop. Contents include

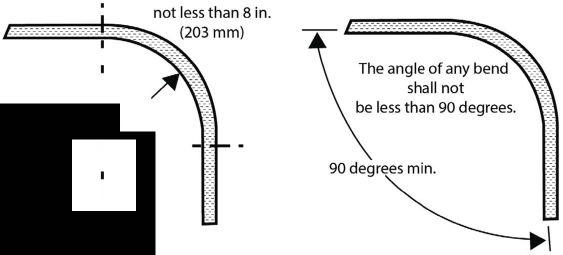

A: 50 ft (15 m) maximum spacing between air terminals

8: 150ft (45 m) maximum length ofcross run conductor permitted without a connection from the cross run conductor to the main perimeter or down conductor

C: 20 ft (6 m) or 25 ft (7.6 m) maximum spacings between air terminals along edges

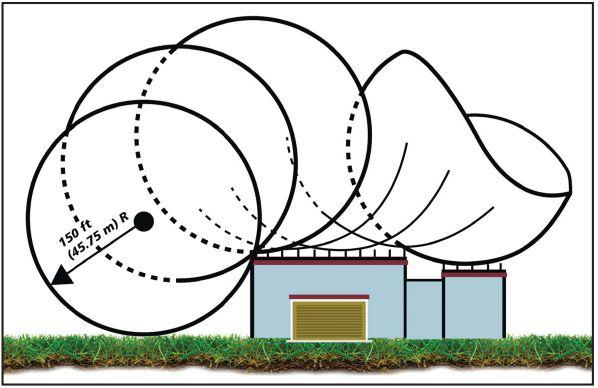

Figure 1: Air terminals must be correctly spaced toprovide completeprotection.

furnishings, combustible and non-combustible materials, population of occupants, livestock, and equipment. This category extends to fine points such as historical nature ofmaterials and mobility ofpersonnel (e.g. bedridden)

Last assessed is lightning frequency, known as isokeraunic level. This is the number of lightning strokes per unit time and is assigned a rating from 100 in much ofcentral and south Florida, especiallythewestern side, diminishing steadilyproceeding north and west, with some uptick in activity in central Colorado and western Montana before dropping along the Pacific coast to a zero to 10 rating. Once these six factors have been assessed, the risk factor is calculated according to:

R =(A+ B + C + D + E)/F

whereFisanindexnumberinverselyproportional to the isokeraunic level. Zero to two is considered light risk, with anything over seven

considered severe. Being able to objectively assign a number to risk helps provide a basis for evaluating the next step, which is to design a protective system.

Applicable standards are NFPA 70 and 780, andUL 96 and 96A. NFPA 780 is the standard for installation oflightning protection systems. It is the most active standard but not an enforced code. UL 96A is also an installation standard, while 96 covers the manufacture of materials. Independent, third-party inspection is described and outlined in 96A. NFPA 70 National Electrical Code includes lightning protection systems and separate but connected grounding electrodes. NFPA 780 describes strike termination devices (lightning rods), the initial contact point at which the lightning stroke is to be deflected into the protective system and away from where damage could occur. These terminals provide the initial line of defense, but they are not required for exposed

metal structural parts of at least 3/16 inch thickness, which can be connected directly to the protective system. For redundant safety, at least two current paths must be provided. The height ofthe air terminal should be at least 10 inches above the protected structure. Ifover 24 inches, the air terminal must also be supported by braces permanently and rigidly attached to the building and at a point not less than onehalfthe height.

Positioning of the devices is also critical and prescribed. On pitched roofs, devices are to be placedwithin twofeetofridge ends. On gently sloping or flat roofs, they are placed at edges and outside corners. Density of placement is not to exceed 20 feet, but for devices 24 inches and above in height, placement can be extended to not more than 25 feet. Flat or gently sloping roofs that exceed 50 feet in length or width shall have additional air terminals spaced not to exceed 50 feet on flat and gently sloping areas (See Figure 1).

There are also standards which describe allowable bend radii for conductors (See Figure 2). Acommon, andpotentially disastrous, error in lightning protection design is to randomly string conductors together and let them fall where they may. For effective lightning protection, the demands are more rigorous. Lightning does not like to travel a curved path and will punch through insulation at rightangle bends. Accordingly, no conductor bend shall have a radius less than eight inches or

form an included angle less than 90 degrees. The down conductor (grounding conductor) terminates at a grounding electrode (ground rod) Depending on local soil conditions, this may be a more elaborate system than a single rod. Its description in terms ofsize, depth, and number of rods is covered by 2014 Edition of the NFPA 780, 4.13.1 through 4.13.8. If it is a dedicated electrode, it should be paralleled with the electrical system ground to prevent voltage gradients that could draw current into building wiring and equipment.

A lightning protection system creates what is called a zone ofprotection (defined in NFPA 780 3.3.45 as the space adjacent to a lightning protection system that is substantially immune to direct lightning flashes) Its breadth can be determined by the rolling sphere method. Described in NFPA 780 Annex A.4.8.3, the zone of protection is the space not intruded by a rolling sphere with a radius of 150 feet. Imagine this as a ball tangent to earth and resting against the air termination. All space in the vertical plane between the two contact points (earth and air terminal) and under the sphere define the zone ofprotection. Similarly, ifthe rollingsphere were resting on two or more strike terminations, the vertical plane under the sphere and between those points defines the zone of protection. The rolling sphere is defined by the formula:

d = horizontal distance

h1 = height ofhigher roof

h2 = height oflower roof(top ofobject)

Use of the formula is based on a 150-foot striking distance. The sphere must be tangent to the lower roof, or in contact with earth and in contact with the vertical side of the higher structure. The difference in height between the upper and lower roofor earth must be no more than 150 feet. As an example, imagine a main building 120 feet in height with an annex 50 feet high and extending 30 feet:

d = -Y[120(300-120)] - -Y[50(300-50)]

d = -Y21,600 - -Y12,500

d = 146.97- 11 1.8

d= 35.17

The calculated distance extends beyond the actual size ofthe structure, and therefore, itfalls within the zone ofprotection (See Figure 3).

Materially, then, a lightning protection system is made up ofterminations in air and ground, conductors, connectors, and fittings. It may also have a surge suppression device. The air terminations intercept the lightning discharge, direct the currents into a safe path to ground, and provide zones of protection. The conductors concentrate the lightning current in a safe path away from equipment and personnel. They must be low impedance paths, and having multiple parallel paths enhances their effectiveness. They can be of copper or aluminum, and some offer UL listing. The ground termination dissipates the current into the earth. It must be of low resistance and not lead to dangerous step potentials in the surrounding area.

Grounding electrodes rangein complexityfrom the single ground rod through plates, meshes, and large grids ofinterconnected rods. Theyall do essentially the same thing, just providing larger and larger amounts ofinterface with the soil to lower resistance and overcome difficult soil conditions. Ufer grounds are concrete encased electrodes using rebar in foundations. They should not be relied upon solely because lightning dissipation can damage concrete foundations. Poor local soil conditions can be countered by the use ofenhanced ground rods, where a bore hole is drilled and backfilled with some form of conductive material around the ground rod. Not to be overlooked are various connectors and fittings that serve to bond conductors to terminals and buildingstructure. These must be tight and well maintained to alleviate potential between metal bodies and prevent flashover. Because of the enormity of lightning strokes, both in magnitude and

variance, no protection system can offer a 100 percent guarantee. But, by following the standards and observing established good practices, the chance of damage can be more like, "getting struck by lightning," as the expression goes. Upcoming articles will examine additional steps in more detail, such as surge suppression and other measures for assuring redundant safety.

Sourceofinforamtion:HargerLightning&Grounding. Grayslake,IL.

Jeffrey R. Jowett is a Senior Applicatiom Engineer for Megger in Valley Forge, Pennsylvania, serving the manufacturing lines of Biddle, Megger, and multiAmp for electrical test and measurement imtrumentation. He holds a BS in Biology and Chemistry ftom Ursinus College. He was employed for 22 years with james G. Biddle Co. which became Biddle Imtruments and isnowMegger.

Use your Windows 7-compatible tablet or PC with the CBAnalyzerTM system to testyourcircuitbreakersinplace. Operate the breaker in any sequence you desire: for example, trip - charge - close. The vibration data created by the breaker operation is captured and analyzed, and the result is instantly returned to your device. The data is saved in your online account for eq uipment management, trending, and fu rther analysis options, including specialized issue diagnosis.

• WORKSONAWINDOWS7-COMPATIBLETABLET,PC,ANDiPHONE

• INCREASESIN-SERVICETESTINGFREQUENCY, BOOSTSUPTIME

• EVALUATESOVERALLMECHANICALCONDITION

• TESTSALLTYPESAND RATINGSOFBREAKERS

• DETERMINESBREAKEROPENINGAND CLOSINGTIMES

• PROVIDESFIRSTTRIPDATA

• Flexible current sensor with direct digital readout

• Measure from 20 milliamps to 4000 Amps (model dependent)

• Resolution to 1 milliamp (sensor dependent)

• Max hold function keeps track of the highest reading during the measurement -a low cost simple data logging solution

• Hold function - retains the measurement reading at the time the button is pressed

• Available with 6", 10" or 14" sensor lengths

• Safety rated to 600V CAT IV

• Up to 70 hours of continuous operation from two AAA batteries

• Easy one hand operation even with a gloved hand

• Bandwidth from 10Hz to 3kHz

• Double insulated case provides an additional safety level

Diane Wjohnson-Hageman

RESA PICKEL, PRITService, Inc. AND KRISTEN WICKS, NETA

The

life ofone we loved is never lost.

Its influence goes through every life it evertouched.

Diane W. Johnson-Hageman, a long-time NETA member and former Man of the Year, passed away on February 17, 2015, after a short illness. Diane is lovinglyrememberedand greatly missed byheradoring husband and best friend, Rod; her three children, Resa, Leeanne, and Michael; her sister, Linda; sixteen grandchildren; and numerous adoring friends Diane was loved by all for her constant kindness, great generosity, and unfailing grace and elegance.

RodandDiane Working Side-By-Side at NETA SRCMeeting

Diane IsAllSmiles the Day She Receives NETA's Man ofthe YearAward in 1993

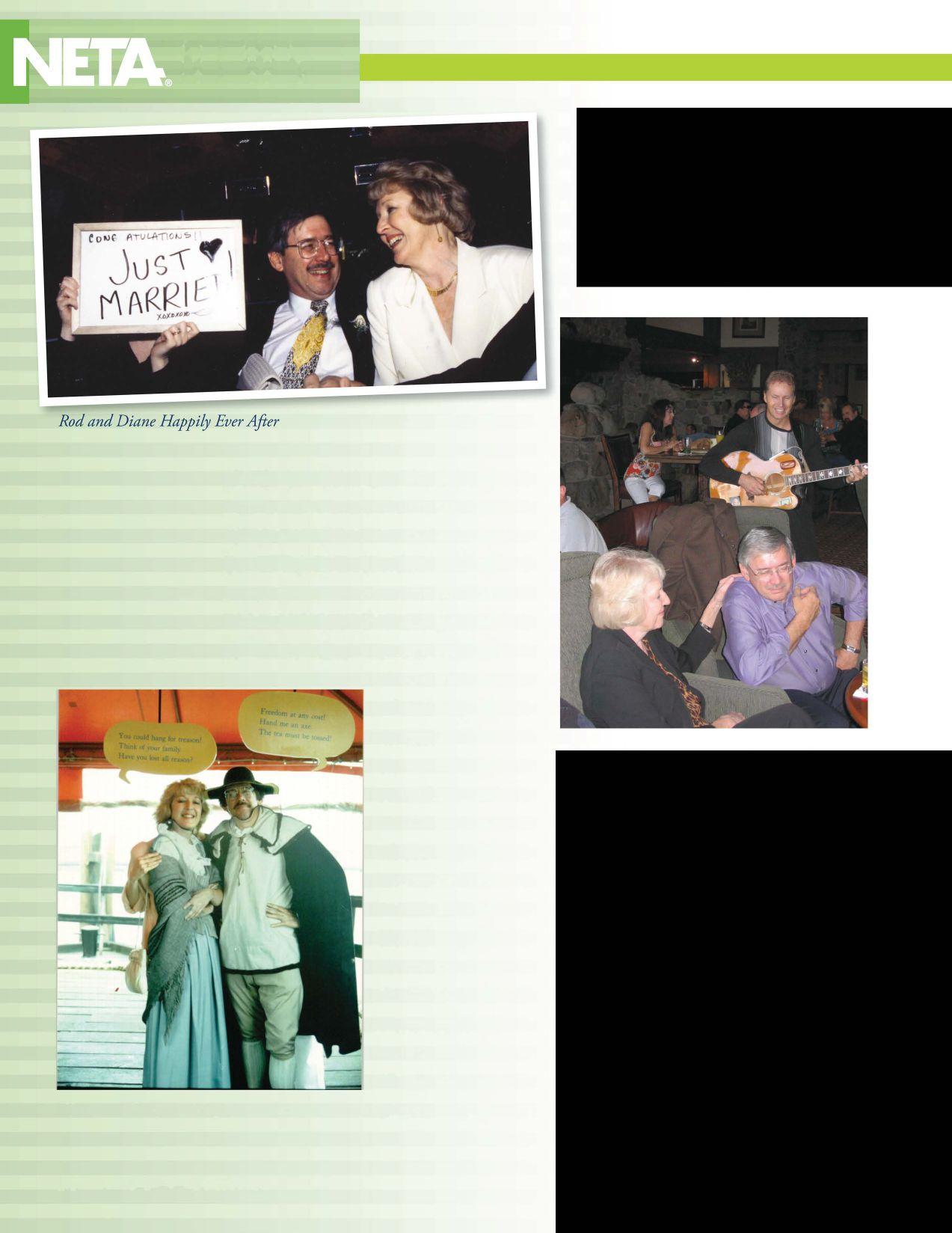

Diane spent her lifetime workinginfieldstraditionally dominated by men and was still working at the time of her death. Diane and her husband, Rod, have owned PRIT Service, Inc., Minooka, Illinois, an electrical power testing company servicing industrial and power-producing companies throughout the Midwest for more than thirty years. It was an ideal partnership that allowed Rod to focus on the engineering and testing aspects of the business while Diane lent her considerable business acumen to the internal day-to-day operations of the business which resulted in a successful company that enjoyed continuous growth over the years. She was a long-time member and volunteer for NETA, where she was a member of the NETA Standards Review Council, editor of NETA World Journal, and became the only woman to be named NETA's Man ofthe Year in 1993.

Prior to moving to Illinois, Diane had lived throughout the southern United States. She worked at Cape Canaveral during the Mercury Space Program from 1958 to 1961, followed by a three-year engagement at Oak Ridge National Laboratory from 1961 to 1965. In the late 1960's, she lived in Paramaribo, Suriname, where she was generally believed to have the first fully airconditioned house in the country.

Diane was born in Jefferson City, Tennessee, and spent her childhood in east Tennessee. She was a classically trained Contralto and attended East Tennessee State University on a music scholarship. Throughout her life she sang in church and community choirs and was often called upon to sing the Contralto solos of the Messiah in those communities where she lived. She was an avid gardener and loved to travel, especially with friends and family. She could often be found in the company of gardeners at resorts and hotels and was known to bring home "gifted" plants for her home garden.

Diane learned to embroider at an early age and became an accomplished seamstress,

creating both beautiful one-of-a-kind clothing and lovely pieces of needlework. Ifsomething didn't look right, she would pull out the stitches and do it over until it was perfect. She loved to cook and the recipes for her sumptuous holidaydishes were in high demand: horseradishcarrots,shoe peg corn salad, and homemade cranberry

relish with walnuts being some of her favorites. Few people knew that she spent hours perusing gourmet cooking magazines for those perfect recipes or that she practiced them in advance to make sure theywere ready

to share. She truly believed that anything worth doing was worth doing well, and she applied that beliefand her exacting attention to detail to every aspect ofher life.

Diane possessed grace and poise that are seldom seen. She was a woman of great moral fiber and gave generously when she saw others in need. She was the type of person young professionals aspire to become: intelligent, assertive, driven, strongwilled, hard-working, and well-respected. She is what every woman

hopes to be: beautiful, graceful, charming, funny, and strong as steel to the core. She lived her life to the hilt every day and put the old adage "early to bed and early to rise makes a man healthy, wealthy, and wise" to

Diane (center) Pictured with Her Coworkers at Cape CanaveralDuring the Mercury Space Program Periodthe test, enjoying a nightcap with the best of them and rising with the sun the next day to get back to work. She was a magical combination of Southern Belle and a shot of whiskey. Even her handwriting had a Southern accent; you could hear it in the gently sloping corrections she made with her redball-pointpenin themarginsoftheNETA standards or articles for NETAWorld, always there in the background softening the blow

of a missed comma or the incorrect use of "proper" instead of cc " correct.

Although Diane took both her work and hobbies seriously, making time to enjoy life and have fun with those who she held dear was especially important. While she worked hard for everything she got, she considered herself an extremely lucky woman and frequently said that Rod was "the best thing that ever happened to me." She loved him dearly and

considered him to be her best friend, never tiring of his companionship whether it be while working, traveling with friends, or simply hanging out at home. She delighted in the accomplishments offamily and friends and took great pleasure in sharing their successes with others. She frequently shared these stories while hosting gatherings in the

beautifully landscaped garden she and Rod created at their home, a magical place where friends were always welcome. No one who knew her could fail to notice the way she tilted her head back and lent her melodic voice to the gales of laughter which were never in short supply when she was with her friends.

One day, those ofus who know and love her will find ourselves walking through a gate into a beautiful spring garden. And there, cool as a cucumber in her chic and breezy clothes, her hair perfectly coiffed, with

Diane in Her Garden

sunglasses donned and diamonds sparkling subtly in the afternoon sun, a glass ofbuttery chardonnay perspiring slowly in her graceful hand, will be Diane. She'll look up, smile sweetly, and ask in her lilting East Tennessee accent, "What in the hell tookyou slowpokes so long?"

While I know that Diane wouldn't want us to rush through the rest of our journeys to reach that garden, I know for certain that she will welcome us with open arms when the time comes, and we'd better have some grand stories and adventures to share with her when we get there.

Ifthereevercomesa daywhen wecan'tbe together, keep mein yourheart,I'llstay thereforever.

- Winnie the Pooh

Ideal for testing thermal, magnetic, and solid state relays, molded case circuit breakers and ground fault trip devices, plus other applications requiring a high current source.

Taiwan

+886.2.2835.9738 info@phenixasia.com

Switzerland

+41.61.383.2770 info@phenixsystems.com

35+ Years

Experience

c 150�9001

> Made for field testing. Models up to 75,000 Amps.

> Features: Proven duty cycle Auto-jog and current-hold capabilities.

> Mobile units offer: Manual or computer operation with numerous automated modes. Precise, repeatable current pulses, minimal distortion. Current wave form display with WIN HC.

, TEXAS OMNI FORT WORTH HOTEL MARCH 14-18, 2016 www.powertest.org

Sentinel Power Services, Inc. was created in December 1998 as a breaker repairshop for industrialclients in the greater Tulsa, Oklahoma area. During 2002, Sentinel Power Services, Inc. added capabilities such as electrical equipment testing, electrical commissioning, troubleshooting, and large motor expertise that transitioned it into being a solution provider, based on client needs. More capabilitieswereadded in 2008 when Sentinel began toperformpowersystemstudies.

As client needs continued to evolve, in 2012 Sentinel Power Services, Inc. added full engineering package capabilities for electrical, instrumentation, and controls, as well as continued to expand service solution offerings.

These expanded services include VLF/Tan-Delta cable testing, partial discharge testing/analysis, first breaker timing, and motor winding diagnostic testing.