The MTO330 transformer ohmmeter and the TTR300 series of 3-phase transformer turns ratio test sets have interchangeable leads, a single user interface and the same set-up file, saving you the cost of additional leads and time learning new interfaces and files.

The MTO330 transformer ohmmeter delivers full eight-terminal/six-winding resistance measurement capability. It is designed to save time by testing all six windings without having to disconnect and reconnect leads.

Any member of the TTR300 series of 3-phase transformer turns ratio test sets can run either stand-alone or remote-controlled.

The one-two power punch of the MTO330 and the TTR300 series can help you save a bit on the bottom line without compromise on performance or productivity.

For more information, call 1-800-723-2861 or email sales@megger.com.

24 LUBRICATION OF ELECTICAL DISTRIBUTION EQUIPMENT

By Bella H. ChudnovskyLubricants are widely used in electrical connectors, switches, and circuit breakers to improve performance and reliability and extend service life of electrical equipment. Electrical distribution apparatus is a complicated electromechanical device made of conductive and insulating materials with sliding and rotating parts and mating surfaces. The role of the lubricants for electrical and mechanical parts is similar, but there are some specifics in choosing a proper lubricant for electrical contacts and mechanical parts. FEATURES

7 PRESIDENT’S DESK

Mose Ramieh, Power & Generation Testing, Inc. NETA President

8 JOHN WHITE ONE OF THE GOOD ONES

Jill Howell and Kristen Wicks, NETA

16 POWERTEST 2012 EVERY THING'S BIGGER IN TEXAS 34 NETA'S FIRST ANNUAL AFFILIATE RECOGNITION AWARD, 2012

Jill Howell and Kristen Wicks, NETA 41 CIRCUIT BREAKERS INVOLVED IN FLOODS

Jim White and Jim Miller, Shermco Industries

67 IMPROPER LUBRICANT SELECTION: A SLIPPERY SLOPE

Mike Orosz, Schneider Electric

50TECH QUIZ

Lubricants Used in Circuit Breakers and Switches

Jim White, Shermco Industries

57THE NFPA 70E AND NETA

Wearing PPE Important or Not?

Jim White and Ron Widup, Shermco Industries

60 NICHE MARKET TESTING

Implementing Lightning Protection Systems

Lynn Hamrick and Owen Wyatt, Shermco Industries

98 TESTING ROTATING MACHINERY

Direct Current (DC) High Voltage Test

Vicki Warren and Ian Culbert, Iris Power LP.

106 SAFETY CORNER

Lubrication: The Dos and Don'ts of Electrical

Equipment Lubrication

Paul Chamberlain, American Electrical Testing Co., Inc.

113 TECH TIPS

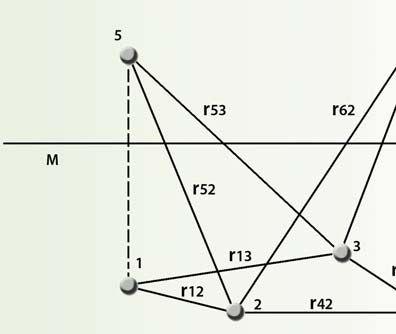

The Theoretical Basis of Resistivity Measurements

Jeff Jowett, Megger

SPECIFICATIONS AND STANDARDS ACTIVITY

118 ASTM F18 REPORT

122 INSULATED CONDUCTOR COMMITTEE NEWS

Ralph Patterson, Power Products and Solutions

124 NEC CODE MAKING PANEL COMMITTEE REPORT

Jim White, Shermco Industries

127 CSA UPDATES

Kerry Heid, Magna Electric Corp.

128 ANSI/NETA STANDARDS UPDATES

INDUSTRY TOPICS

74 POWER FACTOR: EXPLANATION, DEFINITION, IMPORTANCE

John Cadick, Cadick Corporation 87

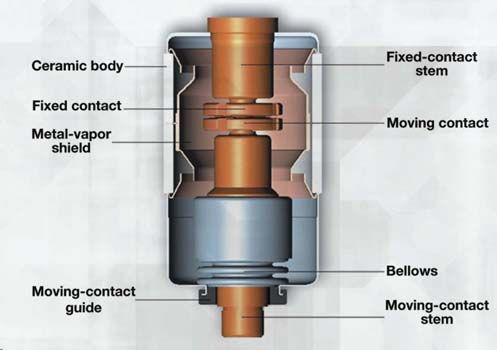

THE REMAINING LIFE OF VACUUM INTERRUPTERS IN THE FIELD

Finley Ledbetter, Group CBS and John Cadick, Cadick Corporation

3050 Old Centre Avenue, Suite 102

Portage, MI 49024

Toll free: 888.300.NETA (6382)

Phone: 269.488.NETA (6382)

Fax: 269.488.6383

neta@netaworld.org

www.netaworld.org

EXECUTIVE DIRECTOR: Jayne Tanz, CMP

NETA Officers

PRESIDENT: Mose Ramieh, Power & Generation Testing, Inc.

FIRST VICE PRESIDENT: David Huffman, Power Systems Testing Co.

SECOND VICE PRESIDENT: Ron Widup, Shermco Industries

SECRETARY: Walt Cleary, Burlington Electrical Testing Co., Inc.

TREASURER: John White, Sigma Six Solutions

NETA Board of Directors

Ken Bassett (Potomac Testing, Inc.)

Scott Blizard (American Electrical Testing Co., Inc.)

Jim Cialdea (Three-C Electrical Co., Inc.)

Walt Cleary (Burlington Electrical Testing Co., Inc.)

Roderic Hageman (PRIT Service, Inc.)

Kerry Heid (Magna Electric Corporation)

David Huffman (Power Systems Testing)

Alan Peterson (Utility Service Corporation)

Mose Ramieh (Power & Generation Testing, Inc.)

John White (Sigma Six Solutions)

Ron Widup (Shermco Industries)

NETA World Staff

TECHNICAL EDITOR: Roderic L. Hageman

ASSOCIATE EDITOR: Diane W. Hageman

MANAGING EDITOR: Jayne Tanz, CMP

ADVERTISING MANAGER: Jill Howell

DESIGN AND PRODUCTION: Newhall Klein, Inc.

NETA Committee Chairs

CONFERENCE: Ron Widup; MEMBERSHIP: Ken Bassett; PROMOTIONS/MARKETING: Kerry Heid; SAFETY: Lynn Hamrick; TECHNICAL: Alan Peterson; TECHNICAL EXAM: Ron Widup; WORLD ADVISORY: Diane Hageman;

CONTINUING TECHNICAL DEVELOPMENT: David Huffman; TRAINING: Kerry Heid; FINANCE: John White; NOMINATIONS: Alan Peterson; STRATEGY: Mose Ramieh; AFFILIATE PROGRAM: Jim Cialdea

© Copyright 2012, NETA

NETA World is published quarterly by the InterNational Electrical Testing Association. Opinions, views and conclusions expressed in articles herein are those of the authors and not necessarily those of NETA. Publication herein does not constitute or imply endorsement of any opinion, product, or service by NETA, its directors, officers, members, employees or agents (herein “NETA”).

All technical data in this publication reflects the experience of individuals using specific tools, products, equipment and components under specific conditions and circumstances which may or may not be fully reported and over which NETA has neither exercised nor reserved control. Such data has not been independently tested or otherwise verified by NETA.

NETA MAKES NO ENDORSEMENT, REPRESENTATION OR WARRANTY AS TO ANY OPINION, PRODUCT OR SERVICE REFERENCED OR ADVERTISED IN THIS PUBLICATION. NETA EXPRESSLY DISCLAIMS ANY AND ALL LIABILITY TO ANY CONSUMER, PURCHASER OR ANY OTHER PERSON USING ANY PRODUCT OR SERVICE REFERENCED OR ADVERTISED HEREIN FOR ANY INJURIES OR DAMAGES OF ANY KIND WHATSOEVER, INCLUDING, BUT NOT LIMITED TO ANY CONSEQUENTIAL, PUNITIVE SPECIAL, INCIDENTAL, DIRECT OR INDIRECT DAMAGES. NETA FURTHER DISCLAIMS ANY AND ALL WARRANTIES, EXPRESS OF IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

ELECTRICAL TESTING SHALL BE PERFORMED ONLY BY TRAINED ELECTRICAL PERSONNEL AND SHALL BE SUPERVISED BY NETA CERTIFIED TECHNICIANS/ LEVEL III OR IV OR BY NICET CERTIFIED TECHNICIANS IN ELECTRICAL TESTING

III OR IV. FAILURE TO ADHERE TO ADEQUATE

PowerTest 2012 is now history and the planning for New Orleans has already begun. We need your input to ensure another great conference.

For those of you that didn’t make it to Ft. Worth, you missed a great time of learning and fellowship. Don’t miss out on next year. Start planning now to attend PowerTest 2013 in New Orleans.

As I prepared this message, I reflected upon discussions I had at PowerTest with the vendors and members about how their businesses were doing during this period of economic uncertainly. I was surprised to hear that the majority were doing quite well. The recovery according to all accounts is very anemic and slow moving. The positive information about how our businesses are doing bodes well for our industry. I can’t speak to the vendors’ success but know that what NETA is doing to promote our test standards and the NACs services has and will continue to have a positive impact for each and every member. Let us hear from you on what you would like to see NETA do to promote your services.

I have stated in previous messages that this is a great time for NETA. We continue to expand services and support to all members. Through our participation, NETA is having a positive impact in many areas of standards and rule making. If imitation is the finest form of flattery, then we are doing a great job as other organizations are creating programs that resemble ours. However, now is not the time for us to maintain the status quo. We need to expand our influence and continue the evolution of NETA!

During the next few months the Board of Directors will be conducting strategic planning sessions. These sessions will have a direct impact on the way NETA will support its members and present itself to the industry in the coming years. Now is the time for your input on the direction you want NETA to take in the future. Let us hear from you.

Mose Ramieh NETA President

Eagles Flock to Honor

JOHN WHITE, NETA’S 2012 OUTSTANDING ACHIEVEMENT AWARD

Recipient.

Each year, NETA selects an individual who has made an impact on NETA and the electrical testing industry as a whole. There are many people each year who are considered for this honor. During the presentation of this award at the Member and Affiliate Lunch at PowerTest 2012, President Mose Ramieh challenged the notion that, “eagles don’t flock; you have to find them on their own.”

He looked around the room and recognized each person in it as an eagle, a leader through commitment to excellence in their field of work. As President of NETA, Mose is challenged with selecting the individual that would receive the 2012 Outstanding Achievement Award. Having a room filled with eagles to choose from can make this task a difficult task. Mose went on to explain that his concern evaporated quickly after realizing that John White of Sigma Six Solutions, longtime NETA supporter, member, and volunteer, had yet to be recognized with this award that honors those who contribute freely of their time and expertise. Read on to learn more about this eagle among eagles.

Many people involved in the electrical testing industry walked a long and winding road that led them to their eventual home in this niche career. They knew a guy that knew a guy, or heard it from a friend who heard it from a friend who, etcetera. Not so with John. When asked how he got his start, he replied, “I was good at science and math in high school so when I started

at Washington State University

I was focusing on math and science. I wasn’t sure what I was going to do with a math degree other than teach, so I talked to a friend of mine who was an upper classman and he suggested I become an electrical engineer. And so I did. The decision process was that simple.”

John’s ability to keep it simple is something that many of his colleagues admire about him. Ron Widup, Shermco Industries, says, “As the Finance Chair he does a great job of condensing the financials down to a succinct presentation that makes sense and gives perspective on where the association is financially, allowing for informed discussions and decisions by the rest of the Board. He is always able to get involved in a discussion in a way that makes everyone think in an expanded way.”

Bob White, Elemco Services, met John White at a NETA conference many years ago. Bob says, “John has always been laid back and quiet. He doesn’t say much in meetings unless he has something worth saying. If there is controversy, he always has a solid opinion or statement that helps find resolution.”

Scott Blizard, American Electrical Testing Co., Inc., agrees that John is, “professional, well-spoken, and well-respected.”

He explains, “When I met John it was in John’s ETI days, ten to fifteen years ago. He was friends with my mother and father, Norma and Charlie Blizard. I always enjoyed talking with him, since he and I were both responsible for operations at our respective companies. John was a big help with when we sold American Electrical Testing Co., Inc.”

It seems that looking at things from different angles has always been one of John’s strengths, and probably one of the reasons that he found his way into his current role at Sigma Six. John recounts his early years as an engineer, “When I got out of school the Vietnam War was going on, and engineers were in high demand. During the interviewing process in my senior year, I decided I didn’t like the typical work that electrical engineers did. It looked boring. When I interviewed at Chevron, they wanted to make me a general project engineer, which involved more disciplines than electrical engineering. That sounded more fun. I was involved with civil engineering, instrumentation engineering, mechanical engineering, project engineering and electrical engineering. I really liked the ‘big picture’. I was fortunate to be able to manage a big design project in South Carolina resulting in the construction of a fiber plant in Dayton, Tennessee. This plant made polypropylene fiber and yarn for use in artificial turf and indoor/outdoor carpeting, both big growth areas in the 1970’s. Other projects included stress analysis on supertanker hulls, underwater pipelines in the Gulf of Mexico, some Fortran IV computer programming, and of course electrical power distribution

design. Eventually, I had achieved a level of responsibility that moved me to the Chevron headquarters in San Francisco in a high-rise building. At that time I was in my late 20s and there was no way I wanted to work in a downtown high-rise for another 30 years. There was too much time left in my career for that.”

“That’s when I met the owner of Electro-Test, Inc. (ETI), John Moore. He had left the electrical design niche to start up a new company. It looked exciting and so that is how I got into the electrical testing industry. Bev and I had three young kids at that time and she and my close friends thought I was nuts for leaving a career with Chevron for a startup company, but it turned out to be a great decision and the start of a lot of fun. And isn’t that what it is all about?”

“A great guy to have in your corner.”

Kerry Heid, Magna Electric Corporation

John’s wife, Bev, and his children have always been important to him. Like many families, they have been through the highs and lows of life but always manage to stay true to their values, keeping family and friends at the top of the list. This is one of the qualities that endear him so quickly to those who meet him.

The White Family

Kerry Heid, Magna Electric Corporation, remembers meeting John. “I sat down next to him at the bar. He introduced himself, and it was just him and me and we got to talking. We learned that we were both newbies to the NETA Board of Directors, and I already had a lot of respect for him having heard great things and knowing that he was one of the top guys at Electro-Test. John was Vice President of NETA while I was President and he was a great guy to have in my corner during some of the challenges NETA was facing at that time. He is a very logical thinker who always gets to the reason behind a decision. His boots have been on the ground for the past 20 or 30 years, and I think that is why he has such good points to offer. ” Kerry also appreciates John’s lighthearted approach to life, saying, “We enjoyed a lot of red wine in the Cayman Islands, and John shared some with the front of his shirt. So, he went for a moonlight swim.”

“You either help to invent change, or become the result of change.”

– John White

When asked for three words describing John, Dave Huffman, Power Systems Testing Company, said, “leader, positive, and humor.” Dave remembers John as being relaxed and easy-going when they first met at a NETA conference. “He’s got a unique sense of humor; you have to pay attention. It echoes through every meeting, and makes them more enjoyable.” Ron Widup agrees, saying, “I can’t go in to too much detail, you know, because of the code… but three words for John would be wine, whisky, and song, but mostly wine. He likes really nice wine, and knows more about it than most people I know.”

Mose and John have become great friends through the years. Mose says, “John and Bev were there for me through the loss of my wife, Linda. They were there to celebrate with me when Janice and I were married. I feel like we are part of the Three Musketeers between us, the Hagemans, and the Whites. As I said when I presented the award, I can’t think of anyone who I would have been happier to recognize. I was truly amazed that he had not received this acknowledgement already.”

Jean-Pierre Wolff, Wolff Vineyards and past Electro-Test colleague, met John at the age of sixteen when they were both employed by ETI in the company’s formative years. They shared in creating a successful business for ETI, Jean-Pierre, saying, “John has a good business mind. We became good friends and still are today.” Lyle Detterman, voices the same opinion of John, stating, “He has proved to be an outstanding leader with good business manner. He can get everyone working in the same direction with cohesion.”

John’s career path is a lengthy and loyal one. From 19681975 he worked at Chevron USA as a Supervising Engineer, Project Manager, and Design Engineer. From there he moved to Electro-Test, Inc., where he stayed from 1975-2005 and served as the Regional Manager, VP of Operations, and President, and now John is the General Manager for Sigma Six Solutions. The highlight reel from these workplaces include learning the wisdom of big-picture thinking at Chevron, helping to grow ETI from a West coast-only operation to a coast-to-coast business with twenty-five offices nationwide, at NETA helping to improve the testing niche and the quality of electrical testing. John says, “I believe you either help to invent change, or become the result of change.” It is clear that John prefers the former.

John doesn’t stop at professional milestones, but goes on to include the relationships that he formed as a result of years spent at ETI and with NETA, but above all else, he credits his family for putting up with all the “self-centered career stuff ”, saying, “it may not be directly related to career, but without family support it is much harder to be successful.” When asked what he is most thankful for, he says without hesitation, “family.”

“Whatever you are, be a good one.”

Part of John’s NETA family, Rod and Diane Hageman, PRIT Service, Inc., share some of their thoughts about John. They describe him as, “an engineer, a business man, a manager, a sports fan (particularly Washington State), a humorist, a gracious host, a family man, and fortunately for those so privileged, a good friend.” Having worked with John for many years as part of the NETA Board of Directors, Rod says, “NETA has had the benefit of John’s attention to detail, knowledge of the financial world, and keen sense of responsibility over the years as John has helped in various roles including President and Chair of the Finance Committee. One sometimes forgets he has a degree in electrical engineering and is as good an engineer as he is a manager.” Rod and Diane have grown close with John and Bev, and happily share, “As a friend, you will find none better. John and Bev are wonderful hosts. Playing croquet or bocce ball (Bev is particularly fun to play bocce ball with) in their yard, rowing out in the sound to set crab traps, and later eating fresh crab from the catch, talking about life, politics, and NETA, and just chillin’ are just a few of the fond memories from trips to Camano Island.”

Abraham Lincoln

With this resume under his belt, John has an up close and personal insight into the change and growth that has taken place in the electrical testing industry over the past 30 years. John says, “I see a lot of positive

When asked what he is most thankful for, John says without hesitation, “family.”

growth in NETA. It’s interesting to look back over the decades. There was a timewhen companies were consolidating through acquisition; bringing firms together and making testing companies larger. Then from those larger companies, people would leave and spin off lots of smaller companies and that is what we are seeing now. The number of our members is growing and that is great. There is always change and it’s great to help create it. Certainly however, one of the biggest changes in NETA has been the outstanding growth in its reputation in the electrical industry; and for good reasons.”

“Our industry trails the computer industry in automation. So, it is somewhat easy to watch the change that computers have brought to the world and to visualize how that will flow into the electrical testing world. It’s exciting. It introduces new methods and instrumentation to engineers. More and more the testing will be driven by computer technology, which will make it more accurate, more efficient, and simpler. On the other hand, NETA Technicians will be increasingly challenged to gain the fundamental knowledge and understanding that the older technicians learned through the manual processes of testing. This “on-the-job” method of learning will need to be replaced somehow.”

To round out the interview, John was asked his favorite color. His response went a little something like this, “When I was younger I used to always say blue. But now I think it depends on the circumstances. I never had a blue car, or a blue house. My cars are black or silver. In some circumstances I like red. Maybe it’s the engineer in me that thinks color is dependent on the circumstance or application. Thinking of color, a lot of people like to categorize things as if they are black or white. That is, apparently, comforting. Really, most things are shades of grey or maybe other colors. It’s this dislike for the grays that creates debate, making life interesting. I like to listen and understand. It’s an education. When we are in discussion and you throw out questions, it gets people into thinking and sharing; so you get to learn from them. And without some uncomfortable quarrel, you don’t maximize wisdom. When I grow up, I’d like to have wisdom.”

Abraham Lincoln said, “Whatever you are, be a good one.” Simply stated and the best kind of quote; it can apply to anyone, anywhere, doing anything; and it suits John White right down to the ground. John has been many things to many people in his life and it seems that no matter whom you ask, everyone agrees. He is a good one.

As they say, everything is bigger in Texas, and PowerTest 2012 this past February 27 through March 1 was no exception. Located at the Omni Fort Worth, Forth Worth, Texas, PowerTest 2012 marked the most well-attended NETA-hosted event to date with attendees, presenters, and exhibitors making a great showing all around. Even though each year’s conference officially kicks off on Monday morning with the Keynote Address, Sunday is a full day for attendees as well.

NETA hosts the largest meeting of its NETA Accredited Companies on the Sunday preceding the conference. This is a great time for Accredited Representatives and employees alike to get a good look at what has taken place over the last twelve months with membership growth, marketing efforts, industry outreach, NETA standards activities, NETA committee projects, and industry standards representation. One of the most exciting announcements at this year’s meeting was that NETA Affiliates are going to be welcomed to the 2013 meeting in New Orleans, Louisiana!

If it’s a day ending in Y then there must be a social event at PowerTest, and Sunday this year was call for the Best Little Pub Crawl in Texas, sponsored by Potomac Testing, a NETA Accredited Company. Crawlers were outfitted with an official pub crawl t-shirt before hitting the town. Food and beverages were plentiful, and everyone crawled safely home in time to make it to the Opening Session and Keynote Address on Monday morning.

Clockwise from Upper Left: The Glittering Glass and Steel of the Dallas Cowboys Stadium House, One of the Most Famous Stadiums in the Country along with the NETA 40th Birthday Celebration; NETA Accredited Companies and Affiliates Smile up at the Camera; Mose Asks Everyone Who is a Long-Standing Member of NETA to Join Him up Front for the Toast; Megger Pulled out all the Stops at Their Luxe Suite at the Birthday Party; A Photographic Look Back at NETA Through the Years.

Conference Chair, Ron Widup, welcomed everyone to his home state during the Opening Session on Monday. Mose Ramieh, NETA President, asked everyone to join in the celebration of NETA’s 40th Birthday with a presentation on the growth of the association over the past forty years. Tim Autrey, Practicing Perfection Institute, gave the Keynote Address. His engaging and charismatic style of speaking always makes an impact, and his morning session didn’t disappoint. He spoke to attendees about creating a culture of safety through leadership at every level, providing illustrative examples and reference points to take back to the workplace.

Packed with 45-minute technical presentations covering five different tracks and one interactive symposium, Monday is one of the busiest days at PowerTest. Safety, reliability, equipment, codes and inspections, and rotating equipment each had a full roster of subject matter experts presenting throughout the day. The Transformer Symposium held on Monday afternoon drew a large audience eager to interact with representatives from Doble Engineering, Hartford Steam Boiler, S.D. Meyers, and Shermco Industries. NETA Accredited Companies and NETA Affiliates gathered for the first annual Member and Affiliate Lunchwhere two outstanding individuals were honored. Everyone gathered for a group shot after lunch.

Clockwise from Upper Left: Janice Ramieh, Roz Demaria, and Pam Heid – Three Lovely NETA Ladies; I’m with the Band; Mose and Janice Ramieh Cutting a Rug; Here’s to a Delicious Forty Years and Many Happy Returns; All Smiles with the Shermco Gang; Rod and Diane Hageman Dance to Their Song, “Wonderful Tonight”.

There is no rest for the weary, with attendees being shuttled to an extravagant Welcome Reception and 40th Birthday Party at the Dallas Cowboys Stadium. A timeline of NETA’s past, complete with photographs, welcomed everyone as they entered. Sponsors Circuit Breaker Sales Co., Inc, Megger, and Shermco made sure everyone enjoyed themselves, and with PRIT Service, Inc. sponsoring the band, there was music and dancing to go along with the fabulous location. Mose Ramieh presided over the official birthday toast, welcoming everyone to salute those individuals that were long-time members and supporters of

NETA. A gorgeous, custom-designed birthday cake made it official, with decadent chocolate gnash separating layers of moist white cake. The only things sweeter than the cake were the two lovely Dallas Cowboys Cheerleaders who graciously signed autographs and posed for pictures with guests (thanks, Shermco)!

Clockwise from Upper Left: Ron Widup and Mag Sibley, Shermco, Pose with a New Friend; Roz and Tony Demaria, Tony Demaria Electric, Janice Ramieh and Jim White, Shermco, Up Close and Personal; Snake Charmers, Charming; Snake Charmer, Don't Try this at Home.

Tuesday morning began with interactive panel sessions, which are always popular with attendees since no two sessions are ever the same. Safety, relays, motors and generators, and circuit breakers gave attendees ample opportunity to engage in discussion with panel experts and peers on their topics of choice. The 2012 Trade Show was held in the Fort Worth Convention Center directly across the street from the Omni Fort Worth, allowing for the largest displays ever presented at PowerTest. Many companies drove in mobile units for training or housing equipment too large for most hotel exhibit halls, and everyone enjoyed the open space with plenty of room to circulate among

over 100 vendors. NETA is always pleased to hear the positive feedback about this four-hour event and how both attendees and exhibitors enjoy the fact that this event has no competing programs. Tuesday evening brought some memorable hospitality suites, courtesy of Protec Equipment Resources, GE, Megger, National Switchgear, Shermco. Shermco won the prize for the most hair-raising suite with Rattlesnake Republic stars Jackie Bibby and Robert Ackerman.

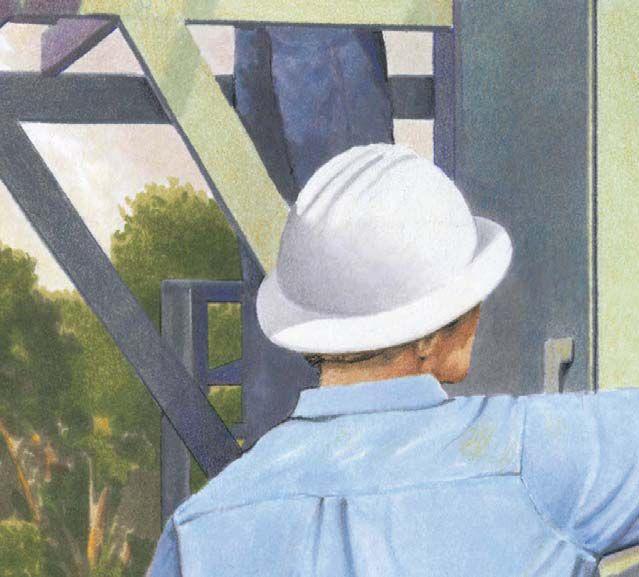

Attendees get up Close and Personal with Equipment while Participating in the Hands-on Seminars.

Wednesday and Thursday allowed attendees the opportunity to register for additional seminars that offer four-hour, in-depth looks at specific subject matter. This year marked the first-ever hands-on, off-site seminars hosted by Astro Controls/Circuit Breaker Sales, AVO Training Institute, and Shermco. Registered attendees were treated to breakfast before being bused to each location for a full day of learning.

Thank you to all of our PowerTest attendees and sponsors for making PowerTest 2012 a true celebration of the best of NETA’s forty years. We hope to see you all again in New Orleans, Louisiana, on February 18-21, 2013 at the Sheraton New Orleans Hotel for PowerTest 2013.

It’s gonna’ be one humdinger of a time, so bring your friends along!

CHOOSE BETWEEN KEEPING MAINTENANCE COSTS DOWN AND KEEPING UP WITH PRODUCTION DEMAND…OR DO BOTH. THAT’S

NETA certified experts at Electrical Reliability Services will keep you in perfect balance. To ensure the reliability of your electrical power, you have to balance the need to reduce maintenance costs with the need to perform regular maintenance. Only the team from Electrical Reliability Services delivers cost-effective services and system expertise to keep you up and running 24/7.

BY BELLA H. CHUDNOVSKY

BY BELLA H. CHUDNOVSKY

Lubricants are widely used in electrical connectors, switches, and circuit breakers to improve performance and reliability and extend service life of electrical equipment. Electrical distribution apparatus is a complicated electromechanical device made of conductive and insulating materials with sliding and rotating parts and mating surfaces. The role of the lubricants for electrical and mechanical parts is similar, but there are some specifics in choosing a proper lubricant for electrical contacts and mechanical parts.

An electrical contact through which current passes is a combination of two surfaces held together by force. Many factors can lead to degradation of contact surfaces. Sliding and rolling contacts constantly move against each other and the surfaces degrade due to friction and wear debris. Static or wiping contacts experience vibration while the current is passing through, and vibration destroys the plating. This degradation process is called fretting corrosion. Formation of nonconductive deposits on the contact surfaces caused by various types of corrosion (atmospheric and galvanic) leads to the rise of contact resistance.

The most important purpose of the lubrication of electrical contacts is protection from environmental, galvanic and fretting corrosion, and reduction in wear of and friction between contact surfaces. A properly chosen lubricant may slow down these processes without interfering with the electrical resistance of the contact. The general principle of electrical contact lubrication is to use a product that protects an electrical connection from degradation and rise of electrical resistance. The function of a lubricant depends on application. In separable contact, it reduces friction during installation, minimizes mechanical wear during service, and slows down the destructive effect of fretting corrosion. In a permanent electrical contact, lubricant blocks access of corrosive gases and particulate material to the interfaces of the conductors.

Every lubricant is basically a nonconductive material, and for this reason the benefits of using lubricant for electrical contacts for corrosion inhibition were not well understood for many years. Many users were concerned that applying a nonconductive substance between contact surfaces would interfere with electrical conduction. Indeed, very few lubricants that provide exceptional long-term corrosion protection without producing any adverse effect on connector surfaces have been identified. Among them, synthetic soap greases and other commercial greases have been tested and proven useful for bolted contact application. Field testing showed that lubricated surfaces may collect and retain dust. Still, liquid lubricants appear to perform better than wax lubricants in sliding electrical contacts in dusty environments.

The choice of the product for electrical contacts should be based on lubricant properties and conditions of application such as contact design, load, heat dissipation, and environment. When these factors are considered together, it provides the best result from lubrication.

The most important purpose of the lubrication of electrical contacts is protection from environmental, galvanic and fretting corrosion, and reduction in wear of and friction between contact surfaces.

An important factor for choosing the right lubrication product is the environment where a particular electrical apparatus is to function. Various environmental factors and their combinations are aggressive towards traditional metals used in electrical contacts (copper, aluminum, and various alloys) and their coatings (silver, tin, and nickel, for example). Corrosive gases and vapors in the environment, which are chemically aggressive towards contact materials and plating, produce a nonconductive deposit on the contacts. Other environmental factors (temperature extremes and humidity) accelerate corrosion. An additional contaminating and corrosive factor is dust.

Another phenomenon that leads to contact degradation is galvanic corrosion between dissimilar metals. Whenever dissimilar metals are in the presence of an electrolyte, a difference in electric potential develops. When these metals are in contact, an electrolytic action causes an attack of the anodic metal, leaving the cathodic metal unharmed. The extent of the attack depends on the relative position of two metals in contact in the electrolytic potential series. Galvanic corrosion is common with aluminumto-copper connections, since copper and aluminum are quite far apart in the series, copper being cathodic and aluminum anodic. Hence, when aluminum and copper are in contact in an electrolyte, the aluminum may be expected to be severely attacked.

The choice of lubricant for corrosion protection should be based on thorough qualification of the product for survival in long-term use. Corrosive environments may also be detrimental for lubrication materials. If the lubricant cannot withstand the service conditions and degrades, it could induce an additional cause of contact deterioration.

Some products, such as petrolatum-type compounds containing zinc dust, effectively protect contacts made of dissimilar metals from galvanic corrosion. However, some lubricants may induce galvanic corrosion. For example, graphite, which has a very noble potential, may lead to severe galvanic corrosion of copper alloys in a saline environment. Therefore, the products for galvanic corrosion protection of dissimilar metal connections should be chosen very carefully.

However, application and operating conditions of electrical connections as well as environmental conditions (such as humidity, temperature, corrosive gases, and dust) are very complicated. This is one reason why it is almost impossible to choose just one kind of lubricant to fulfill all the requirements and to match all conditions. There is no such thing as a universal lubricant for electrical contacts.

Original equipment manufacturers (OEMs) usually specify various oils and greases which have been thoroughly tested for a specific application. Usually each manufacturer lists all greases that should be applied at specific points during routine maintenance, and the greases are usually different for the various parts of mechanism and current carrying parts. These greases are applied during assembly of the original equipment, and it is always recommended to use the same or similar lubrication product for relubrication which guarantees that it will perform properly in service. Lubrication should be performed according to the manufacturer’s recommendations.

The choice of lubricant for corrosion protection should be based on thorough qualification of the product for survival in long-term use.

However, in some cases the lubrication product is obsolete, or the electrical manufacturer is no longer in business. Then an alternative lubrication practice should be implemented. In such cases, the substitute lubricant should be chosen based strictly on application and physical properties of the recommended greases. A change of lubrication product may require testing, which must be performed under the supervision of engineering. The engineering staff must specify what type and brand of grease or oil should be applied during equipment maintenance or overhaul.

Any failure of equipment which might be caused by insufficient lubrication must be analyzed and used to improve lubrication techniques and lubricant choice. Any lubricant specified or chosen for lubrication must be available locally and nationwide. A sufficient supply of greases with MSDS and technical data sheets of all lubrication products should be kept in properly organized storage.

Metal-filled lubricants should not be used for electrical contacts unless tested and proven to be effective long term. Many such products can accelerate corrosion, create conductive paths and eventually cause failure. The general rule is to avoid graphite, molybdenum disulfide (MoS , moly), or PTFE (Teflon®) lubricants for electrical contacts because they could cause a resistance rise after multiple operations. For most switches and breakers that operate infrequently, simply keeping the contacts clean and dry with no lubricant might be a viable option. Main and arcing contacts should never be lubricated.

The procedure for lubrication troubleshooting of electrical equipment such as circuit breakers is usually recommended by the manufacturer. If it is unavailable or ineffective, one can consider using diagnostic instruments which can measure trip time, force, resistance, and vibration. Certain profiles will indicate lubrication problems. If this type of diagnostic is not available, but slow operation is encountered, inadequate lubrication may be the cause.

When analyzing a lubrication problem, it is important to identify a symptom that is specific for the lubrication fault. Among those symptoms are excessive leakage of the lubricant, overheating, wear, and scoring. Other problems, such as use of an incorrect lubrication product or application of too little of the lubricant, may also cause lubrication failure. Presence of water in the system could dramatically change a lubricant’s properties. To take corrective actions, it is important to examine what kind of product was used in previous maintenance and what the properties of the used product are.

Manufacturer Label.

Manufacturer Maintenance Specifications.

Electrical apparatus should be relubricated accordingly to the OEM recommendations. Manufacturers’ user manuals usually list the directions which are recommended to follow during periodic lubrication of electrical power equipment, which includes terms and points of lubrication. However, there are several rules that are the same no matter which type of equipment is maintained.

Before periodic lubrication, all traces of the old lubricant must be removed from surfaces by the use of commercial cleaners such as kerosene or mineral spirits. To loosen the old lubricant, the disassembled parts should be soaked in solvent. To remove contamination from the part, the solvent can be agitated or flushed through the part. If a part cannot be removed, adding oil could be helpful. It is important to use the same type of oil that was used as a base in the grease to be removed. To speed the process of cleaning, soft-bristled brushes may be used. After removal from the solvent, parts should be carefully dried and relubricated as soon as possible. Proper cleaning removes all the residue of old grease, which is very important in order to avoid mixing incompatible greases during relubrication.

For lubrication in the field when disassembling is not supposed to or cannot be done, low or medium viscosity oil is recommended. In some cases, lubrication characteristics of petroleum oils may be improved by adding a stable dispersion of molybdenum disulfide in a premium mineral oil. These materials, applied only to mechanism parts, may extend lubricant and gear life, reduce metal-tometal contact, and lower friction.

Penetrating oil should not be used as a lubricant in electrical equipment. Penetrating oil is not designed for lubrication; it always contains one or more solvents. Because of the solvents’ presence, penetrating oil will attack, dissolve, and wash out factory-installed lubricants and hasten failure. Penetrating oil works only briefly; it is contaminated easily; and many change into a viscous mess. In comparison with grease, penetrating oil has much lower viscosity; therefore, it flows easily. It will leak out under gravity or centrifugal action, leaving lubricated parts dry. Penetrating oils have a very low boiling temperature and high vapor pressure at ambient temperature. Most penetrating oils or aerosols are flammable and should not be applied in areas where sparks or arcing may occur. Penetrating oils are recommended only for rust removal and ease of part disconnection.

A common misconception among maintenance personnel is that it is better to overlubricate than to underlubricate bearings and matching parts. Both methods are undesirable. Underlubrication may leave bare metal-to-metal contact, and overlubrication may cause heat buildup and friction rise as the moving elements continuously try to push extra grease out of the way. To assure that moving parts are not overlubricated or underlubricated, with either grease or oil, the manufacturer’s instructions should be followed. In electrical application, an overgreasing may lead to contamination of nonconductive parts with the grease or oil which will adversely affect dielectric properties of insulating materials. Lubricants should not be applied to the materials with which they are incompatible, such as silicone lubricants to silicone rubber, fluorosilicone lubricants to fluorosilicone rubber, and petroleum lubricants to rubber. The materials will be irreversibly damaged by contact with the lubricants, and the lubricants will deteriorate.

Greases are considered incompatible when the physical or performance characteristics of the mixed greases fall below original specifications. Grease incompatibility is defined as lessening in performance capability and changes of physical properties when two greases are mixed, such as lower heat resistance; change in consistency, usually softening; or decrease in shear stability.

ASTM D6185 Standard, Practice for Evaluating Compatibility of Binary Mixtures of Lubricating Greases, defines the procedure for evaluating the basic compatibility of greases. This procedure includes measuring the dropping point, the mechanical stability, and the change in consistency of the mixture upon heating. The mixture of two greases must be considered incompatible if the test proves that the mixture is significantly softer, less shear stable, or less heat resistant than the original grease. Incompatibility is not predictable, and there is no practical rule one can apply to all mixtures of different greases to determine compatibility properties.

Lubricating oil or grease is a mixture of mineral or synthetic oil with different additives. Grease also contains a chemical substance called thickener, an important component of grease whose properties define grease consistency. When mixed greases are made with incompatible thickeners, substantial softening usually occurs. This is especially dangerous because softened grease can run out, particularly in vertical applications. However, lithium and clay greases harden in some mixtures. Certain thickener combinations are generally recognized as incompatible. For example, soap greases are incompatible with the clay and polyurea greases. Table 1 presents a grease incompatibility chart based on thickener type.

Cleaning the Components.

Application of Lubricant.

Choosing the Right Lubrication Compound.

Greases are considered incompatible when the physical or performance characteristics of the mixed greases fall below original specifications.

Table 1: Grease Incompatibility Chart (Relative compatibility rating: C=Compatible; I=Incompatible; B = Borderline)

Since each of the greases in the mixture is a combination of different thickeners, base oils, and additives, incompatibility is not always caused by the thickener alone as often thought. Sometimes one grease thickener is incompatible with the oil or the additives present in the second grease. Compatibility problems may occur when different types of oils from one or more suppliers are being mixed. Mixtures of various synthetic lubricants should also be avoided, as the various types of synthetics are not always compatible. It is not recommended to mix mineral oils with synthetic oils such as polyglycols.

Very often the cause of incompatibility is a chemical reaction between different types of additives, as grease may have up to a dozen different chemicals added to the base oil to maintain the properties of grease and improve its lubricating abilities. Additives can be diluted when greases with different additives are mixed.

When applying the lubricants to electrical apparatus, mixing different lubricants should be avoided; otherwise, it may lead to lubricant degradation due to incompatibility. If a new brand of grease must be introduced, the component part should be disassembled and thoroughly cleaned to remove all of the old grease. If this is not practical, the new grease should be injected until all traces of the prior product are flushed out. The major rule to prevent grease degradation due to incompatibility problems is do not mix greases under any circumstances.

When applying the lubricants to electrical apparatus, mixing different lubricants should be avoided; otherwise, it may lead to lubricant degradation due to incompatibility.

Grease applied to electrical equipment is exposed to many environmental factors that cause contamination and oxidation of the grease. When the grease oxidizes, it usually darkens due to the presence of oxidation products. These products can have a destructive effect on the thickener, causing softening, oil bleeding, and leakage. Because grease does not conduct heat easily, serious oxidation can begin at the points with high temperature and spread slowly through the grease. At elevated temperature, lubricants may degrade by oxidation or polymerization, forming insulating films. The temperature limits for use of greases are determined by drop point, oxidation, and stiffening at low temperatures, which are usually given in the lubricant’s technical data sheet.

Maximum Working Temperature is a maximum temperature at which a lubricant can safely be used. The higher the temperature to which the grease is exposed, the higher the rate of oxidation. For most greases, heating changes consistency very slowly until a certain critical temperature is reached. At this temperature, the gel structure breaks down, and the whole grease becomes liquid. This critical temperature is called the drop point, which should never be exceeded. When grease is heated above its drop point and then allowed to cool it usually does not fully regain its original consistency, and its subsequent performance may become unsatisfactory.

Minimum Working Temperature is the point at which the grease becomes too hard for the bearing, or other greased component, to operate. Again, the base oil of the grease determines the minimum temperature. Obviously, the base oil of the grease for low-temperature service must be made from oils having a low viscosity at that temperature. For example, if the operational temperature of the unit in operation is lower than the lower limit of the lubricant’s working temperature range, then the lubricant may stiffen at cold temperatures, which could happen in circuit breakers in outside installations in cold climates. Lubricants with petroleum (mineral) oil should not be used in areas with extremely cold temperatures. They get thick and hard and do not function properly below 0°F (-20°C). Synthetic lubricants must be given preference in locations where extreme temperature could be a factor of operation.

Thermal limitations, both high and low, represent the major factors of selecting a correct lubrication product. At low temperatures, many lubricants appear to solidify, developing high shear strength films and leading to high contact resistance. Some lubricants are susceptible to cracking due to longterm exposure to high temperature. All factors including environment, application conditions and working temperature range of the grease should be considered when choosing the correct grease for a specific application.

Bella H. Chudnovsky earned her MS and PhD degrees in Applied Physics and Material Science at Rostov State University (RSU) in Russia. For the first 25 years she worked as a successful scientist for the Institute of Physics at RSU and at the University of Cincinnati. The last 12 years of her career she worked as an R&D engineer for Schneider Electric-Square D Company where her principal areas of activities were aimed at resolving multiple aging problems of power distribution equipment. Dr. Chudnovsky conducted research in various application fields and developed new maintenance, refurbishment and monitoring techniques for electrical apparatus. She has published 40 papers in these fields in national and international technical journals and conferences proceedings.

Partial Discharge Solutions

Detect partial discharge with Doble’s Partial Discharge equipment such as the PDS100 RFI survey tool and the PD-Smart Electric/ UHF test instrument using TEV or HFCT sensors.

Circuit Breakers are a critical effective transmission and distribution system. How can you be sure that breakers will work when they need to? Rely on Doble’s circuit breaker testing that breakers can and will perform

NETA has had many firsts over the past 40 years as an association. 2012 marks the inaugural year of a new honor built to recognize one of NETA’s valued individuals who are part of the NETA Affiliate Program. This program is open to all individuals who are involved in or support the electrical testing industry, serve the industry through the development and use of consensus standards in the electrical power industry, and are focused on providing the highest level of safety and reliability. These individuals include people from all aspects of electrical testing and include consulting engineers, architects, and individuals who work for manufacturers, utilities, hospitals, and universities, to name a few. Many of these individuals volunteer in addition to their regular jobs and have become fixtures in the world of standards creation, training, education, and industry publications. These people that give so freely of their time without looking for recognition are deserving of the thanks of their colleagues, and NETA is pleased to shine the spotlight on the first recipient of this award, Dennis Neitzel.

Dennis Neitzel, CPE, Director Emeritus of AVO Training Institute Inc., is a long-time contributor to and friend of NETA. Dennis has been a strong influence on AVO’s direction since joining their team in 1989. In addition to his work at AVO, Dennis is a NFPA 70E® Principal Committee Member and Special Expert (since 1992), the IEEE 902 (3007) Working Group Chairman, IEEE P45.5 Working Group Chairman, IEEE 1584 Working Group Member, IEEE P1713 Working Group Member, IEEE P1814 Working Group Member, Coauthor of the Electrical Safety Handbook, and a member of the Defense Safety Oversight Council, Electrical Safety Work Group (DoD Electrical Safety Special Interest Initiative). His expertise is requested for speaking events and research committees around the world. We draw on his knowledge of emerging regulations and involvement in electrical research to stay on the forefront of change. He has worked in the electrical industry since 1967, specializing in electrical safety and power systems analysis for commercial, utility, and manufacturing facilities. Dennis received his bachelor’s and master’s degrees in electrical engineering from Columbia Pacific University and is a Certified Plant Engineer (CPE), Certified Technical Instructor (Westinghouse), and Certified Electrical Inspector-General (IAEI).

With this professional experience, Dennis has definite beliefs about the electrical industry, where it has been, what has changed, and where it is going: “The biggest changes in the last five to ten years have been with electrical safety and maintenance awareness. There has been a large impact of electrical safety through arc-flash studies. The quality of protective equipment has increased; advancing technology has significantly reduced the weight and thickness of arc-rated flash suits, and the energy absorption dies for face shields have improved and become less dark, greatly enhancing visibility.” When asked where he foresees future changes, Dennis says, “It will be dealing more with arc-flash issues at lower voltages, configuration of electrical systems, available shortcircuit current, protective device clearing times, and dc arc-flash.”

Navigating the vast oceans of knowledge requires good direction. Dennis follows an internal compass, guided by feedback from presentations he gives, classes he teaches, and from listening to other presenters speak. Some of the individuals regarded by Dennis to be major contributors to the advancement of safety and reliability are, “Ray Jones, former Chair of NFPA 70E, and Bruce McClung, for his work in electrical safety and electrical power systems engineering; Lanny Floyd, for his work on raising awareness of electrical safety in the industry; and Ron Widup and John White, Shermco Industries, for their work in tying maintenance and safety together. The list continues….”

Ron Widup, fellow member of 70E, remembers meeting Dennis, “I think it was as the 70E meeting in 1998. He was a member of the committee and I was new as of July that same year. My first impression was that he was a really smart guy; he really knew his stuff with safety related topics and the rules and regulations associated with them. He writes well and does a great job at presenting, with a good perspective on maintenance as it relates to safety.” Ron continued, “Recently, he and I worked together on the IEEE Yellow Book reorganization. He was the Chair and I was the Vice Chair on the IEEE 3007.3 Recommended Practices for Electrical Safety in Industry and Commercial Power Systems. He is always involved in the industry, which makes him a valuable asset to NETA. He is always at the top of the list for speakers at PowerTest because of his knowledge of testing and maintenance, the quality of his presentations, and his reliability as a presenter.”

When asked to describe Dennis in three words, John Cadick, Cadick Corporation, replied, “Tenacious, hard-working, intelligent, knowledgeable, friendly… oh, you just wanted three?” John doesn’t recall how he and Dennis met, saying, “I honestly don’t remember when we met. I am pretty sure that our meeting was related to the Multi-Amp Institute back in the old days. I feel like I have known Dennis forever, having provided consulting services to the AVO International Training Institute for several years while Dennis was the director there. We have worked together on a number of projects including the development of training courses, IEEE 1584, and the IEEE std 45 safety working group. He was always great to work with, whatever the project. I don’t know how any one person can keep so many balls in the air at the same time.”

Dennis continues to work on 70E, with his current work on the 2015 edition being the sixth edition to which he has contributed. He is a coauthor of the recently released fourth edition of the Electrical Safety Handbook, published by McGraw-Hill. He is responsible for working with Jayne Tanz, Executive Director of NETA, to get the ANSI/NETA Standard for Maintenance Testing Specifications for Electrical Power Equipment and Systems incorporated into AVO’s training courses.

While it may have been no surprise to those who know Dennis that he was chosen for this award, when he received notice that he was the first annual recipient of the Affiliate Recognition Award, Dennis had this reaction: “I was surprised, pleasantly surprised. It is a great honor from NETA. I work with people in different organizations and I am just trying to help; it is always great to know that you are making a difference.”

NETA thanks Dennis for setting the bar high for future recipients of this award and welcomes those involved with NETA’s Affiliate program to contact the NETA office with their suggestions for future recipients. This honor will be bestowed each year at PowerTest during the Member and Affiliate luncheon. To learn more about becoming an affiliate, please visit www.netaworld.org.

In January 2012, Sigma Six Solutions changed its look and logo to better reflect its growing brand presence in the power industry. The company’s website was also redesigned to make it easier for customers to find the information they need, when they need it.

Although the look is new, Sigma Six Solutions’ passionate commitment to quality service, proven experience, and customized electrical power solutions remains unchanged.

Delivering Powerful Reliability Solutions

Power System Acceptance Testing

Commissioning and Start-up

Maintenance

Life-Cycle Extension

Troubleshoot and Repair

Training and Engineering Services

Planning and Operations Support

Project Management

As the leading independent electrical testing, maintenance, and engineering service company, you can rely on Emerson’s High Voltage Maintenance to exceed your electrical equipment performance goals. From testing for problems that could disable your system, to complete turnaround execution, you’ll quickly understand how we are your single source solution for all of your electrical reliability needs. With a network of more than 12 service locations, our service team puts experienced professionals where and when you need them.

Comprehensive Electrical Testing and Maintenance

Commissioning and Startup Services

Engineering Services

Power System and Coordination Studies

Predictive and Preventive Maintenance

Partial Discharge Testing and Monitoring

24/7 Emergency Service

With substations regularly overloaded and equipment often near the end of its life, electric grid operators are challenged to improve overall system reliability. Our mission is to provide our clients with that can be used to better manage the overall life cycle of their critical electrical assets in a manner that is convenient, easy to understand, and assists in critical decision-making.

WEIDMANN DIAGNOSTIC SOLUTIONS INC. provides the vital knowledge you need to help you lower risk and improve your electrical system’s reliability. We provide through our extensive range of diagnostic products and services.

WEIDMANN DIAGNOSTIC SOLUTIONS INC. is a leader in developing condition assessment methods for transformers and all oil- lled electrical equipment, such as OCB’s, LTC’s, regulators, recti ers, and network units. ®

DIAGNOSTIC SOLUTIONS INC.

One Gordon Mills Way, PO Box 799, St. Johnsbury, VT 05819-0799, USA T +800 811 2284, +916 455 2284, F +916 455 0191, www.weidmann-electrical.com

A Member of the Group

Over the past several years a number of severe weather incidents have caused flooding at the facilities of Shermco’s customers. These events cause widespread damage to electrical equipment and facilities and cost companies millions of dollars in repair and replacement of damaged equipment. Floods, hurricanes, and malfunctioning pumps at wastewater treatment facilities can cause flood damage to electrical equipment. This article looks at the damage caused during flood situations to low- and medium-voltage air and medium-voltage vacuum circuit breakers.

My oldest son works at Shermco’s circuit breaker shop and was at a petrochemical plant that had been flooded due to a river overrunning its banks. As he stated it, “We found 90 Port-A-Potties overturned.” That translates into hazardous waste and handling anything becomes a health issue. One never knows what has floated in from the river or what has been released as a result of the flood, so hazmat issues must be a primary consideration.

Near the coast, where hurricanes can dump massive amounts of salt water into switchgear and circuit breakers, the corrosive effects of the salt water can add further damage, much of which cannot be seen.

Circuit breaker lubrication has been and will continue to be the leading cause of circuit breaker misoperation. Lack of lubrication is the number one problem we run into with circuit breakers at Shermco. According to Jim Miller, Shermco’s Circuit Breaker Shop manager, “Typically, 60% of the circuit breakers that come through our shop have lubrication issues when we perform maintenance on them. The result is circuit breakers that won’t open, circuit breakers that won’t close, or circuit breakers that open after a delay.” After a flood situation, it is a sure bet that any lubrication circuit breakers may have once had has been totally removed or contaminated. Bearings used in the circuit breaker’s operating mechanism will also have water and contaminants inside them, rendering them useless.

Tony Demaria wrote an excellent article on circuit breaker lubrication titled Circuit Breaker Lubrication in the Field that was published in the Summer 2007 NETA World. Tony’s article looks at other aspects concerning circuit breaker lubrication and has a table showing where to secure certain lubricants. That table is shown as Figure 1.

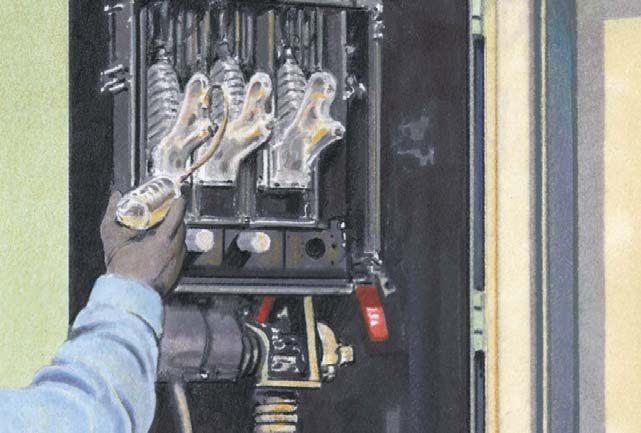

A circuit breaker’s operating mechanism is full of rollers, latches, latch surfaces, and gears, all of which need to be lubricated. Figure 2 shows a Westinghouse/Cutler-Hammer DS circuit breaker that was exposed to flooding from salt water. Notice the deposits throughout the operating mechanism. No part of this circuit breaker can be left untouched.

were dried in k

n a several hours

kiln several hours to

Figu which are wered ar weredriedin an Disassembly cleani arts allowed them to be returned to service. , ed. The arc chutes in thes kiln for several hours to br

However, an external cleaning followed by spraying a lubricant around on the mechanism is not going to provide adequate lubrication. After a flood the entire circuit breaker has to be disassembled because everything will require cleaning and relubricating. Additional care must be used when inspecting parts, as the longer they have been underwater, the more damage will have occurred. Corrosion on metal parts is almost certain, especially if in a water treatment (or wastewater) facility or if exposed to salt water. Petrochemical facilities can also have various corrosive chemicals that can find their way into and onto a circuit breaker. Arc chutes have to be disassembled, cleaned, and probably baked, as will all the insulating components. It’s likely that older air-magnetic circuit breakers will have components that will have absorbed moisture or other contaminants. Figures 3a, 3b, and 3c show GE Magne-Blast arc chutes that had been on a flooded circuit breaker. Figure 3a shows the top of two of the arc chutes and the general corrosion taking place. Figure 3b is the outside of the magnetic pole piece showing deposits on the surface, while underneath there is also mold and corrosion occurring. Figure 3c shows the blowout coil and arc runner, both of which are severely corroded. The arc chutes in these photos were dried in a kiln for several hours to bring their moisture down to an acceptable level. Disassembly and cleaning of the other parts allowed them to be returned to service.

Figure 3a: General Corrosion on Arc Chutes Figure 3b: Mold and Deposits on the Arc Chute SurfaceFor some components, made from fiberglass or Bakelite®, if the insulation quality has been compromised, it will probably have to be replaced. If a circuit breaker has electronic components, replace them. Figure 4 is a molded-case circuit breaker showing water damage to its case, while Figure 4b shows mud and muck inside the circuit breaker. Figure 4c is the contact assembly from another flood-damaged circuit breaker. These circuit breakers were cleaned, restored, tested, and returned to service.

Trying to salvage water-damaged electrical/electronic components is penny wise and pound foolish. The chances of them living a normal life is about the same as me being sixfoot tall tomorrow – won’t happen.

All circuit breaker manufacturers have a specific lubricant they recommend for either the operating mechanism or for components that are in the current path. In general, there are two types of lubricants used: nonconductive for use in mechanical mechanisms and conductive for use in the current path. Some of the choices the manufacturers make for their lubricants may seem odd, such as ITE/BBC using No-Ox-Id Special Grade A as the lubricant in the conductive path of their K-line circuit breakers. Most people would not consider No-Ox-Id to be a lubricant as it is normally used for covering battery terminals. When applied to current-carrying circuit breaker components, it will not run and will cling to the parts to which it is applied. As Tony pointed out in his article, the thickness of the lubricant can also affect the speed of the circuit breaker, as the recommended thicker lubricants may tend to slow it down some. This may not appear to be a good thing, but if some circuit breakers operate too quickly, they may not be able to latch properly each and every time they are closed. This could cause unnecessary issues in facility operation and excessive troubleshooting.

Shermco’s circuit breaker shop has letters from both GE and ABB/ITE stating that Mobil 28 is acceptable to use as a substitute for greases in both the conductive and nonconductive areas of their circuit breakers. Other manufacturers recommend the use of their specific lubricants. This is probably as much due to warranty and liability reasons as anything. The manufacturers have performed exhaustive testing on their specific circuit breakers and know that they work under all conditions for which the circuit breakers are warranted when the recommended lubricants are used. If they recommend another lubricant, it may open them up to some unforeseen liability.

Figure 4a: Water-Damaged Molded-Case Circuit Breaker Case

Figure 4a: Water-Damaged Molded-Case Circuit Breaker Case

Mobil 28, shown in Figure 5, is a red synthetic lubricant that has some excellent qualities, such as life expectancy in adverse conditions and resistance to breakdown. If there is a flaw with Mobil 28, it is that is tends to thin out when heated and will run, unless the high-temperature version is used. Jim Miller, our circuit breaker shop manager, states that they only use the high-temp version of Mobil 28. The proper method of application is to put just enough Mobil 28 onto a part to see it on the surface, assemble the components and then wipe off the excess. The last step is especially important, as any excess will draw dirt into the lubricated parts.

In the past, manufacturers would often state to lubricate only when necessary. Some manufacturers recommended a time period or number of operations between lubrications. If a circuit breaker does not operate as it was designed, and if that misoperation is due to lack of lubrication, then that is a real safety issue. Jim Miller shared a section on lubrication that is starting to appear in some manufacturer’s instruction books. The specification below was taken from a Cutler-Hammer maintenance manual.

All parts that require lubrication have been lubricated during the assembly with molybdenum disulphide grease (Cutler-Hammer Material No. 53701QB). Over a period of time, this lubricant may be pushed out of the way or degrade. Proper lubrication at regular intervals is essential for maintaining the reliable performance of the mechanism. Once a year or every 500 operations whichever comes first, the circuit breaker should be lubricated.

Proper lubrication of bearings and moving parts requires the circuit breaker to be disassembled, the old lubrication removed, and new lubrication reapplied. There is no shortcut.

Lubrication should be limited to those areas that actually need it for components that slide, rotate or rub. Some of the old-school technicians I used to work with always put it on the contact surfaces. They didn’t have a reason; it was just the way they had always done it In reality, current passing through the contacts creates heat. Heat dries the lubricant out, so over time the resistance between the contact faces will increase more than if the lubricant were not used there. That is not what we really want. There are some specific instances where lubricating the contact faces may be of benefit, such as when the circuit breaker is in an atmosphere that can corrode the silver, such as exposure to chloride, fluoride, or hydrogen sulfide. Otherwise, it would be good not to use it on the contact face. Bolted surfaces are another area that should not be lubricated for the same reason that contact faces should not. The heat of the current will cause an additional increase in resistance as the lubricant dries out.

Parts that should be lubricated include the primary and secondary disconnects; sliding, rubbing, or rotating components within the operating mechanism; and the moving contact pivot faces. There are often components within the contact structure that also rub or pivot and they should be lubricated as well. Without lubrication the circuit breaker rotating components will gall, bind and seize, causing the circuit breaker to operate slowly or misoperate. The primary and secondary moving disconnects are not necessarily exactly aligned with their corresponding stationary parts. If they are not lubricated, they may not adjust position to slide together, but actually jam causing them to break or not connect with enough surface area. This could cause an arc flash as the metal fingers scatter within the switchgear, such as happened with the circuit breaker in Figure 6.

There are several factors to consider when the subject of frequency of lubrication comes up. Below are a few of the more important ones:

Load carried by the circuit breaker. The more load current that the circuit breaker carries the higher its operating temperature will be. This in turn causes the resistance of the contact pivot to increase at a faster rate, as the lubricant inside it will dry out quicker. The added resistance tends to create more heat, which causes the lubricant to dry out even faster. More heat equals more resistance, which causes more heat. It is a vicious cycle that only ends when the old lubricant is cleaned off the parts and new lubricant applied. For circuit breakers that are operated at or near their full load capacity, this usually takes about one to three years. Circuit breakers that are more lightly loaded will have their lubricants deteriorate at a slower rate.

A microhm meter (pole resistance) test can be used to help evaluate the condition of the lubricant. The test should be performed annually in order to detect the problem in its early stages. When low-voltage power circuit breaker pole resistance exceeds 300 microhms the breaker should be scheduled for a thorough relubrication. Medium-voltage circuit breakers have more contact surface, so the pole resistance value for requiring service is 200 microhms. Although many manufacturers require lubrication based on time and/or operations, the pole resistance test is almost like having x-ray vision. As the lubricant inside the contact assemblies deteriorates, the pole resistance increases. The above values are rule-ofthumb and would indicate a circuit breaker that requires relubrication. The pole resistance test is quick, easy, and repeatable. (See Figure 7.)

Environment. Circuit breaker loading is number one, but right behind it is environment. Circuit breakers operated in outdoor buildings that are not climate-controlled are going to deteriorate more quickly than those operated in a climate-controlled environment. Moisture intrusion, heat, and dirt create issues with any manufacturer’s circuit breaker. Corrosive or caustic atmospheres may cause circuit breakers to seize or misoperate.

Frequency of operation/use. Some customers use their circuit breakers as across-the-line starters. This type of usage wears a circuit breaker out! The circuit breaker may operate dozens of times each day, or even each hour. Circuit breakers tasked with this type of duty will require rebuilding as often as every six months.

Scheduled maintenance. Or lack of it, depending on your philosophy. Operation to failure is not a real maintenance philosophy, although some facility managers seem to think it is. Annual maintenance identifies circuit breakers having problems that could affect production. Pulling the circuit breaker out and cycling it, performing a quick inspection by removing the arc chutes, and performing a microhm meter test would provide the information needed. This may not be practical in all situations, but should be a goal for critical-load circuit breakers at least.

The reliability of a circuit breaker that is exposed to salt water or any contaminates from a flood is very poor. Following is a list of issues common to such exposure:

develop quickly.

properties due to contaminants from oil, grease, chemicals, and moisture.

contaminated, causing rust, binding, and seizing.

causing loss of conductivity and increasing the resistance of the current path.

causing rust, corrosion to seals, and deterioration of other components.

controldevices are damaged, which usually requires replacement of those components.

Figure 7: Performing a Pole Resistance TestOften, it is not the cost of a component that determines its value; it is the cost if it fails. This is the case with circuit breakers. A lighting panel circuit breaker failure would have little consequence in most cases. If a circuit breaker failure causes the shutdown of a process or an entire facility, the costs associated with that failure skyrocket. Circuit breakers involved in floods should not be reenergized until they have been inspected and tested to ensure they are safe to use. There are so many variables that it would be impossible to say that one circuit breaker could be used and another should not be unless they were inspected and tested. However, that process will probably point to a rebuilding of the circuit breaker and replacement of components such as protective relays and other electrical/electronic pieces. Cleaning and relubrication are almost always needed for flooded circuit breakers, but are also needed for circuit breakers that are in service. Do not neglect your circuit protective devices. They are protecting people as well as property.

A new chapter is being added to NFPA 70B, Recommended Practice for Electrical Equipment Maintenance – 2013 Edition. It will be Chapter 32, Electrical Disaster Recovery and is based on a paper presented to the 2009 NETA PowerTest Conference titled, Flood Repair of Electrical Equipment by Pat Beisert. It is an excellent resource for those wanting more information on preparing for and handling these types of situations.

James H. Miller and Jim White are both employees of Shermco Industries in Dallas, Texas a NETA Accredited Company.

James R. (Jim) White is the Training Director of Shermco Industries, Inc., in Dallas, Texas. He is the principal member on the NFPA technical committee “Recommended Practice for Electrical Equipment Maintenance” (NFPA 70B). Jim represents NETA as an alternate member of the NFPA Technical Committee “Electrical Safety in the Workplace” (NFPA 70E) and represents NETA on the ASTM F18 Committee “Electrical Protective Equipment For Workers”. Jim is an IEEE Senior Member and in 2011 received the IEEE/PCIC Electrical Safety Excellence award. Jim is a past Chairman (2008) of the IEEE Electrical Safety Workshop (ESW).

James H. Miller is currently a Senior Circuit Breaker Technician at Shermco Industries. He has over 12 years of experience in low- and medium-voltage circuit breaker maintenance and testing. His background includes circuit breaker application in the nuclear and nonnuclear power plants; military, marine, municipal, state and federal governments; and commercial industries. At Framatome Technologies (formerly B and W Nuclear Technologies), he served as maintenance instructor for lowvoltage circuit breaker workshops for the Electric Power Research Institute (EPRI) and the Nuclear Maintenance Applications Center (NMAC).

PME 500 TR by Noram SMC

tti i o o n nss. .

1 1 0 0 H Hrr O O n n b b o o a arrd d B B a attt t e erry y m m e e a a n nss N N O O

e e x xtte e n nssi i o o n n cco orrd dss. .

B B u uiil ltt iin n rre e p p o orrt t p prri i n ntte err

R R e essu ullt tss sst t o orra a g g e e & & d d o o w w n nllo o a a d d

N N e e e e d d T Trra a v v e ell? ? N N o o p prro o b blle e m m,, a a d d d d iit t w w h h e e n n

y y o o u u n n e e e e d d iit t u ussi i n n g g A A N N Y Y ttr r a a n nssd d u ucce err. .

A Alll l ffo orr LLE E S S S S tth h a a n n w w h h a att y y o o u u tth hiin n k k!!

Download full specifications at www.noramsmc.com or call (918 622 5725)

Assuring Electrical Performance

Acceptance Testing

Protective Relay Testing and Calibration

Infrared Scanning

Medium Voltage Cable Terminations and Testing

Transformer Testing, Repairs, and Oil Analysis

Ground System Testing

Preventative Maintenance

UPS and Battery Testing and Maintenance

Medium and Low Voltage Breaker Testing

TAN DELTA Cable Diagnostic

Electrical Equipment Start-Up and Commissioning Power Products & Solutions, Inc.

James R. (Jim) White is the Training Director of Shermco Industries, Inc., in Dallas, Texas. He is the principal member on the NFPA technical committee “Recommended Practice for Electrical Equipment Maintenance” (NFPA 70B). Jim represents NETA as an alternate member of the NFPA Technical Committee “Electrical Safety in the Workplace” (NFPA 70E) and represents NETA on the ASTM F18 Committee “Electrical Protective Equipment For Workers”. Jim is an IEEE Senior Member and in 2011 received the IEEE/ PCIC Electrical Safety Excellence award. Jim is a past Chairman (2008) of the IEEE Electrical Safety Workshop (ESW).