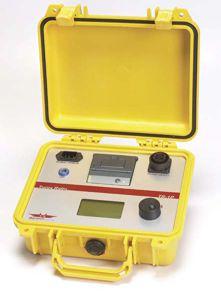

The SMRT36 is the smallest, lightest, highest output powered, complete 3-phase protective relay test system in the world today. This rugged test system may be customized by adding the voltage current generator modules needed for specific test applications. Manual operation is simple through the use of the Smart Touch View Interface (STVI), with a large color high resolution TFT LCD touch-screen.

n Rugged, small and lightweight

n High current, high power (60 Amps/300 VArms) per phase

n Up to 6 currents with convertible channels

n Thermally controlled fans for quiet operation

n New Smart Touch View Interface (STVI) provides manual control

n New STVI Overcurrent Test includes hundreds of relay specific time-curves built-in

With these comprehensive capabilities and extensive testing options the SMRT36 is conceivably the easiest to use 3-phase protective relay test system available today.

For more information on the SMRT36 relay test set contact us today at 1-800-723-2861 or email us at sales@megger.com to receive a SMRT36 brochure and 2011 Megger Power Catalog.

Megger

4271 Bronze Way Dallas, Texas 75237-1019

22 TODAY’S MICROPROCESSOR RELAYS EXPAND THE APPLICATION POSSIBILITIES OF SYMMETRICAL COMPONENT THEORY

By Roy Moxley, Schweitzer Engineering Laboratories, Inc..The use of sequence quantities has increased dramatically since the introduction of microprocessor relays. Sensitivity to faults, especially unbalanced faults, has increased while security has also increased. Motors, feeders, transmission lines, and generators have all benefited from the capability of applying new measuring techniques based on sequence components.

7 PRESIDENT’S DESK

Mose Ramieh, Power & Generation Testing, Inc.

NETA President

10 GRATITUDE – IT’S NOT JUST FOR THE HOLIDAYS

14 COLLECTIVE MEMORIES–NETA’S PAST, PRESENT AND FUTURE

Jill Howell and Kristen Wicks, NETA

35 MULTI-FUNCTION NUMERICAL PROTECTION RELAYS USING SYMMETRICAL COMPONENTS FOR MORE RELIABLE AND SECURE PROTECTION

Steve Turner, Beckwith Electric Co., Inc

63 MODERN PROTECTIVE RELAY TECHNIQUES: USING A 94-YEAROLD CONCEPT TO PROTECT ELECTRICAL EQUIPMENT

Suparat Pavavicharn, Basler Electric Company

72 AN IMPROVED CONSTANT SOURCE IMPEDANCE TESTING METHOD FOR MHO DISTANCE RELAYS

Jason Buneo and Rene Aguilar, Megger

28 MAINTENANCE CORNER

Relay Maintenance Has Changed, Hasn’t It?

Kerry Heid, Magna Electric Corp.

42 TECH QUIZ

Symmetrical Components and Protective Relaying

Jim White, Shermco Industries

47 THE NFPA 70E AND NETA

A New NFPA Process and a Few Words on the 70E Annexes

Jim White and Ron Widup, Shermco Industries

52 NICHE MARKET TESTING

Newer Solid-State Relays Offer Enhanced Flexibility for SCADA Solutions in the Municipal Environment

Lynn Hamrick and Owen Wyatt, Shermco Industries

59 TECHNICAL BRIEF

Instantaneous Ground Fault Relays (50GS) and Zero-Sequence CTs Powell Technical Brief #68

Baldwin Bridger

82 NO-OUTAGE

INSPECTION CORNER

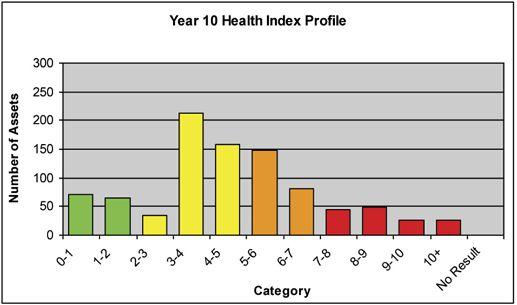

Condition Based Risk Management (CBRM) the Big Picture for Electrical Asset Management and Planning

Don A. Genutis, No-Outage Electrical Testing, Inc.

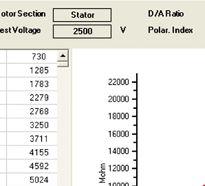

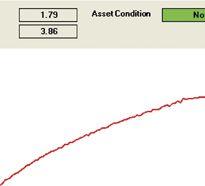

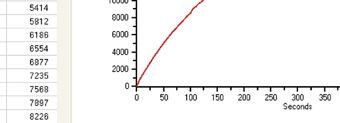

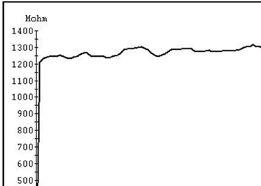

88 TESTING ROTATING MACHINERY

Polarization Test

Vicki Warren and Ian Culbert, Iris Power LP.

94 SAFETY CORNER

Industry Advisory – NERC,

Relay Safe Work Practices

Scott Blizard, American Electrical Testing Co.

101 TECH TIPS

A Closer Look at Soil

Jeff Jowett, Megger

SPECIFICATIONS AND STANDARDS ACTIVITY

116 CSA UPDATES

Kerry Heid, Magna Electric Corp.

118

INDUSTRY TOPICS

12 REAL WORLD LEARNING AT YOUR FINGERTIPS

NETA Handbooks

32 NETA ACCREDITED COMPANY MAGNA ELECTRIC CORPORATION RECEIVES HIGH MARKS FOR SETTING HIGH STANDARDS

105 NETA TECHNICAL SUPPORT–QUALITY CONTROL WITH THE SRC AND EXAM COMMITTEE

122 NETA ACCREDITED COMPANIES

128 ADVERTISER LIST

3050 Old Centre Avenue, Suite 102

Portage, MI 49024

Toll free: 888.300.NETA (6382)

Phone: 269.488.NETA (6382)

Fax : 269.488.6383

neta@netaworld.org

www.netaworld.org

EXECUTIVE DIRECTOR: Jayne Tanz, CMP

NETA Officers

PRESIDENT: Mose Ramieh, Power & Generation Testing, Inc.

FIRST VICE PRESIDENT: David Huffman, Power Systems Testing Co.

SECOND VICE PRESIDENT: Ron Widup, Shermco Industries

SECRETARY: Walt Cleary, Burlington Electrical Testing Co., Inc.

TREASURER: John White, Sigma Six Solutions

NETA Board of Directors

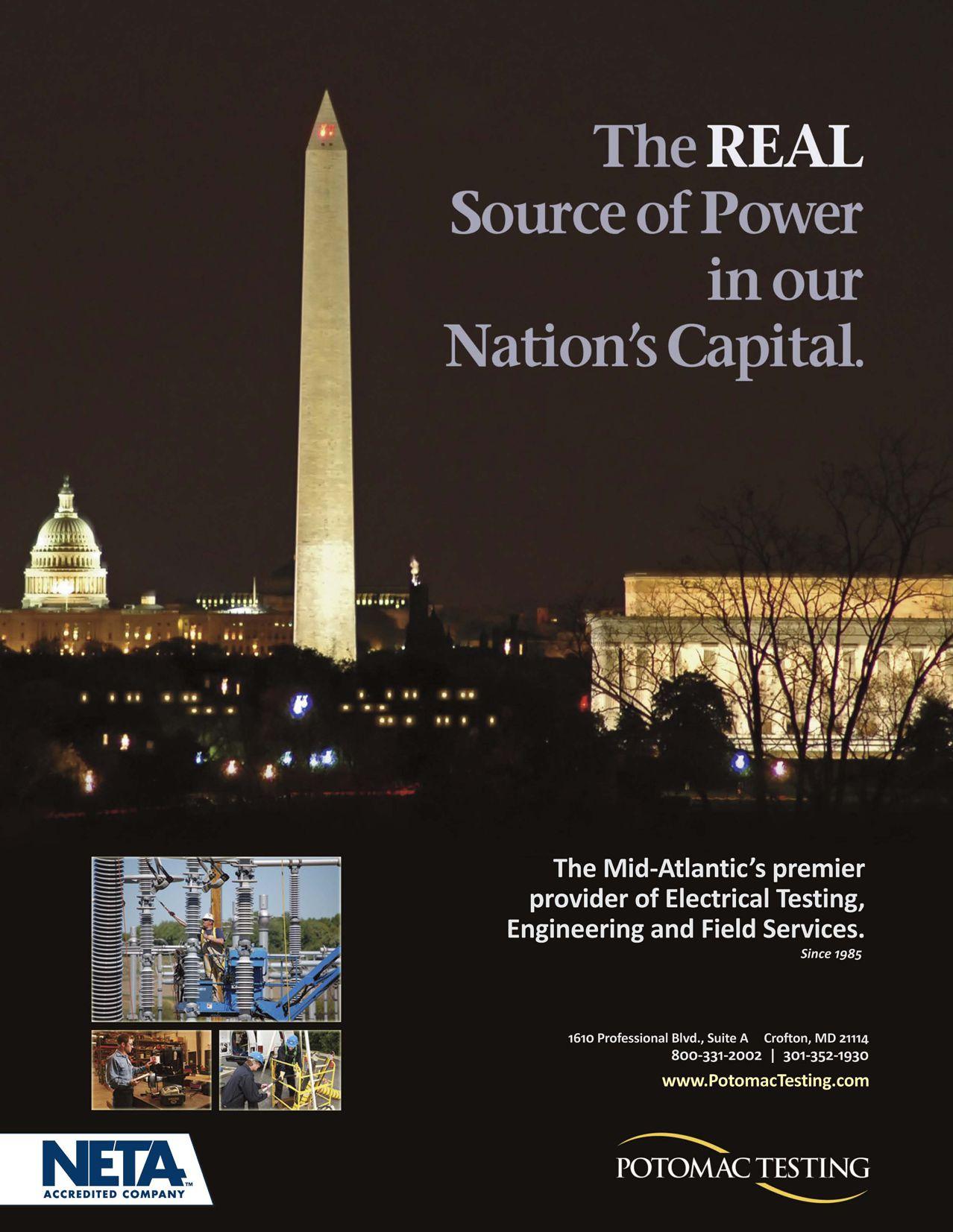

Ken Bassett (Potomac Testing, Inc.)

Scott Blizard (American Electrical Testing Co., Inc.)

Jim Cialdea (Three-C Electrical Co., Inc.)

Walt Cleary (Burlington Electrical Testing Co., Inc.)

Roderic Hageman (PRIT Service, Inc.)

Kerry Heid (Magna Electric Corporation)

David Huffman (Power Systems Testing)

Alan Peterson (Utility Service Corporation)

Mose Ramieh (Power & Generation Testing, Inc.)

John White (Sigma Six Solutions)

Ron Widup (Shermco Industries)

NETA World Staff

TECHNICAL EDITOR: Roderic L. Hageman

ASSOCIATE EDITOR: Diane W. Hageman

MANAGING EDITOR: Jayne Tanz, CMP

ADVERTISING MANAGER: Jill Howell

DESIGN AND PRODUCTION: Newhall Klein, Inc.

NETA Committee Chairs

CONFERENCE: Ron Widup; MEMBERSHIP: Ken Bassett; PROMOTIONS/MARKETING: Kerry Heid; SAFETY: Lynn Hamrick; TECHNICAL: Alan Peterson; TECHNICAL EXAM: Ron Widup; WORLD ADVISORY: Diane Hageman;

CONTINUING TECHNICAL DEVELOPMENT: David Huffman; TRAINING: Kerry Heid; FINANCE: John White; NOMINATIONS: Alan Peterson; STRATEGY: Mose Ramieh; AFFILIATE PROGRAM: Jim Cialdea

© Copyright 2012, NETA

NOTICE AND DISCLAIMER

NETA World is published quarterly by the InterNational Electrical Testing Association. Opinions, views and conclusions expressed in articles herein are those of the authors and not necessarily those of NETA. Publication herein does not constitute or imply endorsement of any opinion, product, or service by NETA, its directors, officers, members, employees or agents (herein “NETA”).

All technical data in this publication reflects the experience of individuals using specific tools, products, equipment and components under specific conditions and circumstances which may or may not be fully reported and over which NETA has neither exercised nor reserved control. Such data has not been independently tested or otherwise verified by NETA.

NETA MAKES NO ENDORSEMENT, REPRESENTATION OR WARRANTY AS TO ANY OPINION, PRODUCT OR SERVICE REFERENCED OR ADVERTISED IN THIS PUBLICATION. NETA EXPRESSLY DISCLAIMS ANY AND ALL LIABILITY TO ANY CONSUMER, PURCHASER OR ANY OTHER PERSON USING ANY PRODUCT OR SERVICE REFERENCED OR ADVERTISED HEREIN FOR ANY INJURIES OR DAMAGES OF ANY KIND WHATSOEVER, INCLUDING, BUT NOT LIMITED TO ANY CONSEQUENTIAL, PUNITIVE, SPECIAL, INCIDENTAL, DIRECT OR INDIRECT DAMAGES. NETA FURTHER DISCLAIMS ANY AND ALL WARRANTIES, EXPRESS OF IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

ELECTRICAL TESTING SHALL BE PERFORMED ONLY BY TRAINED ELECTRICAL PERSONNEL AND SHALL BE SUPERVISED BY NETA CERTIFIED TECHNICIANS/ LEVEL III OR IV OR BY NICET CERTIFIED TECHNICIANS IN ELECTRICAL TESTING TECHNOLOGY/LEVEL III OR IV. FAILURE TO ADHERE TO ADEQUATE TRAINING, SAFETY REQUIREMENTS, AND APPLICABLE PROCEDURES MAY RESULT IN LOSS OF PRODUCTION, CATASTROPHIC EQUIPMENT FAILURE, SERIOUS INJURY OR DEATH.

As you read this message PowerTest 2012 will be in full swing in Ft. Worth. I am looking forward to seeing you all there.

During this PowerTest Conference, we will be celebrating NETA’s 40th Anniversary. As your President I am truly honored to preside over this latest milestone event in the history of NETA. As we look back at the past 40 years there are pictures from the past in the fall issue of NETA World and in this issue. Note the changes in hair styles, clothes, faces, and most of all the growth of the association. In early 1972, a group of Charter Member Companies came together to form what is now a 70-company with more than1400 technicians association. Could the founders have imagined where NETA would be 40 years later? Where do you imagine we will be in the evolution of NETA just five years from now?

We are in the midst of a new era in our industry and our association. The ever changing landscape of equipment and regulations with which we deal has caused major shifts in the way NETA Accredited Companies (NAC) are organized, staffed, and operate. We are no longer an association of companies that test components and systems. We have evolved to a higher level of involvement in the overall project scheme. This evolution has occurred not by accident but by the electrical industry’s recognition of the expertise that exists in our member companies. The services we now provide are more sophisticated than those provided in the early 70’s. NACs are now involved with all aspects of projects from specifying equipment, design considerations, project management, engineering studies, commissioning, and many other areas that were once the exclusive realm of the engineer and constructer.

As we look to the future it is apparent to me that our evolution will come at a faster pace than any of us can imagine. If NETA is to continue its growth and standing in the electrical community, we must continue to keep pace with the ever changing needs of the industry. As your President and Strategic Chair I welcome input from all members as to the direction in which this organization should proceed.

NETA is only as viable and strong as you, the members, make it. This is your association, and we need your input and support.

Mose Ramieh NETA President

National Switchgear has a broad line of new, used and remanufactured electrical switchgear products. And literally millions of parts, new and used. But that’s only part of the story. We also have the willingness to listen, the experience to know what you need, the capacity to have it in stock, and the responsiveness to get it to you fast. Plus, the additional value of full-service electrical testing and onsite maintenance services. So, if you’re still calling anyone else for power distribution equipment, maybe it’s time to switch. 800-322-0149 nationalswitchgear.com

It really doesn’t take very long to learn that NETA’s volunteers are the living definition of gratitude

The air is chillier; snow is falling in many places across the country; and life just seems to encourage us all to slow down a little, take in our surroundings, and be grateful for the many blessings that surround us. Sure, there is the ever-present pressure of locating the perfect gifts for loved ones, chiseling out time for holiday parties, and for those in certain professions, like electrical testing, the seasonal rush to help all of our clients prepare for the winter ahead. Still, there is no denying that one would have to be living under a rock to avoid feeling a little of that nostalgic, seasonal magic associated with giving, generosity, and gratitude.

Working with volunteers is an especially rewarding job, as one realizes that people are making time to write really great articles for NETA World, edit those articles, prepare a year in advance to present technical content at PowerTest, and traverse the continent to attend grueling code panel meetings, all while being savvy business people, little league coaches, caregivers, and friends, just to name a few other hats. On a tough day, it is energizing to think that NETA is blessed with an astounding number of incredible human beings who have probably never worked nine-to-five jobs a day in their lives and wouldn’t have it any other way.

These people have such amazing stories to share; their lives are filled with monumental achievements. They are generous with all their resources, time being the most precious of these. Many of NETA’s volunteers participate in charitable missions close to their hearts; one being a NETA member who goes on mission trips to the heart of the jungle in a dugout canoe, delivering large batteries to villages so the indigenous people are able to provide a better quality of life to their community. Most of these giving people go quietly about their lives and even become a little bashful when commended for their efforts. It really doesn’t take very long to learn that NETA’s volunteers are the living definition of gratitude; it is reflected in all of their contributions as employers, employees, mothers, fathers, grandparents, and friends.

So, from each of us at the NETA office, thank you to all of our volunteers for all that you do. Your partnership in our daily mission of providing quality service and excellent experiences for all involved with NETA is a gift for which we are grateful all year round.

Featuring quality, reliable, on-time service and support for all brands and types of solid state power electronics.

Power electronics are our business

Let us suppoort you with our quality repair, calibration and servicing of your solid state equipment. We also buy, sell and trade:

•Communications devices for power equipment

•Protective relays

•Circuit breaker trip devices

•Motor overload relays

•Rating plugs

In 2012 NETA celebrates 40 years of service to the electrical systems industry – Establishing industry standards and delivering leading-edge technical information and educational resources based on real-world experience.

NETA was founded with the goal of advancing the industry’s focus on safety and reliability. The Association’s contribution is fullfilled through the development of the ANSI/NETA Standards and the creation of educational and training resources that include the NETA Self-Paced Technical Seminars, the annual PowerTest conferences, the quarterly NETA World Journal, as well as a 14 volume series of NETA Handbooks.

Accredited Companies, and NETA’s technical community seeking a comprehensive, subjectspecific technical resource to use for training and reference materials.

All NETA technical materials, publications, and events are authored by industry experts – leadingedge, highly knowledgeable individuals who have many years of experience in the field. NETA is extremely grateful for their contributions.

The NETA Handbooks were first released as a series in 2009. They are a go-to source for highly relevant information about testing procedures, troubleshooting, and real-life solutions to situations encountered everyday in the field. The Handbooks were initially created in response to requests from the electrical industry, the general public, NETA

The NETA Handbooks bring together a collection of over 200 of the very best articles from past issues of NETA World Journal and the most well- received technical presentations from past PowerTest events.

Join us in Celebrating

For each of us there is a mission that guides us, a vision that inspires us, a camaraderie that tie us, a heart - driven professionalism that aligns us. We continually strive for the highest standards in electrical power system safety and reliability. We salute the accomplishments oF our members – past, present, and Future.

neta’s 40th birthday and Powertest 2012 Welcome reception

Date: Monday, February 27, 2012

Time: 6:30 PM - 10:30 PM

Location: Dallas Cowboys Stadium

RSVP: Call 888-300-6382 (NETA) — Transportation Provided

In the last issue of NETA World, we looked back at the history of NETA and compared the world that saw the first years of the InterNational Electrical Testing Association to the world in which NETA exists today, forty years since being founded in 1972. After looking at the organization as a whole, it seemed only right to talk with the people who comprise the heart and soul of NETA. Across the geographical locations and generations of NETA members, some common themes were mentioned; themes like collaboration, electrical expertise, standards, community, and volunteerism all featured prominently in NETA’s collection of stories. Individual stories are woven together like threads to create the brilliant tapestry of NETA’s past, present, and future. Settle in and read on to learn about some of the favorite memories, infamous moments, and hopes for NETA’s future shared by some of the many faces of NETA.

are so many people with

When asked about what first comes to mind when thinking of NETA, Mose Ramieh, NETA’s current President, said without hesitation, “Good Friends. It’s more than just good friends. It’s comrades in arms; people who know where I’ve been and been through the same thing. The bond is very close. The best thing about this organization is that there are so many people with mutual interests focused on the same goals. Even though we are competitors, we are friendly competitors who are happy to lend a hand if someone needs it.” Dave Huffman, President of Power Systems Testing, a fellow NAC, agrees with Mose, saying that he thinks of his peers as “heart-driven professionals” aligned by the belief that “good enough isn’t good enough.” He is happy to have this group of people that he can relate to both professionally and personally. and been through the same thing. The bond is very close.

“Good friends, comrades in arms”

Because Power Systems Testing is a long-standing member of NETA, Dave Huffman inherited his affiliation with NETA when he began working there as a field technician in 1988. His technical prowess, skills at managing projects and people helped him along the way to his current position as President of Power Systems Testing. Even though his company was previously affiliated with NETA, Dave worked to increase awareness of NETA and how valuable time spent volunteering can be: “An interesting side-effect of volunteering with NETA Is that it has made our company more well-known within the industry. In general, it has been good for our business and our brand.” Being involved in the industry from a young age gives Dave a birds-eye view of the shifting landscape of electrical testing, most notably, “the industry’s awareness that electrical distribution equipment does not run forever. There is a higher awareness of this fact now than there was ten years ago. I believe this is directly related to the work of NETA at its members promoting safety, developing standards, getting involved in the code panels. NETA provides the world with a group of experts that know something about taking care of your electrical equipment.”

“Heart driven professionals”

NETA President Power Generation & Testing, Inc.

NETA President Power Generation & Testing, Inc.

Change and evolution are inevitable in life, and the life of an organization is no exception to that rule. At times, change comes easily; at others, one may be acutely awareness of growing pains. Lyle Detterman of Northern Electrical Testing believes that the greatest growth for NETA has taken place with PowerTest, the annual technical conference.

Lyle would know, as he was an attendee at the very first NETA conference at Dunfey’s Hotel in Dallas, Texas in 1977. Lyle remembers that the first conference was organized by Thad Brown, who ran the show without the infrastructure and staff that NETA enjoys today. That first conference was a great leaping-off point for today’s events. Lyle says, “Today’s conference is excellent, better than it has ever been. The current team of volunteers and staff has taken it way beyond where it was in the past.”

Mike Moore, Shermco Industries, says “I came from a non-NETA company. When I first joined Shermco, I became educated on the differences, and now I am spreading the word.Before I was a part of NETA, it seemed like a group that could gang up and keep you out of a job. Now, having been a part of NETA for the past ten years, I know it’s not like that at all. NETA levels the playing field for all competitors and establishes a good base-level of knowledge, experience, and quality of service.” When asked what NETA means to him, he says, “It means a standard of quality and commitment. A commitment to NETA and everything it takes to be a NETA Accredited Company: training, certification, calibration of equipment, knowledge, experience – all the things you have to do to become a NETA member and the ongoing work to maintain that status.”

“NETA–it means a standard of quality and commitment”

NETA Member Northern Electrical Testing

NETA Member Northern Electrical Testing

Another newer face to the NETA family is Eric Beckman of National Field Services. When asked what it means to be a part of NETA, he said, “One and a half years ago we joined NETA, and it has really meant a lot. It’s been a long standing thing, wanting to be a part of NETA. The requirements for accreditation are very stringent; it was a big moment for our company when we got to that point. It will continue to open up more opportunities for our business, allows us to bid on more projects, and provides us with the prestige that NETA accreditation brings.” When asked about what he sees for the future, Eric comments, “NETA will still be the baseline against which everyone is measured. The ANSI/NETA Standards are so well-recognized now and will keep influencing other industry standards and government specifications.”

“NETA–The baseline against which everyone is measured.”

In the early days of NETA, membership was focused solely on electrical testing. As time passed and technology advanced, electrical testing came to include more services, allowing wider diversity among companies eligible to become accredited with NETA. As President, Mose wrestles with the question, “Who is NETA today?” He has participated and led discussions about this topic, driven by a desire to ensure that everyone from the little guy on up to the largest NETA member is given equitable representation and responsibility within the organization. When Mose and his company joined NETA, NETA was a moving force in the industry. He always knew that he wanted to join NETA and that when that time came he wanted to assure that he and his company would be active contributors to movement. While there are no clear answers yet, Mose is “for change”, acknowledging that to stay alive you have to adapt while keeping quality and standards in sight.

Kerry Heid, of Canadabased Magna Engineering Corporation (MEC), talks about MECs growth when it comes to NETA. “Magna has been a member for ten years now. Originally we joined seeking credibility. NETA did provide that through the application process and the certification of our technicians. In the middle years of our membership, there was a steep learning curve on how NETA works. In the present, it is a valuable technical community of friends. It’s great to know that I can land in ten or 20 different American cities and call a friend up for dinner. It’s a great network to have.” One of NETA’s social butterflies, Kerry recalls many happy times with his fellow members. When asked about NETA’s social atmosphere, more than one person interviewed for this article mentioned Camden, Maine. Details were not as forthcoming. Dave Huffman added, “Montana was a lot of fun. That’s all I’ll say.” So as we know, all have survived NETA’s many excursions intact, if not unscathed. Kerry sees NETA’s future as, “a bit of a wild card.” He says, “When I was President of NETA, I was interested in relaxing the membership requirements to allow more people access to become NETA Accredited. I think it will be a slow and steady growth. While there are many great testing firms out there that would be excellent candidates for membership, not every guy that loads up a van can be a NETA guy.”

One thing is certain; the core of NETA will always be the individuals whose expertise and personality bring light and life to this organization.

Bob White, President of Elemco Services, Inc., has been involved with NETA since 1986 when his company joined as an Accredited Company. At that time, Bob recalls, “The association was still in its infancy, fostering the growth of independent testing companies. Years passed and focus shifted from growing the association to where we are now; maintaining the standards that have been established and fought for since 1972.” Bob went on to tell some hair-raising tales of pirate ships, tall, dark intruders, impromptu parade

participation, and the best way to get the bar tender’s

attention (also known as the quickest route to the doghouse). Names have been excluded to protect the innocent, or mostly innocent. To sum it up Bob says, “NETA is camaraderie and fellowship and being on

uniqu

Jayne Tanz, NETA’s Executive Director says, “What really makes this organization unique is the people that breathe life into NETA. The simple fact remains that we are only where we are today because individuals cared enough to start down the path less traveled, and those individuals have been succeeded by likeminded people that want to be involved in something greater than turning a profit. These subject matter experts have gathered together to define not only the practice of electrical testing, but also to establish what makes an individual qualified to perform said tests. Over the course of forty years, these NETA standards have been carved out from practical knowledge, field experience, the school of hard knocks, as well as those on the cutting edge of new technologies. While tests may change, theories shift, and new methods develop, NETA is able to, by the virtue of its volunteers, keep a finger on the pulse of that change.”

“We are only where we are today because individuals cared...”

the forefront of electrical testing technology.” association started. once sought industry. and for technical

One of the most common recurring themes of the interviews was the ANSI/NETA standards. A NETA staff member describes these documents as, “the glue that holds the association together,” or as being, “the keystone and the cornerstone, at the same time.” Lyle recalls, “NETA was just breaking the ground of having standards when my company got started. The purpose of creating the standards was to create a collection of testing knowledge, procedure, and practice that would establish confidence in the testing industry. There has been a huge amount of work done over the years to bring what was once a rather limited set of specifications to where they stand today.” NETA certification and accreditation are sought after throughout the electrical industry. End users value the expertise and assurance brought to their investments; engineering firms are beginning to plan and design with testing in mind; and individuals value the security of a company that has exhibited strength as an employer along with the ability to gain recognition for their technical knowledge and experience.

Happy Birthday, NETA, and many happy returns of the day.

Sets new standards for compact devices in relay testing. This new relay test set can handle any challenge you face in practice. Six current and four voltage outputs allow testing for all relays. Test your relays fast and efficiently with front panel control or software templates. Total weight is only 22 pounds!

Characteristics

n Automatically tests for all types of protection relays

n Freely configurable three-phase function generator

n IEC 61850-compliant protection equipment

n “Play back” function for fault records

n Ergonomic menu and intuitive operation

Is the first relay test set to address the difficult high burden relays. Three built-in sources and a very high output power: up to 1500 VA. In addition to carrying out secondary test on protection relays, the high output current (up to 250 A) makes ARTES 100 capable of a wide variety of tasks, including primary tests for commissioning and maintenance.

Characteristics

n High test current 250 A

n Total output power of up to 1500 VA, one current, two voltage sources both convertible n Front panel or software controlled

Powerful, ergonomic, and versatile: Easy to use template reduces testing time. It leads the market with a brand new graphical interface!

Characteristics

n Testing IEC 61850-compliant protection equipment

n Automatic determination of tripping characteristics

n Watches function for all types of test sequences

n Results correlate to the installation locations of different instrument transformers

n Reproduction of 1-pole and 3-pole automatic reclosing operations (ARCs)

Three-phase power systems make up the bulk of electric power transport and usage because they create a balanced system, and balanced systems produce smooth torque in motors and minimize losses in power lines. An unbalanced system, such as one produced by faults, is an entirely different matter. Coupling between phases makes analysis cumbersome and complicates meeting the need for sensitivity and security in protective relays.

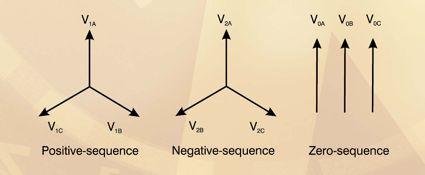

Symmetrical components provide relay designers with three decoupled networks with which to analyze power system conditions: positive-, negative-, and zero-sequence. The advent of microprocessor relays has expanded the application possibilities of this powerful tool even further.

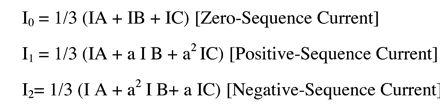

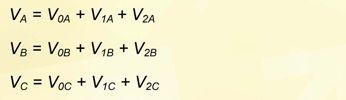

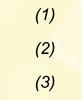

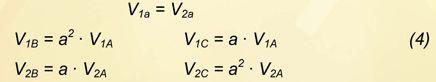

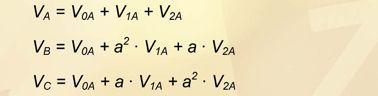

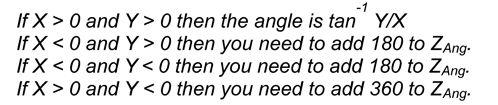

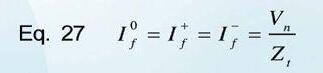

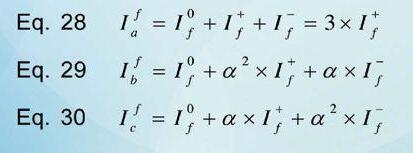

Symmetrical components provide a relatively simple way of looking at the three-phase power system without having to consider the coupling between phases. The identities of the sequence components of current are as follows (voltage has similar identities):

In these equations, the “a” operator rotates the quantity by 120 degrees. In this case, all sequence quantities are referenced to phase A and apply to ABC phase rotation.

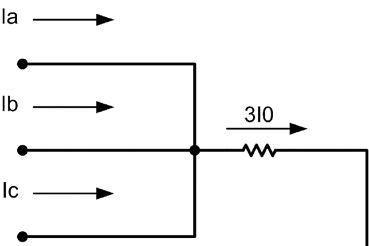

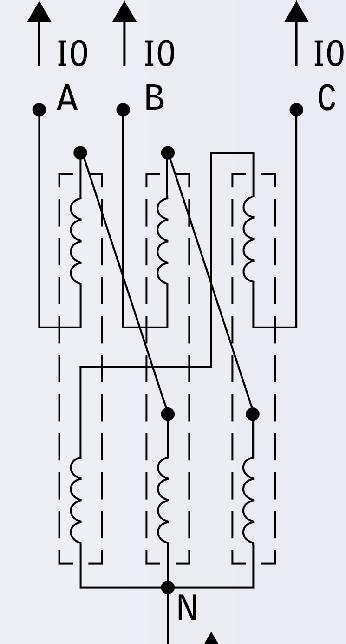

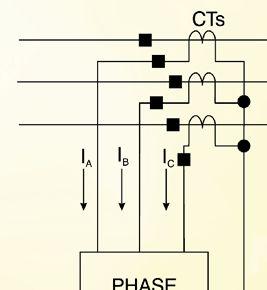

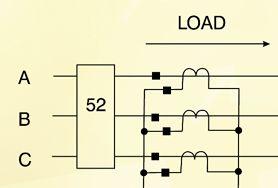

In the physical world, zero sequence involves ground, negative sequence involves a system unbalance (phase-to-phase or phase-toground), and positive sequence involves balanced three-phase faults and load. Because the calculation of zero-sequence quantities does not require phase rotation, it has been used for a long time for ground fault detection. Simply connecting the three phases in parallel, as shown below, provides zero-sequence current.

Some older electromechanical relays, such as the Westinghouse IRQ type, used negativesequence directional elements for applications where ground directional was not practical, but the construction was complex and the application difficult.

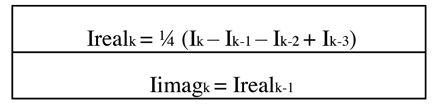

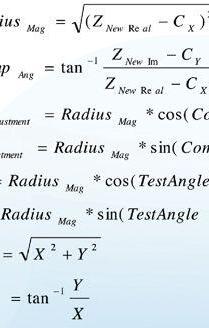

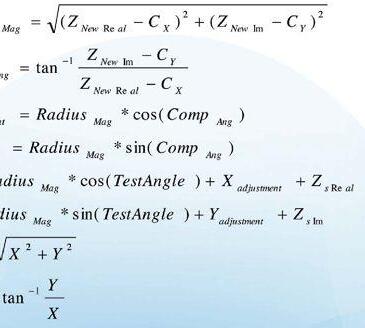

Microprocessor relays have the capability to directly calculate sequence components without complicated filtering. This makes the use of all sequence components not only feasible but simple. For example, the popular cosine filter, with a sampling rate of four samples per cycle, calculates the phasor in the following way:

Equations for Calculating Negative Sequence Current in a Microprocessor Relay

Simple calculations instead of expensive filters make the application of sequence components in microprocessor relays practical for operating quantities, polarizing quantities, and numerous combined elements. Sensitivity and selectivity become tools for the relay designer and protection engineer.

Despite some complexity, it is easy to take advantage of the increased sensitivity offered by negative sequence overcurrent relays. In a 1992 paper by Dr. Edmund O. Schweitzer III, an early pioneer in microprocessor relays, coordinating negative sequence overcurrent relays with downstream phase overcurrent relays in radial systems was described. By multiplying the downstream phase element pickup by √3, and using the same time delay and curve shape, coordination is achieved. Load current need not be considered in setting a negative-sequence relay, so tapped loads and branches on distribution feeders do not need to increase pickup for unbalanced faults.

Detecting the direction of ground faults is an ideal application for sequence-based relays. Because of the calculating capabilities of modern microprocessor relays, it is possible to not only use sequence quantities to polarize directional elements but also select from multiple available quantities to ensure adequate sensitivity. A patented technology in relays by Schweitzer Engineering Laboratories (SEL) referred to as Best Choice Ground Directional Element® logic selects from negative- or zero-sequence voltage or zero-sequence current polarizing. This overcomes problems with polarizing sources that may depend on available sources, such as transformer neutrals.

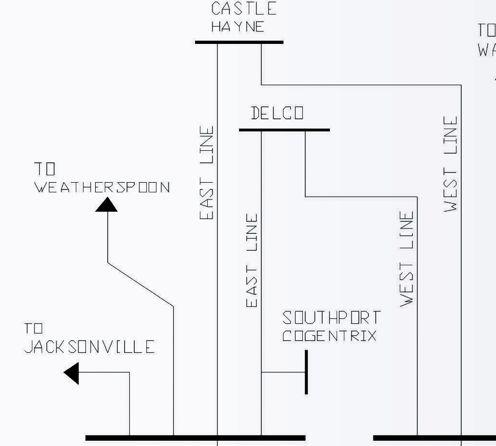

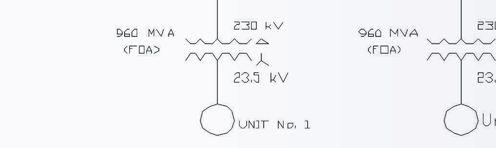

Consider the system diagram below:

3

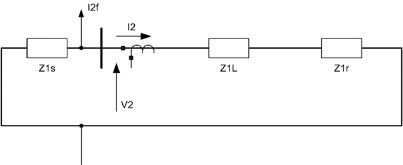

In this case, a fault on Line 1 is considered forward for the relays on Line 1 and reverse for the relays on Lines 2 or 3. Looking only at negative-sequence voltage and current for Lines 2 and 3, we have a measuring network, as shown below with Z1s and Z1r as the positive-sequence source impedances at the two ends, and Z1L as the positive-sequence line impedance.

In this case, the ratio of V2/I2 = + (Z1L + Z1r). If this ratio, as measured at the relay, is positive, then the fault is behind the relay. If it is negative, then the fault is in front of the relay. The sign of the ratio becomes the directional element. For a fault in the reverse direction, the relay measures at least the line impedance.

In the negative-sequence network, the angles of the impedance are highly predictable; they are basically reactance. This makes the negative-sequence directional element application simpler for all networks as opposed to zero-sequence directional elements that may need to consider the grounding of the system for their operation. The negative-sequence directional element reliably determines the direction of all fault types in the power system, except the three-phase fault. This makes the element highly attractive for modern relays that need to provide phase fault protection and ground fault protection. A ground directional element can be designed with zero-sequence quantities. It can be based on impedance or on the traditional phasor comparison of the zero-sequence voltage and the zerosequence current.

The directional element is used to supervise another measuring unit, such as current or distance. This provides coordination with otherrelays on the system.

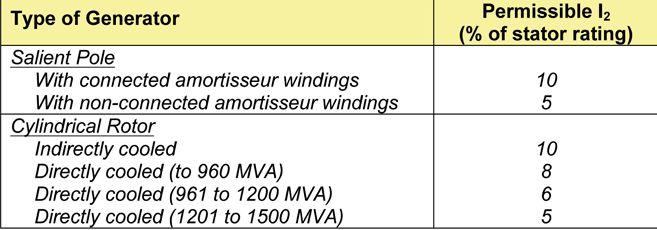

Negative-sequence currents in rotating machines have the effect of producing a counter-rotating flux in the air gap between the stator and rotor. This has no effect on the stator, but it induces a double-frequency current in the rotor. This applies to both generators and motors. Because of the skin effect, that is, the tendency of current to flow more on the surface of conductors at higher frequency, negativesequence current causes far more heating than positive-sequence or load current. Generator manufacturers will typically provide either a negative-sequence current withstand curve or values for their generator. While negativesequence overcurrent protection was an expensive addition in single-function generator or motor protection, in modern microprocessor relays, this is a simple setting within the relay.

It should be noted, and can be seen from the first set of equations in this article, that single-phase testing of relay elements involving sequence quantities is problematic at best. An input to only phase “a” of three amperes, will produce one ampere of zero-, positive-, and negative-sequence current. This may become important if checking a fully configured relay for phase pickup, while a sensitive zero- or negative-sequence element is looking at unbalance or neutral current. Care needs to be taken to avoid inadvertently picking up elements not directly being tested. This could cause contact closures and misreading of pickup levels.

Another consideration is whether the setting of a sequence quantity is 3I0, 3I2, or I0, I2 Because the common connection shown earlier for the zero-sequence filter produces 3I0, it is reasonable to use this as the basis for setting a relay. Some manufacturers do not multiply the quantity by three in the setting, but instead use the sequence current directly in the setting and measurement. This can cause confusion and misoperations if not considered when setting and testing relays from different manufacturers.

The use of sequence quantities has increased dramatically since the introduction of microprocessor relays. Sensitivity to faults, especially unbalanced faults, has increased while security has also increased. Motors, feeders, transmission lines, and generators have all benefited from the capability of applying new measuring techniques based on sequence components. Recognizing these capabilities and testing and application considerations will continue to provide engineers and technicians with advanced tools for solving power system problems.

Roy Moxley received his B.S. in electrical engineering from the University of Colorado. He joined Schweitzer Engineering Laboratories, Inc. (SEL) in 2000 as marketing manager for transmission system products. He is now marketing manager for power systems. He has authored and presented numerous papers at protective relay and utility conferences. Prior to joining SEL, he was with General Electric Company as a relay application engineer, transmission and distribution (T&D) field application engineer, and T&D account manager. He is a registered professional engineer in the state of Pennsylvania and a member of IEEE and CIGRE.

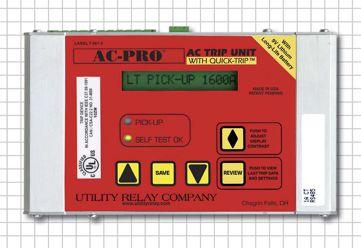

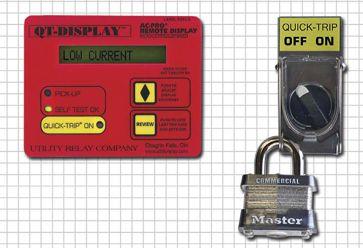

❏ Over 1000 different kits

❏ Microcontroller based, true RMS and 16-character display

❏ All functions included: LT, ST, Instantaneous, GF, Phase Unbalance, QT-GF and QT-Inst with off setting for all (except LT & QT-Inst)

❏ Intuitive programming and easy retrieval of last trip data

❏ 3 Different types of actuators available

❏ Modbus communications available

❏ Quick-Trip™ for arc flash reduction during maintenance

❏ UL and CE labels

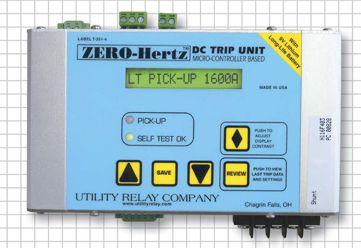

❏ Over 95 different kits

❏ Microcontroller based with 16-character display

❏ Provided with Hall Effect transducers or optionally accepts a 50mV or 100mV shunt input

❏ All functions included: LT, ST, Instantaneous, GF, Reverse Current, QT-GF and QT-Inst with off setting for all (except LT & QT-Inst)

❏ Modbus communications available

❏ Now available with Quick-Trip for arc flash reduction during maintenance

❏ Reduces Arc Flash Hazard during maintenance

❏ The QT-Instantaneous and QT-GF settings are fully adjustable

❏ Easy to install

❏ AC-PRO trip units are Quick-Trip ready and only require the addition of a Quick-Trip Display and a lockable QT ON/OFF selector switch

❏ ZERO-Hertz trip units are now available with Quick-Trip and only require the addition of a lockable QT ON/OFF selector switch with integral indicating light

❏ Provides arc flash reduction during maintenance per 2011 NEC Article 240.87

❏ Plug-in direct replacement for Merlin Gerin & Square D Masterpact MP, IEC or UL rated breakers

❏ User programmed to replace the STR-18M, 28D, 38S or 58U trip units

❏ Same protective functions, settings and time-current-curves as the original STR trip unit

❏ Information and alarm functions are standard

❏ No physical rating plug required

❏ Easy to read OLED display in low or high ambient light

❏ A security code protects against unauthorized changes to settings

❏ Trip events are time and date stamped

❏ USB port and secondary injection test port

❏ Quick-Trip for arc flash reduction is built in, nothing additional is required

In the area of protective relay maintenance, it is well understood that electromechanical relays require servicing to remain within expected pickup and operating specifications. Although electromechanical relays have protected electrical systems for many years, the physical integrity of relays can deteriorate over time. The required frequency of relay calibration and maintenance depends on the type of environment to which the protection is subjected. In harsher environments, the induction disc may need to be cleaned more often so as not to impede the electromechanical action of the magnet on the disc and affect the operation of the relay during a fault.

Photo 1: An Example of a 50/51 Electromechanical Relay.

In years past, it was common to calibrate relays and their various components. This meant adjusting springs, cleaning contacts, and adjusting magnets to ensure the relay operated as designed. This work is still required on existing systems where older, vintage equipment is in service.

With the advent of solid state relays, one might question the value in performing maintenance testing of a protective relay that does not require any form of calibration. Although the manuals for relays from various manufacturers state that specific routine tests are not required, the operation standards for facilities may require regular testing. Most relay manufacturers have various self-testing functions that report any software issues within the relay. As such, routine relay testing is required for the purposes of validating reliability, possible liability, and risk assessment evaluations for insurance purposes. The condition of the output contacts of a solidstate relay cannot necessarily be assessed by the relay’s self-checking feature. The self-check programming within a relay looks at internal PCB trace voltages, processor chip checks, etc. These error checks do not analyze the state of a damaged output contact that could either be welded closed from a previous dc arc or a permanently open contact due to damage to the relay. Obviously these types of hardware failures can severely compromise the integrity of a protection system, and verification of correct operation of the outputs and inputs ofa solidstate relay is well warranted.

Although bench testing of a relay can prove that the protection elements are operating according to manufacturer’s specifications, it is extremely important to perform functionality testing in the field before energizing. Additional testing of relay communications and custom designed control logic can reveal deficiencies in the desired protection scheme. A proactive approach would be to perform testing on the relay to definitively know that all systems are functioning correctly. This is in contrast to assuming that all relay protection systems are operating perfectly and possibly being subjected to a rare relay failure that could remain unnoticed until after a catastrophic fault that was not cleared by the same failed protection relay.

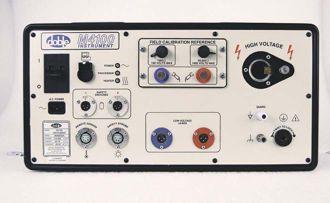

Photo 2: Remember the SR-51? A fabulous machine set up to test a variety of electrical protection components; a bit of a blast from the past for us older techs.

One thing is for sure, relay protection system maintenance is performed considerably differently and more efficiently than in years past. Digital technology has brought about an entirely new way of performing maintenance and in some cases a different philosophy as well.

One of the major challenges is to remove multifunction relays from service. Single phase or individual functional relays of electromechanical style can be safely removed with the power system on line. This is not necessarily the case with multifunction relays as every function is being defeated with the relay out of service.

Even with the advent of new technology, the importance of performing protection system maintenance has not changed. Asset management, system reliability, and personnel safety all hinge on the protection scheme operating according to the coordination study requirements. During power system faults, incident energy is in direct proportion to the amount of time the system takes to operate. Incident energy values are determined using an arc-flash hazard analysis and are based on the equipment working according to the time current characteristics. These TCCs are based on an operating value when the equipment is new from the factory. As time goes on, the maintenance of the protective devices becomes very critical to ensure the operating times found in the study match the times in the field. Service-aged equipment has been found to be unreliable and in some cases even inoperable which creates an obvious variance from the expected operation.

Relay protection maintenance is critical to ensuring that major equipment damage and injury to personnel are not encountered. Maintenance also drives reliability. The frequency and type of relay maintenance depends on a number of factors including criticality, environment, and type of relay system.

Kerry Heid is the President of Magna Electric Corporation, a Canadian based electrical projects group providing NETA certified testing and related products and solutions for electrical power distribution systems. Kerry is a past President of NETA and has been serving on its board of directors since 2002. Kerry is chair of NETA’s training committee and its marketing committee. Kerry was awarded NETA’s 2010 Outstanding Achievement Award for his contributions to the association and is a NETA senior certified test technician level IV.

Kerry is the chair of CSA Z463 Technical committee on Maintenance of Electrical Systems. He is also a member of the executive on the CSA Z462 technical committee for Workplace Electrical Safety in Canada and is chair of working group 6 on safety related maintenance requirements as well as a member of the NFPA 70E – CSA Z462harmonization working group.

NETA and our NETA Accredited Companies invite YOU to become a part of NETA’s technical community and take advantage of the many benefits of becoming a NETA Gold or Standard Affiliate.

As a NETA Affiliate you can participate in NETA’s Technical Working Committee, qualify for substantial discounts, and access industry leading experts and technical resources.

Call or go online to sign up for your NETA Affiliate Subscription today! Go to www.netaworld.org or give us a call at 888-300-NETA (6382).

Kerry Heid, President of Magna Electric Corporation (MEC), a NETA Accredited Company, recently shared some very exciting news with the NETA office. MEC has been recognized by multiple organizations for its outstanding business and employment practices, stepping into the Saskatchewan and Canadian spotlights in the last couple of years by earning some impressive titles. MEC has been named one of Saskatchewan’s top 20 employers for three years running (2010 to 2012) as well as the Saskatchewan Applied Science Technologists and Technicians Outstanding Employer for 2011. On a national level, they have been awarded one of Canada’s Top 100 Employers for 2012.

These employment awards show MEC’s commitment to their employees and the desire to create a positive and rewarding work environment. The Saskatchewan Chamber of Commerce has featured MEC in its “On Track” Campaign which promotes Saskatchewan business success stories (www.ontracksk. ca). MEC is also featured in Saskatchewan Business Magazine’s top 100 Saskatchewan companies for 2011 and has officially gained the number one ranking of electrical services provider in the province.

In speaking about these awards, Kerry stated, “One award the company is very proud of is the 2010 Safe Employer Award received from the Workers Compensation Board,” which is open to all Saskatchewan companies. Kerry says, “MEC showed why we are a true leader in Saskatchewan when it comes to workplace safety. Safety is top priority for MEC and it shows!”

In addition to these honors, Saskatoon Achievement in Business Excellence Awards granted Magna Electric Corporation the Growth and Expansion Award for 2011. In a similar vein, MEC was awarded, on November 19, 2011, the Growth and Expansion Award as well as the Business of the Year Award at the ABEX awards, which is a prestigious province-wide award within Saskatchewan.

Last, but not least, Magna Electric Corporation recently discovered they have been chosen as one of Canada’s 50 Best Managed Companies. Kerry is incredibly gratified at this recognition, noting that this is also an award that is sought after by hundreds of great companies across Canada. Kerry closes by saying, “Magna Electric Corporation is building a future of continued growth and expansion while keeping a firm grip on the high quality and safety standards that have brought us to our current height of success.” NETA is proud to be represented by Magna Electric Corporation as one of its Accredited Companies and looks forward to more stories of success in the future!

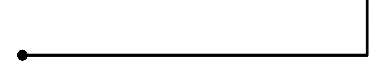

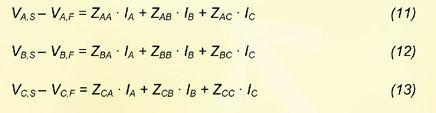

Multi-function protection relays calculate and use symmetrical components to enhance their performance during system faults. Three examples are presented in this article:

• Zero-sequence current elimination for transformer differential protection

• Positive-sequence voltage polarization for mho phase distance elements

• Negative-sequence current detection to inhibit out-of-step blocking

ZIGZAG TRANSFORMER INSIDE TRANSFORMER DIFFERENTIAL ZONE

A shunt connected zigzag transformer provides a zero-sequence current sink for ungrounded systems such as the one shown in Figure 1 by establishing a connection from ground to neutral. Zero-sequence current (I0) flows up through the neutral of the zigzag transformer during ground faults. Therefore, it is simple to apply non-directional overcurrent protection for the detection of single line-to-ground faults. If the system is left ungrounded, high voltage appears on the unfaulted phases during single line-to-ground faults and conventional ground overcurrent protection is useless.

A zigzag transformer consists of three 1:1 ratio transformers. Each leg of the zigzag transformer consists of two windings that are 120 degrees out of phase. Windings are wound around the core such that zero-sequence current flows through the bank when there is system unbalance (i.e., ground fault). Only exciting current flows through a zigzag transformer during balanced system conditions. The grounding transformer appears as the leakage reactance of the core when a ground fault occurs and zero-sequence current flows splitting evenly into the three phases.

Three-Line Diagram

A grounding resistor is sometimes used since the transformer alone equates to reactance grounding. Typically, the zigzag transformer is sized such that its impedance is 100 percent on its own base. For the 10-second rating, 400 amps primary is commonly applied in the United States.

FIGURE 2: Ungrounded System with Zigzag Transformer for Ground Current

If the zigzag transformer is located inside the zone of transformer differential protection such as for the delta connected windings as shown in Figure 2 above then the zerosequence current contribution during external ground faults must be eliminated or else a misoperation can occur. Here is one method in which numerical transformer protection relays can reliably remove the ground current.

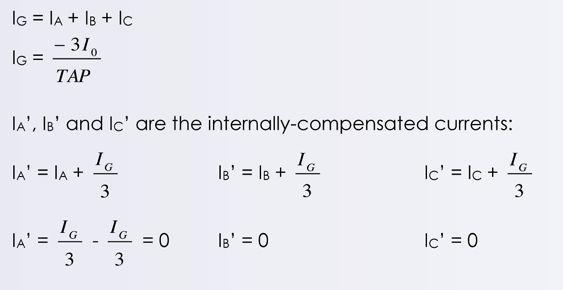

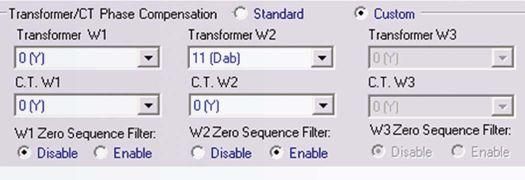

The currents shown are taken directly from the CT secondary and have been divided by the tap setting for the delta winding to convert them into per unit. If zero-sequence current elimination is selected (see Figure 3 as an example), then the relay calculates the ground current as follows:

3: Zero-Sequence Current Elimination

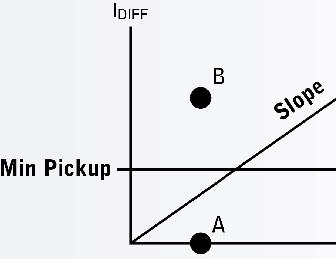

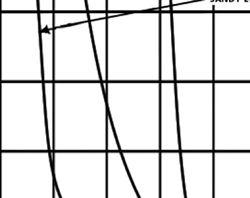

Figure 4 shows the transformer differential operating characteristic. Point A is the filtered operating point for an external ground fault and Point B is unfiltered.

FIGURE 4: Transformer Differential Operating Characteristic

DISTANCE PROTECTION PRE-FAULT POSITIVE-SEQUENCE MEMORY VOLTAGE POLARIZATION

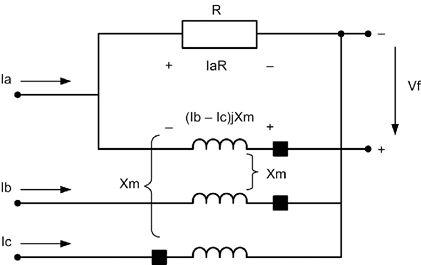

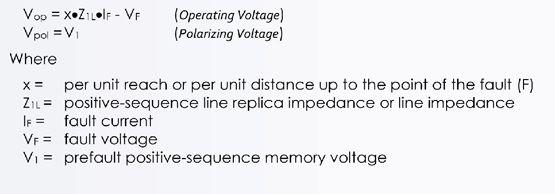

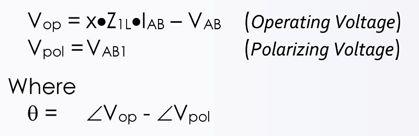

Distance elements applied for the protection of high-voltage transmission lines often use positive-sequence voltage as the polarizing signal or reference. These two equations show a classic method to create a mho distance element:

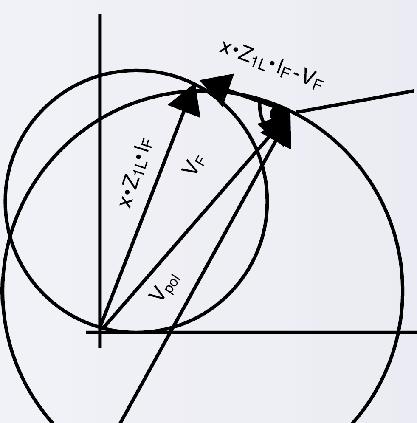

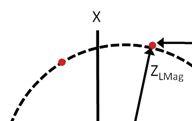

Figure 5 shows the A-Phase-to-B-Phase loop measurement for a phase mho distance element. Note that there are corresponding loops for B-Phase-to-C-Phase and C-Phaseto-A-Phase as well. The mho phase distance element measures the impedance up to the point of the fault (F) for that loop. IAB and VAB are the fault loop current and fault voltage measured by the relay during the fault.

The corresponding mho phase distance element is generated as follows using two internally-calculated potentials:

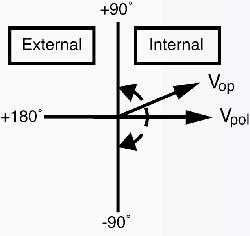

An A-Phase-to-B-Phase fault is internal with respect to the mho element when the absolute value of Ѳ is 90 electrical degrees or less (see Figure 6).

Mho Distance Element Directional Diagram

VAB1 is the voltage recorded prior to the fault (i.e., pre-fault) and is stored in a buffer. If there is no reference signal (e.g., bolted three-phase fault at the secondary terminals of the voltage transformer) then the mho distance element can misoperate during an external fault - this is one of the main reasons for using pre-fault memorized voltage as the polarizing quantity. Note that only positive-sequence quantities are present during balanced system conditions such as pre-fault load flow. The length of the buffer to store the memory voltage should be short enough that a skew is not introduced in Ѳ which can also lead to misoperation. Typically 30 cycles is sufficient. Ѳ is the angle between the two voltage signals and whenever this is equal to 90°, it describes a point along a circle as shown in Figure 7. Some other advantages to using positive-sequence memory voltage as the reference signal are as follows:

• Greater expansion of the mho characteristic along the resistive axis

• Reliable operation for close-in zero voltage faults • Security for close-in reverse phase-to-phase faults

• Security during single pole tripping

Figure 7 shows both the static and expanded dynamic mho distance operating characteristics in the voltage plane which is obtained by multiplying the impedance diagram by the fault current. Expansion along the resistive axis is a direct function of the apparent source impedance behind the relay; i.e., the weaker the source, the greater the expansion.

Static and Expanded Mho Distance Operating Characteristics

FIGURE 5: Phase A-to-Phase B Fault LoopCertain protection functions are typically only intended to operate during balanced three-phase conditions:

• Rate-of-change-of-frequency (81R)

• Loss-of-fi eld (40)

• Out-of-step tripping|blocking (78)

• Under-voltage load shedding

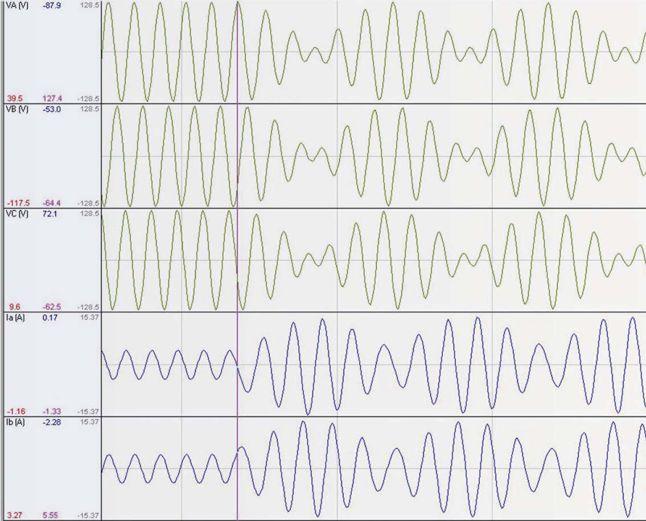

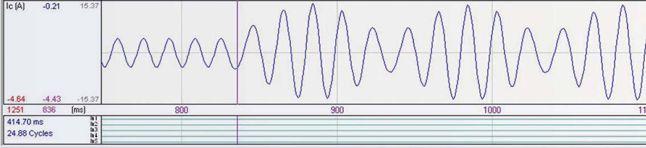

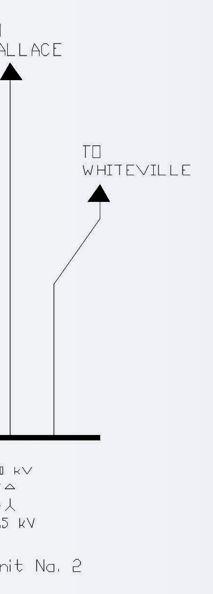

If negative-sequence current (I2) is detected, this is an indication that an unbalanced disturbance is in progress. Figure 8 shows the oscillographic record captured by a relay for the simulation of a large generator that slipped three poles; the event then evolved into a resistive ground fault. Figure 9 shows two large generating units at one plant that are interconnected one substation away via the transmission system. If either machine was to go unstable, then the desired sequence of events is to trip only the runaway generator while

blocking the distance relays protecting the local transmission line terminals. This criterion prevents cascading outages from occurring and preserves the integrity of offsite power sources to the plant. For this particular case, the desired end result would be to unblock the distance protection so as to clear the ground fault as shown in Figure 9.

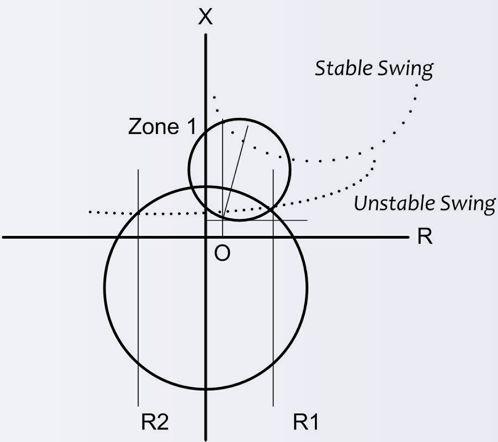

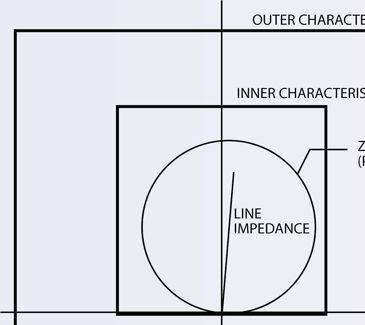

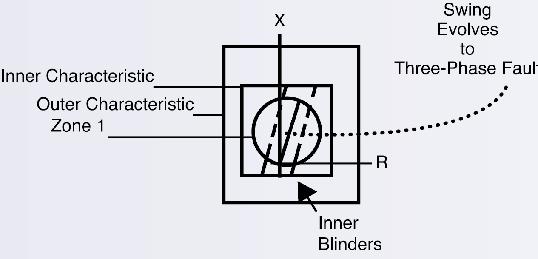

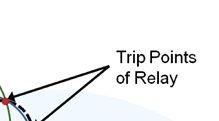

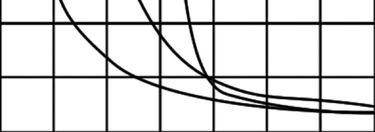

Figure 10 shows the trajectory of an unstable swing that passes through both the generator out-of-step (OST) tripping characteristic and a transmission line relay Zone 1 operating characteristic. Note that the point O in Figure 10 corresponds to the generator voltage transformer terminals. Such a swing could operate both the line protection and the generator outof-step tripping function–thereby illustrating one case why power swing blocking is required for the transmission line protection. Phase distance protection can also operate during a stable swing–also shown in Figure 10.

FIGURE 9: Two Large Generating Units Interconnected via the Transmission Grid

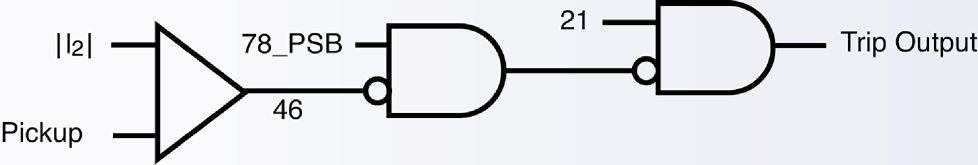

Figure 11 is a simple logic diagram that illustrates how to use negative-sequence current detection (46) to unblock the distance protection (21) after it has been inhibited by power swing blocking logic (78_PSB).

FIGURE 10: Unstable Swing passes through Zone 1 and OST

FIGURE 11: Negative-Sequence Current Unblocking

Another post-swing disturbance that is even harder to detect is if a three-phase fault were to occur on one of the transmission lines terminated at the plant following the first pole slip since there is no negative-sequence current present. Figure 12A shows a typical power swing blocking (PSB) characteristic. If the impedance trajectory passes relatively slowly (e.g., three cycles or more) through the outer characteristic to the inner characteristic, then a power swing is detected and the phase distance protection is blocked. If there is a fault then the measured impedance will quickly (e.g., two cycles or less) jump from the pre-fault location to a point on the faulted power system. A pair of inner blinders is required to detect when a swing evolves into a three-phase fault as shown in Figure 12B. If a balanced line fault occurs, then the measured impedance drops in between the blinders and remains there. Thus, the blinders can detect this condition and quickly unblock the phase distance protection.

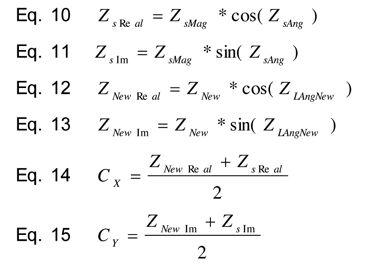

Out-of-step tripping and blocking characteristics operate on the measured positive-sequence impedance since a power swing is a balanced three-phase phenomenon. The positivesequence impedance can be calculated as follows:

This article presented several examples that illustrate how multi-function protection relays calculate and use symmetrical components to enhance their performance during system faults. The use of symmetrical component quantities help to provide protection that is more reliable and secure.

Steve Turner is a Senior Applications Engineer at Beckwith Electric Company. His previous experience includes working as an application engineer with GEC Alstom, an application engineer in the international market for SEL, focusing on transmission line protection applications. Steve worked for Progress Energy, where he developed a patent for double-ended fault location on transmission lines.

Steve has both a BSEE and MSEE from Virginia Tech University. He has presented at numerous conferences including: Georgia Tech Protective Relay Conference, Western Protective Relay Conference, ECNE and Doble User Groups, as well as various international conferences. Steve is a senior member of IEEE.

test equipment answer

■ VLF and Tan Delta (30 and 60kV Systems)

■ Off Line Partial Discharge

■ DC Hipot Testing (To 200kV)

■ Power Factor / Capacitance and Dissipation

■ Insulation Analyzers (To 15kV)

■ Cable Fault and Route Location

■ Fiber Optic TDR

■ Circuit Tracers

Jim White is the Training Director for Shermco Industries and the principal Shermco representative on the NFPA 70B committee. Jim is the alternate NETA representative on the NFPA 70E committee and serves as the NETA representative on the IEEE/ NFPA Arc-Flash Hazard Work Group (RTPC) Ad Hoc Committee. He served as the Chairman of the 2008 IEEE Electrical Safety Workshop. Jim is a NETA Certified Level IV Electrical Testing Technician and a member of the NETA Safety Committee.

1. What is a phasor?

a. Last seen on Star Trek, the Search for Spock, a phasor is a weapon that can be set for stun or kill.

b. Similar to a vector, a phasor is used to indicate both amplitude and phase angle. Phasors can represent any quantity that can be represented by a sinusoid.

c. An instrument used to determine the phase angle between voltage and current.

d. The angular difference between the voltage and current commonly referred to as theta.

2. A negative sequence relay is used to:

a. determine if the generator is supplying an unbalanced load.

b. determine when current flow is in the incorrect direction within an intertied bus system.

c. determine when the phase rotation of a motor is incorrect.

d. determine when the impedance of a generator’s rotor increases to above normal values.

3. A three-phase bolted fault will primarily produce what type of current?

a. Positive sequence current

b. Zero sequence current

c. Negative sequence current

d. Midrange sequence current

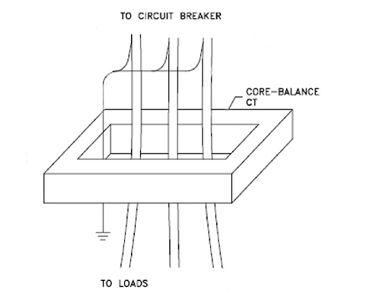

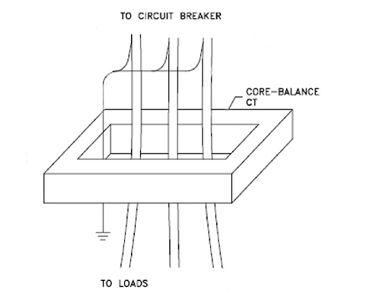

4. The diagram below shows a core-balance CT. What is another name for this type of CT?

a. Positive sequence

b. Negative sequence

c. Zero sequence

d. Phase fault protection

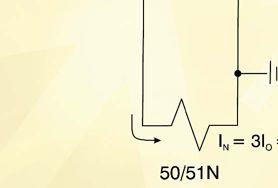

5. Identify the following three currents:

a. IO

b. I2

c. I1

• 50V & 100V Megohmmeters: For testing insulation resistance of phone cables, data cables and power cables

• 500V Megohmmeters: For testing the quality of insulation on equipment powered from sources up to 240Vac

• 1000V Megohmmeters: For testing equipment powered from sources up to 480Vac

• 5000V Megohmmeters: For testing large motors, generators, transformers, cables and other large rotating machinery

• Computer Controlled Models: AC powered, battery powered or hand-cranked models

• Choose from analog, digital or graphical displays

• Perform insulation resistance tests into the GΩ and TΩ ranges

AccurAcy (resolution 5 Digits):

Range 0.8 … 2000 ± 0.06% at 100V or 40V

Range 2001 … 4000 ± 0.1% at 100V or 40V

FeAtures:

• Automatic measurements of voltage, turns ratio, current, and phase displacement

• Measures power transformers PTs and CTs

• Displays deviation from a nominal ratio

• Displays % error vs. name plate value

• Bright full color touch-screen for easy data entry

Range 4001 … 13000 ± 0.3% at 100V or 40V

Range 13001 … 16000 ± 0.4% at 100V or 40V

• Test voltages of 100V, 40V, 10V, and 1V (for CT Testing)

• Graphical tap changer display

• Automatic phase vector detection

• Enhanced heavy-duty protection circuitry

• Data exchange with USB-Key

• Built-in printer

AccurAcy:

Range 100 mAmp … 15 Amp ± 0.1% Rdg 5 Digit Resolution

Range <25 mAmp 1.2kΩ …10kΩ ± 0.1% Rdg 4 Digit Resolution

Range <25 mAmp 10kΩ …100kΩ ± 0.5% Rdg 4 Digit Resolution

FeAtures:

• Core Demagnetizing Circuit (world exclusive)

• Charges inductive loads up to 1500 Henry

• 2 independent measuring channels

• Heavy-duty protection circuitry

• High power DC supply (15A/30V)

• Resistance range from 0.05 μΩ to 100 kΩ

• Battery or line voltage powered

• Visible and audible indicator for discharge status

• Data exchange with USB-key

• Simple touch-screen operation

• Built-in printer

AccurAcy:

Range 0.8 … 4000 ± 0.08% with 40 Volts (PT Mode)

Range 0.8 … 100 ± 0.08% with 1V … 5V (Auto) (CT Mode)

FeAtures:

• Operates on rechargeable batteries or line voltage

• Can be recharged with line voltage or optional

DC car adapter

• Reverse polarity test

• Continuity test

• Test current up to 1A for CT testing

• Internal storage of the last 50 test results

• RS-232 interface with optional adapter

• Over 1000 measurements without recharging

• TR-1P model includes built-in printer

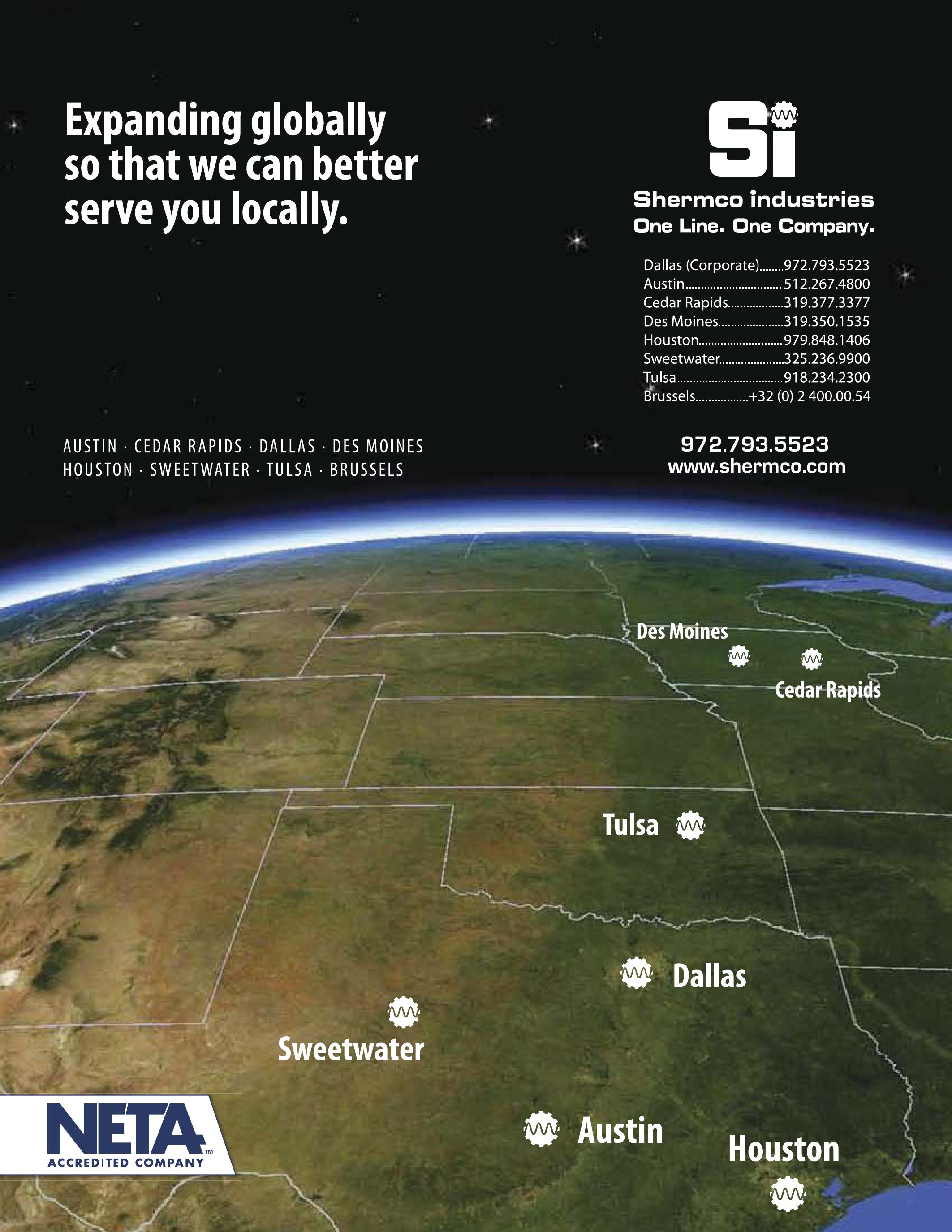

From big cit y to small town, east to west, Nor th America to Europe, we are expanding our resources and ser vice center locations to better ser ve you.

Contac t Shermco Industries for safe, reliable testing, repair, professional training, maintenance and analysis of rotating apparatus or elec trical power distribution systems for all market segments, including industrial, commercial, petrochemical, utilities and more.

BY JIM WHITE AND RON WIDUP, Shermco Industries

BY JIM WHITE AND RON WIDUP, Shermco Industries

One of the benefits of the new process is the new, on-line workflow, as the technical committee report will be available and published on the NFPA Standards Development Web Site as a true on-line publication with hyperlinking, legislative text, and other features, including downloading and printing capabilities. This will make reviewing the standards easier as they are being revised and/or developed.

In conjunction with the new process there will also be a new schedule with a closing date of June 22, 2012, for Public Input (PI), previously referred to as Proposals. The June date is several months earlier than the November closing date to which we have become accustomed under the old process and schedule. Public comments and proposals need to be in soon for the 2015 edition of the 70E, as June 2012 is not that far away!

The National Fire Protection Association (NFPA) has announced a new process for its technical committees starting with the 2013 cycle. Renamed Regulations Governing the Development of NFPA Standards, these new regulations will be in effect for standards reporting beginning with the fall 2013 revision cycle and all subsequent revision cycles. The NFPA 70E, Electrical Safety in the Workplace, will be revised under the new process for the upcoming 2015 edition.

Many members may be familiar with NFPA terms such as ROC (Report on Comments) and ROP (Report on Proposals); therefore, it is noteworthy that those terms will change with the new process.

Proposal (includes Public and Committee Proposals) will now be called Input (includes Public, Committee, and Technical Correlating Committee input; and the Proposal Stage will be called the Input Stage

Comment (includes Public and Committee Proposals), including the Comment Stage terms, remains unchanged.

Accept, Reject, Accept in Principle, and similar terms will now be Agreeing or Disagreeing (with Public Inputs). If one Agrees with a PI, one is accepting or accepting in principle a public comment.

Changes in the text of proposed new or revised NFPA Standards that result from actions of the Committee or Correlating Committee will now be called Revisions and Correlating Revisions (which includes First Revisions and Second Revisions).

Following is a list of some of the more common terms and concepts used in the NFPA process and a description of how they will be changed for the new procedures:

Preprint, which is a complete draft of a proposed new or revised NFPA standard (often published in the ROP or ROC stage), will now be called Draft (includes the First Draft showing all First Revisions and the Second Draft showing the First Draft as further revised by Second Draft Revisions).

Report on Proposals (ROP) will now be called First Draft Report.

Report on Comments (ROC) will now be called Second Draft Report.

Technical Committee Report, which includes the Report on Proposals and the Report on Comments and is published as two publications, will still be called Technical Committee Report and will include the First Draft Report and the Second Draft Report.

The next edition of NFPA 70 (National Electrical Code) will be the 2014 edition and will be completed under the new procedures. The due date for NEC proposals (input) to the 2014 edition has already passed as the cutoff for inputs was November 4, 2011.

The original deadline for proposals for the 2015 NFPA 70E was November 2, 2012. The new deadline is June 22, 2012.

A complete description of the new process is available for review at www.nfpa.org/newregs.

Annexes in NFPA 70E are used to supplement the information in the standard and are not part of the standard insomuch as they are not mandatory. The new title for the annex section is Informative Annexes. While people do not often review the annexes, perhaps because they do not recognize their importance, the annexes help readers to better understand the standard and the reasons the NFPA 70E committee has made some of its decisions.

Annex A is a listing of all standards referenced by NFPA 70E. This list includes ANSI standards, IEEE standards, ICRP standards, ASTM standards, IEC standards, and the NEC. The most recent versions (as of the ROC/ Second Draft meeting) are used as references for each standard.

Annex B contains a listing of informational references, which may also include standards. The primary difference between Annex A and Annex B is that the standards within Annex A are considered part of the standard and thus include mandatory elements, and the documents listed in Annex B are informational only.

Annex C has information about limits of approach. Information contained within Articles 110 and 130 are expanded upon in Annex C, and more detail is provided about the shock approach boundaries. As an example, C.2.1 discusses the following:

• The distances in columns 2 through 5 of Tables 130.4(C)(a) and (b) were derived from the basic minimum air insulation distances in IEEE Standard 4, Standard Techniques for High Voltage Testing, Appendix 2B for voltages 72.5 kV and less, while IEEE Standard 516, Guide for Maintenance Methods on Energized Power Lines was used for voltages above 72.5 kV).

• Column 2, Limited Approach Boundary (Exposed Movable Conductor), uses OSHA’s requirement stated in 29 CFR 1910.333(c)(3)(i).

• Column 3, Limited Approach Boundary (Exposed Fixed Circuit Part) comes from NEC Table 110.26(A)(1) for 151 volts to 600 volts, NEC Table 110.34(A) for 750 volts to 145 kV and OSHA 1910.333 for voltages above 145 kV.

• Column 4, Restricted Approach Boundary, primarily comes from the National Electrical Safety Code, ANSI C2 and

• Column 5, Prohibited Approach Boundary, is from a combination of experience and NEC Tables 230.51(C) and 490.24.

Annex D, Incident Energy and Arc Flash Boundary Calculation Methods, has information concerning several methods that can be used to calculate incident energy and the arc flash boundary with IEEE 1584, Guide for Performing Arc-Flash Hazard Calculations being one of them. Each method discussed has limitations of use, and in some cases, one may be more appropriate than another.

As an example, IEEE 1584 can only be used to determine incident energy for voltages from 208 volts through 15,000 volts in metalenclosed equipment (arc-in-a-box) with short-circuit currents between 700 amperes to 106,000 amperes.

The Doughty/Neal method can be used to determine incident energy for three-phase systems of 600 volts and less, when the shortcircuit current is between 16,000 amperes and 50,000 amperes.

The Ralph Lee method is used for determining incident energy on a three-phase system above 15,000 volts in open air. The text portion of IEEE 1584 is included as part of Annex D for reference. Table D.2 contains very useful information, in that it estimates the arc-flash boundaries for various system voltages and short-circuit currents in a large petrochemical plant. This should be of use to almost anyone who works in a large facility and wants to know the risk of an arc-flash burn, even though the table applies specifically to petrochemical plants.

Some of the arc-flash boundaries are eyeopening, and one should take the time to read and understand Annex D.

One change to Annex D is in D.6 Calculation of Incident Energy Exposure Greater Than 600 V for an Arc Flash Hazard Analysis. Often the soft ware for arc-hazard studies is set at a twosecond maximum fault duration, which is normally satisfactory for the purposes of arcflash analysis. The fault duration is based on the belief that in two seconds the worker is either on his way out of the room or the exposure has passed, but that may not always be the case.

For example, a person working inside a cabinet or in an area that has restricted access such as a bucket truck as described in the following example may be exposed to an arc for longer than two seconds. In situations such as this, the worker has little choice other than to do the best he can to protect himself until the danger passes. Fortunately, most such incidents would probably be from a single-phase fault; therefore, the incident energy would be reduced from a three-phase arc. However, the incident energy is proportional to time, so the longer the arc lasts, the more heat is produced.

The wording for this new section is “If the arcing time, t, in Equation D.7.3(c) is longer than 2 seconds, consider how long a person is likely to remain in the location of the arc flash. It is likely that a person exposed to an arc flash will move away quickly if it is physically possible, and 2 seconds is a reasonable maximum time for calculations. Sound engineering judgment should be used in applying the 2-second maximum clearing time, because there could be circumstances where an employee’s egress is inhibited. For example, a person in a bucket truck or a person who has crawled into equipment will need more time to move away.”

Although there are many more informative and important annexes within the 70E, space restrictions unfortunately prevent us from detailing each one. Readers should take the time to study and understand the remaining annexes.

Information in the 70E standard and the annexes is constantly changing. The NFPA is moving to an on-line submission and review system to streamline the process, and the 70E changes approximately every three years.

Proposals (Public Input) must be submitted before the new closing date of June 22, 2012. Some items could use editing for clarification, and reader suggestions are welcome to help improve this edition. After all, this is your safety standard. Help make it a better by providing constructive inputs for change.

Ron Widup and Jim White are NETA’S representatives to NFPA Technical Committee 70E (Electrical Safety Requirements for Employee Workplaces).Both gentlemen are employees of Shermco Industries in Dallas, Texas a NETA Accredited Company. Ron Widup is President of Shermco and has been with the company since 1983. He is a Principal member of the Technical Committee on “Electrical Safety in the Workplace” (NFPA 70E) and a Principal member of the National Electrical Code (NFPA 70) Code Panel 11. He is also a member of the technical committee “Recommended Practice for Electrical Equipment Maintenance” (NFPA 70B), and a member of the NETA Board of Directors and Standards Review Council. Jim White is nationally recognized for technical skills and safety training in the electrical power systems industry. He is the Training Director for Shermco Industries, and has spent the last twenty years directly involved in technical skills and safety training for electrical power system technicians. Jim is a Principal member of NFPA 70B representing Shermco Industries, NETA’s alternate member of NFPA 70E, and a member of ASTM F18 Committee “Electrical Protective Equipment for Workers”.

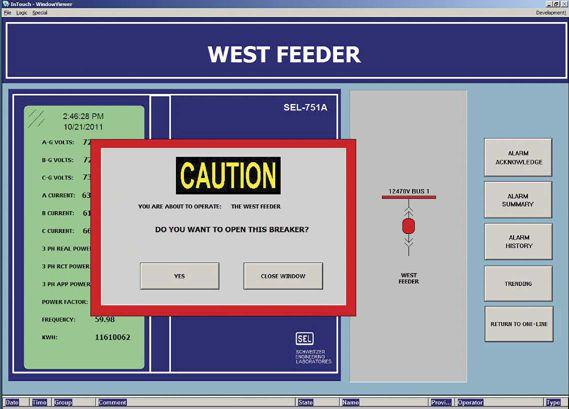

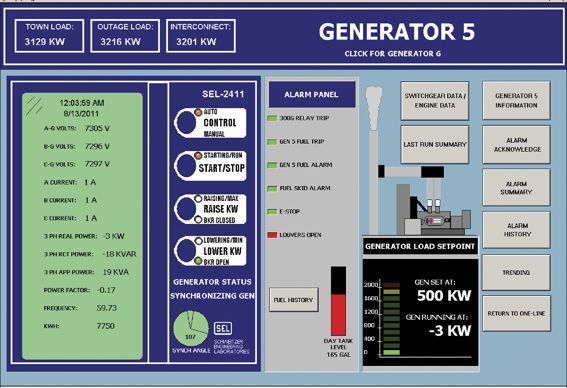

Shermco Industries recently completed a project that upgraded multiple generator control systems and main and feeder breaker control relays as well as provided an upgraded Supervisory Control and Data Acquisition (SCADA) system for an electric municipal utility. To meet customer requirements, the system had to be capable of communicating with and controlling several different protective devices while retaining the potential to expand in the future. In addition to communicating with various protective devices for data input, the SCADA system also had to be user friendly with control being accomplished through a simple touch-screen monitor.

The distribution system for this electric municipal utility consists of one main 15 kV distribution bus fed by a 69 kV to 15 kV transformer through a main breaker. The main bus is also fed individually by multiple generator sets, each with separate generator controls and a generator breaker. Feeder breakers are also tied to the bus for distributing electricity to the town. The two buses then distribute power to the community via 15 kV feeders. Adding complexity to the system is the recent addition of a single wind turbine to one of the distribution feeders. For this project, the utility required the capability of automating the 15 kV main and feeder breakers, as well as the various generators, through the SCADA system while using the SCADA system as a monitoring system for their generation capability.

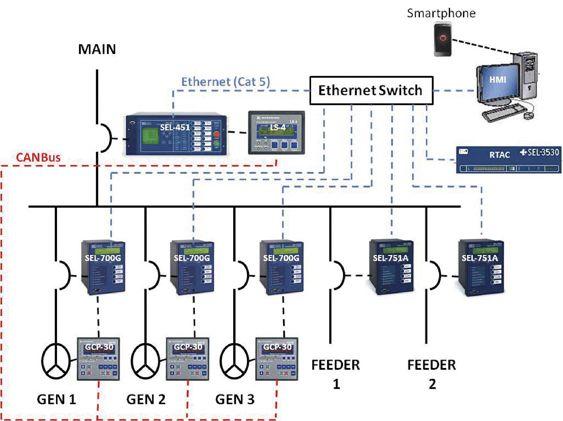

The overall system architecture consists of a variety of SEL relays that control and monitor the 15 kV class breakers. Additionally, a combination of SEL relays and Woodward generator controls are provided for the generators including the wind turbine. To facilitate communication with all the devices, an Ethernet switch and an SEL Real-Time Automation Controller (RTAC) were installed in a star pattern (see Figure 1) for the system communication. By configuring the system in this star pattern, each relay has its own channel to the system communications controller as opposed to a multidrop network where each node must wait in turn to send data. Utilizing the RTAC with IEC 61850 protocol, each SEL relay can broadcast information to the entire SCADA system, thus enhancing data access throughput and speeding up response times.

Figure 1: Typical System Communication Diagram

The SEL RTAC provides a real-time operating system with the functionality of sophisticated communication and data handling required for advanced power system integration projects. The RTAC features secure communications, advanced data concentration, high-speed logic processing, flexible engineering access, and protocol conversion capabilities between multiple built-in client/server protocols. The RTAC also gives integrators the necessary tools to easily integrate and concentrate information from the wide variety of microprocessor-based devices found in today’s substations.

Breaker protection and control is provided using the SEL-451 relay for the main breaker and SEL-751A relays for the feeder breakers. The SEL-451 relay has capabilities to monitor power, including thermal or rolling interval demand, as well as peak demand on positive-, negative-, and zero-sequence current. It also provides sufficient programming capabilities to eliminate the need for a separate programmable logic controller (PLC) to control the various operating scenarios associated with the generation system. The SEL-751A relays provide complete feeder protection with overcurrent, overvoltage, undervoltage, and frequency elements. Both relays also accommodate Ethernet-based communication with IEC 61850 communication protocol for the SCADA system. The SEL-451 accommodates hard-wired digital and analog inputs to communicate with the Woodward LS-4 device.

Generator protection and control is provided using a combination of SEL-700G relays and Woodward’s GCP-30 series of generator controllers. The SEL-700G provides a complete protection and synchronization solution for synchronous generators. They also accommodate Ethernet-based communication with IEC 61850 communication protocol for the SCADA system. The SEL-700G also accommodates hard-wired digital and analog inputs to communicate with the Woodward generator controllers.