• Rugged, small and lightweight

• High current, high power (60 Amps/300 VArms) per phase

• Up to 6 currents with convertible channels

• Thermally controlled fans for quiet operation

• New Smart Touch View Interface (STVI) provides manual control

• New STVI Overcurrent Test includes hundreds of relay specific time-curves built-in

With these comprehensive capabilities and extensive testing options the SMRT36 is conceivably the easiest to use 3-phase protective relay test system available today.

For more information on the SMRT36 relay test set contact us today at 1-800-723-2861 or email us at sales@megger.com to receive a SMRT36 brochure and Megger 2012 Power Catalog.

Megger

4271 Bronze Way

Dallas, Texas 75237-1019

Made in the USA The word "Megger" is a registered trademark

! 3: m " " m '" ;-, o � III

Meggerm

COVER STORY

FEATURES

7 PRESIDENT’S DESK

Mose Ramieh, Power & Generation Testing, Inc.

NETA President

46BATTERY MAINTENANCE RECOMMENDATIONS FOR UPS SYSTEMS

By Lynn Hamrick, Shermco Industries

74WHY REPLACE SERVICEABLE BATTERIES?

By Klas Björck, Megger

20 AN OVERVIEW OF BATTERY ASSET MANAGEMENT ISSUES

By

Kenneth Elkinson, Matthew Lawrence & Tony McGrail, Doble Engineering Company

It is a normal Tuesday afternoon with the sounds of people tapping away on their keyboards filling the office. Suddenly the office goes dark, no one can see their screen anymore, business production is halted, and the person in charge of your company’s UPS system knows they have a problem on their hands.

TABLE OF CONTENTS TABLE OF CONTENTS NETAWORLD 3 74

TABLE OF CONTENTS

IN EVERY ISSUE

28MAINTENANCE CORNER

Determining Criticality in an Electrical Maintenance Program

Kerry Heid, Magna Electric Corporation

34TECH QUIZ

Batteries and Battery Chargers

Jim White, Shermco Industries

39THE NFPA 70E AND NETA

Arc-Flash Clothing and PPE

What Does NFPA 70E Say?

Jim White and Ron Widup, Shermco Industries

SPECIFICATIONS AND STANDARDS ACTIVITY

110ANSI/NETA STANDARDS UPDATES

INDUSTRY TOPICS

32REAL WORLD LEARNING AT YOUR FINGERTIPS

NETA Handbooks

54SOLVING RELAY MISOPERATIONS WITH LINE PARAMETER MEASUREMENTS

Will Knapek, OMICRON Electronics Corp USA

60NICHE MARKET TESTING

Data Center Maintenance–Part 1–

The Electrical Maintenance Program

Lynn Hamrick, Shermco Industries

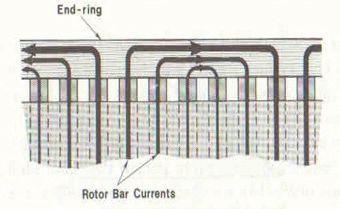

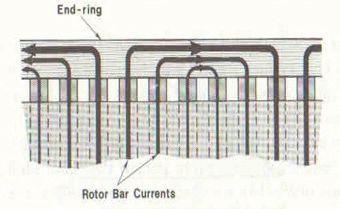

66TESTING ROTATING MACHINERY

Current Signature Analysis (CSA) Test

Vicki Warren and Ian Culbert, Iris Power LP.

89TECHNICAL BRIEF

Capacitor Trip Unit

Jim Bowen, Powell Industries

92SAFETY CORNER

Battery Safety Concerns

Stephen Canale, American Electrical Testing Co.

101TECH TIPS

Current Distribution in Resistivity Measurement

Jeff Jowett, Megger

80WHAT DO I DO IF THE BREAKER TRIPS?

James R. White, Training Director, Shermco Industries, Inc.

NETA NEWS

10WHEN GOOD IS NOT GOOD ENOUGH By Jill Howell & Kristen Wicks

16NETA BOARD AND PROMOTIONSCOMMITTEE CONVENEINCANADA

By Kristen Wicks

114NETA ACCREDITED COMPANIES

120ADVERTISER LIST

4 FALL 2012 TABLE OF CONTENTS

80

3050 Old Centre Avenue, Suite 102

Portage, MI 49024

Toll free: 888.300.NETA (6382)

Phone: 269.488.NETA (6382)

Fax: 269.488.6383

neta@netaworld.org

www.netaworld.org

EXECUTIVEDIRECTOR: Jayne Tanz, CMP

NETA Officers

PRESIDENT: Mose Ramieh, Power & Generation Testing, Inc.

FIRSTVICEPRESIDENT: David Huffman, Power Systems Testing Co.

SECONDVICEPRESIDENT: Ron Widup, Shermco Industries

SECRETARY: Walt Cleary, Burlington Electrical Testing Co., Inc.

TREASURER: John White, Sigma Six Solutions

NETA Board of Directors

Ken Bassett (Potomac Testing, Inc.)

Scott Blizard (American Electrical Testing Co., Inc.)

Jim Cialdea (Three-C Electrical Co., Inc.)

Walt Cleary (Burlington Electrical Testing Co., Inc.)

Roderic Hageman (PRIT Service, Inc.)

Kerry Heid (Magna Electric Corporation)

David Huffman (Power Systems Testing)

Alan Peterson (Utility Service Corporation)

Mose Ramieh (Power & Generation Testing, Inc.)

John White (Sigma Six Solutions)

Ron Widup (Shermco Industries)

NETA World Staff

TECHNICALEDITOR: Roderic L. Hageman

ASSOCIATEEDITORS: Diane W. Hageman, Resa Pickel

MANAGINGEDITOR: Jayne Tanz, CMP

ADVERTISINGMANAGER: Sara M. G. Dillon

DESIGNANDPRODUCTION: Newhall Klein, Inc.

NETA Committee Chairs

CONFERENCE: Ron Widup; MEMBERSHIP: Ken Bassett; PROMOTIONS/MARKETING: Kerry Heid; SAFETY: Lynn Hamrick; TECHNICAL: Alan Peterson; TECHNICALEXAM: Ron Widup; WORLDADVISORY: Diane Hageman; CONTINUINGTECHNICALDEVELOPMENT: David Huffman; TRAINING: Kerry Heid; FINANCE: John White; NOMINATIONS: Alan Peterson; STRATEGY: Mose Ramieh; AFFILIATEPROGRAM: Jim Cialdea

© Copyright 2012, NETA

NOTICE AND DISCLAIMER

NETA World is published quarterly by the InterNational Electrical Testing Association. Opinions, views and conclusions expressed in articles herein are those of the authors and not necessarily those of NETA. Publication herein does not constitute or imply endorsement of any opinion, product, or service by NETA, its directors, officers, members, employees or agents (herein “NETA”).

All technical data in this publication reflects the experience of individuals using specific tools, products, equipment and components under specific conditions and circumstances which may or may not be fully reported and over which NETA has neither exercised nor reserved control. Such data has not been independently tested or otherwise verified by NETA.

NETA MAKES NO ENDORSEMENT, REPRESENTATION OR WARRANTY AS TO ANY OPINION, PRODUCT OR SERVICE REFERENCED OR ADVERTISED IN THIS PUBLICATION. NETA EXPRESSLY DISCLAIMS ANY AND ALL LIABILITY TO ANY CONSUMER, PURCHASER OR ANY OTHER PERSON USING ANY PRODUCT OR SERVICE REFERENCED OR ADVERTISED HEREIN FOR ANY INJURIES OR DAMAGES OF ANY KIND WHATSOEVER, INCLUDING, BUT NOT LIMITED TO ANY CONSEQUENTIAL, PUNITIVE, SPECIAL, INCIDENTAL, DIRECT OR INDIRECT DAMAGES. NETA FURTHER DISCLAIMS ANY AND ALL WARRANTIES, EXPRESS OF IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

ELECTRICAL TESTING SHALL BE PERFORMED ONLY BY TRAINED ELECTRICAL PERSONNEL AND SHALL BE SUPERVISED BY NETA CERTIFIED TECHNICIANS/ LEVEL III OR IV OR BY NICET CERTIFIED TECHNICIANS IN ELECTRICAL TESTING TECHNOLOGY/LEVEL III OR IV. FAILURE TO ADHERE TO ADEQUATE TRAINING, SAFETY REQUIREMENTS, AND APPLICABLE PROCEDURES MAY RESULT IN LOSS OF PRODUCTION, CATASTROPHIC EQUIPMENT FAILURE, SERIOUS INJURY OR DEATH.

My how time flies. It seems like just yesterday I was elected as your president, but I’m now in the second year of my term. This edition of NETA World is addressing an issue that can have the same short time frame thoughts associated with it.

How long has it been since your batteries were serviced? It seems like just yesterday they were installed, and tested, and didn’t you just check the water and clean them? Find out all the important aspects of keeping battery systems in tip top shape in this edition.

This year has been an exciting one for NETA. Our 40th Anniversary at the over the top conference in Texas, four (4) new NETA Accredited Companies (NAC), ANSI/NETA Acceptance Specifications accepted by major engineering and construction firms, the implementation of the NAMO program, and more. All of these successes have come through the work of a few volunteers and the NETA Staff. We owe these hard working folks a well-deserved pat on the back.

The Board of Directors held a Strategic Planning Committee meeting followed by a Marketing Committee meeting during the month of June. These two meetings have given us the frame work to continue the evolution and expansion of NETA’s influence. In the next few months meetings will be held with several large constructors, A & E firms, and insurance companies. The purpose of the meetings is to promote our standards and encourage the use of NETA Accredited Companies to perform the work associated with the testing specifications. Your input and support is critical to the success of NETA and these initiatives. Let us hear from you!

Fall is approaching and with it the political season will be in full swing. Hopefully, after the election the economy will settle down and with it an uptick in our business. Be sure you get out and exercise your right to vote.

Mose Ramieh

NETA

President

PRESIDENT’SDESK PRESIDENT’S DESK

PRESIDENT’S DESK

From Apollo 7 to Today’s Smart Grid

Services:

Preventative Maintenance

Acceptance Testing High Potential Testing

Utility Service Corporation has been providing electrical and technical services for government and industry since 1962.

Solving complex problems, testing under difficult and unusual circumstances and servicing the commissioning and maintenance needs of today’s electrical power systems both new and aged.

Commissioning Services System Studies Arc Flash Analysis

Engineering & Consulting Construction Supervision System Trouble Shooting

(256) 837-8400

C C U U T T Y Y O O U U R R C C B B T T E E S S T TIIN N G G T TIIM M E E IIN N H H A A L L F F

atti i o o n nss. . 1 1 0 0 H Hrr O O n n b b o o a arrd d B B a attt t e erry y m m e e a a n nss N N O O

e e x xtte e n nssi i o o n n cco orrd dss. .

B B u uiil ltt iin n rre e p p o orrt t p prri i n ntte err

R R e essu ullt tss sst t o orra a g g e e & & d d o o w w n nllo o a a d d

N N e e e e d d T Trra a v v e ell? ? N N o o p prro o b blle e m m,, a a d d d d iit t w w h h e e n n

y y o o u u n n e e e e d d iit t u ussi i n n g g A A N N Y Y ttr r a a n nssd d u ucce err. .

A Alll l ffo orr LLE E S S S S tth h a a n n w w h h a att y y o o u u tth hiin n k k!!

Downloadfullspecifications

D D o o tth hrre e e e p p h h a asse e tti i m miin n g g & & cco o n ntta acct t rre essi isst t a a n ncce e m m e e a assu urre e m m e e n ntt w wiit t h h O O N N E E cco o n n n n e ecct tiio o n n.. R R e e m m o otte e C C o o n nttr r o oll ffo orr a a M M U ULLT TIIP PLLE E O O p p e e n niin n g g//C Cllo ossi i n n g g O O p p e erra

PME 500 TRbyNoram SMC

at www.noramsmc.com or call(918 622 5725)

WHEN GOOD IS NOT GOOD ENOUGH

BY JILL HOWELL AND KRISTEN WICKS

In recent years it has become common practice to think that good is good enough. However, with the demands placed on product and service providers in today’s global market, in many situations good is nowhere near good enough. In certain contexts, particularly in the realm of risk management and liability, even 99 percent assurance is not good enough. Work performed in the electrical power systems industry is one of those fields where one can never be too careful or take for granted the importance of standards that ensure the highest level of safety and reliability.

If 99 percent assurance were good enough: parents daily. written this year. performed incorrectly.

…And in the case of the electrical power systems in the U.S. may be at risk of failure incident or potentially causing serious injury.

1. Independent Statistics & Analysis, U.S. Energy Information Administration; How many and what kind of power plants are there in the United States?; December 21, 2011.

PUTTING QUALITY AND SAFETY FIRST

NETA’s mission is to ensure that the electrical power industry is as safe and reliable as possible. NETA’s foundation is built firmly on its third-party, independent NETA Accredited Companies that perform field testing services in accordance with the ANSI/NETA standards for maintenance and acceptance testing specifications (ANSI/NETA MTS and ANSI/ NETA ATS).

Third-party, independent testing provides an unparalleled level of unbiased service. Each NETA Accredited Company is committed to verifying the soundness of electrical power systems and reporting on their findings without the inherent conflict of interest that exists when field testing

is performed by equipment manufacturers, installers, and other parties with divided interests. NETA Accredited Companies are examined during the application process and through ongoing peer review to assure that NETA’s requirements for independence, safety, calibration, test reports, and most importantly, technician qualification and continuing education, are maintained to the highest standard.

NETA also understands that testing is only one aspect of ensuring electrical power system safety and reliability. Without the participation of the many business sectors that comprise the electrical power industry, a 100 percent assurance of safety and reliability is unobtainable. With that knowledge, NETA formed the NETA Affiliate Program.

The NETA Affiliate Program was established with the goal of engaging individuals rather than companies in the pursuit of improving safety and reliability in the industry. The Affiliate Program is subscription-based, meaning that there are no prerequisites or credentials necessary to become an Affiliate. While there is not a certification or qualification attached to being a NETA Affiliate, this program is home to professionals who share NETA’s mission, leaders who bring perspectives from all sectors of the electrical power industry and those who put quality and safety first.

NETA Affiliates are comprised of representatives from all sectors of our industry, such as:

The goal of the NETA Affiliate Program is to build a network of industry professionals committed to promoting and improving safety and reliability within the electrical power industry.

NETA is expanding the program adding initiatives and activities that encourage Affiliate involvement and participation in educational events and in promoting safety. More interaction through expanded networking and business development opportunities allow Affiliates to be more connected to NETA, other industry organizations, and the ever-changing dynamics of this industry. As a result, the NETA Affiliate Program now includes representation among associations such as NFPA, IAEI, AIA, IEEE, and companies and organizations that are shaping and influencing every aspect of the electrical power systems world.

Whether you are currently a NETA Affiliate or will be joining the program, you are encouraged to participate as often as possible and to provide your ideas on how to make the program even better.

One of the first NETA Member and Affiliate events will be the launch of the NETA Affiliate Newsletter, scheduled for October 1, 2012. NETA Affiliates are also invited to attend the February Member and Affiliate Luncheon scheduled for Monday, February 18, 2013, during PowerTest 2013 in New Orleans, Louisiana. Affiliates will join NETA members for a sit down lunch. The agenda includes an update on the association's activities and the announcement of the 2013 Affiliate of the Year. Throughout the luncheon, Members and Affiliates have the opportunity to rub elbows and share stories.

NETA will launch the first NETA Affiliate Newsletter with the goal of providing our Members and Affiliates with opportunities to share technological and business news. Topics will include:

Mark Your Calendars –2012-2013 NETA Affiliate Events

• NETA Affiliate Newsletter Launch; October 1, 2012

• NETA Website Affiliate Section Launch; January 1, 2013

• PowerTest 2013 – NETA Member and Affiliate Luncheon; New Orleans, Louisiana; February 18, 2013

• Affiliate of the Year Award; February 18, 2013

Congratulations to Dennis Neitzel 2012 NETA Affiliate of the Year!

• News about NETA, NETA events, and NETA standards

• A summary of what is happening in the industry regarding

• Industry standards

• Safety training

• Technical training

• A forum for Affiliates to present press releases, new product information, and updates on new technology

Another area in which Affiliates have requested NETA’s assistance is with training. Over the next twelve months, NETA will work to develop course specification and networking with select training organizations to expand course curriculum. These courses will provide Affiliates more educational options that qualify for AIA, IEEE, and general continuing educational credits for organizations outside of NETA.

To support these new initiatives and encourage Affiliate involvement, NETA will launch a dedicated section on the netaworld.org website designed to provide Affiliates with a forum to access and share information and exchange ideas.

Join the neta Community!

NETA and its Accredited companies are extremely excited about the new developments planned for the NETA Affiliate Program. If you are currently an Affiliate, stay tuned for news on these new opportunities in the coming months.

If you are not currently an Affiliate, join today at netaworld.org. We look forward to meeting you and welcoming you to our network of professionals.

If you have additional questions, please feel free to contact Jim cialdea, Affiliate committee chair, or Jill Howell, NETA Staff Liaison.

Jim cialdea

Affiliate committee chair

Three-c Electrical co., Inc. 508-881-3911 jim@three-c.com

Jill Howell

NETA Staff Liaison

Marketing and communications Manager Direct: 888-300-6394 Main: 888-300-6382 jhowell@netaworld.org

The following table provides a visual representation of all the aspects required for the various levels of participation within NETA.

To view the most current listing of NETA Accredited companies, the source for third-party, independent electrical testing, please visit www.netaworld.org or contact the NETA office at neta@netaworld.org.

FEATURE

Introducing a really big idea: “Rent it”

What makes it work, better than what you’re doing now? What’s next? You need a plan

N o1

*

// 866.352.5550 // 877.635.7987 // 855.776.8329

800-258-7044 www.three-c.com Serving the Northeast U.S. CAN YOUR TESTING COMPANY PASS THIS TEST? Why leave the reliability of your electrical equipment to chance? Trust the experts at Three-C Electrical with your generation and power distribution equipment. AS PERFORMANCE REPORT The Power Systems Specialists

NETA BOARD AND PROMOTIONS COMMITTEE

BY KRISTEN WICKS

BY KRISTEN WICKS

June in Regina, Saskatchewan is a great time of year. Contrary to the misguided belief that the land north of the United States border is buried in snow year round, the weather was pleasant and welcoming to NETA’sBoardofDirectorsandPromotionsand NETA’s Board of Directors and Promotions and Marketing Committee for their meetings on June 2122, 2012. Kerry Heid, Magna Electric Corporation, and his wife, Pam, hosted the entire crew at their home for a family style dinner complete with a gorgeous sunset. Another highlight of the meeting was a visit to the Royal Canadian Mounted Police Training Academy in Regina, Saskatchewan, for a private guided tour of the grounds and museum anddinner. and dinner.

The regal atmosphere of the Hotel Saskatchewan, proud host to Queen Elizabeth, was the setting for some very exciting and dynamic planning for the association at the Board of Director’s strategy session. The Promotions and Marketing Committee reported a successful year of executing the plan established in 2012, and looks forward to further expansion of the outreach efforts at the NETA office with the support of the NETA Accredited Companies. NETA is pleased to continue to offer new programs and benefits to its members.

g

u u d d u se a an s o m m n r dinner d

Outside and Inside Views of the Royal Canadian Mounted Police Chapel, Built in 1883.

Top Photo: The NETA Board and Staff Outside Royal Canadian Mounted Police Museum. Below Photos, Clockwise from Left: Stained Glass Window in RCMP Chapel, Memorial at RCMP Training Academy, and BoardDiscussion. Board Discussion.

Top Photo: The NETA Board and Staff Outside Royal Canadian Mounted Police Museum. Below Photos, Clockwise from Left: Stained Glass Window in RCMP Chapel, Memorial at RCMP Training Academy, and BoardDiscussion. Board Discussion.

BCS SWITCHGEAR,INC. www.bcsswitchgear.com 24-HourService: 24-Hour Service: 888-599-0486 Fax: 940-458-4122 MoldedCaseBreakers Molded Case Breakers InsulatedCaseBreakers Insulated Case Breakers AirCircuitBreakers Air Circuit Breakers Medium Voltage Breakers VacuumBreakers Vacuum Breakers VacuumContactors/Starters Vacuum Contactors/Starters Switches Switchgear BCS Switchgear,Inc.is one of the largest stocking distributors and repair facilities of quality equipment. New Used Obsolete Reconditioned

AN OVERVIEW OF BATTERY ASSET MANAGEMENT ISSUES

BY KENNETH ELKINSON, MATTHEW LAWRENCE AND TONY MCGRAIL, Doble Engineering Company

It is a normal Tuesday afternoon with the sounds of people tapping away on their keyboards filling the office. Suddenly the office goes dark, no one can see their screen anymore, business production is halted, and the person in charge of your company’s UPS system knows they have a problem on their hands.

FEATURE

In general, the hope is that the UPS or battery system goes unnoticed by most. It will spend most of its lifetime operating in standby, waiting for its chance to shine. It is that small fraction of time, however, when it is called upon to operate a circuit breaker, or pick up the load of a building when the utility power goes out, that a battery system can be the most important piece of equipment on the property. The battery system needs to be correctly sized and maintained throughout its life cycle. If it was not correctly sized or maintained, when it is called upon to operate, everyone will notice.

Assuming that the battery was properly sized for its intended load, maintaining the battery becomes key to ensuring the battery will perform as designed. A typical battery bank is shown in Figure 1. Something as simple as a monthly or bimonthly visual inspection of the battery and its charger can provide a great amount of information. As these inspections are performed, it is vital to take note of the electrolyte levels; of any corrosion on the terminals, connectors, racks, or cabinets; and if there is any visible evidence of damage, such as cracks or leaks in the cells 2 as shown in Figure 2.

The battery temperature should be recorded along with the float and equalize charges. Care should be taken to ensure that the battery is not in an area of sunlight or near a heater.

AN OVERVIEW OF BATTERY ASSET MANAGEMENT ISSUES NETAWORLD 21 FEATURE

Figure 1: Typical Battery Bank

Figure 2: Battery Cell with Cracks

Since power is such a critical aspect of our lives and society today, most anything that helps keep the lights on is fair game for online monitoring, even battery systems.

The battery temperature should be recorded along with the float and equalize charges. Care should be taken to ensure that the battery is not in an area of sunlight or near a heater. As shown below in Figure 3, temperature can have a significant impact on battery life, especially as the ambient temperature rises. All of these items observed during the visual checks should stay relatively consistent over time, and they can provide a good indication if any cells of the battery have degraded, or cannot be relied on.1 , 2

These simple checks can be so critical to a battery system that the North American Electric Reliability Council (NERC) has mandated they be done regularly for bulk supply points on the transmission system. NERC has provided definitions for monitored, unmonitored, and continuously monitored battery systems and has mandated that test procedures correspond to the type of battery system that is installed. NERC also mandates that utilities have documented maintenance programs with established maintenance intervals for these key bulk supply points, and penalties can be levied when the maintenance programs are not followed. 3

22 FALL 2012 AN OVERVIEW OF BATTERY ASSET MANAGEMENT ISSUES FEATURE

Figure 3: Temperature Effects on Battery Life and Capacity

Batteries are relatively low cost items when compared with other assets in a substation. Depending on the battery size and transformer size in the same substation, the battery may cost 0.1 percent of what the transformer costs, but its job is just as crucial as it provides power to the equipment that protects the transformer from system faults. Battery systems may have life expectancies of approximately 20 years. This may be only half of what the transformer life expectancy is, but the cost comparison will still not rise above 0.2 percent of the cost of the transformer it is there to help protect.

Monitoring has long been an accepted practice for extending the useful life of an apparatus. On-line monitoring has gained traction in recent years with the development of new technologies combined with the decline in price of communication equipment. Since power is such a critical aspect of our lives and society today, most anything that helps keep the lights on is fair game for on-line monitoring, even battery systems, as shown in Figure 3.

Monitoring systems and their accompanying software are now available to perform real time analysis on events such as discharges, system voltage issues, and thermal runaway and to alert when the analysis discovers trends that indicate a failing or problematic unit. The benefit of this type of monitoring is that problems can be detected in real time and, hopefully, corrected before the battery system fails and cannot perform its duty when called to do so. Batteries have certain failure modes that cause the battery to rapidly deteriorate, and it is possible that the visual monthly checks may not be frequent enough to predict that a battery is failing before it actually fails.

It becomes fairly obvious that monthly visual inspections of all batteries on a system can generate a mountain of information. Over time, as multiple inspections on a battery system are performed, the trend becomes just as important as the actual data itself. Ideally, the battery owner will have a system in place that will accept the monthly inspection data, trend the results over time, and

run analytics on the data to alert when a battery is trending towards a set of predetermined limits. This becomes particularly important when one person or a small group is charged with managing a fleet of battery systems over a large geographical area. It can become very difficult to keep track of which batteries need the most attention, which are nearing the end of their useful life, and which should be on the short list of replacement candidates in the next year, five years, and ten years. 4

A software system, such as dobleARMS™ (Figure 4) that combines on-line, off-line, and real time data from various substation apparatus, and per-

AN OVERVIEW OF BATTERY ASSET MANAGEMENT ISSUES NETAWORLD 23 FEATURE

Figure 5: Software Combining On-line, Off-line, and Real Time Data for Analysis of Asset Condition

Figure 4: Battery Bank with On-Line Monitoring System Installed

form powerful analytics can generate alerts and rankings of assets based on this data. It can be programmed to alert the user when any asset is in danger. Managing NERC compliance data for batteries becomes an issue which is manageable with the use of data management software as part of an overall risk system.

In the end, as with just about everything else, battery systems relate back to money. Battery systems are there to provide a backup source of power for when things go wrong. Utilities track customer outages and customer outage minutes, and must report these as key performance indicators (KPI) to their regulators. One major utility estimates that their average customer interruptions due to battery issues are 6,000, and customer minute interruptions are estimated at 70,000. Assuming two interruptions per year, this would put their System Average Interruption Frequency Index, SAIFI, number at 0.0038, and their System Average Interruption Duration Index, SAIDI, number at 0.044. If they were to do away with their battery maintenance and monitoring program, they estimate their SAIFI number would increase to 0.008, and their SAIDI number would increase to 0.09. There is little doubt that their regulators would notice an increase of greater than 100 percent in customer interruptions. With this increase would come significant financial penalties, all due to not maintaining the battery systems. 5

It has been stated that energy storage could be the most influential, game-changing development the electrical world will see in the coming century. 6 Many businesses and government agencies today have realized this and also realized how costly an unexpected power interruption would be to their respective organizations. Just looking at today’s electronic devices, it is easy to see how much we already depend on batteries, and our dependence on batteries will only grow in the future.

Dr. Tony McGrail is the SFRA Product Manager at Doble Engineering. Over the last three years he has developed new SFRA applications and instruments and provided research into analysis techniques for SFRA traces. Prior to joining Doble, McGrail was a transformer engineer with the National Grid Company in the UK. This encompassed both fieldwork in transformer testing and assessment and the development of leading-edge analytical techniques for transformer health studies. He received his bachelor’s degree in physics, a subsequent master’s degree in instrument design and application, and his PhD in electrical engineering.

Kenneth Elkinson is the SFRA Product Manager at Doble Engineering. Over the last three years he has developed new SFRA applications and instruments and provided research into analysis techniques for SFRA traces. Prior to joining Doble, McGrail was a transformer engineer with the National Grid Company in the UK. This encompassed both fieldwork in transformer testing and assessment and the development of leading-edge analytical techniques for transformer health studies. He received his bachelor’s degree in physics, a subsequent master’s degree in instrument design and application, and his PhD in electrical engineering.

Matthew B. Lawrence is the Solutions Manager, SFRA and Circuit Breaker Diagnostics at Doble Engineering Company, focusing on diagnostic testing solutions. Before joining Doble in 2011, Mr. Lawrence held positions in substation maintenance and operations and equipment maintenance engineering departments at National Grid and its New England-based legacy companies. Mr. Lawrence is a member and past chair of the Doble Engineering SFRA Users Group and has coauthored numerous papers on field transformer testing and condition assessment. Mr. Lawrence holds an Associates of Science Degree in Electronics Engineering from New England Institute of Technology and attended Worcester Polytechnic Institute’s School of Industrial Management. He is also an active member in IEEE/PES.

1 As detailed at the Circuit Breaker Battery Tutorial, 80th Annual International Conference of Doble Clients, Boston MA, USA 2011

2 Hydroelectric Research and Technical Services Group, “Storage Battery Maintenance and Principles”, June 1998

3 North American Electric Reliability Council, Protection System Maintenance, Draft Supplementary Reference, November 17, 2010, Prepared by the Protection System Maintenance and Testing Standard Drafting Team, PRC-005-2, Project 2007-17

4 A. McGrail “Data and Decisions”, IEEE Smart Grid Conference, Perth 2011

5 J. Afonso, V. Forte., J. Grimsley, T., McGrail, “Asset Management: From Assets to KPI’s”, 4th EPRI International Conference on Asset Management, Chicago, USA, 2008

6 As detailed at Roundtable Discussion, CIGRE Game Changer’s Symposium, Atlanta, GA November 2011

AN OVERVIEW OF BATTERY ASSET MANAGEMENT ISSUES

24 FALL 2012 FEATURE

CHOOSE BETWEEN KEEPING MAINTENANCE COSTS DOWN AND KEEPING UP WITH PRODUCTION DEMAND…OR DO BOTH.

THAT’S THE CRITICAL DIFFERENCE.

NETA certified experts at Electrical Reliability Services will keep you in perfect balance. To ensure the reliability of your electrical power, you have to balance the need to reduce maintenance costs with the need to perform regular maintenance. Only the team from Electrical Reliability Services delivers cost-effective services and system expertise to keep you up and running 24/7.

Emerson, Business-Critical Continuity, Emerson Network Power and the Emerson and Double Helix Design are trademarks and service marks of Emerson Electric Co. ElectricalReliability.com

“At Arc Flash Study Pro we’ll help you achieve compliance fast and efficiently.

You’ll work with one highly trained specialist from start to finish, from surveying through analysis, engineering, reporting and training. You have my commitment!”

Curtis Latzo, President and Owner, Arc Flash Study Pro

Electrical Power System Services:

Benefits of hiring Arc Flash Study Pro:

Our STUDIES will provide you with FULL COMPLIANCE of NFPA 70E and OSHA 1910 Arc Flash Regulations

“Hire the Pro, Deal with the Pro, Work with the Pro from beginning to end.”

397-2383

Electrical Power Studies

(727)

www.arcflashstudypro.com

Thyritronics has been providing quality and timely trip unit repair to the electrical industry for over 30 years. We wish to thank all our fine customers for their loyalty and many referrals.

With substations regularly overloaded and equipment often near the end of its life, electric grid operators are challenged to improve overall system reliability. Our mission is to provide our clients with that can be used to better manage the overall life cycle of their critical electrical assets in a manner that is convenient, easy to understand, and assists in critical decision-making.

WEIDMANN DIAGNOSTIC SOLUTIONS INC. provides the vital knowledge you need to help you lower risk and improve your electrical system’s reliability. We provide through our extensive range of diagnostic products and services. WEIDMANN DIAGNOSTIC SOLUTIONS INC. is a leader in developing condition assessment methods for transformers and all oil- lled electrical equipment, such as OCB’s, LTC’s, regulators, recti ers, and network units.

30 Years of Repair & Testing Excellence Now repairing: Siemens SB Type TL Square D MICROLOGIC Series B trip units Merlin Gerin ST & STR Units Call for all RMS-9 rating Plug needs Eddie Tate – Owner Damian Hobson – Lead Technician Phone: 601-856-9798 Fax:

AllMajorManufacturers CalibrationusingMulti-Amp’s EpochSystem ExtensiveTestReport Non-RMSUnits—$300 RMSUnits—$500 TestOnlyServices—$100 OneDayRushCapabilities Thyritronics,Inc. IndustryLeaderinTripUnitRepairs SEE OUR WEBSITE for all our services: www.thyritronics.com DIAGNOSTIC SOLUTIONS INC. One Gordon Mills Way, PO Box 799, St. Johnsbury, VT 05819-0799, USA T +800 811 2284, +916 455 2284, F +916 455 0191, www.weidmann-electrical.com A Member of the Group

®

DETERMINING CRITICALITY IN AN ELECTRICAL MAINTENANCE PROGRAM

BY KERRY HEID, Magna Electric Corporation

INTRODUCTION

Worker safety is highly dependent on electrical systems operating exactly as they were designed to operate. Much concentration is put on ensuring that equipment meets stringent codes and standards. One reason for this is to ensure that electrical systems limit worker exposure to arc-flash and shock hazards.

If this is so extremely important to worker safety at the time of design and installation, why is maintenance of the equipment to provide integrity of those standards not always given the same scrutiny? It has become more evident with the new safety

standards that equipment must operate in like new condition or serious threats to workers safety may result.

Realizing this, it is very important for facility managers to put an increased reliability requirement on certain systems that directly impact worker protection from arc flash and shock. This requirement for reliability is quite different than that for uptime or production purposes. Equipment required for electrical hazard mitigation applications can fail undetected, and the loss of protective capabilities may not be known until an injury occurs. Any maintenance program should be designed to address maintenance of equipment critical for electrical safety.

CORNER

MAINTENANCE

High Priority - Circuit Breaker Maintenance

Determining personal protective equipment requirements for flash hazards is based primarily on the overcurrent protective systems functioning exactly as designed. Therefore a robust maintenance management system must be established to assure no deviation from the expected operation of those systems. If the protection systems do not operate as designed, thermal and blast energy may be orders of magnitude higher than expected.

TOP FIVE SAFETY-RELATED CRITICAL MAINTENANCE ITEMS

The following top five items represent the opinion of the author based on recent reliability data, service experience, probability of failure, and consequence to worker safety.

1. CIRCUIT BREAKERS

These devices have been ranked #1, often being culprits in affecting both the incident energy as well as the shock hazard. A recent NETA survey showed that, when performing maintenance testing, over 22 percent of these devices do not operate as designed and 10 percent do not operate at all. The problem with these devices is that they will fail to operate correctly over time and without notice. When they are required to operate during a fault or even during regular switching, they do not.

2. PROTECTIVE RELAY SYSTEMS

These systems are ranked high because they are the systems that respond quickly during a fault scenario. While many times the maintenance issues are with the performance of the hardware, a lot of times the problems are with the settings. Sometimes the settings were not developed correctly from the first installation, particularly in more complex microprocessor-based relays. Often the settings have been adjusted or defeated in the field. In any of these cases, the arc-flash hazard can drastically increase from what is expected leaving workers in highly hazardous situations they do not anticipate.

3. TRIPPING POWER

Catastrophic damage has been witnessed when the power utilized to operate the protective scheme does not function. The problems range from an entire dc system loss to individual switchgear cell or device issues. The extreme hazard exists as the entire protective system is defeated. Incident energy will be greater than expected and there may be substantial loss of equipment due to fire.

4. GROUND FAULT PROTECTION SYSTEMS

Ground fault protection systems including neutral grounding devices, sensors, control wiring, and isolation devices are designed for protective functions to provide worker safety. Failure of these systems can substantially increase arc-flash and shock hazards when not maintained properly.

5. GROUNDING AND BONDING SYSTEMS

These systems are ranked number 5 but are still very important, primarily in preventing the electrical shock hazard. In many cases a simple visual inspection can determine that the connections are deteriorating or missing (copper grounding is a common theft item). There are cases when the step and touch potentials and associated ground potential rise will become a shock hazard. This happens as the ground systems deteriorate in conjunction with an increase in utility fault current.

The gotcha in all cases is that these systems fail, undetected, along with their capability to provide a safe working environment. This is much different than a mechanical failure where normally the issues are easily seen or detected through visual inspection or vibration sensors.

NOTE: Devices such as transformers, cables, capacitors and motors do not have the same impact on worker safety as the five items listed above. However, these devices will have increased hazards when one of the safety-related critical maintenance items does not operate.

MAINTENANCE CORNER NETAWORLD 29 DETERMINING CRITICALITY IN AN ELECTRICAL MAINTENANCE PROGRAM

Safety-Related Critical Maintenance

Utilizing a professionalNET ofessional NETAA A Accredited edited Company with the latest NETAM A Maintenance Testing Specifications helps to ensurethe e the power system equipment will function as designed to protect workers.

CONCLUSION

Electrical maintenance, critical to worker safety, should be performed regardless of reliability and productivity strategies. The arc-flash and shock protection of workers depends on it. Items such as circuit breakers, protective relay systems, and ground fault systems, should be inspected and tested on intervals determined by experience and prior test and inspection data if they are to operate exactly as originally designed. The failure of these items is often undetected until a serious event occurs putting workers in dangerous situations they do not anticipate. Utilizing a professional NETAAccredited Company with the latest NETA Maintenance Testing Specifications helps to ensure the power system equipment will function as designed to protect workers.

Kerry Heid is the President of Magna Electric Corporation, a Canadian-based electrical projects group providing NETA Certified Test Technicians and related products and solutions for electrical power distribution systems. Kerry is a past President of NETA (InterNational Electrical Testing Association) and has been serving on its board of directors since 2002. Kerry is chair of NETA’s training committee and is a Senior Certified Test Technician Level IV. Kerry was awarded NETA’s 2010 Outstanding Achievement Award for his contributions to the association.

Kerry is the chair of CSA Z463 Technical Committee on Maintenance of Electrical Systems. He is also a member of the executive on the CSA Z462 technical committee for Workplace Electrical Safety in Canada and is chair of Working Group 6 on safety-related maintenance requirements as well as a member of the NFPA 70E – CSA Z462 harmonization working group.

Kerry has performed electrical engineering, testing, maintenance, commissioning, and training activities throughout North America for the past 23 years with Westinghouse Service and Magna Electric Corporation. He resides in Regina, Saskatchewan, with wife Pam and sons Brendan and Colby.

MAINTENANCECORNER

30 FALL 2012 DETERMINING CRITICALITY IN AN ELECTRICAL MAINTENANCE PROGRAM

Electrical Insulation Safety MI 3121 SMARTEC Insulation / Continuity High Voltage Insulation Diagnostics MI 3200 TeraOhm 10kV MI 2592 PowerQ4 Single and Three Phase Power Quality Analysis MI3121SMARTEC MI 2 Pow www.avoxtechnolgies.com sales@avoxtechnologies.com Avox has Moved to Better Serve You! 118 S. 2nd Street, Perkasie, PA 18944 Tel: 267 Toll Free 800-272-2818

REAL WORLD LEARNING A T

YOUR FINGER TIPS

In 2012 NETA celebrates 40 years of service to the electrical systems industry – Establishing industry standards and delivering leading-edge technical information and educational resources based on real-world experience.

NETA was founded with the goal of advancing the industry’s focus on safety and reliability. The Association’s contribution is fullfilled through the development of the ANSI/NETA Standards and the creation of educational and training resources that include the NETA Self-Paced Technical Seminars, the annual PowerTest conferences, the quarterly NETA World Journal, as well as a 14 volume series of NETA Handbooks.

The NETA Handbooks were first released as a series in 2009. They are a go-to source for highly relevant information about testing procedures, troubleshooting, and real-life solutions to situations encountered everyday in the field. The Handbooks were initially created in response to requests from the electrical industry, the general public, NETA

Accredited Companies, and NETA’s technical community seeking a comprehensive, subjectspecific technical resource to use for training and reference materials.

A SALUTE TO NETA’S MANY AUTHORS

All NETA technical materials, publications, and events are authored by industry experts – leadingedge, highly knowledgeable individuals who have many years of experience in the field. NETA is extremely grateful for their contributions.

The NETA Handbooks bring together a collection of over 200 of the very best articles from past issues of NETA World Journal and the most well- received technical presentations from past PowerTest events.

A

For more detailed information on the NETA Handbooks or other NETA publications, visit the NETA Bookstore at www.netaworld.org or call the NETA Office at (888) 300-NETA (6382) Volume 1 Transformer Handbook Published by InterNational Electrical Testing Association Published by InterNational Electrical Testing Association RlingHandbook Volume 1 Protective Relaying Handbook Published by InterNational Electrical Testing Association Volume 1 Pb Online Diagnostics Handbook Volume 1 Volume 1 Online Diagnostics Handbook Published by InterNational Electrical Testing Association Published by InterNational Electrical Testing Association Hdbook IR Scanning Handbook Published by InterNational Electrical Testing Association PublishedbI Insulating Oils Handbook Insulating HandbookOils Published by InterNational Electrical Testing Association Published by InterNational Electrical Testing Association kMaintenanceHandbook Volume 1 Volume 1 Circuit Breaker Maintenance Handbook Published by InterNational Electrical Testing Association Portage, Michigan PublishedbI Arc-Flash Safety Handbook Volume 1 Volume 1 Arc-Flash HandbookSafety Published by InterNational Electrical Testing Association OR CHOOSE FROM SEVEN TECHNICAL SUBJECTS. Published by InterNational Electrical T ting BUY THE 14 VOLUME SET FOR ONLY $140*! NETA TECHNICAL HANDBOOKS! *Plus shipping

HVI is the source for VLF Withstand and VLF Diagnostic Cable Testing and cable fault locating, including for 35 kV wind farm cables. Models can test >20 mile lengths and >138 kV cable.

Let us design you a complete cable test & fault locating package. HVI also produces many of the top instruments for testing substation apparatus and other HV applications.

Test miles of cable with VLF AC

Very Low Frequency (VLF) AC Hipots | Tan Delta & Partial Discharge Testing

Find cable faults fast

Cable Fault Locators w/TDR-Radar & Pinpointing Devices

VLF/Thumper Combination unit

Two-in-one, ideal for testing contractors

Reliable, rugged, & portable 0-62kVac@5.5uF 0-62 kVac @ 5.5 uF ≤400mABurn ≤ 400mA Burn VLF-6022CM Thumper

100

BATTERIES AND BATTERY CHARGERS

BY JIM WHITE, Shermco Industries

James R. (Jim) White is the Training Director of Shermco Industries, Inc., in Dallas, Texas. He is the principal member on the NFPA technical committee

“Recommended Practice for Electrical Equipment Maintenance” (NFPA 70B). Jim represents NETA as an alternate member of the NFPA Technical Committee

“Electrical Safety in the Workplace” (NFPA 70E) and represents NETA on the ASTM F18 Committee “Electrical Protective Equipment For Workers”. Jim is an IEEE Senior Member and in 2011 received the IEEE/ PCIC Electrical Safety Excellence award. Jim is a past Chairman (2008) of the IEEE Electrical Safety Workshop (ESW).

Batteries and the supporting charging equipment can easily be overlooked until they are needed. Most facilities use a battery bank to supply dc operating current for opening and closing circuit breakers, spring-charging motors, and indicators. Without the dc supply, circuit breakers will not operate.

1. An indication that a vented lead-acid battery is in trouble is when its internal impedance increases ___% above its as-installed impedance.

a. 5%

b. 20%

c. 30%

d. 45%

2. Which of the following is not an example of a VRLA (valve-regulated lead-acid) battery?

a. nickel-metal hydride

b. gel cells

c. absorbed glass mat

d. maintenance free

3. Sulfation in flooded-cell, lead-acid batteries is indicated by:

a. streaks of oil on the surface of the electrolyte.

b. brownish nodules adhering to the case.

c. white salts appearing on the surface of the plates.

d. white milky substance that appears on the cells and jar.

4. When performing a load test on a battery bank, what percent remaining capacity indicates the need to replace the batteries?

a. 20%

b. 40%

c. 60%

d. 80%

5. The only repair for sulfation is to:

a. equalize and increase float voltage.

b. use a mixture of boric acid and potassium hydroxide.

c. replace the batteries with new ones.

d. retighten all intercell connections.

34 FALL 2012 TECHQUIZ TECH QUIZ See

107.

answers on page

No.

STANDARD fOR CERTIFICATION OF ELECTRICAL TESTING TECHNICIANS

STANDARD FOR ACCEPTANCE

TESTING SPECIFICATIONS for Eledrical Power

CIRCUIT BREAKERS – LOW/MEDIUM VOLTAGE majormanufacturers

TRANSFORMERS – 1000–5000 KVA resintransformersfrom breakswitch&fuse

LIFE EXTENSION state motor

MOLDED CASE CIRCUIT BREAKERS LOW VOLTAGE MOTOR CONTROL breakers buckets mountswitches

SWITCHGEAR – 480V-38KV NEW AND SURPLUS in4weeks fromstock unitsubstations

RENEWAL PARTS –SWITCHGEAR & CIRCUIT BREAKER PARTS & vacuum instock www.circuitbreakerpartsonline.com

MEDIUM VOLTAGE MOTOR CONTROL AIR & VACUUM MOTOR CONTROL fromstock starters contactors

SERVICE & REPAIR service of circuitbreakers ISO 9001 and 14001 Certified circuitbreakerremote switch circuitbreaker

PROVIDING ELECTRICAL SOLUTIONS WORLDWIDE Breaker isachartermemberofthe 24 Hour Emergency Service 800-232-5809 www.circuitbreaker.com | info@cbsales.com 1315 Columbine Dr., Gainesville, TX 76240

We’ve

Smaller

Easier

Rotary switch dial

Unique

Intuitive

Accuracy

Super

WWW.MEGGER.COM Get your FREE copy of Megger’s 2012 Electrical Test Instruments Catalog today! Email us at vfmarcom@megger.com Reference code NETA-FALL when ordering

what matters most in our 5

10 kV insulation testers:

improved

and

size and lighter weight

to use

dual case design

test

operation Ramp

3mA output power

where it matters most

fast

MIT515/525/1025 instruments are designed to meet your needs, not what we think you need.

battery charge Megger

ARC-FLASH CLOTHING AND PPE WHAT DOES NFPA 70E SAY?

BY JIM WHITE AND RON WIDUP, ShermcoIndustries Shermco Industries

NFPA 70E has a wide following in the electrical industry and with good reason. Not only is it generally considered the latest word on protecting electrical workers, but OSHA recommends it as a guide for meeting the federal regulations. It provides proven and workable safe work practices and has been used as the basis for development of other country’s electrical safety standards and regulations.

What does the latest [2012] edition of NFPA 70E have to say about arc-rated PPE?

We will take a look at several nuggets of information within the 70E to explain further.

Informational Note

No. 2: See Table 130.7(C)(15)(a) and Table 130.7(C)(15)(b) for examples of activities that could pose an arc-flash hazard.

Usually, guarded equipment does not pose a hazard from arc flash, but when interacting with electrical equipment in a manner that could cause failure the arc-flash hazard has to be considered, even though there are no exposed energized conductors or circuit parts. This is why Informational Note No. 2 provides guidance regarding activities that may fall in to this category.

We have dicussed it previously, but close attention should be paid to Article 100, Definitions. If you read and understand the definitions, it will help to understand the standard in a more comprehensive and complete manner.

INFORMATION FOUND IN

Informational Note

No. 1: An arc-flash hazard may exist when energized electrical conductors or circuit parts are exposed or when they are within equipment in a guarded or enclosed condition, provided a person is interacting with the equipment in such a manner that could cause an electric arc. Under normal operating conditions, enclosed energized equipment that has been properly installed and maintained is not likely to pose an arcflash hazard.

It is also important to note that equipment in normal operation, installed in accordance with the NEC and other applicable codes and standards, along with being maintained correctly in accordance with manufacturer’s recommenda-tions and industry consensus standards (such as the ANSI/NETA maintenance testing standard), does not pose an arc-flash hazard. This does not mean there is no possibility of an arc flash, just that the possibility is small. If for any reason the equipment is suspect (such as during troubleshooting) wearing additional arc-rated PPE is probably in order. Remember, it all goes back to the hazard assessment.

Arc-rated clothing or equipment indicates that it has been tested for exposure to an electric arc. Flame-resistant (FR) clothing without an arc rating has not been tested for exposure to an electric arc. d finind the derstand hensive and gized con Inf g uida fall I plic wi a

ARC-FLASH CLOTHING AND PPE WHAT DOES NFPA 70E SAY NETAWORLD 39

THENFPA70EANDNETA THE NFPA 70E AND NETA

THE NFPA 70E AND NETA

This is to differentiate an electrical worker’s protective clothing and PPE from that worn by other trades that require flame-resistant clothing such as steel mills, oil and gas, firefighters, etc. They may have FR clothing, but it may not be rated for exposure to electrical arcs.

INFORMATION FOUND

INVOLVING ELECTRICAL HAZARDS

Analysis. Where it has been determined that work will be performed within the

arc flash boundary, one of the following methods shall be used for the selection of protective clothing and other personal protective equipment (PPE):

130.7(C)(15) and 130.7(C)(16)]

The most widely-preferred method for choosing arc-rated clothing and PPE is to have an arc flash hazard analysis performed and have the equipment labeled. However, there are many facilities where that just is not going to happen, so the tables in Section 130.7 can be used instead. Be aware that neither method is foolproof and both have drawbacks, but the arcflash hazard analysis is the best we have right now for determining the correct levels of PPE. It will likely be improved once the findings of the IEEE/NFPA Joint Collaboration Arc-Flash Research Project are released.

Equipment

…….When an employee is working within the arc-flash boundary, he or she shall wear protective clothing and other personal protective equipment in accordance with 130.5. All parts of the body inside the arcflash boundary shall be protected.

Section 130.5 covers the arc-flash hazard analysis or the use of the tables. Note that all parts of the body are to be protected if they inside the arcflash boundary. Hands, ears, eyes, etc. All PPE and clothing specified in tables 130.7(C)(16) or Annex H.3(b) must be worn.

Rather than cover each item in this section, let’s skip down to Article Arm Protection. Maintenance and Use which states, “Electrical protective equipment shall be maintained in a safe, reliable condition. …….”

Arc-flash PPE and clothing must be stored, laundered, and used properly in order to provide adequate protection from an arc flash. This

ARC-FLASH CLOTHING AND PPE WHAT DOES NFPA 70E SAY

40 FALL 2012

Figure 1: It Was Too Big To Fit in a Trash Bag

is really where we want to go in this article. How do we care for and use arc-rated PPE and clothing so it remains reliable?

YOUR LIFE DEPENDS ON IT.

Your life does depend on it! Rolling arc-rated flash suits into a knot, cramming it into a bag or leaving it out to collect dust is not maintaining it (Figure 1). It should be inspected, folded and placed in a suitable container, either a locker or a garment bag. All hook and loop (Vel-

cro®) fasteners should be closed so they are not exposed to lint and dirt. If it gets oil or grease on it, other than just a few spots, launder it. It can be laundered at home, but it must be laundered separately. Just follow the manufacturer’s instructions.

RULE 2: LAYERING REDUCES THE POSSIBILITY OF BURNS.

If you thought that arc-rated PPE provides the level of protection for the incident energy

NETAWORLD 41 ARC-FLASH CLOTHING AND PPE WHAT DOES NFPA 70E SAY THENFPA70EANDNETA THE NFPA 70E AND NETA

Figure 2: Troubleshooting Electrical Equipment is Hazardous Work

THE NFPA 70E AND NETA

embroidered in or on the label, think about this: ASTM F1959 states that at the rated incident energy of arc-rated clothing or PPE for 1/10th of a second there is a 50 percent probability of a second-degree burn on bare skin underneath it. This applies to arc-rated face shields and arc-rated windows as well. If you suspect that the electrical equipment you are about to work on may have issues, for instance when troubleshooting, wear extra layers of PPE. Think of equipment that requires troubleshooting as being in distress; it is no longer operating

normally and you need to wear the maximum recommended arc-rated clothing and PPE when you troubleshoot it. Wearing cotton or arc-rated underlayers provides additional protection from burns.

RULE 3: INSPECT YOUR ARC-RATED CLOTHING AND PPE PRIOR TO USING IT.

Look for any rips, tears, or openings in either the outer layer or the inner layer. On multilayer flash suits all layers are important to meet the

42 FALL 2012 ARC-FLASH CLOTHING AND PPE WHAT DOES NFPA 70E SAY

Figure 3: Come On, Baby, You Can Do It!

identified arc rating. The inside is as important as the outside. Look for seams that are coming loose, especially in the armpits and the crotch. These are high-stress areas and must also be inspected inside the garment as well as on the outside. Inspect the sewing along zippers and Velcro® to ensure they are not curling or becoming detached. If they are, they won’t seal properly. Grease spots larger than about one inch or so in diameter will probably require laundering as grease, oil, and other lubricants increase heat transfer through the fabric. Check the label to make certain it meets ASTM F1505 and NFPA 70E. Also make certain the arc rating is sufficient for your exposure.

On arc-rated face shields and hoods, make certain the face shield is secure to the hard hat. Look for excessive scratching in the viewing area (not to the sides). Excessive means that it limits your vision so you cannot see clearly. Make certain the hard hat suspension is secured inside the hard hat and that the sweat band is not cracked or broken. Ensure any extensions on the arc-rated face shield are secured properly with all needed fasteners, and never use an arc-rated face shield without the chin cup. Some face shields are rated with the chin cup and some without. Not wearing the chin cup would allow the arc plasma to roll up your chest and under the face shield. Inspect the arc-rated windows on arcrated hoods to ensure there are no gaps around them. If the Velcro® is missing in the upper corners an arc flash may cause a burn to the top of your head. Inspect the hood for cuts, rips, tears, grease or oil spots, loose seams, etc., just like the flash suit itself.

LIMITATIONS OF YOUR EQUIPMENT AND PPE.

Exceeding the limitations of your protective clothing and equipment, or your tools and meters, for that matter, is a sure way to be injured or killed. We love the old movies where the pilot is trying to get his plane over the mountain peak and he’s saying, “Come on, girl! Come

on, baby! I know you can do it! Don’t let me down!” Invariably he makes it, but in real life the local authorities would be mounting an expedition to rescue survivors, Figure 3. Don’t think inanimate objects hear you or care about you. Know your own limitations as well. If you are sick, tired, or distracted by crushing issues, you probably should not be performing hazardous tasks.

RULE 5: TELL ME AGAIN

THIS ENERGIZED?

Turn it off!! That is the best way to eliminate the hazards.

SUMMARY

Understanding the application, and more importantly the limitations, of your PPE is vital if you are to go through the work day properly protected from the hazards of electricity. So please take the time to read and understand the definitions, the application, and the limitations of your PPE.

Hey that Rule No. 5 – you might want to move that one up to the top of the list.

Ron Widup and Jim White

Requirements for Employee Workplaces). Both gentlemen are employees of Shermco Industries in Dallas, Texas a NETA Accredited Company. Ron Widup is President of is a Principal member of the Technical Committee on

committee “Recommended Practice for Electrical Equipment

White is nationally recognized for technical skills and safety training in the electrical power systems industry. He is the Training Director for Shermco Industries, and has spent safety training for electrical power system technicians. Jim

Equipment for Workers”.

ARC-FLASH CLOTHING AND PPE WHAT DOES NFPA 70E SAY NETAWORLD 43

THENFPA70EANDNETA THE NFPA 70E AND NETA

AFFILI ATE PROGR A M

NETA and our NETA Accredited Companies invite YOU to become a part of NETA’s technical community and take advantage of the many benefits of becoming a NETA Gold or Standard Affiliate.

As a NETA Affiliate you can participate in NETA’s Technical Working Committee, qualify for substantial discounts, and access industry leading experts and technical resources. Call or go online to

Affiliate.

Join as a NETA

sign up for your NETA Affiliate Subscription today! Go to www.netaworld.org or give us a call at 888-300-NETA (6382).

Electrical Distribution System

24 Hour Emergency Ser vices (937) 439-9660

BATTERYM BATTERY M AINTENAN C E R EC OMMEN DATIONS FOR UPS SYSTEMS

BY LYNN HAMRICK, Shermco Industries

The battery is by far the most vulnerable and failure-prone is allocated to maximizing a battery’s reliability and life. To appropriately maintain a battery system, one must first understand the chemistry associated with the UPS’s battery system.

BATTERY CHEMISTRY

A flooded, lead-acid battery is typically used for larger UPS systems. For a lead-acid battery, lead oxide (PbO ) is the active material in the positive electrode and lead (Pb) is the active material in the negative electrode. The basic electrochemical reaction equation for a lead-acid battery is as follows:

Pb + 2H SO + PbO < > 2PbSO + 2H O + energy

The electrolyte in the battery is the sulfuric acid (H SO ) and the water (H O) associated with the chemical reaction. The direction of the reaction is dependent on whether the battery is charging or discharging. In a discharging battery, the lead oxide and lead react with the sulfuric acid to create lead sulfate (PbSO ), water, and energy. When the battery is being charged, the cycle is reversed with energy being added (charging) and the lead sulfate and water electrochemically reacting to form lead and lead dioxide.

Lead oxide, the active material in the positive electrode, is in the same family as rust (FeO2), which is considered a corrosive molecule. When charging a lead acid battery, the reaction is reforming the corrosive layer of the positive electrode which is necessary for optimal battery performance. To properly corrode the positive electrode, the battery voltage has to reach and then slightly exceed the gassing potential of the battery. When a battery is charging, the electrolytic breakdown of the water in the electrolyte produces oxygen on the positive plates and hydrogen on the negative plates. This is normal. However, if a high charging rate is continued after the battery has been brought to its gassing voltage, the gassing becomes excessive, and abnormally larger amounts of hydrogen and oxygen gases are produced. The best indication of excessive gassing is a very noticeable bubbling action of the electrolyte and high electrolyte temperature. Some gassing in the electrolyte is beneficial since it acts to stir the liquid. Without

FEATURE

46 FALL 2012 BATTERY MAINTENANCE RECOMMENDATIONS FOR UPS SYSTEMS

gassing, a process called electrolyte stratification can occur, where the heavier electrolyte sinks to the bottom of the cell. In the electrolyte, the sulfuric acid is heavier than water so the acid will sink and concentrate at the bottom of the battery. Therefore, an inadequate charging environment will result in ineffective corrosion of the positive plate and inadequate gassing which will lead to electrolyte stratification and reduced performance and shortened life of the battery.

In a new battery, the electrochemical reaction occurs efficiently. Unfortunately, as a battery ages a process called sulfation occurs. Sulfation is the process where the lead and sulfates bond and form crystals. In a crystalline form, more energy is required to break the bond; the longer the crystal lasts and grows, the more difficult this bond is to break. These growing crystals of lead sulfate are insoluble. The formation of these crystals can cause the plate material to warp which can cause the case to bulge, or to push adjacent plates together. Further, electrolyte stratification can result in the lower portion of the plates becoming inactive, which enhances the sulfation process. Undercharging a battery, even to a small degree, can lead to excessive sulfation. The same is true of batteries which have been left standing in an undercharged state for an extended period. High temperatures rapidly accelerate sulfation when batteries are left standing in a partially charged condition. The cells of a sulfated battery will have low specific gravity and open circuit voltage readings. On charge, voltage readings will be unusually high. The battery will not become fully charged after a normal charging cycle when sulfation has taken place over a prolonged period.

A new battery should be checked every few weeks to determine the watering requirement. This prevents the electrolyte from falling below the plates. Avoid exposed plates at all times, as this will cause damage leading to reduced capacity and lower performance. Additionally, with regard to gassing, hydrogen is a highly combustible gas and will explode on ignition when the concentration in air reaches a level between four percent and 74 percent. (Below 4% the concentration is too weak; above 74% there is not enough oxygen left in the air to support combustion.) Therefore, if excessive gassing exists, troubleshooting of the battery and charging equipment should be performed. An unusually high usage of water indicates that excessive gassing is occurring.

Battery charging is probably the second most important factor in maintaining a battery system. A properly functioning battery charging system, with a healthy battery condition, will result in a fully charged and reliable battery system that is available when called upon for service. The following checks are a quick way of determining a proper and fully charged battery.

BATTERY MAINTENANCE

To maximize battery life, appropriate battery maintenance must be based on the simple chemistry lesson presented above.

Watering is the single most important factor in maintaining a flooded lead-acid battery. The frequency of watering depends on usage, charge method, and operating temperature.

Watering

is the single most important factor in maintaining a flooded lead-acid battery. The frequency of watering depends on usage, charge method, and operating temperature.

BATTERY MAINTENANCE RECOMMENDATIONS FOR UPS SYSTEMS NETAWORLD 47

FEATURE

FEATURE

An excessive amount of charge results in high battery temperature and a reduced battery service life. To obtain maximum service life from a battery, it should be charged and operated within temperature ranges recommended by the manufacturer. Overheating can damage the battery and shorten its normal expected service life. The extent of the damage and service life loss depends on the magnitude of the temperature, how often the overheating occurs, and how long the batteries are subjected to high temperatures. A healthy battery charged on a properly functioning charger will have a 10 to 20° F rise in temperature when fully charged. This temperature rise is affected by several variable factors: temperature

thermographic surveys should be performed on battery systems on at least an annual basis. The preventive maintenance program for the battery systems should also include the following:

VISUAL INSPECTION OF BATTERY CELLS

Batteries should be visually inspected under normal float conditions.

Inspect the Electrolyte Level. Flooded cells have translucent or transparent jars, so the electrolyte level can easily be compared to a recommended level that is marked on the cells.

At a minimum, annual testing, verification, and inspection of a battery system should be performed. Additional quarterly or semiannual inspections should be performed if the age and condition of the battery warrant the activity and it is determined that the battery system is critical to the reliability of the associated power system. As with all electrical systems, infrared

At a minimum, annual testing, verification, and inspection of a battery system should be performed.

Inspect the Positive Plates. The positive plates are typically the first to wear out and are located toward the center of the jar. They should be dark brown or black. Sparkle is evidence of sulfation or undercharge. Look for cracks, breaks, and pieces hanging on the side. This is indicative that the cell should be replaced and that other cells may also have a similar problem.

Inspect the Negative Plates. The negative plates are thinner than the positive plates and sit toward the outside of the jar. These should have a clean lead color from top to bottom. Pink discoloration indicates copper contamination.

Look at the Sediment. Inspection of the sediment should provide a general idea of the battery condition as trended from the last inspection. Accumulation of gray material under the negative plates accompanied by sparse black sediment is indicative of an undercharging condition. Excess black sediment under the positive plates with little negative sediment is indicative of an overcharging condition or excess temperature. If excess sediment covers the bottom of the jar, the battery has been cycled heavily or operated at high temperature.

48 FALL 2012 BATTERY MAINTENANCE RECOMMENDATIONS FOR UPS SYSTEMS

A crusty trail or accumulation is evidence of electrolyte leakage. Signs of corrosion on the terminal connections, intercell connections, and racks are also indicative of electrolyte leakage.

flame arrestersable and that suitable eyewash equipment is present.

VERIFY BATTERY CHARGING PERFORMANCE

There is more to verifying battery charging performance than just recording the voltage levels.

Voltage. The cell voltage value should be in accordance with manufacturer’s published data. Low cell voltage is indicative of a problem with the cell.

under close observation for unusual heat rise and excessive venting. Some venting is normal and the hydrogen emitted is highly flammable.

Temperature. Specific gravity is useful in evaluating charger float voltage as well as cell internal health. For most UPSrelated battery systems, a specific gravity of 1.250 is typical for each cell. If the specific gravity drops by .015 to .020 from this value, it is usually indicative of inadequate charger float voltage or a problem with a cell holding a charge. Remember, specific gravity should always be adjusted for internal cell temperature differences from 25 degrees C at a rate of .001 for every 1.67 degrees C difference. Also, electrolyte levels should be taken into consideration when evaluating specific gravity. Cells with low electrolyte levels typically need water added and, therefore, will have a higher specific gravity.

Equalizing Voltage Levels. Charger float voltage is the typical voltage output for a normal charging process. This voltage should be in accordance with the manufacturer’s recommendations, but may need to be increased as the battery ages or degrades. An equalizing charge is nothing more than forced overcharge. Applying an equalizing charge periodically brings all cells to similar levels by increasing the voltage to ~10 percent higher than the recommended float voltage. This process removes sulfation that may have formed during low-charge conditions. One method of evaluating sulfation is to compare the specific gravity readings on the individual cells of a flooded lead-acid battery. Only apply equalization if the specific gravity difference between the cells is 0.030. During an equalizing charge, check the changes in the specific gravity reading every hour and discontinue the charge when the specific gravity no longer rises. This is the time when no further improvement is possible, and a continued charge would cause damage. The battery must be kept cool and

CLEANING BATTERY POSTS AND CONNECTIONS

Before cleaning, note the condition of posts and connectors. Except for a light coating of grease, these should look new. Consider the following colors:

This is lead peroxide, indicating an acid leak around the positive post.

This is corroded copper, indicating connectors need cleaning and close inspection — they may no longer be serviceable.

White- This is lead hydrate, indicating a leak around the negative post.

The jars’ surfaces can be cleaned any time, but cleaning connectors and posts requires opening the battery circuit. If the cleaning requires that the battery be taken out of service without a parallel system, the UPS will not respond to a power loss. Therefore, cleaning should be coordinated with the operator. This following cleaning procedure should be performed when required.

NETAWORLD 49 BATTERY MAINTENANCE RECOMMENDATIONS FOR UPS SYSTEMS FEATURE

connectors, and then neutralize them with a suitable solution like baking soda and water.

until clean lead is exposed. Do not clean too vigorously or with a wire brush because it may remove too much lead.

Neutralize with suitable solution. Replace corroded hardware. Replace lockwashers, regardless of condition. Use only leadplated or 316-stainless steel bolts, washers, and nuts.

connectors with a light layer of antioxidant grease approved for battery use.

away from the connector. If possible, install lockwashers on the nut side, not the bolt side.

specifications. Turn the nut, not the bolt, if possible.

microhmmeter. If resistance is high, check the torque; overtorquing degrades the connection. If the torque is correct but the value is high, disassemble and inspect contact surfaces for proper polishing.

PERIODIC ELECTRICAL TESTING

In addition to the periodic visual inspections and battery system checks discussed above, specific electrical tests should be performed. IEEE Standard 450 details the recommended testing and maintenance for large stationary, wet batteries. As stated in IEEE Standard 450, the practices recommended in these standards “serve as a valuable aid in maximizing battery life, preventing avoidable failures, and reducing premature replacement.” The addition of an occasional load test of the battery system should be considered as the battery system ages or other problems are identified.

The battery is by far the most vulnerable and failure-prone part of a UPS system. battery’s reliability and life.

In support of this recommendation for load testing, some other more sophisticated testing methods can and should be performed more regularly to accurately determine battery health. These methods measure the internal ohmic values of the battery or associated cells.

Ohmic measurement using dc voltage is one of the oldest and most reliable test methods for battery systems. An instrument applies a load to a cell or a small string of cells lasting a few seconds. The load current typically ranges from 25-70 amperes, depending on battery size. The drop in voltage divided by the input current provides an accurate and repeatable resistance value. Alber’s CRT-300 Cellcorder is an example of this type of instrument. A cell’s internal resistance provides useful information in detecting problems and can be used for

50 FALL 2012 BATTERY MAINTENANCE RECOMMENDATIONS FOR UPS SYSTEMS FEATURE

AlberCellcorder Alber Cellcorder

indicating when a battery or battery cell should be replaced. However, resistance alone does not provide a linear correlation to the battery's capacity. The increase of cell resistance only relates to aging and provides some failure indications. Rather than relying on an absolute resistance reading, service technicians take a snapshot of the cell resistances when the battery is installed and then measure the subtle changes as the cells age. An increase in resistance of 25 percent over an initial baseline (100%) or related cells indicates a performance drop to about 80 percent.

Ohmic measurement using ac voltage is also a generally accepted test method for battery systems. An instrument applies an ac signal into a cell or small string of cells at a known frequency between 80-100 hertz. From this signal the conductance is derived in terms of mhos, or Siemens. A major benefit to using conductance is the ability to calculate a battery's capacity without performing an extensive discharge or load test. Midtronic’s Celltron CTM-300 is an example of this type of instrument. A battery's measured conductance correlates linearly with its ability to deliver current. As conductance declines, so does a battery's ability to meet its specified capacity and supply energy. A decrease in conductance of 25 percent over an initial baseline (100%) or related cells indicates a performance drop to about 80 percent.

In summary, the battery is by far the most vulnerable and failure-prone part of a UPS system. Because of this, much time and effort is allocated to maximizing a battery’s