The SMRT36 is the smallest, lightest, highest output powered, complete 3-phase protective relay test system in the world today. This rugged test system may be customized by adding the voltage current generator modules needed for specific test applications. Manual operation is simple through the use of the Smart Touch View Interface (STVI), with a large color high resolution TFT LCD touch-screen.

n Rugged, small and lightweight

n High current, high power (60 Amps/300 VArms) per phase

n Up to 6 currents with convertible channels

n Thermally controlled fans for quiet operation

n New Smart Touch View Interface (STVI) provides manual control

n New STVI Overcurrent Test includes hundreds of relay specific time-curves built-in

With these comprehensive capabilities and extensive testing options the SMRT36 is conceivably the easiest to use 3-phase protective relay test system available today.

For more information on the SMRT36 relay test set contact us today at 1-800-723-2861 or email us at sales@megger.com to receive a SMRT36 brochure and 2011 Megger Power Catalog.

Megger 4271 Bronze Way Dallas, Texas 75237-1019 USA.

a realistic goal.

Techniques for reducing exposure of your personnel to high arc-energy levels fall into three categories:

• Reducing the available arc-energy by designing/redesigning your power system

• Reducing personnel exposure by designing/ redesigning your power system

• Reducing personnel exposure by modifying – and enforcing – working procedures

PRESIDENT’S DESK

PE Sigma Six Solutions President

EVOLUTION OF NETA and Kristen Wicks, NETA

ARC-FLASH

PROTECTION SYSTEM Clapper, GE Specification Engineer

COMTRADE RECORDS

TEST PROTECTIVE RELAYS Turner, Beckwith Electric Co., Inc.

ARC-FLASH HAZARD MITIGATION THROUGH RELAYING Electric Co.

MITIGATION

THREE-STEP APPROACH Cochran, I-Gard

Jim

Electrical Testing for Airports

Lynn Hamrick, Shermco Industries

CORNER

Condition Assessment

Don A. Genutis, No-Outage Electrical Testing, Inc. 22 TECH QUIZ

Arc-Flash Mitigation

Jim White, Shermco Industries

90 SAFETY CORNER

Hazards of Establishing an Electrically Safe Work Condition

Tony Demaria & Dean Naylor, Tony Demaria

Electric, Inc., Mose Ramieh, III, Power & Generation Testing, Inc.

TECHNICAL BRIEF

Arc-Resistant Switchgear Tested to ANSI C37.20.7 and NFPA 70E

Jim Bowen 100 TECH TIPS

Specialized Testing for Line Towers

Jeff Jowett, Megger

SPECIFICATONS & STANDARDS ACTIVITY

ASTM F18 Committee Report

Jim White, Shermco Industries

Insulated Conductor Committee News

Ralph Patterson, Power Products & Solutions ANSI/NETA Standards Update

Jim White and Ron Widup, Shermco Industries

NOMOGRAM FOR INTERPRETATION OF LTC DGA DATA

Fredi Jakob & Karl Jakob, WEIDMANN Diagnostic Solutions, Inc, James Dukarm, Delta-X Research, Inc.

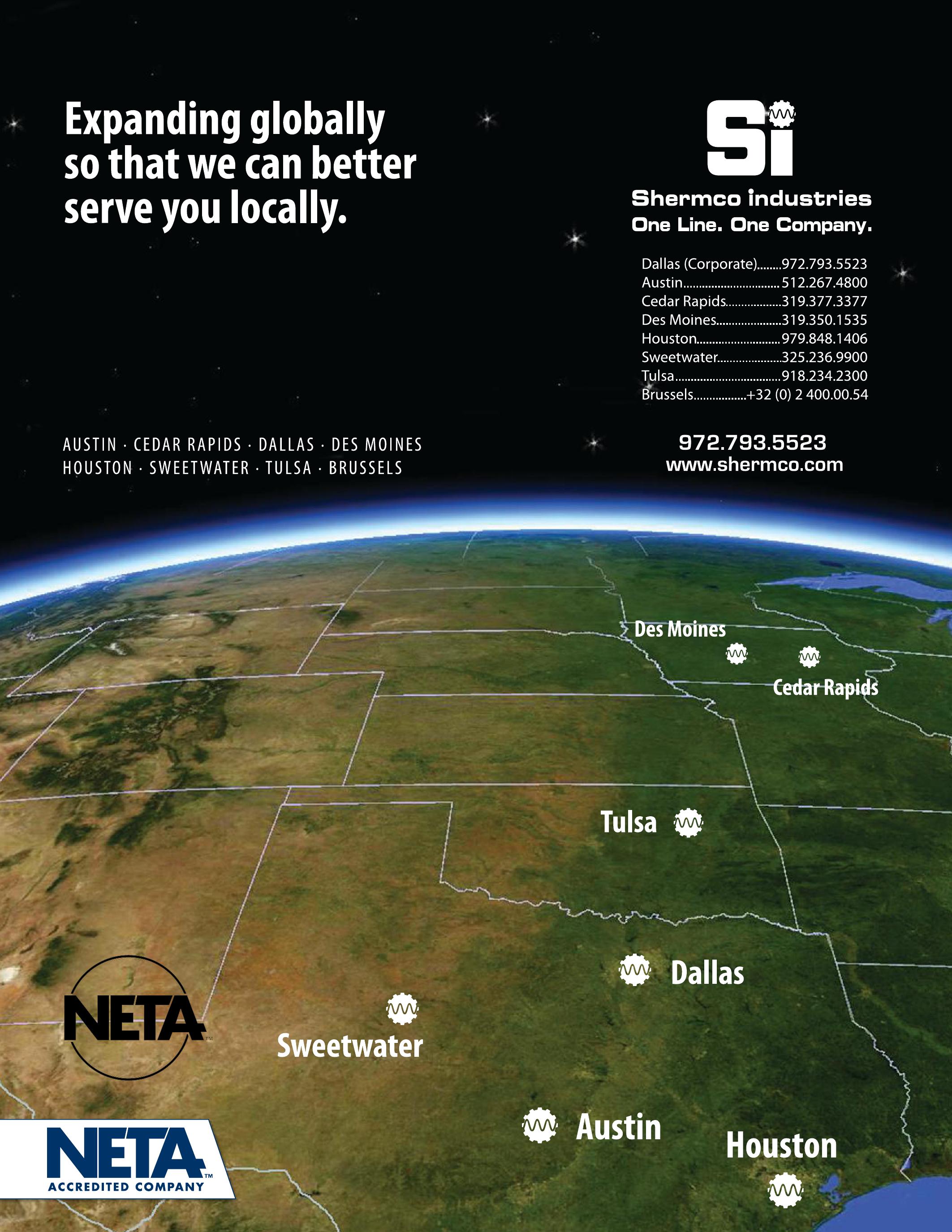

From big city to small town, east to west, North America to Europe, we are expanding our resources and service center locations to better serve you.

Contact Shermco Industries for safe, reliable testing, repair, professional training, maintenance and analysis of rotating apparatus or electrical power distribution systems for all market segments, including industrial, commercial, petrochemical, utilities and more.

3050 Old Centre Avenue, Suite 102

Portage, MI 49024

Toll free: 888.300 NETA (6382)

Phone: 269.488.NETA (6382)

Fax: 269.488.6383 neta@netaworld.org www.netaworld.org

executive DiRectOR: Jayne Tanz, CMP

NETA Officers

pResiDent: John White, Sigma Six Solutions

fiRst vice pResiDent: Mose Ramieh, Power & Generation Testing, Inc.

secOnD vice pResiDent: David Huffman, Power Systems Testing

secRetaRy: Walt Cleary, Burlington Electrical Testing Co., Inc.

tReasuReR: Ken Bassett, Potomac Testing, Inc.

NETA Board of Directors

Ken Bassett (Potomac Testing, Inc.)

Scott Blizard (American Electrical Testing Co., Inc.)

Walt Cleary (Burlington Electrical Testing Co., Inc.)

Roderic Hageman (PRIT Service, Inc.)

Kerry Heid (Magna Electric Corporation)

David Huffman (Power Systems Testing)

Ralph Patterson (Power Products & Solutions, Inc.)

Alan Peterson (Utility Service Corporation)

Mose Ramieh (Power & Generation Testing, Inc.)

John White (Sigma Six Solutions)

Ron Widup (Shermco Industries)

NETA World Staff

technicaL eDitOR: Roderic L. Hageman

assOciate eDitOR: Diane W. Hageman

managing eDitOR: Jayne Tanz, CMP

aDveRtising manageR: Jill Howell

Design anD pRODuctiOn: Newhall Klein, Inc.

NETA Committee Chairs

cOnfeRence: Ron Widup; membeRship: Ken Bassett; pROmOtiOns/maRketing: Kerry Heid; safety: Tony Demaria; technicaL: Alan Peterson; technicaL exam: Ron Widup; WORLD aDvisORy: Diane Hageman; cOntinuing technicaL DeveLOpment: David Huffman;

tRaining: Kerry Heid; finance: John White; nOminatiOns: Alan Peterson; stRategy: Mose Ramieh

© Copyright 2011, NETA

NETA World is published quarterly by the InterNational Electrical Testing Association. Opinions, views and conclusions expressed in articles herein are those of the authors and not necessarily those of NETA. Publication herein does not constitute or imply endorsement of any opinion, product, or service by NETA, its directors, officers, members, employees or agents (herein “NETA”).

All technical data in this publication reflects the experience of individuals using specific tools, products, equipment and components under specific conditions and circumstances which may or may not be fully reported and over which NETA has neither exercised nor reserved control. Such data has not been independently tested or otherwise verified by NETA.

NETA MAKES NO ENDORSEMENT, REPRESENTATION OR WARRANTY AS TO ANY OPINION, PRODUCT OR SERVICE REFERENCED OR ADVERTISED IN THIS PUBLICATION NETA EXPRESSLY DISCLAIMS ANY AND ALL LIABILITY TO ANY CONSUMER, PURCHASER OR ANY OTHER PERSON USING ANY PRODUCT OR SERVICE REFERENCED OR ADVERTISED HEREIN FOR ANY INJURIES OR DAMAGES OF ANY KIND WHATSOEVER, INCLUDING, BUT NOT LIMITED TO ANY CONSEQUENTIAL PUNITIVE SPECIAL INCIDENTAL DIRECT OR INDIRECT DAMAGES NETA FURTHER DISCLAIMS ANY AND ALL WARRANTIES, EXPRESS OF IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE

ELECTRICAL TESTING SHALL BE PERFORMED ONLY BY TRAINED ELECTRICAL PERSONNEL AND SHALL BE SUPERVISED BY NETA CERTIFIED TECHNICIANS/ LEVEL III OR IV OR BY NICET CERTIFIED TECHNICIANS IN ELECTRICAL TESTING TECHNOLOGY/LEVEL III OR IV. FAILURE TO ADHERE TO ADEQUATE TRAINING, SAFETY REQUIREMENTS, AND APPLICABLE PROCEDURES MAY RESULT IN LOSS OF PRODUCTION CATASTROPHIC EQUIPMENT FAILURE SERIOUS INJURY OR DEATH

We are the InterNational Electrical Testing Association, formerly known as the National Electrical Testing Association and always referred to as NETA for short. Have you ever introduced NETA to someone unaware of our organization and found yourself explaining why the letters N-E-T-A don’t exactly match the abbreviation of the name? I certainly have. I guess the need to explain comes from the desire to be exactly correct, something that exists in a lot of technical people.

If you’ve been around the NETA community for a long that the name was changed from “National” to “International” outside the US boundaries joined the organization. That change technically correct. But then to help understand why the acronym the abbreviation, the full name was written as InterNational Association, cleverly capitalizing a letter in the middle of making a connection back to the acronym.

NETA has become very well known in North America. And transition period where people don’t even wonder if NETA longer name. We no longer care that 3M or IBM once had And how many people still remember that the word “laser” Amplification by Stimulated Emission of Radiation?” The is becoming one and the same as the full name.

Our strong name recognition and logo equity are part of Marketing Committee will leverage as they work on a initiative for our organization. This initiative will help the industry understand how the highest level of reliability and in electrical systems can be achieved through the use of our Accredited Companies who test to our ANSI accredited standards.

So be on the lookout for a new, modern image of organization. We’re embarking on the journey that takes NETA to the next level, and it’s all about electrical reliability and safety.

John White, P.E. Sigma Six Solutions NETA President

By Jill Howell & Kristen w icks, neta

By Jill Howell & Kristen w icks, neta

“The

great thing in the world is not so much where we stand, as in what direction we are moving.”

If you met NETA as a person on the street, what would you learn about him? You would learn that NETA is business-minded, qualitydriven, customer-service oriented, philanthropic, entrepreneurial, the life of the party, and loyal. That’s nothing new; NETA has always embodied these admirable traits. The great thing about aging and evolution is that though the outward appearance might change, the characteristics and personality of an individual only get more clearly defined over the course of time. NETA has matured quite a bit since its inception, and the Board of Directors determined it was time

Oliver Wendell Holmes

to refine the look and feel of NETA’s visual presence so that the outstanding qualities of the organization are positioned to take the next step in the evolutionary process.

NETA, the organization, was born thirty-nine years ago as a collaboration of like-minded individuals who believed that the world needed a set of standards to govern the business of electrical testing. These individuals, NETA’s Charter Members, spent a great deal of time and energy defining what the ideal electrical testing company should look like, how it should operate, and what services should be offered.

“NETA Quality” and “Setting the Standard” became the catch phrases of the organization. While the faces of those still carrying the NETA standard forward have changed over the past few decades, these core principles remain the same.

NETA’s branding was in its infancy in the 1970’s. Without the benefit of a large budget, NETA relied heavily on grassroots efforts rather than traditional marketing to promote the association. Word of mouth, social networking,

and relationships with clients were the means responsible for getting the organization off the ground and turning it into a thriving community. NETA’s tenant that electrical testing should be performed by third-party, independent electrical testing firms with certified, field-experienced technicians shook up the old way of thinking about electrical testing, but the philosophy quickly gained a large following of supporters, satisfied clients, and testing firms interested in membership in this elite organization.

NETA’s earliest logo has remained the core logo of the organization for the past thirtynine years, with slight variations depending on its use. The slanted block-lettering of the acronym “NETA” stands strongly against a stylized oscilloscope background, graphically representing the forward motion of the association and the circular unity of those focused on bettering society through their volunteer efforts. These graphic elements hold the key to the visual equity that signifies the reputation for quality service that NETA’s Accredited Companies have created for themselves and the association over the years.

This equity is something felt so strongly among the NETA Accredited Companies, NETA Affiliates, Subscribers, and International Associates, that when the NETA Board of Directors began exploring the idea of updating NETA’s brand identity, there was some concern about losing so many years of history. Thankfully, a very talented group of marketing and branding experts joined the effort. Under their guidance, the NETA Board of Directors and a subcommittee formed specifically to work on the rebranding effort went to work. They asked questions, a lot of questions. The committee gave answers, which prompted more great questions. Eventually, these questions provided the Board with a set of design concepts, a brand statement, and a brand promise. NETA’s facelift was nearly complete.

The only step that remains is unveiling NETA’s new look to the world. The new NETA logo takes all of the vintage logo’s best elements and presents them in a modern way. The forward momentum and energy embodied by the vintage tilted lettering is communicated through the updated use of color; the solid presence and dependability remains in the use of the block lettering; an uncluttered, clean approach is taken with a unifying outer circle. This is a logo that will see NETA well into the future while maintaining the vital connection to the past. PowerTest, NETA World, the NETA Affiliate Program, and each piece of visual collateral that comes from the NETA office underwent the process of drilling down and uncovering the essence of the program’s strength and purpose.

The issue of NETA World you hold in your hands is a tangible result of all those hours, introspective conversations, and discussions about which words in the English language best communicate to the world at large all that NETA is and all that it strives to be. Thankfully, NETA’s founders built such a solid foundation all those years ago; an older logo did not mean the association was in danger of becoming extinct. While the rebranding of NETA was a lot of work, the hardest work is still done by the NETA Accredited Companies and their certified technicians every day in the field for their valued clients. NETA is proud of each accredited company that bears the NETA logo as a symbol of their quality of service. With its powerful heritage and new image, NETA is poised to lead this next generation of individuals committed to safety and reliability.

Maintaining the equity from NETA’s longstanding, well recognized logo was a key consideration in evolving the new NETA corporate identity.

NETA’s new indentity presents itself in two forms: first with the circle symbolizing unification on the issues of safety and reliability, and second using only the letters standing for InterNational Electrical Testing Association.

• 50V & 100V Megohmmeters: For testing insulation resistance of phone cables, data cables and power cables

• 500V Megohmmeters: For testing the quality of insulation on equipment powered from sources up to 240VAC

• 1000V Megohmmeters: For testing equipment powered from sources up to 480VAC

• 5000V Megohmmeters: For testing large motors, generators, transformers, cables and other large rotating machinery

• Computer Controlled Models: AC powered, battery powered or hand-cranked models

• Choose from analog, digital or graphical displays

• Perform insulation resistance tests into the GΩ and TΩ ranges

and

OK – you’ve done the engineering study and you know the arc-energy levels at all of your switchgear, panelboards, and other such equipment. Some of the locations in your facility have unacceptably high incident energy levels. What this means to any given facility depends somewhat on local philosophy; however, it is a safety imperative to reduce incident energy levels to the lowest possible value and/or eliminate the exposure of your workers.

Ideally you would like all incident energy levels to be zero – not a realistic goal. Some would like to have no incident energies above 8 cal/cm2 or some other low goal. Unfortunately, your study shows some locations with incident energy levels of well over 15 cal/cm2, and some locations are over 40 cal/cm2

This article describes several techniques of reducing exposure of your personnel to high arc-energy levels. The several methods described all fall into the following three, broad categories:

• Reducing the available arc-energy by designing/redesigning your power system

• Reducing personnel exposure by designing/redesigning your power system

• Reducing personnel exposure by modifying – and enforcing – working procedures.

You will probably find some of these techniques to be useful in your system, building, or plant. Others will not be feasible for you because of work rules, physical plant limitations, and/or economics. In any event this article presents several common and not-so-common techniques that should be considered by you and/or your engineering consultant.

Reducing the available incident ene R gy by modifying/ R eenginee R ing you R powe R system

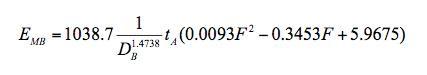

Take a close look at equation 1. This equation is taken from the 2009 edition of NFPA 70E

– Standard for Electrical Safety in the Workplace.

Equation 1:

Where:

EMB = maximum incident energy received from an arc occurring in a 20 in. cubic box (cal/cm2)

DB = distance from arc electrodes in inches (for distances 18 in. and greater)

tA = arc duration in seconds

F = short circuit current in kiloamperes (for the range of 16 kA to 50 kA)

Equation 1 is one of several formulas that have been developed by creating arcs in various controlled environments and measuring the resulting heat energy. Research in the area is ongoing and will undoubtedly lead to changes in the equations that we use; however, the basic relationships will remain the same – available incident energy decreases as:

• time of exposure (tA) decreases

• arcing short-circuit current (F) decreases

For protective devices with adjustable operating times, the engineer can often select a faster tripping time, thus reducing the available incident energy. If the engineer is able to reduce the tripping time from 2 seconds to 1 second, equation 1 shows that the available incident energy will be cut in half.

Prior to about 1995, the time delay settings for protective devices were primarily based on two criteria. The first criteria was the requirement that tripping times be fast enough so that noninvolved equipment would not be damaged by carrying excessive fault current for too long. Transformers, for example, overheat and may be damaged if they are required to carry fault-level currents for too long.

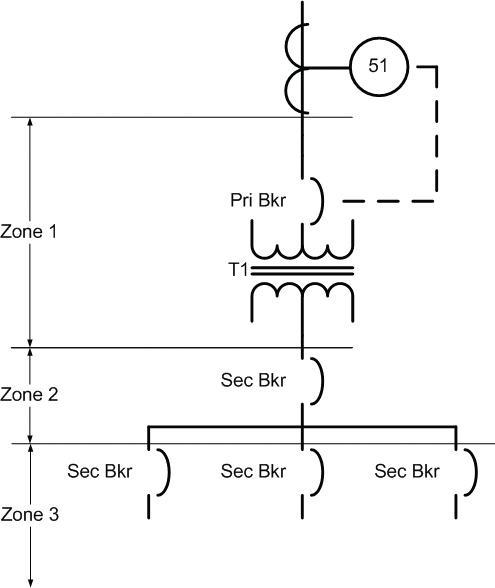

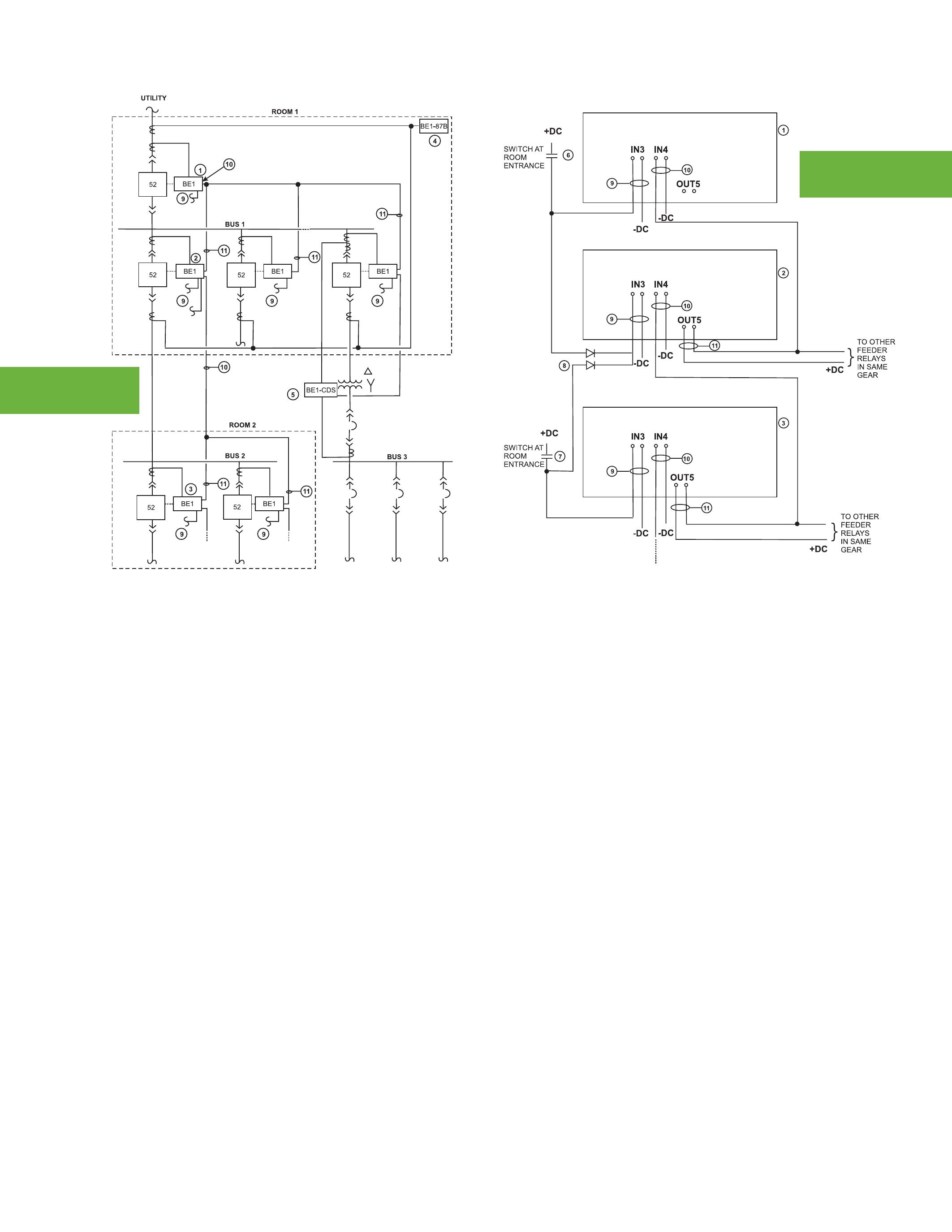

Refer to Figure 1 Short circuits that occur in zones 2 or 3 must be cleared by either the transformer secondary breakers (Sec Bkrs) or other protective devices below the Sec Bkrs (not shown). Since faster tripping times will provide better protection for the transformer, the ideal approach is to set all protective devices in zones 2 and 3 to trip instantaneously. This solution will also decrease the available incident energy – a seemingly perfect solution.

However, tripping times should also provide selective tripping. Selective tripping is defined as tripping the closest protective device upstream of the location of the short circuit. A fault that occurs below one of the transformer feeder breakers (Zone 3) should trip the feeder breaker – not the main secondary breaker. This means the following:

• Pri Bkr should clear faults in Zone 1

• The secondary main breaker should clear faults in Zone 2

• The feeder breakers should clear faults in Zone 3

Prior to 1995, the criterion for time settings was to set them as fast as possible to protect the transformer while still providing selective tripping. Since 1995 the reduction of incident energy has become a third important element. In some cases the settings may have to be based on the likelihood of a worst case short circuit. That is, you may wish to set your tripping times to provide selective tripping for the lower fault currents and sacrifice coordination for higher current/higher energy short circuits. Since the worst case short circuit is a very rare occurrence, you will optimize your selective tripping at the same time you reduce the available incident energy.

In low-voltage systems (less that 1000 V) the use of current-limiting devices (fuses and breakers) will also help to accomplish the desired goal. Fault currents that fall into the current limiting region of such devices can provide tripping times, including arc quenching, of less than 17 milliseconds.

Reducing tripping time is much easier if the engineering is done before the system is built. This allows the engineer to select protective devices that will fit the needed requirements. But what about new or existing systems wherein the devices cannot be adjusted to reduce the arc energies to the lowest possible value?

In such cases the installation of current limiting reactors is advisable. The reactance of these devices increases the system impedance and, correspondingly, reduces the magnitude of the available fault current. While somewhat expensive, this approach may be the only way that a given system’s available incident energy can be reduced to acceptable levels.

There are at least two side effects that must be taken into account when adding additional impedance.

First, a reduction in available fault current will cause the protective devices to operate more slowly. This must be taken into consideration because slower operating times increase available incident energy offsetting the effect of reduced current. This situation is especially pronounced if the reduced fault current causes the protective device to trip in a slower time characteristic.

Assume that the calculated fault current without the reactors will cause a low-voltage power circuit breaker to trip in its STD (short time delay) of less than 0.5 second. Further assume that the calculated fault current with the reactors will trip the same device in a long time delay characteristic. This could increase the trip time to several seconds (or more) resulting in a large increase in incident energy. Clearly, the selection of current limiting reactors must take reduced tripping times into account.1

Second, increasing the system impedance will reduce the system voltage even when operating normally. If the reduction in voltage is objectionable to operations, transformer voltage taps may have to be changed. If transformer taps are not available a second method is to contact the electrical supplier to ask if they can increase their supply voltage slightly. If neither of these methods work, and the voltage reduction is unacceptable, other incident energy reduction approaches must be used.

Experience shows that a significant percentage of arcing incidents occurs during equipment operation. Activities such as opening, closing, and racking put physical stress on the equipment that is not normally present. This can lead to equipment failure and an arc-flash event.

There are at least two ways of reducing personnel incident energy exposure by design and/or redesign.

• Install remote control rooms to allow all switching to be performed remotely

• Install or retrofit arc-resistant switchgear

1 This same problem can crop up when engineers try to determine the worst case scenario. Many assume that the maximum fault current will coincide with the maximum incident energy. For the same reasons as those given above, this is not necessarily true.

2 This is why workers should always be taught to stand to the side of a breaker or switch when it is operated.

3 Many are surprised to learn that in classic designs an arc blast is usually not taken into account for doors and/or panels.

Some facilities choose to install enclosed control rooms that allow remote electrical operation of switching equipment. This approach is especially suitable for new installations, but many companies are retrofitting the rooms in existing systems. Unfortunately not all equipment can be operated electrically. Manually operated protective equipment requires either a remote control appliance (discussed in the next section) or physical presence of the worker.

Permanently installed remote control rooms are very effective and strongly recommended because they put distance and at least one wall between the worker and the arc blast. While an excellent way to reduce exposure during opening and closing, remote control rooms only cover half of the hazard. After the breakers or switches have been opened, personnel must still approach the gear. A viable solution to this exposure is available in the form of arc-resistant switchgear.

Prior to the advent of arc-resistant switchgear, virtually all gear was incapable of enclosing the worst case arcing event. That is to say, if the worst case arc were to occur, the switchgear could sustain a rapid, noncoherent disassembly. It could blow up. The failure point is usually the front and/or back of the gear.2 Sometimes, it didn’t even take the worst case fault to cause a failure.

Modern arc-resistant gear incorporates at least three major features that greatly reduce the possibility of such an explosive failure.

1. The internal bus structures are better insulated to reduce the probability of a sustained arcing event.

2. The construction materials and methods are much sturdier than older designs. Stronger metals, thicker walls, interlocking corners, and heavy duty fasteners and hinges3 are all employed. Figure 2 shows the door construction used by one manufacturer for their arc-resistant gear.

3. The gear has an internal venting system that directs the by-products of the arc away from the personnel. Usually it is directed up and back.

Of course, arc-resistant gear is effective only when it is closed with all fasteners and latches in place. After the breaker or breakers have been opened, the gear must be opened to perform any work that requires access to the internal equipment, thus exposing the worker to the arc-flash hazard.

Unless the bus has been de-energized, the system is still hot; consequently, a failure can occur if the breaker or switch is racked in our out with the door open. External (door closed) racking systems greatly help in the reduction of this hazard. However, even then, if the bus is energized there is a possibility of an arc occurring.

The solution to this problem lies in the use of appropriate safety procedures.

Reducing pe R sonnel exposu R e by modifying – and enforcing –wo R king p R ocedu R es

Increasing distance from the arc location will greatly reduce the incident energy. From equation 1 we see that an increase in distance will reduce the incident energy by the 1.4738 power.4

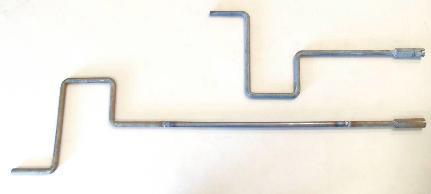

Figures 3 and 4 show two types of equipment that can and should be employed so that workers can operate gear from a remote distance. These types of mechanisms are less expensive than installing separate control rooms, and they provide a very good level of protection. Of course, nothing can be better than having a block wall between the operator and the equipment.

Figure 3 is the Chicken Switch.5 This was one of the earliest and most popular of the remote operating mechanisms. As you can see from the photo, the operating mechanism is mounted on the door of the breaker to be operated. The control box is connected to the mechanism via a long, spiral control cable. Use of this device allows the operator to stand at a safe distance (up to 25 feet or more) while opening or closing the breaker.

Figure 4 shows the CBS ArcSafe® remote switching device. This somewhat more elaborate equipment includes not only open or close operation, but also can be set up to physically rack circuit breakers and other such equipment remotely. Although more expensive than the many open/close devices that are on the market, such equipment adds enhanced safety by allowing opening, closing, and racking from a remote location.

There are many, many electrical safety training options in the marketplace today. They range from classroom/laboratory presentations that require participants to demonstrate their ability to work safely around electricity to simple video-tape/computerbased training packages.

Although employers are always looking for ways to get the greatest bang for the buck, I recommend that more comprehensive training methods be used. Workers should certainly be required to take cognitive skill enhancement training, but they also should be required to include demonstration of their safety skills. A person remembers something they have done much more completely than something they have heard or read.

4 Theory predicts an inverse square relationship for a point source of energy. The slower energy reduction in the real world is caused by the focusing effect of switchgear and arc geometry.

5 Chicken Switch is a registered trademark of MarTek, Ltd.

6 Some are even more conservative and draw the line at locations over 8 cal/cm2 If this is feasible in the given situation, I concur.

Even in late 2010, I am amazed at how many companies are still unaware of the potential for arc injuries. Unfortunately, such companies very often are unaware of their obligation to provide the necessary worker protection.

Simple, easy-to-enforce procedures can go a long way towards preventing electrical accidents. Methods such as:

• Stand to the side when operating a breaker (See Figure 5).

• Always test before you touch (test the meter, test the circuit, retest the meter).

• When testing, wear all appropriate PPE. Remember that it isn’t dead until it’s measured.

• Always wear and/or use properly rated PPE (See Figure 6).

• Observe the shock and flash boundaries. Do not cross them without proper PPE.

• Put signs, barriers, or safety watch personnel in place to keep out unqualified personnel.

• Whenever possible apply equipotential safety grounds in the work area.

• De-energize the system from a location that has relatively low incident energy.

I believe that any location with incident energy over 15 cal/cm2 should be reviewed for possible mitigation solutions.6

Usually solutions exist to reduce the maximum incident energy at an exposure location in a power system. For example, some say that it is impossible to reduce the incident energy of a fault occurring between a transformer secondary and the first secondary protective device. In fact the normally high, incident energy in these locations can be mitigated. Protective schemes such as transformer differential or zone-interlocking protection will provide instantaneous tripping for transformer secondary faults. The cost of mitigation may be high, but the cost of a single injury or fatality will be much higher.

Some consultants, as a normal part of an arc-flash study, will recommend changes in protective device settings in areas where high incident energies are present. In fact, system owners should insist on this as a part of a contracted study.

However, major redesign efforts are usually beyond the scope of a contracted study. Adding current limiting reactors, designing remote control rooms, and checking the effects of different protective devices are examples of such out-of-scope efforts.

If a study reveals locations where a simple setting change is not sufficient, the system owner should commission an engineering review to determine which of the several design options will provide the optimal incident energy mitigation.

Procedural and PPE considerations should be based on the results of an arc-flash study. The use of PPE tables in NFPA 70E should be limited to those locations where a study has not been performed. However, for a given location, this should be a temporary fix. The best and safest approach is the arc-flash study.

Finally, do not forget electrical shock hazards. In the midst of focusing on arc flash it is sometimes easy to forget that shock hazard should also be investigated. Voltage level is certainly the first criteria in selecting proper insulating equipment. However, the overall shock hazard should be investigated to properly assess the need.

John Cadick is a registered professional engineer and the founder and president of Cadick Corporation, John Cadick has specialized for more than three decades in electrical engineering, training, and management. His consulting firm based in Garland, Texas, specializes in electrical engineering and training and works extensively in the areas of power system design and engineering studies, conditionbased maintenance programs, and electrical safety. Prior to creating Cadick Corporation and its predecessor Cadick Professional Services, he held a number of technical and managerial positions with electric utilities, electrical testing companies, and consulting firms. In addition to his consultation work in the electrical power industry he is the author of Cables and Wiring, The Electrical Safety Handbook, and numerous professional articles and technical papers.

Indu S tr I al t e S t S , In C a S a neta aCC red I ted Company

Industrial Tests, Inc. is pleased to announce that it is now a NETA Accredited Company after satisfying the stringent requirements to become a full member. Industrial Tests, Inc. was established by former Westinghouse Engineering Service employees in 1976 and is now an independent, third party testing company which serves the western states and beyond.

Located in Rocklin, California, Industrial Tests, Inc. has been providing start-up and acceptance testing services for the utility,

industrial, and commercial industries for over 30 years. Industrial Tests, Inc. proudly employs a professional team of degreed engineers who are highly trained and experienced in performing specification and maintenance testing in compliance with NETA standards.

Industrial Tests, Inc. looks forward to becoming an active member of NETA and sharing the many benefits of the association with its technical staff and clients. For additional information, please visit the website at www.industrialtests.com.

the test equipment answer

The topic of electrical arc flash has been an important issue for several years now. Engineers have been creating and manufacturers are producing innovative new solutions for this life-threatening problem. This month’s Tech Quiz will cover issues related to electrical arc flash.

Jim White is the Training director for Shermco Industries and the principal Shermco representative on the NFPA 70B committee. Jim is the alternate NETA representative on the NFPA 70E committee and serves as the NETA representative on the IEEE/ NFPA Arc-Flash Hazard Work Group (RTPC) Ad Hoc Committee. He served as the Chairman of the 2008 IEEE Electrical Safety Workshop. Jim is a NETA Certified Level IV Electrical Testing Technician and a member of the NETA Safety Committee.

1. Electrical systems rated less than 240 volts fed by a transformer with a capacity of <125 kVA are not considered an arc-flash hazard.

a. True, according to IEEE 1584

b. False

2. Arc -flash protective clothing and equipment are rated to:

a. Provide protection to the value indicated as the “arc rating” or “ATPV”

b. Provide a 50% probability of a burn at the arc rating or ATPV

c. Provide protection in excess of the arc rating or ATPV

d. Allow a person to safely work on an energized electrical power system

3. Which of the following is NOT a rule-of thumb concerning arc flash:

a. Incident energy decreases by the inverse square of the distance

b. Incident energy is proportional to time

c. Each layer of clothing under arc-rated reduces the heat to the body by ~ 50%

d. Incident energy is inversely proportional to short circuit current

4. At what voltage does the arc flash hazard not exist?

a. 480 volts

b. 277 volts

c. 208 volts

d. None of the above

5. When wearing an arc-rated face shield, what is the correct body position when operating electrical equipment?

a. Extend the left arm and turn the face away from the hazard

b. Extend the right arm and turn the face away from the hazard

c. Extend either arm and turn your face towards the hazard

d. Get an apprentice to do it for you

See answers on page 105.

Joint Colla B o R ation pR o J e C t on the aRC

At this year’s NFPA 70E ROC (Report on Comments) meeting, an update on the IEEE/NFPA Joint Collaboration Project was presented by Dr. Wei-Jen Lee of the University of Texas at Arlington. Dr. Wei-Jen Lee is the Project Manager for the IEEE/ NFPA Joint Collaboration Project. NETA is always looking for ways to improve its worker’s safety and is a major contributor to this project.

By Jim White & Ron Widup Shermco IndustriesDr. Lee began by stating the goals of the project, which are to determine the arc-flash effects, including heat, blast pressures, light intensity, and sound intensity. These effects are to be quantified and equations developed through executing approximately 2500 tests. These tests are being conducted at five different test laboratories around the US and Canada.

The initial series of tests (Phase 1), which have been completed, were to determine instrument functionality, overall accuracy, repeatability and consistency of the various test laboratories. Six calorimeters will be used for testing, and the electrodes will be placed horizontally for some tests and vertically in others. The horizontal electrode placement was to address concerns raised by Dr. David Sweeting who had written a paper pointing out that his research showed that horizontal electrodes could produce arc jets which produce higher incident energy values than when the electrodes are placed vertically. The equations for IEEE 1584, Guide for Performing Arc-Flash Hazard Calculations, will be updated to reflect the new information from these tests once they are completed and analyzed. Dr. Sweeting is also on the technical committee for this project. IEEE 1584 applies only to 208-volt through 15 kV three-phase

systems in enclosures. Higher voltages and single-phase systems are covered using Ralph Lee’s equations (no relation to Dr. Lee).

Five series of tests were performed for Phase 1, during both cold and warm weather, to gauge the effects of ambient temperature on the test results. The video recorders being used can capture (depending on the laboratory) between 600 fps to 1900 fps. Calorimeters can capture between 200 to 5K samples/second and the pressure sensors can capture between 20K to 50K samples per second. Sound is captured at 20K samples per second. I often get questioned about the need for hearing protection for HRC 0 and HRC 1 levels. Dr. Lee pointed out that their tests so far have shown sound levels at 120 db to 130 db for a 480-volt, 5 kA fault and between 130 db to 164 db at 480 volts and 20 kA. These are very substantial acoustic values and can cause damage to a worker’s hearing if he is not protected. As a side note, these sound levels were measured at a distance of 2 to 3 meters from the arc, as the instrument’s sensors were damaged if they were placed closer. This means the actual sound levels were probably greater than that indicated.

At this time the project has almost completed the 480 V testing. During the Spring and Summer of 2011, Dr. Lee hopes to complete testing at the 4.16 kV level, complete the 480-volt to 600-volt testing, analyze their data and possibly conduct some testing at the 208-volt level. It will take a considerable amount of time to properly analyze all the data produced by these tests, so don’t expect any usable information to be forthcoming anytime soon. Testing on 7.2 kV and 13.8 kV is scheduled to be conducted during the Fall and Winter of 2011.

A question was asked about dc voltages and Dr. Lee replied that they will look at dc voltages depending on funding once all the ac tests have been completed. At this time it appears as though there are no definite plans to conduct dc testing, but there are contingent plans if funding becomes available.

James R. White and Ron A. Widup are NETA’S representatives to NFPA Technical Committee 70E (Electrical Safety Requirements for Employee Workplaces). James R. White is nationally recognized for technical skills and safety training in the electrical power systems industry. He is currently the Training Director for Shermco Industries, a NETA Accredited Company. Jim has spent the last twenty years directly involved in technical skills and safety training for electrical power system technicians.

The Report on Comments (ROC) meeting of the NFPA 70E committee is always interesting and always has some surprises. This one was conducted in Savannah, Georgia and was no different. The ROC meeting actually ran seven full days due to several task groups meeting on Saturday and Sunday. The task group meetings lasted nine and eight hours, respectively. Task groups are formed to smooth the process and present recommendations to the full committee in order to reach consensus (hopefully) more quickly. Each proposal still has to be discussed by the full committee, but if the task group is large enough, it usually speeds things up. Usually. But not this time.

The Tables Task Group met on Saturday, and there was a large number of participants. With such a large task group, the results of the vote would normally indicate where the full committee would vote. In the ROP (Report on Proposals) meeting there was very strong support for adding two columns into Table 130.7(C)(9), one for the available short-circuit current and clearing time of the OCPD and one for the estimated Arc-Flash Boundary at the maximum estimated short-circuit current and clearing time. The full committee directed the task group [Ron and Jim were members and it was chaired by Jim Dollard (IBEW)] to develop the values for inclusion into the tables.

On Saturday, the values the task working group had developed were discussed, some modifications were made and sample tables were prepared. During the full committee meeting the entire concept was thrown out the window, and it was decided to move the notes from the bottom of the tables into the headers and not use a two column format. This will mean the headers will be quite a bit larger and contain the maximum short circuit current, clearing time, Arc-Flash Boundary, and working distance. The full committee had concerns that the two column format would lead to some confusion, especially with the 600 V class motor control center section which has more than one note. As I said, many surprises.

On Sunday, the Article 130 task group met. Again, Ron and Jim were on this task group which was chaired by Daleep Mohla. Article 130 (Work Involving Electrical Hazards) generates a lot of interest from the public, and it actually took this task group Sunday as well as Monday and Tuesday evenings to finish its work. Due to the sometimes extensive and protracted discussions involving the comments received, the regular committee meetings ran from 8 am to 5pm, at which point the task groups worked until 6 pm to 7 pm, depending on the day.

A number of significant changes were proposed for the 2012 edition of the NFPA 70E. Bear in mind that these changes have not yet been approved by the Technical Correlating Committee (TCC), nor by the Standards Review Council of the NFPA. Until they are approved they are not part of the standard.

One very significant change was the addition of Kenneth Mastrullo (Region I OSHA) as the alternate representative to David Wallis, who is the principle OSHA representative. Ken was formerly with the NFPA and acted as the liaison for the NFPA 70E committee. Ken co-authored the 2009 edition of the NFPA 70E Handbook with Ray Jones. Ken brings a new insight to the committee based on his experience both from the NFPA side as well as from the OSHA enforcement side. David provides insight on how the standards evolve and OSHA’s view of certain issues. A couple of times a commenter stated he did not think the 70E committee should be driven by OSHA. We believe the 70E should harmonize with federal law, so how OSHA perceives actions taken by the committee is very pertinent. Even though the principle OSHA representative has a full vote on the committee, he abstains from the vote so that it is not influenced.

Everyone is interested in the tables. The 2012 edition of the 70E will see several new tables being added, so the numbering of everything in the 70E will change. Table 130.7(C)(9) will now become 130.8(C)(15)(1) and 130.8(C)(15)(2). Two tables are for hazard/ risk category of clothing, one for ac power systems and one for dc power systems. Table 130.2(C) (approach distance for shock protection) will now be numbered 130.4(C)(1) and 130.4(C)(2), one for ac systems and one for dc systems. Another new table that will appear in the 2012 edition will be Table H.3 which provides recommendations for arc-flash PPE and clothing when an Arc-Flash Hazard Analysis has been performed. In past editions of the 70E there was no guidance for choosing

arc-flash PPE and clothing when an arc-flash study had been performed. Table 130.7(C)(10) was only to be used when using Table 130.7(C)(9), although that was routinely ignored in the field. The 70E committee generally believed that when an arc-flash study had been performed, the tables were not required and that using Table 130.7(C)(10) could lead to choosing PPE and clothing that may not be appropriate in some cases.

Two other tables in Annex H are also new. Tables H.4.1(Low-Voltage Systems) and H.4.2 (High-Voltage Systems) offer guidance for choosing arc-flash PPE and clothing when the short-circuit current and clearing time of the OCPD is known. These two tables are based on the two-level clothing system (8cal/cm2 and 40cal/cm2). For each voltage level there are maximum short-circuit currents that either 8 or 40 cal/cm2 PPE can be used at several different clearing times for OCPD. These tables should be especially useful when a company uses a two-category PPE system.

Table 130.7(C)(11) is being eliminated. Changes made to Table 130.7(C)(10) made the information contained in Table 130.7(C)(11) redundant, so the committee thought it was no longer necessary.

More information on what to expect from the 2012 edition of the 70E will be included in next issue of NETA World magazine.

James R. White and Ron A. Widup are NETA’S representatives to NFPA Technical Committee 70E (Electrical Safety Requirements for Employee Workplaces). James R. White is nationally recognized for technical skills and safety training in the electrical power systems industry. He is currently the Training Director for Shermco Industries, a NETA Accredited Company. Jim has spent the last twenty years directly involved in technical skills and safety training for electrical power system technicians.

Reliable functioning of airport lighted visual aids is essential to airport safety, capacity, and operation especially for low visibility operations. Therefore, it is essential that a preventive maintenance (PM) program be established to ensure reliable service and proper equipment operation. FAA Advisory Circular AC No. 150/5340-26A, Maintenance of Airport Visual Aid Facilities, provides recommended guidelines for maintenance of civilian airport visual aid facilities. MIL-HDBK-1023/4, Maintenance of Visual Air Navigation Facilities, provides recommended guidelines for maintenance of military airport visual aid facilities. These systems include the following:

• Airport lighting vault and series lighting circuits

• Constant current regulators

• Runway and taxiway elevated edge lighting systems

• Runway and taxiway in-pavement lighting systems

• Runway guard lights and stop bar lights

• Illuminated runway and taxiway signs

• Rotating beacons

• Lighted wind cone assemblies

• Precision Approach Path Indicator (PAPI) system

• Visual Approach Slope Indicator (VASI)

• Runway End Identifier Lights (REIL) and Omni Directional Approach Light System (ODALS)

• Medium Intensity Approach Light System (MALS, MALS/F, MALS/R)

• Hazard beacons and obstruction lights

• Standby engine generator systems

The following table represents some of the recommended electrical tests associated with compliance to AC No. 150/5340-26A and MIL-HDBK-1023/4. The recommended testing frequency varies by system from monthly to annually.

Most lighted navigational aids are exposed to weather and moisture and may develop electrical shock hazards through damage from lightning or insulation deterioration from exposure. Because of their design and operational nature, airport runway and taxiway lighting circuits can be very dangerous. This is especially true when working on constant current series circuits because these airport lighting circuits can operate at potentials of several thousand volts depending on the size of the regulator driving the circuit and the load. As an example, a series circuit connected across a 50 kW, 20.0-ampere regulator may have a full load voltage of 2,500 volts. However, the momentary surge before the open-circuit protection device actuates will approach 5,000 volts. Constant current regulators come in two basic types, air cooled and liquid filled. The two basic types of regulators can be further classified as either magnetic or electronic. Magnetic types typically utilize either a resonant circuit or a saturated reactor principal. In a resonant network circuit the current output is proportional to the input voltage and is independent of the impedance of the load. Most resonant network regulators are only manufactured in sizes less than 10 kW. For regulators that are oil filled, an oil sample should be taken to ensure adequate dielectric strength of the oil. A normal range for oil being tested should be 26-30 kV with 22 kV as the minimum acceptable level. For the regulator, a short-circuit test, an open-circuit test, and an overcurrent test should be performed.

It is recommended that manufacturer’s literature on the operations, theory of operation, and recommended maintenance testing procedures for the particular regulator being used be obtained and reviewed prior to performing any maintenance on these devices.

Specialty test equipment, or test equipment not normally owned by an airport or used by the airport’s maintenance electricians, is required for some of the recommended testing. When considering tools and test equipment, an average electrician may have little day-to-day use for anything more than an analog volt-ohm-milliammeter (VOM) or a digital multimeter (DMM). However, when maintaining airport lighting series circuits, the voltage levels (i.e., greater than 1000 V) typically exceed the design of the VOM or the DMM. That means it is dangerous to use the VOM or DMM for troubleshooting these circuits. A specially designed, high voltage meter is required for this application. Additionally, VOMs and DMMs are of little use when performing insulation testing (i.e., megohmmeter, or Megger™, testing of equipment and cables) or low resistance testing (i.e., measuring ground resistance).

In general, insulation-resistance tests should be performed on all field circuits to verify no ground faults exist. For series circuits, the insulation resistance may be measured by simply removing the ends of the loop from the power supply. For parallel circuits, all connections must be removed before insulation resistance may be measured. Whenever possible, these tests should be performed when the ground is thoroughly wet. Circuits which pass insulation- resistance tests during dry weather may fail after a heavy rain. All readings should be compared to previous results. A 10 to 20 percent annual decrease in insulation resistance value (in megohms) is normal. An annual decline of over 50 percent indicates the existence of a problem where further troubleshooting should be performed.

The ground resistance tester is used to measure the effectiveness of grounding systems. The grounding system may be used for beacon towers, lighting vaults, engine generators, and for other lighted navigational aids, or it may be a counterpoise system for underground cables. Ground resistance measurements for each item of equipment should be performed on at least an annual basis. The measurements should be recorded and compared with previous readings in an effort to discover deterioration in the grounding system. The lower the resistance value, the better; a value of 5 to 10 ohms is desirable. If the resistance is greater than 25 ohms, immediate action should be taken to lower the resistance.

When specialty test equipment and experience are required for performing maintenance, it is preferred that a testing company be utilized for performing the work safely and effectively. Accredited companies that are uniquely qualified to perform this type of work should be used. The companies should be accredited based on electrical testing experience and have expertise in working with higher voltage equipment and systems. Their test technicians should be

certified through a standardized testing process and have been trained in the technical and safety aspects (i.e., PPE requirements, safety work practices, etc.) associated with equipment of the type installed in airports.

Lynn Hamrick brings over 25 years of working knowledge in design, permitting, construction, and startup of mechanical, electrical, and instrumentation and controls projects as well as experience in the operation and maintenance of facilities.

Lynn is a Professional Engineer, Certified Energy Manager and has a BS in Nuclear Engineering from the University of Tennessee.

Vanguard’s precision substation testing instruments are designed to be intuitive and easy to use so that you can focus on testing instead of wasting time in training. Our versatile instruments offer a built-in thermal printer and on-board test record storage so that tests can be conducted in stand-alone mode in the field. A computer interface is also offered so that tests can be easily conducted from a PC.

And all of our instruments are competitively priced to provide cost-effective accuracy. For a virtual experience of our instruments, check out the interactive demos on our site at:

www.vanguard-instruments.com/demos

electro rentthe right choice

Electro rent has been renting complete lines of electrical test equipment since 1965. Our experienced sales associates can assist you in selecting the right tool for your job and we usually deliver it to you within 24 hours. We offer daily, weekly and monthly rentals at prices that fit your budget. let us help you achieve success!

rent what you need when you need it. call us or visit us online for a free quote.

From leading manuFacturers

Baker, Biddle, doble, dranetz, Flir, Fluke, High voltage, Hioki, Megger, Multi-amp, Yokogawa and more. Electro rent also rents and leases an assortment of laN cable certifiers, Otdrs, fusion splicers and light sources.

most

For projects with a projected term of 12 to 48 months, Electro rent has an exceptional financing program that offers significant budget benefits while it provides immediate access to products without waiting for capital. You can also purchase your equipment as funds become available.

Key Features include:

• Lower rate for a longer committed term

• Addition of non-hardware items, such as service or software

• Flexible contract options, such as early termination, upgrades and trade-ups

To address the increasing concerns and standards around arcing faults, GE challenged our Global Research Center to develop a new, “active” method of detecting and removing an arcing fault. The goal was to develop a technology that would, in simple terms, reduce the potential for injury and equipment damage. The result is an innovative product called the Arc Vault™ Protection System. This article will outline some basic arc-flash mitigation techniques and culminate with a description of the new GE technology. It should be noted from the onset that this technology is currently in the prototype phase and that the discussion covers applications of 600 V and below.

Arcing F A ults – Why the i ndustry c oncern?

Simply put, the effects may result in serious injury, death, equipment damage, and downtime. Unlike the bolted fault, an arcing fault uses ionized air as the conductor. The cause of the fault normally burns away during the initial flash and the arc is sustained by the establishment of a highly conductive, intensely hot plasma arc. The intense heat vaporizes conductors and barriers and superheats the surrounding air resulting in an explosive volume-metric increase within the space. The consequence is an intense pressure wave, deafening sound, blinding light, toxic gases, molten metal and shrapnel. This is often referred to as the arc blast. Unless action is

taken to either quickly remove the fault or redirect the arc blast, the brunt of these items will impact people, equipment, or both. The magnitude of the arcing fault is only 43-57% of a bolted fault, so traditional overcurrent protection may not detect and clear the fault before the full impact of the arc develops and causes damage or injury.

To gain a better understanding of how to deal with an arcing fault, let’s consider what the contributing variables are and the corresponding incident energy calculations that help categorize them. A complete discussion on arc-flash calculations can be found in IEEE 1584 – “Guide for Performing Arc-Flash Hazard Calculations”.

There are many items that can initiate an arcing fault. Rather than focusing on what the ignition sources can be, the system factors associated with how we quantify the arcing fault will be considered. With the benefit of this information, mitigation techniques can be outlined and categorized. Figure 1 illustrates some of the basic parameters that factor into an incident energy calculation that in turn leads to the Hazard Risk Category labeling.

Clearly, there are many variables that factor into the incident energy calculation. Some are specific to equipment types while others are tied to system parameters or maintenance practices. Each variable plays a particular role in how we categorize the arc-flash hazard and each is briefly touched upon below:

• Voltage – The ability to sustain the arc. Arcing faults are generally limited to systems where the bus voltage is greater than 120 V.

• Available bolted fault current – The punch behind the arc fault magnitude. Recall that the magnitude of a low-voltage arcing fault is approximately 43-57% of the bolted fault value. This implies that systems with significant bolted fault currents will have elevated arcing current levels. The reverse is also true; lower bolted fault levels will lead to lower arcing-fault energies. Items such as system impedance, transformer sizing, utility, motor, and generator contributions establish the available fault current.

• Arc clearing time – This includes detection and protective device operating time. It is tied to the operating characteristics of a specific protective device for a given level of arcing current. Reducing clearing time is critical to reducing the impacts of arcing fault.

• Conductor gap distance – Defines the distance between conductors that an arc must cross. Varies by equipment type and manufacturer, but is fixed for a specific piece of equipment.

• Working distance – The distance from a potential arc source to a worker’s face and chest. Typically assumed to be 18”. Items such as remote monitoring and racking can be implemented to remove the operator from the flash zone for routine maintenance tasks.

• System configuration – Solidly grounded, resistance grounded, etc. This category also takes into consideration whether the arc environment is enclosed or open.

Given a basic understanding of what variables contribute to an incident energy calculation, the next logical question is to ask what the engineer can do to reduce this energy or exposure to it? Since energy is a function of current, voltage and time, there are several strategies that can be explored:

• Reducing the available fault current

• Reducing the arcing time

• Transferring the energy into a less damaging form or place quicker than it could otherwise be interrupted

The paragraphs that follow will highlight several of these strategies.

Over the years, different methods to limit arc flash exposure and incident energy have been introduced and can be divided into two general categories: active and passive. Passive mitigation is defined to be an equipment

option or type that either contains and redirects the arc blast or helps to eliminate the potential of a flash event (i.e., insulated main bus). This type of mitigation does not require any actions or settings by an operator to implement. On the opposite end of the spectrum is active mitigation. Active mitigation takes a proactive approach to reducing both incident energy and the exposure to arcing faults through the active use of technology, design, and maintenance practices. The simplest example of active mitigation is to not approach or work on live electrical equipment. Figure 2 contains a list of passive and active items.

Passive Active

Reduce exposure with equipment options

• Insulated/ isolated bus

• IR scanning windows

• Closed door drawout of breakers

• Side section barriers

• Hinged vs. bolted doors

• Heaters

Reduce exposure with equipment types

• Arc resistant structures

Technology to reduce arcing time & incident energy

• Arc absorber

• ZSI of instantaneous

• Crow bar

• Bus differential (87B)

• Maint settings (RELT)

• Current limiting devices

Design practices to reduce arcing time & incident energy

• Consider fault currents

• Transformer sizes

• Grounding

• Single or double ended

Others?

Reduce exposure via maintenance practices

• Follow NFPA 70E

• No live maintenance

• Remote switching

• Remote racking

• Remote monitoring

• Remove contaminants

• Training & labeling

• Use of proper PPE

One clear distinction between the passive and active methods is that the passive method does nothing in the way of detecting or removing an arcing fault. It is focused solely on containing the arc blast or eliminating a potential starting point for an arc flash via equipment options. One should not employ passive techniques

without thinking through items such as thermal scanning. Equipment options like insulated main bus and isolated phase bus are good preventative measures; however, they present an issue to performing thermal scans of items other than load connections.

The active methods seek to attack on both fronts, incident energy reduction and reduced exposure. The newest technology on the active side is the GE arc absorber protection system. To highlight the application of this new system the following paragraphs will contrast the active arc absorption system vs. the passive, arc resistant structure. The remaining items are listed for reference and will not be covered in detail.

Typical low voltage metal enclosed switchgear is designed and tested to withstand the mechanical forces associated with bolted faults (nonarcing). It is not constructed to contain and re-direct the arc blast away from the operator. The standard construction must be able to withstand (carry) the bolted fault current from the line side of the main breaker through the load terminations on the feeders and is short circuit tested to ensure compliance with the applicable ANSI standards. During a short circuit interruption, there may be some out gassing of arc by-products from the breaker but not to the violent extent of the arcing fault.

An arc resistant line of low-voltage switchgear is also designed to withstand and interrupt a bolted fault, however it provides a level of protection to arcing faults that is not incorporated in the standard design. Arc resistant structures have been around for 30 plus years and can trace their roots back to IEC standards. In North America, this type of structure is tested & categorized to ANSI C37.20.7 (Refer to Figure 3.)The term arc resistant implies that no arc-fault emissions/ blast will occur in the areas described by each category. For example, with a properly installed Type 1 design, an operator could approach the front of a switchgear lineup and not be

exposed to the arc blast if an arcing fault were to occur. If the operator were standing to the side of this design, the same protection would not be provided.

ANSI Type Comments – arc resistant construction applies to

Type 1 The front only.

Type 1C The front, as well as between compartments of the same or adjacent cells.

Type 2 The front, back and sides of the enclosure.

Type 2C The front, back, sides as well as between compartments of the same or adjacent cells.

Figure 3: Arc-Resistant Structure Categories

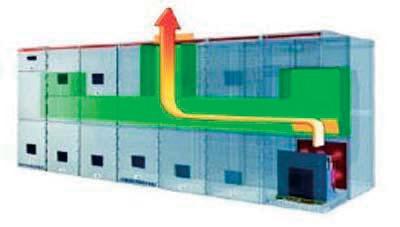

To function properly, arc-resistant structures have several distinguishing characteristics not found in traditional gear.

• Reinforced construction is used to withstand and contain the pressure wave. Front and rear doors, section barriers, etc., may be reinforced and gasketed depending on the ANSI type.

• Exhaust chambers are employed within the structure to safely redirect the arcing fault by products away from the operator and toward the vent flaps.

• Vent flaps that open due to increased pressure vent the arc blast, typically out the top.

• Figures 4 illustrates the redirection and venting of the arcing fault.

Figure 4: Illustration of Arc-Resistant Venting

The arc-resistant structure does an excellent job of protecting the operator from an arc-flash event; however, it is not a panacea. As noted earlier, this passive technique seeks only to contain the arc blast, but nothing to reduce incident energy or remove the arcing fault, which can result in substantial equipment damage and downtime. Like all products, the application of arc-resistant structures requires consideration and awareness of items that are specific to the construction. Several items are listed below for consideration.

What type of downtime will the owner experience for an arcing fault? It is reasonable to expect some structural damage that will require repair as a result of the arc blast. Bus, doors, and barriers are likely candidates for repair. Are there other mitigation methods that can provide operator protection and help reduce equipment damage at the same time?

The protection afforded by the arc-resistant structure can be negated if a door is not properly secured or if the maintenance task requires the operator to open a door or compartment. What are the impacts to operator safety, maintenance practices, etc.?

Where does the effluent go when it is vented from the structure? Does the room size need to be increased? Does a restricted area need to be developed and labeled? Is placement of the structure limited to certain areas?

What are the cost and size impacts associated with the structure itself? Does the room size need to be increased?

The arc-resistant structure cannot be retrofit onto existing equipment.

The comments above are not meant to disparage the arc resistant design. Rather they are meant to highlight that with all products there are application considerations that must be taken into account. Items such as live maintenance, equipment damage, room size, and venting are real concerns that need to be thought through and contrasted against other mitigation techniques.

p and a logic controller.

arallel-connected containment dome, light sensors

The arc absorption is an active mitigation technique and aspires to the same basic goal as the arc-resistant structure; to protect the operator. However it does so in a much different fashion than arc-resistant structures. Instead of containing and venting the arc-flash effluent, it seeks to limit incident energy via the identification and removal of an arcing fault before it escalates into the signature arc blast and elevated hazard risk categories. The result is a solution that addresses three key areas:

• Reduction of the arc-flash hazard

• Improved equipment uptime/ reduced damage

The current sensor looks for the signature of an arcing fault while the light sensor looks for a simultaneous optical event. The combination of the two is fed into a logic controller which makes the decision on whether to engage the absorber or not.

At this point you may be thinking that this is a crow bar. Rest assured, it is not, please read on.

The arc absorber has no moving parts and makes use of a plasma gun and containment chamber. When the logic controller activates the absorber, two simultaneous actions take place. A trip signal is sent to the main breaker, and the absorber is activated. When activated, the absorber triggers the plasma gun to break down the dielectric in the air gap within the absorption chamber. The resulting arc creates a lower impedance, phase-to-phase path than the “in equipment” arcing fault presents to the system. This low impedance path is not a bolted fault and in turn redirects/absorbs fault current originally flowing towards the arcing fault within the controlled environment of the containment chamber. The arc within the containment chamber is then safely cooled and vented. The open air or “in equipment” arc is extinguished as the bus voltage decreases due to the low impedance path within the absorber. The time required to quench the open-air arc is 8 ms. The event is brought to conclusion when the main protective device opens and eliminates current flow within the absorption chamber.

Figure 5 - Architecture

figure 5: Architecture

• Ability to retrofit existing switchgear

he current sensor looks for the signature of an arcing fault while ks for a imultaneous optical event. The combination of the r not.

T the light sensor loo s two is fed into a logic controller which makes the decision on whether to engage the absorber o

The architecture for the absorber is depicted in Figure 5 and consists of a current sensor, a parallel-connected containment dome, light sensors, and a logic controller.

At this point you may be thinking that GE has created a crow bar. Rest assured, we have not, p

lease read on.

The Arc Absorber has no moving parts and make use of a plasma g W simultaneous actions take place. A trip signal is

s

un and containment chamber. hen the logic controller activates the absorber, two

It is important to note that since this system works at arcing fault current levels, as opposed to bolted fault levels, there is a significant energy reduction. The result is 63% less energy, and considerably less stress on the system, when compared to crowbar type systems. This energy reduction applies to not just the local switchgear but also to other system components like transformers.

The prototype of the arc absorber containment dome is about the size of an 800 AF breaker and is rated for applications of 100 kA at 480 volts.

The arc absorber protection system will contain an arc fault in less than 8 ms with the circuit breaker compartment doors open during operation and maintenance. The incident energy in accordance with IEEE 1584 at 24" from the arc event will be less than 1.2cal/cm2, which is equivalent to HRC0, for a 480 V HRG system with available fault currents up to 100 kA.

In addition to incident energy/HRC reduction, eliminating the arcing fault, reducing equipment damage, and eliminating arcing fault effluent. The arc absorber offers the following benefits not found in traditional arc resistant structures:

New and retrofit applications

The arc absorber can be implemented in new or existing low-voltage switchgear platforms while the arc resistant structure is tied to new installations only.

The arc absorber will be reusable, with minor maintenance or parts replacement, depending on the available fault currents where it is applied. Arc-resistant structures will in all likelihood sustain some form of damage and require repair to place them back into service.

The arc absorber does not depend on doors being closed to provide arc-flash protection. Hence the established Hazard Risk Category does not change whether the doors are open or closed.

No need for increased ceiling heights or the creation of restricted areas to avoid potential exposure to redirected effluent.

There are many techniques that can be employed to help mitigate the damaging effects of arcing faults. This article has introduced the concept of the arc absorber as a feasible alternative to arc-resistant structures. It can at minimum offer the same or similar Hazard Risk Category (HRC) protection as the arc resistant structure but far exceeds the structure in the areas of equipment protection, uptime, reuse and others. GE presented this concept on the arc absorber to the IEEE Petroleum and Chemical Conference Technical Conference in September of 2009.

Refe R en C es

IEEE 1584 – Guide for Performing Arc-Flash Hazard Calculations

IEEE C37.20.7: “Guide for Testing Medium-Voltage Metal-Enclosed Switchgear for Internal Arcing Faults.”

Mark Clapper is a Specification Engineer for the Industrial Solutions division of GE Energy. He has 20 years of power distribution experience and holds a degree in electrical engineering from Michigan State University.

You can get older equipment to take advantage of new technology, with the EntelliGuard® TU trip unit. It improves arc flash protection, reducing the HRC level to 1 or 2, depending on available fault current.

Neat trick, isn’t it?

The EntelliGuard TU retrofits quickly and easily, too –via plug-and-play on legacy GE low-voltage breakers or with a kit for those from other manufacturers.

See for yourself. Call 1-800-431-7867 and press “2” for dedicated technical support. Email geelectrical@ge.com. Or visit geelectrical.com/industrial. You’ll be impressed.

EntelliGuard is a registered trademark of the General Electric Company.

This purpose of this paper is to demonstrate how to use COMTRADE records to test protective relays. COMTRADE records that have been captured by numerical relays and digital fault records during actual system events are of particular interest since these provide the ability to test protection for critical faults or disturbances such as an out-of-step condition that are hard to create using off the shelf test set software. Utilities and other customers can build a library of test cases.

d iffe R ential Relay o pe R ation du R ing tR ansfo R me R e ne R gization

The first example is the case of transformer differential protection operating during energization due to low second harmonic current content in the inrush current. This event was recorded by the numerical relay protecting a 400 MVA 230/115 kV autotransformer that was energized from the high side while the low side was open. The autotransformer is connected to a 230 kV straight bus through a motorized disconnect switch. The CTs are wye connected on both sides. The 230 kV CTs are on the transformer bushings connected with the full ratio (1200:5). Note that a tertiary winding feeds the station service load but does not have CTs connected to the bank differential.

Figure 1: Autotransformer Energization from High Side

This is an excellent case to use the COMTRADE record captured by the relay since you can test transformer differential protection to ensure it does not operate during inrush for many applications; that is most two winding transformers and autotransformer banks with five ampere rated CT secondary values on the high side.

Figure 2: High Side CT Secondary Fundamental versus 2nd Harmonic Current

Figure 2 shows there was very little restraint current and high magnitude differential current in B-phase during the transformer energization. The trip occurred when the ratio of B-phase 2nd harmonic to fundamental current dropped too low.

The relevant current phasors measured by the relay at the time of the trip along with the 2nd harmonic contents are listed to the right in Figure 3.

The numerical transformer differential relay that tripped uses internal zero-sequence current compensation to prevent unwanted operations during external ground faults, since the current transformers are connected wye and the transformer is an autotransformer bank.

Calculating the phase-to-phase current automatically eliminates zero-sequence current as follows:

I a = I1 + I2 + I0

Ib = a2 I1 + a I2 + I0

I c = a I1 + a2 I2 + I0

Iab

I

If the transformer differential relay uses phase-to-phase current to eliminate zero-sequence current then Ibc is the most depleted of 2nd harmonic content and also corresponds to the phase that actually tripped (B-Phase). Figure 5 illustrates the following:

• Ibc

• fundamental component

• 2nd harmonic content

• ratio of 2nd harmonic to fundamental

The ratio decreases in magnitude over the first two cycles following energization. The relay tripped at the point when the ratio dropped to 14 percent. Note that transformer differential relays are typically set to restrain at 15 percent.

Ratio = diff nd diff I I 2 100%

Figure 3: Current Phasors Measured at the Relay with 2nd Harmonic Current

Figure 4: Current 2nd Harmonic Restraint Logic

Figure 5: Current Phasors Measured at the Relay with 2nd and 4th Harmonic Current

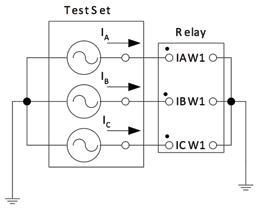

t est Requi R ements

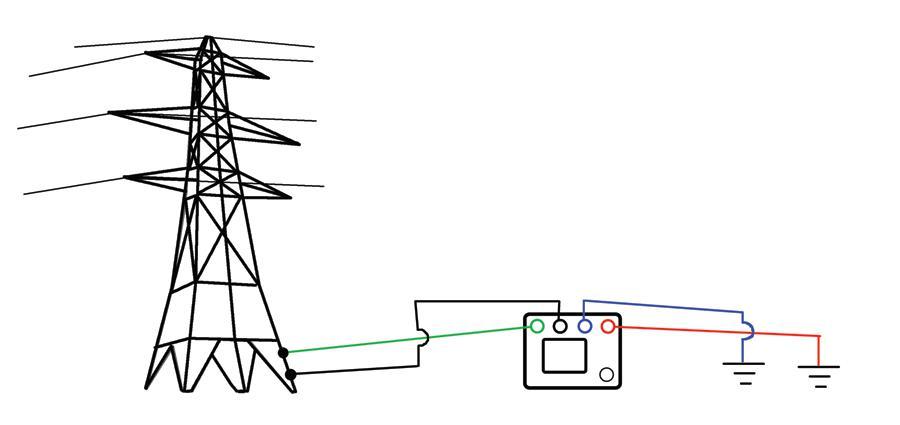

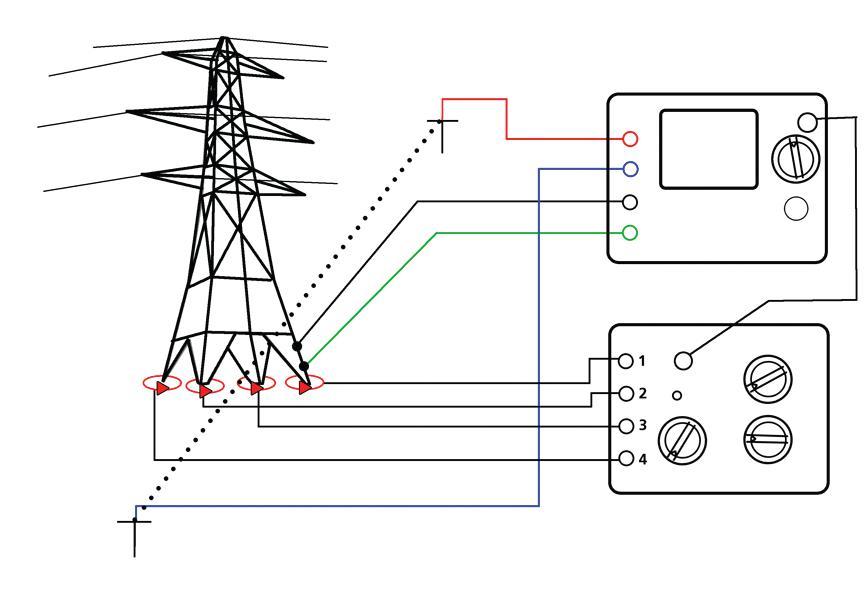

You will need a three-phase test set that can playback COMTRADE records. Three current channels are required. Connect the three-phase test set to the relay as shown in Figure 6A (See following page).

Figure 6B shows off-the-shelf software available to play back this particular COMTRADE record through the test set to the relay.

t est pR ocedu R e

1. First play back the inrush case to the relay with harmonic restraint disabled.

2. The relay should trip when harmonic restraint is disabled.

3. If the relay trips then play back the inrush case again with harmonic restraint enabled.

4. The relay should not trip when harmonic restraint is enabled. (See Figure 7)

a dvanced t est – a djusting the l evel of 2nd h a R monic c ontent