Megger, the first to bring you Dc insulation testing in 1890 now brings you the latest in Ac insulation with the DeLTA4000 Series, a fully automatic 12-kV insulation power/ dissipation factor test set.

n NEW built-in intelligent temperature correction (patent pending) allows you to estimate the actual temperature dependence on the test object.

n Generates own test signal independent of line frequency enabling a clean, reliable signal and the highest accuracy.

n Lightweight, rugged two-piece design with unit weights of 31 lb and 48 lb.

n Easily transportable and convenient for field use, yet built sturdy and robust.

Faster!

n Quick test times - dynamic noise suppression minimizes measurement time in situations with low interference.

n Advanced signal acquisition and noise suppression circuitry results in 25-50% shorter measurement times.

And More!

n PRIORITY ACCESS provides guaranteed support and other valuable services to ensure that you get the best out of your investment in Megger DELTA Power Factor Test Equipment.

n Accurate and repeatable measurement results with high noise suppression.

n Easy to use with automatic and manual operation.

Want to know more? To learn more about the new Megger DELTA4000 Series contact us today at 1 800-723-2861 or email us for a copy of our new 2011 Power catalog at: sales@megger.com. Megger 4271 Bronze Way Dallas, Texas 75237-1019 USA.

February 27 - March 1, 2012 Omni Fort Worth , Fort Worth, Texas

PowerTest 2012–

Join us February 27-March 1, 2012

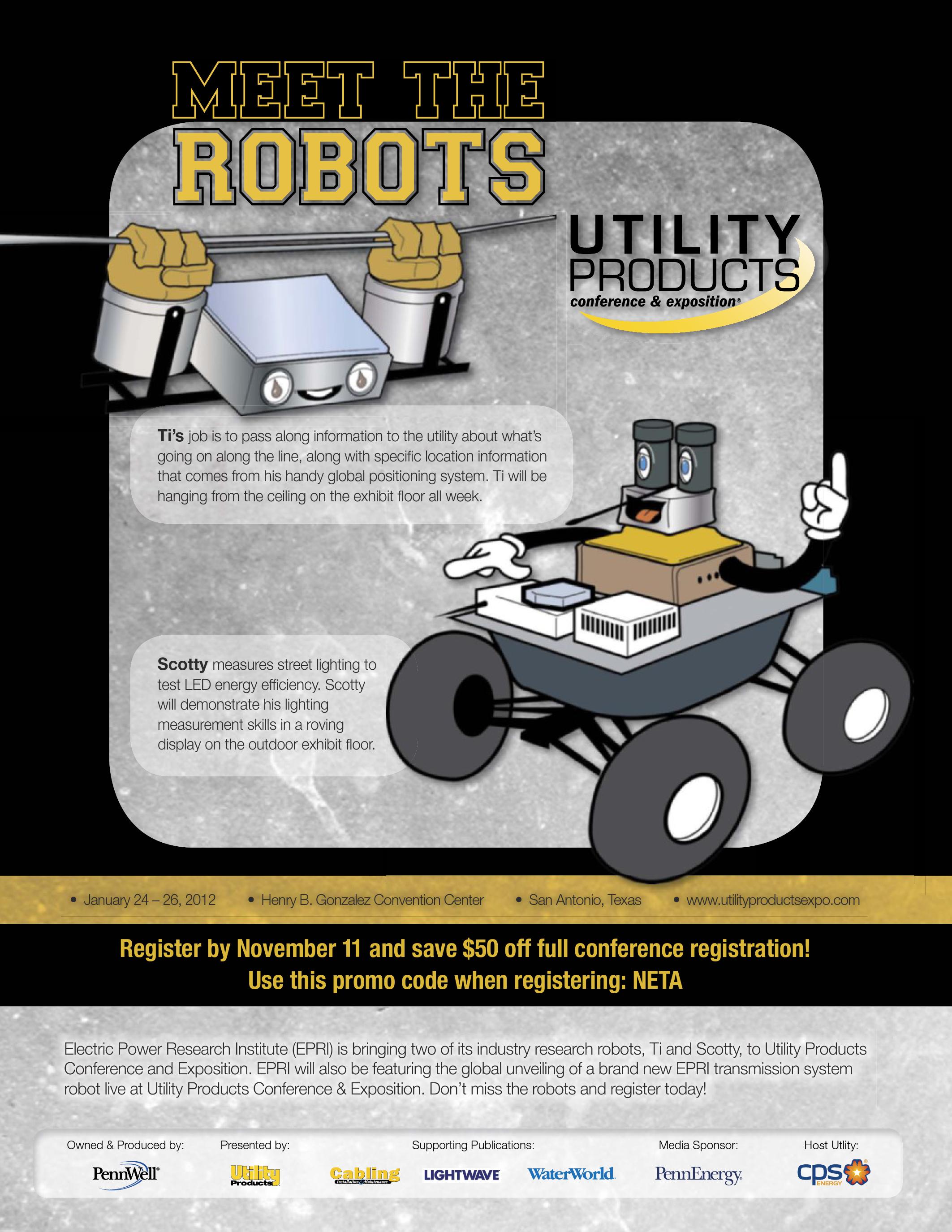

Electrical power system experts, technicians, managers, inspectors, contractors, engineers, manufacturers, operators, and industry leaders will ride into town to harness the power that comes from sharing knowledge, networking, and being a part of a community dedicated to promoting safety and reliability.

Our Keynote Speaker, notorious for packing the house

Featuring: Tim Autrey of Practicing Perfection Institute Driven by Passion. Devoted to Perfection. Human Error Reduction and Electrical Maintenance.

Monday -

We’ve rustled up the best presenters in the industry and staged a full day of 45-minute presentations that will expand your thinking and generate new ideas. Choose from 27 detailed technical presentations and participate in the Transformer Symposium.

• Safety Technical Tracks

• Reliability Technical Tracks

Life is not about how fast you run, or how high you climb, but how well you bounce Do it right or get off the horse.

Cowboy Wisdom:

• Equipment Technical Tracks

• Codes and Inspections Technical Tracks

• Rotating Equipment Technical Tracks

• Symposium - Transformers

Day Two:

Tuesday -

Heart of Texas

Step up and be heard. Join the PowerTest 2012 Safety Summit and be a part of the discussion. Up the ante by joining one of three other panel sessions during the morning gathering.

• Safety Summit

• Relays Panel

• Motors and Generators Panel

• Circuit Breakers Panel

In the afternoon you won’t want to miss the main event: PowerTest 2012 Tradeshow

Wednesday and ThursdayTwo days are dedicated to high power learning. Choose from 12 in-depth, four-hour seminars. The first-class lineup covers important industry issues that will broaden your horizon and expand your knowledge, preparing you to get a head-start on the challenges and opportunities ahead.

Sunday Evening – February 26, 2012

Fall in for the Best Little Pub Crawl in Texas – Four hours, four pubs, and endless fun. Be sure to sign up on-line when you register for the conference.

Welcome Reception:

Monday evening from 6:00 till the cows come home.

Put on your best bib and tucker and join the hootenany as we gather at the Dallas Cowboy Stadium. There’ll be a heap of tasty grub, plenty of socializing, dancing, and all around good fun.

Come bend an elbow and toast to NETA’s 40th Birthday during the Welcome Reception!

February 27 - March 1, 2012 Omni Fort Worth Fort Worth, Texas

Register on-line at: www.powertest.org

Or Call: 888-300-NETA (6382)

PowerTest 2012

Registration

Save time by registering on-line! Visit www.powertest.org to view the full conference lineup and submit your registration.

Hotel Reservations:

Omni, Fort Worth Hotel

1.817.535.6664

1300 Houston Street Fort Worth, TX 76102

Reservation Deadline:

January 23, 2012

Group Name: NETA/PowerTest Group Rate: $185.00

Payment:

NETA accepts all major credit cards. Save time and register on-line at www.powertest.org or Call 888-300-NETA (6382)

Join as a Gold Affiliate for $775 and your PowerTest conference registration is included!

Current Affiliates can upgrade to Gold Affiliate status for only $600 to receive a free PowerTest conference registration! Extras!

• NEW! – Tuesday Evening Hospitality – A gang of PowerTest 2012 Sponsors will circle the wagons, each hosting a suite featuring their own brand of hospitality.

• PowerTest 2012 Technical Papers - Registered conference attendees will receive all PowerTest technical presentations on a USB drive on site in their registration bag.

1. Go to www.powertest.org and review the complete PowerTest 2012 on-line brochure.

2. Decide the number of days you will attend the conference.

3. Tuesday attendees select up to two panels. (Cost of panels included in registration fees)

4. Wednesday attendees sign up for one or two seminars. (Cost of seminars are in addition to the registration fees)

5. Thursday attendees sign up for one or two seminars. (Cost of seminars are in addition to the registration fees)

6.Sign up for the Best Little Pub Crawl in Texas. Space is limited, so register early. (Cost of pub crawl is in addition to the registration fees)

7. Sign up for Spouse/Guest Passes (Cost of passes is in addition to the registration. fees)

8. Sign up for PowerTest 2012 conference polo shirt and select size. (Cost of polo shirts are additional to the registration fees)

February 27 - March 1, 2012

By Tony McGrail – Doble Engineering

By Tony McGrail – Doble Engineering

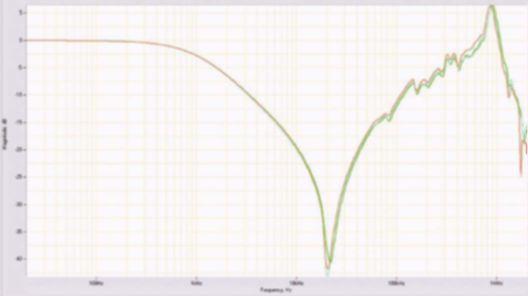

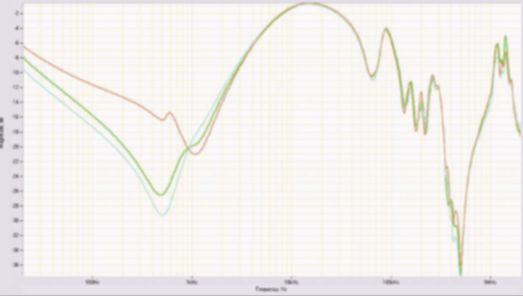

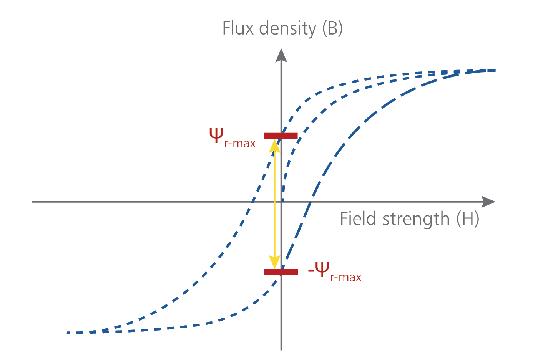

Excessive temperatures both cold and hot, rain, snow and other ambient conditions can make the evaluation of electical equipment difficult. This issue will examine problems such as power factor/dissipation factor test results of equipment having temperatures

Vicki Warren and Greg Stone, Iris Power, LP

Kyle Springinatic, Magna Electric Corp.

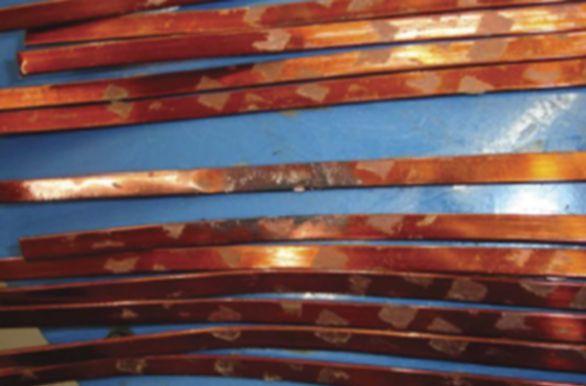

Insulation

From big cit y to small town, east to west, Nor th America to Europe, we are expanding our resources and ser vice center locations to better ser ve you.

Contac t Shermco Industries for safe, reliable testing, repair, professional training, maintenance and analysis of rotating apparatus or elec trical power distribution systems for all market segments, including industrial, commercial, petrochemical, utilities and more.

3050 Old Centre Avenue, Suite 102

Portage, MI 49024

Toll free: 888.300 NETA (6382)

Phone: 269.488.NETA (6382)

Fax : 269.488.6383

neta@netaworld.org

www.netaworld.org

EXECUTIVE DIRECTOR: Jayne Tanz, CMP

NETA Officers

PRESIDENT: Mose Ramieh, Power & Generation Testing, Inc.

FIRST VICE PRESIDENT: David Huffman, Power Systems Testing Co.

SECOND VICE PRESIDENT: Ron Widup, Shermco Industries

SECRETARY: Walt Cleary, Burlington Electrical Testing Co., Inc.

TREASURER: Ken Bassett, Potomac Testing, Inc.

NETA Board of Directors

Ken Bassett (Potomac Testing, Inc.)

Scott Blizard (American Electrical Testing Co., Inc.)

Jim Cialdea (Three-C Electrical Co., Inc.)

Walt Cleary (Burlington Electrical Testing Co., Inc.)

Roderic Hageman (PRIT Service, Inc.)

Kerry Heid (Magna Electric Corporation)

David Huffman (Power Systems Testing)

Alan Peterson (Utility Service Corporation)

Mose Ramieh (Power & Generation Testing, Inc.)

John White (Sigma Six Solutions)

Ron Widup (Shermco Industries)

NETA World Staff

TECHNICAL EDITOR: Roderic L. Hageman

ASSOCIATE EDITOR: Diane W. Hageman

MANAGING EDITOR: Jayne Tanz, CMP

ADVERTISING MANAGER: Jill Howell

DESIGN AND PRODUCTION: Newhall Klein, Inc.

NETA Committee Chairs

CONFERENCE: Ron Widup; MEMBERSHIP: Ken Bassett; PROMOTIONS/MARKETING: Kerry Heid; SAFETY: Lynn Hamrick; TECHNICAL: Alan Peterson; TECHNICAL EXAM: Ron Widup; WORLD ADVISORY: Diane Hageman;

CONTINUING TECHNICAL DEVELOPMENT: David Huffman; TRAINING: Kerry Heid; FINANCE: John White;

NOMINATIONS: Alan Peterson; STRATEGY: Mose Ramieh; AFFILIATE PROGRAM: Jim Cialdea

© Copyright 2011, NETA

NETA World is published quarterly by the InterNational Electrical Testing Association. Opinions, views and conclusions expressed in articles herein are those of the authors and not necessarily those of NETA. Publication herein does not constitute or imply endorsement of any opinion, product, or service by NETA, its directors, officers, members, employees or agents (herein “NETA”).

All technical data in this publication reflects the experience of individuals using specific tools, products, equipment and components under specific conditions and circumstances which may or may not be fully reported and over which NETA has neither exercised nor reserved control. Such data has not been independently tested or otherwise verified by NETA.

NETA MAKES NO ENDORSEMENT, REPRESENTATION OR WARRANTY AS TO ANY OPINION, PRODUCT OR SERVICE REFERENCED OR ADVERTISED IN THIS PUBLICATION. NETA EXPRESSLY DISCLAIMS ANY AND ALL LIABILITY TO ANY CONSUMER, PURCHASER OR ANY OTHER PERSON USING ANY PRODUCT OR SERVICE REFERENCED OR ADVERTISED HEREIN FOR ANY INJURIES OR DAMAGES OF ANY KIND WHATSOEVER, INCLUDING, BUT NOT LIMITED TO ANY CONSEQUENTIAL, PUNITIVE, SPECIAL, INCIDENTAL, DIRECT OR INDIRECT DAMAGES. NETA FURTHER DISCLAIMS ANY AND ALL WARRANTIES, EXPRESS OF IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

ELECTRICAL TESTING SHALL BE PERFORMED ONLY BY TRAINED ELECTRICAL PERSONNEL AND SHALL BE SUPERVISED BY NETA CERTIFIED TECHNICIANS/ LEVEL III OR IV OR BY NICET CERTIFIED TECHNICIANS IN ELECTRICAL TESTING TECHNOLOGY/LEVEL III OR IV. FAILURE TO ADHERE TO ADEQUATE TRAINING, SAFETY REQUIREMENTS, AND APPLICABLE PROCEDURES MAY RESULT IN LOSS OF PRODUCTION, CATASTROPHIC EQUIPMENT FAILURE, SERIOUS INJURY OR DEATH.

As I contemplated what to write in my first message I reviewed the changes that have occurred over the last few years and now look to the future with excitement about what we are doing and the impact it will have, not just on NETA, but the entire electrical industry.

With our new marketing campaign, the emphasis is shifting from NETA being a standards developer and certifier of electrical technicians to the promoting of NETA Accredited Companies (NAC). In the past NETA pushed for inclusion of the ANSI/NETA ATS and MTS to be written into specifications throughout the electrical industry. Our added emphasis, as those of you saw in the presentation at the February member meeting, is now for use of NETA Accredited Companies to perform the testing. The new look of the NETA logo, NETA World and other publications is just the first step in changing how we look in the market place. Many hours and much thought have gone into our approach on how we go to market. Sincere thanks are due the NETA staff and the Marketing and Promotions Committee.

This issue’s emphasis is weather-related testing. By the time you read this,

This issue’s emphasis is weather-related testing. By the time you read this, the hot, humid days of summer will have started to turn into warm days and cool nights. In the southeast and elsewhere this is a prime time for outdoor substation maintenance. However, soon we will be in the throes of winter and, of course, all the problems related to outdoor work and testing complications. We should all become aware of the personnel safety issues and the special problems that come with any weather condition. By reading this issue we should all be better prepared for whatever Mother Nature throws at us.

As you read this issue, if you see an area that has been missed or could use expansion, your input with articles will be appreciated by all our members. With a call to the NETA office you can find out the themes of future issues and submit articles on those subjects. Remember NETA’s best resource is our volunteers.

As President I will do my best to continue the evolution of NETA and work to make it a more valuable asset to all member companies. Thanks to all for your support.

Mose Ramieh NETA President

NETA is pleased to announce a new classification of accredited organization, the NETA Approved Military Organization (NAMO). Because all other accredited organizations are companies, this classification is unique and extends the reach of NETA by providing select United States military organizations with the opportunity to gain recognition as NETA-accredited organizations as well as an avenue through which active military personnel can become NETA Certified Technicians.

The creation of the NAMO classification was born out of the desire to recognize the United States military’s support of the NETA philosophy and ideology that adherence to voluntary standards, continuing education, and certification of technicians is necessary to ensure the highest standards of performance and personal safety of electrical testing technicians.

In conjunction with this announcement, NETA welcomes its first NAMO, the U.S. Army 249th Engineer Battalion (Prime Power) out of Fort Belvoir, Virginia. Chief Warrant Officer Four (CW4) Michael Richards, Senior Power Systems Technician for Prime Power approached NETA in the fall of 2010 about the possibility of obtaining NETA accreditation for the 249th and certification for their individual active members. Along with CW4 Phillip Mowatt and First Sergeant Derek Harvin, CW4 Richards presented his case for Prime Power to an ad hoc collection of NETA board members at PowerTest 2011, describing the activities of the 249th, how their mission is in line with NETA’s, and why a new NETA classification for military organizations would be beneficial to NETA as well as the army and its soldiers.

CW4 Richards’ motivations for seeking accreditation for Prime Power and certification for his soldiers were clear from the outset and based primarily on the fact that the army wants its members to perform to the highest possible standards. Richards believes that the path to excellence lies in standardization of practices, education and certification of individuals, and most importantly, recognition that the structure that supports these individuals in

the field at home and abroad is one that assures the highest level of service. He is strongly backed by his commanding officer, Lieutenant Colonel Matthew Tyler, and by his fellow soldiers who are eager to be recognized for their accomplishments as soldiers of the 249th.

Richards believes that NETA Certified Technicians meet the OSHA requirement that qualified individuals perform all electrical testing and maintenance. This belief is based on the fact that NETA’s certification program follows the structure set forth in the ANSI/ NETA Standard for Certification of Electrical Testing Technicians, which clearly establishes the framework for ensuring that certifying bodies for electrical testing technicians are of the highest caliber. This document clearly defines the minimum requirements for qualification and certification of electrical testing technicians, for training and experience required for each level of certification, and for an independent and impartial certifying body.

Similar to NETA’s historical emphasis on quality at both the company and individual level, CW4 Richards believes that the personal growth of its individual soldiers is as important to the mission of the 249th as the overall achievements of the organization itself. Richards embraces the army’s philosophy that a soldier is better when given personal goals to achieve, especially when those goals include professional development that will serve them throughout their military careers and beyond. NETA Accredited Companies have long sought out soldiers from the 249th because of their experience and because, as Richards states, “Soldiers are team players,” a characteristic appreciated by all. He knows that any company seeking a testing technician will welcome one who comes with NETA certification in hand.

“The path to excellence lies in standardization of practices, education and certification of individuals, and most importantly, recognition that the structure that supports these individuals in the field at home and abroad is one that assures the highest level of service.”

~CW4 Michael Richards~

Members of NETA’s Ad Hoc Committee on NAMO had the honor of attending an event at the U.S. Army Prime Power School at Fort Leonard Wood, Missouri, in June of 2011. Committee members toured the state-of-the-art facility where soldiers entering the 249th begin their careers as Prime Power Production Specialists. The education is rigorous, demanding that these individuals perform at

the highest mental and physical levels. Soldiers must learn how to install, operate, and maintain every piece of equipment within the medium-voltage power systems they deploy. They are also required to learn the electrical theory that applies to their operations so that technicians who encounter foreign or older pieces of equipment are able to effectively utilize those assets to complete their missions. This rich history of the army engineer is chronicled in the U.S. Army Engineer Museum, one of the three museums housed at Fort Leonard Wood.

As the group toured the exhibits, CW4 Richards described how he always impresses upon each soldier the importance of history and tradition. He poses the question “If you don’t know where you came from and how you got where you are today, how can you be sure you are heading in the right direction?” Richards is incredibly proud to bear the standard of the 249th and of his predecessors who paved the way for the soldiers who serve today. As he made his way among shadowy displays from the American Revolution, the War of 1812, the Civil War, the Korea War, World War I, World War II, the Vietnam War, and the Cold War, he wondered aloud what it might have been like to have been at those conflicts. He paused near the exit, before a large color photograph of a group of soldiers heaving cables up from a bombed-out bridge in Baghdad, Iraq. “That’s us,” he stated quietly, almost to himself, the weight of his words heavy with a sense of pride.

Alan Peterson, President of NETA Accredited Company Utility Service Corporation and NETA’s Technical Chair, states, “NETA is extremely gratified to receive recognition from the United States military for our certification program. Those of us that are involved with this line of work on the civilian side have a vast amount of

respect for military men and women who serve in the same roles that we do.” Mr. Peterson continues, “Throughout the process of developing this new program, the 249th was adamant that it was an association with NETA that was as important as the seal of certification itself. That speaks volumes for NETA and the quality of the individuals who hold NETA Certification.”

This new relationship between NETA and the military will be beneficial to those directly involved in the program and will touch lives around the globe, both military and civilian, by improving safety, reliability, and power quality. With the addition of the 249th as the first of what we hope will be a number of military organizations in the future, NETA strives to continue its mission of Setting the Standard.

“Throughout the process of developing this new program, the 249th was adamant that it was an association with NETA that was as important as the seal of certification itself. That speaks volumes for NETA and the quality of the individuals who hold NETA Certification.”

~Alan Peterson~

•

•

•

•

•

The words “technical support” may conjure images of waiting on hold for what seems like days, hoping the technician on the other end offers something other than, “turn it off, wait thirty seconds, and turn it back on.” At NETA, this term has a much more positive connotation. Thankfully, NETA volunteers make themselves available for hundreds of hours every year ensuring that NETA’s technical community receives the support it deserves. Two of these committees are the Exam Committee and the Standards Review Council.

The NETA Exam Committee has invested a large amount of time and energy in the review, revision, and enhancement of the NETA Certification Exam over the past year and a half. Under the direction of the NETA Standards Review Council, the Exam Committee was charged with stepping-up the routine review of questions to a complete review of all questions at Levels II, III, and IV. The review examined each question for technical relevance, psychometric structure, technical references, and placement within the exam to assure that each specific competency is given equal difficulty and weight within the examination.

This rigorous attention to detail and the broad scope of material covered is what sets the NETA Certification Exam apart and is why NETA Certification is sought by technicians, employers, and end users alike. The goal of this review is not to make the exam more difficult, but to ensure that the same level of quality technician exists today as has since the inception of the certification program years ago as outlined by the ANSI/NETA Standard for Certification of Electrical Testing Technicians, a document whose scope encompasses not only the competencies of individual technicians, but also contains requirements for bodies offering electrical testing-specific certification. Currently, NETA is one of two bodies that offer certification that meets the ANSI/NETA ETT requirements, with the Electrical Testing Technician Certification Institute being the other.

During the 2011 April Exam Committee meeting, more progress was made with the review of the exam bank and new question generation. The committee plans to reconvene in November of 2011 to continue their work.

NETA was founded on technical accuracy and excellence of service. NETA looks to the NETA Standards Review Council to assure that each piece of information published and distributed by NETA is as technically accurate as possible. The Standards Review Council, or SRC, is a body of eight individuals appointed by the Technical Chair. These individuals are proven leaders when

it comes to technical knowledge as well as people who understand the history of the testing industry, leveraging that knowledge with each project.

Meeting twice a year and keeping in touch via email and conference calls allows members of the SRC to manage the technical business of the association. They are responsible for overseeing and maintaining the three ANSI/NETA Standards, directing and assisting the Exam Committee, overseeing the outside technical representation to other industry associations like IEEE, ICC, and NFPA, balloting on industry standards on behalf of NETA, and providing technical support for users of the ANSI/NETA Standards whether they be NETA Accredited Companies or members of the industry at large.

These volunteers met most recently in Dallas, Texas, this past May to continue the review of the ANSI/NETA Standard for Acceptance Testing Specifications for Electrical Power Equipment and Systems, a revised edition that will be published in 2013. They also discussed other technical items such as direction for the NETA Safety Committee, technical inquiries, and Article 230.95(C) of the National Electrical Code. So, if you ever wondered who answers all of your technical questions when you call or email the NETA office or where the ANSI/NETA standards come from, now you know!

the test equipment answer

■ Secondary Injection Test Sets

ABB

Cutler Hammer

Eaton

GE

Merlin Gerin

Satin American

Siemens

SureTrip

Utility Relay

Westinghouse

■ High Current Test Sets from 500A to 60,000A

■ Low Resistance Ohmmeters and Insulation

Resistance Analyzers

888.902.6111

972.317.0479

info@intellirentco.com

www.intellirentco.com

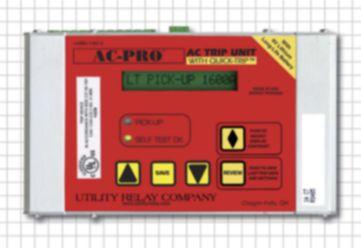

❏ Over 1000 different kits

❏ Microcontroller based, true RMS and 16-character display

❏ All functions included: LT, ST, Instantaneous, GF, Phase Unbalance, QT-GF and QT-Inst with off setting for all (except LT & QT-Inst)

❏ Intuitive programming and easy retrieval of last trip data

❏ 3 Different types of actuators available

❏ Modbus communications available

❏ Quick-Trip™ for arc flash reduction during maintenance

❏ UL and CE labels

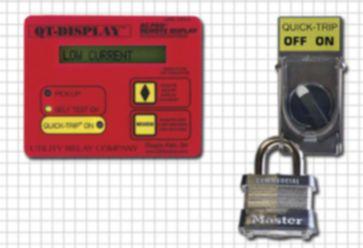

❏ Over 95 different kits

❏ Microcontroller based with 16-character display

❏ Provided with Hall Effect transducers or optionally accepts a 50mV or 100mV shunt input

❏ All functions included: LT, ST, Instantaneous, GF, Reverse Current, QT-GF and QT-Inst with off setting for all (except LT & QT-Inst)

❏ Modbus communications available

❏ Now available with Quick-Trip for arc flash reduction during maintenance

❏ Reduces Arc Flash Hazard during maintenance

❏ The QT-Instantaneous and QT-GF settings are fully adjustable

❏ Easy to install

❏ AC-PRO trip units are Quick-Trip ready and only require the addition of a Quick-Trip Display and a lockable QT ON/OFF selector switch

❏ ZERO-Hertz trip units are now available with Quick-Trip and only require the addition of a lockable QT ON/OFF selector switch with integral indicating light

❏ Provides arc flash reduction during maintenance per 2011 NEC Article 240.87

❏ Plug-in direct replacement for Merlin Gerin & Square D Masterpact MP, IEC or UL rated breakers

❏ User programmed to replace the STR-18M, 28D, 38S or 58U trip units

❏ Same protective functions, settings and time-current-curves as the original STR trip unit

❏ Information and alarm functions are standard

❏ No physical rating plug required

❏ Easy to read OLED display in low or high ambient light

❏ A security code protects against unauthorized changes to settings

❏ Trip events are time and date stamped

❏ USB port and secondary injection test port

❏ Quick-Trip for arc flash reduction is built in, nothing additional is required

Founded in 1972, NETA has seen nearly forty years of activity in service to the electrical testing industry. This organization remains firmly rooted in the established traditions of quality and excellence of service that got things started so many years ago. The number of NETA Accredited Companies and Affiliates has climbed steadily over the years, and NETA’s family tree is still growing strong.

NETA invites you to join in celebrating the 40th Birthday of this great organization. As preparations begin for the 40th Birthday Celebration at PowerTest 2012, we welcome the submittal of your anecdotes, photographs, and memories of how being involved with NETA has made a positive impact on your career, your company, or your life. During 2012, a collection of subscriber submittals will be published in each quarterly issue, starting this winter.

BY TONY MCGRAIL, Doble Engineering

BY TONY MCGRAIL, Doble Engineering

Apparatus testing in poor and/or extreme weather conditions presents several challenges –access to equipment, safety, and setting up the equipment under test so as to provide useful results. is paper looks at some individual case studies which demonstrate the precautions needed and the “Do’s and Don’ts” of such testing.

In general, any outdoor activity in bad weather constitutes a risk and should not be performed without a thorough risk assessment and appropriate authorization. A severe risk is posed by lightning. Doble Engineering does not recommend testing in any situation where lightning is a present or an imminent threat.

Before we start testing, are there reasons to suspect the equipment may be in poor condition? If not – can the testing be deferred? If there are, then the motivation for testing is based on suspicions in regard to the equipment condition, and we must use that knowledge to guide us toward the tests to be performed and subsequent interpretation of test results.

Poor weather will affect results through temperature and through contamination of the test object with water, ice, snow, etc. Lower temperatures will affect the inductance, capacitance, and resistance directly, but will also lead to water crystallization in dielectric material. The ice crystals will affect results and may lead to erroneous conclusions.

In situations where the equipment, say a power transformer, has recently been switched out of service, it is likely still warm; therefore, testing should be planned to take place before it has significantly cooled down. As long as appropriate safety measures are taken, valid test results should be obtained.

Different tests will be affected by poor weather in different ways.

Power Factor – Surface contamination and low temperatures may affect both the current and watts losses, giving either overly pessimistic or overly optimistic power-factor results. Care should be taken to include test guards and in interpretation of results in low temperatures.

Capacitance and DC Resistance – These tests should not be significantly affected by temperature or surface contamination, but this will depend on the level of contamination and the temperature change. DC resistance should decrease with lower temperatures – but the effect may be masked through connection and contact resistances and appropriate correction curves should be used.

Sweep Frequency Response Analysis – This test relies on inductance-capacitance combinations to produce resonances to a low-voltage ac signal. Impulse tests used to produce a frequency response may be very susceptible to temperature and surface contamination issues while sweep systems are relatively immune, unless the surface contamination is extreme.

Leakage Reactance – This is a high current test which may be significantly affected by surface contamination but much less affected by temperature variations.

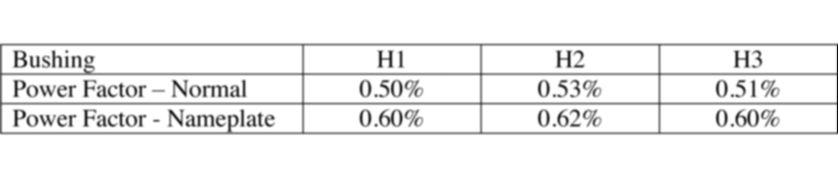

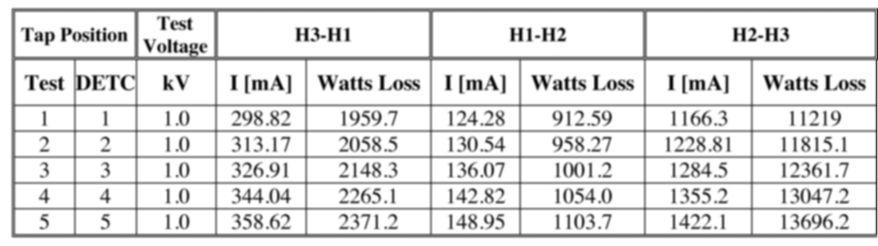

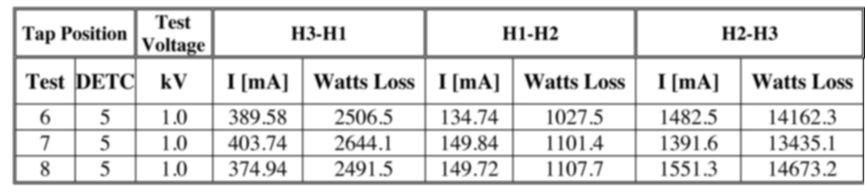

Three high voltage General Electric type U bushings were tested in a large, oil-filled, power transformer during a winter storm that had snow, ice, and freezing rain as part of the weather conditions. The transformer was tested with the oil temperature well below freezing. The three bushing temperatures were also below freezing when tested.

TABLE 1:

Power Factors Measured in Freezing Conditions

The test results for the transformer’s power-factor overall winding tests were not acceptable for service, with power-factor values greater than 1.0 percent for low-voltage and high-voltage windings (CL & CH). Bushing power-factor values, the C1 test as given in Table 1, were also higher than acceptable for in-service bushings of this type.

TABLE 2:

Power Factors Measured in Normal Conditions

Inverted C1 test values for the bushings were comparable to the standard C1 test values which indicated the high C1 power factor-values were attributed to the bushing’s internal main core insulation and not being influenced negatively by exterior conditions. Such testing is very useful to further determine the impact of surface contaminants on results.

The transformer was warmed up and all bushing surfaces were dried. The power-factor tests were performed a second time and the transformer overall power factor improved significantly. The bushing C1 test values remained at the higher than acceptable test value that was obtained in the previous test. The bushings were tented, and heat was applied to warm the bushings above freezing. After several hours of heating, the bushings were again tested and all of the C1 and inverted C1 power-factor values were within 0.1 percent of the nameplate value, as shown in Table 2.

TABLE 3:

Test Results in High Humidity, Damp Conditions

The results above freezing are significantly improved and demonstrate the susceptibility of such test results to temperature. Interpretation of such results requires an understanding of the impact of surface contaminants and of temperature on the test process and the results themselves.

Bushing temperature studies performed by Doble have shown that GE, type U bushing C1 powerfactor value is influenced by temperature. When this type of bushing is tested below freezing, the power factor values increase and level off to an elevated value above the recorded nameplate value. This change in power factor with temperature was seen in both a known good bushing and a known defective bushing.

Doble Engineering provides temperature correction tables which begin at 0°C.

In this case, a power transformer was tested in high humidity, over 94 percent, with onshore ocean breezes simultaneously bringing aerosol moisture to the unit. Overall test results are given in Table 3.

Both high-voltage and low-voltage winding power factors (CH and CL) are higher than normal, while the interwinding power factor (CHL) is acceptable. This type of variation is an indication of possible surface contamination effects as the interwinding insulation test does not include ground path losses as part of the measurement.

The same transformer was tested later on the same day. Winds were now offshore, bushings were cleaned and dried, and the sun had warmed the porcelain which helped to remove any remnant moisture accumulated before retesting the bushings. Test results are given in Table 4.

Under the same test regime, the mA results have not changed greatly, but the watts loss results have reduced substantially, reflecting the surface contamination impact. CHL has not changed significantly, but the values of CH and CHL have come within expected ranges for a new transformer and are acceptable.

The drying of bushings has produced acceptable CH and CL values, as expected.

In this case a 230/72 kV 50/67/83 MVA power transformer had come out of service after a lowvoltage bushing failure. The bushing was replaced and the transformer cleaned internally. A range of tests was performed to ensure the integrity of the transformer had not been compromised prior to reenergization. Leakage reactance results had not been taken for the unit since factory tests, and sweep frequency results were taken for the first time. The transformer is pictured in Figure 1.

With appropriate precautions, the following tests were performed:

• Bushing C1 and C2 and power-factor measurements

• Winding power-factor and capacitance

• HV single-phase excitation

• DC winding resistance

• Turns ratio

• Sweep frequency response analysis

• Leakage reactance

Everything was acceptable except for anomalous leakage reactance measurements which indicated a variation that was not seen in the sweep frequency response analysis measurements. Leakage reactance responses which included the tertiary winding showed an anomaly, indicating variation on one phase.

By ensuring that the test object had been suitably cleaned and prepared, there was sufficient support for the integrity of the measurements for a cause of anomaly to be found within the transformer. This was eventually traced to two CT shorting blocks which had both, in fact, not been shorted and which thus showed as extra burden on the leakage reactance results.

In this case good test practices allowed for reliable results and subsequent analysis which identified the cause of the anomaly within the transformer.

When power-factor testing in subzero conditions, water or moisture in the apparatus could condense and freeze. This will alter the overall dielectric condition, affecting the test results, typically reducing the watts loss, and subsequently yielding lower power-factor values. This may give the false impression of an improvement in the overall condition of the insulation system! Care should be taken when testing in freezing conditions to make sure the context and interpretation of results are clear and understood.

Can power-factor tests be performed on apparatus which is at a temperature above freezing but when the ambient is below freezing? Yes! Again, care must be taken and there are correction curves available to reference test results to standard temperatures.

There are clear risks when testing in rain or snow that are associated with safety. They include electrocution and slip and trip hazards. The variation in surface leakage impedances will mean that power-factor and related measurements will be compromised as watts loss will rise as the ground path capacity increases. High humidity may have the same effect. However, sweep frequency response analysis measurements and dc resistance measurements should be relatively unaffected and may be performed unless the surface contamination yields a short circuit across the surface. Addition of a collar to the testing regime may yield further information about the state of the insulation and thus aid in diagnoses.

It is important when testing in poor or unfavorable weather to understand both the motivation for test and the likely impact of the adverse weather on actual test results. In terms of motivation, we must consider what we expect to find – are there reasons to suspect the integrity of the apparatus under test? In terms of interpretation of results, we must consider the individual test made and the likely impact of adverse conditions on those results and thus the interpretation of those results.

The author would like to thank his colleagues at Doble Engineering, including Long Pong, Manuel Salmeron and Marshall Turley, for their thoughtful comments and contributions.d.

Tony McGrail is presently the Doble Engineering Solutions Manager for On-Line diagnostics, providing condition, criticality and risk analysis for utility companies. Previously Tony has spent over 10 years with National Grid in the UK and the US; he has been both a substation equipment specialist, with a focus on power transformers, circuit breakers and integrated condition monitoring, and has also taken on the role of substation asset manager and distribution asset manager, identifying risks and opportunities for investment in an ageing infrastructure. Tony is a Fellow of the IET, a member of the IEEE and the IAM, is currently chair of the Doble Client Committee on Asset and Maintenance Management and a contributor to SFRA and other standards at IEEE, IEC and CIGRE. His initial degree was in Physics, supplemented by an MS and a PhD in EE and an MBA. Tony is an Adjunct Professor at Worcester Polytechnic Institute, MA, leading courses in power systems analysis.

•

•

•

•

•

•

•

•

•

•

With substations regularly overloaded and equipment often near the end of its life, electric grid operators are challenged to improve overall system reliability. Our mission is to provide our clients with actionable information that can be used to better manage the overall life cycle of their critical electrical assets in a manner that is convenient, easy to understand, and assists in critical decision-making.

WEIDMANN DIAGNOSTIC SOLUTIONS INC. provides the vital knowledge you need to help you lower risk and improve your electrical system’s reliability. We provide actionable information through our extensive range of diagnostic products and services.

WEIDMANN DIAGNOSTIC SOLUTIONS INC. is a leader in developing condition assessment methods for transformers and all oil-lled electrical equipment, such as OCB’s, LTC’s, regulators, rectiers, and network units.

• Analytical Testing Services

• Specialized Diagnostic Programs

• Engineering Diagnostic Evaluations

• Engineering Consulting Services

• AIM 2.0 Customer Information Portal

• Education Services

• InsuLogix® Monitoring Products

WEIDMANN DIAGNOSTIC SOLUTIONS INC.

One Gordon Mills Way, PO Box 799, St. Johnsbury, VT 05819-0799, USA

T +800 811 2284, +916 455 2284, F +916 455 0191, www.weidmann-electrical.com

A Member of the WICOR Group

While other manufacturers develop new sets, the Mentor will continue to EVOLVE meaning that you will always have the state of the art testing abilities.

FIELD UPGRADABLE

Need more power or ready to add GPS? No Problem! The Mentor is ready to go in minutes with Plug-n- Play.

If your Mentor needs attention, no need to send it anywhere, SMC will handle it on the spot. Noram-SMC Inc. Tulsa, OK 74155 Contact us today! Call 918-622-5725

Surveys have shown that rotor and stator winding failure account for about half of motor failures in motors rated 2300 volts and above. Thus to improve motor reliability and move to predictive maintenance for motors, tools are needed to assess the condition of the windings. There are several old and new test methods that have gained popularity with ac induction motor maintenance specialists. Stator winding tests are usually performed to detect problems within the electrical insulation. Rotor winding tests are todetect broken rotor bars and air-gap eccentricity.

These include:

• Low- and high-voltage insulation resistance

• Capacitance and capacitive impedance

• Inductance and inductive impedance

• Surge testing

• Partial discharge testing

• Current-signature analysis

The insulation-resistance, surge, partial-discharge, and currentsignature tests are examined and evaluated for effectiveness, for which windings or types of machines the test is effective, limitations, ease of performance, ease of interpretation, and the impact of the ambient environment on the test results.

Typically, large squirrel cage induction motors (greater than a few hundred horsepower) last 20 years or more during normal operation in utility and industrial applications before either the rotor or stator windings need to be replaced. However, if the motor is overloaded or subjected to a polluted

environment, or the motor is not well made, failure may occur in just a few years due to premature aging. A number of tests and monitors are available that can detect aging problems that may lead to failure, quite often months or even years before failure occurs. These tests, when properly done, can all but eliminate unexpected in-service winding failures and thus, increase process reliability.

Tests can be separated into two main classes:

• Off-line tests

o Performed during a shutdown (insulation-resistance test, motor circuit analysis, surge test, high potential test, growler test, visual inspection)

o Tests produce abnormal operating stresses and are highly influenced by ambient conditions

• On-line monitoring

o Performed during normal operation of the motor (current-signature analysis and partial-discharge monitoring)

o Identify motors that are most in need of off-line tests or repairs

o Tests performed under normal operating conditions with minimal influence from ambient conditions

Four of the most useful tests to assess rotor and stator winding conditions for motors rated 2300 volts and above are described in this paper: insulation resistance, partial discharge, surge, and current-signature analysis tests.

The megohmmeter test is the most widely used diagnostic instrument for motor stator and rotor windings. This test successfully locates pollution and contamination problems in windings. In form-wound stators using thermoplastic insulation systems (usually made before 1970), the tests can also detect thermal deterioration as long as the awareness of hygroscopic systems is considered. Unfortunately, there is no evidence that thermal deterioration or problems such as loose coils in the slot can be found in modern windings.

Insulation resistance (IR) and polarization index (PI) tests have been in use for more than 70 years. Both tests are performed with the same instrument, and are usually done at the same time. IEEE 43-2000 describes the test method and basic interpretation. In the test, a relatively high dc voltage is applied between the winding copper and the stator or rotor core (usually via the machine frame). The IR/PI test is now recommended to be performed with voltages that are higher than those suggested in the past, because tests at higher voltages are more likely to find major defects such as cuts through the insulation in the endwindings.

The IR test measures the resistance of the electrical insulation between the copper conductors and the core of the stator or the rotor. Ideally this resistance is infinite, since the purpose of the insulation is to block current flow between the copper and the core. In practice, the IR is not infinitely high. Usually, the lower the insulation resistance, the more likely it is that there is a problem with the insulation.

PI is a variation of the IR test. PI is the ratio of the IR measured after voltage has been applied for ten minutes (R10) to the IR measured after one minute (R1), i.e.: PI = R10/R1 (Other ratios are described in IEEE 43-2000.)

A low PI indicates that a winding may be contaminated with oil, dirt, insects, etc., or soaked with water. The current flowing in the circuit is then measured.

Measuring R1 has proved to be unreliable, since it is not readily trended over time. The reason is that IR is strongly dependant on temperature, and results will swing wildly due to humidity effects, especially in the presence of conductive contamination. Although some temperature correction graphs and formulae are in the IEEE 43, they are unreliable for extrapolation by more than 10°C or so, and are never useful when trending test results taken when ambient conditions are both above and below the dew point.

The PI test was developed to make interpretation less sensitive to temperature. Experience shows that if the PI is about one for stator windings, then the leakage current over the winding is large enough that electrical tracking will occur, which is a condition that is also highly variable with ambient humidity. A good reading or a bad reading depends on the nature of the insulation system and the winding being tested. Until 2000, the minimum R1 and the acceptable range for PI was essentially the same for all types of stator winding

insulation. However, it has been recognized that the modern insulation materials in random-wound and form-wound stators have essentially no conduction current (as long as there are no cracks or pinholes). Thus a clean, dry, form-wound stator winding should have an R1 > 100 megohms. Randomwound stator windings and rotor windings should have R1 > 5 megohms at 40°C, which is R1 > 20 megohms at 20°C. The PI should be greater than 2 for stator windings and greater than 1 for rotor windings. If R1 is greater than about 5000 megohms, then PI seems to have little meaning.

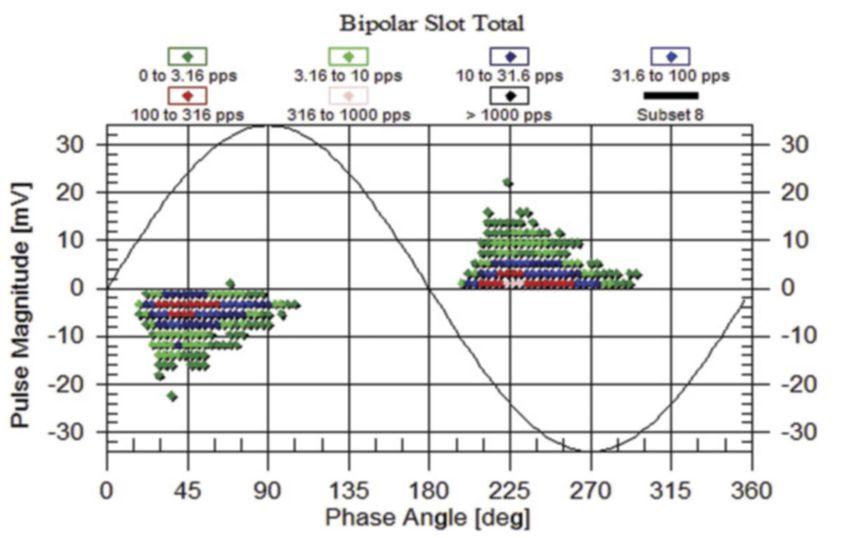

Partial discharges (PD) are small electrical sparks which occur in stator windings rated 3.3 kV or higher. PD is nonexistent or negligible in well-made stator windings that are in good condition. However, if the stator winding insulation system was poorly made or the winding has deteriorated due to overheating, coil movement, or contamination, then PD will occur. As described in IEEE 1434-2000, PD is a symptom of several stator winding problems:

• Thermal deterioration

• Load cycling deterioration

• Loose windings

• Semiconductor or grading coating problems

• Contaminated winding

• Endwinding discharges

Each PD produces a current pulse that has high frequency components to the hundreds of megahertz. Any device sensitive to high frequencies can detect the PD pulse currents. In a PD test on complete windings, the most common means of detecting the PD currents is to use a high-voltage capacitor connected to the stator terminal. Typical capacitances are 80 pF to 1000 pF. The capacitor has high impedance to the power frequency ac current in the stator, while having low impedance to the high frequency PD pulse currents. PD pulse current that passes through the capacitor will create a voltage pulse across the resistor which can be displayed on an oscilloscope, frequency spectrum analyzer, or other display device. The lower band of the detector is the frequency range of the high-voltage detection apacitor in combination with the resistive or inductive-capacitive network load. Modern detectors can be sensitive up to the several hundred megahertz range. In addition, high frequency current transformers are sometimes installed on surge capacitor grounds to detect the PD.

The PD test is a comparison test and can be performed either using on-line or off-line methods. Due to the likelihood of noise interference, on-line monitoring requires sophisticated noise suppression or an expert to perform the analysis. One can determine which phase has the highest peak PD magnitude, Qm, and thus which phase has the greatest deterioration. One can also compare several similar machines to see which has the highest PD. Finally, one can compare the PD from the same stator over time, i.e., trend the data. In general, if the PD doubles every six months, then the rate of deterioration is increasing.

Figure 2. Inadequate Spacing can Lead to Partial Discharge

For off-line results it is important that the ambient temperature, ambient humidity, and winding temperature be included in the evaluation as these will highly influence the PD values. Though these are recorded for on-line results, their impact is less of an issue unless the source of the activity is outside of the motor housing at the terminals.

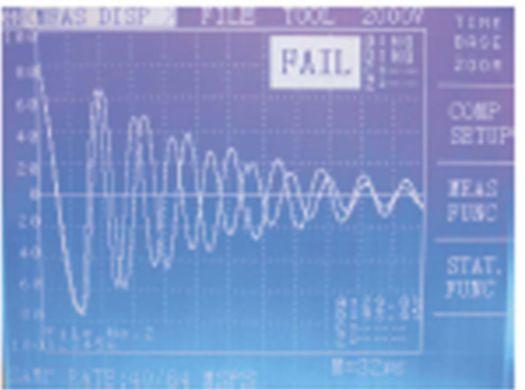

If the turn insulation fails in a random-wound or form-wound stator winding, the motor will likely fail in a few minutes. Thus the turn insulation is critical to the life of a motor. Low-voltage tests on form-wound stators, such as inductance or inductive impedance tests, can detect if the turn insulation is already shorted, but not if it is weakened. Only the surge voltage test is able to directly find stator windings with weakened turn insulation. The surge test applys a high-voltage surge between the turns. This test is an overvoltage test for the turn insulation, and may fail the insulation, requiring bypassing of the failed coil, replacement, or rewind. The test is valid for any randomwound or multiturn, form-wound stator. The test method for form-wound stators is described in IEEE 522-2002.

The surge test duplicates the voltage surge created by switching on the motor. The surge test is a destructive go/no-go test. If the turn insulation fails, the assumption is that the stator would have failed in service due to motor switch-on, PWM inverter voltage surges, or transients caused by power system faults. If the winding does not puncture, then the assumption is that the turn insulation will survive any likely surge occurring in service over the next few years.

Modern surge testers use a digitizer to capture the surge voltage waveform on a phase, as the voltage is gradually raised. Digital analysis then provides an alarm when the waveform changes at a high voltage due to a turn fault. The test voltages are described in IEEE 522-2002. Since this is a test of the internal insulation, ambient weather conditions have minimal impact, but as winding temperature alters winding resistance, winding temperature will always have an effect.

Current signature analysis (CSA) monitoring has revolutionized the detection of broken rotor bars and cracked short-circuit rings in squirrel cage induction motor rotors Error! Reference source not found.. Some of the problems CSA finds are: • cracked rotor bars • cast rotor bars with large internal voids • broken bar-to-short circuit ring connections • cracked short-circuit rings, • static and dynamic rotor eccentricity

In simple terms, CSA theory is that the current flowing in the stator winding not only depends on the power supply and the impedance of the stator winding, but it also includes current induced in the stator winding by the magnetic field from the rotor. That is, the stator winding acts as a probe or transducer for problems in the rotor. The key issue is separating normal currents that flow through the stator to drive the rotor from the unusual currents that the rotor induces back into the stator when there is a problem. This separation is accomplished by using high-resolution frequency spectrum analyzers to measure current components at frequencies other than the power frequency and its harmonics.

The rotor currents in a cage winding produce an effective three-phase magnetic field which has the same number of poles as the stator field but is rotating at slip frequency with respect to the rotating rotor. If rotor current asymmetry occurs, there will be a resultant backward (i.e. slower) rotating field at slip frequency with respect to the forward rotating rotor. The asymmetry results if one or more of the rotor bars is broken preventing current from flowing through the affected slots.

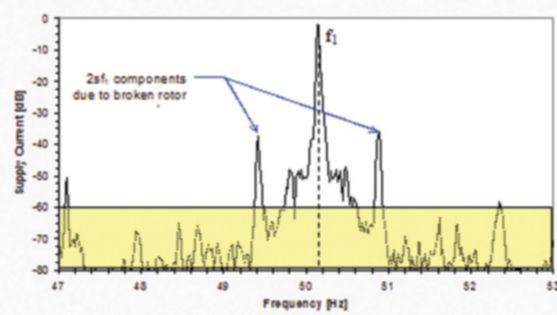

To perform a CSA, the stator current in one phase is analyzed with a spectrum analyzer or customized digital signal-processing unit while the motor is operating under normal conditions. If there are no broken rotor bars, then there will be no frequency

sidebands, fsb. If sidebands are present, then broken rotor bars are likely. Typically, the sidebands are only one Hz or so away from the very large power frequency component, and the sideband currents are typically 100 to 1000 times smaller than the main power frequency currents. The greater the sideband current is (that is, the larger the fraction of the power frequency current), the more severe the rotor deterioration. As with most other monitors, it is best to trend the sideband magnitude over the years. If the sideband increases over time, it is reasonable to expect that a greater number of bars have broken in more locations.

Early CSA monitoring was prone to false indications (that is, indicating that a rotor had problems when it had none) and less frequently, missing defective rotor windings. Thus early users of this test had low confidence in the results. However, improvements in theory, soft ware, and spectrum analyzer/digital signal processor resolution have made detection of rotor bar problems much more reliable. Ambient weather conditions have little impact on these results, as the apparatus is operating in normal conditions within the motor housing.

Powerful tools are available that detect most (but not all) of the rotor and stator winding problems in motors rated 2300 volts and above. Two of these tests – PD and CSA –can be performed during normal operation of the motor, which reduces the impact of ambient weather conditions. This enables the motors most likely to fail to be removed from service before failure, where they can be subjected to further off-line testing, visual examination, and maintenance when required. Thus, these on-line tests are very useful for implementing predictive maintenance and avoiding in-service failures and unnecessary shutdowns. All off-line tests should be evaluated with consideration of the impact of ambient conditions, specifically temperature and humidity, on the test results.

Ms. Vicki Warren, Senior Product Engineer, Iris Power LP. Ms. Warren is an electrical engineer with extensive experience in testing and maintenance of motor and generator windings. Prior to joining Iris in 1996, she worked for the U.S. Army Corps of Engineers for 13 years. While with the Corps she was responsible for the testing and maintenance of hydrogenerator windings, switchgear, transformers, protection and control devices, development of SCADA software, and the installation of local area networks. At Iris, Ms. Warren has been involved in using partial discharge testing to evaluate the condition of insulation systems used in medium- and high-voltage rotating machines, switchgear, and transformers. Additionally, Ms. Warren has worked extensively in the development and design of new products used for condition monitoring of insulation systems, both periodical and continual. Ms. Warren also actively participated in the development of multiple IEEE standards and guides, and was Chair of the IEEE 43-2000 Working Group.

Dr. Greg Stone was one of the developers of online partial discharge test methods to evaluate the condition of the high voltage insulation in stator windings that are used on most large generators and many large motors throughout the world. From 1975 to 1990 he was a dielectrics engineer with Ontario Hydro’s Research Division. Since 1990, Dr. Stone has been employed at Iris Power in Toronto, Canada. He is a past-President of the IEEE Dielectrics and Electrical Insulation Society and continues to be active on many IEEE standards working groups. He is also active on several IEC rotating machine standards working groups. He has published two books and many papers concerned with rotating machine insulation. Greg Stone has a PhD in Electrical Engineering from the University of Waterloo (Canada), is a Fellow of the IEEE, a Fellow of the Engineering Institute of Canada and a registered Professional Engineer in Ontario, Canada.

Whenyoubuyapieceofequipment,yougetapieceofequipment.

WhenyourentfromProtec,youexpandyourteamand yourcapabilities.Youmaytakeitforgranted,butrentingfrom Protecdeliversmorethanequipmentinabox.

> The best application support available 24/7.

> Multiple locations put the right equipment where you need it.

> We can ship today so you have instant access to vital equipment.

> Our minimum rental period is just one day.

You'vegotbetterplacestoputyourworkingcapital. Rentwhatyouneed,whenyouneedit.Inthebestpossiblecondition.

www.protecequip.com

For more money saving ideas visit blog.protecequip.com

BY JIM WHITE Shermco Industries

BY JIM WHITE Shermco Industries

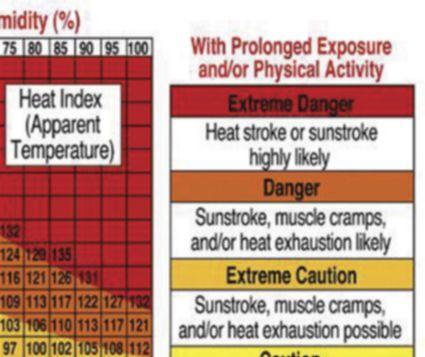

With summer fast approaching (at least in Texas) I thought it might be a good time to do a little weather trivia and IQ. Answers are from the National Weather Service.

Jim White is the Training Director for Shermco Industries and the principal Shermco representative on the NFPA 70B committee. Jim is the alternate NETA representative on the NFPA 70E committee and serves as the NETA representative on the IEEE/ NFPA Arc-Flash Hazard Work Group (RTPC) Ad Hoc Committee. He served as the Chairman of the 2008 IEEE Electrical Safety Workshop. Jim is a NETA Certified Level IV Electrical Testing Technician and a member of the NETA Safety Committee.

1. Which state had the most heat-related fatalities in 2010?

a. Texas

b. Nevada

c. Pennsylvania

d. Florida

2. Which state had the most cold weatherrelated fatalities?

a. Wisconsin

b. South Carolina

c. Florida

d. Illinois

3. Which state had the most weather-related fatalities in 2010?

a. Tennessee

b. Arkansas

c. Illinois

d. Pennsylvania

4. What are the signs of heatstroke?

a.____________________

b. ____________________

c. ____________________

d. ____________________

5. What steps should you take to treat heatstroke?

a. _____________________

b. _____________________

c. _____________________

d. _____________________

See answers on page 107.

You can get older equipment to take advantage of new technology, with the EntelliGuard® TU trip unit. It improves arc flash protection, reducing the HRC level to 1 or 2, depending on available fault current.

Neat trick, isn’t it?

The EntelliGuard TU retrofits quickly and easily, too –via plug-and-play on legacy GE low-voltage breakers or with a kit for those from other manufacturers.

See for yourself. Call 1-800-431-7867 and press “2” for dedicated technical support. Email geelectrical@ge.com. Or visit geelectrical.com/industrial. You’ll be impressed.

EntelliGuard is a registered trademark of the General Electric Company.

imagination at work

Drawout style circuit breakers are commonly used in industrial facilities in voltages ranging from 208-volts to 15 kV. Higher voltages are also used, although less frequently. These devices are frequently connected and disconnected from the bus by technicians without incident, usually by means of a manual screw-type racking mechanism as shown in Figure 1.

The typical racking operation involves attaching a handle (often shaped like a speed handle) to the screw mechanism of the circuit breaker frame, rotating the handle in order to cause the circuit breaker to move in or out of the cubicle, as well as connecting or disconnecting the circuit breaker’s load-carrying elements, referred to as primary disconnects or stabs. It is the connecting or disconnecting of the primary disconnects from the energized bus that creates a safety hazard. There are many situations that can cause a failure when the circuit breaker is being racked, ranging from the circuit breaker reclosing instead of discharging the springs or the circuit breaker being in the CLOSED position while being racked in or out of the cubicle. Other problems include inadequate spring tension on the primary disconnect fingers, primary disconnect fingers breaking, internal failure of the circuit breaker insulation system, and vacuum bottle or arc chute failure. There are many other reasons, but you get the idea. If anything goes wrong during the racking process and an electrical arc is created at the primary disconnect/ bus connection, there are no arc chutes to extinguish the arc. It will likely be a large scale event with severe consequences as it is on the main bus, and it will do a lot of damage. Figure 2 shows a low-voltage circuit breaker primary disconnect assembly as it is about to make contact with the bus.

Figure 3 shows a medium-voltage vacuum circuit breaker that reclosed when racked in. The springs were charged and the circuit breaker was open. As he was racking the breaker in, the technician heard the springs discharge which is normal, but the circuit breaker discharged and closed the main contacts instead of just discharging the springs. The result was a 30+ calorie arc-flash event that severely damaged the circuit breaker and cubicle. Fortunately, the worker’s employer had just purchased a 40 cal/cm2 arc-flash protective suit and required the employee to wear it. According to the employee, six months earlier he would have only had on safety glasses and a t-shirt. The end result was that the worker did not suffer any serious injuries.

How did the worker involved in the incident shown in Figure 3 determine what PPE would be adequate for the hazard? Probably like most other workers; his company told him to wear it, so he did. How did his company determine what PPE was needed? In this case the company had performed an arc-flash hazard analysis. The flip side is that many companies have not yet had an arc-flash hazard analysis performed, and many more have no intention of doing so. Chances are, those same companies don’t require a job hazard safety analysis to be performed before this hazardous task is completed. A technician arrives at the circuit breaker, inserts or attaches the racking handle, and begins racking the breaker. Racking circuit breakers is, in fact, one of the most hazardous tasks electrical workers can perform! Further evidence of the hazards is shown in Figure 4, which is a photo of a 5 kV circuit breaker cubicle after a fault that occurred during racking in of a circuit breaker.

In the current [2012] cycle of the NFPA 70E, a proposal (70E-199) and the resulting comment (70E-180) was discussed at great length. This comment was on a proposal that would require the use of an energized electrical work permit anytime a worker is inside the limited approach boundary or the arc-flash boundary. Some of the deliberation revolved around whether a permit would then be required for tasks such as racking a circuit breaker. It should be noted that the 70E committee clarified that an energized electrical work permit is not required when conductors are not exposed.

(Reference: 70E Report on Comments, June 2011, 70E-175, Log #58) During discussions of comment 70E-180 many of the objections appeared to be based on convenience; that is, racking of breakers is a task performed many times throughout the day, often in a routine manner. To require a permit would place undue hardship on companies that perform this task routinely. Is that the right consideration?

Circuit breaker failure during racking is a pretty rare event. The chances of such an event occurring are probably in the several thousand to one range. While we do not have the exact numbers to plug in, knowing that racking takes place in thousands of facilities at hundreds of locations in the U.S. alone makes the above assumption fairly sound. So, is this a concern? The problem with looking at the odds of an event happening is that we are now gambling on safety. We are, in effect, rolling the dice and hoping that we do not lose the roll. This attitude is not part of a sound safety process. All accidents are fairly rare occurrences. Through OSHA’s enforcement and the industry’s concerted efforts, accidents

on the job are becoming even rarer. That’s the good news. The bad news is the results can be catastrophic or fatal. The real question is – why take the chance? There are some jobs that pay extremely well due to the danger involved in doing them. Capping a blown-out oil well is an example (remember John Wayne in the movie Hellfighters?) As far as we know, no electrical worker is getting paid to put his life on the line in the normal course of his job duties. So, again – why take the risk?

An energized electrical work permit may not be necessary. Having upper management approval each and every time a circuit breaker is racked in or out may get a bit tedious (although a standing permit could be issued for a set period of time) and likely not necessary if you do a proper hazard assessment. But certainly the elements of an energized electrical work permit are needed. Call it a JHA or a JSA, or whatever, but the hazards and the risks must be looked at and evaluated each and every time a circuit breaker is racked. The amount of arc energy created at the power bus is tremendous. Although the risk of an event happening due to racking is low, when it does happen the results can be catastrophic. It only makes sense to take a few minutes to evaluate the equipment, the environment,

the location (and other workers who may be in the area), and the risk. The results of the evaluation are then documented, and the necessary PPE, signage, barriers, etc., are gathered. The task or tasks are then performed in a safe manner.

After all, given a roll of the dice – isn’t it all worth it?

Widup Ron Widup and Jim White are NETA’S representatives to NFPA Technical Committee 70E (Electrical Safety Requirements for Employee Workplaces).Both gentlemen are employees of Shermco Industries in Dallas, Texas a NETA Accredited Company. Ron Widup is President of Shermco and has been with the company since 1983. He is a Principal member of the Technical Committee on “Electrical Safety in the Workplace” (NFPA 70E) and a Principal member of the National Electrical Code (NFPA 70) Code Panel 11. He is also a member of the technical committee “Recommended Practice for Electrical Equipment Maintenance” (NFPA 70B), and a member of the NETA Board of Directors and Standards Review Council. Jim White is nationally recognized for technical skills and safety training in the electrical power systems industry. He is the Training Director for Shermco Industries, and has spent the last twenty years directly involved in technical skills and safety training for electrical power system technicians. Jim is a Principal member of NFPA 70B representing Shermco Industries, NETA’s alternate member of NFPA 70E, and a member of ASTM F18 Committee “Electrical Protective Equipment for Workers”.

CirCuit Breakers

Low & MediuM VoLtage

• General Electric • Westinghouse

• Cutler Hammer • Siemens

• Allis Chalmers • ITE/ABB

• Federal Pacific • Square D

transforMers

1000 – 5000 kVa

• Dry type transformers from stock

• Cast resin from stock

• Load break switch & fuse

Life extension

Let us design a prograM to extend the Life of your switChgear

• Vacuum retrofill

• Vacuum retrofit

• Solid state conversion

• Vacuum motor control upgrades

MoLded Case CirCuit

Breakers & Low

VoLtage Motor ControL

• Circuit breakers

• Motor control components

• Upgraded buckets

• Panel mount switches

switChgear

480V – 38kV new and surpLus

• New General Electric switchgear in 4 weeks

• Match existing lineup

• Reconditioned from stock

• Complete unit substations

• Indoor and outdoor available

renewaL parts

switChgear & CirCuit Breaker parts

MediuM VoLtage

• New General Electric available from stock

• Reconditioned starters and contactors

serViCe & repair

• Field service and testing

• Shop repair of all switchgear and circuit breakers

• Universal circuit breaker remote racking system

• Safety switch for remote switchgear operation

• All low & medium voltage renewal parts, 1945–today

• Obsolete vacuum interrupter in stock

• www.circuitbreakerpartsonline.com

A surge arrester is a protective device that limits surge voltages on equipment by discharging or bypassing surge current, currents that are not around 60 hertz, to ground. Surge arresters allow only minimal flow of the 60-hertz-power current to ground. After the surge current has been discharged, a surge arrester, correctly applied, will be capable of repeating its protective function when another surge voltage must be discharged. For this article, surge arresters associated with higher voltage applications (> 1000V) will be discussed.

Surge arresters used for protection of electrical distribution and transmission lines are typically either of the metal oxide or gapped silicon-carbide type:

Metal-oxide surge arresters are the most common and typically provide the best performance. Surge voltage conduction starts and stops promptly at a precise voltage level, thereby improving system protection. Due to their design, there is no air gap; therefore, there is minimal failure due to contamination. There is, however, a small value of leakage current present at power frequencies. Therefore, the arrester’s maximum power-frequency, continuous operating voltage (MCOV) cannot be exceeded.

Silicon-carbide has more nonlinearity than metal-oxide. Because of this nonlinearity, an air gap is provided in the design to decrease the amount of leakage current and mitigate the arrester burning out and failing. A gap prevents burnout, but it does mean that the arrester will not operate until the gap sparks over. As the spark overvoltage of a gap varies with the atmospheric pressure, the protective characteristics of arresters are affected by the altitude at which they are installed. Standard arresters are considered suitable for altitudes up to 6,000 feet.

Both surge arrester types do the same job, but the need for selection of higher voltage levels for the silicon-carbide type means the protection is slightly less. When gapped type arresters fail, they are typically replaced with the metal-oxide type. ANSI/IEEE C62.11-2005, Standard for Metal-Oxide Surge Arresters for AC Power Circuits (> 1 kV), provides an MCOV rating and a corresponding duty-cycle voltage rating for metal-oxide surge arresters. The most common reason for an arrester failure is that the arrester has been sized for the application based on the phase-to-ground voltage. When a ground fault occurs, a line-to-line voltage may be applied, which would exceed the MCOV rating of the arrester and potentially damage the arrester. Over time, this could result in an eventual arrester failure.

Modern surge arresters require little operational maintenance and the type of maintenance to be performed is usually limited to visual inspection and simple electrical tests. A suggested list of these inspections and electrical tests can be found in ANSI/NETA MTS-2011, Standard for Maintenance Testing Specifications for Electrical Power Distribution Equipment and Systems, Section 7.19.

There are some predictive maintenance techniques that are useful when evaluating surge arrester condition. The fastest growing method of assessing the condition of arresters is with the use of infrared thermography. This inspection should be performed while the system is energized and in service. The reason for its popularity is its clear differentiation between a good arrester and one nearing the end of life. A 10 8C difference between arresters in service is indicative of a potential problem, and plans should be made for replacement at the next opportunity. A 20 8C difference between arresters in service is indicative of a more immediate problem, and consideration should be given for immediate replacement. Another predictive technique that should be considered is an ultrasonic emission (UE) survey. A failure mode of arresters includes partial discharges which can be found by using ultrasonic emission surveys.

Once the system has been de-energized, the physical and mechanical condition of the surge arrester should be inspected for indications of tracking and corona. Visual inspection should also include inspection associated with anchorage, alignment, and grounding. The arrester housing should also be inspected for cracks, chips, or evidence of external flashover. Maintenance should always include cleaning the unit and verifying that the stroke counter, if present, is correctly mounted and electrically connected.

There are some basic electrical tests that should be considered:

CONTACT-RESISTANCE MEASUREMENTS should be made through bolted connections with a low-resistance ohmmeter to verify tightness of bolted connections. The line lead should be securely fastened to the line conductor and the arrester. Investigate any values which deviate from similar connections by more than 50 percent of the lowest microhm value.

MEASUREMENTS should be made at the appropriate voltage levels. This measurement is a means of determining if an arrester is shorted or open. It cannot tell anything else about the health of the tested arrester. This is not a recommended test method by most arrester manufacturers; however, it can diagnose an arrester failure. Unfortunately, this test will not provide indication of a functioning arrester. In the absence of manufacturer’s recommendations, it is suggested that the levels presented in ANSI/NETA MTS-2011, Table 10-1, be used. As with any type of insulationresistance measurement, temperature correction factors should be utilized.

Table 10.1:

Insulation Resistance

Test Values Electrical Apparatus and Systems

should be made between the arrester ground terminal and the ground system. The resistance between the arrester ground terminal and the ground system should be less than 0.5 ohm.

WATTS-LOSS TEST for a surge arrester is considered optional by ANSI/NETA MTS-2007. However, a watts-loss measurement of an arrester can be very effective in determining surge arrester condition. Many manufacturers measure watts loss during final production tests since the IEEE standards imply that it be measured. The measurement is generally done near the units MCOV, where it is a more valid measurement. At any other voltage, it is only a relative number. The problem with available watts–loss, field-test equipment is that the maximum voltage used in the test is typically around 10 kV. A 10 kV watts-loss on a 120 kV MCOV arrester is not very accurate at best. However, periodic watts-loss testing of an arrester will show little deviation from the original watts-loss value as long as the arrester remains in good operating condition. Therefore, it is not recommended that a watts-loss measurement of an arrester be used as a reliable means to assess the quality of an arrester without repeating the test many times on many arresters. A significant deviation from previous values and the values of similar arresters indicates that the arrester is suspect and may have been mechanically damaged or contains moisture. Investigate any values which deviate from similar tests by more than 15 percent of the lowest watts-loss value. At transmission voltages (69 kV and above), it is not surprising to see a near-term, catastrophic failure of an arrester which has a deviation of greater than 25 percent watts-loss value from companion arresters.

To ensure reliable electrical distribution and transmission system operation, associated surge arresters should be included in a periodic maintenance program. This program should include predictive elements, like infrared thermography and ultrasonic emission surveys, as well as preventive maintenance testing that includes visual inspection and electrical testing. Electrical testing should include measuring contact resistance on the line leads and continuity testing on the ground connection. Electrical testing should also include insulation-resistance testing and watts-loss values should be trended.

NETA’s tagline, Setting the Standard, holds many meanings. It speaks to the quality of each NETA Accredited Company that completes the rigorous application process, the stringent NETA certification examination for testing technicians, and the quality of service the association itself strives to achieve for its members. Originally chosen for these reasons, it also encompasses a very literal meaning when speaking about the ANSI/NETA standards.

The first NETA testing specification was published in 1973. It was written by a small collection of dedicated individuals who saw the movement toward voluntary consensus standards as being critical to the growth of their industry. After nearly thirty years of standards development, NETA was accepted as an American National Standards Developer for ANSI in 1996. This achievement marked the advent of a new level of awareness for the NETA standards. Those who already referenced the NETA standards now had the ANSI approved mark backing their decision to require testing to NETA specifications. This new designation also opened up new avenues for NETA and NETA Accredited Companies and gave credence to the work they perform across many industries.