Senior Design

Textile Engineering and Textile Technology 2025

Textile Engineering and Textile Technology 2025

Amanda C. Mills (Ph.D., NC State University, Mechanical Engineering) is an assistant professor in the Department of Textile Engineering, Chemistry and Science at NC State University. Her focus is on developing innovative methods for electronics integration into textiles. She creates full system demonstration platforms to examine the impact of the textile on the device and vice versa. For example, this has included system level electronic designs and knit structure designs for human energy harvesting and physiological sensing.

Philip Bradford (interim co-director) (Ph.D., NC State University, Materials Science and Engineering) is a full professor in the Department of Textile Engineering, Chemistry and Science at NC State University. Through our Summer Textile Exploration Program, he discovered the field of textiles and received both his bachelor’s and master’s in textile engineering at the Wilson College of Textiles. His research group focuses on the synthesis and production of ultra-high aspect ratio carbon nanotubes (CNTs) and explores their wide range of applications such as composites, sensors, electrodes and filtration.

Bailey Knight (M.T., NC State University, Wilson College of Textiles) is a lab manager for Senior Design and for the Zeis Textiles Extension’s Prototype Lab. She supports students by providing them with the technology and knowledge to create soft-good prototypes and to conduct physical testing. She also helps students interface with the Zeis Textiles Extension labs as they request to have materials knit, spun, woven, dyed, finished and tested.

Erin Tillery is a second-year Ph.D. student in textile and technology management. With a background in e-textiles development and entrepreneurship, Erin assists students in Senior Design with technical needs and encourages students to think about how their product fits into a wider business context.

Tytianah Ward (B.S. in textile engineering ’24) is currently pursuing dual master’s degrees in textile engineering and industrial engineering, with expected completion in May 2026. Her research focuses on developing a sustainable network for hemp processing depots across the southeastern United States.

Lauren Navarro, Weaving Lab Manager

Zoe Hezrony, Knitting Lab Manager

Jeffrey Krauss, Dyeing and Finishing Lab Manager

Teresa White, Physical Testing Lab Manager

Tim Pleasants and Maddie Wilson, Spinning Lab Support

Sophie Guevel, Research Associate

Shawn Deaton, Deputy Director

TECS administrative staff, Textile and Apparel, Technology and Management Composites Facility staff: Dr. Ang Li and Dr. Abdel-Fattah Seyam, The Triangle Shooting Academy, RICOH Center for Additive Manufacturing, Allison Blanchard, Dr. Emiel DenHartog, Dr. Jeff Joines, Sara Kempin, Beth Palmer and the North Carolina Textile Foundation.

This capstone course in the Department of Textile Engineering, Chemistry and Science provides companies the opportunity to work with student teams to innovate in product and/or process development. In working with the student teams, companies explore materials property design, develop new directions for existing products or take their materials/product into a new marketspace. Our students utilize their expertise in engineering fundamentals, information systems, medical textiles, product development, supply chain management, testing and consumer behavior to solve a current product/process challenge. Through sponsored projects, student teams learn project management and product design principles that leverage the global textile complex.

The purpose of this course is to deliver a ‘real-world’ experience that prepares students to solve open ended problems that they will face upon entering the workforce. The sponsored student team is expected to:

• Communicate effectively on the project problem, objectives and proposed solutions.

• Work efficiently in teams to deliver high-performing results.

• Assess, select and learn the latest and most appropriate technologies for project success and be able to adapt those technologies as needed.

• Analyze the project and solution from financial, economic, technical, ethical and commercial perspectives.

• Develop ideas with appropriate patent mapping and intellectual property assessment.

• Produce proof-of-principles prototype(s).

The annual Rice Bag Challenge is sponsored by Rise Against Hunger, an international organization that annually distributes millions of meals around the world through community meal-packing events. Each Senior Design team is given one week to create a useful prototype that would solve a problem in developing areas around the world using a maximum $10 budget and two, 50 pound rice bags. At the end of the week, each team pitches their product to a team of judges from Rise Against Hunger.

This academic year our top three products are:

First Place: Team 9 Second Place: Team 10 Third Place: Team 1

While most sponsors spend an average of one to two hours per week on the project, many find interaction with the students to be the most rewarding aspect. Beyond that minimal time commitment, other expectations include:

• Helping define project scope and metrics for project success.

• Holding regular meetings with the team and providing specific project feedback.

• Providing technical mentoring and feedback on the team’s materials and process deliverables.

• Providing specific training on unique tools that are pertinent to the project.

• Providing coaching to help the student team reach the best solutions.

• It is important for the sponsor not to tell the team exactly what to do. This is an open-ended problem.

• Address any issues as they arise. If you encounter team issues or technical project issues, contact the program directors immediately.

• Encourage information sharing. Visit NC State and schedule times for the team to visit your company. Consider introducing the team to your company in mid-October and bringing them back at the end of March to present their hard work.

The project submission period is March 1 to July 1. Prior to submission, two short phone interviews are required with the Senior Design co-directors. This helps to identify the project scope and determine if the project fits well with our students’ skill sets. Sponsors are notified of project acceptance by Aug. 20, and projects begin the first day of classes in mid-August.

Student teams are carefully selected based on their project interest, complementary skill sets and leadership style inventory. Each year, 45 to 60 students participate in the program, forming 12 to 18 teams of three to four students per team.

The rigorous Senior Design capstone program spans both fall and spring semesters. Course directors guide the teams through a design process to develop innovative products/processes that meet the projects’ defined criteria and constraints.

A required donation of $12,000 is due by the end of September. This contribution supports project expenses as well as strategic growth of the capstone lab space and program.

When a project is funded by a donation, NC State does not exert intellectual property (IP) ownership unless an NC State employee is involved; undergraduate students in this course are not NC State employees. The IP generated from the project is owned by the students unless otherwise agreed upon with the sponsor in the form of a non-disclosure agreement between the two parties at the onset of the project. Existing inventions and technologies are the separate property of the sponsor company or NC State. Sponsored research agreements are also available. Two public presentations by the team are made each year — one in the fall semester and another in the spring semester. Teams are required to review content with the sponsor before this presentation.

The culmination of the course is a “Design Day” poster session generally held in April at NC State.

Molly Barnes, Lucy Caraballo, Jay Charbonneau

Electrical transformers are the backbone of the power grid, and a shutdown of a single unit may result in neighborhoods, cities, or even portions of states facing prolonged blackouts.

In 2022 alone, there were 2 terrorist attacks on electrical substations in North Carolina, resulting in millions of dollars in damages and lives put at risk. To mitigate this problem, Hitachi tasked us with developing a bulletproof panel system that can protect these critical pieces of electrical infrastructure, limiting the use of ferromagnetic materials.

The group ideated many structure designs with varied combinations of polymeric materials. By contacting manufacturers, testing materials and creating models, they came up with a final structure and panel design. In the end, they were able to meet the target measurables of this project with great success. The final product had a 38.5% decrease in weight and a 25.5% decrease in cost from a commercially-bought ballistic panel of equal bullet-resistance. A minimal, if any, decrease in strength due to weathering is estimated. Further details cannot be shared in this booklet due to Intellectual Property aspects.

Annabelle Greene, Felicia Krekeler, Katelyn Dunlay

There are many opportunities to advance productivity in manufacturing using 3D printing technology, and a novel concept is the use of 3D printing to enhance the functionality of textiles. Our team was specifically tasked by our sponsor, Hanes, with finding a way to enhance the functionality of a garment by directly 3D printing onto it. With the immense help of the team at Ricoh USA, Inc. 3D printing lab on Centennial campus, we quickly got to work on learning about the different machines and printing processes available to us, and the advantages and disadvantages of each. With some initial prototyping in the lab, we were able to narrow down our ideas, especially in deciding on which garment and functionality would be most suitable for the main goal of our project.

Considering the possibilities and limits with 3D printing filament material onto pieces of fabric, our team selected a garment that we, and over half of women who wear one, agree tends to cause discomfort... bras. While aligning with the Hanesbrands mission to deliver comfortable products to their customers, the concept of a more comfortable bra utilizing 3D printed technology also incorporates the eficiency that comes with additive manufacturing. This includes cost savings and faster production rates due to decreased material waste and continuous automated processing. To create a more comfortable bra, we looked at what specific components or features could be improved and how to do that using 3D printing. Key factors in the comfort of a bra include support and lift. Support and lift became the emphasis as we looked to developing our bra; what kind of structures we would create and where we would place them in the bra, what materials we would use and how we would test them.

Due to the novelty of 3D printing directly to a garment, many of the tests we needed could not be found in existing standard test methods. This required us to develop many of our own test methods to analyze the properties, interactions, and performance between the 3D printed material and the fabric. These included but were not limited to adhesion, washability, and lift/ support tests. In succeeding to create a supportive structure with minimal lightweight material and finding optimal placement along the band and cup, this bra allows the user to receive added lift and support without sacrificing comfort.

Devon Poulin, Fatemeh Heydari, Jordan Everett

Our Senior Design Capstone Project focuses on developing a sustainable alternative to kinesiology tape by creating a knitted compression garment with targeted compression. Sponsored by Lycra, the project utilizes thermally activated, air-covered elastomeric yarn to modify compression levels in different areas of the garment. The goal is to mimic the function of kinesiology tape, particularly for patella tracking, while addressing sustainability concerns associated with the single-use nature of traditional tape.

The first prototype consists of two yarn types: Coolmax for breathability and a thermoset yarn that stiffens upon heat activation at 175°C for 30 seconds. Key design challenges have included determining the correct garment sizing and kinesiology tape pattern, managing fabric shrinkage, and ensuring the garment stays in place without slipping. Through this process, we have aimed to create a functional and reusable solution that enhances user comfort while reducing waste.

Throughout the project, we have navigated both technical and logistical challenges, gaining valuable insights into material behavior, knitting techniques, and performance testing. One of the major hurdles was developing a reliable method to test the garment’s compression capabilities and comfort, requiring us to refine our testing protocol and consider real-world applications. Additionally, coordinating with the knitting lab and analyzing the effectiveness of the prototypes required careful planning and iteration. This project has deepened our understanding of functional textiles, sustainable material innovation, and the complexities of bringing a concept to reality. Overall, we have learned how to integrate textile engineering, biomechanics, and sustainability principles into product development, equipping us with essential skills for future roles in textile innovation and manufacturing.

Abby Montanus, Meredith Fennie, Nika Sumikawa

Sponsored by Apple, our project aimed to establish and improve color process capability for woven softgood textiles. Variability in color during mass production can affect product-level color harmony, resulting in material waste and negatively impacting brand image. Ensuring color consistency is essential to optimizing production efficiency and upholding company’s high standards for quality and sustainability.

We began with analyzing data provided to our team of 24 existing product color samples using the CIELAB color space. This color system utilizes the L*a*b scale, which is a three-axis method used to measure color values. From the given L*a*b values, our team focused on conducting data analysis to pinpoint the least capable colors with the highest variation.

After we selected the three colors our team wanted to focus on, we worked with one of Apple’s partners to get the dyes needed to replicate the colors of the master samples.

Based on our findings, we constructed a Design of Experiment (DOE) for a small dyeing scale. We cut up samples of the polyester fabric, weighed out the fabric samples, created stock solutions for each of the dyes, and measured out the correct amount of stock solution and water needed for each batch. The solution was then distributed among smaller beakers where acetic acid was added and pH was measured to ensure each beaker in the trial had similar pH levels. These smaller beakers were placed in a Datacolor Ahiba IR machine. Each 5-gram fabric sample was carefully removed from the beaker, washed, dried, and read in both the warp and weft direction on a spectrophotometer. We ran 8 trials to test out four different parameters we thought would have the biggest impact on color variability. These parameters included liquor ratio, max temperature, time held at max temperature, and the ramp rate.

Throughout our project, we learned how to navigate the challenges of balancing visual perception with measured color accuracy. By optimizing the dyeing processes, we have taken a meaningful step toward a more sustainable and precise approach to textile coloration in the industry.

Taha Givehchian

This year we were tasked by a startup company to make a quick wick and dry performance headband. During an hour of exercise, your forehead can produce up to 15 grams of sweat and that sweat can cause discomfort. The goal of a headband is to keep the sweat out of the wearer’s face and eyes. The main features that we want our headband to have is quickly wicking and drying sweat and having a soft next to skin hand feel. In the fall semester, we focused on benchmarking. We ordered headbands from different competitors, performed various tests on them, and did an analysis to pick the best performing headbands. We tested the benchmarks on their wicking and breathability. We made a conventional test method for evaluating hand feel. Fall semester was also focused on doing research on novel technologies. One of the main technologies that we found worth investigating, based on superior performance in wicking, was multi-layered fabric. In the spring semester, we focused on constructing our prototypes, creating a design of experiments, and designing our own dry time test that can analyze headbands as a multi-layer system. Drying test methods that were available to us were not suitable for a headband, so we decided to make our own. All test methods that currently exist for wicking and drying time, can only be done on a single layer fabric. There are tests that can be done on multi-layer fabrics, but that requires a cap style headband.

For our design of experiments, we aimed to investigate statistical interactions found between yarn type and knit structure. We chose to work with three types of yarns, two different varieties of polyester and nylon. Benchmark performance aided our decision in picking yarn. We created two design of experiments, one for the next to skin layer and another for the external layer. Changing both the yarn type and structure would give us insight into what leads to the highest performing headband. For the next to skin layer we used a perforated structure because we noticed our best performing benchmark products used a similar structure in their next to skin layer. For the external layer design of experiments we used a single jersey and a structure that was similar to one we observed from our best performing benchmarks’ internal layers. It featured a bumpy surface to encourage sweat movement and drying away from the skin. Our second prototype was based on the multi-layered fabric. Through various testings, we found that the multi-layered fabric visibly shows moisture on the outer layer. For our prototype we sewed a single jersey fabric to the multi-layered fabric so that the sweat would not be visible. The single jersey fabric that we used was heavier than what we desired, therefore we used a lighter weight single jersey from our external layer design of experiments for our second prototype. For prototype three, we used a perforated multi-layered fabric construction with a perforated fabric structure from our next to skin design of experiment fabrics to provide a softer hand. For our pictures, the first 3 are our top priority to be used in the booklet.

Adrienne Albanese, Sophia Leydon, Lane Sherrill

For our senior design project, HanesBrands challenged us to create an Affordable Posture Correcting T-shirt. Our team focused on designing a solution for women who have a higher risk of developing kyphosis, a condition that causes excessive rounding of the upper back. With the increasing prevalence of desk-based work and sedentary lifestyles, many individuals struggle to maintain proper spinal alignment throughout the day.

We began by researching existing posture-support garments and analyzing their construction, materials, and effectiveness. Posture correction shirts currently on the market rely on rigid structures or tight compression, which can be uncomfortable and limit mobility. Items on the market are costly, making them less practical for everyday wear and limiting consumer access. Benchmark products were evaluated based on the level of posture correction, force of posture correction, and wearer feedback to identify key areas for improvement. To quantify the effectiveness of our posture-correction t-shirt, we conducted tensile testing and determined the level of elongation on the competitor’s posture-correcting panels to measure the force the posturecorrecting panels exerted on the wearer. Our prototype process focused on testing different knit structures to determine the best combination of support and comfort while not exerting too much force on the muscle undergoing posture muscles, which can lead to injury. Tensile testing combined with competitor item data allowed us to determine the force different knit structures would exert on the wearer.

A standardized test method was developed to measure the level of posture correction in our competitor items and prototypes using PostureScreen. PostureScreen is a software that measures each garment’s posture correction level through an AI-assisted version of a posture grid, which is the industry standard for physical therapists. The testing involved capturing posture measurements before and after wearing the competitor item to track shoulder and spinal positioning. Breathability testing was also conducted on potential materials to ensure that the final product would be comfortable for extended wear without causing overheating.

To ensure the long-term effectiveness of our design, we conducted accelerated wash testing to evaluate how repeated laundering would impact both the posture correction functionality and the durability of the materials. After wash testing, the correct posture was re-evaluated using PostureScreen software to determine if the support panels maintained their intended level of tension and structure. By incorporating wash durability testing into our development process, we aimed to create a posture correction t-shirt that provides consistent support over time while maintaining comfort and affordability for the consumer.

The final prototype integrates the best-performing knit structures, reinforcement zones, and construction methods identified through our research and testing. Unlike high-priced competitor products, our t-shirt offers an affordable, functional, and wearable solution. This project aims to bridge the gap between supportive function and everyday comfort, encouraging long-term use to promote better posture and musculoskeletal health.

Kayla Coppin, Cydney Cole, Tyler Hodges

Sponsored by Under Armour, our team was tasked to design a washable, wearable electronic device capable of lasting 50 at-home wash and dry cycles. The team brainstormed far and wide about potential ideas, as this project was open-ended. The team thought of ideas ranging from garment-integrated sweat analysis to pressure-sensing technology. Finally, we reached the idea of replacing the often irritable fabric care tags with wearable technology. The team decided to replace the typical fabric care tags on the inside of garments with a smart tag using NFC technology. The concept is for the customer to scan this tag with their phone to show the washing/drying instructions as well as the expected lifespan of the garment. Additionally, with the help of a smart washer/dryer, the NFC tag can use its two-way communication to record the number of times and how the garment was washed/dried. This will ideally replace the need for fabric care tags that customers either cut off anyway or can’t read after washing several times because of running ink or tag degradation.

NFC tags are composed of a conductive antenna and a chip. The chip holds the information for the tag, in this case, the ideal wash conditions for the garment. The antenna is what allows the tag to communicate with the NFC reader, in our case, a customer’s phone. Conductive circuits are often embroidered into textiles with conductive yarns, but because of the uniquely small and complex design of NFC antennas, the team determined early on that this would not work. Instead, they decided to test conductive ink printing on a TPU substrate, then heat-pressed onto fabric to maintain design quality and precision. Before prototyping, the team did extensive research into the field of smart and electronic textiles. We narrowed down two different NFC designs that we felt could be replicated. The first step in making our NFC tag was the antenna design. Using Inkscape, we traced the antenna design and scaled the size to match our NFC chips. Next, we printed on the Direct Ink Write printer with silver conductive ink. The last step was to apply the chip to the antenna. This was done using a sliver of epoxy on top of the two antennas to connect to the correct leads of the chip. Prototype testing included the Grab Test, Abrasion Test, and a custom DOE Wash Test to simulate everyday wear and tear and predict the tag’s durability. Before senior design, our team had minimal experience in the field of E-textiles. With the help of faculty and graduate students, we were able to gradually learn more and shape our project. Having an open-ended project allowed our creativity and innovation to explore a proof of concept rather than a solution to a problem. We hope that our project leads to greater advancements in the world of washable, wearable technology.

Jake Brodnitzki, Natalie Neal, Naomi Southerland

Sponsored by Celanese, our project focuses on sustainable swimwear by evaluating Neolast, a melt-extruded elastomeric yarn, as a sustainable alternative to spandex. Use of Neolast stretch fibers helps reduce environmental concerns associated with elastane, including its reliance on potentially hazardous chemicals in the solvent-spinning process and challenges with recycling blended fabrics containing spandex fibers. We showed additional value-added properties by designing comparative tests between Neolast and Lycra elastomers and fabrics in different conditions, including high chlorine concentrations and agitation over time. To evaluate the performance of Neolast in a swimwear application, we deconstructed and performed benchmarking tests on 6 swimsuits on the market right now to gain data for the industry standards.

Our analysis covered mechanical properties such as tensile strength, stretch recovery, and fabric opacity. Through SEM imaging and ASTM-standardized tensile testing, we observed that Neolast elastomers exhibited superior chlorine resistance and higher elastic recovery. However, upon the fabric test, inconsistencies in results became evident. We noted these are likely due to the low percentage of elastomer in our fabric samples (10%), which would not typically be used for swimwear applications. Further testing using a higher percentage of elastomer fabric may yield more conclusive results.

To further validate Neolast’s viability, we constructed generic swimsuits using Lycra and Neolast circular knit fabrics and conducted wear testing to compare the suit on a person while being worked in a pool. Finally, we constructed a performance slimming swimsuit out of Neolast double interlock fabric. We tested opacity and dry time versus industry standards to find the viability of the fabric prototype with positive results. Additionally, we researched and discussed with experts, ruching techniques to further enhance our final swimsuit prototype. Throughout this project, we gained valuable insights into the complexities of fabric testing, elastomer degradation, and sustainable material integration in performance wear. We encountered technical challenges, such as optimizing fabric stretch and dealing with opacity concerns in a single-layer circular knit swimsuit. With guidance from industry experts, we incorporated ruching techniques to enhance both the design and functionality of our final prototype. Despite these challenges, our results demonstrate that Neolast has significant potential as a sustainable alternative to traditional elastane, particularly if used at a higher percentage in fabric construction and when applied in swimwear used in chlorine pools due to the inherent chlorine resistance of the elastomer. Moving forward, additional research on durability, wear comfort, and recyclability will be essential to advancing sustainable innovations in swimwear.

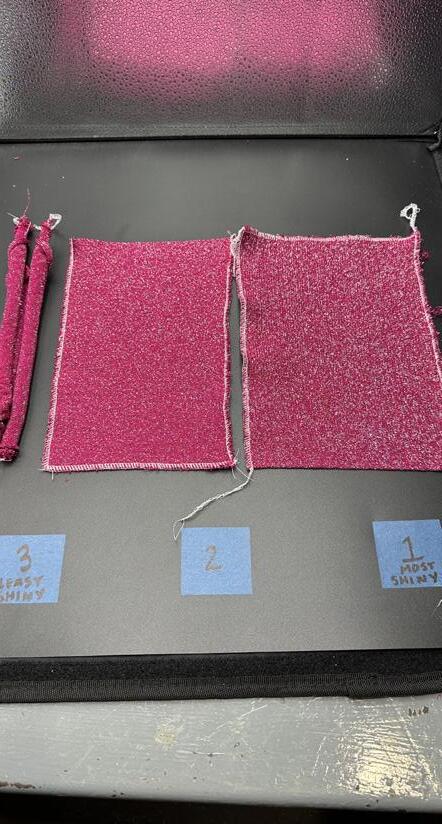

Microplastic pollution is one of the significant environmental disasters of the modern world. One study found that more than 60% of researched fish were found with microplastics in their stomachs. With that in mind, our startup sponsor, Cacci, tasked us to create a sustainable, no-shed, and brilliantly shining glitter fabric for the next generation of glitter apparel. Initially, the team had been experimenting with cellulosebased glitters, but these glitters did not have the desired shine characteristics, as they were too dull when compared to their traditional plastic glitter counterparts. Because of this, the team realized that a no-shed shiny fabric was inherently more sustainable than typical, scratchy, craft store glitter fabric. Therefore, we made it our goal to eliminate or minimize the shed of glitter altogether. During the past eight months we’ve been working on three different prototypes that would fulfill the requirements given to us by our sponsor.

Our prototypes included a multilayer fabric and two iterations of single-layer fabrics that incorporated various combinations of shiny yarns and fibers. Our sponsors were able to provide us with a plethora of benchmarking fabrics to initiate our ideation and prototype development. One unexpected learning outcome of our senior design project was how impactful color is in perceived optical shine. Initial prototypes involved a white base fabric with a light blue shine. After this initial trial, the team elected to select colors that would increase the contrast, and therefore, would increase the optical shine levels. The team decided on a black and silver color scheme for our prototypes, and the resultant shine drastically increased due to the higher contrast. Color science ended up playing a crucial role in our decision-making throughout the year. Another more challenging aspect of our project was our shine and shed testing. There was no existing test for the shed of glitter fabrics, so we had to adapt the Martindale pilling test to measure the percentage of weight loss through glitter shed. For shine testing, we initially wanted to employ an objective method through the utilization of a spectrophotometer. However, the testing results directly contradicted the optical shine seen by group members and others. After this discovery, the team elected to have students do a subjective ranking of our benchmarks and prototypes, regarding their optical shine levels under standardized lighting conditions.

Andrea Lee, Andrew Sarnowski, Ally Seganish, Joey Zhao

As cell phones and other wireless devices become more widespread, radar systems capable of transmitting and supporting these signals are essential. The radar systems market size is estimated at 36.12 billion USD in 2025 and is expected to reach 47.64 billion USD by 2030. To protect these systems from the environment, radomes are designed to encapsulate radars and satellites. These structures must be made out of materials that offer protection from moisture, extreme temperature, and physical impact while allowing signals to pass through with minimal interference.

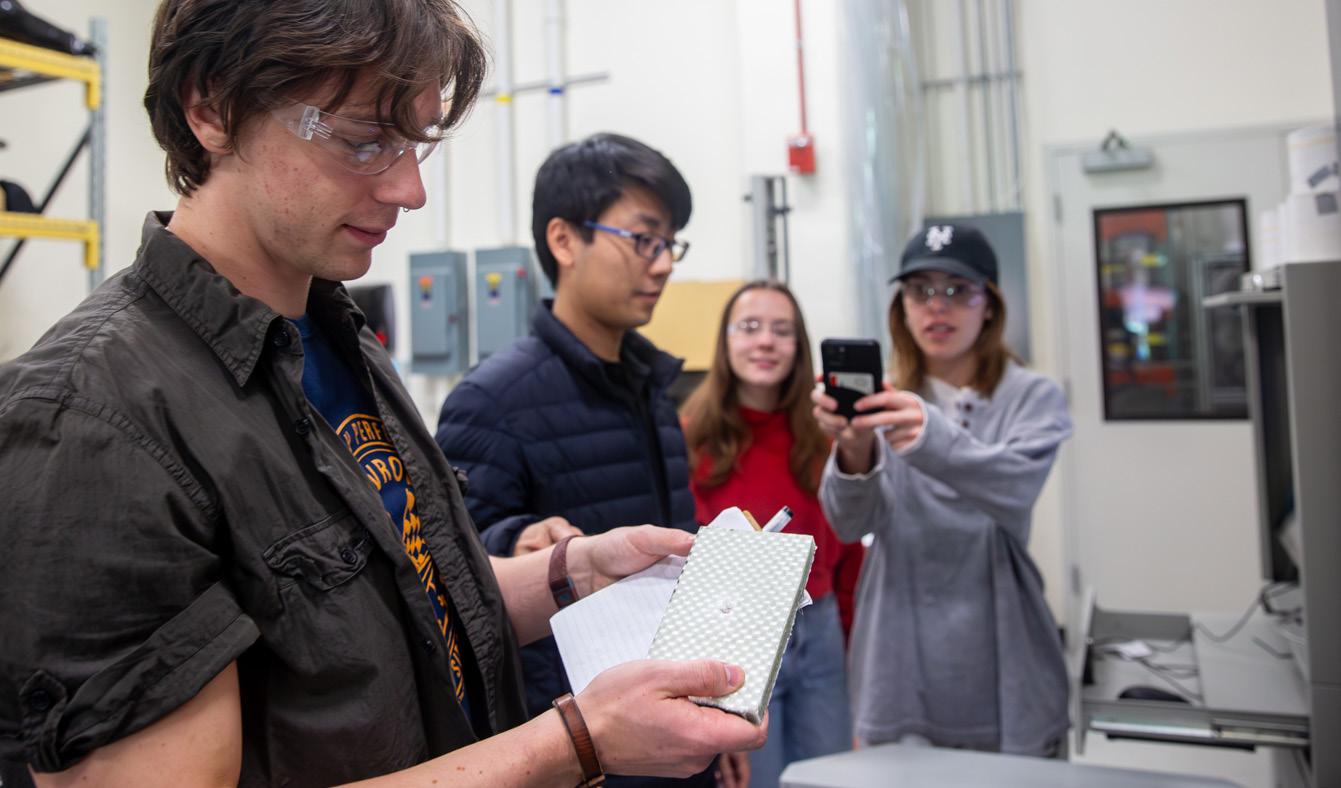

Our sponsor, Quantum Materials, specializes in manufacturing Innegra, a high-modulus polypropylene fiber known for its exceptional low dielectric properties, lightweight nature, and compatibility with other fibers in composite materials. These characteristics make Innegra an ideal candidate for enhancing radome technology. For our Senior Design Project, we delved into radome materials and thermoplastic composite manufacturing. We designed and produced 12 different composite panels where we experimented with the fiber content and layup order. To assess how our panels would perform as radomes, we tested their mechanical, dielectric, and environmental resistance properties. The majority of the fabrication and testing took place at the Wilson College of Textiles. We used the weaving lab to produce Innegra fabric, the dyeing and finishing lab to fabricate composite samples using the heat press, and the composites lab to evaluate mechanical properties with three-point bend and impact testing machines. Additionally, samples were sent to a lab in Switzerland in order to complete dielectric testing at high frequencies. Innegra’s low dielectric constant is a feature that makes it an ideal choice for radome applications, so it was important for us to pursue these tests.

Caitlyn Barnwell, Niamh Williams, Hannah Kirk

Workwear Outfitters is seeking a cooling methodology to enhance workwear garments across various industries where workers are required to perform in extreme heat and with high levels of physical exertion. These conditions put workers at risk of heat stress, a condition that affects over 70% of the global workforce. We chose to focus on the sectors of high physical labor that are most impacted by high temperatures, which included road construction workers and linemen. This choice maximized the impact of our project and incorporated the risk of heat stress as a focal point for our project. Our approach was to research passive cooling methods that did not add to the burden already placed on workers. As a team, we felt that it was important to understand how the body thermoregulates, creating a research plan that distinguished between the sections of the body and their unique methods of cooling. We used the human heat balance equation to estimate the time to reach a core body temperature that would be dangerous. This allowed us to calculate and graph the time it takes to reach this dangerous core temperature while wearing each of the fabrics we tested. Our research led us to a solution with a zoned pattern that specifically targeted high sweating zones and thermally sensitive zones of the body. These workers commonly choose to wear an undershirt under their protective clothing.

To replicate this, our team created a garment ensemble with coordinated technologies in an inner and outer layer.

We sourced knit fabrics for our inner layer to prioritize comfort and flexibility and looked at the fabric properties to see how they would potentially contribute to our design. For the outer layer, we looked for woven fabrics that would provide more durability. The importance of each measurable varied for each zone of our garment, with ranked averages utilized to down-select fabrics. We relied on fabriclevel data to finalize the materials selection for our garments. Once fabrics were chosen for each zone and layer, we used patterns matching our baseline garments to cut-and-sew our prototype garments with these sourced fabrics. We kept the seam types and garment fit consistent to ensure our results would be more indicative of the performance of the zoned pattern specifically. Our team worked with the Textile Protection and Comfort Center (TPACC) to complete our fabric-level sweating hot plate testing and our garment-level Manikin PC testing. The Manikin PC test simulated real-world conditions by controlling several environmental and physiological variables to show whether the garment ensembles help or hinder the body’s natural ability to thermoregulate. The results of this testing demonstrated the enhanced performance of our zoned technology and helped us to make recommendations to our sponsor on what methodology could be used to achieve the desired performance in their garments.

Tailor a Program to Fit Your Educational Goals

Three Specialized Curriculum Tracks

• Medical Textiles: Allows students to gain experience in the design and production methods for textile medical applications.

• Supply Chain Operations: Prepares students to manage the entire supply chain from raw materials to retail.

• Technical Textiles: Enables students to develop expertise and analytical skills needed to design and manufacture textiles for nonwovens and high-tech applications.

One General Curriculum Track

• Textile Technology: Allows students the flexibility of designing their own interests or transferring from other programs or community colleges.

Dual Degree Options

• French Language Minors in a Variety of Disciplines

• Environmental Sciences

• Business Administration

• Statistics

• Arts Entrepreneurship

• Sports Science Accelerated Bachelor’s Master’s (ABM) Program

• Five-year program that enables concurrent pursuit of a B.S. in TT and an M.S. in Textile Engineering for academically strong students.

• Sample careers: materials developer, product designer, quality control engineer, R&D specialist, strategic sourcing manager, logistics manager, production project engineer, technical marketing manager, technical sales

• Athletics and Apparel: Nike, Adidas, The North Face, New Balance, Reebok, Levi’s, Fruit of the Loom, HanesBrands

• Healthcare / Medical Textiles: Medline, Secant Medical

• Homewares: Target, Kohl’s

• Government Agencies / Defense: United States Patent and Trademark Office, State Bureau of Investigation (SBI)

• Traditional Textiles: Milliken, Unifi, Parkdale Mills, Glen Raven, Springs Global

• Plus: SAS, All Trails, Lenovo, Cisco, Accenture, IBM, Wolfspeed Inc.Dual Degree Options

Graduate School

• Textile Engineering: NC State

• Textiles: NC State Professional School

• Analytics Program: NC State

• Nursing School: Queens College

• Law: Campbell University

The Advantages are Impressive

• Average starting salary: $60,000 in 2023.

• 95% of May 2023 B.S. degree recipients were working in a related field or continuing their education within six months of graduation (of 95% who reported).

• Small class sizes with < 1:25 professor-to-student ratio.

• Access to one of the largest college-based scholarship programs.

• Lifelong access to Wilson College’s Career Center via Wilson for Life.

• Undergraduate research with renowned and diverse faculty (go.ncsu.edu/ tecs-reu).

• Classrooms and labs that rival those in industry.

• Exciting summer internship opportunities: Adidas, DEVCOM Soldier Center, METXY, Technimark, Berry Global, Kohl’s, Nike, HanesBrands, Elevate Textiles, JB Martin, Mohawk, Lenovo, Intel.

• Many TT students are recipients of the Centennial scholarship program.

Tailor a Program to Fit Your Educational Goals

Three Curriculum Tracks

• Chemical Processing: Develop improved chemical processes for industries related to polymer and fiber fabrication.

• Information Systems Design: Learn how to use computer information systems to develop more efficient decision making.

• Product Engineering: Focus on designing new innovative products with this multi-disciplinary and flexible concentration.

Dual Degree Options

• TE / BME (Biomedical Engineering)

• TE / CHE (Chemical Engineering)

• TE / MSE (Materials Science Engineering)

• TE / CSC (Computer Science)

• TE / ISE (Industrial and Systems Engineering)

• TE / PCC (Polymer and Color Chemistry)

Minors in a Variety of Disciplines

Accelerated Bachelor’s Master’s (ABM) Program

• Five-year program that enables concurrent pursuit of a B.S. and an M.S. in TE for academically strong students.

• Sam Jasper was the second TE student awarded national Astronaut Scholarship Foundation Award.

• Won overall Engineering Senior Design Award for multiple years.

• Joseph Moo-Young was the third TE student to be selected for the prestigious COE Faculty Rising Senior Scholar program.

• Many TE students are recipients of the Park, Centennial, Goodnight, Shelton Leadership and Caldwell scholarship programs.

A

• Government Agencies / National Defense: NASA, The U.S. Army, Lockheed Martin, Natick, United States Patent and Trademark Office

• Athletics and Apparel: Nike, Adidas, Under Armour, The North Face, Lululemon, Patagonia, Levi’s, Peter Millar, HanesBrands

• Healthcare / Medical Textiles: ATEX, Merck & Co., Stryker, Medline

• Automotives: Tesla, BMW, Volvo Trucks, Nissan, Goodyear, Michelin

• Homewares: Home Depot, Lowe’s, Mohawk Flooring, Hunter Douglas

• Traditional Textiles: Milliken, Unifi, Elevate Textiles, SteinFibers

The Advantages are Impressive

• Average starting salary: $70,000 in 2023.

• 95% of May 2023 B.S. degree recipients were working in a related field or continuing their education within six months of graduation (of 96% who reported).

• Small class sizes with 1:30 professor-to-student ratio.

• Joint program between the Wilson College of Textiles and the College of Engineering (COE).

• More than 50% of TE students receive scholarships.

• Lifelong access to Wilson College’s Career Center via Wilson for Life.

• Undergraduate research with renowned and diverse faculty (go.ncsu. edu/ tecs-reu).

• Classrooms and labs that rival those in industry.

• Only ABET-accredited textile engineering program in the United States.

• Only NC State engineering program that trains students in Lean Six Sigma Quality process improvement methodology.

• Exciting summer internship opportunities: Under Armour, Tesla, Lutron Electronics, ATEX, Cotton Inc., Elevate Textiles, Standard Textile, Phifer, Gore, Adidas, Cortland Biomedical, Sonoco, Medline, Contempora Fabrics, Smartwool, Nike, Stryker, UL.

• Advanced Materials: Technimark, DuPont, Eastman, Honeywell

• Other Employers: SAS, All Trails, Lenovo, Cisco, Accenture, IBMOne General Curriculum Track Graduate School

• Materials Science Engineering: NC State

• Chemical Engineering: Georgia Tech, University of Florida

• Textile Engineering: NC State

• Biomedical Engineering: Duke University, Johns Hopkins University, NC State

• Industrial and Systems Engineering: Rensselaer Polytechnic Institute

• Polymer Science: NC State, UMass Dartmouth Professional School

• Analytics Program: NC State

• Dental School: UNC Chapel Hill

• MBA: Harvard, NC State, UNC Chapel Hill, Wake Forest University

• MHA: UNC Chapel Hill

• Medical School: UNC Chapel Hill, Wake Forest University

• Law School: UC Berkeley, UNC Chapel Hill, Wake Forest University