State Officials Visit Round House Industries COVER STORY IN THIS ISSUE MEMBERSHIP NATM Announces Board of Director, Committee Changes for 2023 EDUCATION Page 12 Page 20 Member Invitation: Regulatory Round Up, Capital Hill Visits GOVERNMENT AFFAIRS Page 11 Page 74 The Official Publication of the National Association of Trailer Manufacturers Volume 36 • Issue 2 March/April 2023 TRACKS Priefert Steel Story to be Featured on 'The Rural Americans'

w w w.el k r i verproduc t s.c om ElkRiver Trailers 1400 W Brist ol St reet Elkhar t , IN 46514 Aluminum and Steel Trailers Partner Wi t h Us D e a l e r O p p o r t u n i t i e s Await +57 4-22 6-0 362 Sc an t o w at c h v id e o i nf o@el k ri ver produc t s.c om

STAFF

Tracks Editor

Samantha Darling LaCount • Samantha.Darling@natm.com

Interim Executive Director

Alex Stowe • Alex.Stowe@natm.com

Assistant Director

Meghan Ryan • Meghan.Ryan@natm.com

Marketing Director

Savana Morrison • Savana.Morrison@natm.com

Compliance Manager

Scott Crimmins • Scott.Crimmins@natm.com

Senior Compliance Consultant

Sean Sloan • Sean.Sloan@natm.com

Compliance Consultant

Aaron Langer • Aaron.Langer@natm.com

Member Outreach Specialist

Scott Simons • Scott.Simons@natm.com

Membership & Events Coordinator

Catie Rutkowski • Catie.Rutkowski@natm.com

Administrative Services Coordinator

Abby Wiebler • Abby.Wiebler@natm.com

Bookkeeper

Sherry Palmeroni • Sherry.Palmeroni@natm.com

OFFICERS

President Marty Lorick • Triple Crown Trailers Inc.

Vice President

Josh Johnson • Big Tex Trailer Manufacturing, Inc.

Treasurer Marco Garcia • U-Haul International, Inc.

Associate Member Representative John Kerr • Marsh & McLennan

Past President Owen Shelton • BoatMate Trailers, Inc.

DIRECTORS FEB. 2021 - FEB. 2024

Leo Akins • Forest River, Inc.

Andy Derr • M.H. Eby, Inc.

Rick Huddleston • White River Marine Group

John Kerr • Marsh & McLennan Agency

DIRECTORS FEB. 2022 - FEB. 2025

Charles Daugherty • Red Fern Dynamics

Andy Gehman • MGS Incorporated

Daniel Luby • BoatMate Trailers, Inc.

Nathan Uphus • Felling Trailers

DIRECTORS FEB. 2023 - FEB. 2026

Bill O'Hara • Dexter

Jon Devitt • Midwest Industries, Inc.

Jeff Jones • Statistical Surveys, Inc.

Dustin Miller • Cross Trailers, Inc.

Mike Story • LOOK Trailers

Michael Etheridge • Wylie & Son, Inc.

About this publication: Tracks Volume 36, Issue 2 March/April 2023 is published six times a year (bi-monthly) for $50 per year by the National Association of Trailer Manufacturers, 2420 SW 17th St, Topeka, KS 66604. Periodicals postage paid at Topeka, KS. POSTMASTER: Send address changes to NATM 2420 SW 17th St, Topeka, KS 66604.

DISCLAIMER: The inclusion in this magazine of advertising, logos, or website links, or reference to any products, services, trade names, or manufacturers is not an endorsement by NATM of any such advertisers, links, entities, products, services, or names. NATM through this magazine provides news and opinion articles as a service to its members and readers. Often these articles come from sources outside of its organization. Statements and opinions expressed in these articles are solely those of the authors and do not necessarily reflect the opinions, beliefs and viewpoints of the National Association of Trailer Manufacturers, its staff or management, or the official policies of NATM. Nor does NATM accept responsibility for any errors or omissions made in publishing or reproducing articles or advertising appearing in Tracks or for the return of unsolicited manuscripts sent to NATM.

1552-2415

Number: 022438

ON THE COVER NATM Announces Board of Director, Committee changes for 2023 State Officials visit Round House Industries COVER IN THIS ISSUE MEMBERSHIP You are Invited: Regulatory Round Up, Capital Hill Visits GOVERNMENT The Official Publication of the Association of Trailer Manufacturers March/April2023 TRACKS Priefert Steel Story to be Featured on 'The Rural Americans' NATM Headquarters • 2420 SW 17th St. • Topeka, KS 66604 • (785) 272-4433 • Fax: (785) 272-4455 Contents Table of Priefert Steel Story to be Featured in 'The Rural Americans' Episode Page 20

USPS

ISSN Number:

Advertising Index › › › › › › › › › › › › › › › 2 President’s Report › › › › › › › › › › › › › › 4 Headquarters Report › › › › › › › › › › › › 6 Priorities in Implementing the Infrastructure Law › › › › › › › › › › › › 8 Member Invitation to Regulatory Roundup, Capital Hill Visits › › › › › › › › › › › › › › › 11 NATM Announces Board of Directors Updates › › › › › › › › › › › › 12 NATM 2023 Committees Announced › › › 13 NATM Announces 2023-2026 Strategic Plan › › › › › › › › › 17 Statistically Speaking › › › › › › › › › › › › › › › 31 Celebrating Trailer Safety Week as Dealerships › › › › › › › › › › › › › › › › › › › › › › 34 NAM Addresses Diversity, Inclusion in Virtual Summit › › › › › › › › › › › › › › › › › › › › › 38 Breakaway Battery Setup May Cause Charging Concern › › › › › › › › › › 45 Shining a Spotlight on Compliant Lighting › › › › › › › › › › › › › › › › 47 Trade Actions Impacting US Business › › › › › › › › › › › › › › › › › › › › › › › › 50 How to Take Your Profit First › › › › › › › › › › 53 Dealer Problems Solved with NATM's Dealer Affiliate Resources › › › › › › › › › › › › › › › › › › › 56 NHTSA Cautions Buyers, Trailers Must Meet Federal Safety Regulations › › › › › › › › › › › 60 Convention Sponsors › › › › › › › › › › › › › › › › › 62 Know Your Association; Know Your Decal › › › › › › › › › › › › › › › › › › › › › 66 Marketing Intern Impresses at LOOK Trailers › › › › › › › › › › › › › › › › › › › › › › 68 NATM Looks Forward to Serving You in 2023 › › › › › › › › › › › › › › › › 71 Get to Know Affiliated Resources › › › › › › 72 Officials Visit Round House Industries New Facility › › › › › › › › › › › › › › › 74 1st Year Anniversaries › › › › › › › › › › › › › › › › 77 Welcome New Members › › › › › › › › › › › › › › 78 Press Releases › › › › › › › › › › › › › › › › › › › › › › › 80

2 March/April 2023 www.NATM.com

5 Star Trailers › › › › › › › › › › › › Inside Back Cover A.L. Hansen Mfg. Co. › › › › › › › › › › › › › › › › › › 92 Affiliated Resources, Inc. › › › › › › › › › › › › › › › 70 Apex Trailer Parts › › › › › › › › › › › › › › › › › › › 19 ASA Electronics › › › › › › › › › › › › › › › › › › › › 26 Bear Track Trailer › › › › › › › › › › › › › › › › › › › › 10 Bob Clements International Inc. › › › › › › › › › › › 52 Canadian Load Divider Dollies Inc › › › › › › › › › › › › › › › › › › › 10 Clicklease › › › › › › › › › › › › › › › › › › › › › › › › › 64 Coe Press Equipment › › › › › › › › › › › › › › › › › › 40 Craftmark › › › › › › › › › › › › › › › › › › › › › › › › 89 Demco › › › › › › › › › › › › › › › › › › › › › › › › › › 23 Dexter › › › › › › › › › › › › › › › › › › › › › › › › 16, 63 DK2 Warrior Wenches › › › › › › › › › › › › › › › › › 46 Eagle Hydraulic Inc. › › › › › › › › › › › › › › › Back Cover East Penn Manufacturing Co., Inc. › › › › › › › › › › 37 ElkRiver Trailers › › › › › › › › › › › Inside Front Cover EQ Systems › › › › › › › › › › › › › › › › › › › › 32-33 Felling Trailers, Inc. › › › › › › › › › › › › › › › › › › › › 37 H.E. Parmer Company, Inc. › › › › › › › › › › › › › › 76 Heskins, LLC › › › › › › › › › › › › › › › › › › › › › › › › 9 Hometowne Capital › › › › › › › › › › › › › › › › › › › 54 Hutchens Industries, Inc. › › › › › › › › › › › › › › › 91 Huth Ben Pearson › › › › › › › › › › › › › › › › › › › › 29 IDC Spring › › › › › › › › › › › › › › › › › › › › › › › › 18 Kenda/Americana Tire & Wheel Corporation › › › › › › › › › › › › › › › › › › 35 LaVanture Products Company › › › › › › › › › › › › 30 LINK Trailer Parts › › › › › › › › › › › › › › › › › › › › 45 Lippert › › › › › › › › › › › › › › › › › › › › › › › › › › › 79 Napoleon/Lynx › › › › › › › › › › › › › › › › › › › › › › › 76 Optronics International › › › › › › › › › › › › › › › 65 Peerless Industrial Group › › › › › › › › › › › › › › 29 PPG › › › › › › › › › › › › › › › › › › › › › › › › › › › › › › 5 Ridewell Suspensions › › › › › › › › › › › › › › › › › 3 Roto-Fab Inc. › › › › › › › › › › › › › › › › › › › › › › › › 2 Simpson Strong-Tie › › › › › › › › › › › › › › › › › › › › 7 Stillwell › › › › › › › › › › › › › › › › › › › › › › › › › › 22 The Raynor Company › › › › › › › › › › › › › › › › › › 55 TecNiq › › › › › › › › › › › › › › › › › › › › › › › › › › › › 31 Tex Trail › › › › › › › › › › › › › › › › › › › › › › › › › › 36 Tie Down Engineering, Inc. › › › › › › › › › › › › › › › 11 TOWKING › › › › › › › › › › › › › › › › › › › › › › › › › 37 Wire Works Technologies, Inc. › › › › › › › › › › › › 61 TRACKS

Advertising Index

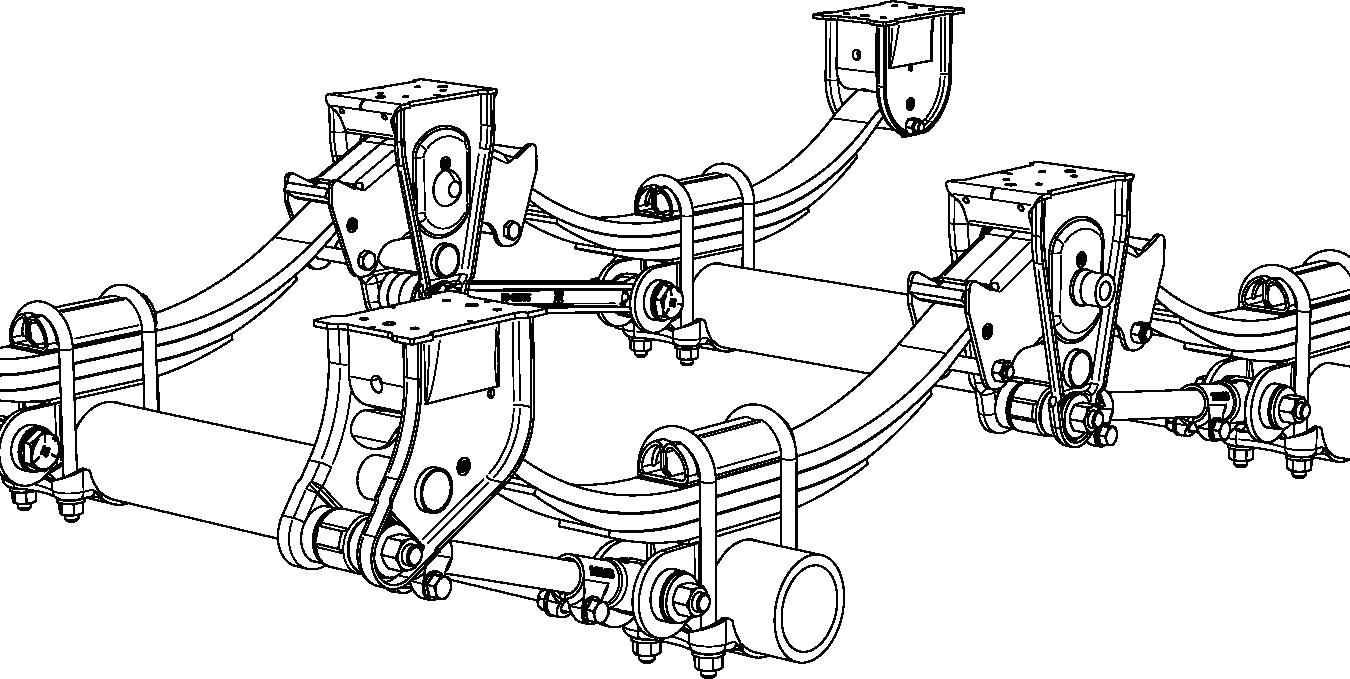

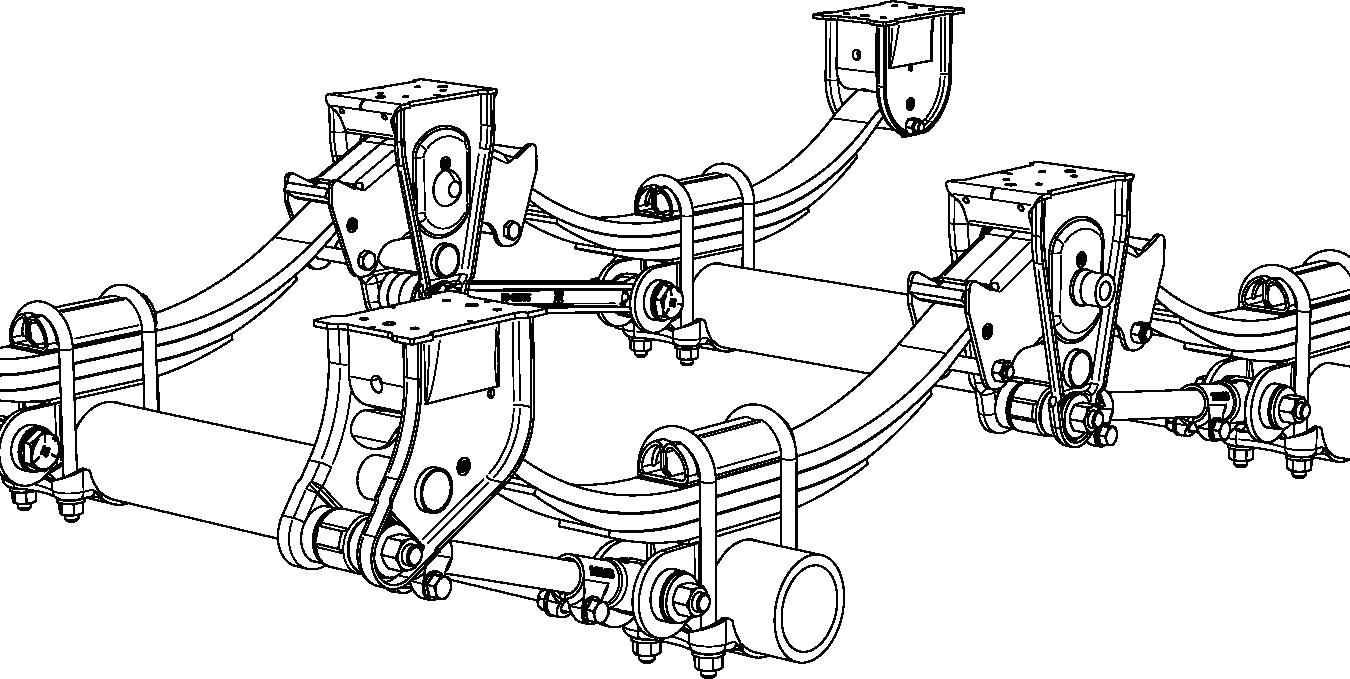

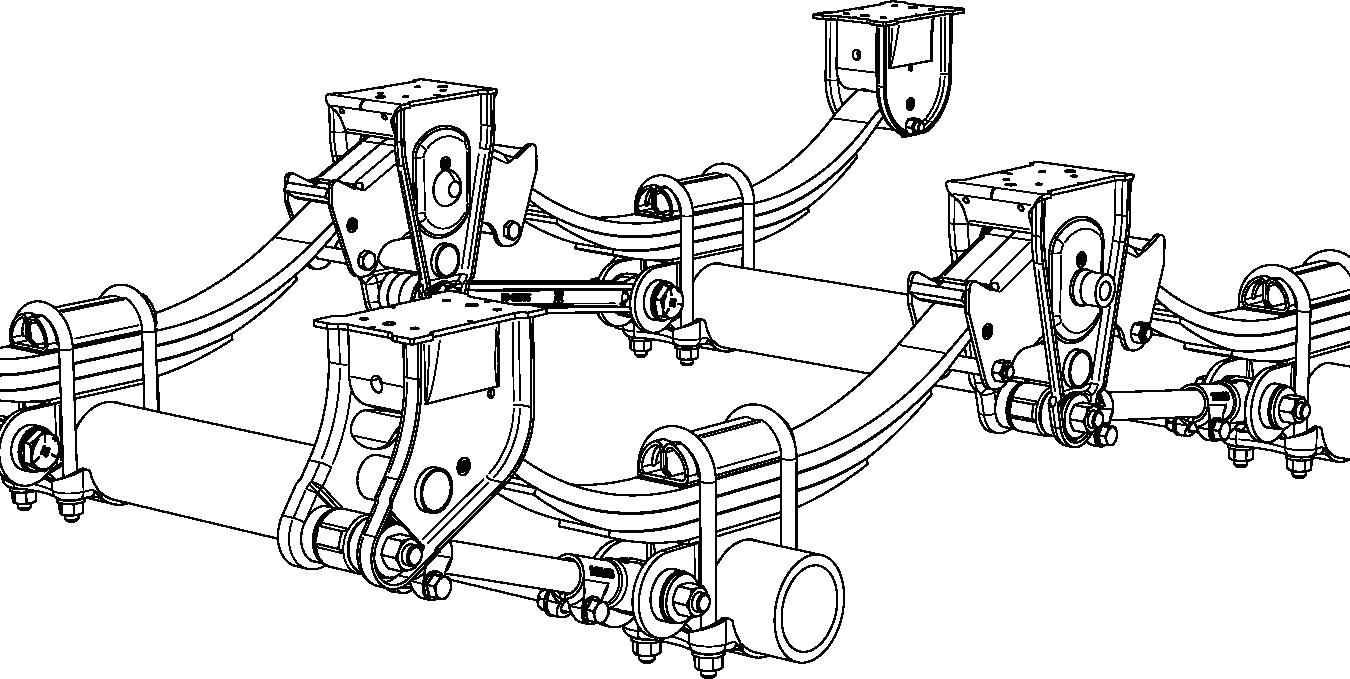

800.641.4122 | info@ridewellcorp.com ® GET BETTER WITH RIDEWELL BETTER SUSPENSIONS BETTER ENGINEERING BETTER VALUE www.ridewellcorp.com The RAR-244 8K & RAR-244 16K Air-Ride suspensions are the better choice for light and medium duty applications. The 8,000 lb capacity 244 Featheride is the perfect fit for horse, race car and other specialized light duty trailers. For more robust applications up to 16,000 lb, the RAR-244 16K is the perfect balance of durability, quality and value. RAR-244 16K RAR-244 8K

President’s Report

By Marty Lorick, Triple Crown Trailers, Inc.

I am proud to welcome you to this year’s Special Dealer Issue of Tracks magazine. In addition to our usual circulation of readers, this issue is sent out to thousands of trailer dealers across the United States in order to spotlight compliant trailer manufacturers, as well as educate dealers on industry issues and the importance of compliance.

It is important for trailer manufacturers, suppliers, and dealers alike to understand that the National Association of Trailer Manufacturers (NATM) is a 501(c)(6) not-for-profit association that is dedicated to making roadways safer through compliance with applicable federal safety regulations and education on safe trailering practices.

The Association was founded in 1987 by five trailer manufacturers in Chickasha, Oklahoma. Their original intention for coming together was to get better rates for product liability insurance, but over the years, the mission and member benefits evolved. In 1991, NATM debuted trailer manufacturing guidelines and, by 2002, had established the NATM Compliance Verification Program (CVP). In 2012, participation in and successful completion of the CVP became a mandatory component of membership for all trailer manufacturers.

While this is an important Tracks issue for the Association, it is also my last as president. With my term ending in February, I would like to use this last President’s Report to reflect on my time spent on the NATM Executive Board and as president. The mission of NATM is to promote trailer safety and the success of the trailer manufacturing industry through education and advocacy, and I am proud to say that the current performance of our Association is meeting those goals. During the last two years as president, NATM has expanded the Dealer Affiliate Program, launched the online Resource Library, published the online job board on natm.com, made improvements to the Compliance Verification Program, launched a new website and database, and introduced both health and retirement plans to members of the Association.

I was appointed to the NATM Board of Directors in 2015. In addition, I have served on various committees such as the Finance, Government Affairs and Convention Committees, including serving as a treasurer and vice president, before being president. Volunteering on these committees was not only about what I could contribute but was also a learning experience for me in association management, strategic

planning, and regulatory issues. I believe in what NATM is trying to achieve and am honored to contribute to its mission.

I would like to note that I have had a gratifying experience personally serving as president. I found the Board and committee meetings interesting and engaging, and I look forward to continuing as past president and serving on the Executive and Government Affairs Committees. Working with such an impressive group of leaders has been a very rewarding experience. I spent enough time volunteering on the Board to become familiar with the Association, its mission, and its members that once it was my time to serve as president, I realized the position of president of NATM was not intimidating, but instead rewarding. I would like to encourage those that have reservations about getting involved to go ahead and join this great group of volunteers and serve on a committee or on the NATM Board. NATM staff and other Board members are more than willing to coach new volunteers and help them settle into their roles. I am proud to be a very small part of the accomplishments that the Association made during my tenure.

Those that took the step further to attend the 2023 Convention & Trade Show, volunteer on a committee, or attend the Regulatory Roundup also deserve recognition. It is only with your commitment and support that we will raise awareness of our industry and continue to improve trailer safety. I had the honor to work with great Board members that were willing to sacrifice their time to serve this industry, and I wish my successor and the next president the best of luck. Very little would be possible without a strong staff to keep the day-to-day operations running smoothly. Interim Executive Director Alex Stowe and the NATM staff have proven they are adaptable and determined to keep the Association upright, on course, and pointed in the right direction. The NATM staff has evolved into an extremely dedicated and dynamic unit that is ready to show the membership that they will provide the information, workshops, and publications that can benefit you. I encourage all of you to be active in this Association and to provide additional input to keep this Association strong and of value to you. The staff welcomes feedback to continuously improve. Thank you for a wonderful two years. ■

Marty Lorick

4 March/April 2023 www.NATM.com

TRACKS PRESIDENT'S REPORT

To learn more, visit ppgversolon.com Versolon is a trademark and the PPG Logo is a registered trademark of PPG Industries Ohio, Inc. ©2022 PPG Industries, Inc. All rights reserved. Versatility defined for trailer manufacturers

Headquarters REPORT

By

By

Spring is finally here at headquarters. I am thankful the National Association of Trailer Manufacturers (NATM) was able to start another year with an amazing convention! Our 35th Annual Convention & Trade Show in Fort Worth, Texas, was our largest yet. I am thankful to both NATM staff and members of the Association for helping to bring our industry together to continue our mission of promoting trailer safety and the success of the trailer manufacturing industry. NATM welcomes in our new members of the Board (turn to Page 12 for more information), new committee members (turn to Page 13 for more information), and the introduction of NATM’s new strategic plan (turn to Page 17 for more information).

NATM staff is definitely looking forward to warmer weather and the usual boost in production and sales it brings to this great industry. Focusing on trailer safety will again be key as trailer users get back out on the road in full force. As the weather improves and the holiday season ends, NATM’s compliance team will begin traveling to visit members again and conduct our Compliance Verification Program (CVP) consultations throughout the rest of the year. These consultations aim to help ensure trailers are compliant with our program and meet minimum standards relating to trailer safety. This year also will see NATM creating more resources to provide to dealers in an attempt to better reach end-users and assist them with understanding how to safely use their trailers.

NATM has released several fantastic resources for dealers since they have been able to join NATM as affiliates, including the Dealer Compendium, which includes over 300 pages of federal and state regulatory information as well as consumer resources. The Association also launched a resource library, opening up access for members and dealer affiliates to technical and general business management resources, including archived educational articles and on-demand webinars. Importantly, the online Resource Library contains information about how to use NATM Compliance as a sales tool. Communicating the importance and depth of the CVP to end-users can be difficult, but helping to understand the rigorous standards manufacturers using the NATM Decal comply with without overburdening an end-user is important to help consumers make informed decisions about purchasing a compliant, road-

ready trailer. NATM is continuing to look for ways to regularly grow the Resource Library content to ensure members and affiliates have the information they need at the touch of a button.

The Association’s efforts to grow consumer awareness about safe trailering and regulatory compliance don’t end with manufacturers and dealers. NATM will be hosting the sixth annual Trailer Safety Week (TSW), June 4-10, 2023. The Association is always looking for new TSW partnerships and expanding content curated by industry experts. Finding an opportunity to engage with the event is easy! NATM offers three levels of participation – Allies, Champions, and Partners. Allies sign up online and are provided a marketing kit with pre-crafted materials and resources for industry members to support Trailer Safety Week through social media posts and direct-to-customer communications. Champions take participation to the next level, committing to online posts and customer outreach, and are rewarded with brand promotion. The Partner level is the most intensive commitment to Trailer Safety Week and is reserved for industry experts who plan to curate content for TSW within their area of expertise. I hope you’ll join our effort to make roadways safer and sign up at TrailerSafetyWeek. com/interest. Read more on TSW on Page 34.

2023 is off to a strong start, and the Association has much in store for members and dealer affiliates this year! New committees are underway with goals that will continue to propel the industry forward and ensure the continued accomplishment of the NATM mission. While the Association continues to grow and expand, the staff work to educate our members and affiliates about all the resources available to them.

Stay up to date on NATM news by signing up for the NATM Insider eNewletter with the QR code to the left! ■

6 March/April 2023 www.NATM.com

HEADQUARTERS REPORT

Alex Stowe, NATM Interim Executive Director

MARCH/APRIL 2023

TRACKS

Alex Stowe Interim NATM Executive Director

Speed up trailer bed production. Step on it.

Introducing the Simpson Strong-Tie ® Quik Drive ® PROHSD Wood-to-Steel fastening solution — a fast, reliable and easy way to install truck and trailer beds. Our Quik Drive PROHSD and PROHSDM tools have an optional extension and footstep for stand-up use, eliminating the strain of working on hands and knees. The PROHSDM also features a unique nosepiece for greater stability and accuracy. Save time by using the Quik Drive tool with collated strips of Strong-Drive® TB Wood-to-Steel screws for steel up to ¼" thick, or with Strong-Drive TF Wood-to-Steel screws for thicker steel up to 15/32".

To learn more about the Quik Drive PROHSD Wood-to-Steel solution, visit go.strongtie.com/prohsd or call (800) 999-5099.

7 © 2023 Simpson Strong-Tie Company Inc. QDPROHSD22

SSTM-QDPROHSD22_8_1-2x11.indd 1 1/3/23 11:04 AM

Priorities in Implementing the Infrastructure Law

By Brody Garland, K&L Gates

In December 2021, the Federal Highway Administration (FHWA) issued its Policy on Using Bipartisan Infrastructure Law Resources to Build a Better America, highlighting the agency’s preferred projects for funding within the Infrastructure Investment and Jobs Act (IIJA). Released as a memo by Deputy Administrator Stephanie Pollack to FHWA members, the policy identified projects that would “Build a Better America,” such as promoting road safety and prioritizing climate-resistant infrastructure. In addition, the preferred FHWA investments would also:

› Improve the condition, resilience, and safety of road and bridge assets

› Make streets and other transportation facilities accessible to all users

› Address environmental impacts ranging from stormwater runoff to greenhouse gas emissions

› Future-proof transportation infrastructure by accommodating new and emerging technologies

› Reconnect communities and reflect the inclusion of disadvantaged and under-represented groups in the planning, project selection, and design process

The FHWA memo emphasized the need to update and modernize existing infrastructure, like highways, as opposed to expanding it, and noted the policy’s role in guiding state decisions on future infrastructure projects. This guidance is indicative of how the Administration intends to implement the funding priorities of the IIJA.

As a result of both the memo’s potential influence over state decisions and its dismissal of highway expansion, Sen. Shelley Moore Capito (R-WV), ranking member of the Senate Environment and Public Works Committee, requested Government Accountability Office (GAO) intervention in February 2022. GAO’s involvement served to determine whether FHWA’s memo was subject to the Congressional Review Act, which would establish it as a rule to be reviewed by Congress before it takes effect.

In December 2022, GAO concluded the memo is a rule, allowing for congressional review, as it is an agency statement, provides guidance for projects to be funded by IIJA, and announces a preference for certain types of projects and instructs agency employees to encourage funding recipients to select these types of projects. As a result, the FHWA memo could potentially be overturned if a joint resolution is signed by the president. Shortly after GAO’s determination, Capito stated she would introduce a resolution of disapproval.

While it is unlikely that a joint resolution passes in a time of divided government and narrow majorities, it would serve stakeholders that intend to apply for federal IIJA grant funding to stay engaged throughout the process. As the industry grows in 2023 and continues to prioritize safety and sustainability in its production and operations, interested parties must be familiar with both the FHWA’s policy and the reasons for its disapproval. Ensuring lasting and effective changes are made to our infrastructure will depend on the input, interest, and involvement of all impacted industries.

For more information about NATM’s government affairs advocacy initiatives, contact NATM Interim Executive Director Alex Stowe at Alex.Stowe@natm.com. ■

8 March/April 2023

TRACKS GOVERNMENT AFFAIRS

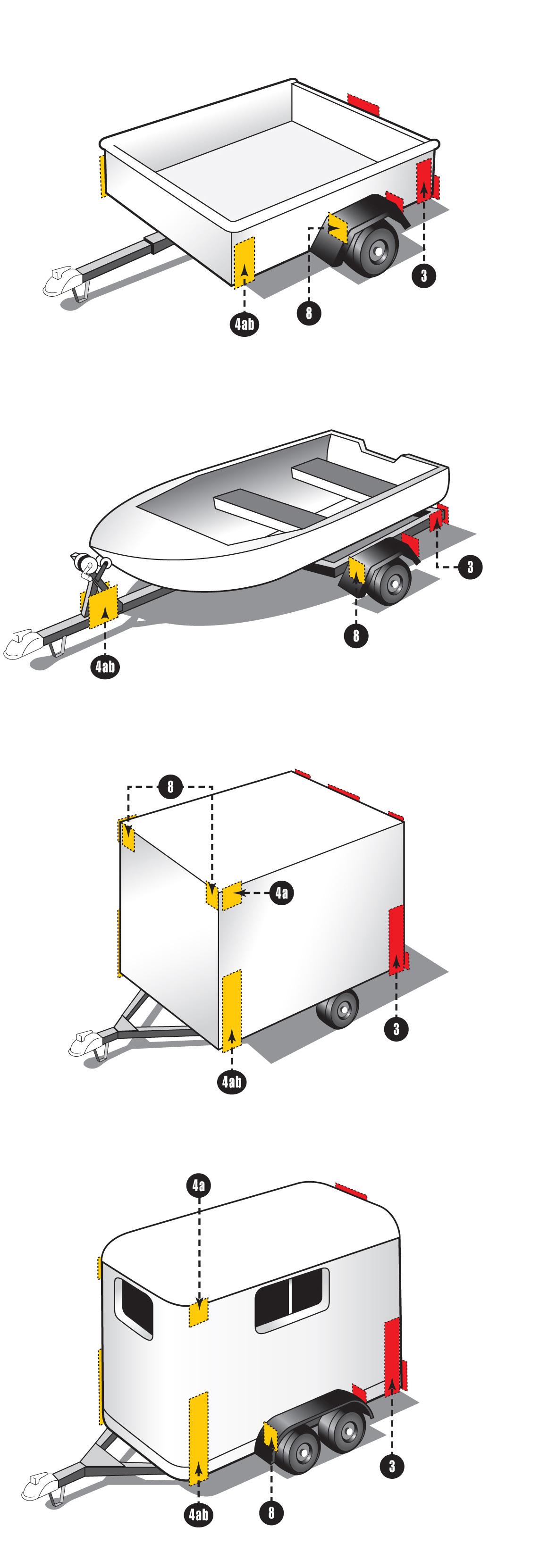

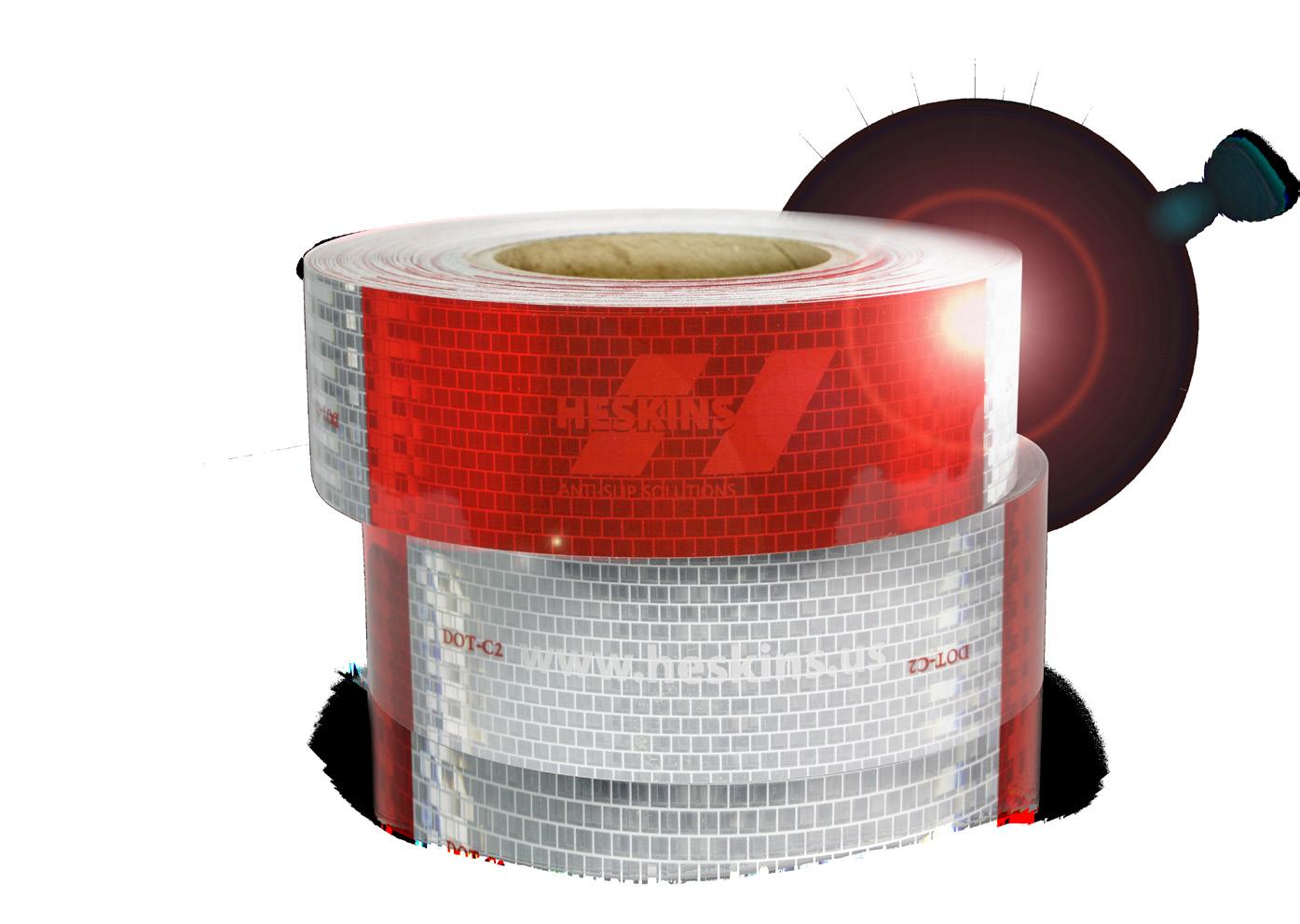

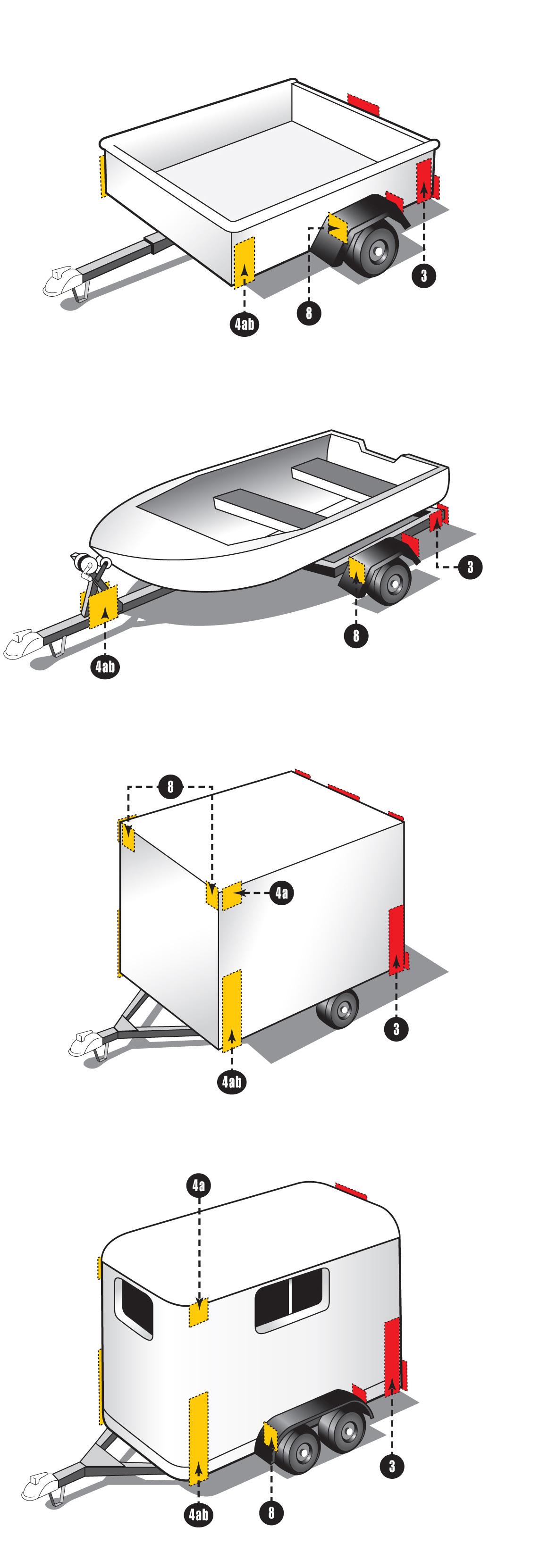

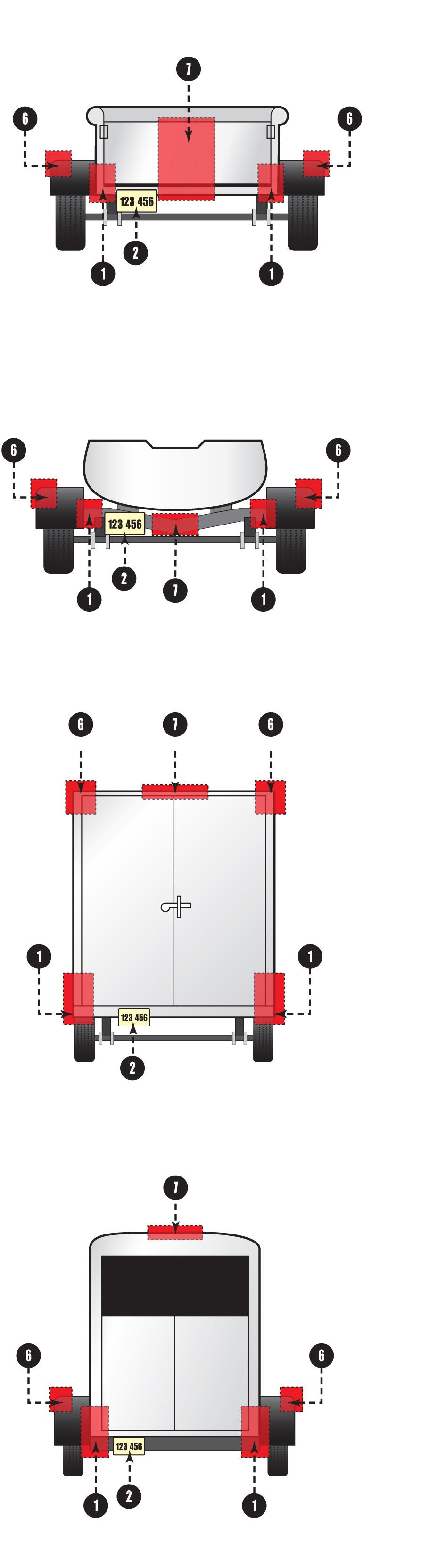

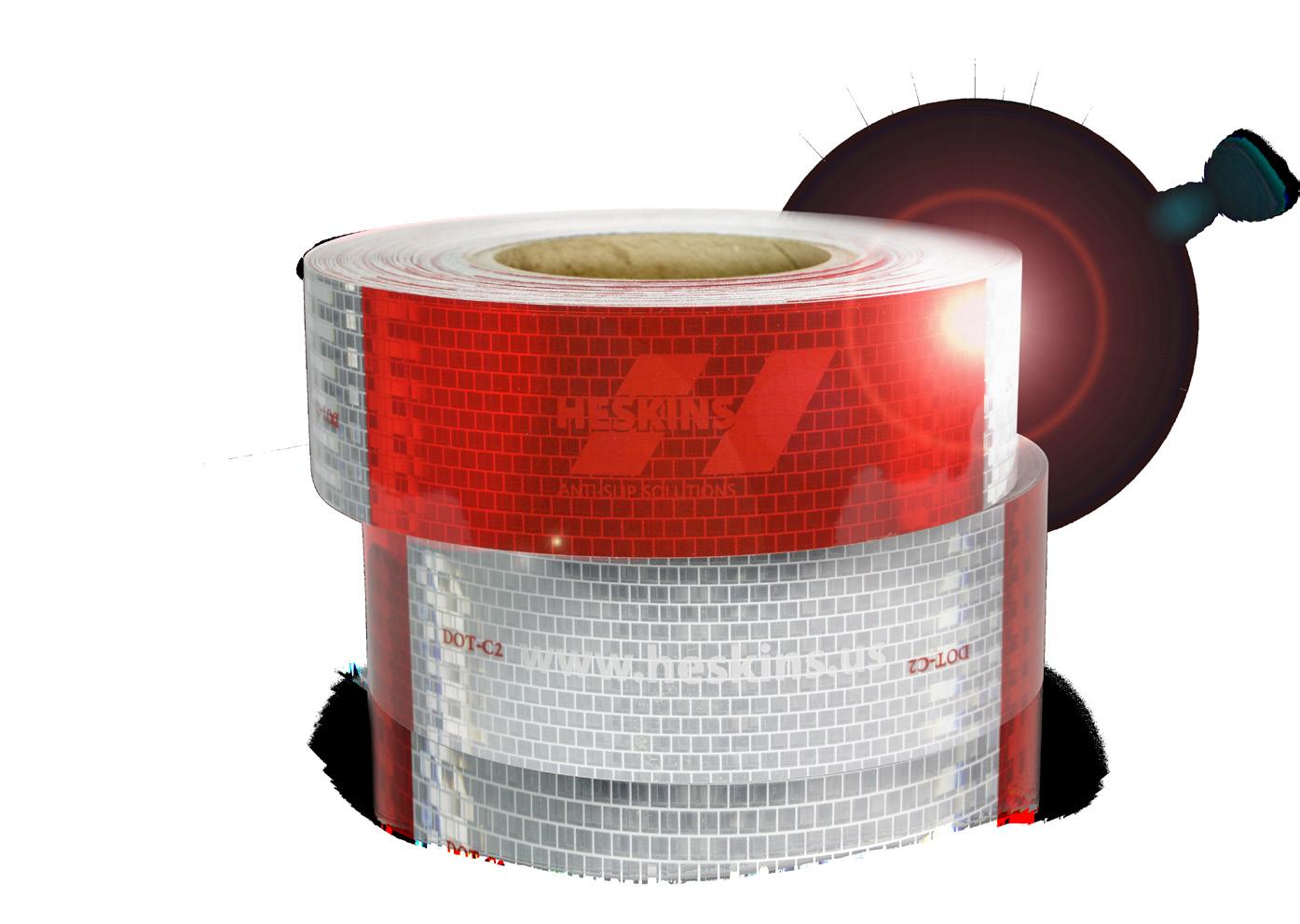

9 REFLECTIVE TAPES DESIGNED TO MEET FMCSA REQUIREMENTS FOR VEHICLE CONSPICUITY Conspicuity DOTC2 Tape The consistently high performance of Heskins reflective materials make them some of the most competitive products on the market. The Vehicle Conspicuity Marking range is chemical, corrosion and impact resistant, and is FMVSS 108 and ASTM D4956 DOT certified. Glass bead or microprism options

printed

It doesn’t have to be our logo - it can be yours, or your customer’s. Heskins can customize DOT tape with logos or web addresses. Resellers and OEMs can use custom printed DOT tape to spread brand awareness. Tel 877-900-8359 heskins.us Heskins LLC, PO box 559, East Butler, PA 16029

Custom

DOT tapes

10 March/April 2023 www.NATM.com TRACKS GOVERNMENT AFFAIRS

Member Invitation to September Regulatory Roundup, Capital Hill Visits

By Meghan Ryan, NATM Assistant Director

By Meghan Ryan, NATM Assistant Director

The National Association of Trailer Manufacturers (NATM) will be hosting the Regulatory Roundup and Capitol Hill events in Washington in September and welcomes members across the nation to participate. Along with the Convention & Trade Show, this is one of NATM’s most important events of the year.

The NATM Regulatory Roundup and Capitol Hill Visits are hosted in person in Washington and play a pivotal role in improving legislators’ knowledge of the light- and medium-duty trailer industry. The event will be split into two separate days to allow participants to spend a full day on Capitol Hill to meet with members of Congress.

During the Capitol Hill Visits, teams disperse to visit with three to four congressional offices. Teams are comprised of three to four participants with an experienced team leader. Handout materials and talking points are provided to each participant, along with educational materials to share with the Senator, Representative, and/or their staff. This is a great opportunity for members to learn more about what is going on in the industry, as well as build positive relationships with those regulating the industry. NATM members in key districts will be contacted to attend in order to have a constituent present at the meetings.

NATM’s long-term approach to, and investments in, government relations continue to pay dividends to the Association and its members. Legislative and regulatory enactments are important and beneficial to NATM, but preventative activities are perhaps more important from NATM’s perspective. The Association has been successful on both counts. The current government relations program is strong, maintains a steady course, and will continue to provide tremendous value to NATM members. Expanding the participation at the Regulatory Roundup and Capitol Hill Visit will help build on that success and help NATM educate members of Congress about the trailer manufacturing industry.

The Regulatory Roundup will be held at the K&L Gates offices in Washington and feature expert speakers on the topics of trade, tariffs, and government affairs. During previous Regulatory Roundups, attendees have heard from Congressional staffers, officials from the National Highway Traffic Safety Administration (NHTSA), and experts from the National Association of Manufacturers (NAM).

For more information about participating in the 2023 Regulatory Roundup and Capitol Hill Visits, contact NATM Assistant Director Meghan Ryan at Meghan.Ryan@natm.com or (785) 272-4433. ■

11 March/April 2023 www.NATM.com

Tie Down Is Your #1 Source For Manufacturing The Most Reliable Trailer Parts & Accessories: • Custom Aluminum, PVC, & Steel Fenders • Boat Trailer Accessories • And All Your Custom Fabrication Needs Atlanta, GA. • www.tiedown.com TRACKS GOVERNMENT AFFAIRS

NATM Announces Board of Directors Updates

By Alex Stowe, NATM Interim Executive Director

For 35 years, the National Association of Trailer Manufacturers (NATM) has been fortunate to be guided by committed, forward-thinking Boards of Directors. It is these visionary boards that pushed for the development of the Compliance Verification Program (CVP), determined the need for government affairs representation in Washington, pulled trailer dealers into the Association through the Dealer Affiliate Program, and developed fiscal policies that ensured NATM had the reserves to weather recessions and even the pandemic.

NATM’s Board of Directors is comprised of 16 to 17 individuals (this variance in size is related to Board terms as dictated by the Bylaws): 12-13 trailer manufacturers and four suppliers or service providers to the industry. These individuals are nominated by their peers and before advancing to the ballot, each nominee’s qualifications, including industry experience and participation in the Association, are reviewed by the nomination committee, and a slate of candidates is prepared for election by the membership.

Split into three classes with rolling term expirations, roughly one-third of Board seats are up for election each year. The 2023-2026 term of the NATM Board of Directors, as elected by the membership will include the return of Bill O’Hara (Dexter), Jon Devitt (Midwest Industries, Inc.), Jeff Jones (Statistical Surveys, Inc.), Dustin Miller (Cross Trailers, Inc.), and Mike Story (LOOK Trailers), as well as new Board member Michael Etheridge (Wylie & Son, Inc.).

These new Board members officially joined their peers on

Feb. 13, 2023. The Association is looking forward to continuing its work with these new and returning Board members! As always, the NATM Board of Directors is interested in and open to member feedback. While members are encouraged to reach out to staff with ideas about how to improve the Association, Board members are also available to the members to discuss!

These new Board members will join the rest of the NATM Board of Directors, broken down by term:

2021-2024 Term

› Leo Akins - Forest River, Inc.

› Andy Derr - M.H. Eby, Inc.

› John Kerr - Marsh & McLennan Agency

› Rick Huddleston - White River Marine Group, LLC

2022-2025 Term

› Charles Daugherty - Red Fern Dynamics, Inc.

› Andy Gehman - MGS Incorporated

› Daniel Luby - BoatMate Trailers LLC

› Nathan Uphus - Felling Trailers ■

12 March/April 2023 www.NATM.com

TRACKS MEMBERSHIP

NATM 2023 Committees Announced

By Alex Stowe, NATM Interim Executive Director

The National Association of Trailer Manufacturers (NATM) is a not-for-profit directed entirely by its membership base and their elected representatives. NATM’s Committees serve a vital function in guiding the work of the Association. Committee members support the adaptation and evolution of the Association while seeing to it that the strategic vision established by the Board of Directors is being carried out.

Committee volunteers signed up in record-breaking numbers to serve in 2023. With 115 individuals signing up to volunteer their time, nine committees with specific goals were established by the Executive Committee. These nine committees are Compliance, Convention, Trailer Dealers, Education, Finance, Government Affairs, Membership, Technical, and Technology.

Meeting from monthly to quarterly, these committees will tackle big goals in 2023. These include, but are not limited to:

• Updating NATM’s Generic Owner’s Manuals

• Reviewing and updating NATM’s Investment and Reserves policies to ensure the Association is both prepared for the future and reinvesting in members today

• Working with OEMs to try and find ways to involve trailer manufacturers in their processes

• Expanding Dealer Affiliate benefits

If you are interested in learning about NATM Committees or would like to get involved, please contact NATM Interim Executive Director Alex Stowe at Alex.Stowe@natm.com

Operations Executive

› Marco Garcia – U-Haul International, Inc.*

› Andy Derr – M.H. Eby, Inc.

› Nathan Uphus – Felling Trailers

› Marty Lorick – Triple Crown Trailers, Inc.

› John Kerr – Marsh & McLennan Agency

Finance

› Nathan Uphus – Felling Trailers*

› Haden Anderson – C3 Rentals LLC

› Charles Daugherty – Red Fern Dynamics, Inc.

› Andy Derr – M.H. Eby, Inc.

› Marco Garcia – U-Haul International, Inc.

› Josh Gurley – Truck and Trailer Makers

› Bob Harris – AmeraTrail, Inc

› John Kerr – Marsh & McLennan Agency

› Richard Lavanture – LaVanture Products Company

› Marty Lorick – Triple Crown Trailers, Inc.

› Don Taylor – BrakeQuip

› Kevin Ten Haken – Demco

Member Services Convention

› Doug Beaver – M.H. Eby, Inc.*

› Kyndal Clark – Marsh & McLennan Agency

› Angela Collins – Twister Trailer

› Brent Freel – Kampco Steel Products, Inc.

› Marco Garcia – U-Haul International, Inc.

› Melanie Gibson – Dexter

› Robert Roden – H.E. Parmer Company, Inc.

› Dustin Smith – Optronics International

› Ami Stombaugh – TASKMASTER COMPONENTS

› Paula Travis – WESCO Distribution

› Devlun Whiteing – Midwest Industries, Inc.

› Andrea Wolf – PPG

Continued on Page 14

13 March/April 2023 www.NATM.com

MEMBERSHIP TRACKS

NATM Committees Announced Continued

Education

› Andrew Caine – Bludot Manufacturing*

› Kevin Foust – ContainGo Transport Solutions

› Juan Hernandez – The Trailer Parts Outlet

› Eric Kazmierzak – Laclede Chain Mfg. Co.

› Tim Lamers – Chilton Trailers Mfg.

› Scott Smith – SIRCO Industries, Inc.

› Richard Walker – TASKMASTER COMPONENTS

Government Affairs

› Leo Akins – Forest River Inc.*

› Deborah Edwards – SteelPoint

› Andy Gehman – MGS Incorporated

› Patrick Jennissen – Felling Trailers

› Brett Johnson – Optronics International

› John Kerr – Marsh & McLennan Agency

› Justin Kurth – White River Marine Group, LLC

› Randy McMann – Dexter

› Dustin Miller – Cross Trailers, Inc.

› Eddie Rackleff – Lippert

› Ty Scott – Cargo Towing Solutions

› Mike Story – LOOK Trailers

› Conrad M. West – EZ Loader Boat Trailers

› Konrad Pilatowicz – U-Haul International, Inc.

› Marty Lorick – Triple Crown Trailers, Inc.

Membership

› Marcus Hester – Optronics International*

› Lisa Clark – Marsh & McLennan Agency

› Joshua Coster – Wil-Ro, Inc.

› Shane Feng – American Trailer Works (ATW) Corporate

› Doug Houlahan – Clicklease

› Kevin Janiak – Terran Axle

› Jeff Jones – Statistical Surveys, Inc.

› Mark Lysaght – Supply Technologies, LLC

› Bill O’Hara – Dexter

› Mike Trull – Peak Metals, Inc.

› Wen Zhang – Miller Auto Technology LLC

Trailer Dealer

› Greg Blaser - Trailer World of Oregon*

› Henry Boer - 1000 Islands RV Centre

› Rod Hathaway - Maine Trailer, Inc.

› Lisa Huntley - Trailers Plus Inc

› Nicholas Jameson - 51 Trailer Sales

› Royal Kropf - Diamond K Sales

› Mark Mayfield - Leonard Aluminum Utility Buildings, Inc.

› Charles Morrison - Truck’n America

› Josh Widdes - Widdes Trailer Sales

› Scott Yates - Smoky Mountain Trailers

14 March/April 2023 www.NATM.com

TRACKS MEMBERSHIP

Technical Compliance

› Rick Huddleston – White River Marine Group, LLC*

› Andrew Alger – TRP International, LLC

› Willie Bauer – CAR MATE Trailers, Inc.

› Mike Becker – Forest River, Inc.

› Michael Daly – Kenda/Americana Tire & Wheel Corporation

› John Dietz – Sewer Equipment

› Charles Lange – Legend Manufacturing, Inc.

› Bryce McIntyre – American Eagle Accessories Group - Division of Stellar Industries, Inc.

› Erica Matthews – Optronics International

› John Terrell – Big Tex Trailer Manufacturing, LLC

› Bob Harris – Ameratrail, Inc

› Shane Buckner – GPS Trailers

Technical

› Michael Etheridge – Wylie & Son, Inc.*

› Dave McKee – Bwise Manufacturing, LLC

› William Craig – U-Haul International, Inc.

› Nathan Dosmann – Dec-O-Art, Inc.

› Murat Gocay – TASKMASTER COMPONENTS

› Al Henderson – Kenda/Americana Tire & Wheel Corporation

› Taylor Jones – B & W Trailer Hitches

› Tom Kaufman – Hillsboro Industries

› Kevin Koyle – TecNiq

› Sam Lievore – Dexter

› Sam Loganathan – Triple Crown Trailers, Inc.

› Rod Ludwig – Midwest Industries, Inc.

› Bill Pharmer – Airgas, Inc.

› Owen Shelton – BoatMate Trailers LLC

› Iqbal Singh – Hopkins Manufacturing Corporation

› Brandon Starkey – EZ Loader Custom Boat Trailers

› Patrick Turley – Bludot Manufacturing

› Julia Poppe – 3M

Technology

› Jeff Gray – ASA Electronics*

› Steven Aiuto – General Motors

› Eric Bierwagen – LANE Trailer Mfg. Co.

› Michael Buckner – GPS Trailers

› Michael Burbey – Atotech USA LLC

› Matt Christian – KTI Hydraulics, Inc.

› Shaun Douglass – Optronics International

› Andrew Duggan – Hillsboro Industries

› Jonathan Gravell – Truck System Technologies

› Josh Jaspers – Demco

› Scott Kleman – Champion Hoist & Equipment

› Cary Kronebusch – Peerless Industrial Group

› Joe Livingston – Vitracoat America, Inc.

› Daniel P Luby – Boatmate Trailers LLC

› Mark Nave – Dexter

› Darren Opsahl – Galeo

› Christopher Rauch – Crystal Welding, Inc.

› Nathan Uphus – Felling Trailers

› Marco Garcia – U-Haul International, Inc.

› Mark Sawicki – American Trailer Works (ATW) Corporate

› Chris Skallerud – Ford Motor Company

* Indicates Committee Chair ■

15 March/April 2023 www.NATM.com

TRACKS MEMBERSHIP

FOR EVERYTHING TRAILER TRUST DEXTER

Tomorrow is uncertain, but you can rely on Dexter for quality and reliable trailer parts and accessories. Our dedication to providing highly-tested aftermarket products to our customers since 1960 has stood the test of time.

With locations and distributor partners across North America, we have the right part when you need it quickly. When you depend on Dexter, you can get your customer's trailer out of the shop quicker and keep it on the road longer.

TRAILER PARTS AND ACCESSORIES

AXLES | BRAKES | TIRES & WHEELS | FENDERS | JACKS

16 WWW.DEXTERGROUP.COM

NATM Announces 2023-2026 Strategic Plan

By Alex Stowe, NATM Interim Executive Director

In July of 2022, the National Association of Trailer Manufacturers (NATM) Board of Directors met in person to discuss the Association’s new strategic plan for 2023-2026. NATM staff, the Board, and Executive Committee quickly began to work on structuring committees and committee goals to ensure there would be alignment between committee goals and the newly developed strategic plan. The strategic plan sets out four areas of focus for the Association:

1. Advocacy and Partnerships

2. Education

3. Decal Awareness

4. Cohesive Industry

Advocacy and Partnerships

The goal of Advocacy and Partnerships for the Association is to promote and protect the light- and medium-duty trailer industry through key legislative and industry relationships.

Regulatory Roundup, Government Affairs, and NHTSA

NATM will continue working with legislators and the National Highway Traffic Safety Administration (NHTSA) on gathering additional funding for Trailer Safety Week. Further, through lobbying efforts and the Regulatory Roundup, NATM will seek to gain advocates for our industry on key external committees in Congress. NATM will also work to collaborate with state Departments of Transportation (DOTs) on understanding the value of the NATM Decal and what it means for trailer safety and compliance.

To achieve these goals, the Association will work to increase member participation in grassroots efforts. NATM will explore legislative relationships in key states for our members with the assistance of K&L Gates. Further, NATM will work to establish a network of members in key states and actively work to build relationships between those members and their state-level legislators.

Industry Alignment

NATM will work to build relationships with organizations like the Truck Trailer Manufacturers Association (TTMA), the National Marine Manufacturers Association (NMMA), the RV Industry Association (RVIA), and other relevant groups to identify current issues and determine opportunities where our Associations may be able to collaborate and

assist the industry as a whole. This will involve setting up standing meetings with these other organizations to ensure we are in regular contact and are able to assist as needed.

Education

NATM will provide the industry with access to educational resources and promote the production of safe trailers. In addition to this, NATM will work to increase dealer and end-user knowledge of NATM and provide those groups with accessible educational information about safely towing a trailer.

Industry Access to Educational Information

NATM will work to build more shared repositories of educational resources that can be shared with members to assist in building safe trailers. NATM will engage subject matter experts who can provide educational webinars or presentations to members on areas of interest to the industry. In addition to engaging with the subject matter experts, NATM will work to expand participation in webinars and forums taking place during our annual Convention & Trade Show.

NATM will hire an Education Director, whose job will be to focus on expanding educational content offerings and work to build out the NATM Academy. The NATM Academy will assist members with training their staff on identified best practices in the industry and offer a resource library that can be used to store this information for on-demand viewing.

Increasing Dealer, End-User Knowledge of NATM

NATM will work with staff and members to generate educational content that is intended to assist end-users in safely towing their trailers. To achieve this goal, NATM will continue to collaborate with our Dealer Affiliate members and work to grow this network. NATM will provide resources to our Dealer Affiliates that can be shared with end-users. End-users will be encouraged to visit TrailerSafetyWeek.com and view materials created by the Association that are intended to provide best practices while towing a trailer. NATM also will work to make sure Dealer Affiliates and end-users have a better understanding of our Association’s decal and what steps manufacturers must take in order to place the decal on members' trailers.

Continued on Page 18

17 March/April 2023 www.NATM.com

TRACKS MEMBERSHIP

Decal Awareness and Growth

NATM will work to expand our dealer network and provide education on what our decal stands for, along with the process manufacturers must complete in order to display it on their trailers. The Association will work to increase decal sales amongst the membership and seek to increase membership participation by providing more “value” in our decal. NATM will utilize compliance verification consultations to educate manufacturers and their interested employees on both NATM and the decal.

Through a collaboration with NATM’s Dealer Affiliates and members, dealers will seek out trailers featuring the decal as it will help ensure that the trailers they are selling have had a third party verify that the company has the processes in place to build trailers that meet the required Federal Motor Vehicle Safety Standards. The NATM staff, and specifically the member outreach specialist, will work to grow our Dealer Affiliates and provide feedback on the value NATM is providing to the Dealer Affiliates. By increasing the understanding and awareness of the decal, NATM seeks to increase members participating in the decal program.

Cohesive Industry

NATM, with the assistance of the Board and Committees, will work to ensure we are the reputable resource of trailer information for consumers, trailer

manufacturers, component suppliers, trailer dealers, OEM vehicle manufacturers, and regulators.

Industry Participation Growth

By continuing to expand our educational offerings, trailer safety information, and compliance programs to the entire industry, including end-users, NATM will continue to grow our membership in all areas. NATM, the Board, and Committees will seek to engage non-members on the benefits of NATM and what we offer to the industry. NATM members will also work to bring their dealer networks into the Association’s Dealer Affiliate Program, this continued growth will assist in providing information to both dealers and end-users.

NATM’s membership increases engagement and participation in Trailer Safety Week. By having a cohesive and concerted message shared by members about the importance of trailer safety, brand awareness will grow, and NATM can continue to further its mission of promoting trailer safety and overall industry success.

Member companies can expect to see much more value in the coming years as the Association Board, Committees, and staff continue to put together additional programming and benefits in these four key areas. Members are also encouraged to provide feedback and participate in surveys so that NATM may better tailor these new opportunities to its members. ■

18 March/April 2023 www.NATM.com

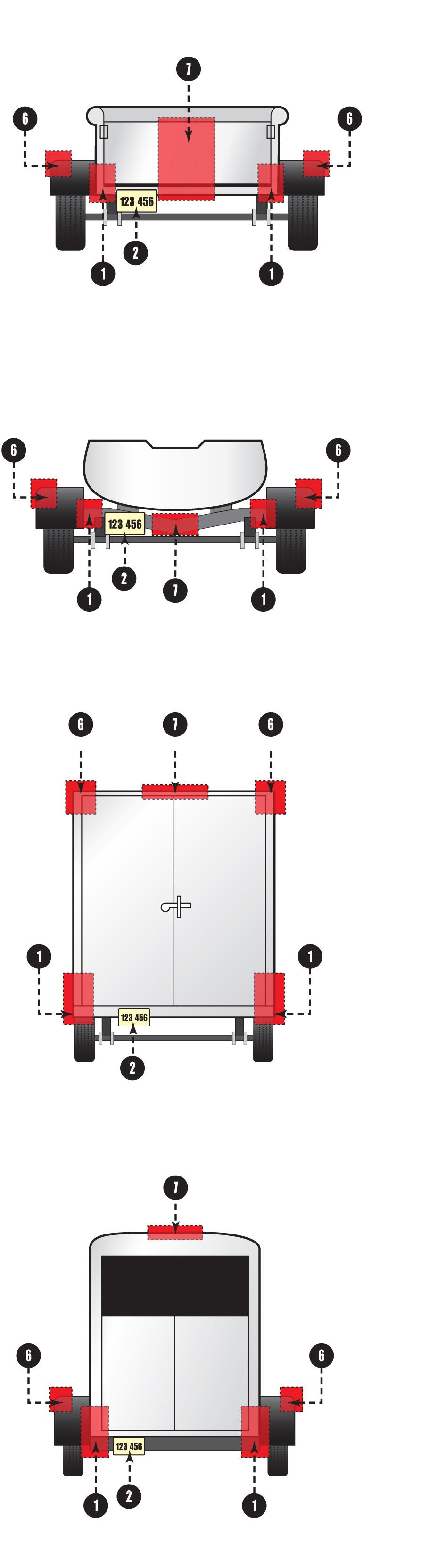

IDCspring.com | 763-786-6527 Follow Us @idcspring ©2022 IDC Spring. All rights reserved. Springs are our thing. TRACKS MEMBERSHIP

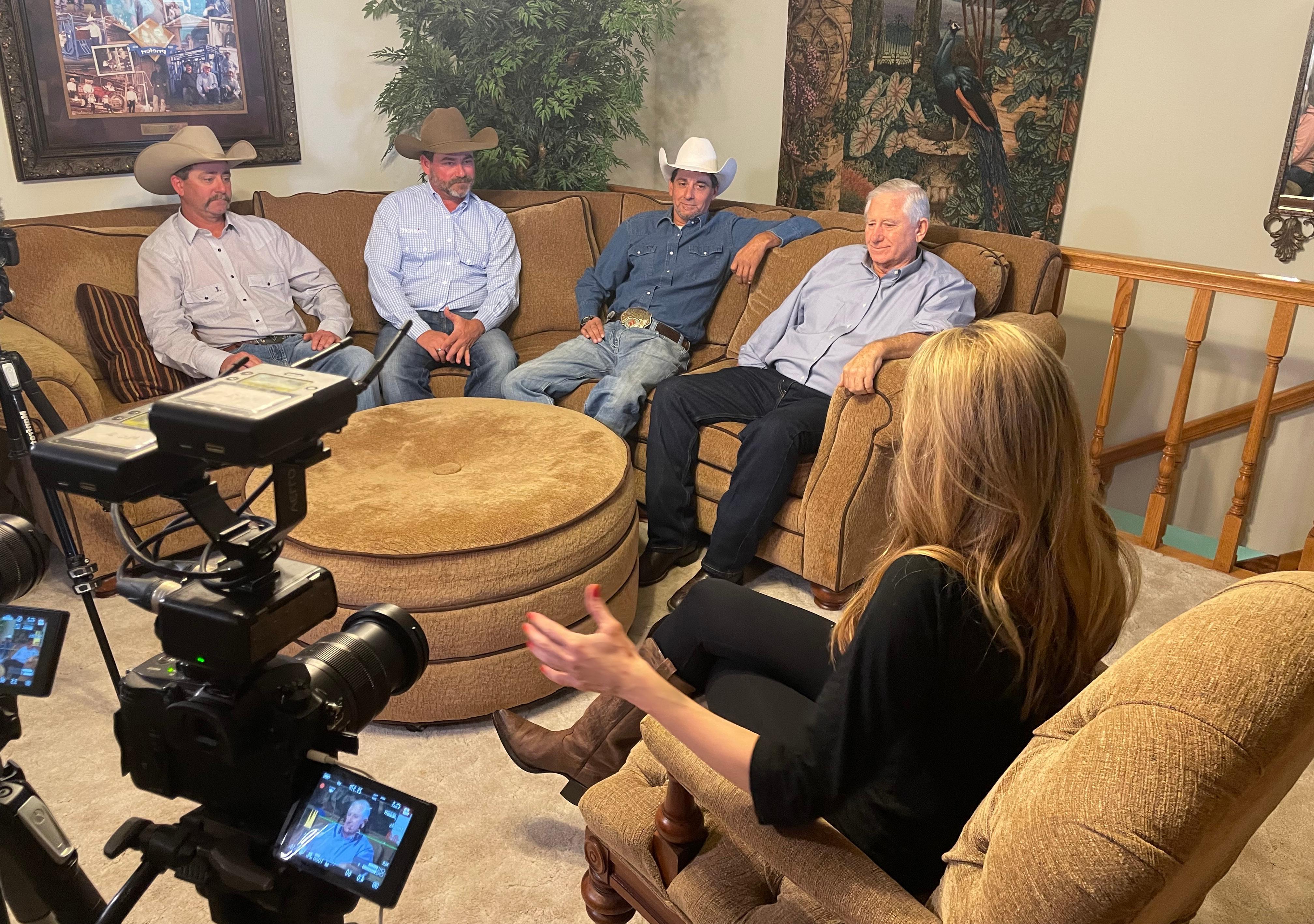

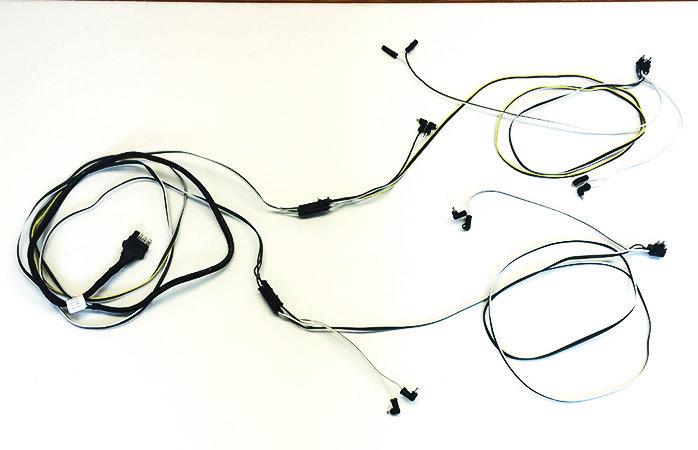

Priefert Steel Story to be Featured in 'The Rural Americans' Episode

By Samantha Darling LaCount, NATM Tracks Editor

The National Association of Trailer Manufacturers (NATM) member Priefert Steel is one facet of the Priefert family business. And that family business is slated to be featured on RFD-TV’s upcoming episode of “The Rural Americans.”

RFD-TV is a cable network dedicated to the rural community. “The Rural Americans” is in its second season and is described by the showrunners as, “A documentary-style show featuring the pioneers of business, entertainment, and agriculture. The legends of days past, and the architects of a bright future. The men and women who transformed their lives from humble beginnings in small town USA, to world-famous captains of industry. These are their stories, in their words, as only they can tell them.”

Christina Loren is a meteorologist and anchor for RFD-TV as well as the host of "The Rural Americans." She was part of the crew to visit Priefert and see more about how to company runs.

"Each family member plays an intricate role in the harmonious success of Priefert, and our team thoroughly enjoyed learning about the evolution of the company in Mount Pleasant, Texas," Loren said. "As the Priefert family upholds and passes down the teachings of Jesus Christ to their children and grandchildren, my confidence is restored in the next generation. The Prieferts are living proof that God, family, and country still reign supreme in rural America."

20 March/April 2023 www.NATM.com

MEMBERSHIP TRACKS

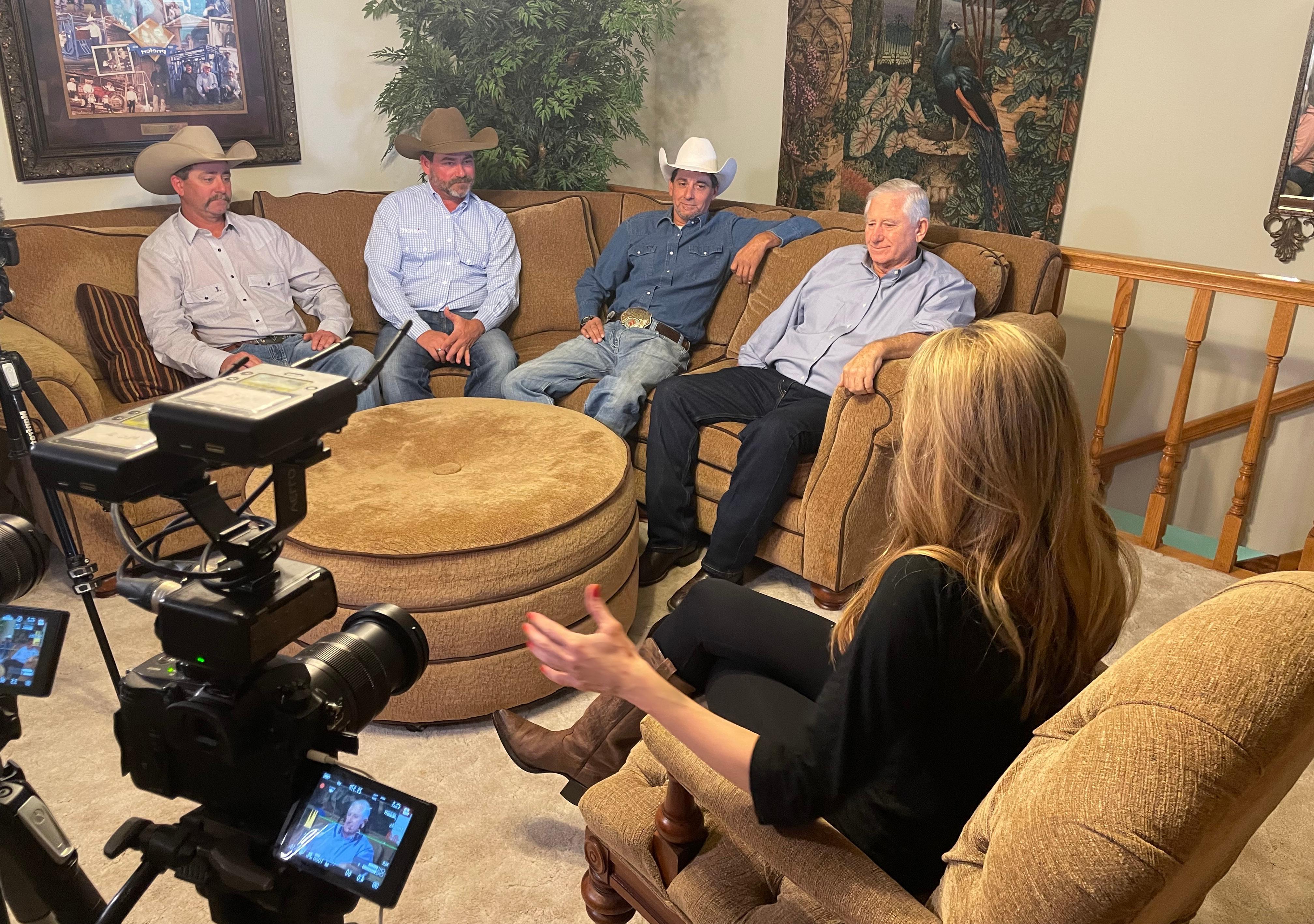

The RFD-TV crew visited the Priefert ranch in

(Left to right) Nate, Eddie, Travis, and Bill Priefert sit down for an interview with Christina Loren to be featured in an upcoming episode of "The Rural Americans." Photo submitted by RFD-TV.

RIGHT: Host of "The Rural Americans," Christina Loren (left), sits down with Travis Priefert for an interview on the family property in Mount Pleasant, Texas.

BELOW: Eddie Priefert (left) walks the shop floor with Christina Loren, the host of "The Rural Americans," when her and the RFD-TV crew visited the facility in late October 2022.

October 2022 to film an episode highlighting the family business that started with one invention in the backyard.

“I think really the core of it is the American dream and American manufacturing,” said Courtney Dyer, Marketing Director for Priefert. “Not a lot of manufacturing happens in the U.S. anymore. Us being a family-owned manufacturing company that’s in its third generation of family leadership, I think it’s something really cool and unique.”

Priefert founder Marvin Priefert was a farm kid from Nebraska. He didn’t have a lot of experience with livestock, but he did have several patents and inventions under his belt. He moved his family to Texas, and his innovative mind found a new target in cattle headgates.

“A headgate you use when you're doctoring cattle. At the time, the predominant style of headgate back in the early '60s was what they called a guillotine-style headgate. It's very much like what it sounds like,” Dyer said. “It would close over the top of the head and underneath the chin. You have to back them back out of it before you can bring the next one in. It wasn't super efficient for working cattle.”

“Not a lot of manufacturing happens in the U.S. anymore. Us being a family-owned manufacturing company that’s in its third generation of family leadership, I think it’s something really cool and unique.”

Priefert was helping a neighbor with their cattle. The innovator in him couldn’t help but think there must be a better way. He went home and welded together a new prototype.

“His concept was the headgate should close around the sides of the animal’s neck, so imagine walking into sliding glass doors that open and close to the side,” Dyer said. “It closes around the side of the animal’s neck once she sticks her head through, then you're not choking them down. You don't have anything underneath their chin or under their neck to choke them on. Then when you get done, Marvin’s

Continued on Page 24

21 March/April 2023 www.NATM.com

Courtney Dyer

Photo submitted by RFD-TV.

TRACKS MEMBERSHIP

Photo submitted by RFD-TV

22 Stillwell Push Pull Lift Level stillwellinc.com 612-248-1110 Vaquero ST516 & ST521 Hoists Atlas Made in America Valves, Hoses & Adapters Welded Cylinders YOUR SOURCE FOR CUSTOM HYDRAULIC SOLUTIONS

23 Composite handles only www.demco-products.com 1.800.543.3626 Doing Our Best to Provide You the Best Scan the QR code or go to: https://bit.ly/3FyAY6w Find out more about Demco! NEW JACKS! NOW Jacks that match your couplers TOYOTA PART # DESCRIPTION GVWR COATING DIM RET/EXT TUBE 16730 Top wind side mount swivel 2000 lbs. Plated/Plated 9” / 18” Welded Foot 17238 Top wind pipe mount 2000 lbs. Black/Plated 11” / 21” Welded Foot 17240 Top wind A-frame 5000 lbs. Black/Plated 8.25” / 24.25” Open Tube 17241 Side wind pipe mount 5000 lbs. Black/Plated 10” / 20” Welded Foot 17245 Side wind weld-on drop leg 7000 lbs. Black/Plated 24” / 53” Welded Foot 17247 Top wind weld-on drop leg 7000 lbs. Black/Plated 24” / 53” Welded Foot For pricing: call 800-543-3626 or email sales@demco-products.com

concept was it should open up wide as a barn door, let one animal walk right out the front, and entice the next one in line to come in behind her, assembly line style.”

The neighbor loved the idea, so Priefert got to work on a real, working model. It was 1964, and the Priefert family business was born.

“He would sign that vet up as a dealer and leave him three headgates to sell to different customers, so that was kind of how our dealer network got started,” Dyer said. “Today, on the ranch equipment side, we’ve got over 1,200 dealers, and we export ranch equipment to 27 different countries internationally.”

The company has grown a lot over the last almost 60 years. Bill Priefert was 14 when his father started the company. Marvin passed away in 1988, and Bill took over and oversaw the company's rapid expansion in the ‘90s and early 2000s.

“That was the headgate he created, and he believed in it. He actually showed it to a couple other manufacturers and they were like, ‘Yeah, that’s too different. That's not how it's done.’ He believed in it enough that he was like, ‘You know what? I'm going to go into manufacturing. I’m going to make this and sell it,” Dyer said. “He recruited his brother to help. They welded one of those headgates onto the back bumper of a 1967 Mustang.”

The brothers drove that Mustang and headgate to veterinary offices, where they would back it up to the front door and show the local vet.

“A lot of (the show’s) interview is going to focus on Bill and the changes he saw and what it was like seeing his dad start a company basically with one product that he made in a dirt floor shop out in the backyard at the time, then, watching that grow into one of the largest ranch equipment companies in the world, then, seeing the sons come and become part of the family business, and then, expanding into steel and all of the things that that has brought with it,” Dyer said.

Bill has three sons: Eddie, Nate, and Travis. It is very much a family business, and all four Prieferts have their roles to play.

“Bill is our CEO. He is very involved in the growth aspect, the future planning of the site. We've got 30 acres right now that are under development. Bill’s usually here in the mornings and makes the big, important meetings, and then he spends his afternoons on a piece of heavy equipment doing dirt work on the land that's being developed because that's Bill’s happy place,”

24 March/April 2023 www.NATM.com

“At the end of the day, yes, we’re a company, but it's their name on our products. If it's going out with their name, that means something to them and to their family legacy.”

TRACKS MEMBERSHIP

(Left to right) Nate, Bill, Eddie, and Travis Priefert gather for a company family photo. Photo submitted by Priefert.

Dyer said. “Eddie is our president, and Bill handed the reins over to him a few years ago for more of the day-to-day. He's very heavily involved in all things administration, all things sales. He has a real passion on the rodeo side of the business because his kids are all involved in junior rodeo. He does a fair amount of inventing on those products and that product category, but he's the one that runs our weekly leadership meetings and things like that. He's very much entrenched in the day-to-day.”

“Nate is very involved in engineering and logistics. Those are his passions. He's the production-minded guy. He's literally the guy that walks around with a pair of calipers in his pocket at all times because that’s just the way he’s wired. If you saw him at the shop, you wouldn’t think, ‘Oh, that’s a Priefert.’ He’s literally in dirty jeans and a dirty t-shirt from being out in the shop with the engineers or out in the machine shop tinkering on stuff. He's very involved in that side of the business,” Dyer said. “Travis has been more involved on the ranching side, the cattle operation. The family — they are ranchers. They live the lifestyle. It's not just, ‘Oh we're going to build ranch equipment and sell it to people.’ They actually have a cowcalf herd. They’ve got horses. Nate raises horses. Eddie's kids rodeo. Travis breeds dogs. They live the lifestyle. They are part of rural America — the Western lifestyle. They do still have a family ranch, hay operation, cattle operation, all of those things, and that's what Travis is more involved in.”

The second and third generations of Priefert got into steel almost by accident. What started as

lending a helping hand during the 2008 recession turned into a major facet of the business.

“We're located in Northeast Texas. It's kind of the heart of trailer manufacturing country, lots of trailer manufacturers in the area, three or four here just in town, so it was actually one of the other trailer companies that called us during that time,” Dyer said. “They were having trouble getting the steel that they needed.”

Priefert wanted to help out and gave the other manufacturer a quote. The company came back and said the price was so low it had to be wrong. Priefert confirmed that it wasn’t. That’s when they realized they were processing such a large volume of steel, they were getting a better price than other companies.

“We started selling some steel just to fill in the gaps during those harder times during the recession,” Dyer said. “As we came out of the recession, I think it was 2012, when we officially created a division called Priefert Steel. It came from this side hobby and taking care of some folks here in town, helping out some friends.”

Once Priefert’s own manufacturing operation had to wait for

steel because they were selling so much to other companies, they knew it was time to make it a separate division. Priefert Steel was created in 2012, and Dyer says it took off.

Throughout all this growth, they’ve stayed true to their roots. One of their most popular products is still the headgate and another early product.

“The first product was a headgate. He moved on to eventually doing a full squeeze chute. The headgate is just the part that catches them around the head,” Dyer

Continued on Page 27

25 March/April 2023 www.NATM.com

A young Bill Priefert examines a cow held in the headgate designed by his father, Marvin.

Photo submitted by Priefert.

TRACKS MEMBERSHIP

Marvin Priefert poses with the headgate he designed. This design revolutionized the industry and is now the most common design of headgate. Photo submitted by Priefert.

Contact Jeff Gray at jgray@asaelectronics.com for more information thinking ahead on backing up. Voyager ® Vision turns your smart device into a short-range, wireless camera monitor, for use with the Voyager WVOS2TX Wi-Fi transmitter and up to two wired Voyager cameras. The transmitter delivers the camera feed directly to your device to assist during low-speed maneuvers, stationary observation or for surveillance. learn more on youtube

said. “The squeeze chute is where the animal walks into it, the whole thing, and it actually squeezes them gently around the sides to hold still so that you can access them for vaccination, for branding, for worming, for checking hooves, anything that you need to do to treat that animal.”

The concept of the side-to-side headgate changed the industry. Dyer says most headgates follow that model now instead of the old guillotine style. It’s still how their headgates operate to this day. Unsurprisingly with this family, there have been innovations along the way.

“There's definitely a lot more bells and whistles, but at the core, the idea that it needs to fit comfortably around the animal's neck and not tug them down and then open up let them walk through, that’s pretty much how most headgates are today,” Dyer said. “The squeeze chute today has a ton more features to make it more animal safe, more user-friendly, make it more efficient so the animal spends less time in the chute. It’s got contoured sides to match the shape of cattle. You can adjust the floor in and out, so if you're working young calves, all the way up to your great big bull. You can change the fit of the shoe, so to speak, pretty quickly so it fits the animal that you're working. Lots of additional access points, so if you need to get to a hoof, you need to get to a hip, there are safe ways to access all the different parts of the animal. Just lots of little innovations and tweaks along the way.”

Bill takes after his father and is always thinking of ways to improve their products.

“Very much like his dad, Bill has that inventor gene,” Dyer said. “You'll see him standing out the shop just staring at a piece of equipment for long stretches of time, and you're like, I don't want to go up and interrupt because you know he's building something in his head or he's figuring out how to change that or how do we tweak that.”

All the Prieferts are that hands-on. The family ranch and the company manufacturing facility are all on the same plot of land.

“These guys, if they wanted to, could just hop on their fourwheeler or on their side by side and drive to the office. It's all one big campus, which is great for the ranch equipment side of the business because they live the lifestyle. They have the livestock. It's a great idea factory,” Dyer said. “After it goes through R&D, we send it right back out to the ranch. It's kind of our proving ground. We'll get to go test stuff and break it, figure out what worked and what didn't work.”

Dyer has been with the company since 2008 and has gotten to witness the growth and expansion firsthand. She started out as the company’s event coordinator.

“At the time, we had two Guinness World Record holders for tallest living horse, and they still traveled and toured. We had a draft horse hitch, kind of similar to the Budweiser Clydesdales that traveled and toured, and I handled booking all of their

Continued on Page 28

27 March/April 2023 www.NATM.com

TRACKS MEMBERSHIP

Nate (left) and Bill Priefert do a walk through of one of the company's shops. Photo submitted by Priefert.

events,” Dyer said. “That was my first job here at Priefert.”

After 14 years at the Priefert family business, Dyer says she sees their values trickle down through all employees and that they strive to make sure the entire company feels like part of the family.

“The Priefert family is fantastic. I have an amazing team in the marketing department that I get to work with,” Dyer said. “We're a big family and that sounds very like, oh sweet, we're a big family, but we literally mean that. You spend a lot of time with these folks because you work with them, and it's just a real pleasure to spend time with these people. They become part of your life outside of eight to five, Monday through Friday. Definitely good people at every level in the company.”

Dyer says the Prieferts are humble people who would never seek out recognition for themselves. That makes the TV show reaching out to feature them even more special to the company and all its employees.

“At the end of the day, yes, we’re a company, but it's their name on our products. If it's going out with their name, that means something to them and to their family legacy,” Dyer said. “We're just really thrilled anytime we get to see their story being told because it's an amazing family, and they deserve that recognition.”

Priefert Steel has been an NATM member since 2012. To learn more about them, visit www.priefertsteel.com.

Watch the Priefert family episode of “The Rural Americans” on Sunday, Feb. 26, at 8 p.m. CST, on RFD-TV. Check your local cable provider for channel information. The episode also will be available to stream at www.watchrfdtv.com.

To submit article ideas or your own membership stories, contact Tracks Editor Samantha Darling LaCount at Samantha.Darling@natm.com. ■

28 March/April 2023 www.NATM.com

Eddie (left) and Bill Priefert sit for an interview with the RFD-TV crew. The Priefert company, how it got it's start, and how it has grown since will be the focus of an upcoming episode of "The Rural Americans" that is set to air on Feb. 26.

TRACKS MEMBERSHIP

Photo submitted by RFD-TV

29 March/April 2023 www.NATM.com The

Benders for Frame Fabrication are now part of NATM! Simple. Tough. Powerful. Fast-working. Affordable. • Quick and efficient ram-style bending ideally suited to trailer frames • Bends square, rectangular, round with the power and versatility you need • Long lasting … lasts decades • Ergonomic, efficient, quiet • Wide assortment of tooling in stock • Custom tooling available! Huth has helped Trailer Manufacturers bend tubing for over 25 years. www.HuthBenders.com 800-558-7808 Follow us on Made in the USA TRACKS MEMBERSHIP

Best

For Challenging a ppli C ations

All of these have passed our rigid quality standards. If we sell it... we stand behind it!!!

PVC Foam and High Bond Tapes: As the exclusive distributor of Gaska Tape products we offer high density foam tapes, Hi-Bond tapes, vinyl glazing tape, and polyethylene foam tapes at competitive prices.

Since 1969 LaVanture Products Company has been providing customers with the highest quality products to meet the challenging applications of today’s competitive markets. LaVanture offers products to meet the needs of custom applications in the industry.

LPC Gas Springs are available in both Black Nitride and Stainless Steel all at factory pricing and a large inventory is in stock for immediate shipment.

Call for our new catalogs.

PRODUCTS FOR CHALLENGING APPLICATIONS TRIMS,SEALS,FOAMTAPES,CAULK,

INNOVATIVE

Applications:

• Tool Boxes

• Door and Window Seals

• Truck Caps and

New LaVanture Line of Sealants: LaVanture Products is proud to announce our new sealant line including great quality products including, MS Polymers, Silicones and many others. We have partnered with a quality manufacturer to provide a great product at a great price.

Tonneau Covers

• Truck Bodies

• Cargo Trailers

Made

• Utility Boxes

• Fiberglass Doors

• Work Truck Doors

• Marine

• Recreational Vehicles

• Roof Sealant

We also stock complete lines of high quality EPDM Seals, Trim Seals, Edge Trims, Butyl Tapes, Caulks and Sealants.

30

LaVanture Products | Post Office Box 2088 Elkhart, IN 46515-2088 | E-mail: sales@lavanture.com Phone: 800-348-7625 | Fax: 800-348-7629 www.lavanture.com | www.conspicuity.com

Conspicuity Tapes: We are a national distributor for 3M D.O.T. Diamond Grade Conspicuity Tape. in the

SEALANTS,INDUSTRIALCOATINGS

USA

Statistically Speaking

By Jeff Jones, Statistical Surveys, Inc.

Registration for the light- and medium-duty trailer industry was down 20.9% in October 2022. Below are the details of the market’s performance for the five trailer segments as reported by Statistical Surveys:

The following are the top five states in sales growth for all trailer segments in the first 10 months of 2022.

Percent of Growth

Industry registrations for the first 10 months in 2022 are down 19.7% over 2021.

If there are any questions, or if Statistical Surveys, Inc. can help, please contact Jeff Jones at (254) 715-1314 or jjones@statisticalsurveys.com. ■

31 March/April 2023 www.NATM.com

Trailer Type Industry Open Enclosed Livestock Horse Boat Ranking 1 2 3 4 5 Oct. 2022 -20.9% -22.1% -16.7% -10.6% -24.7% -20.7 State Tennessee South Carolina Montana Utah Colorado Jan. - Oct. 2022 -19.7% -20.5% -20.5% -21.9% -16.3% -16.5%

74.8% -8.8% -9.7% -10.6% -11.8%

1693 Sutherland Dr SE Grand Rapids MI 49508 (616) 281-9898

TRACKS EDUCATION

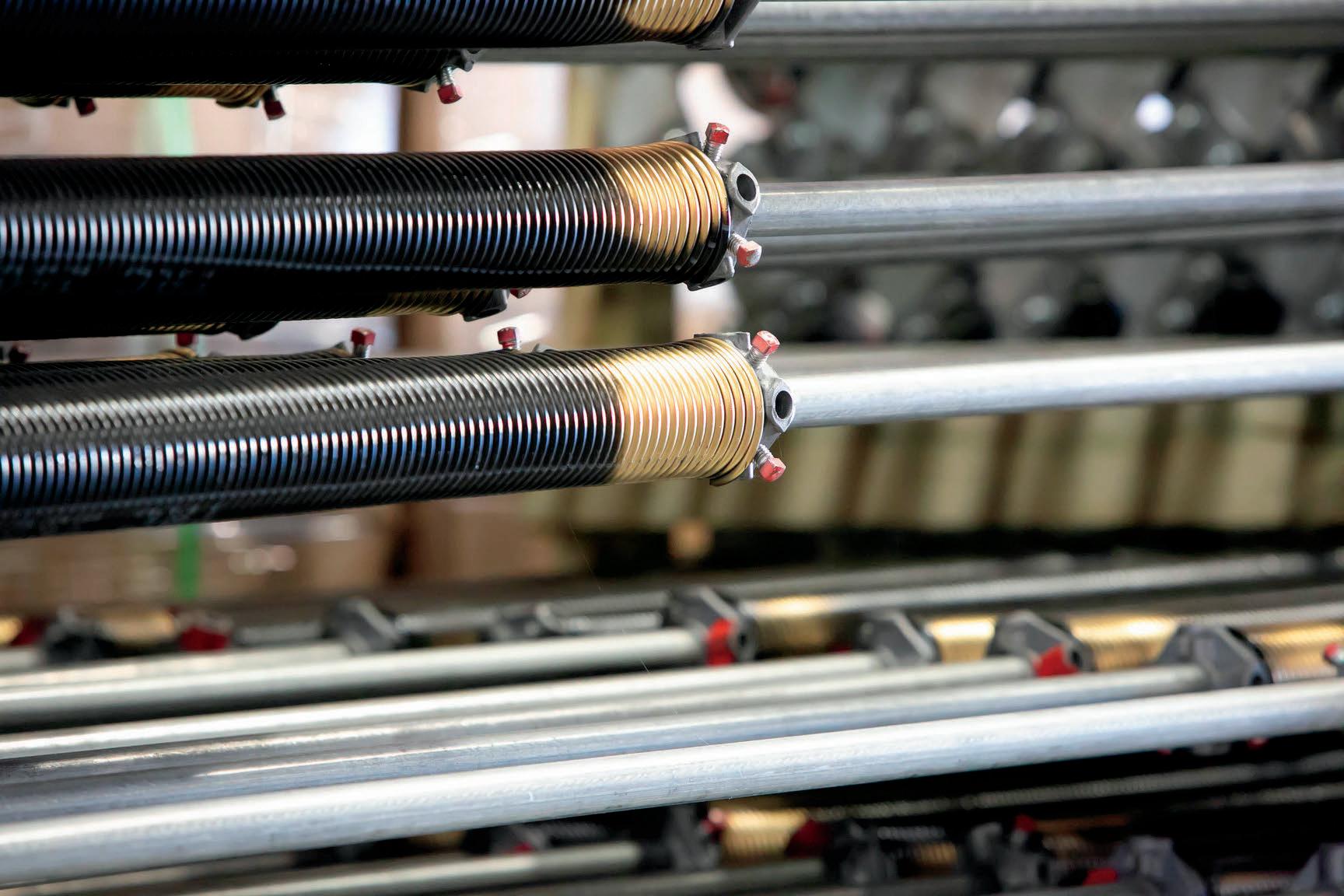

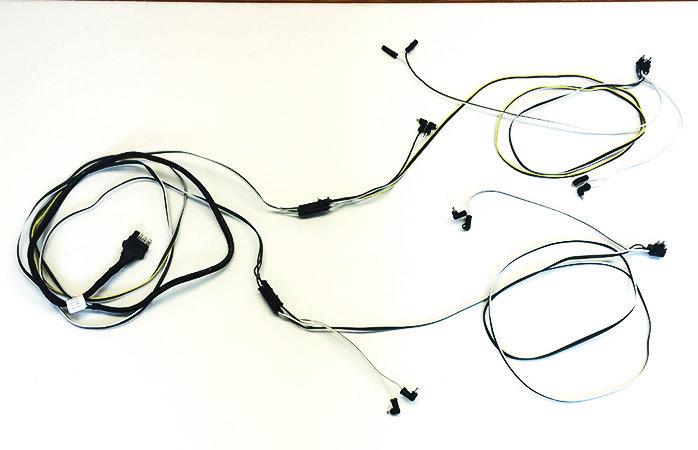

We Offer Custom Wire Harness & Battery Cable Solutions

WE

GET CONNECTED!

· RV · Commercial · Horse Trailer · Industrial Equipment Motorsport Trailers · Marine · Generators · Utility Vehicles Portable Restrooms

Agriculture

HAVE OVER 20 YEARS OF EXPERIENCE IN WIRE HARNESS BUSINESS EQHARNESS.US Amphenol TE Connectivity

BOXES

BATTERY CABLE ASSEMBLIES POWER & GROUND CABLES

CABLES & CUSTOM POWER SUPPLY SOLUTIONS 6 5 4 3 2 1 4/0 3/0 2/0 1/0 CABLE AND WIRE GAUGES FROM 6 AWG - 4/0

JUNCTION

ASSEMBLY: QUALITY

BATTERY

Celebrating Trailer Safety Week as Dealerships

By Savana Morrison, NATM Marketing Director

Trailer Safety Week (TSW) is an annual nationwide awareness campaign launched by the National Association of Trailer Manufacturers (NATM) aimed at increasing awareness of the importance of trailer safety, educating end-users about proper trailer maintenance and usage, and creating a stronger alliance between stakeholders of the industry, including trailer dealers, manufacturers, and end-users. Last year alone, TSW reached hundreds of thousands of individuals.

First launched in 2018, TSW sought to help bridge the gap of communication between trailer manufacturers and end-users. Talking about the importance of trailers built to meet required Federal Motor Vehicle Safety Standards (FMVSS) can be daunting as end-users do not understand the complex regulations governing compliant trailer manufacturing. They recognize that they would not purchase a car without seat belts, but they do not understand that buying a trailer without key safety features can be just as dangerous. End-users are vastly under-educated on the proper use of trailers, and it is crucial to utilize the connections that dealers and manufacturers have with consumers in order to raise awareness of proper towing techniques and maintenance.

Getting involved in this important industry campaign shows potential customers that the dealership is a leader in the industry and truly committed to trailer safety. By joining this trailer safety movement, impress customers and instill confidence in the company’s dedication to safety. Participating in TSW is easy!

Becoming an Official Trailer Safety Week Ally is a wonderful opportunity for companies who want to be involved in the safety movement but don't have significant time to invest.

The TSW team provides Allies with the official Trailer Safety Communications Kit to promote their involvement in Trailer Safety Week and to share information about safe trailering practices. This digital kit includes:

› Pre-crafted social media posts

› Downloadable Trailer Safety Week graphics

› A blog post

› And much more!

Promoting the dealership’s involvement with Trailer Safety Week is a breeze with this jam-packed kit. The content can even be customized to include content specific to the dealership’s typical customer.

TrailerSafetyWeek.com also houses a free towing safely guide to ensure trailer users have readily accessible safety information at their fingertips. Wow your customers by highlighting this free safety resource that reminds them your dealership is looking out for them and their wellbeing long after they leave the lot. Topics include:

› Hitching

› Loading

› Trailer Maintenance

› And more!

Now especially, safe trailering practices are important. The National Highway Traffic Safety Administration (NHTSA) is cracking down on compliance violations, and two recent accidents have brought to light the importance of safe trailering practices. One accident, previously covered in an article on behalf of NHTSA, resulted in a fatality due to inappropriately connected safety chains between the tow vehicle and towed unit which led to disconnection on a highway. More recently, safety chains saved a couple dangling nearly 100 feet above a river.

Safe trailering practices save lives, and with millions of trailers — used by businesses, local governments, and individuals — traversing the nation’s roadways every day, it is crucial to ensure that trailers are being towed safely for the sake of everyone on the roads. NATM calls upon trailer dealers to join the movement in making roadways safer one trailer at a time.

Learn more at www.TrailerSafetyWeek.com/interest, email TrailerSafetyWeek@natm.com, or scan the QR code to the left. ■

34 March/April 2023 www.NATM.com

EDUCATION TRACKS

35 March/April 2023 www.NATM.com Kenda Americana Tire & Wheel controls the quality from design to manufacturing through assembly and warehousing all within our Kenda family of companies. Visit Americanatire.com for sizes, styles and to learn more. ©2023 Kenda Tires. All rights reserved. KENDA HAS YOU COVERED. TRACKS EDUCATION

Team Lead of TexTrail Support 38 years of experience Proud to be a member of the Dexter family. Visit us at Textrail.com for all your trailer parts needs. RIGHT PARTS. RIGHT PRICE. RIGHT QUICK.

37 March/April 2023 www.NATM.com TRACKS EDUCATION

National Association of Manufacturers Addresses Diversity, Inclusion in Summit

By Samantha Darling LaCount, NATM Tracks Editor

The Manufacturing Institute (MI) hosted its third annual Diversity, Equity and Inclusion (DE&I) Summit on Dec. 16, 2022. The Manufacturing Institute is the workforce and education partner of the National Association of Manufacturers (NAM), of which, the National Association of Trailer Manufacturers (NATM) is a member.

DE&I encompasses many different approaches to improving the representation and participation of diverse groups, including people who are of varied genders, ages, and backgrounds in the workplace.

The focus of the first summit discussion was on the deficit in workers the manufacturing industry is facing and how attracting a more diverse workforce will help fill that void.

“There are 2.1 million jobs expected to go unfilled in the industry by 2030,” said Marisa Brown, Manager of Diversity & Inclusion for MI. “Manufacturers need to find new populations of potential employees. Recruiting more women, racial and ethnic minorities, and neuro-diverse workers can expand companies’ talent pools and strengthen their workforces.”

The current manufacturing workforce is 29% women. According to a recent study by MI and Colonial Life, if that percentage was raised to 35% females in manufacturing, that alone would fill the current 746,000 open jobs in the industry.

“The manufacturing industry is facing a labor shortage, and we have been for quite some time. One of the industry's biggest opportunities is broadening the talent pipeline and prioritizing actions that recruit and retain a diverse workforce,” said Carolyn Lee, President of MI. “Frankly, we are a little bit behind on this. There are steps that we can take … that can accelerate the creation of more inclusive environments and make our industry a more attractive place for people to come to work and stay and build a career.”

Keybridge Research and MI teamed up and conducted a survey of over 160 participants that represented more than 15 manufacturing sectors and firms of varying sizes. The findings of this survey were presented during the summit.

There are 10.3 million job openings in the U.S., and only 6.1 million Americans are unemployed, says Chad Moutray, Director for the Center of Manufacturing Research at MI. The current demographic breakdown of the manufacturing industry shows 29.2% female, 17.5% Hispanic or Latino, 10.3% Black or African American, and 7.1% Asian.

“We’ve made strides over the last few decades, but we

still have overwhelming male, overwhelmingly white populations, as far as the overall sector,” Moutray said. “That phenomenon is something, at least in my view, is structural. We’re going to continue to have this issue of where we are going to find workers over the next decade. I think part of that conversation of where we are going to find those workers has to include diversity and inclusion.”

“One way that companies can do so is by partnering with more diverse pipelines,” said Megan Yeh, an Associate with Keybridge Research. “If we recruit from talent pools that might not have traditionally been a part of the manufacturing workforce that can go a really long way in terms of filling the gap.”

According to the survey, 72% agreed that improving and/ or maintaining DE&I is a key focus for their business with 27% disagreeing or remaining neutral.

“Culture matters as well. Having a culture that embraces diversity, that embraces inclusion, you can bring your whole self to work, is something that is attractive not just for attracting workers but also helps keep them on board once they're there,” Moutray said.

Yeh explained that 52% of respondents said they struggle with hiring diverse candidates and 37% said they struggle with retaining diverse candidates.

“Making the workplace more inclusive and more equitable can help with retention,” Yeh said. “For example, offering things such as training, mentorship, clear onboarding guidance — these are all ways employees can be retained. Everyone benefits from an equitable and inclusive workplace.”

38 March/April 2023 www.NATM.com

EDUCATION TRACKS

The President of The Manufacturing Institute Carolyn Lee gives the opening remarks for the Diversity, Equity and Inclusion Summit. Screen grab from summit.

The survey showed an increase in flexible work policies, the most popular being hybrid work, flexible work hours, and remote work.

“We’ve seen a lot of great strides in policies that impact the broader employee base,” Yeh said. “Companies are able to pull from talent pools that might not live locally to their company because they offer things like remote work.”

Policies that affect broad workforces were on the rise. But policies aimed at specific workforce groups were not as strong. For example, only 25% of companies surveyed offer gradual retirement, which is a benefit specifically for older workers.

“Adoption of policies that are targeted toward specific groups can help make companies more attractive, particularly for younger workers, who are more often noting that DE&I is something that they really value,” Yeh said.

Another facet the survey looked into is what roles diverse hires are filling. Respondents showed that 65% of women are concentrated in administrative or HR roles.

“This does align with the larger reality of women’s typical roles in the workplace with 75% of workers in the HR sector being women,” Yeh said. “This is not unique by any means for the manufacturing sector, but this is something that we do want to address. We would love to see more women on the fabrication floor, or in engineering, or in other positions.”

Yeh says it was promising that over 60% of companies reported that their female demographics have

increased, including in leadership roles.

The next round table of the summit was with Jennifer McMillion, Senior Manager of Global Diversity, Equity, and Inclusion with McCormick and Company; Oather Taylor, Diversity, Equity, and Inclusion Manager with Pella Corporation; and was moderated by Erica Singleton, Associate Director of Human Resources and DE&I with the National Association of Manufacturers.

They discussed Employee Resource Groups (ERGs), which are employee-led groups whose goal is to foster a diverse, inclusive workplace for their demographic and offer support to under-represented populations. They’re usually formed by employees who share a common characteristic whether it be gender, race, religion, etc., and allies of those parties.

Taylor shared that at Pella, there were 18 months of initial planning work done with an outside consultant before starting any ERGs, including developing a DE&I council within the company to help drive and establish the ERGs.

“The ERGs that will get started as pilots will come from a small group of options that were based on the consultant feedback and employee feedback as to where the group will start,” Taylor said. “Those will include the classic categories of racial and ethnic diverse groups, women in the industry, those living with disabilities or having folks around them with disabilities. One that I've injected and that I'm

Continued on Page 42

39 March/April 2023 www.NATM.com

TRACKS EDUCATION

Chad Moutray (left), Director for the Center of Manufacturing Research at MI, and Megan Yeh, an Associate with Keybridge Research, hold the first session of the summit. Screen grab from summit.

If you’re tired of dealing with material delivery delays and the high cost of shipping, bringing your blanking in-house can help. A COE cut-to-length (CTL) line can:

• Provide better operational control

• Reduce transportation and outside costs

• Streamline processes

• Reduce scrap

• Optimize floorspace

• Reduce inventory

• Improve quality

• Save money

Using

SCAN the QR Code for a full set of resources on this business strategy.

40 WANT