For more than 40 years, Murphy Geospatial has been providing geospatial certainty to our clients in Ireland, the UK, Europe and globally. Our expertise and tech-enabled solutions support our clients to make informed decisions using verified geospatial data and consultancy.

We operate in six distinct sectors and multiple subsectors.

Murphy Geospatial has decades of experience in monitoring, with our awardwinning team working on some of the most significant infrastructure in the UK, Ireland and across Europe. We have over 80 monitoring experts across all specialisms within our team. Our experts help you spot issues before they become problems, helping you to minimise delay, disruption and unnecessary costs.

Our integrated monitoring consultancy will work with you to understand the unique needs of your project and develop a bespoke programme of monitoring services that’ll help you meet your end goal.

Whether it’s one time data capture, or the installation of sensors for real-time data analytics and reporting, our experts collect, collate, govern, and interpret your monitoring data to support you to make informed decisions.

Our monitoring services allow you to deploy a predictive maintenance approach, helping you to be more strategic with budget and any disruptive works to key infrastructure.

Our monitoring solutions such as IoT sensors and LoRa data communication are essential to the development of smart buildings and infrastructure. Providing a continual feed of data, you can bring your assets to life, making them more efficient and profitable.

Monitoring can benefit your project at every stage of its lifecycle. By consistently measuring changes throughout your project, you can detect issues early on, act and avoid delay, disruption and unplanned costs.

Our monitoring solutions can be deployed throughout your project’s lifecycle. We’ll work with you to choose the right services from our tech stack that align with your project’s goals.

Structural health monitoring measures the strength and performance of structures over time helping to maintain operational integrity throughout the asset’s lifecycle. By proactively analysing changes, potential issues can be quickly identified and managed. This type of monitoring is perfect for asset management that’s five years or more in duration. Information can be integrated with your existing building management systems.

Ground movement monitoring measures changes of ground conditions over time to confirm design assumptions. This includes monitoring soil and rock movement, deformation, and other changes that can significantly impact the stability of buildings and infrastructure. By monitoring ground conditions over time, we can ensure that predicted heave or settlement during construction aligns with expectations.

Environmental monitoring measures factors such as air quality, noise, and ground vibration. It also tracks conditions that are affected by weather, including wind, pH levels, rainfall, and barometric pressure. By doing so, the impact on the surrounding environment can be reduced and we can ensure compliance with project-specific environmental standards. In the UK, our environmental monitoring supports your compliance with Section 61 in the proactive limitation of noise, vibration and dust pollution (NVD) impact.

Read more from our Director of Monitoring on why Section 61 is important for successful construction and demolition projects.

Asset performance monitoring involves the continuous surveillance of your built assets through IoT sensors. This integrates all our monitoring solutions to create a bespoke plan on how to maintain the asset over long periods of time. This approach not only enables targeted maintenance but also optimises asset performance, ultimately extending the asset’s lifecycle.

Infrastructure and its ability to work efficiently can be compromised by ageing assets, increased demand on resources and extreme weather. Urbanisation and population growth further stress these systems. Smart infrastructure monitoring, leveraging IoT, AI, and data analytics, is key to addressing these challenges. It provides real-time data and

Our tech stack

Geodetic monitoring

Equipment sales

Tech integration workshops

Customised AI solutions

Customised software solutions

Vibration monitoring

Noise/sound monitoring

Dust/particulate monitoring

Air quality/gas monitoring

Weather/climate monitoring

Geotechnical installations

Geotechnical monitoring

Geotechnical sensors

Structural sensors

Project management

Project preparation

Rapid Deployment Team (RDT)

Smart buildings IoT sensors

We’ll bring together the most suitable expertise and technologies from our monitoring department and teams from across Murphy Geospatial.

We work with you at the start of you project to provide tailored solutions that fit with your project and its goals.

Our team will ensure that the most appropriate and best value engineering solutions are recommended from our complete portfolio of specialist engineering solutions.

We deploy expert oversight to deliver large and complex projects with efficient management, providing certainty in every project.

Our production team ensures the engineering team has all the equipment required to install and commission automated monitoring projects.

Our highly skilled team will carry out any additional survey needs whilst installing your monitoring network on site, ensuring minimal disruption to your timelines.

Our engineering team can safely install, commission, and decommission the monitoring network with minimal risk to your team and asset, setting up streaming to our servers, as needed.

Data is no good if it can’t be interpreted. That’s why we have a dedicated team of data processors and engineers to ensure data is accurate, relevant, and complete.

Consultancy

Value

Project

Production

Surveying

Data

Our monitoring team specialise in structural health monitoring and data analytics. Our attentive approach in tracking temporal changes ensures real-time alerts and detailed reporting, safeguards the integrity and longevity of critical infrastructure and other assets.

The Sky Pool is a clear acrylic swimming pool suspended above the Embassy Gardens in Wandsworth, London. Our team monitored the pools structural performance to confirm design and engineering predictions, by installing autonomous monitoring system, measuring horizontal and vertical relative deflection of the acrylic structure. The monitoring team provided accurate monitoring solutions, that measured the pool’s structural performance as it was filled with water over a set period.

The Dunkettle Interchange upgrade improved road connectivity by replacing a congested roundabout that has long been a bottleneck for both local traffic and the national highway system. Murphy Geospatial’s monitoring team played a pivotal role in implementing a geospatial monitoring system that measure ground movement across the construction site. Due to the absence of prior geospatial data for the site, the team integrated a userfriendly monitoring solution. This approach not only addressed the immediate needs of the project but also ensured simplicity for non-specialists for long term data collection.

‘‘I found the Murphy Geospatial team very good and knowledgeable. Materials were always on hand, and they kept with the programme, leading to no lost time. The service provided was excellent. They were exceptional at showing the young (Sisk) engineers how to collect the data from the various instrumentations to be then able to compile and have it in a format for the DSR to review.

‘‘

Philip O’Connor

Site Engineer, John Sisk & Son (Holdings) Ltd

At the Cherry Park DLR development, our team conducted control network, rail, and platform geometry surveys, along with a photographic condition assessment. These efforts ensured geospatial certainty for our client. The measured data was accessible through an online portal and summarised in bi-weekly reports, with additional data calculations integrated into the database for comprehensive analysis.

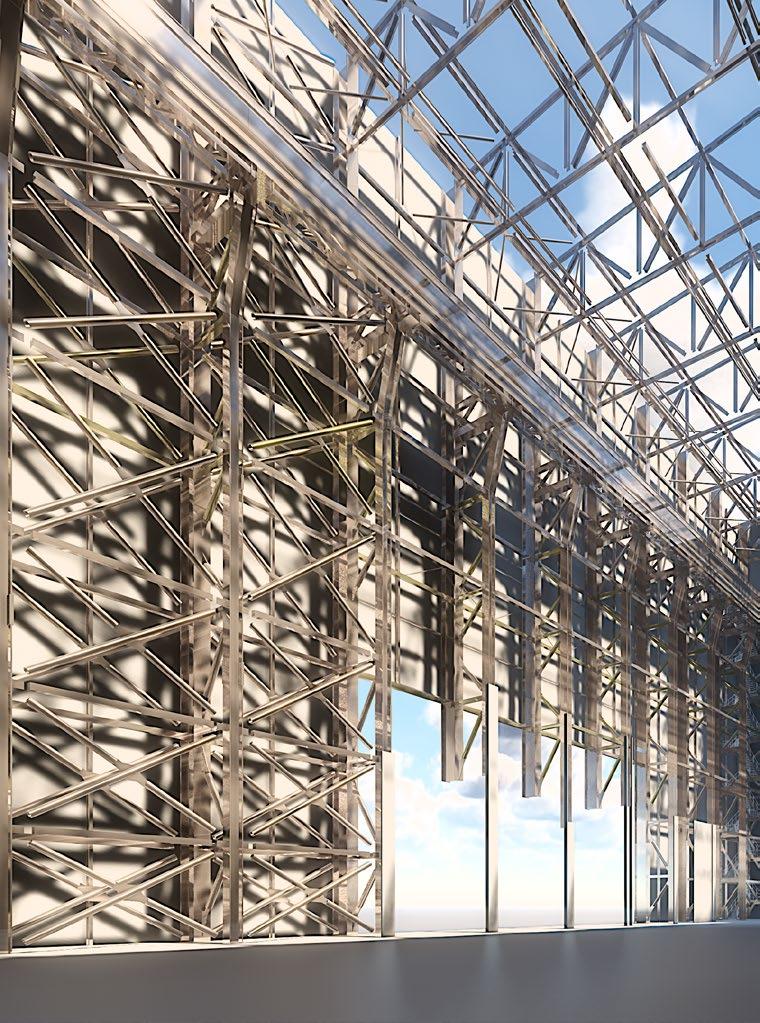

The award-winning construction of the towers at East Village utilised a ‘Rising Factory’ technique, where the structure climbed weekly on pinned jacks, creating a waterproof environment for modular construction. Temporary steel factories, supported by overhead cranes, facilitated one floor per week. Our monitoring ensured safety and assessed load impact. A real-time strain gauge system on corner columns provided accurate data for design validation and operational efficiency. A wind monitoring system was also implemented to track wind speed, direction, and load.

The Lower Thames Crossing is a highway project that is an essential component of the UK’s future transport infrastructure. There are also two 4km tunnels crossing below the river. The scheme will add 23km of new highway to connect the tunnels to the existing road network. We completed ground investigation monitoring at the planning stage of the project. Our task was to create a stable control network in an area influenced by tidal movements, from the nearby River Thames, and from the ground dewatering works to monitor the surrounding area which included a live railway line. The observation data from the stations was captured and transmitted fully automated.

Renovations to the gallery included roof and glazing repairs, along with modern climate, heating, fire suppression, lighting, electrical, and security systems. The Office of Public Works oversaw the project, with Heneghan Peng as consultant architects. Our work involved continuous monitoring, BIM laser surveys, and the installation and maintenance of various monitoring equipment.

Read this project case study in full

Global House

Kilcullen Business Campus

Kilcullen R56 K376

Ireland

T: +353 (0)45 484 040

E: info@murphygs.ie

9 Millfield House Croxley Park

Woodshots Meadow Watford

WD18 8YX

United Kingdom

T: +44 (0)192 362 4800 E: info@murphygs.com

Ireland

T: +353 (0)21 489 5704

E: cork@murphygs.ie

3HW

United Kingdom

T: +44 (0)160 626 3019

E: info@murphygs.com

DY4 7HN

United

T: +44 (0)121 630 3074 E: info@murphygs.com

Block 2

Westpoint Court Business Park

JFK Drive, Naas Road

Dublin D12 E138

Ireland

T: +353 (0)1 690 9799

E: info@murphygs.ie

Ireland Head Office

T: +353 (0)45 484 040

E: info@murphygs.ie

UK Head Office

T: +44 (0)192 362 4800

E: info@murphygs.com

Book a free monitoring consultation with our experts