SINCE 1934

- A gateway to ideas and insights -

Welcome back to Tranemo News & Inspiration a place where we share stories, spark ideas and connect with you around the world of workwear and safety. In this issue, we explore the topics shaping our industry and our everyday work at Tranemo.

You will meet some of our long-term partners and see how collaboration builds lasting value. We talk about inclusive workwear and what it means to design solutions for all workers. We will discuss the new safety standard EN 17353 and why enhanced visibility matters more than ever.

This magazine is a way for us to share our vision, exchange knowledge and inspire each other.

We are glad to have you with us.

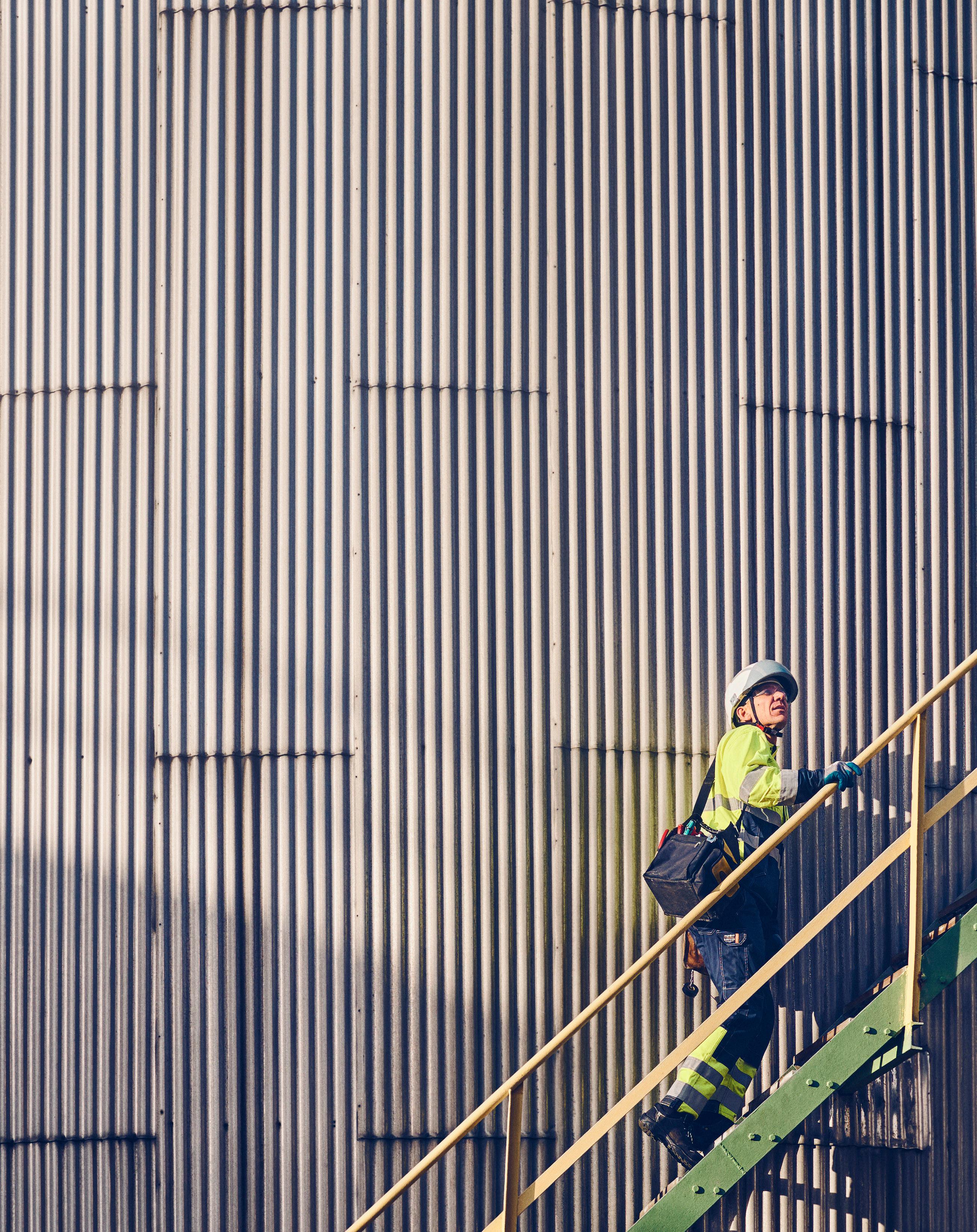

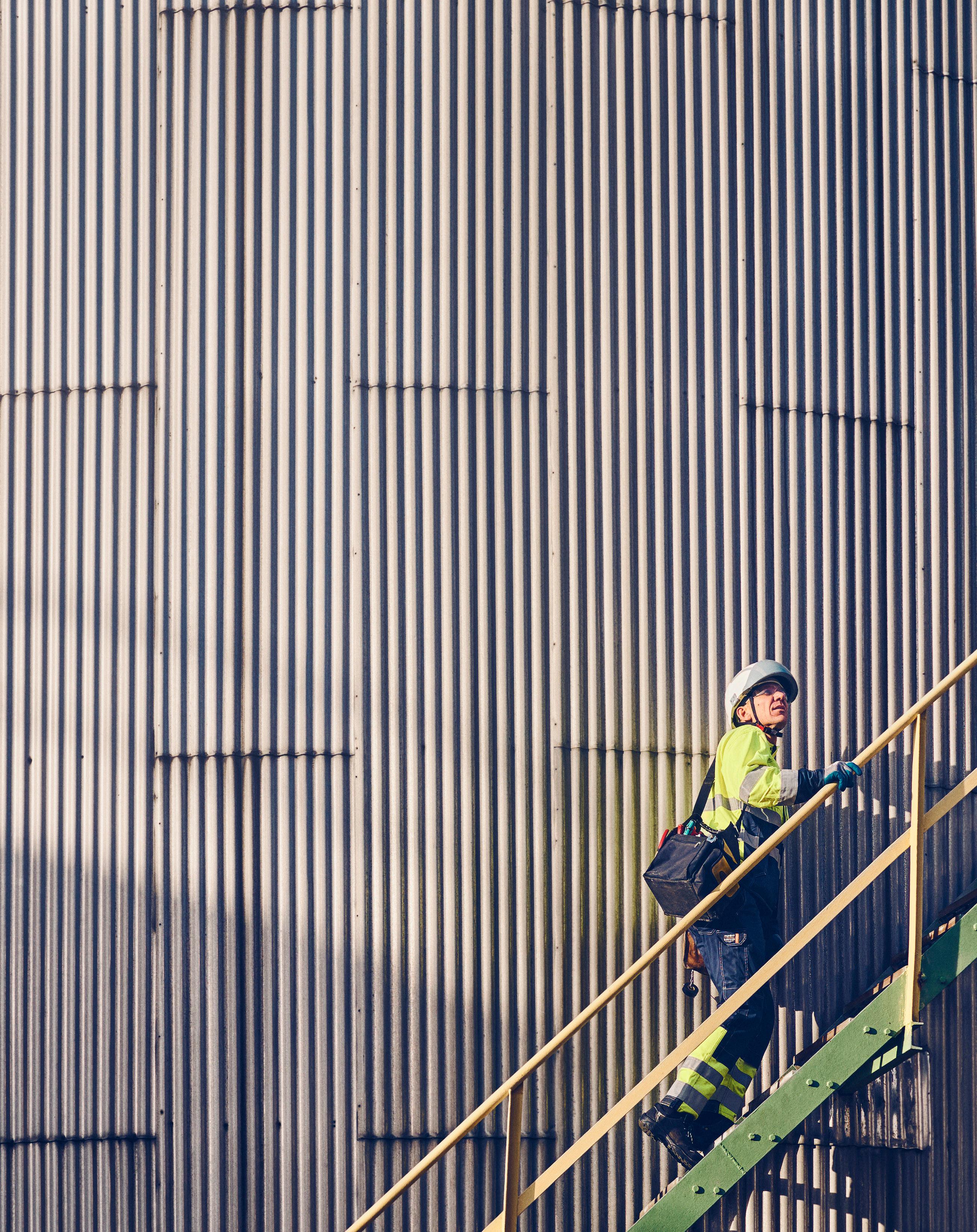

Port of Tyne handles millions of tons of cargo each year. In such complex operations, PPE is not optional but essential. Through its partnership with Tranemo, the port provides its workforce with garments that meet strict safety standards whilst promoting innovation and sustainability.

Port of Tyne is one of the UK’s largest deep-sea ports. It handles everything from bulk cargoes such as coal, grain and chemicals to container shipments and roll-on/roll-off ferries. Bulk handling brings its own safety challenges, not only because of the enormous volumes but also due to the risks associated with dust, weight and in some cases hazardous substances. The port also provides marine services, engineering solutions and a wide range of logistics support. Passenger traffic through the International Passenger Terminal in North Shields is steadily growing and has become an important link for international travel to and from the region.

The port contributes over £658 million to the local economy and supports more than 10,000 jobs. As one of the UK’s largest trust ports, it has no private owners. All profits are reinvested into the port’s facilities, equipment and the environment along the River Tyne. Every success achieved by the port not only strengthens its operations but also creates long-term value for the local community, regional businesses and the people who live and work there.

Terry Lendrum, Senior Health and Safety Advisor, Port of Tyne.

Work at the Port of Tyne takes place in challenging conditions. Heavy equipment, vessels, vehicles and people operate side by side. Safety must always come first.

Terry Lendrum explains: “Safety first means never taking unnecessary risks. It’s about following procedures designed to prevent harm and thinking about potential dangers before starting a task. Safety is embedded in every part of our operations.”

The risks are varied. Container handling, vessel loading and unloading, hazardous materials, ro-ro operations, working at heights and in poor visibility, as well as equipment maintenance. Each task demands coordination and careful planning.

To manage these risks, the port follows a structured approach to assessments. Hazards are identified, likelihood and severity are evaluated, and controls are put in place. The right PPE is then selected.

Knowledge and personal protective equipment (PPE) are equally vital. The port invests heavily in training to make sure every worker understands the risks and knows how to use PPE correctly.

Terry describes how the port achieves this: “We use a mix of methods, including hazard awareness sessions, hands-on exercises, accessible materials and refresher sessions. We keep detailed training and PR records and promote a culture where safety is second nature. It has to be led by example at every level of the organisation.”

The collaboration with Tranemo began through the ports PPE provider. Port of Tyne was reviewing its protective clothing provision and needed a supplier that could combine strict safety standards with innovation. Tranemo’s long experience in Flame Retardant and Arc garments made the choice clear.

Terry explains that the ports “operations involve a variety of high-risk environments. They needed garments that provide flame and arc protection, withstand tough conditions and remain comfortable for long shifts.”

As a Security Officer, my role means I’m constantly on the move across different areas of the port, often in challenging conditions and at all times of day and night.

Having the right workwear gives me confidence that I’m protected whatever the task, whether that’s working around heavy vehicles, responding to incidents, or carrying out patrols in poor weather.

The Tranemo garments are durable, comfortable, and designed with safety in mind, which means I can focus on doing my job effectively while knowing I’m protected.

Tracey McGuckian, Security Officer, Port of Tyne.

For the port, safety is always the priority, but innovation and sustainability are key when choosing suppliers.

Terry explains that “innovation keeps us competitive, improves efficiency and supports our development as a forward-thinking organisation. Sustainability is equally important, not only for environmental responsibility, but also as a risk and reputation factor. We expect suppliers to meet standards such as ISO 14001 and Fair Trade. Tranemo’s focus on sustainable production and continual product innovation aligns perfectly with our objectives. That helps us protect our people, meet compliance requirements and strengthen our reputation for doing things the right way.”

Tranemo’s commitment to these values is central to the partnership. The garments are designed to meet high safety requirements while incorporating sustainable materials and processes.

The partnership between Tranemo and the Port of Tyne reflects a shared commitment to protect workers, drive innovation and strengthen sustainable practices. Introduced through a supplier, Tranemo worked closely with the Port to understand its operational risks and delivered protective garments and training to keep their teams safe in various highrisk environments. At the same time, Tranemo’s sustainable production practices and values reflect the Port’s own environmental priorities, reinforcing the value alignment at the core of the partnership.

Tranemo’s responsible production methods and use of environmentally considerate materials align with the Port of Tyne’s commitment to reducing environmental impact while maintaining operational excellence.

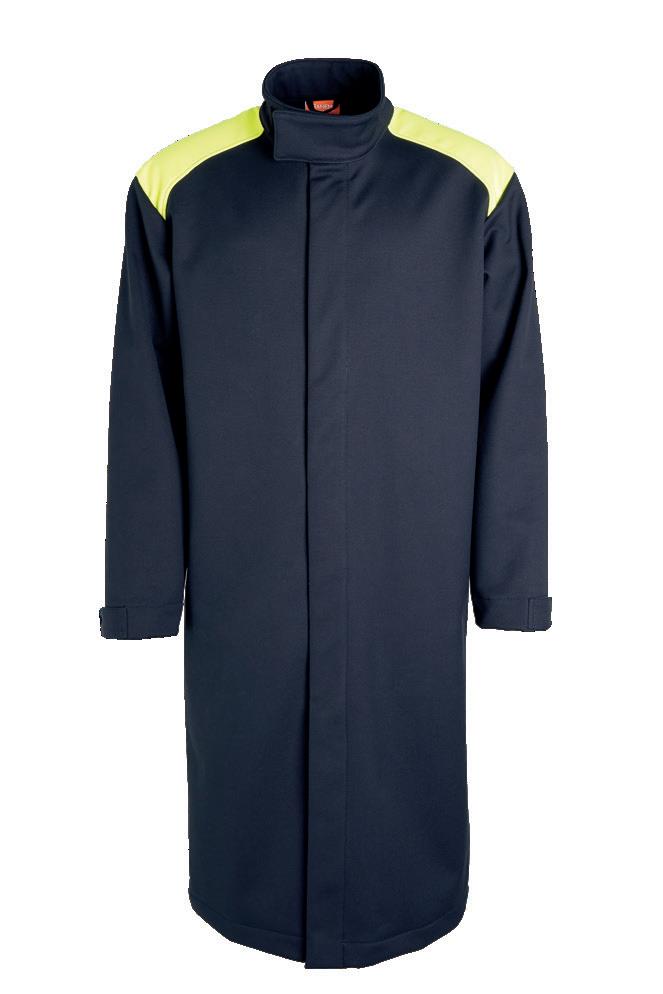

For electrical work, a jacket can be the ideal addition to workwear when a quick and flexible solution is needed to adapt to the task at hand. Designed with Velcro fastenings for rapid release, our switch jackets can be easily worn over other garments to provide extra protection during shorter jobs.

To suit different risk levels and arc flash protection needs, we offer two coats in the same design, crafted from different fabrics with varying Arc Ratings.

FLAME RETARDANT

SOFTSHELL COAT, ELIM 45

Non-Metal and Inherent Flame Retardant coat with velcro closing for ”quick release” that reaches PPE category 4 (higher than 40 cal/cm²). PFAS-free¹.

5193 95 94 yellow/navy

EN ISO 11612 A1 B2 C2 F2

EN 61482-2 APC 2,

ELIM: 45,0 cal/cm² EBT: 49,0 cal/cm²

EN 1149-5

EN 13034 type PB[6]

FLAME RETARDANT

COAT, ELIM 12, ELIM 12

Non-Metal and Inherent Flame Retardant coat in Cantex WS with ELIM 12 cal/cm². The coat is a thinner version of the Switch coat 5193, and can be worn over a Tera TX jacket to reach ELIM 30 cal/cm². PFAS-free.

5179 88 94 yellow/navy

EN ISO 11612 A1+A2 B1 C1 E3 F1

EN 61482-2 APC 1,

ELIM: 12,0 cal/cm² EBT: 16,0 cal/cm²

EN 1149-5

EN ISO 11611 CL.2 A1+A2

EN 13034 type PB[6]

EN ISO 15797 50 WASHES

TRANEMO SKINSAFE

ELECTRIC ARC HOOD + VISOR + HELMET

Combined set with Electric Arc hood 9179, integrated lift-front visor RX0018 and helmet with chin strap.

SA00 01 03 navy

ASTM F2178

ATPV 40 cal/cm²

EN 17353 is the European standard that defines requirements for clothing and equipment designed to enhance the visibility of individuals in medium-risk environments. It includes being visible in daylight and/or darkness, when illuminated by vehicle headlights or searchlights. Protective clothing certified according to this standard is intended for situations where only enhanced visibility is necessary. It should not be used in high-risk environments with highvisibility requirements.

As Certification Manager, Linnéa ensures that Tranemo’s protective workwear meets the international standards for safety and quality.

With expertise in regulations and testing, she manages certifications and compliance processes, securing customer confidence in every garment.

EN 17353 - SYMBOLS AND TYPES

Type A

Equipment for daylight

Type B1, B2, B3

Equipment for dark conditions

Type AB2, AB3

Equipment for daylight and dark conditions

Further details are available on our website

EN 17353 is a standard that applies to products used in medium-risk environments, such as controlled areas with lower vehicle speeds, provided the user is attentive to traffic. The standard specifies design requirements and surface area demands together with requirements for colour and retroreflection. This supported us during the development phase, enabling us to design new protective clothing for medium risk environments. By applying the standard, we ensure workers have access to enhanced visibility clothing.

Always remember to carry out a thorough risk assessment to determine whether you need workwear with high-visibility (EN ISO 20471) or if enhanced visibility (EN 17353) is adequate.

Our approach ensures that garments marketed as ‘visible’ meet the appropriate certification. Customers can select EN ISO 20471 for high-risk or EN 17353 for medium-risk environments. This means workers can trust that their protective clothing provides the right level of visibility for the job.

When selecting visibility clothing, it is essential to conduct a thorough risk assessment. The following factors should be considered to determine whether your work environment is classified as high-risk or medium-risk.

• Work environment

• Vehicle speed

• Traffic density

• Weather

• Background contrast

• Type of road user

Once your risk assessment is complete, we can help you identify the right garments based on your work environment, risk level and regulatory requirement, ensuring maximum safety and comfort for your team.

FLAME RETARDANT

JACKET

PFAS-free and Inherent Flame Retardant jacket with sleeves and front in Cantex Weld and back in Cantex Stretch. Cantex Stretch provides the jacket with flexibility and gives you freedom of movement with high levels of comfort, while Cantex Weld at the front gives you extra high protection against welding and grinding splashes.

5730 88 94 yellow/navy

5737 88 94 yellow/navy

EN ISO 11612 A1+A2 B1 C1 E3 F1

EN 61482-2 APC 1, ELIM: 18,0 cal/cm² ATPV: 20,0 cal/cm²

EN 1149-5

EN ISO 11611 CL.2 A1+A2

EN 13034 type PB[6]

EN 17353 type A

EN 13758-2

EN ISO 15797 50 WASHES

TRANEMO SKINSAFE

At Tranemo, we are continuously developing our product range to meet evolving safety needs, including the enhanced visibility standard for medium-risk environments. The first garments certified according to EN 17353 are part of our Cantex WS range, which is often used in dark indoor work settings.

PFAS-free and Inherent Flame Retardant boilersuit. Sleeves and front in Cantex Weld and back in Cantex Stretch. Cantex Stretch provides the boilersuit with flexibility and gives you freedom of movement and high comfort whilst Cantex Weld at the front gives you extra high protection against welding and grinding splashes. PFAS-free.

5710 88 94 yellow/navy

EN ISO 11612 A1+A2 B1 C1 E3 F1

EN 61482-2 APC 1, ELIM: 18,0 cal/cm² ATPV: 20,0 cal/cm²

EN 1149-5

EN ISO 11611 CL.2 A1+A2

EN 13034 type PB[6]

EN 17353 type AB2

EN 13758-2

EN ISO 15797 50 WASHES

TRANEMO SKINSAFE

PFAS-free and Inherent Flame Retardant bib ’n’ brace with front in Cantex Weld and back in Cantex Stretch. Cantex Stretch provides the bib ’n’ brace with flexibility and gives you freedom of movement with high levels of comfort, while Cantex Weld at the front gives you extra high protection against welding and grinding splashes.

5740 88 94 yellow/navy

EN ISO 11612 A1+A2 B1 C1 E3 F1

EN 61482-2 APC 1, ELIM: 18,0 cal/cm² ATPV: 20,0 cal/cm²

EN 1149-5

EN ISO 11611 CL.2 A1+A2

EN 13034 type PB[6]

EN 17353 type B2

EN 13758-2

EN ISO 15797 50 WASHES

TRANEMO SKINSAFE

PFAS-free and Inherent Flame Retardant trousers with front in Cantex Weld and back in Cantex Stretch. Cantex Stretch provides the trousers with flexibility and gives you freedom of movement with high levels of comfort, while Cantex Weld at the front gives you extra high protection against welding and grinding splashes.

5720 88 94 yellow/navy

5729 88 94 yellow/navy

EN ISO 11612 A1+A2 B1 C1 E3 F1

EN 61482-2 APC 1, ELIM: 18,0 cal/cm² ATPV: 20,0 cal/cm²

EN 1149-5

EN ISO 11611 CL.2 A1+A2

EN 13034 type PB[6]

EN 17353 type B2

EN 13758-2

EN ISO 15797 50 WASHES

TRANEMO SKINSAFE

The A+A is held every 2 years in Düsseldorf, Germany and is the world's leading trade fair for personal protection, occupational safety and health at work. Tranemo is a regular exhibitor always showcasing innovative protective clothing with a focus on Flame Retardant workwear.

The trade fair focuses on innovations and presents new products and solutions that help to make workplaces safer, healthier and more efficient. As an indispensable platform, A+A brings together international experts, innovative companies and forward-thinking solutions. You can expect to find the latest trends, products and technologies that are enhancing workplaces worldwide.

From 4th – 7th November 2025, Tranemo will be welcoming visitors to our stand, built with inspiration from Scandinavian architecture and aesthetics. Our stand features multiple rooms dedicated to highlight and show off the top segments of our advanced Flame Retardant workwear. The rooms serve as an immersive showcase of our latest product developments, featuring protective garments for men and women. Every piece is designed in Sweden and manufactured in Europe to ensure the highest standards of quality, safety and sustainability.

Our global sales representatives will be present throughout the exhibition to offer expert advice and guidance. With a deep understanding of industry needs and protective standards, they will work closely with you to identify the most suitable solutions for your business.

Interview with Christopher Smith, ABB Global Health and Safety Auditor

ABB is a global technology leader in electrification and automation, delivering innovative solutions across a wide range of industries. With 270 factories worldwide and teams working in electrical environments, ABB operates in high-risk environments where safety is a core priority.

This article tells the story of a rare Arc Flash incident that took place at one of ABB’s sites. It highlights how Tranemo protective clothing played a crucial role in mitigating what could have been a life-threatening event. Most importantly, it demonstrates the vital role that personal protective equipment (PPE) plays in keeping people safe. Ultimately, this is a story about how PPE can save lives.

Tranemo and ABB work together to protect workers and reduce risks in challenging electrical environments around the world. Like at Tranemo, safety is embedded into every aspect of work at ABB.

We interviewed Christopher Smith, HSE Audit & Assurance Manager at ABB and he explains: “Health and safety at ABB is referred to as our license to operate. We need this to perform safely, and it is critical to our operations. ABB focus on creating their own systems, rules and processes to protect our contractors and colleagues when they are working in high-risk environments.”

In environments where electrical hazards are part of daily operations, wearing the right protective clothing to mitigate the specific risks of the role are essential. Tranemo Advanced Workwear’s long-standing relationship with ABB has created a partnership in which we work closely alongside the relevant teams to ensure the clothing they are wearing is certified for their safety.

The Arc Flash incident took place at a low-voltage site where a field engineer was completing a task which would usually come with minimal risk. Unfortunately, this was no ordinary day. During routine repair work in a lowvoltage area, the engineer was unexpectedly exposed to a severe Arc Flash. What makes this incident exceptional is that the Arc lasted between two and three seconds. This is far longer than the fraction of a second typical for such incidents, due to a local protection system failure. An Arc Flash of that duration is extremely rare and extremely dangerous. PPE serves as the last line of defense, and in this instance, it is likely that the PPE saved a life.

The injured employee was wearing two layers of Tranemo protective clothing at the time. A long-sleeved base layer (ELIM 4,6 cal/cm²) and a long-sleeved sweatshirt (ELIM 8,6 cal/cm²) over the top. The two Arc Flash layers, the base layer and outer layer combination, provided more Arc Flash protection than the sum of their individual ratings. The outer layer of his clothing was badly damaged by the Arc Flash, but crucially, the protective underlayer remained intact. The employee sustained first, second and third degree burns to their face and hands, which were not fully covered; but avoided torso injuries that could have been life altering. Most importantly, the injured person’s body remained completely unharmed avoiding any devastating torso injuries, with no skin redness or burns at all.

Christopher reiterates how serious this incident could have been if protective clothing was not worn. He states that "the severity of the burns would have caused serious life-threatening injuries. The potential outcome is unthinkable.”

This story highlights the vital role that properly selected and correctly worn protective clothing plays in electrical work. Personal protective equipment can protect employees from fatal hazards, giving them the best possible chance of walking away from high-risk settings without harm. Christopher resonated “that the most important lesson from this incident is simple but powerful. Arc Flash protective clothing saves lives. Too often in the electrical industry, high-risk activities are still carried out without the right protection.”

Tranemo and ABB share the belief that protective clothing is essential whenever electrical equipment is involved, no matter how simple the task may seem. Even seemingly ordinary jobs carry risks, and the right PPE is vital. By prioritising safety, we help ensure that if an incident occurs, its impact is minimised and workers remain protected. Ultimately, our mission is to strive towards zero flame and heat related injuries. Christopher shares his advice to all companies working in electrical environments:

Put your people in Arc Flash protective clothing as a standard uniform.

At ABB, worker protection is regarded as deeply personal. PPE is the last line of defense, and for it to truly serve its purpose, it must be both effective and practical for every single individual who requires it. Alongside the safety features of protective clothing that keep people safe, it must fit correctly and be comfortable so that employees don’t think twice about wearing it throughout their working day.

This ongoing focus on innovation, safety and inclusivity strengthens the partnership between ABB and Tranemo, with one clear priority at its core: keeping people safe in working environments.

*Always protect the whole body with appropriate PPE.

*Always protect the whole body with appropriate PPE.

TRANEMO SKINSAFE™ Radiant heat: C2 RHTI24: 25,8s

Purchasing protective clothing for a specific work environment is a complex process that requires focus and precision in addition to risk analysis and testing. Tranemo has developed a checklist that provides a clear overview of the purchasing process and ensures that you do not miss any important steps.

The first and most important step in the purchasing process is to conduct a comprehensive risk analysis of the business. What potential hazards exist in the workplace? Is there any risk of the employee being exposed to an electric arc, molten metal, chemicals, batteries, explosions or vehicle traffic? How great is the risk of an incident and how serious could the consequences of the incident be?

Once the risks have been identified and the required protective clothing has been determined, it is a good idea to conduct fabric and material tests in the workplace. The tests can be used to identify the best option for the task at hand. This is because protective clothing certified to the same standards but made from different fabrics can react differently when subjected to tests.

Strive for long-term use and sustainability, take good care of protective clothing and repair it if it breaks. High-quality clothing lasts longer! Does your business require protection against chemicals? If so, it is particularly important, for the sake of the environment, to keep track of exactly what type of chemicals are being used. For protection against acids, bases or water, we offer many PFAS-free alternatives!

Is everything working as it should? Is anything missing? What could be improved? We recommend that you form a clothing council consisting of users and decision-makers. With the clothing council, you can continuously evaluate the need for protective clothing for different work tasks. In the long term, the council can also develop within risk assessment, with the competence to identify and report new risks.

7 8

Involve the users in the purchasing process at an early stage as they are the ones wearing the clothing. Allowing users to test the clothing under real working conditions is an effective way to engage them. Once the evaluation is complete, it is easier to achieve the desired balance between protection and comfort.

Protective clothing washed in industrial launderers can quickly lose its protective properties if it is not suitable for this type of handling. It is also important to be aware that protective clothing may require re-impregnation after washing to maintain its protective properties. To ensure quality and washability, we test all our fabrics and protective clothing at professional industrial laundries.

Comfortable protective clothing that fits correctly can be crucial for safety in the workplace. We have a wide range of Flame Retardant clothing for men and women and can offer well-fitting garments for most users. We also offer made-to-measure protective clothing for those who require it.

5

Optimise the level of protection by adapting protective clothing to the risk.

Incorrectly adapted protective clothing can cause discomfort and heat stress in some cases. This can impair concentration and increase the risk of accidents and injuries. A good way to achieve lightweight, adapted protection is to use the Tranemo Skinsafe™ multi-layer system.

At Tranemo, sustainability is not just a goal, it is a commitment woven into every step of our production and innovation processes. From phasing out harmful substances to advancing circular practices and extending garment life, our focus is on creating safer, more responsible workwear.

Our production facility in Svea has doubled the number of solar panels this year. Kostadin Kyorgogov, Managing Director of Tranemo Bulgaria says “We are becoming more independent, more sustainable and we can guarantee even higher quality.”

In the following text we will answer four questions that highlight key areas of our ongoing sustainability efforts and how we are turning ambition into action.

1Tranemo is working hard to phase out PFAS on workwear where it is not essential. How is this transition progressing?

It has been an interesting journey, and we have learned a lot along the way. We are currently working on phasing out PFAS in the last of our workwear fabrics. Before transitioning to a PFAS-free fabric, we conduct extensive testing to ensure quality. Once the final round of testing is successfully completed, Tranemo will only purchase PFAS-free fabrics. The exception is the fabric for our APEX chemical range, which protects the user against oil, o-xylene and butanol. We will have a mixed stock for some time.

2

Oeko-Tex® Standard 100 certifies that workwear is free from harmful substances. For Tranemo this certification is very important. Are all Tranemo workwear products Oeko-Tex® certified?

We are continuously adding more styles to our Oeko-tex certificate. We have a close dialogue with our suppliers to get all fabrics and trims certified. As of now all stock items are Oeko-tex standard 100 class 2 (some with PPE) certified.

3 Tranemo is a participant in the EU-founded Life Cirtechtex project aimed at implementing circular economy processes to reduce textile waste in the production of personal protective equipment (LIFE22ENV-ES-LIFE-CIRTECHTEX). What is the status of the project?

We are entering year three of the project. The project focuses on reducing both pre- and post-consumer textile waste. We are actively sending fabric waste from our factory in Bulgaria back to the weaver to create new fabrics. Additionally, we are also improving the collection of used garments from our customers which are to be shredded and then repurposed.

4

High-quality, durable workwear is crucial for sustainability. Why is garment longevity so important, and what measures does Tranemo take to ensure it?

The most environmentally friendly garment is the one that was never produced. The second best is the one that lasts. Extending the life of a garment is one of the most effective ways to reduce its environmental impact.

The most environmentally friendly garment is the one that was never produced. In second place is the garment that lasts.

Fewer garments produced means fewer resources consumed, less waste generated and a smaller carbon footprint overall. At Tranemo, we believe that durability is the foundation of sustainability. That is why we design our workwear to withstand the toughest conditions and the test of time. Here is how we ensure long-lasting quality:

RIGOROUS MATERIAL TESTING

Every fabric and reflective material are tested before production begins, to ensure it meets our high standards for durability and performance.

THOUGHTFUL DESIGN

Our patterns are developed with comfort, fit and resilience in mind. We reinforce garment parts that are prone to wear and tear to extend the garment’s life.

REPAIRABILITY

We aim to design garments that can be repaired when needed. Replacing a zipper on an otherwise intact garment is often more environmentally responsible than replacing the entire item, even if it’s not always the most economical choice.

COMMITMENT TO REPAIRS

Our goal is to repair all product claims whenever possible, helping to keep garments in use for longer.

CONTINUOUS IMPROVEMENT

We monitor how our products perform in the field. If a garment does not meet our expectations, we update the design to ensure it lives up to the Tranemo standard.

WEARER TRIALS

Real-life testing gives us valuable insights into how our garments perform over time. These trials help us refine our materials and construction methods to achieve the durability our customers rely on.

By focusing on quality and longevity, we protect workers and the planet.

Established in 1934, the Tranemo group now consists of Head Office in Sweden and subsidiaries in Norway, Denmark, Finland, United Kingdom, Ireland, France, the Netherlands, Germany, Switzerland, Portugal, and Bulgaria. Together, we offer one of the strongest sales and service organisations in Europe.

Subsidiaries

Sales Regions

We continue to grow, expanding into new markets and enhancing our development and production processes.

Since 2023, Tranemo has used AutoStore to streamline the warehouse and order management. This year, the system is being expanded with additional delivery gates, boosting picking efficiency and ensuring it can keep pace with the growing volume of orders.

We are also improving our On Demand Branding services by installing two new embroidery machines, which will significantly reduce delivery times for embroidered garments. This upgrade allows us to offer printing and embroidery services in-house.

A lot is going on at our Bulgarian production facilities, Svea and Gustav. At Gustav, we are expanding our sewing department to meet the growing demands of production and to improve the working environment for our employees.

At Svea we have doubled the number of solar panels and Svea is now practically selfsufficient during the summer, significantly reducing our CO2 footprint.

Another improvement is the new laundry department which gives us full control over the pre-washing process and ensures we meet functional and sustainability requirements.

We are proud and excited to announce the launch of Tranemo Workwear France, a major step in our international growth journey. With strong market potential and increasing demand for PPE solutions, France offers opportunities to strengthen our presence and develop the delivery of our high-quality garments. Welcome and good luck to our new French Managing Director, Germain Jore.

Founded in 2019, Tranemo Ireland continues to strengthen its market presence with the launch of a new showroom and training centre, setting new standards for customer education and engagement.

Tranemo Denmark has relocated to a new facility in Hjørring, designed with sustainability in mind. To reduce the CO2 footprint, the use of concrete was minimised and limited to the floors. The building is equipped with rooftop solar panels and charging stations for electric vehicles. We are proud and grateful to move into a modern space that brings together multiple offices, a meeting room, a warehouse and a contemporary showroom.

Wearing Flame Retardant workwear is essential for many of our railway customers. From the UK market, we received a request to add a ladies’ boilersuit to our assortment, specifically designed for British railway workers. This new addition expands our EDGE range, offering excellent performance for cutting and welding, and certified for high-visibility in accordance with EN ISO 20471 and RIS-3279-TOM.

To achieve the best fit possible, the boilersuit was tested on women with a variety of body shapes and proportions. One key finding was that many women prefer to wear a belt at the waist rather than letting the boilersuit hang loose, a small but meaningful adjustment that greatly improves comfort. We believe that creating clothing for everyone helps build more diverse and inclusive workplaces. Everyone deserves to feel comfortable and confident in their workwear.

FLAME RETARDANT

LADIES BOILERSUIT

PFAS-free, Non-Metal, Flame Retardant Hi-Vis ladies boilersuit in double weave fabric with comfort finish on the inside, developed for the railway industry.

6111 82 50 orange

6118 82 50 orange

EN ISO 11612 A1 B1 C2 D2 E3 F1

EN 61482-2 APC 2, ELIM: 9,2 cal/cm² ATPV: 11,0 cal/cm²

EN 1149-5

EN ISO 11611 CL.2 A1

EN 13034 type PB[6]

EN ISO 20471 CL.3

RIS-3279-TOM

Comfortable, well-fitting protective clothing is essential for workplace safety. Garments that provide comfort are more likely to be selected for work every day. Tranemo provides a wide selection of Flame Retardant clothing in both women’s and men’s sizes, ensuring a great fit for most users. If you can’t find the right size for you, we offer a made-to-measure protective clothing service.

Beatrice is one of Tranemo’s skilled Garment Technicians, and one of her main tasks is creating patterns for made-to-measure clothing. Customers who have difficulty finding their size in our size chart can request protective clothing tailored to their specific measurements. This does incur an additional cost and longer delivery time.

Sometimes, it can be a real challenge to create custom-fit clothing when the obtained measurements differ. Often one dimension leads to another, and the finished result will be a wellfitted, comfortable garment.

Another challenge is fitting pockets on smaller sizes while preserving the overall design. It is also important to ensure that surface area requirements and other details specified by the relevant standards are maintained.

Every worker deserves clothing that fits, feels good, and keeps them safe.

Every made-to-measure garment is a lesson in how unique bodies really are.

Beatrice Eklund, Garment Technician

Non-Metal and Inherent Flame Retardant coat in Cantex WS with ELIM 12 cal/cm². The coat is a thinner version of the Switch coat 5193, and can be worn over a Tera TX jacket to reach ELIM 30 cal/cm². PFAS-free.

Concealed front closing with velcro for ”quick release”. Adjustable cuffs. Back length in size L=122 cm.

W T N C M

Size: S, L, XXL, 4XL

Colour: 94 yellow/navy

Quality: 885: Cantex Weld - 50% modacrylic / 36% cotton / 12% polyamide / 2% antistatic, 365 g/m²

c95mt

Non-Metal, soft and comfortable Inherent Flame Retardant sweatshirt with round neck. PFAS-free fabric, where 50% of the cotton is recycled.

Ribbed neck, cuffs and waistband. Heat sealed reflective stripes for greater comfort.

R O M

Size: XS-4XL

Colour: 93 orange/navy

Quality: 899: Cantex Terry - 60% modacrylic / 19% recycled cotton / 19% cotton / 2% antistatic, 290 g/m² 925: Zenith JP 220AT - 42% modacrylic / 29% polyester / 14% recycled cotton / 13% cotton / 2% antistatic, 220 g/m²

c95mt

Non-Metal, soft and comfortable Inherent Flame Retardant Hi-Vis sweatshirt with hood. PFAS-free fabric, where 50% of the cotton is recycled. Kangaroo pocket in front. Ribbed cuffs and waistband. Heat sealed reflective stripes for greater comfort.

Non-Metal and Inherent Flame Retardant cardigan in a soft sweatshirt fabric, where 50% of the cotton is recycled. PFAS-free. Concealed zip closing. Chest pocket with zip. Front pockets. Ribbed cuffs. Heat sealed reflective stripes.

Non-Metal and Inherent Flame Retardant Hi-Vis ladies joggers in sweatshirt material. The fabric is PFAS-free and 50% of the cotton is recycled. Elastic waistband with drawcord. Side pockets with zip. Elasticated cuffs. Heat sealed reflective stripes.

Size: Ladies S-XXL Colour: 94 yellow/navy Quality: 899: Cantex Terry - 60% modacrylic / 19% recycled cotton / 19% cotton / 2% antistatic, 290 g/m² c95mt

Non-Metal and Inherent Flame Retardant Hi-Vis boilersuit in Tera TX, lined with a light fabric to achieve a higher protection against Electric Arc, EN 61482-2 APC 2. PFAS-free¹.

Concealed 2-way zip and press stud closing. Two loops for communication equipment. Two loops for attaching ID-pocket. Vertical chest pockets with zip. Adjustable waistband. Actionback for free movement. Adjustable cuffs. Side pockets with hidden side access. Shaped knees with adjustable inside kneepad pockets. Hip pockets with flap. Cargo pocket with flap. Ruler pocket with flap. Zip in legs from knee to ankle. Contrast stitching. Special order - please allow an additional 5 days approximately. ¹This garment is produced with new PFAS-free fabrics. For a period, we will have a mixed stock and the transition to PFAS-free will be a running replacement.

Non-Metal and Inherent Flame Retardant Hi-Vis ladies boilersuit in Tera TX, lined with a light fabric to achieve a higher protection against Electric Arc, EN 61482-2 APC 2. PFAS-free¹.

Concealed 2-way zip and press stud closing. Two loops for communication equipment. Two loops for attaching ID-pocket. Vertical chest pockets with zip. Belt loops and adjustable waistband. Actionback for free movement. Adjustable cuffs. Side pockets with hidden side access. Shaped knees with adjustable inside kneepad pockets. Hip pockets with flap. Cargo pocket with flap. Ruler pocket with flap. Zip in legs from knee to ankle. Contrast stitching. Special order - please allow an additional 5 days approximately.

¹This garment is produced with new PFAS-free fabrics. For a period, we will have a mixed stock and the transition to PFAS-free will be a running replacement.

Non-Metal and Inherent Flame Retardant Hi-Vis bib ’n’ brace in a fabric with a comfortable feel and good tear resistance. PFAS-free.

Adjustable braces with hidden fixed lock closing and elastic on the back. Chest pocket with flap and D-ring. Inside pocket. Side pockets. Back pockets with pocket flaps. Cargo pocket with flap, mobile phone pocket, hidden D-ring and strap for ID-pocket. Ruler pocket with flap and reinforced bottom. Shaped knees. Kneepad pockets with two different placement levels. Long and short sizes - will be amended after order. Approximately 5 days extra delivery time. *If the garment is mainly intended for welding processes, please ask Tranemo for usage advice.

30”- 50”R, 32”- 40”T, 34”- 48”S

Colour: 94 yellow/navy

Quality: 811: Tera TX - 45% modacrylic / 35% cotton / 18% polyamide / 2% antistatic, 260 g/m²

c95mt

PFAS-free, Non-Metal, Flame Retardant Hi-Vis ladies boilersuit in double weave fabric with comfort finish on the inside, developed for the railway industry.

Concealed front zip and press stud closing. Arm ventilation. Left chest vertical pocket with zip. Right chest pocket with flap and loop for radio/gas monitor. Side pockets with flaps and hidden access. Belt loops in waist. Cargo pockets with flaps. Shaped knees. Inside kneepad pockets with two different placement levels. Hip pockets with flaps. Adjustable waistband. Adjustable cuffs. Zip in legs from knee to ankle.

Size: Ladies S-XXL

Colour: 50 orange

Quality: 821: Edge HVO - 50% polyester / 27% modacrylic / 22% cotton / 1% antistatic, 370 g/m²

c95nt

TRANEMO WORKWEAR IE LIMITED Unit 2

7-9 Knockmitten Close Western Industrial Estate Dublin D12 FW5D Ireland

Ireland Sales Office: +353 156 86366

Ireland Sales Mobile: +353 858 150381

UK Sales Office: +44 1670 732 333

sales@tranemo.ie www.tranemo.ie

QR-code shortcuts