CHANGE EMBRACING

How the Nyentap family used their forward-thinking approach to build a better farm

Future-Proof Your Herd

Embrace a proactive approach to the health and wellness of your herd.

Hold Your Herd to a New Standard

From software to smart reports, we’ve inspired dairy farmers with tools for a clear picture of the dairy cows they want today and for the next generation.

What can you do today to ensure a better tomorrow? Contact us.

PUBLISHED BY

DAIRY FARMERS OF ONTARIO

6780 Campobello Road Mississauga, ON L5N 2L8

MANAGER, COMMUNICATIONS

Sharon Laidlaw sharon.laidlaw@milk.org

ADVERTISING

Pat Logan pat.logan@milk.org 519-788-1559

GRAPHIC DESIGN

Katrina Teimo

CONTRIBUTORS

Robert Matson, Bruna Mion, Pedro Nogueira, Rajan Niraula, ACER Consulting, Mireille Thériault, Annie Claessens, Annick Bertrand, Solen Rocher, Jeanine Moyer, Rick Burton , Conor McCabe, M.S., Julia Fouts and Veal Farmers of Ontario

PHOTOGRAPHY

Lyndsay Berry Photography

Canada Post Publications Mail Sales Product Agreement No.40063866.

Return postage guaranteed. Circulation: 8,000. ISSN 0030-3038. Printed in Canada.

SUBSCRIPTIONS

For subscription changes or to unsubscribe, contact:

MILK PRODUCER

6780 Campobello Road Mississauga, ON L5N 2L8

Phone: (905) 821-8970

Fax: (905) 821-3160

Email: milkproducer@milk.org

Opinions expressed herein are those of the author and/or editor and do not necessarily reflect the opinion or policies of Dairy Farmers of Ontario.

Publication of advertisements does not constitute endorsement or approval by Milk Producer or Dairy Farmers of Ontario of products or services advertised.

Milk Producer welcomes letters to the editor about magazine content.

*All marks owned by Dairy Farmers of Ontario.

WEBSITES & SOCIAL MEDIA

www.milkproducer.ca

www.milk.org

Facebook: /OntarioDairy

X: @OntarioDairy

Instagram: @OntarioDairy

LinkedIn: dairy-farmers-of-ontario

CON TENTS

FARM MANAGEMENT

When Theo and Maria Nyentap established their eastern Ontario family dairy farm in the late 1970s, they likely didn’t realize the foundation of their forward-thinking and strategic farm management approach would inspire their son, Mark, some 50 years later.

Effective farm management strategy crucial to running thriving farm operation

By Roger Boersen, Board Member, Region 10, Huron and Perth, and Vice-Chair, Dairy Farmers of Ontario. Roger chairs

the Audit Committee and the

Markets

and

Allocation Committee

and serves on the Quality Assurance Committee.

Optimizing our farm management practices is an area many of us think about as we go about our daily chores. Whether it’s improving calf health, deciding on what equipment to replace or meeting with our veterinarian to discuss the latest herd health data, there’s always something to manage and tweak on our farms. Having an effective farm management strategy is crucial to running a successful and thriving dairy operation.

According to Britannica, farm management can be referred to as the “making and implementing of the decisions involved in organizing and operating a farm for maximum production and profit … Because farms differ widely, the significant concern in farm management is the specific individual farm; the plan most satisfactory for one farm may be most unsatisfactory for another.” The latter part of this definition is especially true of dairy farms in Ontario and across our country. We may encounter differing climates, inputs and access to resources and

expertise. What may work on my farm, may not work for those located elsewhere in the province, but one thing is for sure, we all strive to maintain high production standards and commit to continuous improvement while raising healthy, sustainable herds.

When I think about our family farm, Boern View Farms Ltd., we regularly benchmark our farm with others in our area. We compare our yearly numbers to our previous year’s numbers, as well as other farms and set goals for the next year. Knowing how your farm compares with your peers can provide valuable insight on areas that are working well and where needs improvement. We also believe in bringing our team together – which includes five employees and two children working full-time - on a yearly basis to review how we’re doing. These meetings also include our feed specialist, veterinarian and field services representative, as well as representatives from Lactanet and our genetics company. You can’t fix what you

don’t know, which is why it’s essential to us to be able to take a holistic approach to managing the farm and adjust where needed.

In this month’s cover story, starting on page 18, the Nyentap family clearly demonstrate why change can be a good thing. With the benefit of outside experience, the family has adopted a guiding rule that has brought them much success, which is that any decision made on Marvellane Farms must be business focused and make financial sense. All farm management decisions are carefully considered, and priority is given to working with resources they already have. Mark Nyentap, who runs the farm alongside his parents, Theo and Maria, credits their open-mindedness and early adoption of innovations as the solid foundation of their farm’s management strategy.

Many of us have heard it takes a village to raise a child. I’d like to think it takes a strong team and supportive staff to run a profitable dairy farm.

Increase profits, not headaches

From ever-evolving regulations to dietary trends and global producers penetrating Canada’s dairy market, you face a myriad of challenges. Let MNP help you capitalize on new opportunities, streamline operations, and improve your bottom line.

Roger Boersen

QA &

ENSURE MILK SAMPLES

Dairy Farmers of Ontario’s (DFO) Field Services Representatives (FSRs) are not only milk inspectors, they are also your support for everything from milk quality troubleshooting to quota questions and paperwork, questions about policies and regulation, and anything else related to DFO and how it applies to your farm. Our 13 FSRs have seen and heard a lot. This column was created to use their collective expertise to share answers to some of the most common questions received.

THE PROCESS OF MILK TESTING plays a crucial role in ensuring consumers receive safe, high-quality products. At the heart of this process lies one fundamental step: taking representative milk samples on the farm.

Milk sampling, the cornerstone of bacteria and composition testing, involves the collection of representative samples from every farm bulk tank. This sampling must adhere to strict protocols to ensure accuracy and reliability. The Bulk Tank Milk Grader (BTMG) is responsible for sampling and measuring milk in a producer’s bulk tank. Once at the farm, the BTMG will grade the milk by sight, smell and temperature. If it passes the grade, the milk is accepted. Every producer’s bulk tank milk is sampled with a single-use pipette or a sanitized sample dipper (provided by the producer). The sample is collected in a tamper-evident vial that is linked by the BTMG’s handheld device to the barcode on a producer’s licence on their milkhouse wall.

insert filled with a mixture of ice and water and placed in an insulated cooler in the milk truck. It is then transferred to a fridge at the milk depot, which is monitored by a time temperature recorder. It then moves to a temperature-controlled courier van where the temperature is verified by a data logger while on route to the laboratory in Guelph, Ont. At every stage throughout the process, samples are monitored to verify they stay between 0 and 4 Celsius. These sampling procedures are meticulously followed to reflect the quality of the milk harvested, minimize the risk of sample contamination and ensure sample suitability on route to official testing.

Increased bacteria testing serves as a proactive measure for dairy producers. It enables them to quickly identify potential issues in their production processes and act promptly. By pinpointing areas of concern, producers can implement corrective actions swiftly, mitigating risks and preserving the integrity of the milk offered for sale.

By pinpointing areas of concern, producers can implement corrective actions swiftly, mitigating risks and preserving the integrity of the milk offered for sale.

A farm bulk tank milk sample shall only be used for testing by the laboratory if it is maintained within an acceptable temperature range (apart from inhibitor testing) from the time of collection until prepared for testing, thus making it suitable for testing. To accomplish this, after the sample is collected in the milkhouse, it is placed in an

The importance of taking representative milk samples on the farm cannot be overstated. It forms the foundation for accurate testing, protects the milk supply chain and, ultimately, ensures consumer confidence in dairy products. By upholding these standards, dairy farmers not only safeguard their own livelihoods but also contribute to the broader goal of delivering safe and reliable dairy products to consumers.

ENGINEERING A BETTER FARM

Industry representatives come together to discuss ways they could promote crosssector research opportunities to help develop practical on-farm solutions

By Robert Matson; Production Research Manager; Dairy Farmers of Ontario

THE AGRICULTURAL INDUSTRY has consistently embraced innovation, and with recent developments in artificial intelligence and automation, producers may have additional opportunities to embrace change in their farm operations. This was the topic of conversation at the annual Livestock Research Innovation Corporation (LRIC) symposium, held on June 20, 2024. Dr. Mary Wells, dean of engineering at the University of Waterloo, presented on innovation at Waterloo outside the agricultural space.

Her presentation highlighted projects showcasing autonomous vehicles, chemical engineering of bioproducts, automation of processes and incorporating societal, health, sustainability, technology and economic factors into broader initiatives. The topic of innovation through collaborative capstone courses, hackathons and design teams was also brought forward as exciting opportunities to students at the university. The question then became how the livestock sector could use and further develop these innovations and initiatives for practical use.

This question was posed to a panel moderated by LRIC vice-chair R.J. Taylor. The panel included Dr. Wells, dairy producer Chris McLaren of Larenwood Farms, Darrell Petras, chief executive officer of the Canadian Agri-Food Automation and Intelligence Network, and Dr. Rebecca Hallett, associate dean of research and graduate studies at the Ontario Agricultural College. The panel discussed how the innovations outlined in Dr. Wells’ presentation could be cross-applied to the agricultural sector and how technology could optimize labour and energy use and help steward the environment. McLaren started the panel by noting, “Our farm is transitioning to more and more robotics, and we are interested in technologies that could monitor (our) cows and predict problems before they happen. By using technology and robotics to complete tasks on the farm, we can get things done faster and use our time more effectively.”

Taylor further suggested much of this technology already exists, but some of it needs to be cross-applied to other sectors, including agriculture, to have an impact. The idea of putting research and

technology into action was of particular interest to those on the panel. Also of note was the potential creation of “collision events” where researchers from different sectors could come together to share ideas and ways to increase the impact of their innovations.

The symposium was not just a platform for experts to share their insights but also a space for the audience to actively contribute. The moderator invited participants from various sectors to share their perspectives, underscoring the sector-specific aspects that need engineering solutions. Those attending the event noted potential economic concerns and the privacy and security of data. Panel members pointed out these were important concerns since technicians would need to be trained to fix these new advancements in the agricultural sector, and more people would need to be trained to help protect the data and systems that support these initiatives. The panel ended with some final thoughts:

• Knowledge transfer needs to go both ways and take advantage of feedback from the end user and their barriers to using the technology.

• There is a need to embrace the ecosystem of innovation already occurring in other sectors to promote further advancements in agriculture.

• There is still a need to support broader livestock research that generates data and insights that make engineering solutions possible.

Overall, many of the participants in the discussion left the event having created more connections and with ways they could promote crosssector research opportunities to help engineer a better farm.

that Maximizes Nutrition

Laying the right foundation for optimal lactation

Tips on how to maximize dairy cow performance through the challenging transition period

By Bruna Mion, PhD, Dairy Production Expert – Nutrition and Herd Management, Lactanet

THE WEEKS SURROUNDING CALVING are among the most challenging periods for dairy cows, marked by increased stress, metabolic challenges and immune function issues. Many have compared the transition period for dairy cows with a person running a marathon. I believe the comparison should be made with a full Ironman. An Ironman entails a hard four-kilometre, open-water swim, followed by a punishing 180-km bike ride through varied terrain, often including hills and challenging road conditions, and finishing with a full 42-km marathon. If the swim and bike ride are excessively challenging, the athlete might still reach the marathon but will be significantly impaired. Similarly, dairy cows facing too many challenges during the dry and fresh period (referred to as the transition period) will have their performance compromised throughout the entire lactation.

Common challenges during the transition period

The transition from the dry period to the start of the next lactation requires a substantial amount of nutrients, including energy, protein, minerals, etc. During the third trimester of gestation, cows require significant nutrients for calf growth. After calving, energy requirements increase by four times to support milk production. Paradoxically, this period is typically accompanied by a decrease in feed intake, leading to unmet nutritional needs, and often resulting in losses in body condition score. A mineral imbalance is also observed due to high calcium requirements for colostrum production.

Calving itself is a stressful event, and a certain level of inflammation is required for uterine recovery. However, sometimes this inflammatory response can become exaggerated, posing additional challenges. The animal response against infection is also somewhat impaired during this period because immune cells also need energy to function, and much of the energy available is redirected to the mammary gland for milk production. Consequently, there is an increased probability of diseases during the first few weeks after calving.

Frequent diet changes, whether on smaller farms with one dry and one lactation diet or larger farms with multiple diets, impose a challenge for rumen adaptation, and could also affect feed intake. Frequent pen and group changes affect animal welfare and behaviour. Moving from a dry pen to the calving area, then to the fresh/lactating group requires the animal to adapt to the new environment and reestablish their hierarchy within the new group.

Consequences of challenges imposed during the transition period

The transition period is the foundation for the rest of the lactation. Some cows overcome transition challenges and perform well, while others struggle, affecting their performance throughout the whole lactation.

Reduced feed intake leads to weight loss and decreased body condition score, impairing a cow's ability to meet energy demands and produce milk. Inadequate calcium regulation results in hypocalcemia, causing issues like milk fever and further reducing productivity. Excessive inflammation due to tissue damage or infections diverts resources from lactation and reproduction, leading to lower milk yields and decreased fertility. Additionally, a compromised immune response increases susceptibility to diseases, such as retained placenta, metritis and mastitis, which, despite prompt treatment, have lasting negative impacts on milk production and reproduction throughout the lactation period.

Therefore, for good herd management and to maximize efficiency, it is essential to identify the bottlenecks in farm management to minimize common challenges of the transition period, reduce the consequences if cows fail to overcome those challenges and improve practices to maximize productivity.

Transition Management Index (TMI)

In your herd, do you currently evaluate fresh cows to ensure they are overcoming transition challenges and producing at their full potential? Which metrics do you use and how confident are you this is the best they can achieve? Could they be doing even better?

In 2024, Lactanet will launch a tool to assess the transition period, providing producers with an objective metric to evaluate the transition period management and identify areas of improvement.

The TMI calculates the difference between expected milk production (based on breed, lactation number, genetics, previous lactation information, calving month, dry period information and production and composition in the first test) and the 305-day projection in the first milk test (five to 45 days in milk). This methodology is based on a previous tool created in the United States (Transition Cow Index™, Nordlund 2006) but incorporates more variables and is tailored to the Canadian industry. By the incorporation of different variables, including genetic information, TMI can also be calculated for first lactation cows, even though information from past lactation is not available.

If a cow has consistently good milk production, good genetics and a normal dry period, she is expected to have good milk production in her next lactation. A smooth transition period results in a high 305day yield projection, yielding a positive TMI. In contrast, if the cow had a bad transition, her 305-day projection would be lower than expected, yielding a negative TMI. Thus, the TMI provides an objective measure to support producers in evaluating transition success. The index interpretation is straightforward: an increase in herd average by 100 points is equivalent to an average increase in 100 kg of milk/cow/ lactation.

Data from 5,070 herds across Canada shows TMI is affected by transition challenges. Herds with lower TMI averages have a higher proportion of cows with high somatic cell counts and high BHB in milk (a marker of subclinical ketosis) in the first test (five to 45 days in milk). Additionally, the occurrence of clinical diseases also affects the TMI. Using data from seven Canadian herds with excellent disease recording, we observed the average TMI is 1.73 times lower in cows with metritis, 1.84 times lower in cows with mastitis and 4.73 times lower in cows with displaced abomasum.

Action plan for a successful transition period

For optimal herd management and maximized efficiency, it's essential to identify and address bottlenecks in farm management. The transition period poses significant challenges for all cows, but recognizing areas for improvement can help minimize these common obstacles and mitigate their consequences. To achieve this, diligent attention to your herd, clear goal setting and establishing concrete and objective performance metrics are required. Adopting a critical perspective on current practices and proactively implementing improvements are essential steps toward enhancing production and profitability.

Transition Management Index is funded through the Innov’Action AgriFood Program under the Canadian Agricultural Partnership, as part of an agreement between the governments of Canada and Quebec.

“Our go-to for quality, comfort, peace of mind.”

daughters Laura (Ryan) and Amanda (Brandon) Milking 64 Registered Holsteins, 11,700 kg M, F 410 kg, P 355 kg, 11 EX, 26 VG

We have been using Udder Comfort™ for over 20 years. At Brookturn Farms, we believe in being proactive not reactive. We use Udder Comfort on our fresh cows to ensure our cows are off to a great start to set the stage for a successful lactation. By using Udder Comfort, we are able to prevent problems and keep the milk owing into our bulk tank!

We believe our cows are like professional athletes – Brookturn Dempsey Pleasant EX-94 4E* Lifetime Production (6 lactations): 82508 KG3.9%F 3.4%P the perfect example! The kind of cow that will get any Dairyman excited! By putting cow comfort rst and using Udder Comfort it has been a contributing factor to sustaining great udder health. We breed for the kind of cow the lasts and improves our bottom line with ease and she does just that!

Scan QR or go to link to read more about Brookturn https://wp.me/pb1wH7-k8

INTEGRATING SOUND MANAGEMENT PRACTICES

Dairy farmers can optimize productivity while supporting sustainability in food production

By Pedro Nogueira, Dairy Technical Services Support, Trouw Nutrition

It is important to strive to achieve a balance between maximization of profits and the wellbeing of dairy cows. This is fundamental for a sustainable dairy sector.

MILK HAS BEEN CALLED ONE OF NATURE'S MOST NEARLY PERFECT FOODS, supplying humans with essential nutrients, such as energy, as well as being an excellent source of protein with all the essential amino acids. Milk production is a key part of the agriculture industry, providing fundamental nutrients to the global population and supporting the livelihood of many people throughout the supply chain. As with any business, the drive for profitability often raises concerns among consumers. Specifically, within the dairy industry, animal welfare and sustainability are among the top concerns. As such, it is important to strive to achieve a balance between maximization of profits and the well-being of dairy cows. This is fundamental for a sustainable dairy sector. Maximizing profitability in milk production is possible through a combination of different systems, from genetics, nutrition and infrastructure to management practices. The dairy industry has been very successful over the years in making improvements using these techniques and, as a result, has created more productive, profitable and healthy animals.

Genetics

High milk production yield is an important objective of any dairy farm since it’s associated with increased profitability, which, in turn, leads to genetic selection emphasis on high-producing dairy cows. High milk production often raises concerns about animal welfare since higher milk yields can be associated with strain on a cow’s health and longevity. Still, the expression of genetics is influenced by cows that are well fed, in

a clean and comfortable environment and have regular veterinary care, including vaccinations, and disease monitoring programs.

Nutrition

Nutrition plays an important role in dairy production. Well-balanced diets, aimed at meeting cows’ nutritional needs, are essential for optimizing milk yield while supporting health and longevity. Poor nutrition, either through deficiency or excess nutrients, is equally negative since it reduces the cow’s ability to express its genetic potential. Proper nutrition is critical for a profitable business as well as in helping to reduce dairy production’s carbon footprint. Additionally, the dairy industry has been a great "up-cycler" for food waste byproducts that other species simply cannot digest. Used within a balance diet, this further supports the reduction of dairy production’s carbon footprint.

Technology and infrastructure

Investments in modern technologies and infrastructure can contribute to both profitability and cow health. Cow monitoring technologies, such as activity trackers and rumination sensors, enable early detection of health issues and inform management decisions, thereby enhancing both productivity and animal welfare. This principle applies to well-built barns that create a comfortable and cow-friendly environment, which is necessary for high-producing cows that value comfort and rest.

Management practices

To contribute to sustainable production, it’s important to implement measures that reduce dairy farms’

Animal

Nutrition plays an important role in dairy production. Well-balanced diets, aimed at meeting cows’ nutritional needs, are essential for

optimizing milk yield while supporting health and longevity.

environmental footprint, such as good waste management and correctly using resources. This not only improves dairy farming’s reputation, it also addresses potential regulatory risks and improves long-term profitability. Non-conventional models of milk production, such as organic or pasture-based systems, can offer opportunities to differentiate products in the market while providing alternatives for consumers.

In terms of the bigger picture, adopting sustainable farming practices can produce long-term benefits for dairy farmers, the environment and society at large. A recent article by Conor McCabe from the University of UC Davis, in California, asked “What is the difference between the glass of milk you enjoy today and the one your grandparents drank decades ago?” to which the author replied “While they may look and taste similar, the present day one has a much lower carbon, water and land footprint. In short, it’s better for the environment than ever before.” This quote highlights why it's an excellent time to be involved in the dairy industry. By integrating sound management practices, nutrition strategies, healthcare protocols and technological innovations, dairy farmers can optimize productivity while supporting sustainability in food production.

Dairy Farmers of Ontario (DFO) has an annual scholarship program that offers up to six $3,000 scholarships to high school students entering a post-secondary degree or diploma program in agriculture.

To be eligible for these scholarships, an applicant must:

• be a son or daughter of a DFO licensed dairy producer (sons or daughters of current board members are not eligible);

• be entering semester one of a post-secondary agricultural degree program or a diploma program in agriculture;

• have achieved an 80 percent or greater average in Grade 12 credits (best six to be averaged).

Selection criteria will be based on:

• academic achievement;

• future career plans;

• demonstrated leadership in secondar y school and community activities.

How to Apply:

Application forms are available on DFO’s website at new.milk.org under Industry Login. On the lefthand side, go to Documents > Forms > Application for DFO Scholarships.

Dairy Farmers of Ontario must receive complete application forms by Aug. 30, 2024, to be considered. New this year, emailed applications are now being accepted and are preferred.

For details, contact Robert Matson at robert.matson@milk.org or 905-208-7981.

THE EFFECT STACK

Likelihood of poor air exchange in the calf housing area is common because of ineffective air flow

By Rajan Niraula, P. Eng., Engineering Specialist, Livestock Housing & Equipment (Dairy, Beef and Goat), OMAFRA

THE TREND OF KEEPING CALVES INDOORS is increasing among dairy farmers because of challenges faced in feeding, watering and cleaning during harsh winter conditions, as well as the growing popularity of automatic calf feeders and group housing.

Since calves have different environmental requirements than mature cows for housing, it is critical to manage the environmental conditions within the calf housing area to suit calves' specific needs. In barns where small and mature animals share the same space (combined housing), the likelihood of poor air exchange in the calf housing area is common because of ineffective stack effect.

Researchers recently monitored temperature and humidity over a fourweek period to study patterns in combined housing in Ontario. It showed different levels of humidity and temperature in mature cow housing and calf housing area (pens). The barn was a compost bedded pack barn with a natural ventilation system and housed 90 milking cows. The pre-weaned and weaned calves were housed in individual pens and in a group housing system within the barn.

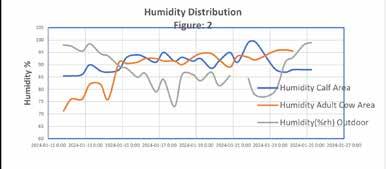

When outdoor temperature was below zero, the mature cow area was above zero (between 0 to 8 Celsius) whereas the temperature in the calf housing area dropped to below zero as shown in Figure 1. Also, humidity levels in the calf housing area were higher than the rest of the areas in the barn as shown in Figure 2. Both the humidity level and temperature recorded during the trial were outside the desired target levels for calf housing.

Improving microenvironment

Young calves generate a lot of moisture but do not generate sufficient heat to initiate the stack effect and encourage this moist air to rise and escape via chimneys. This creates dead spots in this area of the barn, which means no negative pressure is created to draw fresh air to enter this area. Fresh air is usually colder and drier (lower relative humidity),

Figure 1. When outdoor temperature was below zero, the temperature in the mature cow area was above zero (between 0 to 8 Celsius) whereas the temperature in the calf housing area dropped below zero.

Figure 2. Also, humidity level in the calf housing area was higher than the rest of the areas in the barn.

so it has more capacity to absorb moisture as it moves through the barn space.

Calf housing areas are often located at the corner of the barn with limited openings. This makes the area prone to poor air movement and lack of fresh air in winter and colder periods when the sidewall openings or end doors are closed. Fogging (smoke test) the calf area and observing air movement will help assess stale air zones.

The positive pressure air tube ventilation (PPAT) system is an effective way to bring fresh air into the calf area to mitigate such conditions. The PPAT system consists of a wall-mounted fan blowing fresh outside air into the calf room via a distribution tube with equally spaced holes that runs the length of the room. The room is pressurized by the fan, and air finds its way out of the room through the natural ventilation system, usually through chimneys. The fresh air fan is sized to provide the minimum fresh air requirement for calves, which is 15 cubic feet per minute (CFM) per calf or designing the system for four air changes per hour. The fan is selected based on which is the larger air flow: 15 CFM/ calf or four air changes per hour.

It is critical to have an exhaust point, such as a roof chimney(s) over calf areas, open during winter for stale air to escape. The exhaust points in the main barn area may not be large enough or close enough to receive air from the calf housing area.

Pay attention to improve ventilation

The environmental conditions in a combined housing system could vary across the barn as shown in the study. Farmers should pay attention to assess and improve the ventilation system in calf housing areas to ensure optimum calf health and welfare.

In the winter and shoulder seasons (spring and fall), the goal should be to introduce fresh air and exhaust moisture to maintain relative humidity levels between 60 and 75 per cent without creating drafts on the calves. In summer, as the ambient temperature rises above 25 Celsius, aim to introduce fresh air and control temperature rise since calves can be exposed to heat stress. It is often necessary to supplement the natural ventilation system with mechanical fans to avoid risk of heat stress.

How Soniusfield Farms improved animal care

MIKE BARDOEL IS A SECOND-GENERATION DAIRY FARMER, who owns and operates Soniusfield Farms, a 150-cow dairy farm in Ingersoll, Ont. The cows are housed in deep, sand-bedded freestalls and the facility uses a robot milking system. Mike, his wife, and three young children are proud of their growing business and strive to keep animal care as a top priority day to day.

As an Ontario dairy farmer, Mike participates in the proAction program and receives regular on-farm assessments like all other farmers across Canada. Soniusfield Farms was identified as a farm that showed substantial improvement in reducing lameness and hock injuries in their herd over two proAction assessments. Here are some of Mike’s perspectives on animal care as an Ontario dairy farmer and the on-farm changes he made to improve the health of his dairy herd.

At Soniusfield Farms, Mike knows prioritizing animal care will not

Lessons learned from Ontario dairy farmers

Ingersoll, Ontario

only improve his herd’s health and welfare, but also increase farm profitability. By taking care of his animals, and keeping them healthy, comfortable and well-bred, Mike feels his cows will be more productive and his business more profitable. Sometimes though, a second set of eyes on your herd can help identify priority issues on your farm you might have overlooked. For Mike, this was the case with his proAction assessment. While he already knew there were some improvements to be made with hock injuries, knee injuries and lameness, participating in a proAction animal care assessment helped bring those issues to the forefront.

Making a decision to expand

During the time of his assessment, Mike and his family were already building a new barn. The old facility was overcrowded and they felt they were better off building a new barn as the cow-comfort limitations in the old barn could not be overcome. The assessment was a great opportunity to learn about priority areas and opportunities for improvement that could be made with the new facility. Mike toured other dairy facilities and spoke with advisers, such as his veterinarian and nutritionist, to get a better understanding of what would work best for the new barn. When touring other facilities, he noticed cows tended to have fewer hock injuries on sand rather than mattresses, and this was a big factor in helping him decide to put in deep, sandbedded stalls. “For the new barn, deep bedded sand was a no brainer for us, it is so much better for hocks and the knees.”

Bigger, better freestalls

With some good help, the transition to the new facility was quite smooth and the cows were almost entirely switched over to robot milking within a few weeks. As with most big changes, there were a few areas to figure out at the start, but once things started to come together, Mike knew building a new barn was the right decision. “The cows thrived in the new barn ... they had space, bigger, better free stalls. It was more comfortable for them.”

Within the first six months, Mike saw noticeable improvements in his herd. Milk production increased by two litres per cow, lying time and rumination increased, fewer cows were experiencing issues with lameness, and they no longer had issues with hock injuries. With the new design, fewer cows were slipping and falling on the improved flooring, and the overall environment was calmer since cows were going to milk individually at the robot and there was no need to move large groups of animals at once.

Make it easy

In addition to owning and operating the farm, Mike also does all the trimming for his cows, so he knew they were struggling with digital

dermatitis in the old facility. Setting up a good system in the old barn for foot baths was a challenge. With the opportunity to build fresh, designing a facility that made routine foot baths easy was a priority. When they transitioned to the new barn, Mike began foot bathing aggressively to get the digital dermatitis under control. This, along with the other improvements made, worked like a charm. For Mike, the improvement in the health of his animals after moving to the new facility was almost immediate and he was very pleased to see his cows seemed happier in their new environment.

A different mindset with crossbred cows

In addition to the facility and management changes Mike implemented in his new barn, he also looked to breeding and genetics to improve his herd. Around a decade ago, Mike embarked on the journey to transition his herd from purebred Holsteins to crossbred cows. Today, his entire herd is made up of ProCROSS cows, which is a cross between Holstein, Montbeliard and Viking Red. While there aren’t many crossbred herds in his area, and his cows look a bit more beef than dairy, Mike doesn’t mind and feels this transition made a huge improvement in his herd’s health. The transition period was long and a bit challenging, but the hard work was worth it for Mike. The longevity and profitability of his cows has increased, and his production is on par with other robot herds in his area. Overall, the big changes, as well as the small changes, made over the years have made a tremendous improvement in his herd’s health, welfare and productivity.

Perspectives gained from advisers

While the decision to build a new barn was the right one for Mike and his family, he recognizes this isn’t always the case for farmers looking to improve animal care: “The easy answer is build a new barn, but that is definitely not in the cards for everybody.” When considering what he would recommend for other farmers, Mike highlights the importance of leaning on advisers for their guidance, perspective and as an informational resource. Veterinarians, nutritionists and hoof trimmers see many farms in their day-to-day work, so chatting with them about what they’ve seen work well for other farmers is a great way to learn about your options. Taking the time to walk around the farm and talk with his advisers allowed Mike the opportunity to discuss their thoughts, as well as his own, for areas of improvement on his farm. Improving animal care, health and welfare is a journey and one Mike continues to strive for every day.

This project was developed by ACER Consulting and funded and supported by the Ontario Ministry of Agriculture, Food, and Rural Affairs, the Dairy Farmers of Ontario, and the University of Guelph.

Reference

“Decisions supported by science” statements are supported by the Lameness and Injuries section of the Code of Practice for the Care and Handling of Dairy Cattle: Review of Scientific Research on Priority Issues. 2020.

The best start for healthy performance

Optivia™ includes a full range of products covering all stages of your dairy her replacement program.

Contact your Dairy Nutrition Advisor to benefit from Optivia and the LifeStart science opportunities! w w w. t rouwnu t ri tion .ca

Alfalfa is

“GREENER” on the neighbour's farm

Developing energy-rich alfalfa with the aim of reducing its environmental footprint

By Mireille Thériault, Annie Claessens, Annick Bertrand and Solen Rocher, Agriculture and Agri-Food Canada, Quebec Research and Development Center

RUMEN MICRO-ORGANISMS NEED

ENERGY to use the protein contained in a cow’s ration and synthesize microbial proteins, which then can be used by the animal to produce milk as shown in Figure 1 When the supply of degradable proteins in the rumen is high, as is the case for alfalfa, and the readily available energy in the ration is insufficient, part of the forage’s nitrogen escapes microbial digestion and may be lost into the environment in the form of urea (Figure 1).

To minimize these nitrogen losses and ensure efficient conversion of feed proteins into microbial proteins, sufficient energy must be readily available, which is said to be a good energy-to-protein balance. To verify this theory specifically in forages, in vitro incubations of alfalfa with higher and lower energy-to-protein ratios were carried out as part of a major research project funded by the Dairy Research Cluster 3 (Agriculture and Agri-Food Canada and Dairy Farmers of Canada under the AgriScience Program of the Canadian Agricultural Partnership). The purpose of these incubations was to simulate the fermentation and nutrient degradation processes that take place in the rumen. This trial confirmed alfalfa forages with a better energy-to-protein ratio led to higher microbial protein synthesis and less ammonia (NH3) in the rumen fluid.

Now, how can the energy-to-protein balance of forages be improved? For several years, we have examined this question with our colleagues from a number of angles. For example, in addition to afternoon harvesting, which increases concentration of sugars and starch in forages, two important sources of readily available energy, we have recently demonstrated adding other legumes to alfalfa, such as red clover or birdsfoot trefoil, improves energy-toprotein ratio of forage mixtures. Our team

Figure 1: Schematic diagram of ruminal protein utilization by dairy cows.

We have recently demonstrated adding other legumes to alfalfa, such as red clover or birdsfoot trefoil, improves energy-to-protein ratio of forage mixtures.

has also conceived a genetic selection method aimed at developing an energyrich alfalfa, which we used to create four successively "enhanced" populations. These populations were evaluated in a field trial at three sites in Canada (populations from one to three cycles of selection) and/or in a greenhouse trial (populations from one to four cycles of selection) and compared with a non-selected population (control). In the field trial, a gradual increase in energy concentrations was observed, up to 1.4 per

In this project, increasing the energy concentration of alfalfa led to a decrease in fiber concentration only, resulting in improved in vitro dry matter digestibility for populations from the third and fourth cycles of selection.

Figure 2. Nutritive value of alfalfa and interrelationship between the various components.

cent dry matter for the population from the third cycle of selection. In the greenhouse trial, an increase in energy of 4.6 per cent dry matter was observed for the population from the fourth cycle of selection. By comparison, the scientific literature reports an energy increase of four per cent dry matter has beneficial effects on animal performance. The population from the fourth cycle of selection is therefore very promising.

Further, since nutritive value is expressed as a percentage of dry matter, any change in one of its components, such as energy, inevitably impinges other components (white dot line shown in Figure 2). In this project, increasing the energy concentration of alfalfa led to a decrease in fiber concentration only, resulting in improved in vitro dry matter digestibility for populations from the third and fourth cycles of selection. As the crude protein concentration of the alfalfa was not affected, the energy-to-protein balance of these new populations was improved. It is also important to note, their annual yields were comparable to those of the control population.

Over the next few years, we plan to evaluate the protein use efficiency of dairy cows fed with this improved alfalfa following four cycles of genetic selection. We will continue our work, both in the laboratory and in the field, to develop an energy-rich alfalfa with the aim of reducing the environmental footprint of the queen of forage legumes.

embracing on the farm

The family’s guiding rule is that any decision made on Marvellane Farms must be business focused and make financial sense.

By Jeanine Moyer

WHEN THEO AND MARIA NYENTAP ESTABLISHED THEIR EASTERN ONTARIO FAMILY DAIRY FARM in the late 1970s, they likely didn’t realize the foundation of their forwardthinking and strategic farm management approach would inspire their son, Mark, some 50 years later.

Today, 26-year-old Mark Nyentap works alongside his parents, Theo and Maria, building on the farm’s progressive approach to enhance the sustainability and prosperity of their Marvelville, Ont. dairy farm, located south of Ottawa.

Raised with the understanding that change is a good thing, Mark was encouraged at a young age to visit and work on dairy farms outside of Canada to gain new knowledge and experiences, and the ideas he brought home were welcomed and often

adopted. As a result, the family farm has increased their labour, diversified to include a specialized calf raising business, and enhanced herd performance, all since Mark returned to the farm from university five years ago.

“I’m fortunate we have a great family-working dynamic,” says Mark. Today, Marvellane Farms Ltd. milks 200 Holstein cows in a double-8 parlour, milking three times daily, and employs six full-time workers.

It has to make sense

The family’s guiding rule is that any decision made on Marvellane Farms must be business focused and make financial sense. All farm management decisions are carefully considered, and priority is given to working with resources they already have.

We focus on being detailoriented and take advantage of opportunities as they arise.

– Mark Nyentap

For example, Mark explains he does his own pregnancy diagnosis using ultrasound yet chooses to outsource some of their field work. Mark also does the hoof trimming and offers his services to fellow farmers as a side business. He points out the family’s cost-conscious approach means they have never purchased a new tractor, but that hasn’t stopped progress.

“We focus on being detail-oriented and take advantage of opportunities as they arise,” says Mark, noting he and his parents regularly meet for lunchtime management discussions. Like many farm families, the kitchen table is the place they review their paperwork and make decisions together. The Nyentap family also relies on a team of advisers to help with decision making, keep them informed and manage specialized areas of the farm. They work closely with their accountant, financial adviser, nutritionist, veterinarian and custom field operators.

Herd management is also a key factor in the farm’s overall management strategy. The family’s focus on cow longevity means their management decisions encompass the health, comfort and production of their herd. As one of the first farms in Ontario to add sand bedding to their barn more than 25 years ago, animal comfort has always been a central part of the family's herd management approach.

Mark says they have enhanced the focus of their genetic selection by emphasizing conformation traits that correlate with herd longevity. He explains, “we’re working toward an older herd and keeping our cows producing longer just makes sense. New genetic technology is helping us achieve this.”

The Nyentap family work closely with their accountant, financial adviser, nutritionist, veterinarian and custom field operators to manage their farm.

Mark Nyentap.

Diversification and growth

As a young farmer who recently graduated from the dairy sciences program at Iowa State University, Mark has invested time touring and working on farms across the U.S., the Netherlands and parts of Central America. As a result of his keen observations and growth-focused mindset, he has introduced new business ventures and growth opportunities to the home farm that he picked up along his travels.

Most notably, Mark has adopted a U.S.-based calf raising model, where he takes in replacement heifer calves from other farms at birth and raises them to 10 weeks or six months in age, depending on the needs of his customers. Now in the third year of his custom calf raising business, Mark is growing his capacity to 250 calves. “After consulting with plenty of large farms that offered this service in the U.S., I thought it was an idea I could bring home,” he says, explaining the specialized care and cost savings passed on to his clients through his economies of scale have proven this business to be very attractive to his fellow dairy farmer clients. The new business also required training employees to provide the specialized care needed to raise healthy calves.

More employees have been added in the past five years to accommodate the farm’s new management focus and increased labour requirements. The Nyentaps have had success hiring foreign employees. Mark, who speaks Spanish fluently, organizes regular team meetings where he brings everyone together to

share pizza and provide training. At these meetings, he also discusses production targets, upcoming changes and current projects. He notes the meetings have helped everyone on the farm keep pace with the farm’s progressive growth.

“Our employee meetings are an opportunity to help understand the impact everyone has on the farm and why we implement the processes we follow,” says Mark. “We’re always looking to improve, and the employee meetings are really paying off.” He explains bringing everyone together not only saves him time managing employees, but also helps answer questions in an engaging and productive way. Mark is open with his staff, sharing his goals and setting targets for everyone to work toward together, and conducts these meetings in Spanish to make communication with employees more effective.

“Not only have we maintained our herd performance, but we’ve improved it over the past

Our employee meetings are an opportunity to help understand the impact everyone has on the farm and why we implement the processes we follow.

– Mark Nyentap

decade,” Mark proudly says. He points out recent farm management changes haven’t affected the family's ability to maintain their high level of quality and herd performance. In fact, Marvellane Farms was ranked in the top 25 of Lactanet’s 2023 Canada’s Best Managed Herds award.

Herd management

The family’s current farm management structure is influenced by Mark’s travels and experiences on dairy farms across the U.S. As they grow and set new farm management goals, Mark continues looking for new ideas, innovations and methods to continue enhancing the farm.

The farm’s milking and calf feeding schedule – three times daily at 6 a.m., 2 p.m. and 10 p.m. – means someone is present in the barn 24/7. Mark believes this provides significant herd health and operations advantages, by having a person available to attend to an animal or address an equipment concern in the moment.

The Nyentaps also milk their fresh cows six times each day during the first three weeks of lactation. Mark says this herd management approach helps increase dry matter intake and reduce post-calving health concerns.

Calf and replacement heifer feeding also follow the same schedule. They are fed three times daily at some point during each milking shift. The high labour requirements mean Mark and his parents invest in detailed employee training that continues to be updated through his frequent team meetings.

Another idea Mark picked up from his U.S. contacts is their method of cutting corn silage. The Nyentaps

The Nyentaps milk their fresh cows six times daily during the first three weeks of lactation.

currently feed a silage ration of 75 per cent corn/25 per cent alfalfa and exclusively grow BMR corn for silage. For the past few years, they have been taking a ‘high chopping’ approach, leaving 18 to 24 inches of stalk in the field. The result is higher quality feed and Mark says this new management style is making a significant difference.

Daily feeding of lactating cows happens between night and morning milking (2 a.m. and 6 a.m.) when the cows are least active. Mark notes this timing seems to appeal to the cows and reduces crowding at the bunk.

The focus on improving cow longevity drives Marvellane’s genetic strategy. Early adopters of genomic testing, the family values the information provided and combines genomic and classification data results to make their breeding decisions. Mark says they have also transitioned to using only sexed semen with their top Holsteins, targeting seven to eight heifer calves each month for replacements and have implemented a beef breeding strategy, all within the past five years. He points to the higher conception rate using beef semen as a key factor in contributing to longevity.

“As our herd reproduction improves and we’re able to keep our cows longer, we’re identifying shortcomings as they age,” says Mark, noting some legs and udders in older cows aren’t supporting the animals as they age as well as he would like. As a result of

these discoveries, their genetics and trait selection strategy have transitioned to emphasize the functionality of each animal.

“Now, we’re focused on traits that support the conformation of our animals, and we look forward to continuing to extend the production of our herd.”

The Nyentaps are already seeing their genetic strategy pay off. Ten years ago, 35 per cent of their herd reached a third lactation and higher, and in 2023, the herd scored 47 per cent, and an average 2.8 lactation per cow.

Attitude of achievement

“Building and maintaining our high-production herd takes a lot of strategic planning and labour,” admits Mark, who continues to work alongside his parents to expand on what they built by implementing new ideas and practices. He credits his parents open-mindedness and early adoption of innovations as the solid foundation of their farm’s management strategy.

Today, Mark is harnessing that same attitude to help expand their farm business while setting Marvellane up for success for future generations. Succession is obviously part of the Nyentap’s management plan and is already in process. “I’m proud of our farm, our strategic management strategy and the new ideas we discover by learning from other farms across North America,” says Mark. “I love seeing healthy cows and contributing to the health and prosperity of our farm.”

Mark credits his parents openmindedness and early adoption of innovations as the solid foundation of their farm’s management strategy.

Safeguard your farm from uncertainties

Effective business planning: optimizing strategy and adaptability for Canadian dairy producers

By Amanda Hammell, Senior Manager, Farm Management Consulting, MNP

HAVING A BUSINESS PLAN is not a novel concept but building a solid foundation for the future with thoughtful planning can safeguard your operation from the uncertainties of business ownership. From market fluctuations to environmental considerations, there are always a lot of irons in the fire. To navigate this complex terrain, it is important to employ effective business planning that serves as a roadmap to guide you through strategic decision-making and foster adaptability.

What is a business plan?

Every operation will have different goals they want to achieve through a business plan but there are a few key elements that can help the process go smoothly. At its core, a business plan is a strategic document. It explains how your farm operates, how you bring in revenue and details your business objectives and how you plan to reach those goals. Think of a business plan as a blueprint that provides a structured approach to achieving success and sustainability. It should go beyond financial projections and dive into the entire spectrum of farm operations, from production to risk management and everything in between.

What questions should a business plan answer?

Think of your business plan as a roadmap to success. It should answer these three questions: Who are you? Where do you want to go? How do you get there? The first thing you need to know to answer all these questions is where you are within the industry. Understanding the external environment your farm is operating in – the trends and challenges – will give you a jumping off point that can contextualize the document.

Strategic elements of an effective business plan

SWOT analysis

A SWOT (Strengths, Weaknesses, Opportunities, Threats) analysis helps you dig into your own operations. This element should cover both internal strengths and weaknesses and external opportunities and threats in the marketplace. The results of a SWOT analysis enable critical thinking and will set you up to complete other parts of the business plan.

Risk identification

The weaknesses and threats identified in the SWOT analysis make way for contingency planning as it relates to risk. In this section, it’s helpful to look at your operations realistically. What if you become unable to work? What if a key member of your staff quits or retires? What if you can’t afford new loan terms? Each challenge will have a unique solution only forward-thinking can identify.

Mission and vision

This section will be your anchor and purpose that explains to external parties what your core values are. It should answer what you do, why you do it and what is important to you.

Goals and objectives

Setting clear and attainable goals and objectives empowers you to make informed decisions based on what you want to achieve. It should provide a structured framework for aligning your day-to-day activities with long-term objectives.

Financial position

Assessing finances is one piece of a much larger puzzle. Comprehending your financial position and projections will help you understand what key stakeholders are looking for and how your financial situation either supports or detracts from your mission and goals. Having an experienced adviser by your side will help you objectively determine where you’re at financially and where you need to be to reach your goals.

Why do dairy producers need a business plan and what value does it bring?

Of all the benefits of a business plan, the most important might be the peace of mind it brings business owners. There’s genuine comfort in knowing you have a plan for yourself, your business and your family. Business plans help you prepare with strategic thinking and informed decision-making so you’re not caught off guard when an unexpected scenario arises. Accessing financing is another big benefit of business planning in that a well-prepared plan demonstrates to lenders your operation is a sound investment with thoughtful leadership at the helm. Lastly, you are given the gift of adaptability when you have built a roadmap for your operation. A dynamic business plan encourages versatility, helping you respond effectively to changes in consumer preferences, technology and industry regulations, among others. This flexibility is crucial for staying competitive in an evolving market.

For dairy producers, work and personal life are often so intertwined that separating the two can be next to impossible. Having a team of professionals to support you with these processes ensures you have access to an objective, unbiased third-party who can share any vital market information they have at their fingertips.

OxfOrd Cattle COmpany wants yOur Beef / dairy CrOss Calves

• Oxford Cattle Company is working with genetic companies to select sires for use in our guaranteed calf buy back program.

• We are now pleased to announce that we are interested in buying your holstein bull calves and can include them in your regular pick up. We will take calves that are over 92 lbs and 10 days old. The price will be negotiated on a weekly basis.

• Presently serving southwestern Ontario region and Ottawa region.

• For a Calf Pick Up Request text (519) 788-1399 by 1:00 pm Mondays

P5 MESSAGE – FALL INCENTIVE DAYS – SEPTEMBER AND OCTOBER - CONVENTIONAL

Due to a continued higher than usual market demand in 2024, P5 boards announced an additional incentive day in each of the months of September and October, to be issued on a non-cumulative basis.

The P5 provincial boards’ primary objective is to continuously monitor the milk market situation and meet demand in the most optimal way

and will continue to adapt production signals to address market changes, as required.

“We want to make sure we are going to meet the fall market and hope the market for the rest of the dairy year will show some signs of strength, so we won’t have to readjust the production signal by the end of the fall,” says Patrice Dubé, Dairy Farmers of Ontario’s chief economics and policy development officer.

In May 2024, butter stocks reached 36, 506 tonnes, up from April by 1,686 tonnes. May butter stock levels are higher compared with May 2023.

Cheese stock levels for May 2024 were at 97,765 tonnes, which is slightly lower compared with April and the lowest they have been for the same month in at least five years.

For the 52-weeks ending April 27, 2024, sales for fluid milk, fluid cream, yogurt, ice cream, cheese and butter increased/decreased by -0.5, -0.4, 2.7, 2.5, 2.4 and 1.0 per cent, respectively, compared with April 29, 2023.

A monthly recap of markets and production trends in Canada and Ontario

CANADIAN REQUIREMENTS AND PRODUCTION

Canadian butterfat requirements in kilograms and actual butterfat production across the P10.

12-month production (in millions of kilograms)

12-month requirements (in millions of kilograms)

Canadian production has increased by 2.4 per cent over the previous 12 months, and requirements have increased by 3.0 per cent over the previous 12 months.

Average increase in retail sales for dairy products sold in Ontario and the dairy product’s share of the total market sales, including at hotels, restaurants and institutions.

JUNE HIGHLIGHTS

This graph shows Ontario’s SNF-BF ratio for the last 12 months.

As of March 26, 2022

* Source: AC Nielsen & StatsCan

• Due to a continued higher than usual market demand in 2024, P5 boards announced an additional incentive day in each of the months of September and October;

• In May 2024, butter stocks reached 36, 506 tonnes, up from April by 1,686 tonnes. May butter stock levels are higher compared with May 2023;

• Cheese stock levels for May 2024 were at 97,765 tonnes, which is slightly lower compared with April and the lowest they have been for the same month in at least five years.

ONTARIO UTILIZATION

202405

Percentage of the total milk produced in Ontario that was used to produce dairy products.

Fluid Milk & Cream Yogurt and Ice Cream Cheese

Butter & Powders Skim Milk Disposal

May 2024

P10 UTILIZATION BY CLASS

For May 2024 (kg of butterfat/kg of solids non-fat)

*There is a two-month lag reporting these figures

Class 5c Confectionery products % Butterfat % Solids non-fat

Class 1a1 (includes Classes 1a2, 1a3, 1c and 1d for confidentiality reasons) Fluid milk and beverages

Class 1b Fluid creams Class 2a Yogurt, yogurt beverages, kefir and lassi

Class 2b4 (includes Classes 2b1, 2b2 and 2b3 for confidentiality reasons) Fresh dairy desserts, sour cream, milkshakes and sports nutrition drinks

Class 2b5 Ice cream and frozen yogurt

Class 3a1 Specialty cheese

Class 3a2 Cheese curds and fresh cheeses

Class 3b2 (includes Class 3b1 for confidentiality reasons) Cheddar cheese and aged cheddar

Class 3c1 Feta

Class 3c2 Asiago, Gouda, Havarti, Parmesan and Swiss

Class 3c4 (includes Classes 3c3 and 3c5 for confidentiality reasons) Brick, Colby, farmer’s, jack, Monterey jack, muenster, pizza cheese, pizza mozzarella and mozzarella other than what falls within 3d

Class 3c6 Paneer

Class 3d Mozzarella used strictly on fresh pizzas by establishments registered with the Canadian Dairy Commission

Class 4a Butter and powders

Class 4d (includes Classes 4b1, 4b2, 4c and 4m for confidentiality reasons) Concentrated milk for retail, losses and animal feed

Class 5a Cheese for further processing

Class 5b Non-cheese products for further processing

ONTARIO MONTHLY PRODUCER AVERAGE GROSS BLEND PRICE

A total 3,189 producers sold milk to DFO in May compared with 3,233 a year earlier.

For May 2024

P5 AND WESTERN MILK POOL BLEND PRICES *

The graph below shows the 12-month blend price for the P5 provinces and Western Milk Pool (WMP).

*There is a two-month lag reporting these figures

P5: $91.44 May 2024: $ 96.60

WMP: $90.35

* These figures are based on Ontario’s average composition for May 2024 of 4.2050 kg butterfat, 3.2498 kg protein and 5.9311 kg other solids, rounded to the nearest cent.

U.S. CLASS PRICES

The June 2024 Class III Price, US$19.87 per hundredweight, is equivalent to C$61.86 per hectolitre. This equivalent is based on the exchange rate US$1 = C$ 1.37147 the exchange rate when the USDA announced the Class III Price.

The Class III Price is in $ US per hundredweight at 3.5 per cent butterfat. One hundredweight equals 0.44 hectolitres. Canadian Class 5a and Class 5b prices track U.S. prices set by the U.S. Department of Agriculture.

Source: USDA

Co-ordinated by Dairy Farmers of Ontario’s communications and economics divisions. Questions? Please email questions@milk.org.

STAY UP TO DATE!

Weekly Update email newsletter every Friday for Ontario dairy producers.

Milk Producer magazine is the voice of Ontario dairy producers. Subscribe for free or read online at www.milkproducer.ca.

Dairy Farmer Update provides updates with the monthly milk cheque.

Producer Dashboard , a secure platform behind your password on MMS that contains important news, updates and forms.

www.milk.org

Facebook: /OntarioDairy

Twitter: @OntarioDairy

Instagram: @OntarioDairy

LinkedIn: /company/Dairy-Farmers-of-Ontario

From tag activation to animals entering or leaving your herd, DairyTrace makes reporting events simple. As traceability requirements grow to include our partners in the dairy traceability chain, DairyTrace continues to innovate.

Stay tuned for more DairyTrace resources and tools to make joining the movement

REDUCE,

REUSE, RECYCLE

How water is managed on western U.S. dairies

By Conor McCabe, M.S., and Julia Fouts, University of California

alone, this water resource can be used four times before reaching its final destination. Despite the high use of green and gray water sources, research has focused on how farmers can limit blue water use due to increasing competition among residential, wildlife and agriculture stakeholders.

How farms use water

On a typical dairy farm in the West, the main users of water include cows, infrastructure and crops, with water reused throughout the system.

In places like California where temperatures may reach 43.3 Celsius during the summer, it is imperative to keep cows cool. Holstein cows, the predominant breed in the U.S. and many countries around the world, begin to feel heat stress when temperatures rise above 20 C. Heat stress makes cows not want to eat, feel uncomfortable and produce less milk. Chronic heat stress can also increase disease susceptibility and other welfare concerns if not properly managed.

Marked gains in water use efficiency have been made in dairy production over the past 60 years, with the California dairy industry reducing its use of surface and groundwater intensity by almost 90 per cent.

Access to safe, quality water is more uncertain throughout the West today, meaning effective management of this precious resource is increasingly important. Contrast that with the Eastern U.S. dairy states of Wisconsin, Michigan and New York, where many of their crops do not have to be irrigated and too much water is a greater concern than not having enough.

Nearly 50 per cent of the country’s dairy production is in the Western U.S., but farms face an arid climate with moderate to extreme drought conditions. These harsh drought conditions correspond to an increased risk of fire, damages to agricultural land and strained water sources. Marked gains in water use efficiency have been made in dairy production over the past 60 years, with the California dairy industry reducing its use of surface and groundwater intensity by almost 90 per cent. By reducing, reusing and recycling water, Western U.S. dairy farmers get the most out of every drop.

Not all water is created equal

Before discussing water management on dairy farms, we should establish the various types of water that exist - blue , green and gray. Blue water is sourced from streams, lakes and groundwater. Green water is rainwater held in the soil for plant and crop utilization. Lastly, gray water, although the name is the least appetizing of all, is recycled wastewater. All three are used on Western U.S. dairies in differing quantities. Figure 1 demonstrates the water types needed to produce one metric ton of milk in the U.S. More than 80 per cent of water use is in the form of green water, or water from rainfall. In breaking into gray water

As global temperatures rise, solutions must be implemented to keep cows cool. One solution is to use a soaker system to cool cows with water when temperatures exceed the threshold. The water provides cooling relief directly to the skin via conductive cooling. However, the water doesn’t go to waste since it’s collected and then stored to irrigate crops for future use. A common location for these soaker systems is directly next to the feed bunk to motivate cows to eat while being rewarded with cold water. On hot days, this water will evaporate off the animal and more cool grey water will need to be applied. Further cooling can also occur from using high-speed fans in pens to create evaporative cooling. A soaker system for cows requires about 600 gallons of water a day for the average 100-foot-long barn setup.

Milk is mostly water. Therefore, the more milk a cow produces, the more drinking water she will need to achieve that level of production. The average dairy cow drinks 30 to 50 gallons of water daily. In addition to milk production, much of the water cows consume is released when they urinate. Scientists who have studied cows' daily routines have found they urinate about 10 to 20 times daily to make about eight gallons of urine. This urine is a beneficial fertilizer for farmers’ crops and is collected and used in the irrigation system.

Many dairy cows in the Western U.S. are housed in open dry lot systems, and some in freestall barns. A common method used in freestall barns is a flush lane system, which reduces some of the air pollutants associated with cattle production while removing

and alfalfa, while requiring less water use to produce a successful harvest. Although research on cow performance is needed, these creative crops have the possibility to have the greatest impact on driving down dairy farm water use.

Reducing the amount of water required to grow crops is an important

waste. However, this isn’t “new” water, but recycled water collected from previous flushes stored in on-farm lagoons.

Water is also used to keep milk safe. For milk to achieve Grade “A” status, it must be cooled to 4 C before leaving the farm. To lower milk’s temperature, plate heat exchangers are used where cold water runs through pipes adjacent to the pipe carrying milk. This heat is transferred from the milk to the water, lowering milk’s temperature and raising the water’s temperature. This countercurrent cooling process is the most efficient way to cool milk. Water used to cool milk never touches it since its only contact is through pipes located next to the freshly harvested milk. However, this water is subsequently collected and pooled for irrigation and other forms of cleaning.

Along with cooling milk, water is needed for general cleaning and maintaining the milking parlour. Although these factors contribute to a farm’s total blue water use, they are a minor contribution compared with the other categories that require this water source (Figure 2).

Driving down dairy’s water footprint

Investigations are increasing soil carbon, growing less waterdemanding crops and finding novel irrigation techniques. A variety of practices exist to increase soil organic matter, including cover crops, reduced tillage and compost. For every one per cent increase in soil carbon, there is an observed two per cent increase in soil water holding capacity. In many Southwest states facing drought and more variable rainfall patterns, there is almost a five per cent increase in water holding capacity. This strategy can help farms increase their use of green water and lower the size of their blue water footprint. However, it may take years for farms to find the right combination of practices that work to increase soil organic matter given their environment, soil type and available resources.

Of all the aspects of dairy farming, feed production is the largest source of blue water use (Figure 2). The traditional dairy farm diet comprises corn silage and alfalfa base, along with byproducts from the food processing industry. However, these crops are water intensive, with corn requiring 22 to 30 inches and alfalfa needing 20 to 46 in. of water annually to achieve high production levels. In water-limited states, such as California, there is ongoing research into opportunities to feed both safflower and sugar beet silage to dairy cows. These crops have a similar nutritional value compared with corn

Housing and Water for Milking

Cow Drinking Water

Lagoon Aeration

Surface or Diffused Aeration Systems

Crops

Figure 1.

Figure 2.

Provides

Side

Bump

MAX PACK SILAGE COMPACTION ROLLERS

step in the right direction, but accurate delivery of water can provide a more immediate impact. Irrigation is used in areas with limited and/or variable rainfall to control the timing and amount of water available to plants. Many irrigation technologies have been used since the mid-20th century, and improvements have been made in water use efficiency throughout the years. Traditional crop irrigation occurs through flood irrigation, whereby water is delivered between rows of plants across the entire surface level. With flood irrigation, the entire field receives the same amount of water. This is great for parts of the field where plants grow but not useful where the ground is bare between rows of crops. Therefore, flood irrigation can waste water, which is subsequently lost to evaporation.

One alternative to flooding an entire field is drip irrigation, which delivers water directly to plant roots. Drip irrigation operates through hoses distributed between rows and have openings at the plant roots where the water can be used by the plants and not wasted via evaporation. Additionally, wastewater collected from parts of the dairy mentioned earlier can be added to subsurface drip irrigation, providing additional nutrients to plant roots. However, adding this organic fertilizer to the irrigation system is easier said than done since it requires additional infrastructure, planning and management to get the nutrients to where they’re most needed.

Another irrigation technology is center pivot irrigation, which is composed of a pivot point (where water enters the system) and a long, suspended pipe attached to wheels. The pivot point is a fixed point that will rotate the pipe around to spray water on crops, creating the crop circle pattern you may see when flying in a plane over the Western U.S. Some of these central pivots are so large, the diameter of a crop circle can span up to a mile (1.7 kilometres). A large advantage of center pivot irrigation systems is they can be operated remotely, allowing farmers to precisely and efficiently control the amount of water applied to the fields. Through delivering water to where it is needed most, the dairy industry can make its greatest impact in reducing its water footprint.

bothtimesinstead of grooving because it works and lasts. We have experience, grooving does NOT work! Thank you AGRI-TRAC.

Vriens Friendly Farms

Farmers are predominantly paid on the amount of protein and fat in milk. Yet, as of 2019, only 11 per cent of the U.S. milk supply went toward producing fluid milk. Over the past couple of decades, there has been a concept to concentrate milk fat and protein before the milk leaves the farm. Water can be removed from milk via reverse osmosis to increase fat and protein content. This extra water could then be used as an irrigation option for farms to increase gray water utilization. It would also cut down on transportation costs because the amount of milk volume being shipped per cow would be decreased. Although this idea hasn’t been implemented on farms, as water becomes a more valuable resource, there may be greater interest in adopting this practice in drought-stressed areas.

AGRI-TRAC gives thecows the Traction they need without being too aggressive on their feet

Western U.S. dairy can and will continue to reduce and recycle water

For the foreseeable future, the Western states will continue to be a major contributor to the U.S. dairy industry. The need to conserve water will continue to rise with greater competition between agriculture, wildlife and residential areas, as well as impacts from climate change. Although dairy farmers have altered their water use and recycling over the past few decades, there is continued need for improvement to get the most out of this precious and limited resource.

WHY PRO ACTION?

HIGHLIGHTING THE VALUE AND IMPACT OF THE QUALITY ASSURANCE PROGRAM FOR CANADIAN DAIRY FARMERS

The expectations of the Canadian dairy industry are changing at every level of the supply chain, from farmers and individual farms, to processors, retailers, and the public. Major brands are striving to appeal to consumer values while also addressing issues and reputational risks for their businesses. The “triple bottom line” of people, profit, and the planet has become a core driver for food business and companies are looking for assurance to support their efforts. The way we produce milk and manage cows and farms is also changing rapidly. Coupling this with increased competition for shelf space, it is clear that change is our new reality, and it is happening across the supply chain.