MILK PRODUCER MAGAZINE CELEBRATING 100 YEARS 19 25-2025

FEBRUARY 2025 | THE VOICE OF ONTARIO DAIRY PRODUCERS

MILK PRODUCER MAGAZINE CELEBRATING 100 YEARS 19 25-2025

FEBRUARY 2025 | THE VOICE OF ONTARIO DAIRY PRODUCERS

PUBLISHED BY

DAIRY FARMERS OF ONTARIO

6780 Campobello Road Mississauga, ON L5N 2L8

MANAGER, COMMUNICATIONS

Sharon Laidlaw sharon.laidlaw@milk.org

ADVERTISING

Pat Logan pat.logan@milk.org 519-788-1559

GRAPHIC DESIGN

Katrina Teimo

CONTRIBUTORS

Constantin Urtilescu, Veal Farmers of Ontario, Catherine Cross, Simon Jetté-Nantel, Janet Harrop, Robert Matson

Canada Post Publications Mail Sales Product Agreement No.40063866.

Return postage guaranteed. Circulation: 8,000. ISSN 0030-3038. Printed in Canada.

SUBSCRIPTIONS

For subscription changes or to unsubscribe, contact: MILK PRODUCER

6780 Campobello Road Mississauga, ON L5N 2L8

Phone: (905) 821-8970

Fax: (905) 821-3160

Email: milkproducer@milk.org

Opinions expressed herein are those of the author and/ or editor and do not necessarily reflect the opinion or policies of Dairy Farmers of Ontario. Publication of advertisements does not constitute endorsement or approval by Milk Producer or Dairy Farmers of Ontario of products or services advertised.

to the

about magazine content.

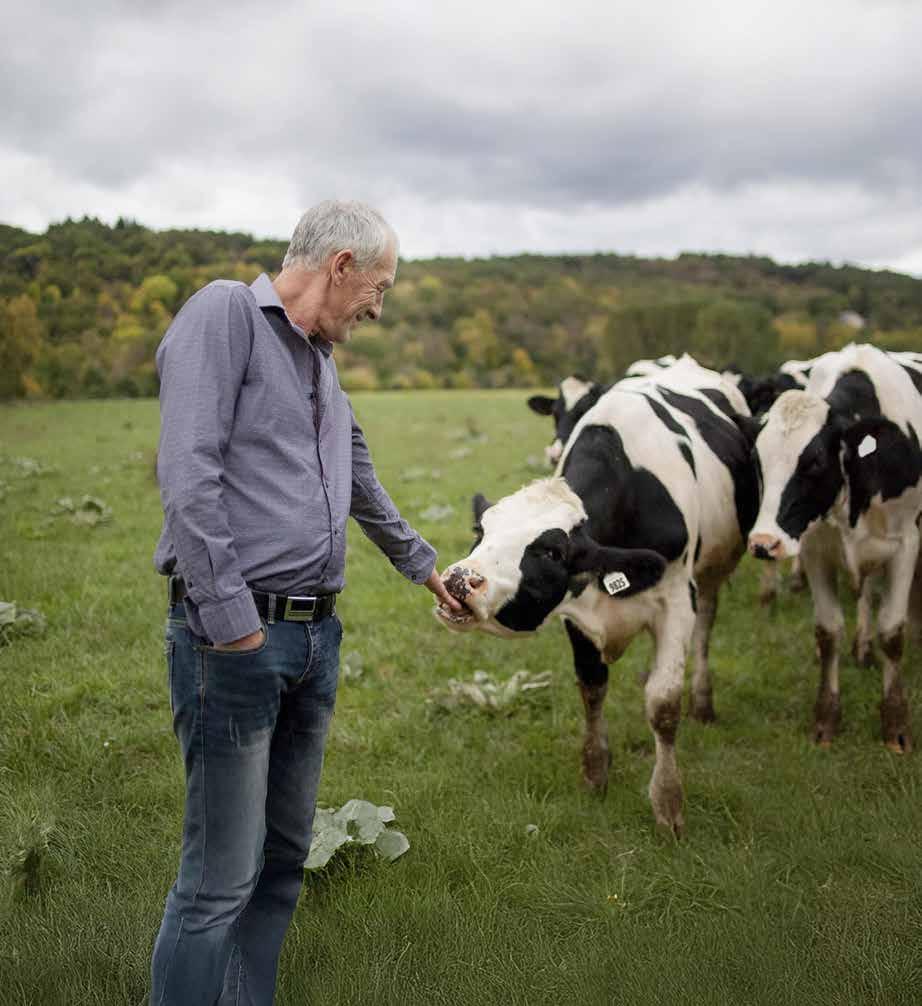

Neil Modler, winner of the 2025 Lifetime Achievement Award, praises his family and the people he’s encountered throughout his farming career as integral to his success.

www.milkproducer.ca www.milk.org

Facebook: /OntarioDairy

X: @OntarioDairy

Instagram: @OntarioDairy

LinkedIn: dairy-farmers-of-ontario

By Mark Hamel, Chair, Dairy Farmers of Ontario, and Board Member, Region 11, Bruce and Grey.

For sixty years, Dairy Farmers of Ontario (DFO) has served dairy farmers and the people of Ontario by providing leadership and excellence in the production and marketing of Canadian milk; and maintaining rigorous quality and food safety standards that have earned the confidence of government and trust of consumers.

Then and today, the impact of our actions, our activities and our investments reach beyond our farms and the dairy industry. At DFO, we recognize we have an important role in the continued viability and success of Canada’s agriculture and food sectors.

Our leadership contributions and support - to agriculture, to food and beverage manufacturing, to the up and downstream agribusinesses that provide goods and services, to the communities where we live, invest and raise our families - reflect our shared values of respect, trust, integrity, teamwork, fairness and accountability.

Our collective impact is critical to ensuring a continued, reliable domestic supply of food that fuels Canadians, our communities and the economy. This is Ontario dairy. This is our story

to share. In 2025, we have reason to celebrate – six decades of delivering high-quality milk, 30 years of award-winning dairy education programs and 100 years of Milk Producer as the voice of dairy farmers. We also have reason to ensure our nation’s decision makers understand and respect the economic and societal contributions we bring to Ontario and Canada.

Together, with our national partners and provincially with the government of Ontario, we have been working on programs and policies in support of our dairy system. I truly believe collaboration across the entire dairy industry is our best path forward. As we work on industry policies and investment programs, seeking common ground on solutions, we should always remember our starting point is what unites usa shared passion for milk and the value it brings to Ontario and Canada.

Through troubled or uncertain times, our relationships and partnerships we have built and nurtured in the past, will be critical to supporting and defending our sector. Our 2025 Lifetime Achievement Award recipient, Neil Modler, embodies the selfless commitment

to volunteering by organizing and connecting people for the betterment of all in Canadian dairy.

I am proud to be a dairy farmer. I am proud to be a Canadian dairy farmer.

We have built and retained consumer confidence in our collective ability to produce and market quality, safe, nourishing milk that is enjoyed by Canadians every day. We need to continue to work together to maintain our ability to deliver milk as part of a reliable and stable domestic food supply despite the many hurdles and challenges that are emerging in 2025.

I am excited to share and celebrate the many accomplishments and people that have helped make them possible over the last 60 years. I am motivated by the promise and opportunities that are before us, opportunities that are only limited by imagination, in a great country blessed with resources.

Together, we can shape our future to ensure another 60 years of dynamic and profitable growth.

Together, we are Ontario dairy.

At a Special Board meeting held on Jan. 16, 2025, following Dairy Farmers of Ontario’s (DFO) 2025 annual general meeting, the board elected its 2025 board executive.

Arlene Minott was reappointed as corporate secretary to the board. Rey Moisan was re-appointed as treasurer to the board.

By Cheryl Smith, Chief Executive Officer, Dairy Farmers of Ontario.

Resilient. Dedicated. Hardworking. That is Ontario dairy.

For six decades, Dairy Farmers of Ontario (DFO) with dairy producers, and the support of customers, consumers and government, has been successful in growing a dynamic and sustainable sector that contributes $8.5 billion to Ontario’s gross domestic product while supporting more than 89,000 jobs.

As the largest agriculture sector in Ontario, we work every day to keep this economic engine operating efficiently while maintaining rigorous standards for high-quality milk and food safety.

Through the efforts of a dedicated and hardworking team, DFO coordinates the collection of more than three billion litres of milk annually, with a farmgate value of more than three billion dollars, supporting producers on more than 3,000 farms across Ontario, and serving our industry partners and customers. Everything we do is for the betterment of dairy farmers.

By working together, our collective efforts to ensure high-quality milk, wellmanaged farms and healthy herds, all contributes to maintaining strong public confidence in every drop of Canadian milk. Consumers love milk and they trust dairy farmers. DFO’s innovative marketing efforts have led to consumers seeing our milk logo a staggering 17 billion times in 2024 in Ontario alone.

This is our story. In 2025, it will be important for all of us to take every opportunity to share our Ontario dairy story. As we celebrate 60 years of excellence in the production and marketing of high-quality milk, as we work together to strengthen and safeguard our proven model of supply management, and as we remind governments of the value dairy brings to Ontario and Canada.

The DFO team recognizes the importance of our role as stewards of Ontario’s dairy system. The Government of Ontario oversees DFO as the regulator and

sole delegated authority for the production, quality and marketing of raw milk, enabling farmers to receive a fair return while delivering quality, safe, nourishing milk to Canadians. Our collective efforts are focused on maintaining the trust and confidence of government and consumers in the quality milk that is produced on Ontario dairy farms by dedicated, hardworking, resilient dairy farm families.

As we acknowledge 60 years of hard work, dedication and success, DFO is focused on advancing high-impact initiatives to deliver continued growth for the next generation of dairy farm families. We are working on continued progress against our strategic plan and targets of generating value through processing increases and production growth, while maintaining our high level of operational efficiencies and regulatory compliance. With provincial and national colleagues, DFO is working to secure processing investment in our sector, drive consumption of dairy, advance sustainable net-zero and explore circular economy solutions for dairy.

Everyday, across Ontario, dairy farmers are caring for their herds, land and communities. And, everyday, DFO is working to support dairy farmers through the effective delivery of milk quality and food safety standards, transportation, transaction management, policy development, marketing innovation and consumer investment.

Together, we are delivering high-quality milk for Canadians.

Together, we are Ontario dairy.

• Reinforced pump head

• Gate valves all around

• Twin short agitation nozzle with position indicator

• Stainless steel nozzle ball joint

• Thicker sprocket and motor mount

• Inline cooling pump (no more belt)

• New oil cooling reservoir bolted on the housing

• Remote control

Trailer model features:

• Can reach up to 4’ in pit depth difference

• PTO stays connected on the trailer

• Transport mode locking mechanism on trailer

BRITISH COLUMBIA

Mountain View Electric Ltd.

Enderby — 250 838-6455

Pacific Dairy Centre Ltd.

Chilliwack — 604 852-9020

ALBERTA

Dairy Lane Systems

Leduc: 780 986-5600

Blackfalds: 587 797-4521

Lethbridge: 587 787-4145

Lethbridge Dairy Mart Ltd.

Lethbridge — 888 329-6202

Red Deer — 403 406-7344

SASKATCHEWAN

Dairy Lane Systems

Warman — 306 242-5850

Emerald Park — 306 721-6844

Swift Current — 306 203-3066

MANITOBA / NW ONTARIO

Penner Farm Services Ltd.

Blumenort — 204 326-3781

Thunder Bay ON – 800 461-9333

Tytech

Grande Pointe — 204 770-4898

Claire Snoddon Farm Machinery

Sunderland — 705 357-3579

Conestogo Agri Systems Inc.

Drayton — 519 638-3022 1 800 461-3022

County Automation

Ameliasburg — 613 962-7474

Dairy Lane Systems

Komoka — 519 666-1404

Keith Siemon Farm Systems Ltd.

Walton — 519 345-2734

Lamers Silos Ltd.

Ingersoll — 519 485-4578

Lawrence’s Dairy Supply Inc.

Moose Creek — 613 538-2559

McCann Farm Automation Ltd.

Seeley’s Bay — 613 382-7411

Brockville — 613 926-2220

McLaren Works

Cobden — 613 646-2062

Melbourne Farm Automation

Melbourne — 519 289-5256

Watford — 519-876-2420

Silver-Tech Systems Inc.

Aylmer — 519 773-2740

Dunnville — 905 981-2350

ATLANTIC PROVINCES

Atlantic Dairy Tech.

Charlottetown, PE — 902 368-1719

Mactaquac Farm Equip. Ltd.

Mactaquac, NB — 506 363-2340

Sheehy Enterprises Ltd.

Shubenacadie, NS — 902 758-2002

Sussex Farm Supplies

Sussex, NB — 506 433-1699

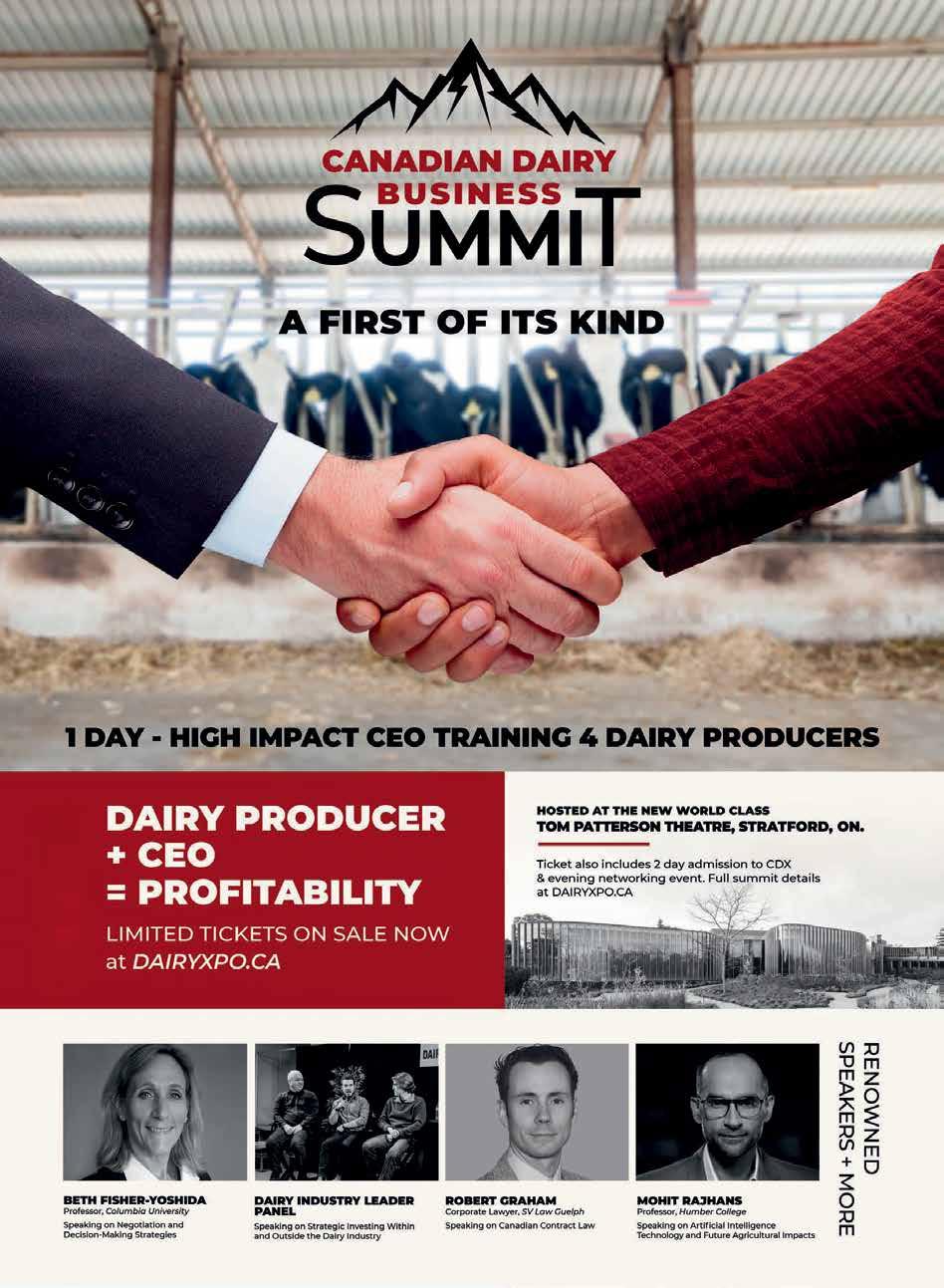

Dairy Farmers of Ontario (DFO) kicked off its 60th anniversary by celebrating its shared past, present and future at the annual general meeting (AGM) held at the Fairmont Royal York hotel in Toronto, Ont., Jan. 14 to 16, 2025. This milestone event not only celebrated the organization’s remarkable achievements but also commemorated significant accomplishments that highlight the collective efforts of the DFO community, including 30 years of impactful dairy education programming, and Milk Producer’s 100th anniversary as the voice of Ontario’s dairy farmers.

In this special edition, Milk Producer brings you highlights from the 2025 AGM, including photos of the displays and special features honouring the significant milestones of DFO, dairy farmers and the communities DFO proudly serves and nourishes with Ontario milk.

DFO chair and CEO talk about importance of collaboration in dairy industry and its future success

“FOR THE LAST SIX DECADES, DFO has served dairy farmers and the people of Ontario providing leadership and excellence in the production and marketing of Canadian milk, with a steadfast focus on milk quality, food safety and production standards,” said Mark Hamel, DFO chair, as he addressed the more than 600 attendees at Dairy Farmers of Ontario’s annual general meeting (AGM).

Hamel began his address by reflecting on the sector’s legacy and future, emphasizing the importance of collaboration among producers, processors and government to achieve shared goals for Canadian dairy.

“Our collective impact is critical to ensuring a continued, reliable domestic supply of food that fuels Canadians, our communities and the economy,” he said. “Together, with our national partners, and provincially with the government of Ontario, we have been working on programs and policies in support of our dairy system.”

Hamel pointed out the significance of a strong supply management system and the impact of DFO's actions on the agriculture and food sectors. He stressed the need for collaboration across the dairy industry to achieve sustainable solutions and a viable future for tomorrow’s farmers.

“(We need to) craft the winning conditions for Canadian dairy to succeed as a growing, dynamic and sustainable sector for farmers, our communities and the economy,” he said. “This includes investment programs to add processing capacity, addressing structural surplus, and positioning (us) for growth and new opportunities.”

It is this collaborative effort that will continue to propel the industry forward, said Cheryl Smith, DFO’s chief executive officer, in her address. Like Hamel, Smith praised the resilience, dedication and hard work of the Ontario dairy sector, and reflected on the journey of Ontario dairy over the past decades and the organization’s unwavering commitment to leadership and excellence in

milk production and marketing activities. She highlighted the economic impact of the sector, which contributes $8.5 billion dollars to Ontario’s gross domestic product and supports more than 89,000 jobs.

“Through the efforts of a dedicated and hardworking team, we co-ordinate the collection of over three billion litres of milk annually with a farmgate value of more than $3 billion dollars,” Smith said. “This supports producers on more than 3,000 farms across Ontario and serves our industry partners and customers.”

DFO, through its accountability to the Ontario Farm Products Marketing Commission and the Ontario Ministry of Agriculture, Food and Agribusiness, once again delivered on its responsibilities as the sole delegated authority and regulator of milk in Ontario, Smith said, including management of the raw milk quality program. “Our accountability to the Commission was upheld as we continued to deliver on our new administrative agreement,” she said, adding quality regulatory compliance, coupled with policy support and enforcement are critically important work for DFO.

Some notable achievements this year include close to 2,000 farm inspections and enhancing laboratory testing to daily frequency. “And we did all that efficiently. Our continued focus on cost containment allowed us to offset more inflationary increases than expected and end the year well ahead on all budgets,” she emphasized.

Smith further highlighted DFO's strategic goals, such as increasing processing capacity and driving dairy consumption.

“The stability and predictability of Canada’s dairy supply management system has proven its foundational value to our sector, province and country. Heading into 2025, we are working to safeguard and strengthen this critical resource for Canadian agriculture and healthy communities,” she said.

Both Hamel and Smith underscored the importance of leadership and shared their vision and commitment to positioning the sector to successfully navigate market, political and economic pressures ahead.

“My family and community keep me focused, inspired and determined to strengthen our dairy supply management system and, by doing so, continue nourishing Canadians with Ontario milk. Never taking for granted the high level of trust our sector has earned from Canadian consumers and the support from all levels of government. They are our legacy and future,” Hamel said.

“It is a privilege to work in Canadian dairy; where every day, every glass of milk is a testament to the farms, employees, industry partners and communities we proudly nourish. That is something to celebrate,” Smith added.

the Canadian Dairy Commission (CDC) plays a pivotal role in maintaining stability in the sector by setting support prices for butter and influencing farm milk component prices, said Jennifer Hayes, CDC chair.

“What we’re most recognized for is the support price, even though the work to set support prices is a very small portion of the dedicated effort of our team, it is by far the highest profile activity we undertake at the dairy commission,” she said.

Support prices are in direct correlation to the CDC’s mandate, which is to enable a fair return for efficient producers, Hayes said. The CDC carries out its mandate by using key tools, including the cost of production study, national pricing formula and exceptional circumstances. Additionally, the CDC manages seasonal supply and demand and establishes quotas, works closely with processors and marketing boards to measure demand, provide forecasts, monitor stock levels and publishes monthly market bulletins.

“One of our major roles at CDC is to offer support to the regulatory system,” Hayes said. “The CDC’s focus is nationwide and dairy sector wide. Our team strives for efficiency and impartiality to provide data and analysis stakeholders need to make fact-based decisions.”

The CDC administers various programs to support the dairy industry, Hayes said, adding these programs are varied and are done on behalf of the Canadian Milk Supply Management Committee (CMSMC). Essentially, the CDC exists to ensure the supply management system functions efficiently using the latest tools and policies. Some of these tools include resources to promote growth and stability, such as the dairy direct payment program, revenue pooling among producers, seasonality programs, special milk class permits, market development and innovation, and the dairy innovation investment fund.

The CDC also manages production through its domestic seasonality programs to ensure a reliable supply of dairy products by buying and storing butter and cheese at pre-set support prices, added Benoit Basillais, CDC’s chief executive officer. The special milk class permit program facilitates access to Canadian manufactured dairy ingredients for eligible processors, helping them remain competitive. One way the CDC monitors production levels is by managing the delicate balance between butterfat and solids non-fat (SNF), which generate no or marginal producer revenues.

“SNF is the milk produced on farm for which we do not have demand. It’s not disposed, it usually goes to animal feed,” Basillais said.

The good news, he said, is the butterfat test in raw milk improved from 4.23 per cent to 4.30 per cent, which decreased the structural surplus by an estimated 120 million litres. What does this mean? Only 0.9 per cent of SNF components did not generate revenues, which is a 58 per cent reduction compared with the previous year. “Our goal is always zero per cent. It’s very important for the CDC that all SNF be valued-added and generate income,” Basillais said, adding the CDC expects additional drying capacity to come online over the next five to 10 years in all regions of the country.

Improvements in butterfat tests and reduction in nonrevenue-generating SNF components are positive steps toward managing this surplus more effectively, he said.

In 2024, the CDC focused on evaluating pricing consultations, supporting innovation and investment through the dairy innovation investment fund, and enhancing collaboration with processors. Other activities included completing negotiations regarding market growth programs and embarking on a strategic planning exercise. Continuing to collaborate with the industry to maximize growth and innovation underpins the CDC’s strategic priorities and decision-making processes, Basillais said.

“Our role at the CDC is to support market growth, to help come up with consensus, not to tell people what to do, but to make sure we help (industry) come up with favourable outcomes … we will continue to ensure there continues to be a natural flow of communication,” he said.

The CDC plans to continue supporting the regulatory system while ensuring an adequate supply of dairy products to consumers and supporting the industry’s growth and innovation. Basillais thinks the Canadian dairy industry is poised for two per cent growth per year.

“There’s definitely risk, but there’s also opportunity. We just have to be ready. We have to be efficient. So, we’re thinking what can we do at P10? What can we do at CMSMC? Can we make faster decisions? Do we understand each other, and can we reach consensus faster? We need a strategy to move forward, and we need to make sure we have all the structure in place to serve the markets in five years and work collaboratively,” he said.

Hayes reiterated DFO and the CDC are dedicated to advancing the dairy industry through strategic initiatives, innovative programs and collaborative efforts. “As we look to the future, our commitment to excellence and sustainability remains unwavering,” she said.

To learn more about CDC’s programs and services, visit https://rb.gy/44jsbn.

Milk quality took center stage during a panel discussion moderated by Alex Hamilton, DFO’s executive director of regulatory compliance and quality assurance. The session featured current and past milk quality award winners, who shared their daily practices, tips and techniques for consistently achieving high standards of milk production. Attendees gained valuable insights into the methods that set these farmers apart in the industry.

The panel featured three respected producer families, each recognized for their commitment to excellence in milk quality. They included:

• Oasis Acres, led by the Westerhof family in Middlesex county, which earned the milk quality award in both 2024 and 2025;

• Slits Dairy Farm #2, operated by the Slits/Schapendonk family, which received the award in 2023 and 2024;

• Ontowa Farms Inc., run by the Martin family, which was honored with the milk quality award in 2023.

Joining the panel were three members of DFO's field services team: Karen Thomson from Zone A, Scott Hartle from Zone I, and Emily McDonald, manager of field services.

These experts brought relevant field perspective to the discussion, sharing insights on how small adjustments can have a significant impact on the daily operations of a dairy farm and contribute to overall milk quality. Their input helped deepen the understanding of the practical steps farmers can take to improve their milk production practices.

You can read more about the milk quality award winners in Milk Producer’s March issue.

Hayes reiterated DFO and the CDC are dedicated to advancing the dairy industry through strategic initiatives, innovative programs and collaborative efforts.

Alex Hamilton, DFO's executive director of regulatory compliance and quality assurance, moderated a panel discussion on milk quality featuring current and past milk quality award winners and DFO production staff and field services representatives.

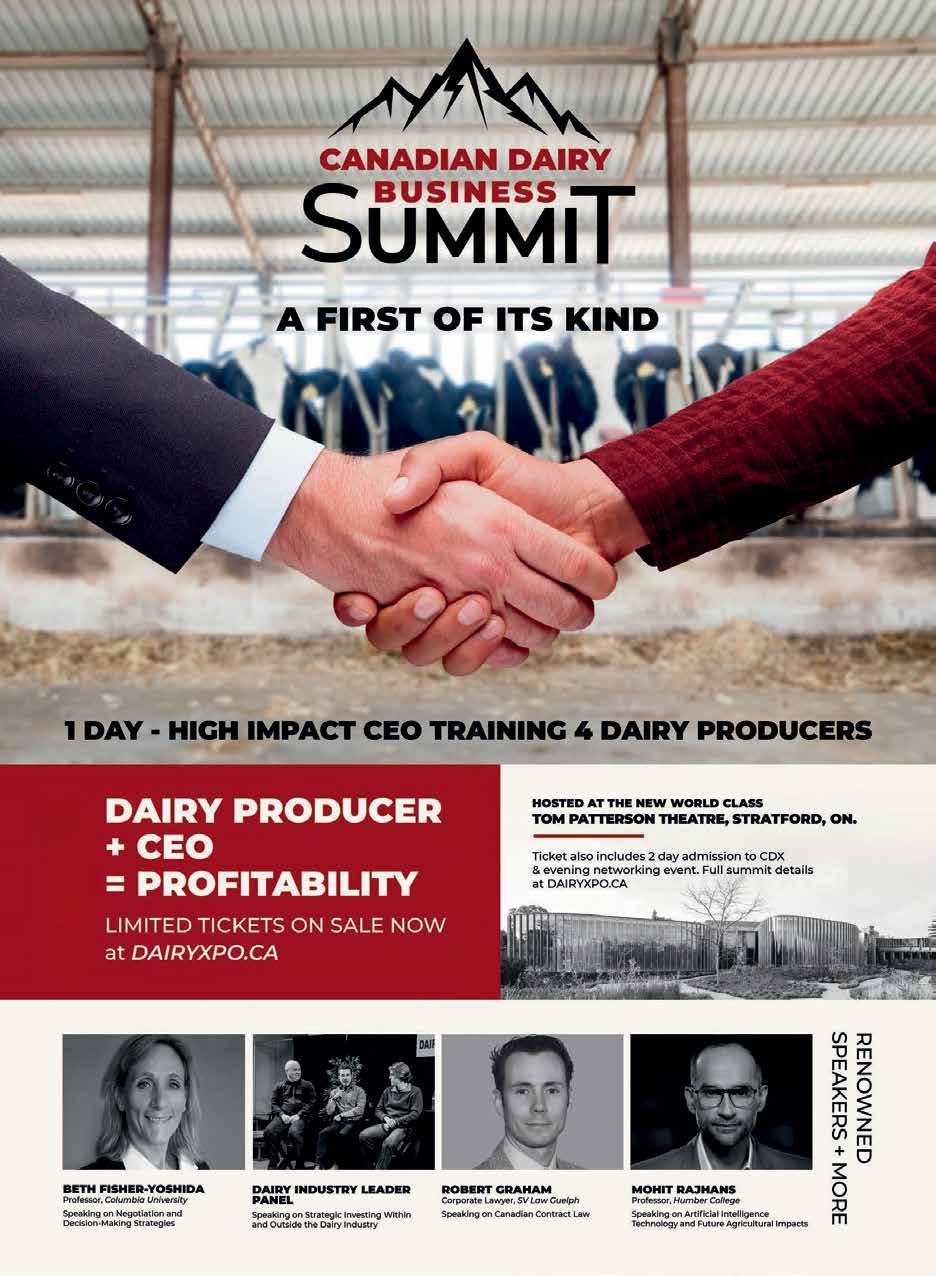

Keith Pelley, MLSE's chief executive officer, shares how making a difference in kids’ lives strengthens communities

DAIRY FARMERS OF ONTARIO (DFO) has been a key partner in nourishing healthy communities through youth sports, said Keith Pelley, chief executive officer of Maple Leaf Sports & Entertainment (MLSE). DFO’s commitment to supporting minor sport associations and initiatives like Woolner Park has allowed countless kids to be part of something special and innovative. “If we can make a difference with the kids, we can make a difference in communities,” Pelley said.

Pelley expressed gratitude for DFO's partnership, and the work Ontario dairy farmers do with youth and sports. “I know DFO does so much more, but we are grateful for the work you do with youth and sports, and for your partnership with our team,” he said. "Your commitment and creativity, chemistry and culture are second to none.”

MLSE, which owns the Maple Leafs, Toronto Raptors, Toronto Football Club, restaurants, and partners with Live Nation, considers itself a community-focused business, Pelley said.

“In the last 15 years, we’ve given $65 million to the community,” he said. “For instance, we launched MLSE launchpad in Regent Park, which touches 30,000 kids a year and is the largest programming in Ontario sports in the province. But very few people know this … our goal is to launch five by 2030.”

Pelley shared that MLSE is also looking to launch a new program called fan access and further increase its impact on the community. It plans to offer four versions including a free one that will provide free tickets to fans through a lottery. The goal is to give away 300 tickets this year at all levels of seating, he said.

“Anyone will have an opportunity to go into the lottery. It will allow more people to touch our programs,” he said. “Our focus is to be changemakers. We want to be the best organization in the world, and we want to be the most efficiently run, but our real impact is in the community. This is the opportunity we have with the World Cup coming to Toronto in 2026, which is like having six Super Bowls.”

Having travelled to 45 countries during his career, Pelley said he’s always felt like an ambassador for Canada. “The good thing about sport is that it can be used to improve a city’s outcome ... sport can unify us, just think what the World Cup can do.”

Pelley emphasized one of MLSE's key objectives is to use the power of sport to positively impact the community. One way it does this is through its partners, such as DFO, which shares the same passion to nourish healthy communities through youth sports. This is reflected in DFO recently teaming up with the Professional Women's Hockey League (PWHL) Ottawa Charge and Toronto Sceptres as their official dairy partner. The partnership underscores DFO’s commitment to not only promote the growth of women’s sports, but to also support diversity and inclusion and create more meaningful opportunities for women and girls in sports, while connecting communities across Ontario.

“We’re grateful for the partnership and the support with the milk logo on the Leafs jersey, but we’re equally grateful for the impact you have on the community. And that’s our goal at MLSE,” Pelley said.

We’re grateful for the partnership and the support with the milk logo on the Leafs jersey, but we’re equally grateful for the impact you have on the community. And that’s our goal at MLSE.

IN A RAPIDLY EVOLVING POLITICAL LANDSCAPE, educating members of Parliament (MPs) about the dairy and agriculture sectors cannot be overstated. This was a key message delivered by Andrea van Vugt, chief operating officer and practice lead of trade at Wellington Advocacy, during her presentation. As Ontario and Canada prepare for potential elections1, the need for MPs and members of Provincial Parliament (MPPs) to understand the intricacies of these vital industries is more pressing than ever, she said.

With Premier Doug Ford expected to call a snap election soon, and the Progressive Conservatives likely to secure a majority government, the focus will be on southern Ontario ridings, she said. The Ontario Liberal Party, led by Bonnie Crombie, faces significant challenges due to her association with the federal Liberals and lack of differentiation from the NDP, van Vugt explained.

On the federal front, Prime Minister Justin Trudeau is expected to resign once a new leader is chosen, with Parliament prorogued until March 24. Potential leadership contenders include former Bank of Canada governor Mark Carney and former Minister of Finance and Deputy Prime Minister Chrystia Freeland. The federal government could face non-confidence motions as early as March 26, she said, potentially leading to an election with opposition leaders determined to topple the Liberal government.

Speculating on what may be a likely outcome, van Vugt said the Conservative Party of Canada has maintained a significant lead in opinion polls for the past 15 months, with projections indicating they could secure as much as 236 seats. A government led by Pierre Poilievre may see a shift toward a more suburban and urban caucus, necessitating a critical need to educate new MPs on the importance of the dairy sector. While the Conservatives have shown no intention of deviating from the consensus on supply management, they may require guidance on the matter, van Vugt added.

“This is a very interesting dynamic in the Conservative party we’ve never seen before,” van Vugt said. “Typically, conservative governments have been very rural in Ontario. This one is not going to be. What does that mean? There will be smaller representation of rural MPs in the Conservative caucus in Canada, and this is a different

dynamic in a Conservative party. This is something every ag sector will have to contend with. You may ask yourselves, ‘How do we lobby and how do we ensure our issues are heard?’”

Along with providing her expert analysis of the current political dynamics in Ontario and Canada, van Vugt talked about the bilateral relationship between Canada and the United States. She said President Donald Trump is likely to target supply management, with trade further impacted by proposed tariffs and the upcoming CanadaUnited States-Mexico Agreement (CUSMA) review. The outcome of these negotiations remains uncertain, but it is crucial for producers to engage with MPs in their ridings during this period, she warned.

“This is a smarter, more effective, more efficient Trump. His government has learned some things. And he’s learned how to arrange his cabinet and his policies and has a surgical approach to the issues he cares about,” van Vugt said, citing President Trump appointing Howard Lutnick, chief executive officer of Cantor Fitzgerald, as commerce secretary to lead the U.S. trade and tariff agenda as an example.

“Supply management, I believe, is going to be a target for Trump (because) he’s going after legacy items that have been irritants between countries for some period of time. You have to be very careful with someone like Trump and not give up too much in the beginning,” van Vugt said.

She further emphasized the need for proactive engagement and strategic planning from Canadian officials to navigate the challenges and opportunities ahead.

“Trump responds not to weakness but to strength,” she added.

1 This presentation occurred prior to Ontario's election call.

When examining the Canadian consumer landscape from 2020 to 2025, it’s clear the dairy sector has shown remarkable resilience and growth, noted Carman Allison, vice-president of new business development at NielsenIQ, a global information service company that specializes in consumer and retail measurement and analysis. Despite the challenges posed by the pandemic, inflation and economic uncertainty, the dairy industry has managed to thrive, Allison said as he shared the latest insights on global marketing dynamics.

This growth has brought numerous benefits to both the dairy category and consumer consumption. Categories, such as yogurt and cottage cheese, have particularly stood out, showing significant increases in both dollar and volume sales. This robust performance has not only boosted the overall revenue of these dairy categories, but the introduction of new and improved dairy products has provided consumers with more choices, catering to their diverse tastes and dietary preferences, Allison pointed out. Additionally, the emphasis on value-based shopping has made dairy products more accessible to a broader range of consumers, ensuring they can enjoy high-quality dairy products without straining their budgets.

“Where are consumers going to spend more? It’s all about the necessities of life. The good news is consumers are willing to spend more on a lot of consumer packaged goods (CPG) and food items, and dairy is right on that list. In fact, 70 per cent of consumers said they’re going to spend more on dairy this year,” he said.

When looking at consumption data over the last year, ending in December 2024, dairy is up four per cent nationally and up five per cent in Ontario, with volume up two per cent in the province. This compares with inflation at around three per cent. “This is a good case scenario for the dairy industry right now and that we’re not seeing these swings you see in other categories that have been hit by inflation,” he said.

Dairy products are also experiencing strong dollar growth. In fact, cottage cheese is “having a moment” Allison said, with sales up 22 per cent and flavoured creamers up six per cent.

Canadian consumers’ need for value continues to fuel overall CPG growth. Shopping discount retailers and buying on promotion have

driven growth in the dairy category. For instance, 51.2 per cent of CPG growth in the dairy aisle is attributed to shopping at discount retailers. Additionally, 45.9 per cent of CPG growth comes from consumers buying on promotion, with a five per cent growth rate. Regions like Ontario and Alberta have reported the highest increases in total dairy sales, with Ontario seeing a five per cent increase and Alberta a six per cent increase.

Though consumers continue to be price conscious, Allison said it’s essential for industry stakeholders to continue adapting to shifting consumer needs and preferences. “We have a consumer who is being more intentional with their purchasing behaviour … value remains the number one motive right now for consumers and that’s not going away.”

Anticipating consumer spending by category will be defined by their willingness and ability to spend, he said. Consumers will continue to focus on essentials and household priorities and understanding their needs amid rising food costs will be key to keeping dairy top of their minds.

The concept of “value” has broadened and evolved and is expected regardless of brand and retail format, Allison said. “Today, consumers of all financial circumstances are seeking value in multiple ways, with every purchase ... The good news is that Canadians continue to spend and expand their dairy consumption.”

Dairy products are also experiencing strong dollar growth. In fact, cottage cheese is “having a moment” Allison said, with sales up 22 per cent and flavoured creamers up six per cent.

Ontario Minister of Agriculture, Food and Agribusiness Rob Flack and Ontario Farm Products Marketing Commission Chair Amy Cronin praise industry’s efforts at AGM

MINISTER OF AGRICULTURE, FOOD AND AGRIBUSINESS ROB FLACK

recognized the industry’s dedication and contribution to Ontario’s agri-food sector during the recognition dinner. He thanked DFO, both board and staff, for the excellent work done on behalf of producers across Ontario’s dairy industry. He spoke about jobs created and supported by the industry, farmgate sale values and the sector’s contribution to Ontario’s gross domestic product (GDP). He also touched on the dairy processing modernization initiative, which aims to boost processor efficiency and production to help grow the dairy sector.

Flack highlighted two-way agri-food trade between the United States and Ontario, which generated more than $45 billion in 2023. With President Donald Trump targeting supply-managed commodities, Flack said both he and Premier Ford are ready to fight and defend the supply management system and Ontario agri-food’s best interests.

“Families across Ontario have access to safe, high-quality dairy products day in and day out, and that should never, and I repeat never, be taken for granted,” he said, reiterating dairy is the most rewarding industry in the world.

He commended the industry’s economic contributions to the province, saying the sector’s GDP contributions from 2020 to 2023 increased eight per cent. During the same three years, farmgate sales increased by 21 per cent.

“We’re an economic driver, make no mistake about it,” Flack said. “All that means more jobs, more prosperity and more investment for the people of Ontario.”

Since 1965, when Bill Stewart was Ontario’s Minister of Agriculture and introduced the Milk Act, successive governments have continued to support supply management, Flack said. And though it has served farm families and Ontarians well over the past 60 years, it does not mean the industry can be complacent, he said. “Looking ahead, we have to remain competitive, reduce barriers to entry and provide fair value to all consumers.”

Producers are to be commended for their dedication to the dairy industry and commitment to providing high-quality milk every day, said Amy Cronin, chair of the Ontario Farm Products Marketing Commission. Cronin praised producers for constantly finding new ways to improve the industry, such as exploring new technologies to implement on-farm. Cronin also congratulated DFO on its 60th anniversary.

“Thank you for the work you continue to do for the people of Ontario in providing on-time, right amount of high-quality milk people get to enjoy in many products,” she said.

She referenced recent proposals currently being consulted on for the Milk Act as a way to continue refining policies to benefit the sector. “For the past 60 years, that act has served us very well, but we’re all about continuing to think about where this industry needs to go,” she said.

Cronin reviewed activities the Commission is currently working on, including the P10 agreement and market development program, which she said allows farmers to recognize the importance of the processing sector and the need for more processing capacity to deal with solids non-fat. “It enables processors to expand, a key point for the dairy industry to continue to prosper,” she said. With regard to the market development program, Cronin thanked DFO for looking to the future and working on what the industry needs to continue thriving and succeeding.

Dr. Shari van de Pol delves into how AI can be used to enhance dairy farm management

(AI) is transforming various industries, and dairy farming is no exception, said Dr. Shari van de Pol, chief executive officer of CATTLEytics. The integration of AI in dairy farming is poised to revolutionize the way farmers manage their herds, optimize production and enhance overall efficiency, she said. van de Pol offered attendees a glimpse into key aspects of AI in dairy farming, highlighting the expertise of the CATTLEytics team and the promising future of AI in farming.

“To stay current as an industry, we have to know what’s out there. We can’t just hear about it in the press and try to form an opinion. Until you’ve tried it, you can’t really talk about any new technology, whether it’s robotic milkers or when cars were new. It might first seem scary and wrong, but then people try them out and realize there’s a place for them,” van de Pol said.

During her presentation, van de Pol delved into what AI is and isn’t, types of AI and how they work and machine learning. One of the few agritech dairy companies in Canada, van de Pol founded CATTLEytics in 2014. With a background in computer engineering and veterinary medicine, she assembled a team that merged decades of cattle industry expertise with software and hardware engineering. Today, CATTLEytics offers dairy farmers and cattle owners tools to farm using the latest advancements. The team designs and maintains software and data systems that enable proactive animal health management, and their hardware solutions, such as cattle thermometers and automated dosing devices, further elevate efficiency.

“We’re here, we’re local and we’re looking to solve cool problems on the farm,” van de Pol said.

She told delegates to think of AI as a helpmate. “Whatever you’re best at, you’re probably better than AI. You should use AI to help you with other aspects of what you do,” she said. “AI is good at the stuff you hate the most, such as technology. (It) can take some of that off your plate.”

The CATTLEytics team is at the forefront of AI innovation in dairy farming, van de Pol said. Comprising experts in hardware, software, data analytics and AI, the team is dedicated to advancing cattle management and dairy farming practices. AI applications in dairy farming are diverse and impactful. Key areas where AI is making a difference include:

• Shift scheduling: AI algorithms optimize shift schedules, ensuring labour resources are utilized efficiently;

• Task management: AI-driven task management systems streamline daily operations, thereby reducing manual workload and increasing productivity;

• Custom analytics: AI-powered analytics provide valuable insights into herd health, milk production and other critical metrics;

• Breeding decisions: AI assists in making informed breeding decisions, enhancing genetic improvement and overall herd quality.

Machine learning is a cornerstone of AI in dairy farming, van de Pol said. Techniques, such as regression models, exploratory data analysis, neural networks, random forests and time series forecasting, can help predict trends and help farmers make data-driven decisions. These tools enable farmers to anticipate challenges and optimize their operations for better outcomes, she said.

“That’s what computers can do ... take all of these and make the best suggestions for where you are, when you’re doing it and what you need to accomplish, as well as other considerations into account … that’s pretty much machine learning,” van de Pol said.

The future of AI in dairy farming is bright, with numerous advancements on the horizon. Precision management, automation, robotic milking, connected device integration and sustainability are key areas where AI will continue to drive progress. The ultimate goal is to improve efficiency, reduce resource use and enhance overall productivity, ensuring a sustainable and profitable future for dairy farmers, van de Pol said, adding CATTLEytics’s dairy management software will soon be able to empower farmers to manage their operations seamlessly while promoting sustainability metrics.

DAVID WIENS, DAIRY FARMERS OF CANADA (DFC) PRESIDENT, presented on DFC’s achievements from the past year, including federal advocacy efforts, dairy promotion to consumers, advancing and maintaining policies to reinforce dairy, defending dairy’s interest with respect to trade, and collaborating with members on various industry issues.

DFC also continued to defend the supply management system, played an instrumental role in securing improved access to veterinary products to combat microbial resistance, and championed the implementation of a solid, rural strategy.

Maintaining trust in dairy is another area DFC prioritized this past year. One way it does this is through the blue cow logo and consumer campaigns that explain what is behind the logo.

DFC also invests in research that informs farming practices and its nutrition education programs. It recently launched the Canadian Dairy Hub to share research knowledge with producers. For more information on the hub, visit https://lactanet.ca/en/learning/canadiandairy-hub/.

Significant progress was made in support of dynamic, profitable growth for dairy benefitting all Ontario producers collectively.

DFO finished 2024 strong, and the blend price and dollar volume growth remained very robust. In addition, P5 quota allocation was almost two per cent and quota issued was positive at one per cent with an additional one per cent in December.

At the organizational level, results for 2025 were favourable to budget, said Rey Moisan, DFO’s chief finance officer. DFO has a healthy reserve fund that is above target, and which will help the organization weather any inflationary pressures. Moisan provided delegates an update on the 2025 budget, which was largely the same as what was presented during DFO’s fall regional meetings in October and approved at the November board meeting. Of note is that the admin licence fee will remain at the current rate of $0.675.

More information on the organization’s financials can be found in DFO’s 2024 Annual Report at this link: https://new.milk.org/ all-documents/all_categories-2/dairy-farmers-of-ontario-202324-annual-report/.

Attend a local workshop to secure your farm’s future

Don’t settle for generic advice. Our workshops provide your family with direct consultations with a team of advisors, including an accountant, lawyer, and financial advisor. Scan the QR code to find a workshop near you. Scan Here

Neil Modler, winner of the 2025 Lifetime Achievement Award, praises the people he’s encountered throughout his farming career and their contributions to the industry

By Sharon Laidlaw, Communications Manager, Dairy Farmers of Ontario

NEIL MODLER, DFO’S 2025 LIFETIME ACHIEVEMENT

WINNER, humbly accepts his award and says his career as a dairy farmer, active community member and family man would not have been possible without his wife of 60 years, Marie, his two sons, Scott and Joey, and the many helpful and dedicated people he has encountered along the way.

“I accept this award but it’s because a lot of people have helped me all through life. I can go back to the early 1960s when people started asking me to get involved or join an organization. It’s been a real privilege and honour to take the concerns of fellow farmers to meetings and bring resolutions and updates back to them, and have them trust me to do that,” he says.

Neil found out he’d been bestowed the award from DFO board member John Wynands during his local dairy producer committee (DPC) meeting in December. “It was quite unexpected,” he says. “I thought it was a mistake. I’d never thought I’d done that much to be thought of by other people like that. It’s a tremendous feeling.”

Modler Farms has been in the family for eight generations, dating back to 1837. It’s been 188 years and counting as Neil’s sons continue to farm alongside their dad. Neil took over the farm from his parents in the 1970s, along with his brother, Jack. However, when his brother left the operation in 1990 to pursue another career, Neil and Marie decided to buy out his brother and start farming on their own.

Modler.

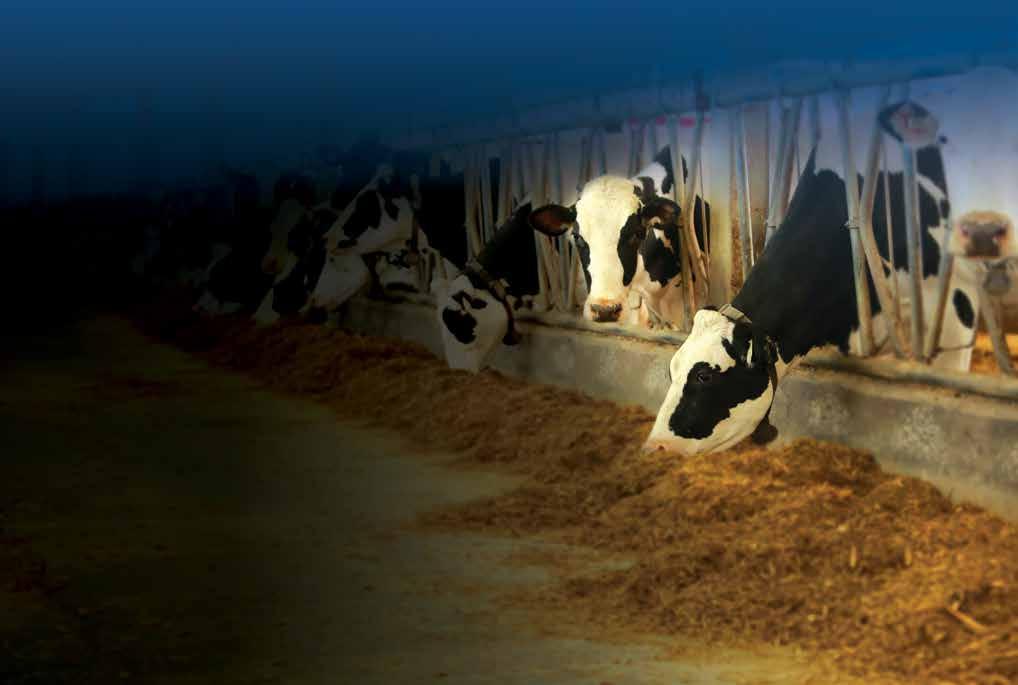

Scott, the eldest son, joined the farm in the mid-1990s, while Joey, who is 12 years younger, joined in the early 2000s. Today, the Modlers milk 75 cows and two years ago installed two GEA milking robots, which brought significant changes in how they manage the farm, Neil says.

“Before, we couldn’t get help on the farm and my age was a factor. My sons were working long hours, and the robots have improved their family life tremendously. Now, they don’t have to be as punctual with milking, (whereas) before it took 2.5 hours, and they would have to shut everything down and milk. Our time can be managed better now, which gives my sons more time with their families,” Neil says.

Though it’s been two years since installation, Neil says they’re still figuring out all the robots’ capabilities, “it’s a learning experience for us. I don’t have a computer and don’t know how to turn one on,” he quipped, adding he considers himself to be old fashioned and likes to talk to people in person or on the phone. “I stay in the barn and look after heifers. I can’t do much manual labour, but I do the total mixed rations and do a lot of the running around that’s required and some administrative tasks. My sons look after the robots, that’s their domain.”

The Modlers also run a cash crop and have a small beef herd of about 20 to 25 cattle, which has allowed them to supply a local senior citizen home with beef for the last 10 to 12 years.

Neil, who is 81 years old this year, says he enjoys watching his sons farm and continue the family legacy. “My sons have been running the farm for the last 10 years and I’m proud of the fact we bred two cows that became all-Canadian cows.”

Joey adds he and his brother have learned valuable lessons observing their dad on the farm, especially when it comes to caring for their cows. “Dad has great attention to detail. He could always remember the cows’ records and pedigrees, and their milking stats, which always impressed me,” he says.

It’s been a real privilege and honour to take the concerns of fellow farmers to meetings and bring resolutions and updates back to them, and have them trust me to do that.

– Neil Modler

Neil Modler’s contributions on the Leeds DPC has included building lasting relationships with local government officials, connecting them with policy advisers and industry leaders to get the facts on dairy and secure their support for supply management. The Honourable Steve Clark, member of Provincial Parliament for Leeds-Grenville-Thousand Islands and Rideau Lakes, has worked with Neil for many years, and presented him an honorary scroll from the Government of Ontario in recognition of all the contributions he has made to Ontario dairy.

Neil Modler

Family means a lot to Neil; he says he wouldn’t be where he is today without their support. He also credits his daughters Tracy and Alison, who sadly passed away in June 2023, with providing him different perspectives when needed. He also appreciates the contributions of various staff he’s encountered while serving on various committees and working with organizations, including Dairy Farmers of Ontario. He notes it’s the dedication of these staff that has been integral to the success of the industry, which has left a lasting impression on him. He’s grateful for everyone’s commitment to supporting dairy farmers and to industry leaders for continuing to champion the sector.

“He’s been in countless organizations his whole life and, in my opinion, when he’s in the organizations, it’s not what they can do for him, it’s (about) what he can do for the organizations,” Scott says. “He always tries to promote the industry, to make the industry better and make other farmers’ lives better as a whole.”

“I think it makes a lot of sense for my grandpa to get the award,” says grandson Cole Modler. “I think he’s always been incredibly passionate about farming and the dairy industry, and it makes sense to me he’d be honoured for such a thing.”

Family means a lot to Neil; he says he wouldn’t be where he is today without their support.

Neil is positive about the industry’s future and thankful for Canada’s supply management system. “I see our industry continuing to thrive, despite all the challenges in the world. I think being in food production is good and people always need food,” he says. “People seem to be coming back to a balanced diet with dairy, just look at the increased sales of yogurt and ice cream. We have good demand for our products, even in tough times.”

Neil knows he’s lucky to still be involved in something he likes to do. “I’ve always enjoyed being a dairy farmer. The better you look after your animals, the better they treat you.”

Having served on the Leeds DPC since 1986, Neil has a vast amount of knowledge to pass on to younger farmers. He remarks that he was only 21 years old when supply management took effect in 1965 and knows what the industry was like before orderly marketing took effect. “For dairy producers today, 1965 is just a date to them. They don’t know how lucky they are that we have this system we work under. I think the rest of the world would gladly have it back. We have a fairly strong voice within the supply-managed commodities, and I hope we keep it that way.

Neil is positive about the industry’s future and thankful for Canada’s supply management system. “I see our industry continuing to thrive, despite all the challenges in the world. I think being in food production is good and people always need food,” he says. “People seem to be coming back to a balanced diet with dairy, just look at the increased sales of yogurt and ice cream. We have good demand for our products, even in tough times.”

Neil knows he’s lucky to still be involved in something he likes to do. “I’ve always enjoyed being a dairy farmer. The better you look after your animals, the better they treat you.”

Having served on the Leeds DPC since 1986, Neil has a vast amount of knowledge to pass on to younger farmers. He remarks that he was only 21 years old when supply management took effect in 1965 and knows what the industry was like before orderly marketing took effect. “For dairy producers today, 1965 is just a date to them. They don’t know how lucky they are that we have this system we work under. I think the rest of the world would gladly have it back. We have a fairly strong voice within the supply-managed commodities, and I hope we keep it that way. We have to keep a strong voice,” he says. “I tell my sons how lucky we are. On Jan. 1 every year, as dairy farmers, we can sit down and predict 85 to 90 per cent of our income for the year. How many businesses can do that?

Neil says he doesn’t think much about the legacy he’ll leave behind, rather he aims to enjoy the privilege of being able to farm every day. “I don’t think much about my legacy … I just carry on with the farm. Each generation on the farm, from my grandparents, dad, myself and now my sons, has just kept things going and tried to make it a better farm with each generation. I tried to do things so that my sons would have it easier if they wanted to farm.”

“Grandpa is still working. He’s the hardest working person you’ve ever met, and he loves what he’s doing. He cares so much for the farm. Honestly, that’s why he deserves it,” says McKenna Modler, one of six grandchildren. Neil’s daughter-in-law, Lisa Modler, echoed her sentiments. “The way he involves his kids, his grandkids, the community; he’s always trying to educate, he’s always trying to help. He sacrifices a lot to be here and loves it.”

Neil says of his dairy farming career “I’m really amazed people think I contributed that much and to the committees I’ve been on. I can’t thank

He always tries to promote the industry, to make the industry better and make other farmers’ lives better as a whole.

– Scott Modler

them enough for even considering me to get the award. I have a lot of people to thank, (as well as) my family and friends, to be in this position. Thank you very much for giving me the award. I have to say it’s getting close to being the highlight of my career.”

Some quotes are from a video taping of the family on the farm as part of the award recognition.

Though robotic milking has gained popularity, there are many factors to consider to ensure it’s the right fit for your farm

By Catherine Cross, agr, Strategic Advisor, and Simon Jetté-Nantel, agr, PhD, Economist

ROBOTIC MILKING IS BECOMING INCREASINGLY POPULAR, especially given current labour challenges. However, it's not a one-size-fits-all solution. Some farms find it suits their needs, while others do not. What factors contribute to a successful operation?

The start-up period is crucial for the success of a transition to robotic milking. During the first

120 days after startup, farms typically see an average drop of 0.71 kg milk/cow/day or 0.34 kg fat/cow/day. Over the next year, these farms generally work back up to their pre-robotic production levels. By the second year, there is usually a six per cent increase (1.7 kg milk/ cow/day or +0.060 kg fat/cow/day), and by the third year, an eight per cent increase from the initial level. Quebec Holstein herds, for example, achieved an average annual increase of 1.2 per

cent in milk production per cow (or 1.8 per cent in fat production per cow) over the same period, regardless of the type of operation. The net gain attributed to the robot is closer to 5.6 per cent in the second year and 4.4 per cent in the third year.

Productivity gains vary depending on production level before startup. Less productive herds achieve gains of almost three kilograms of milk/cow/day or around 0.1 kg fat/cow/day, while more productive herds before startup see more modest gains. Factors such as housing, feed management, overall herd management and the ability to adapt to the new management style (between cows and people) explain some of the variability observed between farms.

A seasonal effect was also observed: 70 per cent of the farms started in autumn/winter, with the remainder in spring/summer. Productivity in both groups was initially similar, with an average of 31 kg of milk/cow/day. Herds transferred

production decrease during the first few months after startup, likely due to heat stress and division of working time between the herd and seasonal tasks. After the first year, both subgroups returned to similar production levels.

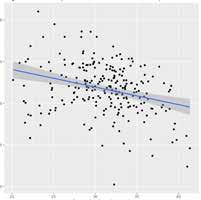

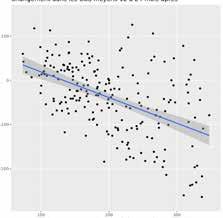

Changes in milking method and cow environment also affect milk quality. Herds with somatic cell count (SCC) averages around 100,000 cells per millilitre before startup show no improvement afterward and may even show a slight deterioration. However, herds with a starting average of 200,000 cells/mL can expect an average reduction of 45,000 cells/mL, and those with an average closer to 300,000 cells/mL can expect an improvement of 100,000 cells/mL. These trends are influenced by several factors, including bedding type, stall management, vaccination protocols and tolerance thresholds for intervention.

Robotic milking adds additional concentrate

Change in average SCC (000) two years after

Change in SCC - 12 to 24 months after startup.

costs per kilogram of fat and per cow. However, although the total cost of feed per cow increases, the cost per kilogram of butterfat produced is slightly lower than other operation types. When all variable costs are considered (feed, veterinary, reproduction, bedding, etc.), robotic herds compare favourably over pipeline herds due to productivity gains per cow.

In 2023, the average advantage was $0.60 per kg fat/cow/day associated with robotic milking.

Investment cost is a key factor in determining robotic systems’ profitability. The investment cost per robot and per cow varies from one company to another due to several factors, such as site planning and management, new versus used equipment and space per cow. Once in place, the success of an operation is linked to its efficient use of assets.

For robotic milking, efficiency is measured by quantity of milk or fat produced per robot. Lactanet periodically publishes Quebec references on the subject2, and the latest 2024 figures show, on average, milking robots produced 71.8 kg of fat per day, while optimal use 3 is calculated to generate 91.1 kg of fat per day on average. Assuming an operating margin of $10 per kg of fat, an additional production of 20 kg of fat per day for the same robot represents approximately $73,000 more in operational profit annually (i.e., revenue minus variable expenses).

There are several challenges to optimizing a robot’s efficiency, one of which is quota availability. Robotic milking can result in production increases and substantial operational savings. To optimize robots and ensure their profitability, the focus should be on their efficiency, cow selection (kilogram of milk per minute in the robot), management improvement, and building design and maintenance, among others.

PACKED WITH A HIGHER CONCENTRATION OF IGG, IMMUNOLIFE | 200 IS THE ULTIMATE CHOICE FOR YOUR CALVES' HEALTH AND VITALITY

Start-ups since 2018 show no significant improvement in criteria, such as production, culling or milk quality, compared with those prior. There is still room to improve and adapt methods, such as protocols for preparing cows for robotic milking, subject selection, cow transfer methods and feed management. Successful robotic start-ups make it possible to stand out from the crowd and have a healthy, profitable herd.

Footnotes:

1. Agritel Data, 2023

2. Lactanet, 2024

3. This accounts for 10% free time and 8% wash time

By Janet Harrop, Producer and DFO Environmental Consultant, and Robert Matson, DFO Production Research Manager

THIS YEAR MARKS DAIRY FARMERS OF ONTARIO'S (DFO) 60TH ANNIVERSARY, a milestone reflecting decades of dedication to supporting dairy producers and advancing excellence in dairy production. Just as DFO’s legacy is built on a solid foundation, the future of agriculture relies on another essential foundation: healthy soil.

Dairy producers have been responsible stewards of the land for generations, constantly seeking ways to reinvest in their soil. The recent Ontario topsoil sampling project (OTSP) report published by the Ontario Ministry of Agriculture, Food and Agribusiness (OMAFA) highlights how farmers can measure their soil health and how producers can improve key measures, such as soil organic matter (SOM).

SOM represents the total organic material in soil, expressed as a percentage by weight. It includes decomposed plant and animal materials, living organisms and stabilized organic compounds. Soils with higher levels of SOM have better structure, greater nutrient supply and more robust biological activity. These characteristics render soils with elevated SOM content more resilient to extreme weather conditions like droughts and heavy rains—a

crucial advantage for producers who require reliable production.

The Ontario topsoil sampling project underscores the importance of testing soil for SOM and other health indicators. These include active carbon, respiration, potentially mineralizable nitrogen and aggregate stability. Here are some key findings from the project:

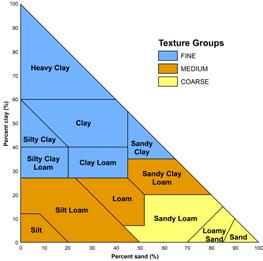

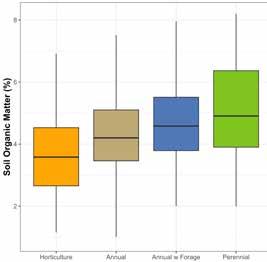

1. Soil texture affects SOM levels: When examining the type of soil (Figure 1), coarse-textured soils (sandy) exhibit the lowest SOM levels, while fine-textured soils (clay-based) have the highest. Loamy soils fall between clay and sandy soils. This variability arises from the capacity of fine-textured soils to store and retain organic matter more effectively (Figure 2). Understanding your soil’s texture is the first step to interpreting SOM levels and determining appropriate management strategies.

2. Cropping systems and SOM: The topsoil project also demonstrated SOM varied based on cropping system. Annual cropping systems with perennials in rotation and long-term pastures and forages had greater SOM than annual cropping systems without forages in rotation.

FAST FEEDING - High output – smooth-running discharge auger and fast apron speed cuts feeding time. Unload a 30 bushel cart full of corn silage in 35 seconds.

EASY FEEDING - Hydrostatic drive – one hand fingertip control lets you select any traveling speed in either forward or reverse.

BATTERY POWER - Efficient electric power provides smooth operation with no toxic fumes. Series 5 carts are equipped with extended life batteries, field-tested for durability and long life.

This highlights the importance of perennial crops in increasing SOM and soil health (Figure 3). For dairy producers, these findings align with the benefits of pastures and forage crops for soil.

3. Impact of landscape position: Soil health indicators vary depending on the field's position in the landscape. Upper slopes tend to have thinner topsoil and lower SOM, resulting in lower soil health scores. The report suggests targeted management, such as erosion control, is recommended for vulnerable areas.

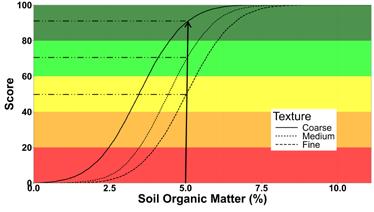

The topsoil project developed a scoring system to help interpret soil health test data. For each soil health indicator, including SOM, the lab result can be converted to a score on a scale of 0 to 100. To account for the influence of soil texture on SOM, the interpretation varies based on soil texture. You can determine your SOM “score” either using the scoring graphs or soil health assessment and plan (SHAP) calculator. For example, a coarse-textured soil with five per cent SOM scores 90 points, whereas the same SOM content in a fine-textured soil scores only 50 points (see Figure 4 for scoring graphs).

The SHAP guidebook is a valuable resource for interpreting soil health indicators like SOM, pH and respiration. By providing scoring curves and Ontario-specific benchmarks, it allows producers to assess their soil’s condition relative to regional standards.

If you test your soil for the parameters outlined above, you will gain a lot of information. Understanding your score across different fields can influence your decision to implement best management practices (BMPs) in those fields. One of the most effective ways to improve SOM is through organic amendments. The topsoil sampling project found 51 per cent of participants used amendments like manure, compost and biosolids, with manure being the most common. These amendments enhance SOM and aggregate stability, leading to healthier and more productive soils. This is good news for producers who typically use these organic amendments in their soil.

more convenient compared with manually referencing the graphs.

If one field is lower than others, BMPs that help increase SOM might be prioritized for that field (e.g., organic amendments, reduced/no till, cover crops, incorporation of perennials). Crop rotation, cover crops and reduced tillage are identified as key BMPs for improving soil health indicators.

Understanding and managing SOM is a crucial step toward improving soil health and resilience on your farm. Testing your soil, interpreting the results using tools like the SHAP guidebook, and implementing targeted BMPs can make a significant difference. As we celebrate 60 years of working alongside producers, let’s also commit to continuing to nurture our soils for the next 60 years and beyond. By prioritizing soil health, you’re investing in a sustainable future for your dairy operation and future generations.

Thank you to the Ontario Ministry of Agriculture, Food & Agribusiness (OMAFA) Environmental Management Branch for their assistance with this article.

References

https://www.ontario.ca/page/ontario-topsoil-sampling-project-2024, https://omafrasoilteam.shinyapps.io/SHAP_Scoring_Calculator/ https://bmpbooks.com/series/soil-health/

• Oxford Cattle Company is working with genetic companies to select sires for use in our guaranteed calf buy back program.

• We are now pleased to announce that we are interested in buying your holstein bull calves and can include them in your regular pick up. We will take calves that are over 92 lbs and 10 days old. The price will be negotiated on a weekly basis.

• Presently serving southwestern Ontario region and Ottawa region.

• For a Calf Pick Up Request text (519) 788-1399 by 1:00 pm Mondays

‘‘ I really like how fast the attachment is. The GEA DairyRobot R9500 is very cow friendly, the cows are comfortable in the box. It milks a quarter at the time which help us keeping only the good milk in the tank. ’’

Michael Flaman

Chris Adie Holsteins, Vibank, SK

COLOMBIA

Pacific Dairy Centre Ltd. Chilliwack — 604 852-9020

ALBERTA

Dairy Lane Systems Alberta

Leduc: 780 986-5600

Blackfalds: 587 797-4521

Lethbridge: 587 787-4145

Lethbridge Dairy Mart Ltd.

Lethbridge — 888 329-6202

Red Deer — 403 406-7344

Scan the QR code to watch the complete story of Chris Adie Holsteins of Vibank, Saskatchewan.

SASKATCHEWAN

Dairy Lane Systems Saskatchewan Warman — 306 242-5850

Emerald Park — 306 721-6844

Swift Current — 306 203-3066

MANITOBA

Tytech Grand Pointe — 204 770-4898

ONTARIO

Conestogo Agri Systems Inc. Alma — 519 638-3022

Dairy Lane Systems Komoka — 519 666-1404

Lawrence’s Dairy Supply Inc. Moose Creek — 6 13 538-2559

McCann Farm Automation Ltd. Seeley’s Bay — 613 382-7411

McLaren Works Cobden — 613 646-2062

Performance Dairy Centre Inc. Embro — 519 423-9119

Wood’s Dairy Source Keene 705 295-3247

ATLANTIC PROVINCES

Atlantic Dairy Tech, Inc.

AMS Sub-dealer for Sheehy Entreprises Ltd. Charlottetown, PE — 902 368-1719

Sheehy Entreprises Ltd. Shubenacadie, NS — 902 758-2002

Lower Queensbury, NB — 506 478-4878

DAIRY FARMERS OF ONTARIO (DFO) MARKETING HAS LAUNCHED MANY INNOVATIVE CAMPAIGNS AND PARTNERSHIPS that drive the consumption of milk and dairy with Ontarians. These programs reach everybody – from students to Gen Zs, to millennials and milk lovers of all ages – in new and engaging ways. Through these activations, DFO marketing is proud to execute innovative programs that have been “firsts” both for DFO and for Canada. Through integrated campaigns, digital presence, partnerships and in real life (IRL) moments, DFO reminds consumers of the role milk plays in their lives and together celebrates the universal love for milk.

As part of its corporate responsibility initiatives, DFO launched a holiday campaign that reinforces the beloved tradition of putting out milk and cookies for Santa, while sharing Ontario dairy farmers' commitment to supporting children's hospitals across the province. First launched in December 2019, this successful campaign has evolved over the years and continues to share the magic of milk at the holidays.

First launched in September 2019, this campaign aimed to remind consumers of the vital role milk plays in their lives –showcasing the many benefits of milk. This highly impactful creative was adjusted during the pandemic to lean more into the health benefits of milk and today, DFO's nutritional messaging continues to highlight all the goodness in one glass of milk

Launched in 2020, Dairycraft is a highly immersive education experience built in/on the popular Minecraft platform. It lets students explore the world of dairy farming through digital gaming. Dairycraft has remained a popular resource for students with seven million downloads to date.

To tap into the Gen Z audience, MilkUP created the first ever post-to-pay pop up in Canada. This pop up connected with younger audiences through their passion points –showcasing how dairy fits with their lifestyles. Since then, the MilkUP brand has successfully launched 11 post-to-pay events reaching millions of Gen Z consumers.

Joining forces with the Ottawa Senators in 2023 has resulted in many innovative marketing executions; a milkbranded softserve ice-cream and chocolate milk stand, milk-branded penalty box, and our very own milk zone.

In 2022, DFO became the first official jersey sponsor of the Toronto Maple Leafs. The iconic milk patch on the Toronto Maple Leafs’ jerseys garnered unprecedented exposure with more than 25.7 billion impressions over the last two years.

Showcasing the irreplaceability of milk and dairy in great-tasting culinary creations, DFO partnered with local chefs in 2023 for its first-ever cooking competition. Talented local chefs whipped up delicious dishes through several rounds of competition to win the title of “Milk Master.”

In 2024, DFO began a partnership with the Professional Women's Hockey League with the Toronto Sceptres and Ottawa Charge.

In recent months, P5 demand growth is tracking with the Canadian Dairy Commission’s (CDC) optimistic scenario. It is good news and the P5 is hoping this trend continues for the remainder of the 2024-25 dairy year. P5 butterfat production is significantly higher than what was forecasted since the beginning of fall 2024, which is mainly due to high butterfat content level in milk that has reached higher levels than the record level of fall 2023.

“The higher-than-expected butterfat production means P5 production is leading the current and anticipated market, with P5 producer quota being overissued by more than 101 per cent of the market than is anticipated for December 2025,” says Patrice Dubé, Dairy Farmers of Ontario’s chief economics and policy development officer.

The western milk pool (WMP) recently provided producers a very strong production signal by issuing two per cent quota in January 2025, March 2025, and two incentive days from April to November 2025. The WMP decision was made to realign production to fill their allocated pool quota, as well as meet an increase in cheese demand. This decision could impact overall P10 production levels and will need to be taken in consideration for the coming year in terms of impact on butter and cheese stocks, Dubé says.

In December 2024, cheese stocks reached 98,452 tonnes, down from November by 1,480 tonnes. December cheese stock levels are higher than they have been for the same month in at least three years.

December 2024 butter stocks were at 33,327 tonnes, which were higher than November by 1,800 tonnes, and higher than they have been for the same month in at least five years.

For the 52-weeks ending Dec. 30, 2024, sales for fluid milk, fluid cream, yogurt, ice cream, cheese and butter increased by 0.3, 2.1,4.1, 1.5, 2.5 and 4.5 per cent, respectively.

To mark DFO’s 60th anniversary, throughout 2025, we will be looking back through our shared history, how it has shaped Ontario dairy and provide a foundation for tomorrow. This month, we are sharing a brief history of supply management in Ontario, from the origins of the Milk Act in 1965, to the creation of DFO in 1995, along with data from 1966 and 2024 to show how the dairy industry in Ontario has changed over the years.

In 1963, Ontario requested a commission of inquiry led by S. J. Hennessey to make recommendations on dairy industry management in the province. Noting Ontario farmers had been comparatively reluctant to join co-operatives, and that marketing associations found it difficult to collaborate, Hennessey recommended Ontario adopt the British system of statutory (mandatory) milk marketing programs. Not long after, former Premier of Ontario John Robarts implemented his recommendations and passed the Milk Act in 1965.

The act called for the creation of the Ontario Milk Marketing Board (OMMB), which was delegated responsibility and authority for buying all milk produced on Ontario farms and selling it to processors. The organization was led by founding chair George McLaughlin from its inception in 1965 until 1977. McLaughlin unified Ontario’s regional producer associations, established production quotas, quality standards and marketing strategies, and negotiated farmgate prices for milk so producers could earn a fair return for their labour.

The OMMB replaced the Concentrated Milk Producers’ Marketing Board and the Whole Milk Producers’ League and, in 1966, the Ontario Cheese Producers’ Marketing Board merged with the OMMB. Four years later, the Cheese Producers’ Co-operative established an agreement with the OMMB. Then in 1995, revised Ontario legislation merged the Ontario Cream Producers’ Marketing

Board with the OMMB and called the new entity Dairy Farmers of Ontario. Since that time, DFO has been the marketing board for the largest sector of Ontario agriculture.

When examining the history of milk production in Ontario, there have been significant changes, such as the number of farms decreasing to 3,187 farms in 2024 from 40,420 farms in 1966, while overall annual production has remained about the same. Milk production has been steady at 3,182,687,117 litres in 2024 compared with 3,083,676,059 L in 1966. Also, the number of cows dropped to 320,000 in 2024 from 903,000 in 1966, while milk produced per cow has increased to 9,946 L from 3,415 L. Thanks to advances in the dairy industry, production has increased in volume and efficiency with almost three times fewer cows, and the number of cows per farm has grown to 100 cows in 2024 from 22 cows in 1967.

Processing has seen similar results over the years with fewer plants processing higher milk volumes per plant. The table on second page shows the split between industrial and fluid has remained relatively the same from 66.88 per cent and 33.12 per cent in 1966 to 69.3 per cent per cent and 30.7 per cent in 2024.

Producer pricing has also varied over the years due to rebalancing of negotiating power between industry players and production cost increases. In 1966, the producer price was $7.95 per hectolitre, which is equivalent to $73.09 per hL in 2024.

There have been major transformations in Ontario’s dairy industry, but some factors have not changed, such as Ontario dairy farms are still family-run in all regions of the province. As DFO looks forward, its mission remains the same, which is to continue providing leadership and excellence in the production and marketing of Canadian milk for a dynamic, profitable, growing dairy industry.

Canadian butterfat requirements in kilograms and actual butterfat production across the P10.

12-month production (in millions of kilograms)

12-month requirements (in millions of kilograms)

Canadian production has increased by 2.2 per cent over the previous 12 months, and requirements have increased by 2.2 per cent over the previous 12 months.

This graph shows Ontario’s SNF-BF ratio for the last 12 months.

Average increase in retail sales for dairy products sold in Ontario and the dairy product’s share of the total market sales, including at hotels, restaurants and institutions.

As of March 26, 2022

Percentage of the total milk produced in Ontario that was used to produce dairy products.

For December 2024 (kg of butterfat/kg of solids non-fat)

*There is a two-month lag reporting these figures

% Solids non-fat

Butterfat

Class 1a1 (includes Classes 1a2, 1a3, 1c and 1d for confidentiality reasons) Fluid milk and beverages

Class 1b Fluid creams Class 2a Yogurt, yogurt beverages, kefir and lassi

Class 2b4 (includes Classes 2b1, 2b2 and 2b3 for confidentiality reasons) Fresh dairy desserts, sour cream, milkshakes and sports nutrition drinks

Class 2b5 Ice cream and frozen yogurt

Class 3a1 Specialty cheese

Class 3a2 Cheese curds and fresh cheeses

Class 3b2 (includes Class 3b1 for confidentiality reasons) Cheddar cheese and aged cheddar

Class 3c1 Feta

Class 3c2 Asiago, Gouda, Havarti, Parmesan and Swiss

Class 3c4 (includes Classes 3c3 and 3c5 for confidentiality reasons) Brick, Colby, farmer’s, jack, Monterey jack, muenster, pizza cheese, pizza mozzarella and mozzarella other than what falls within 3d

Class 3c6 Paneer

Class 3d Mozzarella used strictly on fresh pizzas by establishments registered with the Canadian Dairy Commission

Class 4a Butter and powders

Class 4d (includes Classes 4b1, 4b2, 4c and 4m for confidentiality reasons) Concentrated milk for retail, losses and animal feed

Class 5a Cheese for further processing

Class 5b Non-cheese products for further processing

Class 5c Confectionery products