• Holistic repairs which address current as well as known points of failure

• Trusted by multiple OEMs, dozens of ISOs, and partnered with the most recognized names in healthcare

• Engineering expertise includes proprietary test fixtures based on each coil’s unique design, 3D printing, plastic molding, and state-of-the-art machining enable full mechanical restoration, full-cable harness fabrication, and array manufacturing

• Exclusive repair processes informed by our legacy in FDA registered manufacturing

P.12 SPOTLIGHT

p.12 Department of the Month:

Northwest Territories Health and Social Services Authority

Biomedical Engineering Department

p.14 Professional of the Month: Benjamin Tinsley

p.16 Next Gen: Aaron Febre

p.18 Association of the Month: The Nevada Healthcare Technology Association (NVHTA)

P.20 INDUSTRY UPDATES

p.20 News & Notes

p.28 Tech Choice Award Finalists

p.32 Welcome to TechNation

p.36 Ribbon Cutting: ERD Medical Equipment Solutions

p.38 AAMI Update

p.40 ECRI Update

P.42 THE BENCH

p.42 Biomed 101

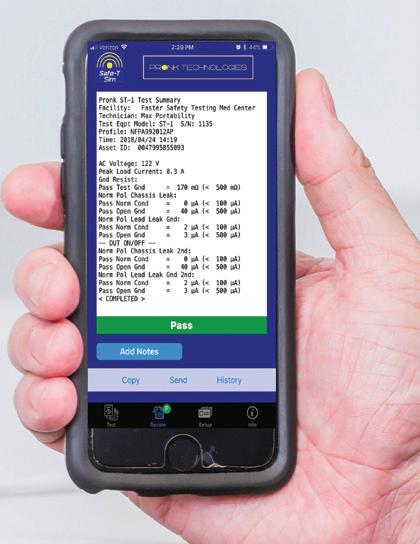

p.45 Tools of the Trade

p.46 Webinar Wednesday

p.48 Shop Talk powered by MedWrench

P.50 FEATURE ARTICLES

p.50 Roundtable: CMMS

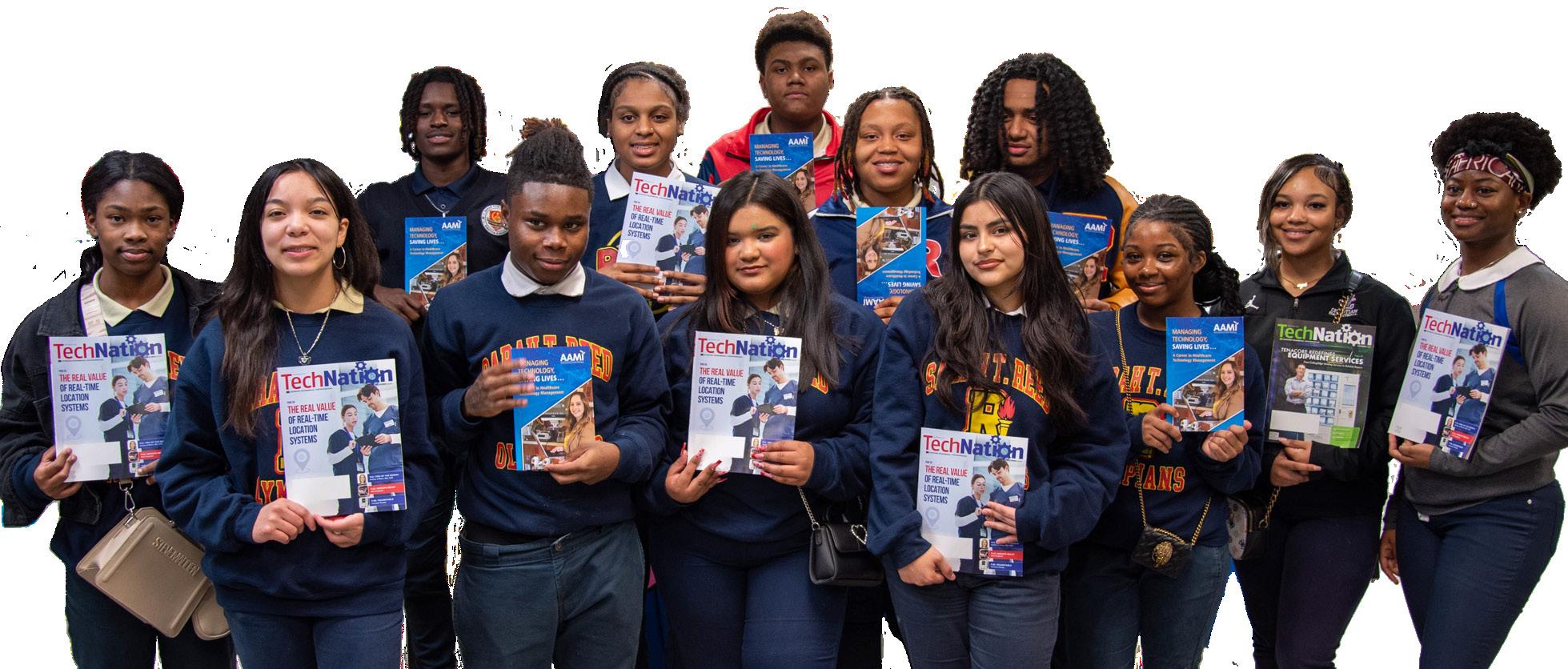

p.58 Cover Story: Influencing the Future of HTM: Platforms That Promote the Profession

P.65 EXPERT ADVICE

p.65 Career Now

p.66 SPONSORED: MultiMedical System

p.68 Right to Repair

p.72 Networking Notes

p.74 Health-ISAC

PUBLISHER John M. Krieg

VICE PRESIDENT Kristin Leavoy

VICE PRESIDENT Jayme McKelvey BUSINESS DEVELOPMENT

EDITORIAL John Wallace

CONTRIBUTORS K. Richard Douglas Joie Marhefka

Steven J. Yelton

Garrett Seeley

Phil Englert

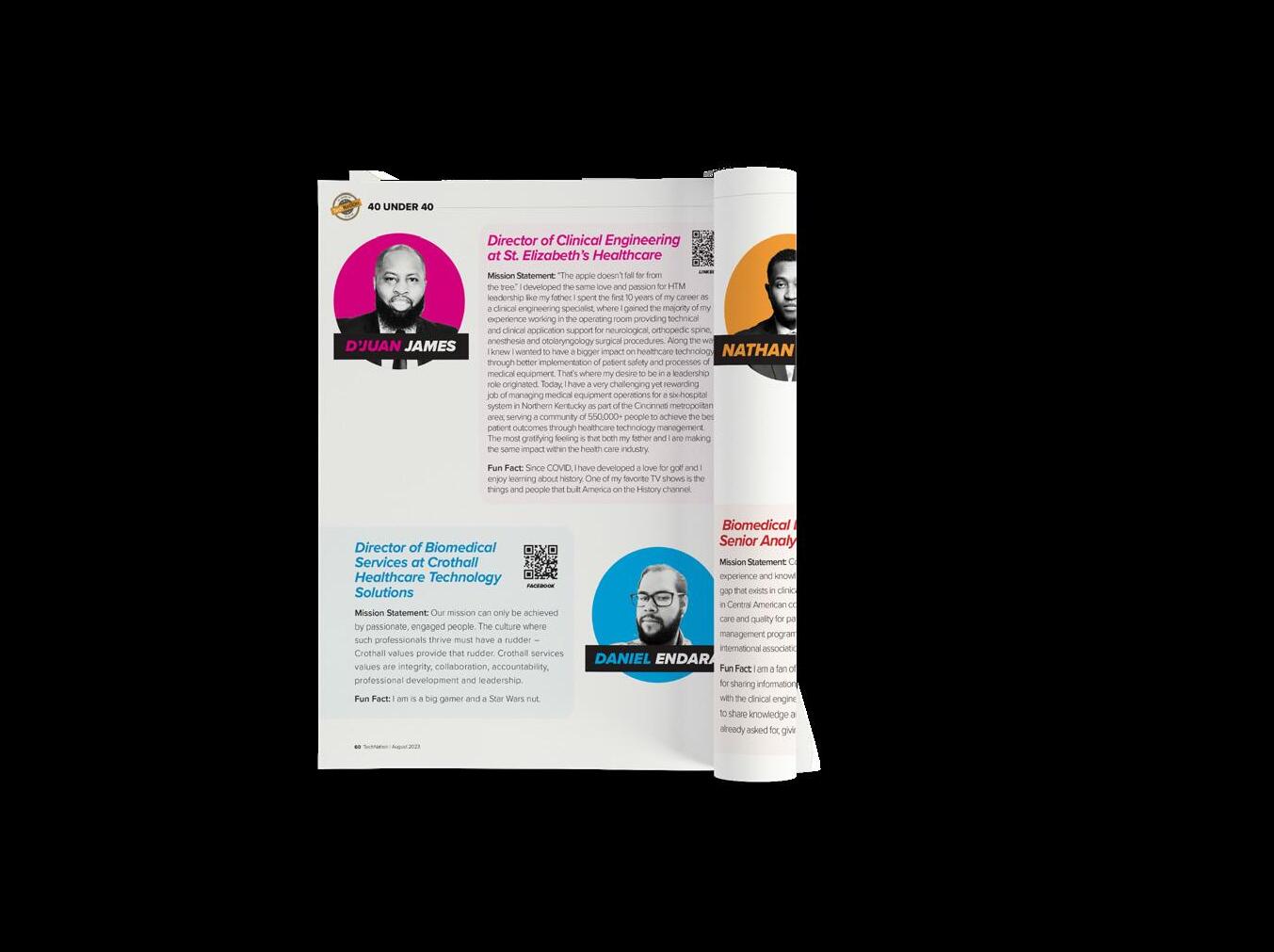

Nathan Proctor

Nadia ElKaissi

ACCOUNT Megan Cabot

EXECUTIVES Emily Hise

ART DEPARTMENT Karlee Gower

Taylor Hayes

Alicia Brown

DIGITAL SERVICES Cindy Galindo

Kennedy Krieg

Haley Harris

EVENTS Kristin Leavoy Sydney Krieg

WEBINARS Linda Hasluem

HTMJOBS.COM Sydney Krieg

ACCOUNTING Diane Costea

CIRCULATION Joanna Manjarrez

Rob Bundick, Director HTM & Biomedical Engineering, ProHealth Care

Carol Davis-Smith, CCE, FACCE, AAMIF, Owner/ President of Carol Davis-Smith & Associates, LLC

Nadia ElKaissi, CHTM, Biomedical Engineer, HTM, VA Central Office (19HTM)

Bryant Hawkins Sr., Site Manager, Children’s Hospital of New Orleans

Earl Morris Jr., BMET, Director of Clinical Engineering, Harrison County Hospital

Leticia Reynolds, Clinical Engineering Operations Manager at UCHealth Parkview Medical Center

Our nationally recognized programs include Biomedical Equipment Technology (BMET), Biomedical Equipment Support Specialist (BESS), and the Dental Repair Technician (DRT) Certificate. Each is designed to equip you with the advanced skills needed to thrive in today’s evolving healthcare and dental technology landscape.

Virtual

(VR) labs offer a flexible and immersive learning experience that adapts to your busy schedule. our VR labs allow you to practice and perfect your skills in a controlled, risk-free environment.

BY K. RICHARD DOUGLAS

Far north of the U.S. northern border, high up in Canada and almost to Alaska, are the Northwest Territories. The capital, and largest community, is Yellowknife. It is one of the best places on earth to view the northern lights in the evening, especially in fall and winter.

As the largest city in the Northwest Territories, Yellowknife is also the epi-center for the area’s medical care. The region’s HTM experts comprise the Northwest Territories Health and Social Services Authority (NTHSSA) Biomedical Engineering Department.

The biomed team is made up of 11 professionals. The Territorial Manager Biomedical Engineer is Kevin Taylor, PEng.

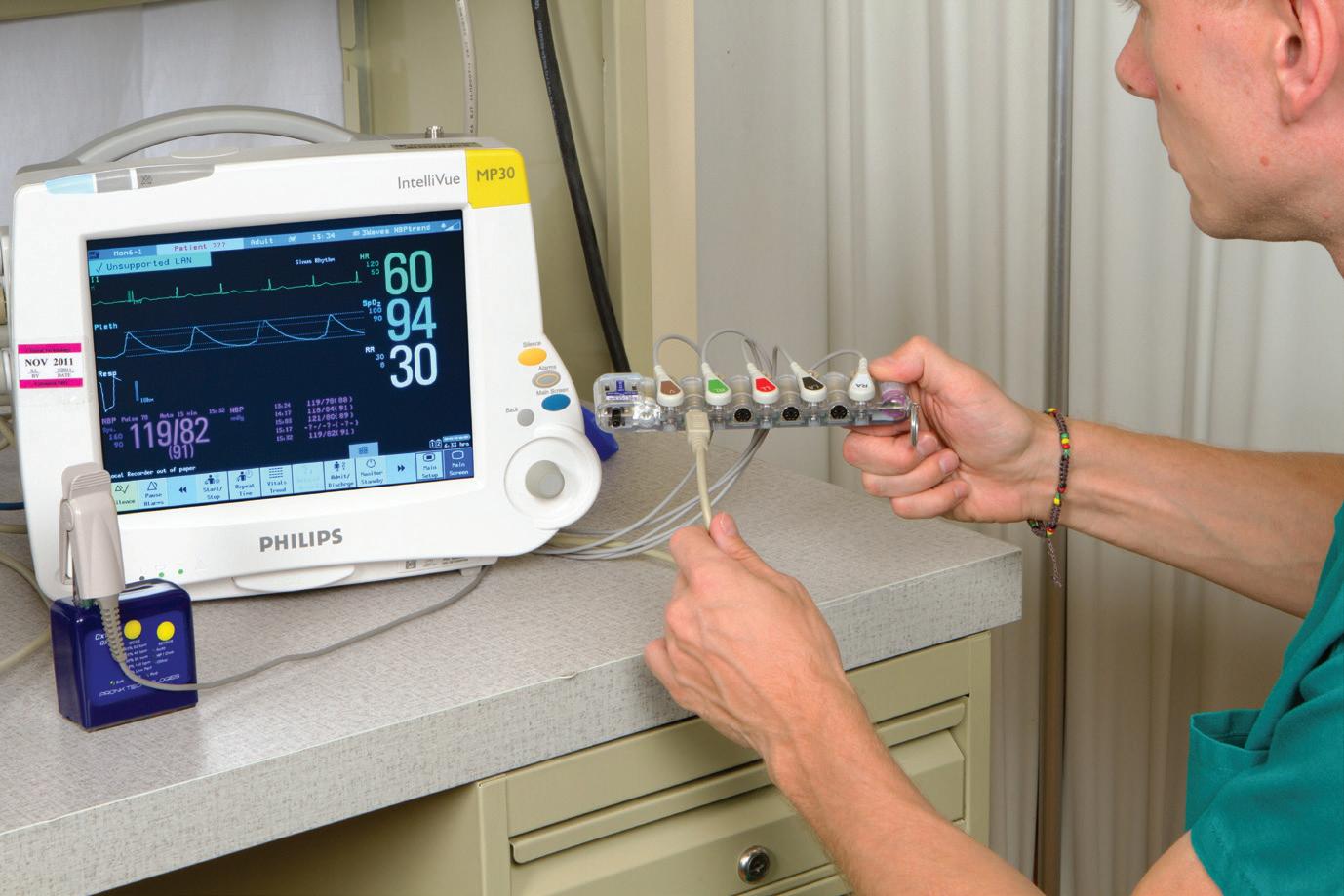

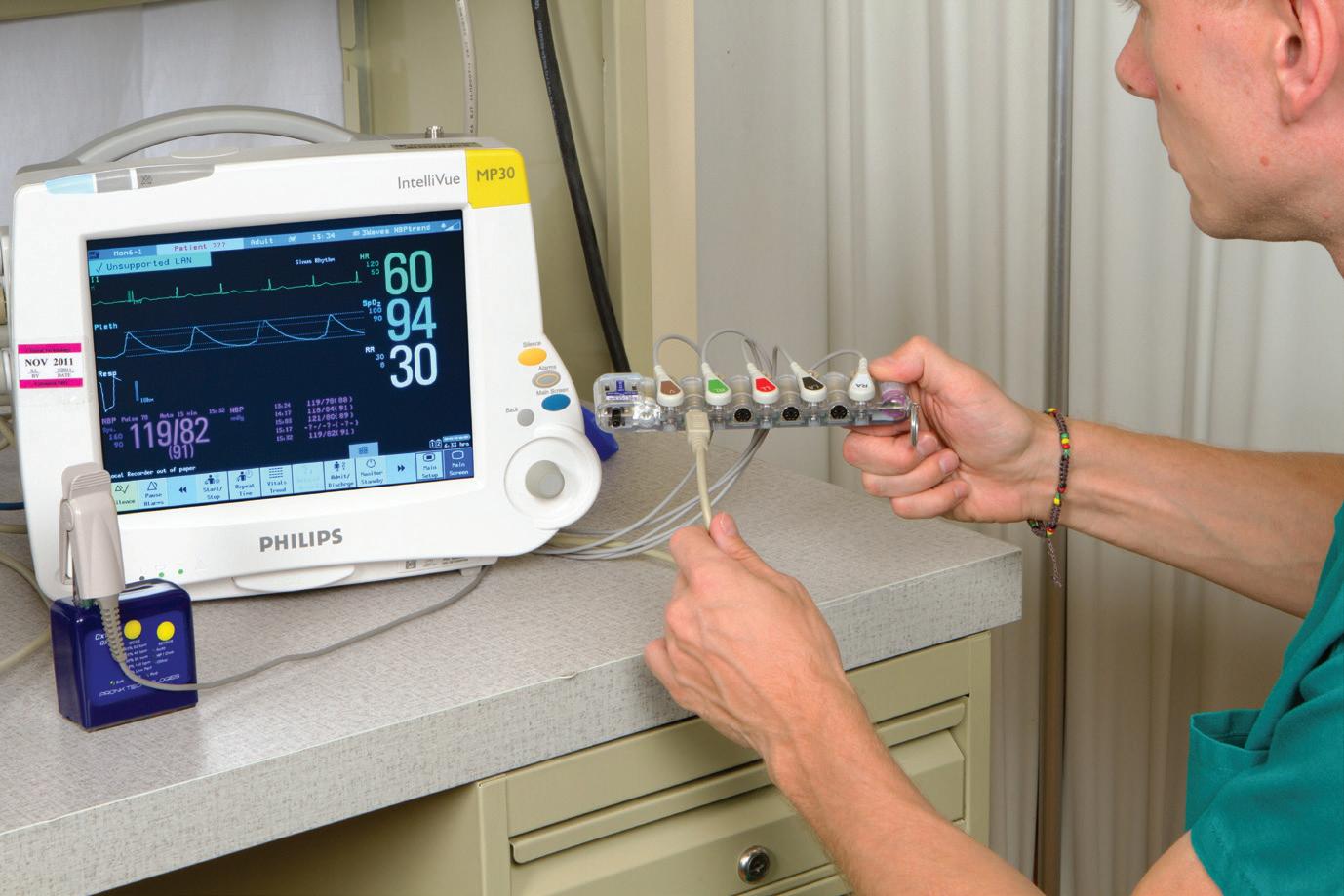

“Our department includes Chief Biomedical Engineering Technologist Erwin Sumcad, six senior BMETs (Jason Bell, Jillian Tobin, Shane Simms, Alanna Hinchey, Samantha Powell), one Casual Biomedical Engineer (Lydia Sochan, MASc), and two Casual/Term Senior BMETs (Timothy Ebbeling and Sarah Berg). In terms of scope, we service a wide range of technology in-house and off-contract. This ranges from basic technologies such as pulse oximeters, suction devices, infusion pumps, etcetera, to intermediate technologies such as physiological monitors and defibrillators; as well as high-level technologies such as X-ray, anaesthesia, ventilators and mammography,” Taylor says.

He says that the department also budgets and manages all the Government of the Northwest Territories’ (GNWT) health technology service contracts for areas such as CT, fluoroscopy and lab technology.

“Moreover, not only do we support all health technology in GNWT health facilities, but we also support two-thirds of the Government of Nunavut’s (GNU) health facilities (i.e., specifically the Kivalliq and Kitikmeot Regions). Our service area represents a geographic area of about onefifth of the United States, and more than half of these communities have no road access (i.e. only accessible by air

or in the winter by ice road),” Taylor says.

The team provides equipment management support to one 80-bed tertiary hospital in Yellowknife, one 51-bed secondary hospital, two health centers with in-patient capacities with a combined 26 beds, but no OR and three higher-level health centers in regional hub communities. These facilities will have a few doctors each, but no in-patient capacity.

Their responsibilities also extend to 16 standard health centers, which are staffed by two to five nurses, as well as seven health cabins, which are staffed by a first aid trained community health representative.

Taylor says that the team also manages medical equipment for two primary care facilities in Yellowknife, eight long-term care facilities, which have a total 183 beds across the territory, 12 health centers in Nunavut and the Yellowknife Fire Department.

Team members are well-trained and future recruits will bring with them a firm foundation.

“The goal is that within two years, all BMETs who are hired are factory-trained on dialysis, anaesthesia, X-ray, physiological monitoring, and ventilators. BMETs in the NWT are specialists in being generalists: they must be able to work in all specialty areas and the NWT invests heavily in that training,” Taylor says.

There is good reason why this group needs to be able to work on nearly everything. Taylor says that “service vendors can spend up to three days travelling to do a 30-minute service call or get trapped in a community for three to five days due to bad weather.”

He says that there have been times when a vendor had not set foot in the territory for a year even with a full-service contract.

With such a large and diverse geographical area and diversity of facilities, the need for special projects above and beyond PMs and maintenance is an expected reality.

The department has participated in several, including the replacement of a hospital.

“The Stanton Territorial Hospital (i.e., the Government of the Northwest Territories tertiary care facility) was replaced

with a new facility in 2019 and Biomedical Engineering, along with biomeds at the Department of Health, played a heavy role in the planning and installation of all new health technology,” Taylor says.

The COVID-19 pandemic challenged biomed departments everywhere and the NTHSSA team was not exempt.

“Biomedical Engineering assisted in the planning, and then purchased, an entire year’s capital budget in medical equipment in just one month at the start of COVID. BMETS from the NWT were also the first BMETs in Canada to volunteer to support the Federal Governments National Emergency Strategic Stockpile and two NWT BMETS each spent a month inspecting incoming COVID medical equipment that was purchased by the Canadian Government to distribute throughout Canada,” Taylor says.

The team really went above and beyond when they were called up to help out with a major evacuation.

“The entire capital city of Yellowknife, as well as the major towns of Fort Smith and Hay River, along with other smaller communities were evacuated in August 2023 due to wildfires (two-thirds of the population of the NWT was evacuated more than 1,000 miles south). Biomedical Engineering supported the mothballing of the tertiary hospital and also participated in setting up evacuation centers for patients. We went so far as to support clinical staff in the care of patients at the military hanger due to limited available clinical staff, as well as the loading of patients onto military transports,” Taylor says.

Because of the team’s broad skills and experience working in harsh conditions, members have helped out with Kosovo after the war in 2000s; Argentina with ORBIS International in the early 2000s; Gambia in the late 2000s; and most recently in Sierra Leone in 2023.

The department is skilled at problem-solving and enjoys working under a unique policy that would be the envy of many U.S. biomeds.

“One of the features that makes our biomedical engineering department unique is our health technology right to

repair policy which applies to all health technology purchased for the government of the NWT health facilities,” Taylor says.

He says that the NWT is the first government health system in Canada to have a health technology right to repair policy.

“In short, the policy essentially states that unless there is no clinically acceptable alternative, it is a mandatory procurement requirement that the provision of service manuals, service training, service software, and service parts are all provided at the same level as provided to the original equipment manufacturer service engineers. This policy allows us to best protect patient safety,” Taylor adds.

He says that while the need to ensure patient safety through timely service is true for all areas of North America, because of the remote and rural nature of the team’s territory, sending equipment for repairs can be an incredibly lengthy process, putting patients at risk of delayed care.

“By servicing equipment in-house, we become much more self-sufficient and are able to provide better service to the territory. This policy came out of the challenges faced during COVID-19 and aligns with the Canadian Medical Biological Engineering Society’s (CMBES) Clinical Engineering Standards of Practice and the CMBES position statement on right to repair,” Taylor says.

The team came to the rescue several other times, including during the pandemic when the demand was extra urgent.

Off the job, Taylor is the co-chair of the CMBES’s right to repair committee as well as the national champion on this issue.

“The NWT has presented nationally and internationally on their right to repair program,” he says.

The NTHSSA are a special breed and work far away from OEMs and suppliers. They are highly skilled and take advantage of being able to apply those skills when some biomeds might be blocked. They have shown that, to the greatest degree possible, they are self-sufficient HTM professionals.

In very remote, and often harsh conditions, this team of biomeds reflects the best of the profession.

BY K. RICHARD DOUGLAS

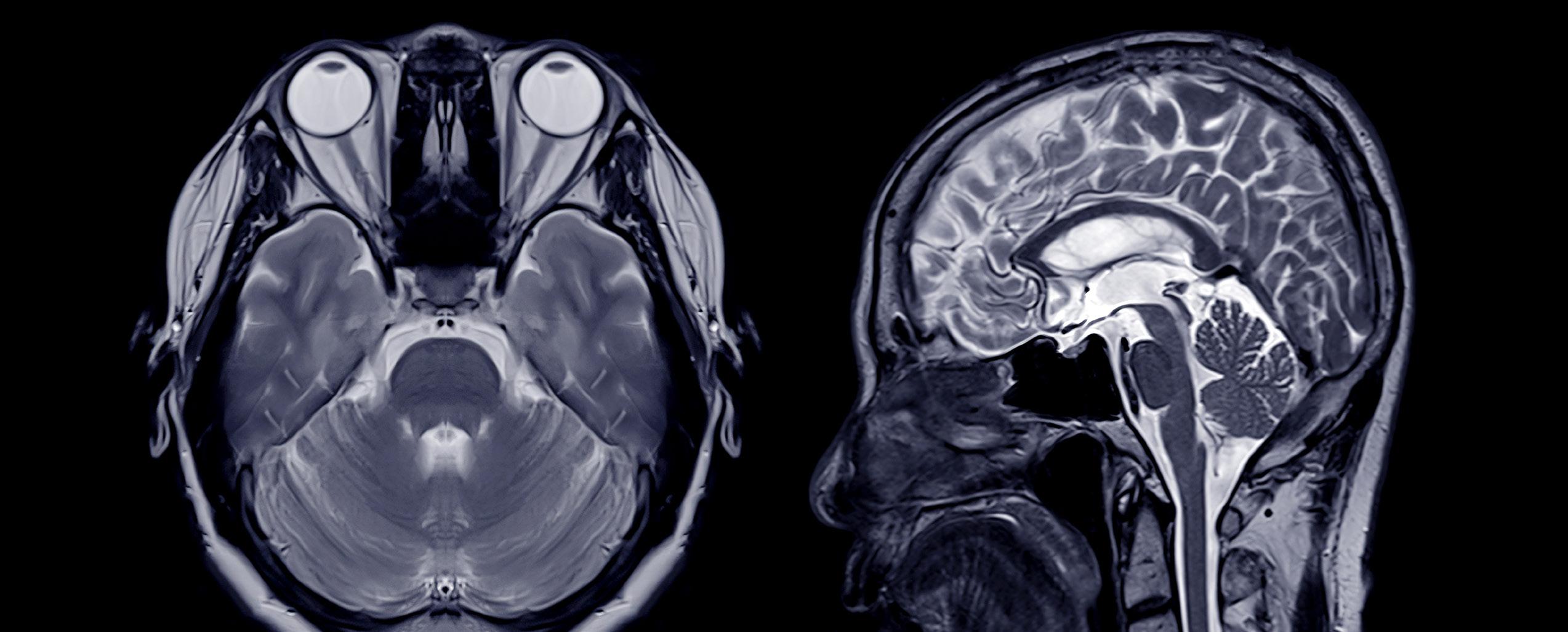

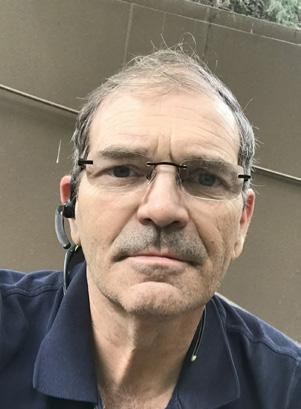

For Benjamin Tinsley, diagnostic imaging support, advanced field service engineer II at Baylor Scott & White Health in Dallas, Texas, the introduction to HTM came out of the realization for the need for biomeds.

“My journey into the HTM field started while I was working with a nonprofit organization in Nicaragua, where I helped coordinate mobile medical clinics. During that time, I noticed that a lot of the equipment we relied on was constantly breaking down – and there was rarely anyone around who could fix it properly. It got me thinking someone out there has to be responsible for keeping this equipment running. That sparked my interest in the technical side of healthcare,” Tinsley says.

He says that when he returned to the U.S., he started looking into how he could get involved in that kind of work and came across the biomedical and imaging technology programs at Texas State Technical College (TSTC) in Waco, Texas.

“I ended up enrolling and earning degrees in both biomed and imaging. That decision set me on the path I’m on today – and I’ve never looked back,” Tinsley says.

While enrolled in the TSTC courses, Tinsley received hands-on training in both fields.

“As part of the program, I also completed an internship with Baylor Scott & White in Plano, which gave me valuable real-world experience working alongside seasoned professionals in a clinical environment,” he says.

After graduation, Tinsley began his career with Siemens Healthineers as an imaging field service engineer.

“That role gave me the opportunity to apply everything I had learned while continuing to expand my knowledge and skills by working directly with

“I’ve focused my experience on keeping this equipment running smoothly. It’s rewarding to know that my work helps support accurate diagnoses and effective treatments,” he says.

As many in HTM have come to realize, scheduling maintenance of high-demand medical equipment can be a challenge.

“One of the main challenges I’ve faced in my current role as an advanced engineer is maintaining a consistent preventive maintenance schedule in the cath labs. These labs are high-demand environments where patient care is always the top priority, so finding the right windows of time to perform thorough maintenance without disrupting critical procedures can be quite challenging,” Tinsley says.

He says that to address this, he has had to work closely with clinical teams to coordinate maintenance during off-peak hours or scheduled downtimes.

“It requires flexibility, strong communication and careful planning to ensure that the equipment remains reliable without interfering with patient care,” Tinsley adds.

He says that in addition to these challenges, he has been involved in projects focused on upgrading and optimizing the imaging systems within the cath, IR, OR, and EP labs.

“These projects have included system updates, integration of new technologies, and workflow improvements aimed at improving operational reliability and supporting the clinical teams in delivering quality care,” Tinsley says.

Away from the job, Tinsley enjoys 3D printing as a hobby and has a corgi named Rooster.

As a member of the HTM community and workforce, Tinsley describes himself as a simple guy who enjoys taking X-ray machines apart and figuring out how they work.

“I like the challenge of troubleshooting and repairing these complex systems because it’s rewarding to know my work helps keep critical medical equipment running smoothly,” he says.

When somebody enjoys their vocation, it means that they likely do excellent work. Diagnostic imaging is made that much more precise thanks to this HTM professional.

FAVORITE BOOK: Harry Potter books

FAVORITE MOVIE: “Star Wars”

FAVORITE FOOD: Pizza

HIDDEN TALENT: 3D printing

FAVORITE PART OF BEING A BIOMED?

What I enjoy most about being a biomed is getting to solve problems every day. Whether it’s fixing a piece of equipment that’s critical to patient care or troubleshooting unexpected issues, it’s rewarding to know that my work directly supports healthcare teams and helps keep things running smoothly.

My manager keeps a stack of TechNation magazines in the shop. It’s a good read that helps me stay connected with what’s happening in biomedical and imaging repair.

Aaron Febre began his healthcare technology management career with education at Durham Tech and UNC Charlotte. He earned both an associate degree and bachelor’s degree before joining Duke University Hospital as a biomedical equipment technician. TechNation recently found out more about his start and his future goals.

Q: WHERE DID YOU GROW UP?

A: Born and raised in Durham, North Carolina

Q: WHERE DID YOU RECEIVE YOUR HTM TRAINING/ EDUCATION?

A: I got my associate degree from Durham Technical Community College.

Q: HOW DID YOU FIRST DISCOVER HTM?

A: I did a Google search for healthcare jobs that weren’t a doctor or a nurse. This was one of the first ones to pop up in my search.

Q: WHY (OR HOW) DID YOU CHOOSE TO GET INTO THIS FIELD?

A: I wanted to have a career in healthcare, but I had no aspiration to be a doctor or a nurse. Especially coming from a family full of nurses, so in a way I wanted to rebel in my family. Ha, ha. As I’ve mentioned earlier, I did a Google search of the various healthcare jobs that weren’t those two titles and this was one of the first to come up. From there, I discovered the Better Biomed YouTube Channel and found out that Durham Tech had a 2-year program to get into this field. And the rest of it was history.

Q: WHAT DO YOU LIKE MOST ABOUT YOUR POSITION?

A: You don’t get bored. You are always doing something different and there’s a ton of things to learn. And I’m happy that I am working with experienced technicians who have a ton of knowledge and are willing to share it.

Q: WHAT INTERESTS YOU THE MOST ABOUT HTM?

A: One part of HTM I am interested in is integration. There’s one

things. But it’s fun once you get the hang out it.

Q: WHAT GOALS DO YOU HAVE FOR YOURSELF IN THE NEXT 5 YEARS?

A: Professionally? I hope to acquire my CBET and gain a lot more experience in the field. Personally? I hope to have traveled to places, start/join a band, complete a marathon, etc

FAVORITE HOBBY:

Playing guitar

FAVORITE SHOW OR MOVIE:

My favorite show (anime) is “Yu Yu Hakusho”.

FAVORITE MEAL: Sushi

WHAT WOULD YOUR SUPERPOWER BE?

Running fast (like the Flash)

1 THING ON YOUR BUCKET LIST:

Visit Manchester, England so I can watch my football (soccer) club, Manchester City FC.

SOMETHING YOUR CO-WORKERS DON’T KNOW ABOUT YOU:

When I was kid, I wanted to be a Formula 1 driver. (It’s a little late to do that now ha ha).

Onsite

On-demand BMET/HTM Technician(s) & Manufacture Remediation/Recall Support

Repair estimate within 48 hours, quick turnaround time & extensive list of loaners available at no charge

MMS will deploy a team of technicians to your facility to complete Annual Periodic Maintenance on your Infusion Pumps All types of medical equipment - new or refurbished

K. RICHARD DOUGLAS

The HTM profession faces some short-term challenges in the coming years as the need to replenish staffing is vital. The retirement of experienced biomeds leaves a void and every avenue must be explored to bring new talent into the field while promoting a little-known profession.

That makes the creation of a new biomed association that much more welcome and needed.

The state of Nevada has not had an organization where biomeds can connect for several years. That has all changed with the formation of the Nevada Healthcare Technology Association (NVHTA).

Kevin Davis, a biomedical service professional and the owner of ERD Medical Equipment Solutions, an ISO-9001 certified independent service organization based in Nevada, founded the new group.

Other Nevada HTM professionals, both active and retired, will hold potential roles as officers, board members or advisor. They include Skylar Bogardus, Candi Robles, Reagan Jordan, Michael Lane, Dr. Binseng Wang, James Knight and Davis.

“The Nevada Healthcare Technology Association (NVHTA) was officially formed in 2025. While our official launch is recent, the vision behind the association has been developing for several years through collaboration with healthcare technology management (HTM) professionals in Nevada,” Davis says.

Davis and his Nevada HTM colleagues recognized a growing gap in professional support, training, and community-building for HTM professionals in Nevada – a state without a dedicated biomed association of its own until now. NVHTA was created to fill that void.

“Our mission is to bring together technicians, educators,

healthcare systems, and industry partners to build a stronger, more connected HTM community – one that promotes innovation, workforce readiness, and long-term career development,” he says.

Davis says that while NVHTA is newly formed in 2025, its roots lie in a much longer conversation about the future of healthcare technology in Nevada.

“For years, local HTM professionals lacked a central hub for networking, peer support, continuing education, and advocacy. As Nevada’s healthcare systems grew – and as retirements created gaps in the workforce – the absence of a unifying association became more visible. NVHTA was created to meet that need. In its founding year, NVHTA’s goals are to begin engaging with hospitals, schools, independent service organizations, and national partners to make NVHTA visible and to gain buzz and membership,” he says.

Davis says that the group’s focus is on building a solid foundation with clear values: community, education, transparency, and workforce development.

“Rather than replicating the model of larger, legacy associations, NVHTA is rooted in action-oriented leadership – developing hands-on BMET training opportunities, planning regional chapter events, and partnering with schools to raise awareness about careers in HTM. We’re proud to be building something new, dynamic and tactile in our approach, and aligned with the evolving needs of our profession,” he says.

Education will be a priority for the new group along with a focus on several other areas that will help grow and strengthen the field.

“While education is absolutely central to NVHTA’s mission, we’re also focused on several unique, high-impact initiatives that set us apart from traditional associations,” Davis says.

He says that one of NVHTAs top priorities is creating entry points into the HTM profession for people who might not otherwise discover it – high school students, veterans,

trade school grads, and career changers.

“NVHTA wants to create exposure to HTM careers that show interested professionals that the HTM field can be agile, affordable, and directly aligned with the needs of hospitals, ISOs, and manufacturers and, most importantly, individual’s skills and passion,” Davis adds.

He says that beyond that, they are invested in publicfacing HTM awareness.

“Through creative outreach efforts we aim to educate not only future biomeds but also parents, school counselors, and the broader community about the critical role HTM plays in safe patient care. We also emphasize partnership development with healthcare systems, equipment manufacturers, and local service providers to bridge gaps between education and employment. By aligning stakeholders early, we create a more sustainable and coordinated pipeline into the profession,” Davis says.

As a brand-new organization, NVHTA has not yet scheduled its first symposium/conference. For now, more routine get-togethers are the norm until a formal conference can be planned.

“Since NVHTA is in its founding year, we are currently in the planning stages for our first annual event, which we expect to host in late 2025 or early 2026. Rather than launching with a large-scale symposium, we’re taking a more focused and grassroots approach – starting with regional chapter meetings, community-driven workshops, and hands-on training events that reflect the needs of our members and partners,” Davis says.

He says that the group’s goal is to create events that are educational as well as deeply collaborative and practical – bringing together biomeds, educators, students, hospital leaders, and vendors in a setting that fosters direct learning, recruiting, and relationship-building.

“For example, providing hands-on training along with networking creates both skill-building and community socializing in one event. We also envision a joint end-ofyear gathering to celebrate our launch year, share insights

from early initiatives and introduce the community to what’s coming in 2026,” Davis adds.

He says that these events will serve as stepping stones to a larger, statewide symposium in the near future – one built on real engagement and measurable value.

For the time being, the new HTM organization is organizing its first round of chapter meetings and planning a calendar of regularly scheduled events. They are also investigating the formation of a scholarship program, which Davis labels a “top priority.”

“We are currently laying the groundwork for a scholarship and sponsorship program tied directly to our BMET workforce training initiative. NVHTA welcomes interested sponsors to help develop scholarship programs and would love interested readers to reach out and collaborate,” he says.

Aligned with this goal is a mission to partner with local biomed training and education programs.

“We are actively working with institutions in northern Nevada, particularly around Carson City and Reno, to bridge the gap between education and employment in the HTM field. Our vision is to work alongside community colleges, not compete with them, by offering flexible, short-format, equipment-based training that prepares students for field work and ISO/hospital-based roles. In the process, we’re also raising awareness of HTM careers among school counselors, educators, and students who may never have heard of biomedical technology,” Davis says.

He says that replacing retiring biomeds is a primary focus and the organization’s strategy focuses on building a pipeline of new talent through outreach, training and awareness.

In the meantime, the group has filed for not-for-profit status and registered with the state. A constitution and bylaws have been outlined. A website has been in development and can be found at: NVHTA.com

There are few advancements within HTM more important than organizing, training and recruiting biomeds, so the newly formed NVHTA is big news.

Ultimo has acquired FSI, a U.S.-based category leader in healthcare facilities and healthcare technology management software. This acquisition marks Ultimo’s second in the U.S., its third overall since 2024, and reflects its strategic commitment to the region’s long-term growth.

FSI has the only computerized maintenance management system (CMMS) platform purpose-built for healthcare service professionals, according to a press release. Its solutions span digital transformation, data management, and in-person asset discovery – serving over a thousand departments across hospitals, healthcare systems and universities.

“Hospitals and healthcare operators are under pressure to digitize fast, stay compliant, and drive down risk in environments where asset performance directly impacts patient care,” said Steven Elsham, CEO of Ultimo. “By bringing FSI’s trusted capabilities together with Ultimo’s EAM capabilities and AI-first vision, we’re delivering a suite

of solutions and intelligence customers need to take control of their assets, reduce operational friction, and drive measurable impact.”

The acquisition builds on Ultimo’s long-standing expertise as the market leader in healthcare asset management in the Netherlands and Belgium and unlocks a deeper presence in the U.S.’s asset-intensive industries. Ultimo will continue the investment to drive market leadership for FSI, with a focus on providing stability for FSI customers.

“This is an exciting new chapter for FSI and its customers as we accelerate investment in solutions that equip customers to tackle regulatory complexity, drive operational efficiency, and accelerate digital transformation” said Zachary Seely, CEO of FSI. “Our customers will have the opportunity to access Ultimo’s AI-first roadmap, including its agentic AI framework.”

This acquisition has been signed and closed by Ultimo.

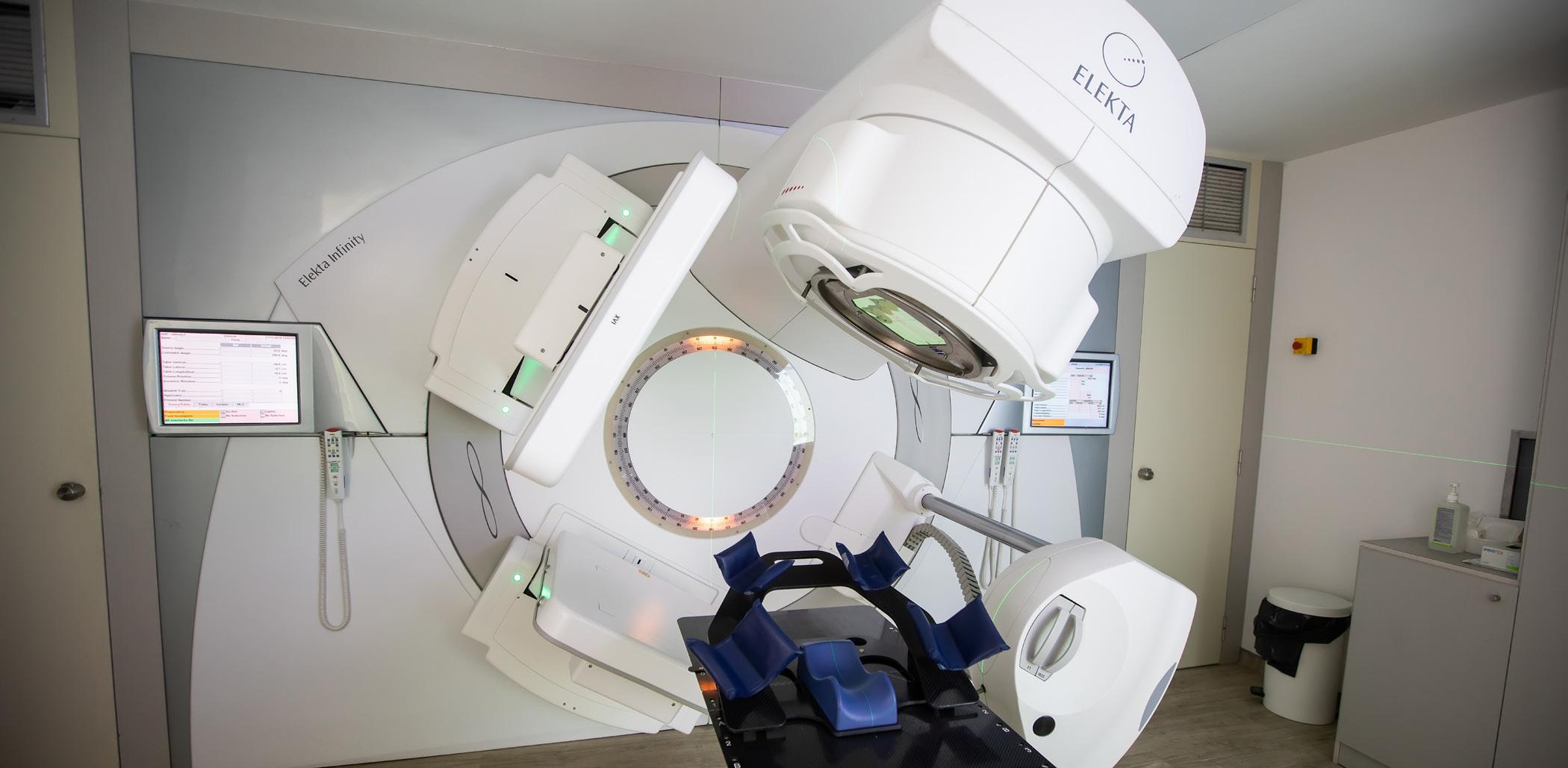

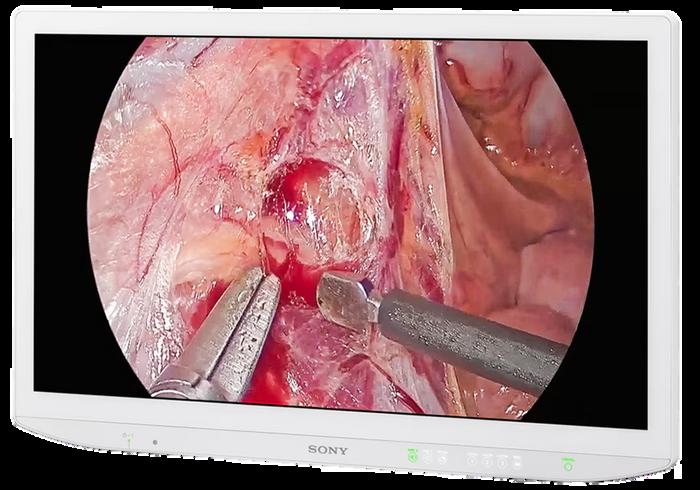

The College of Biomedical Equipment Technology (CBET), Radiology Oncology Systems Inc. (ROS) and Linax Technologies LTD (Linax) have announced a collaboration in establishing and delivering a new and innovative series of online and simulator-based courses designed to teach the technical, operational, and physical principles behind medical linear accelerators used in radiation therapy – a critical technology for current and emerging cancer treatment strategies.

Medical linear accelerators, targeting radiation to treat a broad range of cancers, are among the most complex medical devices routinely used in hospitals. Owing to equipment complexity and the potential dangers associated with radiation errors, it is essential that these devices are operated with the highest degree of precision and maintained by fully qualified and knowledgeable technicians. Providing technicians with high quality and affordable training to maintain and service this equipment with the requisite skill set and accuracy serves an important industry need for the HTM community.

John Vano, president of ROS, a provider of reliable, high quality reconditioned radiation therapy and diagnostic imaging solutions, said, “Developing a strong HTM workforce with expertise in linear accelerator training is not just a technical need – it is a patient safety imperative.”

Noting that training needs are critical in North America as well as globally.

“More and more manufacturers are entering this space, and this new CBET educational track offers a progressive, multi-level curriculum that equips students with the fundamentals to begin or continue a career in medical linear accelerators,” Vano added.

The CBET LINAC Fundamentals courses are designed to provide students with a firm and structured understanding of the medical linear accelerator and its utilization of external beam treatments for high-quality patient care. Preparing students to

effectively triage and manage linear accelerator operations and maintenance, progressing from basic and intermediate levels of LINAC physics, engineering, and application factors of this specialized equipment in a cancer care clinical environment through deeper navigation of LINAC equipment and subsystems, serves an essential HTM industry skills gap and demand.

Marco Carlone, CEO of Linax Technologies, a creator of simulators of complex radiotherapy devices, notes, “Up until now, the only way to learn the principles of medical linear accelerators was to attend a vendor course. With the collaboration between Linax, ROS and CBET, we aim to broaden the medical LINAC service technician community and provide an affordable, accessible, and long-overdue training course for service technicians. Our vision is that of an empowered and flourishing profession, ensuring that cancer patients never have to worry about having access to a high-quality linear accelerator for their treatment.”

The College of Biomedical Equipment Technology provides high quality, stakeholder-based training solutions for the HTM industry, including certificate and associate degree training in biomedical equipment technology and biomedical equipment support specialists, as well as a broad suite of high-quality business training solutions to deliver foundational, advanced, and product specific education to meet the evolving needs of professionals and HTM organizations.

Richard Gonzales, president of CBET, noted that, “Empowering biomeds with linear accelerator training is essential as their expanding roles drive initiatives that enhance quality, patient care, and innovation in healthcare technology.”

By incorporating these courses into its education and training portfolio, CBET continues to expand its robust suite of HTM industry business training solutions in close alignment with the industry’s evolution.

The Army is continuing its transformation effort to bring medical maintenance support closer to operational units without organic maintainers within their ranks.

Under an initiative called Medical Logistics in Campaigning, or MiC, the Home-Station Medical Maintenance Support, or HMMS, program was launched last year at Fort Bragg to begin closing a crucial readiness gap for the warfighter.

Work is ongoing to bring a planned second wave of locations online in the near future, including Fort Benning, Georgia; Fort Campbell, Kentucky; and the U.S. Army Medical Materiel Agency’s Medical Maintenance Operations Division at Tobyhanna Army Depot, Pennsylvania.

“Borne out of MiC, the HMMS program is helping us align medical maintenance with existing sustainment processes of other Army commodities, saving time and money, and ensuring readiness in the process,” said Alfred Zamora, an equipment specialist at USAMMA and acting deputy director for HMMS.

In the Northeast region, units like the 3rd General Support Aviation Battalion, 10th Combat Aviation Brigade, out of Fort Drum, New York, are already utilizing a future HMMS site at MMOD-PA, using Tobyhanna’s helipad recently to drop off over 30 pieces of equipment.

Staff Sgt. Michael Silbart, flight paramedic for the 10th Mountain “DUSTOFF” unit, said the capability to drop off dozens of pieces of equipment at once for recalibration, repair and return to service within a month is “invaluable” to continued operations.

“Being the most deployed unit in the Army requires us to have top-tier maintenance, and that is what USAMMA provides us with,” Silbart said. “Flying directly to USAMMA makes the process seamless and controlled. The lack of a middleman always gives us more control over our equipment and prevents things from getting lost.”

DUSTOFF is used as a callsign by Army air ambulance units, including helicopters dedicated to medical evacuation.

Silbart emphasized the importance of USAMMA’s support, saying it’s the only way to ensure service for their specialized equipment.

“The current facilities here at Fort Drum are not equipped to handle our specific equipment,” he said. “Without USAMMA, we would not be capable of completing our mission here.”

Minimizing downtime and increasing overall readiness are two primary drivers of the planned HMMS program expansion, and the ability to utilize Tobyhanna’s helipad adds more logistical benefits for customers and the team at MMOD-PA alike.

“We’re able to accelerate delivery timelines, reduce ground transport requirements and strengthen relationships with our customer base,” MMOD-PA Director William Wall said. “At the same time, aviation units utilize this resource as part of their training flight hours, making it a mutually beneficial arrangement.”

MMOD-PA technicians successfully completed maintenance and calibration on 18 medical devices, including infusion pumps, ventilators, defibrillators and more, which were exchanged during a coordinated helicopter drop-off for 20 newly arrived devices requiring service.

“This seamless transition, occurring approximately two weeks later, ensured uninterrupted operational readiness and mission support,” Wall said, adding that he expects more use of the Tobyhanna helipad with the future HMMS expansion plans.

Seeking to close critical maintenance gaps that affect readiness, HMMS was developed under MiC, which aims to integrate medical logistics into the Army Sustainment Enterprise as part of the Army’s Campaign Plan 2023-2030.

The first site was established at Fort Bragg during MiC’s proof-of-concept phase in 2024. The North Carolina installation now supports over 100 units, including active-duty and National Guard, throughout the state.

After wave two’s planned rollout later this year, additional proposed sites include Fort Carson, Colorado; Joint Base Lewis-McChord, Washington; and USAMMA’s other two MMODs in Utah and California.

USAMMA is a direct reporting unit to Army Medical Logistics Command, which has been tapped by Army Materiel Command to lead the MiC effort.

The Oregon Biomedical Association (OBA) will host its 2025 Expo & Vendor Fair on Oct. 23-24 at the Holiday Inn-Portland Airport, offering two days of education, networking and industry engagement for healthcare technology professionals.

This year’s theme, “Cascading You Into the Future of Healthcare,” highlights OBA’s commitment to advancing biomedical and imaging technology through training, collaboration and innovation.

The event features three educational tracks with nine

seminars per day, covering imaging, biomedical, and hot-topic discussions. Attendees will also have access to a vendor fair, networking opportunities and door prizes. Breakfast, lunch, and snacks will be provided.

Attendance is limited to 100 tickets per day. Early RSVP is encouraged to secure a spot.

For more information, visit orbmet.org.

A recent Baxter Research Center survey provides an unbiased third-party view of TechNation magazine. The survey examined readers’ habits in regard to editorial content and advertisements. For over 35 years, the Baxter Research Center has provided magazines with valuable feedback and statistics.

Seventy-nine percent of readers stated that TechNation magazine is either important, very important or their personal favorite.

The report states that 78% of respondents read the print issue of the magazine with 22% reading the digital issue of TechNation. A whopping 80% read the magazine at least twice. Not only do HTM professionals read TechNation, but they also share it with colleagues. Baxter found that readers on average share their copy of the magazine with 1.3 people.

TechNation is also a trusted source for decision makers. Eighty percent of respondents indicated that they or someone in their organization took or are likely to take a

2025 MD Expo Dallas just keeps getting better. MD Expo Dallas is approved for CEUs by the ACI. And, MD Expo continues to offer free registration for hospital employees, members of the armed forces and students.

ACI breaks down the available CEUs as follows:

• H.O.T. Workshop: Contrast Injector Operation and PM Training (Session #1) – 4 CEUs

• H.O.T. Workshop: Contrast Injector Operation and PM Training (Session #2) – 4 CEUs

• H.O.T. Workshop: Ultrasound Systems – 7.5 CEUs

• The MD Expo, held November 11-12, 2025, is pre-approved for up to 8 CEUs.

Registration is open for the upcoming fall conference that promises to be one of the biggest MD Expos ever!

MD Expo Dallas is set for Nov. 10-12 at the Renaissance Dallas Addison Hotel in Addison, Texas. Hosted by MD Publishing and TechNation, this premier conference is one of the year’s must-attend events for biomedical technicians, clinical engineers, asset managers and other healthcare technology management (HTM) professionals.

The three-day agenda features industry-leading sessions on HTM best practices, cybersecurity, IT integration,

purchasing actions after seeing an ad in TechNation.

Readers shared their feedback regarding TechNation magazine.

“It keeps me informed on current trends in the industry,” Biomed Supervisor Robert Lampe said.

“I get a lot of insight about so many different areas. I actually have found it very useful for learning and find a lot of the articles very interesting,” Service Technician Terry Absher said.

“TechNation provides articles that are timely and relevant to the field. Challenges faced by biomeds as well as what is on the horizon, are often discussed,” BMET ll Joshua Abner said.

“Keeps me up to date on everything biomedical,” said Biomed Anthony Mack.

Sign up for a free subscription to the industry’s leading publication at 1TechNation.com/subscribe.

compliance and equipment service – delivered by top experts in the field. An expanded exhibit hall will showcase the latest medical technologies and services, offering hands-on demos and direct access to vendors.

The event kicks off on Nov. 10 with H.O.T. (hands-on training) workshops and the invitation - only Leadership Summit, featuring a kickoff session, welcome reception and dinner. On Nov. 11, attendees may also take part in “Lunch & Learn” seminars offering complimentary meals paired with expert insights.

In addition to informal meetups, the event will host exclusive receptions and the highly anticipated “Texas Throwdown” on Nov. 12: a spirited evening featuring live music, Texas-style BBQ, whiskey tasting and line dancing – complete with a build -your- own bandana bar.

Specialized H.O.T. workshops and Leadership Summit events require pre - registration and additional fees; early-bird pricing is available.

For full schedule details, speaker updates and registration information, visit MDExpoShow.com.

Enter the contest and help TechNation celebrate. Fill out the short form at 1technation.com/contest for a chance to win one of 12 prizes, each valued at $150 or more!

Additional entries to win can be acquired by sharing on LinkedIn or submitting a photo. Each month, a winner will be selected and featured in TechNation magazine! August winner is Emily Pleadwell.

Find out more information on Page 92.

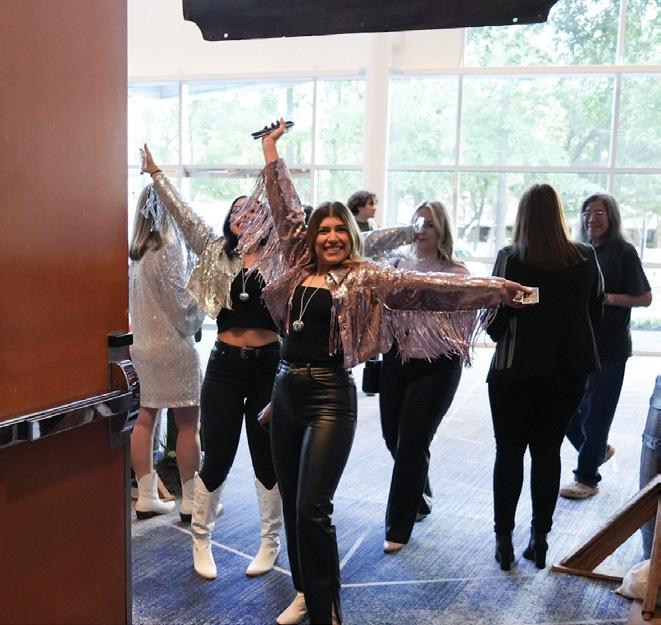

A return to Wisconsin for an HTM Mixer supported by the Wisconsin Biomedical Association (WBA) attracted 133 attendees with 49 industry-specific companies showcasing their solutions in a busy exhibit hall.

“This is our third time teaming up with the Wisconsin Biomedical Association and each time keeps getting better and better. They are an exceptional organization to work with,” MD Publishing’s Kristin Leavoy said.

WBA members praised the HTM Mixer for its quality educational sessions, exhibit hall and networking events. It helped that the HTM Mixer was approved for 10 CEUs by the ACI.

WBA Secretary Mitch Von Ruden, who also serves as HTM manager at Mayo Clinic, provided a glowing review.

“The Mixer this year was really excellent, seemed to attract a lot of attendees and vendors. It was great to see and network with so many Women in Leadership (WIL) that came to the event and honestly enhanced the environment and discussion!” Von Ruden exclaimed.

“The amount of vendors at the vendor show was excellent! Great variety and multiple modalities represented,” he said and mentioned that rad, biomed and ultrasound were just some of the modalities represented.

“The HTM Mixer in Milwaukee was a great event, it was really well organized with an upbeat vibe. The food and drinks were excellent, the entertainment was fun, and the vendor show was impressive with lots of variety and chances to connect with people in the field,” Von Ruden said. “It was a perfect mix of networking and having a good time.”

In addition, Von Ruden was thankful for the HTM Mixer.

“I just want to thank John, Kristin, and the entire team at MD Expo for their support of the WBA and the entire HTM community,” he said.

Larry Fennigkoh, Ph.D., P.E., is a professor emeritus, biomedical engineering at the Milwaukee School of Engineering. He has attended several HTM Mixers and MD Expos. He said this HTM Mixer stood out because of its ability to generate excitement among biomeds.

“The Milwaukee HTM Mixer, again, provided another great value-added educational, emotionally therapeutic, and networking opportunity for regional biomeds,” Fennigkoh said. “Even though these events are a bit shorter in duration, they are no less valuable in serving and supporting our HTM community. Comparatively, this Mixer captured and preserved all the benefits of the others being just as good or better.”

“The usual and now ‘standard,’ even essential, pre-conference happy hour continues to provide a fantastic opportunity for attendees to connect and reconnect with their peers and old buds. The welcoming atmosphere, great food, and entertainment just sets the stage for a collaborative and learning-filled remainder of the conference,” he added.

Fennigkoh also mentioned the Women in Leadership and the group’s positive impact.

“The women in HTM session was very well attended and received,” he said. “Ann Rovito, her great panel, and especially, the openness of attendees was most enlightening but still sadly revealing on the struggles women continue to face. Nonetheless, the progress, growing numbers of women in HTM, and their contributions continues to be most encouraging. These sessions have been similarly popular and informing at other MD Expo and Mixer events and should be continued.”

Overall, Fennigkoh applauded the ability to consistently deliver quality HTM events.

“Having now attended a number of these Mixers, since their COVID beginnings, the consistent benefits are many and energy is always palpable. Not only do they also give a considerable boost to the co-sponsoring local or state biomed societies, they reach a number of biomeds who may be unable to attend the larger conferences,” he said. “Kudos to MD Publishing and the many consistent and incredibly supportive vendors for making these events happen. The entire HTM community benefits and continues to evolve because of these events.”

See HTM Mixer Wisconsin photos on page 86.

Tri-Imaging Solutions introduces a cutting-edge platform that enhances supply chain management, engineer performance, and system monitoring. It provides engineers with diagnostic tools and video tutorials, and streamlines parts ordering and tracking. Designed for efficiency, the platform minimizes downtime and optimizes operations, setting a new standard for reliability in medical imaging.

Tri-Imaging Solutions introduces a cutting-edge platform that enhances supply chain management, engineer performance, and system monitoring. It provides engineers with diagnostic tools and video tutorials, and streamlines parts ordering and tracking. Designed for efficiency, the platform minimizes downtime and optimizes operations, setting a new standard for reliability in medical imaging.

XperTIS proactively monitors system health, supports engineers in repairs, and enhances the supply chain process by giving teams seamless access to parts ordering and order tracking

XperTIS proactively monitors system health, supports engineers in repairs, and enhances the supply chain process by giving teams seamless access to parts ordering and order tracking.

XperTIS offers step-by-step repair guidance, helping engineers troubleshoot efficiently while ensuring faster, more accurate parts ordering. This helps maximize uptime and minimize repair costs.

XperTIS offers step-by-step repair guidance, helping engineers troubleshoot efficiently while ensuring faster, more accurate parts ordering. This helps maximize uptime and minimize repair costs.

VOTING ONLINE OPEN THROUGH JANUARY

SCAN TO VOTE

New England Society of Clinical Engineering (NESCE)

HTMA-Ohio

SPONSORED BY

CABMET: Colorado Association of Biomedical Equipment Technicians

California Medical Instrumentation Association (CMIA)

Wisconsin Biomed Association (WBA)

SPONSORED BY

SPONSORED BY

SPONSORED BY

Kevin Curtiss, biomedical equipment specialist III, Renovo Solutions

Jennifer Stilley, biomedical supervisor, Renovo Solutions

Brandi Caton, supervisor of clinical engineering, Trimedx

Eric Massey, regional director, Intelas

Ryan Gonzalez, director, cybersecurity partnerships, Trimedx

James Swandol, manager HTM, Baylor Scott & White

Andrea Brainard, senior director HTM, Children’s Health

Lynne Holland, director HTM, HonorHealth

Daniel Adams, director, Renovo

Bryant Hawkins Sr., site manager, Trimedx

Allison Woolford, clinical engineering operations manager, Duke University Health System

Chris Avila, intern, Eskenazi Health

Jose Zambrano, HTM service delivery manager, Kaiser Permanente

Mayra Becerra, clinical engineering manager, University of Miami Health System

Jamal Guio, biomedical equipment technician III, UT Southwestern Medical Center of the year

Neisa Massey, clinical engineering, periop team lead, Duke University Hospital

Arleen Thukral, VISN 2 healthcare technology manager, U.S. Department of Veterans Affairs of the year of the year of the year of the year

SPONSORED BY

Erika Colombe, biomedical engineering technologist, TRH Services

Jason Garcia, system manager biomedical engineering, HonorHealth

Nathan Manning, senior site manager, Trimedx

SPONSORED BY of the year

Luisa Howell, Air Force, biomedical equipment technician, BMET Instructor, METC BMET training program

Lynnsei Leach, Army, biomedical equipment support specialist, Memphis VA Medical Center

Chris Lopez, Navy, biomedical equipment technician, BMET instructor, METC BMET training program

Greg Palmer, Army, biomedical equipment support specialist, information systems, VA Heart of Texas Healthcare Network

Adrese Atkins, Air Force, 931st Aerospace Medical Squadron medical administration

Pronk Technologies

MW Imaging

J2S Medical

PartsSource

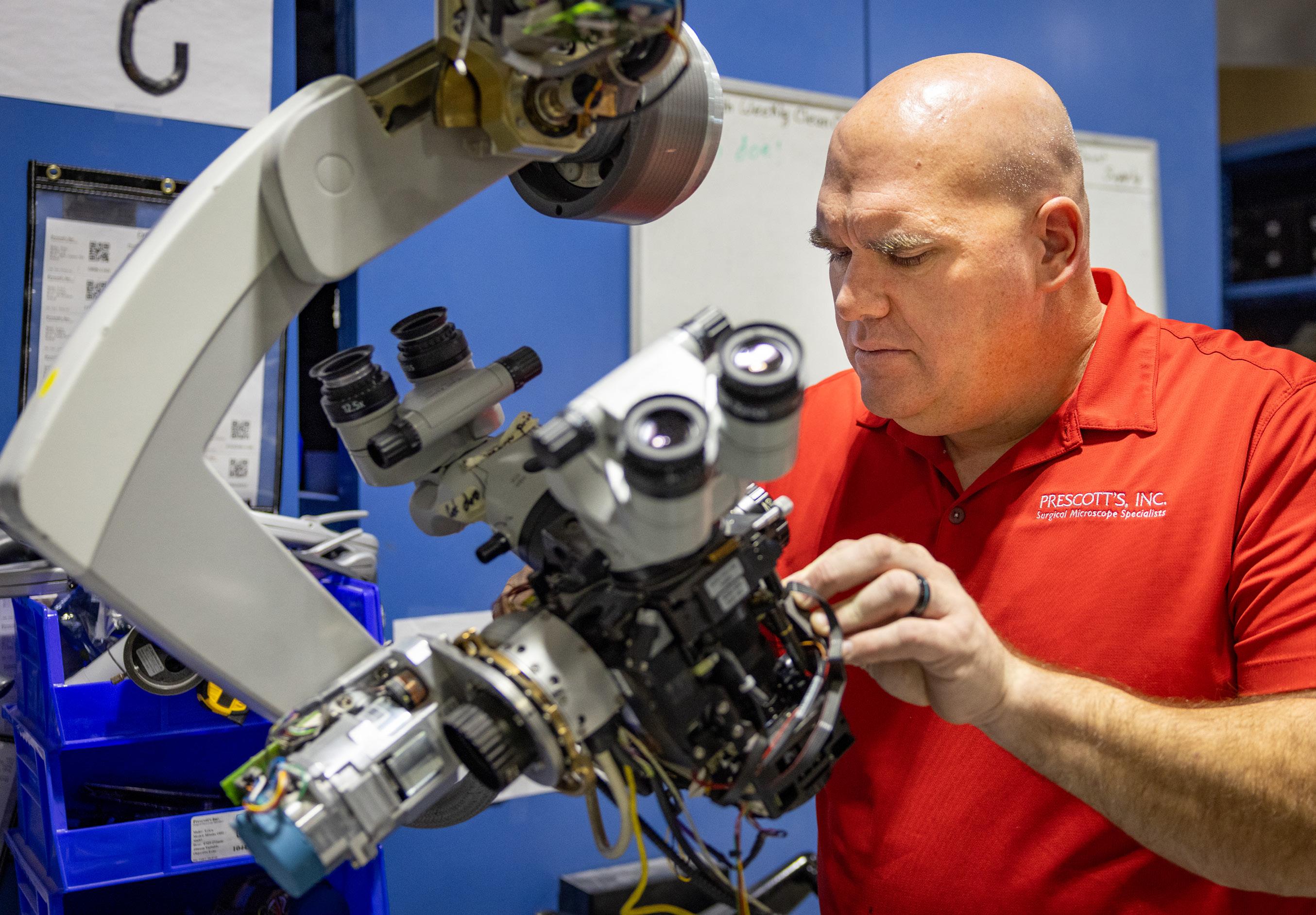

Prescott’s

SPONSORED BY of the year

Steve Cannon

Ed Sloan

Ray Dalton

Mike Busdicker

Sheila O’Donnell

SPONSORED BY

Justin Barbour, Better Biomed Channel

Jennifer Chester, NextJenn TechMom, creator of “Bella the BMET”

Jewel Newell, co-founder I-HTM

Chace Torres, Bearded Biomed, Ohms Law Foundation

April Lebo, president, Women In Leadership (WIL)

award

SPONSORED BY

Jessica Hudson-Rahming, deputy chief healthcare technology manager, U.S. Department of Veterans Affairs

Lisa Fry, region vice president, Intelas Health

Danielle McGeary, vice president HTM, AAMI

Rachel Yarnevic, vice president operations, western region, Renovo Solutions

Lani Bartkowiak, HTM program manager, ProHeath

James Linton, professor & program coordinatorbiomedical engineering, St. Clair College

Todd Boyland, CEO RSTI training, Radiological Service Training Institute (RSTI)

Janet Thomason, director of national procurement Project C.U.R.E.

Clement N.Y.A Appiah Anokye, medical capacity building program partner, Mercy Ships

Deborah Nutsugah, biomedical technician, Mercy Ships

Brian Gore, EP engineering specialist, cardiovascular services, Duke University Health System

Jeff Ruiz, Miles for Myles, senior site manager, Trimedx

James “Jim” Rickner, director of service and training, Advanced Ultrasound Systems

Anntonett Gillins, senior HTM adjunct instructor, College of Biomedical Equipment Technology

Joie N. Marhefka, biomedical engineering technology faculty, Penn State New Kensington

Phoebe Putney Memorial Hospital

Biomedical Engineering Team

Clinical Engineering at University of Kentucky Healthcare

AHS Morristown Medical Center

Biomedical Engineering Team

Sentara Clinical Engineering Department

VISN 2 New York/New Jersey VA

Healthcare Network HTM Department

Memorial Hermann Northeast Hospital Clinical Engineering Department

ProHealth Waukesha Memorial Hospital Biomedical Engineering Department

Western North Carolina VA Health Care

System Biomedical Engineering Department

Reid Health Clinical Engineering Team

Rochester Regional Health’s St. Lawrence Region Biomedical Services Department

Q: WHAT PRODUCT, SERVICE, OR SOLUTIONS DOES YOUR COMPANY PROVIDE TO THE INDUSTRY?

General Anesthetic Services Inc. is the world’s leading provider of anesthetic vaporizer service and calibration. With over four decades of specialized expertise, we deliver unmatched precision, regulatory compliance, and operational reliability to healthcare institutions and medical device manufacturers across the globe.

In addition to vaporizer calibration, our expanded capabilities include:

• Medical device assembly, tailored to OEM specifications and quality system requirements

• Secure device storage, supporting inventory control, fleet readiness, and logistical efficiency

Whether supporting hospitals, surgical centers, or device innovators, G.A.S. ensures that critical equipment is maintained, assembled, and stored to the highest standards—so our clients can focus on patient care and innovation.

Q: TELL US WHAT DIFFERENTIATES YOUR COMPANY FROM THE COMPETITION?

What sets General Anesthetic Services Inc. apart is our uncompromising commitment to quality, responsiveness, and technical excellence.

• We operate under the highest standards—ISO 13485:2016 and FDA 21 CFR Part 820—ensuring full regulatory compliance across every service touchpoint.

• Our customer service is unmatched: no voicemails, no call centers—just a knowledgeable staff member every time you call.

• With unparalleled expertise in anesthetic vaporizers, we offer industry-leading preventative maintenance programs that reduce downtime and eliminate the need for reactive, corrective repairs.

• G.A.S. maintains the largest vaporizer inventory in the industry, enabling a seamless service/exchange program through our depot repair model—so your facility is never without a vaporizer.

• Every service is backed by our warranty guarantee, reinforcing our commitment to reliability and long-term partnership.

• We don’t just meet expectations—we redefine them.

Q: WHY DID YOU CHOOSE TECHNATION FOR ADVERTISING?

We chose to advertise in TechNation because its audience aligns directly with our mission. General Anesthetic Services Inc. operates at the heart of the biomedical HTM space, specializing in preventative maintenance, service, and supply of anesthetic vaporizers and medical equipment.

TechNation reaches clinical and biomedical engineers who are actively seeking reliable, compliant, and responsive solutions to equipment maintenance challenges. These professionals understand the value of uptime, regulatory alignment, and technical precision—exactly what G.A.S. delivers through our depot exchange model, ISO 13485:2016 systems, and FDA-compliant service programs.

By partnering with TechNation, we’re not just advertising—we’re connecting with the very professionals who rely on our expertise to keep operating rooms safe, efficient, and compliant.

For more information, visit generalanestheticservices.com.

Q: WHAT PRODUCT, SERVICE, OR SOLUTIONS DOES YOUR COMPANY PROVIDE TO THE INDUSTRY?

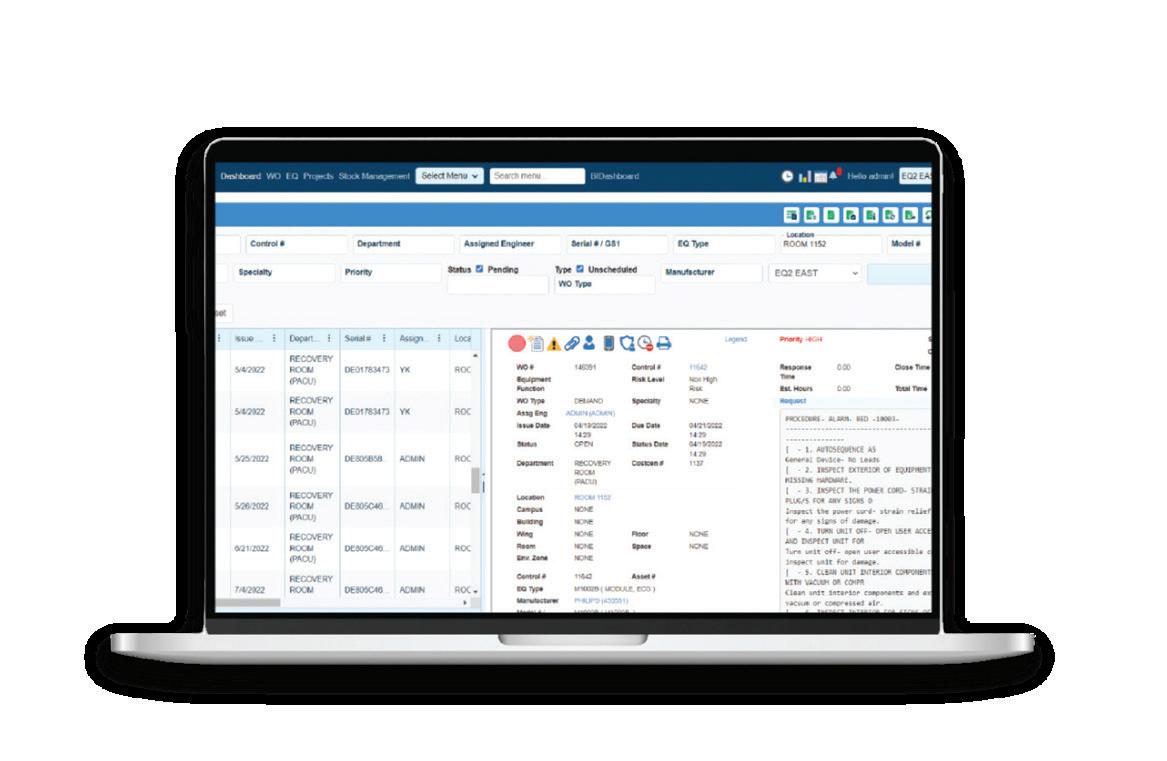

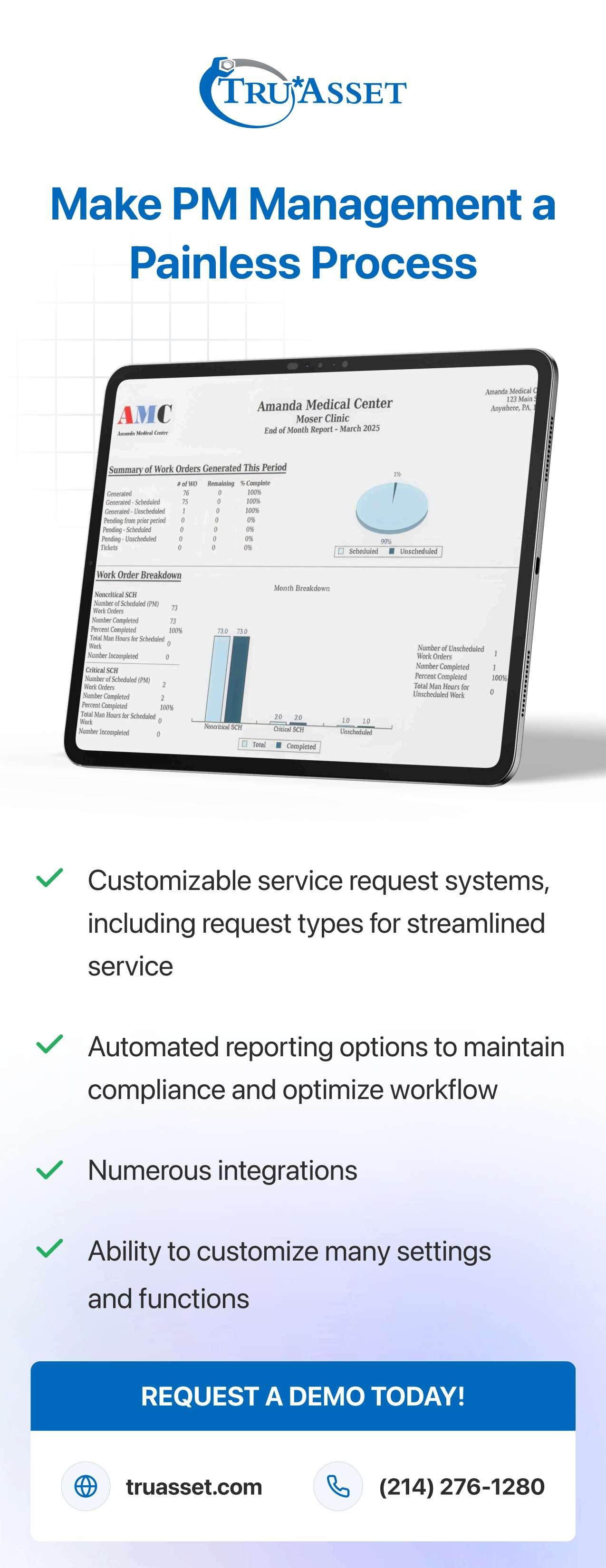

Phoenix Data Systems offers a unified yet flexible approach to healthcare technology management. Celebrating its 40th anniversary this year, Phoenix brings over 300 years of combined direct industry experience. AIMS 3 represents the culmination of that expertise, providing technician-focused usability, operational efficiency, and built-in automation that streamlines tasks, reduces manual effort, ensures complete data capture, and presents essential information at a glance for faster, more effective job execution.

Through its three partners - AIMS 3, Superior Analytics, and HTM Consulting - Phoenix provides solutions that can function independently or together. Superior Analytics ensures data accuracy, normalization, and performance benchmarking, turning information into actionable insights, while HTM Consulting offers management solutions that guide strategy and optimize operations. This integrated approach enables organizations to improve operational efficiency, maintain high-quality data, and achieve long-term strategic outcomes.

Q: TELL US WHAT DIFFERENTIATES YOUR COMPANY FROM THE COMPETITION?

Phoenix Data Systems, Inc. partners with healthcare organizations through three specialized offerings that deliver complementary solutions for healthcare technology management. AIMS 3 provides leading CMMS software to streamline asset management and operational workflows; Superior Analytics focuses on data cleaning, normalization, and performance benchmarking to ensure actionable insights; and HTM Consulting offers management solutions to guide strategic decision-making and optimize operations. Each company delivers significant standalone value, but together they form a powerful, integrated partnership—helping healthcare organizations overcome operational challenges, improve data integrity, and achieve measurable excellence. It’s the Power of Three: Powerful Alone. Transformative Together.

Q: WHY DID YOU CHOOSE TECHNATION FOR ADVERTISING?

We chose to advertise with TechNation because it is the premier monthly publication and essential resource for over 12,000 medical equipment service professionals. TechNation provides in-depth coverage of healthcare technology management, regulatory updates, and industry trends, making it a trusted source of information in the field. Its authoritative voice and extensive reach ensure that our message is seen by a highly engaged and relevant audience, aligning with our commitment to support the healthcare technology community.

For more information, visit goaims.com.

Q: WHAT PRODUCT, SERVICE, OR SOLUTIONS DOES YOUR COMPANY PROVIDE TO THE INDUSTRY?

Quality services - We provide end to end services for Nuclear Medicine equipment to support our customers goals and requirements for patient care. We also help customers with camera maintenance, repair, crystal replacement, and detector reburns.

Q: TELL US WHAT DIFFERENTIATES YOUR COMPANY FROM THE COMPETITION?

Experience – particularly with nuclear medicine imaging equipment at end of life who’s use needs to continue to be maintained and can help avoid and/or delay acquisition of costly newer equipment. We support nuclear equipment wherever you are – hospitals, clients and medical centers throughout the US.

Q: WHY DID YOU CHOOSE TECHNATION FOR ADVERTISING?

TechNation’s focus is communicating with medical imaging professionals who make up a large portion of our customer base.

For more information, visit nuclearcameraservices.com.

OUR AD ON PAGE

Kevin Davis, Owner

Q: WHAT PRODUCT, SERVICE, OR SOLUTIONS DOES YOUR COMPANY PROVIDE TO THE INDUSTRY?

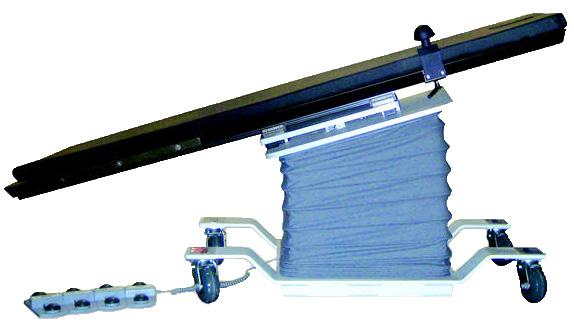

ERD Medical Equipment Solutions is a full-service biomedical organization supporting clinics, surgery centers, and hospitals across the western U.S. We provide preventive maintenance, repair, and ancillary staffing under an ISO 9001:2015 quality management system. While we support a broad range of clinical equipment, our specialization is in three high-impact areas: surgical lights/booms and integration systems, surgical tables, and sterile processing equipment such as sterilizers and washers. By focusing on these mission-critical systems, we help organizations maximize uptime, control capital spending, and remain safe, compliant, and survey-ready.

Q: TELL US WHAT DIFFERENTIATES YOUR COMPANY FROM THE COMPETITION?

ERD stands out for combining deep technical expertise with a responsive, partnership-driven approach. We stay personal and agile, tailoring our services to each client’s needs while maintaining the highest quality standards. We also help health systems safely extend the useful life of mature and end-of-life equipment through disciplined maintenance, legacy parts sourcing, and risk-based assessments — enabling them to direct capital dollars to higher-priority clinical needs. Beyond service, we are deeply committed to workforce development, helping train the next generation of biomeds through hands-on education and industry engagement.

Q: WHY DID YOU CHOOSE TECHNATION FOR ADVERTISING?

TechNation reaches the core of the HTM community — biomedical professionals who are often stretched thin as they balance growing device inventories, expanding facilities, and compliance requirements. These are the professionals we partner with to deliver reliable support. Advertising here allows us to connect directly with biomeds and healthcare organizations who benefit most from having a trusted, quality-focused partner like ERD at their side.

For more information, visit erd-us.com.

“EQ2

HEMS by TMA Systems is designed specifically for healthcare and the unique needs of HTM....(with) specialized workflows for managing medical equipment and advanced compliance tools and reports, including AEM program management and everything needed to be ready for the next survey.ˮ

Rich Sable, Manager of

Client Success

interdependence or independence are designed for Our offerings

®

• AIMS 3

Keep technicians in the field,

• not in the software

Give managers tools to manage

• departments effectively

Automate routine tasks and

streamline communication

analytics ®

• Superior Analytics

• wide perspectives -industry internal & effectiveness with Improve efficiency and

• foundation of data and deploy based on a solid Strategically plan, purchase,

Standardize & normalize

device definitions, codes,

• HTM Consulting categories, & documentation

Monitor KPIs to track and

• inventory, & contracts labor & budget reporting, Optimize processes for

• productivity, & visibility improve accountability,

Define and deploy targeted

customer surveys for

improvement

At ERD, biomedical technicians bring the skill sets and scheduling flexibility healthcare facilities need to supplement and support the clinical engineering staff. ERD’s biomedical technicians are factory-trained and certified to work on equipment from all leading medical device manufacturers. Healthcare facilities can trust that each item will be tested with the utmost attention to detail. ERD technicians are able to work on a wide variety of equipment including tables, monitors, ESUs, lights and sterilizers.

ERD Owner Kevin Davis recently shared more information about the company and its services.

Q: WHAT ARE SOME OF THE SERVICES AND PRODUCTS YOU OFFER?

A: ERD provides full-scope biomedical support across the western U.S. We specialize in surgical suites and sterile processing – supporting washers, sterilizers, surgical lights/ booms, and surgical tables – and we also offer select medical device sales (including MAVIG). Beyond our specialties, we provide preventive maintenance, corrective maintenance, incoming acceptance checks, compliance documentation, and field service staffing. Lately, we’re excited about our expanded OR/SPD safety assessment program focused on ceiling-mounted equipment and sterility workflows; it pairs hands-on inspections with clear, audit-ready reporting for AAAHC/TJC/DNV/CMS environments.

Q: HOW DOES YOUR COMPANY STAND OUT IN THE MEDICAL EQUIPMENT FIELD?

A: ERD stands out by pairing an ISO 9001:2015 quality system with deep OR/SPD specialization (washers, sterilizers, surgical tables and ceiling-mounted lights/booms). Our team leans into the high-impact, high-uptime areas – surgical suites and SPD – where responsiveness, documentation and clear communication matter most. We are vendor-neu-

tral, and pride ourselves on safely extending the useful life of mature/end-of-life systems through disciplined maintenance, legacy parts sourcing and risk-based assessments. This enables health systems to direct capital dollars to other higher-priority clinical needs. Customers report that they value our audit-ready documentation, transparent, timely communication, and an education-first approach that helps teams stay survey-ready while maximizing uptime.

Q: WHAT IS ON THE HORIZON FOR YOUR COMPANY?

A: Near term, we’re expanding throughout the West – with growth in Northern & Southern Nevada and Northern, Central, and Southern California, plus project work in Idaho, Colorado and Arizona. Our dedicated efforts enable us to provide reliable, local support to ASCs and health systems. We’re deepening our OR/SPD capabilities (lights/booms, sterilizers, washers, surgical tables) and continuing to mature our ISO 9001:2015 program and safety initiatives, including broader rollout of our OR/SPD Safety & Uptime Assessment.

We’re also laying groundwork for an ERD education & training program aimed at preparing the next generation of HTM technicians – more to share soon. Through our advanced, polished facilities like the ones in Carson City and Sacramento, we aim to provide training for ready-to-hire future biomedical technicians. At our core, we believe that education is power and we live out that mission every day. We are on the brink of exposing ready individuals to a career that is entirely rewarding and in-demand.

A: ERD’s mission is simple: be the trusted partner that keeps critical equipment safe, compliant and ready for care. If your team needs reliable PMs, clean documentation, or experienced support in the OR or SPD, we’d love to collaborate –whether that’s a one-time assessment or ongoing service. I pride myself in creating a company that is approachable for clients, collaborative in creating opportunities that support customers and, most importantly, passionate about not only our company but supporting the growth of healthcare technology management.

For more information, visit erd-us.com.

BY MARGARET KOGA WARD & MIKE ZIEMELIS

The Food and Drug Administration (FDA) has issued a final rule to amend the requirements of the existing Quality System (QS) Regulation, 21 CFR 820 (Part 820). The amended Part 820 will take effect February 3, 2026, and will be called the Quality Management System Regulation or QMSR.

QMSR incorporates by reference ISO 13485:2016, the well-established, international, quantity management system standard for medical devices. ISO 13485 is used internationally by many regulatory authorities and forms the basis for the Medical Device Single Audit Program (MDSAP). For those unfamiliar with the legal terminology, to “incorporate by reference” means to include a second document within another, in this instance, ISO 13485 will be part of the Part 820 regulation, as if it were fully written out.

FDA will begin to enforce the QMSR requirements upon the effective date, February 2, 2026. Until then, all manufacturers are required to meet the current Part 820 requirements (the QS Reg).

For many years the FDA has recognized the value of global harmonization and has been an active participant in programs to drive harmonization, such as international standard committees (e.g., ISO), the Global Harmonization Task Force (GHTF), and the International Medical Device Regulatory Forum (IMDRF), a voluntary group of medical device regulators from around the world who work together to harmonize medical device regulations.

When ISO 13485:2016 was released, many medical device professionals were surprised by the similarities with the existing FDA QS Regulation, however, ISO 13485 reflected almost 20 years of progress, and placed additional emphasis on risk management and risk-based decisions throughout a

manufacturer’s quality management system (QMS).

In amending the Part 820 regulations, the FDA reviewed ISO 13485 and stated:

“We have determined that the requirements in ISO 13485 are, when taken in totality, substantially similar to the requirements of the QS regulation, providing a similar level of assurance in a firm’s quality management system and ability to consistently manufacture devices that are safe and effective and otherwise in compliance with the Federal Food, Drug, and Cosmetic Act (FD&C Act).”

Industry professionals must not assume that the QMSR is the same as 13485. Although FDA has incorporated 13485 by reference, they have also published additional FDA requirements that organizations must meet. Many of these requirements are listed in QMSR Part 820.10.

The QMSR is available on the FDA website. The layout of the QMSR differs from the existing QS Reg:

• The first section, titled “Supplemental Information” contains the majority of the information in the QMSR, but not the actual regulations. Valuable information is contained within this section, notably the following:

• Executive Summary (a summary of the major provisions of the Final Rule).

• Table of Abbreviations and Acronyms.

• Background (why the change).

• Comments on the Proposed Rule and FDA’s Responses (the preamble).

• Effective Date and Implementation Strategy.

To gain clarity on the FDA’s thoughts on the 13485 requirements, expectations for your Quality Management System (QMS) including risk management read the preamble (Section V. Comments on the Proposed Rule and FDA’s Responses).

FDA received feedback when the proposed rule was published. The preamble lists the comments, and the FDA response. Although the preamble is not enforceable, it clearly outlines FDA’s expectations. For example:

• What are the FDA’s expectations for a culture of quality within

your organization? Refer to comments 27 and 55.

• What are FDA’s expectations for risk management in the QMS? Refer to comment 19 and 32.

• 13485 does not require an independent reviewer in design and development reviews (13485 Clause 7.3.5). FDA discusses their expectations in their response to comment 46.

• 13485 Clause 8.2.2, Complaint handling, does not require a formally designated complaint unit. The FDA discusses their expectations in their response to comment 54.

The word “risk” appears in the QS Reg once under section 820.30(g) “Design Validation shall include software validation and risk analysis, where appropriate.” Compare this to the work risk(s) appearing in the 2016 version of 13485 over 25 times. FDA’s expectations for risk management are now codified in 13485 and are expected to be integrated throughout the quality system. As an example, Section 4.1.2 states “The organization shall … apply a risk based approach to the control of the appropriate processes needed for the quality management system.”

While the mentioning of risk differs between the QS Reg and the 13485 standard, the FDA’s expectation that risk is applied throughout the quality system was explicitly stated in the preamble to the existing QS Reg, and in FDA guidance documents. Having the QMSR incorporate by reference the 13485 standard now explicitly states the application of risk management throughout an organization’s QMS.

The actual regulations for combination products and medical devices are located (or referenced) towards the end of the Final Rule.

21 CFR Part 4 – Regulation of Combination Products

21 CFR Part 4 – Regulations of Combination Products: The FDA has made conforming edits to Part 4 to clarify the device QMS requirements for combination products. (For additional information refer to Supplementary Information section III. Background, C. FDA’s Current Regulatory Framework)

Part 820 – Quality Management System Regulation

Here is where you will find the amended Part 820 regulations for medical devices. There are two Subparts: The General Provisions and the Supplemental Provisions.

This section includes:

• The scope of the regulation (essentially unchanged from the QS Reg)

• The definitions – Pay attention to the definitions! The QMSR also incorporates by reference Clause 3 of ISO 9000:2015 as this is a normative reference for definitions used in 13485. However, the QMSR has a definition hierarchy as follows:

1. A definition from the FD&C Act always takes precedence (e.g., manufacturer).

2. A definition from Part 820.3 of the QMSR (these are listed in the Final Rule, for example, the term “Component” is defined in the QMSR).

3. A definition from ISO 13485:2016.

4. A definition from ISO 9000:2015.

• Incorporation by reference: This section contains the statement that the QMSR is incorporating by reference

ISO 13485:2016, and ISO 9000:2015 Clause 3 (definitions). Note that the actual text of these standards is not included, however, this section contains information for accessing the information (although most organizations have purchased these two standards)

• Requirements for a quality management system: This is a very important section as the QMSR includes more than ISO 13485, and an organization must meet additional FDA regulations. This part clarifies some of the additional regulatory requirements! Remember, ISO 13485 is an international standard, and includes many statements such as “in accordance with applicable regulatory requirements,” when you see that term, please refer to Part 820.10 of the QMSR for guidance on the meeting the applicable FDA regulatory requirements.

FDA determined that some additional regulations are required, these regulations go above and beyond 13485:

• Part 820.35 Control of records: Includes the additional information required for complaint records, service records, unique device identification (UDI), and information for marking documents as confidential.

• Part 820.45 Device labeling and packaging controls. Contains numerous requirements for packaging and labeling, many of which have been carried over from the QS Reg.

The transition date is approaching fast, and a gap analysis should be performed to ensure your organization will be compliant!

FDA will have a new inspection process From FDA’s website: “FDA will develop a new inspection process to align with the requirements of the new QMSR. The process will be developed for implementation when the rule takes effect.” This comes from the Quality Management System Regulation Frequently Asked Questions page that was last updated on August 7, 2024.

FDA will phase out the Quality System Inspection Technique (QSIT) once the QMSR is fully implemented and replace it with a new inspection program. Additionally, the MDSAP Audit model will be updated but is expected to be minimally impacted because the MDSAP program was already aligned with the requirements within 13485.

AAMI has several training courses that can be taken to keep you up to date on the new requirements:

• AAMI Expert Insights: Transitioning to the FDA Quality Management System Regulation

• AAMI Quality System and Risk Management Courses.

This entry for AAMI’s new Insights into Innovation series is authored by Margaret Koga Ward, the principal engineer and owner of Teragram Consulting, and Mike Ziemelis, the Vice President of R&D for Hologic. Their insights and opinions are their own and do not represent the views of AAMI or AAMI Foundation.

ECRI assessed evidence surrounding single-use versus reprocessed medical devices in hospitals.

One way healthcare providers attempt to reduce hospital-acquired infections (HAIs) is to discard medical devices following use rather than disinfect and reuse them – but this practice carries significant cost and environmental implications. ECRI, a global healthcare and patient safety nonprofit, released a series of assessments analyzing the evidence surrounding single-use versus reused or reprocessed medical devices in hospital settings.

The research was conducted by the ECRI-Penn Evidence-based Practice Center and involved a systematic literature review of more than 2,000 studies, primarily focused on devices used for HAI prevention such as hospital gowns, and bedside care devices, including laryngoscopes. The research also includes other types of scopes and surgical items.

Each assessment report includes a chart that indicates whether the available evidence supports single use, reuse, or is inconclusive – across clinical, economic, and environmental categories. The findings emphasize that local factors such as infection rates, supplier agreements, reuse frequency, and reprocessing methods influence outcomes and should be considered.

• Clinical impact: Clinical outcomes sometimes favored single-use disposable devices depending on the specific device, particularly for infection rates.

• Economic considerations: Economic analyses of single-use versus reusable devices gave mixed findings, though in most categories, reusable devices are less costly.

• Environmental footprint: Environmental impact evidence often favored reused or reprocessed devices, as disposable devices are more harmful for the environment.

While single-use devices are often favored for infection prevention, the evidence supporting this is not consistent across all device types, and reusable options often present economic and environmental advantages. The research highlights the complex tradeoffs between clinical outcomes, economic costs, and environmental impact when choosing between single-use disposable and reusable or reprocessed medical devices.

“There’s no one-size-fits-all solution when it comes to choosing between single-use and reusable medical devices,” says ECRI’s Director of Clinical Evidence Evan LeGault. “These assessments are designed to support hospitals, supply chain professionals, infection control teams, and sustainability officers in weighing the tradeoffs and identifying what works best for their organization.”

ECRI searched for primary studies and systematic reviews comparing single-use and reused or reprocessed medical devices for in-hospital use. The systematic literature search captured publications from 1/1/2010 to 1/6/2025 and identified 2,133 citations to screen, ultimately yielding 48 studies in 21 device categories.

Substantial gaps exist in the current evidence base, with clinical outcomes and economic costs reported far less frequently than environmental impact, and most of the 21 device categories were examined by few studies. In the absence of strong direction from clinical or economic evidence, environmental impacts may become a deciding factor.

This study highlights the need for further research as well as increased transparency from manufacturers, reprocessing companies, and healthcare institutions.

Download the full research reports from the ECRI Newsroom at www.ECRI.org/News.

BY ELYSSA EL-HAJJ

enerative artificial intelligence (Gen AI) is becoming increasingly more common and normalized. Surveys indicate up to 40% of the nation’s workforce currently utilizes AI. This number will only increase as more organizations shift to embracing Gen AI. This is how to become more efficient and save time and energy.

Everyone experiences the repetitive or routine tasks that happen day to day. They take time away from larger or more complex projects. Things like filling in paperwork, summarizing meeting notes, and looking up information can easily be streamlined using Gen AI. There are infinite ways of implementing AI in the workplace. My concern with the never-ending possibilities of AI is that we won’t slow down to consider issues like misinformation, privacy violations and inauthenticity.

To understand the pitfalls of Gen AI, first we need to understand how the model is built and where all the information comes from. Gen AI functions based on