TOP TOOLS TECHS WANT

Instead of waiting for problems to arise, scheduled service keeps your anesthetic vaporizers reliable.

Protects your patients by ensuring accurate, consistent anesthetic delivery and vaporizer reliability.

Stay compliant with regulations from the FDA, Joint Commission, and other governing bodies.

Minimize disruptive downtime and avoid the high costs of last-minute emergency repairs with scheduled service.

Investing in preventative maintenance protects your assets, ensures patient safety, and provides peace of mind.

P.12 SPOTLIGHT

p.12 Department of the Month:

GE HealthCare/AdventHealth

Fish Memorial Hospital Biomedical Department

p.14 Professional of the Month: Jonathan Hatley, CBET

p.16 Next Gen: Michael Miller

p.18 Shifting Gears: Mike Chuma, Getting Past the Rail

P.20 INDUSTRY UPDATES

p.20 News & Notes

p.25 TechNation Pulse

p.27 Ribbon Cutting: AdmarNeuro

p.28 AAMI Update

p.30 ECRI Update 46

P.32 THE BENCH

p.32 Biomed 101

p.34 Webinar Wednesday

p.35 Tools of the Trade

p.36 How I Use MedWrench in my Classroom

P.39 FEATURE ARTICLES

p.39 Roundtable: Test Equipment

p.46 Cover Story: Unveiling the Latest Trends & Tech

p.50 Top Tools Techs Want

P.58 EXPERT ADVICE

p.58 Careers Now

p.60 Cybersecurity

p.62 The Future

p.64 Right to Repair

p.66 SPONSORED CONTENT: Multimedical Systems

p.68 The Massey Method

p.70 Networking Notes

p.72 Health-ISAC

PUBLISHER John M. Krieg

VICE PRESIDENT Kristin Leavoy

VICE PRESIDENT Jayme McKelvey BUSINESS DEVELOPMENT

EDITORIAL John Wallace

CONTRIBUTORS

K. Richard Douglas

Joie Marhefka

Steven J. Yelton

Garrett Seeley

Phil Englert

Nathan Proctor

Nadia ElKaissi

ACCOUNT Megan Cabot

EXECUTIVE

ART DEPARTMENT Karlee Gower

Taylor Hayes Alicia Brown

DIGITAL SERVICES Cindy Galindo

Kennedy Krieg

Haley Harris

EVENTS Kristin Leavoy Sydney Krieg

WEBINARS Linda Hasluem

HTMJOBS.COM Sydney Krieg

ACCOUNTING Diane Costea

CIRCULATION Joanna Manjarrez

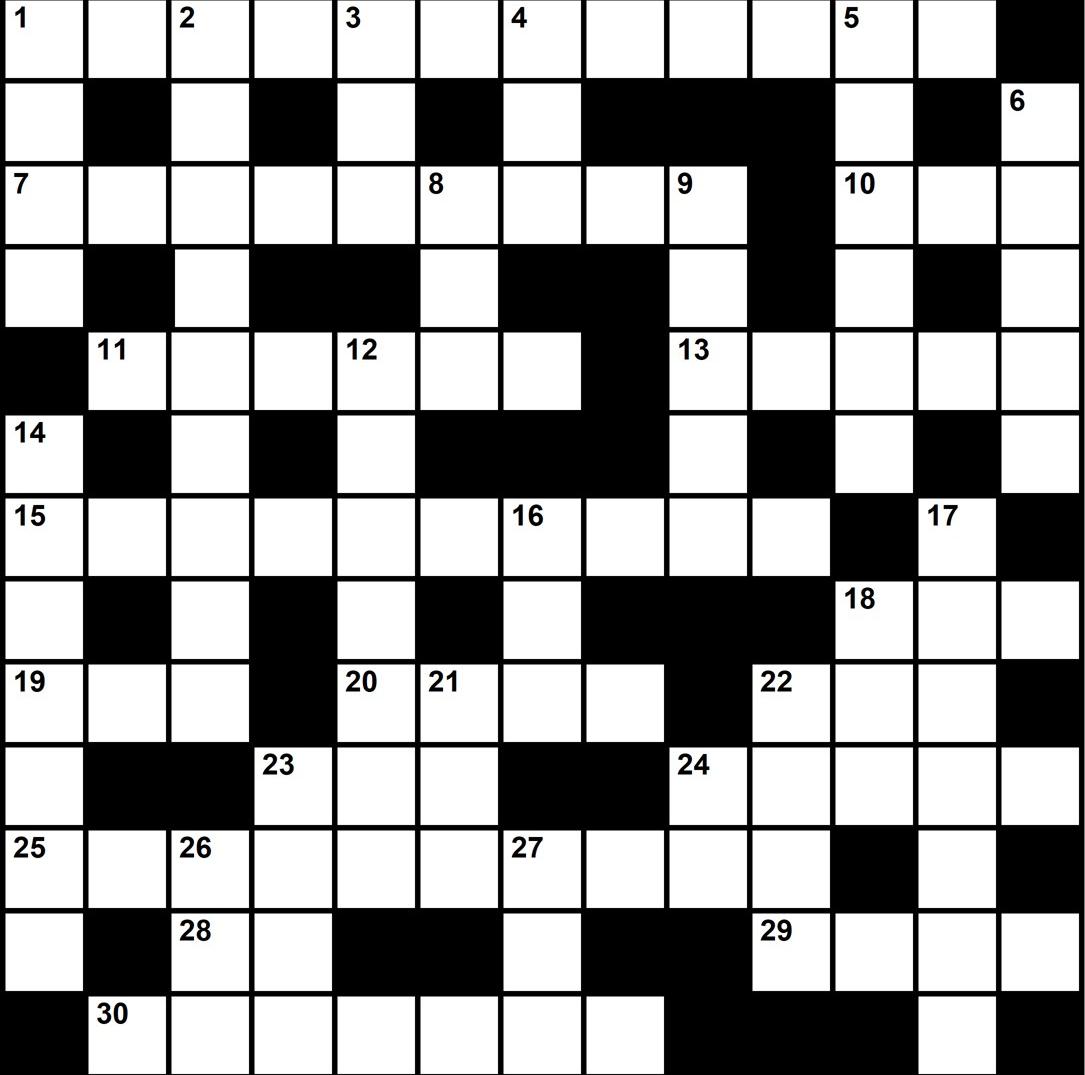

p.80 Biomed Brainbuster

p.81 Word Search

p.81 [Contest] What’s on Your Bench?

p.82 NCBA Scrapbook

p.84 Preferred Vendors

p.88 Service Index

p.91 Alphabetical Index

p.92 Time Capsule

Rob Bundick, Director HTM & Biomedical Engineering, ProHealth Care

Carol Davis-Smith, CCE, FACCE, AAMIF, Owner/ President of Carol Davis-Smith & Associates, LLC

Nadia ElKaissi, CHTM, Biomedical Engineer, HTM, VA Central Office (19HTM)

Bryant Hawkins Sr., Site Manager, Children’s Hospital of New Orleans

Earl Morris Jr., BMET, Director of Clinical Engineering, Harrison County Hospital

Leticia Reynolds, Clinical Engineering Operations Manager at UCHealth Parkview Medical Center

Our nationally recognized programs include Biomedical Equipment Technology (BMET), Biomedical Equipment Support Specialist (BESS), and the Dental Repair Technician (DRT) Certificate. Each is designed to equip you with the advanced skills needed to thrive in today’s evolving healthcare and dental technology landscape.

CBET’s Virtual Reality (VR) labs offer a flexible and immersive learning experience that adapts to your busy schedule. our VR labs allow you to practice and perfect your skills in a controlled, risk-free environment.

and are available through

formats. These programs can include foundational, advanced, product-specific, or professional development training and education specifically designed to serve the diverse needs of the HTM industry.

BY K. RICHARD DOUGLAS

Orange City, Florida, is a city of about 13,000 known for Blue Spring State Park. It is located approximately 30 miles northeast of Orlando or about halfway to Daytona Beach.

Serving the healthcare needs of the community is AdventHealth Fish Memorial Hospital. In 2021, the hospital added a new four-story patient tower.

M anaging the hospital’s medical equipment inventory is the GE HealthCare/AdventHealth Fish Memorial Hospital Biomedical Department. The biomed team consists of four members including GE HealthCare apprentice Adrian Figueroa, GE HealthCare Lead Tech Ruben Sebastian, GE HealthCare Tech Robert Cherry and GE HealthCare Program Coordinator Rana Helou.

Because of the small size of the team, the techs are all generalists.

“ We all learn all departments and get exposed to all equipment to be able to provide service to the facility and not have a delay. I always say you never know what happens so always have a plan and do not depend on one person for everything. That is why technicians tag team with lead technicians and program coordinators to learn and advance in the field. The service manual, tech support and an amazing team working together to learn performs a faster route to success. Never specialize or put yourself to a limit,” Helou says.

The team handles Fish Memorial with 253 operating beds, a AdventHealth Deltona ER with 12 beds as well as doctor offices offsite.

“ With AdventHealth growing rapidly in Florida, we continue to help our surrounding areas. GE HealthCare has imaging field service engineers for imaging, and with the

amazing apprentice program, many apprentices get to join the lead techs and program coordinators to understand the field and responsibilities of a hospital on a day-to-day basis, but as well as how important we are in the field making a difference in the hospital and helping save lives alongside the hospital staff,” Helou says.

She says that with the different experiences the team members have in the field, they help each other tackle anything from every-day correctives to projects and maintenance.

“One hand helps the other with success. I like when technicians get exposed to everything in the field and the challenges that they can face, and how to approach it. This is why we do things as a team, but if a technician is specialized on a special unit, we all tag team to learn and expand. Always have a backup plan just in case one person is out of the office the next person can take over and not affect the operation of the facility with a delay,” Helou says.

She says that the team was created to improve preventive maintenance completion, reduce the turnaround time for corrections, help the hospital with cost savings and bring awareness to how much biomed is involved in every department.

“ By having every technician dedicated to a department and contribute to the projects for the hospital as they grow, we are able to help ensure the safety, reliability, security and availability of medical equipment,” Helou says.

H ow is data collection accomplished?

“ The different dashboards created help manage collecting data across the board being able to run reports, data sheets and numbers in real time which helps in providing the ability to review metrics, operations, time, performance as well as decisions,” Helou says.

The biomed team has also cemented its relationship with its IT counterparts.

“ We have built a strong and wonderful relationship

with AdventHealth IT, which has also helped us support medical equipment. But also working with each nurse leader in each department, attending management as well as staff meetings, listening to concerns and compliments helped with how to approach the work force,” Helou says.

H elou is certain that with the expansion of AdventHealth, the team will continue to have projects and challenges.

A solution to a recent challenge was accomplished through the resourcefulness of the team.

“ Bed rentals are a budget by themselves. We were able to help the facility get bed repairs completed on a timely manner by having the staff tagging beds with a red tag

explaining the defect and it has helped with a quicker turnaround time limiting down time. Having a process in place was the solution to all problems,” Helou says.

T he four-member team may be small, but they keep up with involvement in the biomed world. They also support their leader.

“As a team we always keep up with AAMI information, Central Florida Biomed Society, and MD Expo within our state, as well as Friday I-HTM. This most amazing team of gentlemen has been very supportive of my WIL (Women in Leadership) involvement,” Helou says.

I n central Florida, the GE HealthCare biomed team at AdventHealth Fish Memorial is getting the work done and ready to tackle future projects.

BY K. RICHARD DOUGLAS

The U.S. economy impacts people in many ways including a higher cost-of-living, the ability to buy a house or a rising or falling stock market.

It can also lead some people to the HTM profession.

“I became interested in the biomed profession when I was between electrical jobs. I was doing electrical work, but when the housing market crashed in 2008, very few homes were being built and very few electricians were needed, except for service calls, which was no longer steady work,” says Jonathan Hatley, CBET, technical manager, biomedical services, McLeod Health in South Carolina.

He says that he held out for about a year before he had to find another means for steady work. A friend helped him get a job at a place that makes and sharpens saw blades for giant sawmills found in North and South Carolina.

“I was the delivery driver, and I hated that job, but it was work. The saws can be quite large, some with a diameter of six feet; they were very heavy, it was hot in the summer, cold in the winter and I bled on a daily basis,” Hatley adds.

He says he worked at that job for a couple years, and during that time, he met with a guy through his father-in-law who said he was a biomedical equipment technician.

“I was like what’s that? He asked me, ‘Have you ever thought about what happens when equipment breaks in the hospital? It’s all machines, they break sometimes and need maintenance, and don’t you perform maintenance on your car by changing the oil periodically, your lawnmower or other things to help prevent them from breaking?’ As we talked, I found that the job mostly consisted of troubleshooting problems with equipment, repairing those problems, performing maintenance and customer service; all of which I was good at. My thoughts were that as long as hospitals are open, there will always be a need for people like him to repair equipment. I could do that,” Hatley says He enrolled in the biomedical equipment technology

program at Stanly Community College in Albemarle, North Carolina.

Hatley worked his way up in the field from a BMET I to entering his current position as a technical manager of biomedical services in 2023.

In the challenges/projects department, Hatley says infusion pump remediation stands out as a task that requires an understanding of patient flow.

“As manager for the biomedical department, I am involved in many projects, some of them over a year out. By far, some of the toughest projects that I have led, and been involved with, are the infusion pump remediations. They seem to happen

department because it involves every department in the hospital,” he says.

Hatley says that each time it is difficult because of the sheer volume of devices that have to be found and swapped out across each of the facilities; usually simultaneously.

“It takes great coordination between biomed and nursing staff, as well as the vendors to see that each and every aspect of it is calculated and purposeful. We can’t take too many devices out of service at one time without having new/ replacement devices to fill their place. Because it usually takes a week or more at the main hospital, we can’t bank up devices in the evening to have for swap out the following morning because it will cause a shortage on the floors for the night staff and the on-call biomed would get called non-stop throughout the night,” he says.

Hatley says that during the remediations they rely heavily on nursing staff to help swap the devices that are in use on patients.

“We have to circle back through the same departments multiple times because patients are always moving, and new patients are always coming in. That’s why it helps to understand patient flow and having a good working relationship with the

FAVORITE BOOK:

I still read the Goosebumps original set. I’m a ’90s kid.

FAVORITE MOVIE:

“Back to the Future” and all the Marvel movies and “Tombstone”

FAVORITE FOOD:

BBQ

HIDDEN TALENT:

When I close my eyes, I can make people disappear until I open them again.

FAVORITE PART OF BEING

Although my calling is not direct patient care, I take great pride in being able to provide comfort to staff and patients by using my skills to give them assurance by letting them know i am here to support them in their equipment needs, and in most cases, we can fix it if it breaks.

WHY DO YOU READ TECHNATION?

TechNation is a great magazine for the biomed career field that provides useful and insightful information about products from vendors and different perspectives from biomeds across the country. I also enjoy the webinars hosted by TechNation on Webinar Wednesday.

nurses and nursing administration,” he says.

Away from work, Hatley enjoys the simple things in life.

“Grilling, smoking meat and cooking food is a hobby that I have had for many years. I have three kids and a wife, so my hobbies mostly revolve around and benefit them. Mowing grass and lawncare is also a hobby because it’s the only time I am left to my own thoughts without interruptions. Other than that, I like to collect antiques,” he says.

Hatley says that his wife and he have been together for 16 years and married for 11 and they have three kids together; two girls ages seven and six and a boy who is three.

Hatley’s efforts received recognition from his employer.

“In 2018, I received the McLeod Merit Award, which is only given out to about four recipients per quarter in our organization and I am very proud of it. It is ‘For consistently exceeding the standards of excellence and quality set by McLeod and demonstrating cheerful and compassionate service to others,’ ” he explains.

It was well-deserved for this HTM professional who has been in the field since 2011, obtained CBET certification in 2018 and worked his way into leadership. The field is better with people like this.

Michael Miller is a College of Biomedical Equipment Technology alum achieving great things in HTM. He is currently a Clinical Engineering Equipment Technician II with Intermountain Health McKay-Dee Hospital. TechNation recently had a chance to catch up with Miller.

Q: WHERE DID YOU GROW UP?

A: Smithfield, Utah

Q: WHERE DID YOU RECEIVE YOUR HTM TRAINING/ EDUCATION?

A: Online classes through College of Biomedical Equipment Technology.

Q: HOW DID YOU FIRST DISCOVER HTM?

A: My dad started in HTM before I was born.

Q: WHY (OR HOW) DID YOU CHOOSE TO GET INTO THIS FIELD?

A: My dad suggested I look into it after I mentioned medical problems from working in construction.

Q: WHAT DO YOU LIKE MOST ABOUT YOUR POSITION?

A: The great group of people that I work with is what I like the most about my current job.

Q: WHAT INTERESTS YOU THE MOST ABOUT HTM?

A: What interests me the most about HTM is being a part of the healthcare community.

Q: WHAT HAS BEEN YOUR GREATEST ACCOMPLISHMENT IN YOUR FIELD THUS FAR?

A: My greatest accomplishment thus far is taking on three different models of scope washers for two hospitals.

Q: WHAT GOALS DO YOU HAVE FOR YOURSELF IN THE NEXT 5 YEARS?

A: One goal I have for myself is to become a Tech III before 2030.

FAVORITE HOBBY: Riding motorcycles

FAVORITE SHOW OR MOVIE: Gladiator

FAVORITE MEAL: Anything I make on my smoker

WHAT WOULD YOUR SUPERPOWER BE? Wolverines healing

1 THING ON YOUR BUCKET LIST: See Greece, Italy, and Israel

K. RICHARD DOUGLAS

How many people consider leaping off of a 486-foot tall bridge as a celebratory act on their 73rd birthday? This is something that HTM professional Mike Chuma had planned on, but due to weather conditions and other conflicts it was delayed.

Chuma’s plan was to do a tandem BASE jump from the Perrine Bridge over the Snake River in Twin Falls, Idaho. The location is a famous BASEjumping location because it’s the only man-made structure in the United States where BASE jumping is permitted yearround without a permit.

BASE jumping is an extreme sport where jumpers leap from high, fixed objects and deploy a parachute to descend safely to the ground. The name “BASE” is an acronym for the four types of objects jumpers leave from: Buildings, Antennas, Spans (bridges) and Earth (cliffs).

“My son called me and asked me the day before Father’s Day if I wanted to jump. So, we combined it into a birthday/ Father’s Day jump and that’s how we did it. This jump was my third jump off of Perrine Bridge. I have also done two jumps off of KL Tower in Malaysia, both tandems with my son,” Chuma says.

Chuma’s son just happens to be one of the premier BASE jumpers globally.

“My son, Sean, is the pioneer of tandem BASE jumping. He is known as one of the best in the world with over 9,000 BASE jumps. I believe over 1,500, maybe more, are tandem,” Chuma adds.

What is required to do a tandem BASE jump?

“You have to be less than 175 pounds and that’s about it. He goes through the safety routine, what you need to do and all that stuff and then you go out to the bridge. He goes over everything again at the bridge and then you go out there and

you try to stay home which is impossible and you jump. It is one of the most fascinating things I think I have done; everybody will enjoy it. You can also go to Moab, Utah, and jump and also Monte Brento, Italy, and jump,” Chuma says.

The Italian location has established strict requirements, although self-enforced, in order to jump there.

For solo jumping, Chuma says that taking a class would be a good starting point. He says classes require students to have many skydives. His son’s class requires 200 skydives.

“There are some people out there that teach BASE jumping with no experience at all; that is crazy. I have watched many people hit the trees and get hurt by not having any experience whatsoever. I did solos because my son is a base jumper. I did two and that’s about all I’ll ever do, because as other people watched, they wanted to let their friends do BASE jumps and it was too dangerous, so my son said stop and we did,” Chuma says.

In terms of safety protocols, Chuma says that with BASE jumping, there are no reserve chutes, so you really can’t make a mistake.

“Off of Perrine Bridge, six seconds you hit the water or the ground if you’re chute doesn’t open. There have been many people that get line tangled, they have to get out of it quick enough to not get hurt; some do, some don’t. The best thing to do in BASE jumping is not be stupid; most people that get hurt bad, or don’t make it, do stupid things,” Chuma says.

He says that there are very few that have fatalities that keep their head straight and stay calm.

“Not saying that you’re not going to get hurt. It is one of the most dangerous sports in the world. The biggest thing is packing your chute,” Chuma says.

He says that this is the primary safety protocol, and his son is very meticulous about it.

Did Chuma’s previous jumps prepare him for the Father’s Day jump; especially at 73?

“I’m not sure a whole lot prepared me for my Father’s Day/

birthday jump. Getting over the rail of the bridge every time is scarier than hell. It’s difficult because I am old and my body doesn’t bend and my legs were terrible getting over that rail. Your mouth gets dry, you look down you’re scared,” Chuma says.

He says that the experience with the rail was the same with the previous jumps.

“But once we jump, it’s the most fascinating sensation you’ll ever feel. I would do it again and again. I’m going to be scared as hell getting over that rail. Now I do plan to go to Moab, Utah, and jump off of a cliff and I do plan someday hopefully, before I get too old, to go to Brento, Italy and jump out there off of a 5,000-foot cliff. Will I be scared; hell yes!” Chuma says.

What extra challenges are there, even with a tandem jump, for a 73-year-old?

“I think the biggest challenge is, no matter who you jump with on a tandem skydive, a tandem BASE jump, you have to trust that person with your life. I used that analogy in a safety huddle to give a perceptive of a safety moment and I said patients need to trust us in the hospital as I had to trust my son on that tandem BASE jump,” Chuma says.

He says weather conditions are also a big factor.

“There are times we stood on the bridge for 45 minutes watching the wind. One of the good things about my son is, if he doesn’t feel comfortable, we walk off the bridge; that’s why I’m safe and alive today,” Chuma says.

What advice would Chuma give to someone contemplating their first BASE jump?

“If you’re going to do a tandem, investigate the person you’re going to jump with. There are several out there. Check them out, check their history. As far as doing your first BASE jump, have skydives and take a class from some reputable instructor. I highly recommend that before attempting to BASE jump,” he says.

Chuma has been in the biomed business for 54 years. He started out in the Air Force and then worked for ServiceMaster. He entered the management ranks, but later went back to work as a technician, which he considers a good decision.

“I have enjoyed my career; I wouldn’t trade it for anything. I would urge anybody that loves healthcare and being part of the system to go for it,” he says.

Take it from a 73-year-old who jumps off bridges; biomed is a good career. Anyone with the guts to jump off a 486-foot bridge is worth listening to.

“You’re never too old to feel alive.” — Mike Chuma

Royal Philips and Masimo have renewed a multi-year strategic collaboration. The companies are taking a bold new approach in accelerating the development and delivery of next-generation patient monitoring solutions, according to a press release.

“This expanded agreement reflects our commitment to empower clinicians with smarter, more integrated technologies that support better outcomes across the continuum of care,” the release states.

A central objective of the partnership is a joint effort to integrate Masimo’s advanced monitoring technologies –including SET pulse oximetry, Radius PPG, and a range of sensor technology – into Philips’ multi-parameter patient monitoring platforms.

“This integration supports clinicians with reliable data and actionable insights across bedside monitors, central stations, and wearable solutions, while giving them the flexibility to use their preferred measurement technologies within a single, unified system. By embedding these capabilities into Philips’ monitoring ecosystem, the collaboration aims to reduce complexity, enhance interoperability, and deliver streamlined tools that support timely decision-making and continuity of care,” the release states.

“Building on this foundation, Philips and Masimo also plan to

collaborate on the development and co-promotion of nextgeneration monitoring solutions that reflect emerging clinical needs and evolving market demands such as the need for greater patient mobility,” it adds. “These efforts are focused on advancing smart, connected care and expanding access to innovative technologies, including AI algorithms, that have the potential to improve patient care over time.”

“Our priority is helping clinicians deliver the best possible care to their patients, and that means staying ahead of the curve,” said Julia Strandberg, executive vice president and business leader of connected care at Royal Philips. “This partnership allows us to respond quickly to evolving clinical needs and market trends, integrating proven technologies into solutions that are easy to use, reliable, and scalable.”

“We are excited to continue to partner with Philips to bring Masimo’s newest innovations in wearables and artificial intelligence to Philips’ platforms,” said Katie Szyman, CEO of Masimo. “Expanding our strong, long-standing partnership with Philips allows us to build on our shared legacies of innovation and helps ensure that Masimo’s best-in-class technologies reach even more patients. Together, Masimo and Philips will continue to empower clinicians to transform patient care.”

TRIMEDX has been named one of the Top 100 Global Inspiring Workplaces by the Inspiring Workplaces Group, ranking #45 on the 2025 list. This global recognition follows TRIMEDX’s recent selection as a Top 100 in North America (30th) announced earlier this year.

“Being named among the world’s most inspiring workplaces is a testament to our associates and the culture we’ve built together,” says TRIMEDX Chief Human Resources Officer Dawn Griffin. “Leadership at TRIMEDX means listening, supporting, and growing together. This recognition reflects our shared commitment to making TRIMEDX a place where people thrive.”

TRIMEDX was previously ranked #30 globally and #29 in North America in 2024. The 2025 Global Top 100 list was drawn from the highest-scoring winners across seven regions,

including North America, Europe, Asia, and Australasia. Entrants were evaluated on six key elements:

• Culture and purpose

• Leadership

• Wellbeing

• Inclusion

• Employee voice

• Employee experience

According to a statement from Inspiring Workplaces, “The quality of submissions from each region has raised the bar, making it the strongest year our independent judges have ever seen. It shows that more business leaders are truly putting their people first and seeing real benefits. It also highlights the positive, meaningful changes happening in workplaces around the world, as reflected in entries from every region.”

Kaiser Permanente and Renown Health announced their agreement to jointly own and operate a health plan and outpatient care delivery system that will bring Kaiser Permanente to northern Nevada beginning in 2026.

This relationship brings together two nonprofit organizations with a shared purpose; to bring high-quality, value-based care to more people by improving access and expanding convenient and affordable care options in northern Nevada.

“Our mission calls us to bring high-quality, affordable health care and coverage to as many people and communities as we can. Our members, employers, physicians and community members have been asking us to provide our unique offering of value-based care in Nevada for some time,” said Greg A. Adams, chair and chief executive officer of Kaiser Permanente. “Working with the leading health care provider in northern Nevada, we will now have the opportunity to care for more people, help more employers offer coverage to their employees, and in collaboration with Renown Health, improve the health of this growing community.”

“We are pleased to introduce this relationship in Nevada, enhancing access to affordable care and coverage. By joining our health plan together with Kaiser Permanente, a respected national partner, we can expand access to affordable, highquality insurance coverage for even more Nevadans,” said Brian Erling, MD, MBA, president and CEO of Renown Health. “This collaboration strengthens our ability to keep care local, while bringing the scale, expertise and innovation of a national leader. Together, we are ensuring that individuals, families and employers across the state have more choices and better coverage. Together, we can improve the overall health of the

communities we serve and create additional capacity to care for more people.”

Under this new agreement, pending regulatory approval, Kaiser Permanente Nevada will offer health plan coverage to employers and the people of northern Nevada starting with open enrollment in 2026.

Kaiser Permanente Nevada creates a unique opportunity by pairing Hometown Health, the insurance arm of Renown Health, with Kaiser Permanente’s value-based care model to deliver what local consumers have asked for; high-quality and affordable care and coverage, close to home. Kaiser Permanente Nevada plans to open a multispecialty ambulatory health system with convenient locations in central and northern Reno. Members and patients will access multispecialty care, diagnostic, pharmacy and ancillary services at these locations and at the existing Del Monte Senior Care Plus Clinic in Reno.

Renown Health is a leading health system in Nevada and has owned and operated Hometown Health since 1988. Renown Health is the region’s largest, locally governed, not-for-profit academic health care network serving Nevada, Lake Tahoe, and northeast California. Renown Health will continue to operate as an independent nonprofit organization and health system and will continue to accept all current health insurance plans for patient care.

Through this agreement, Kaiser Permanente and Renown Health will enter into a joint venture. Kaiser Permanente will acquire a majority interest in Hometown Health. There are no immediate changes to Hometown Health/Senior Care Plus plans, networks or points of contact. The transaction is anticipated to close in early 2026 following required regulatory approvals.

Mindray has announced a deepened commitment to Mercy Ships through an expanded partnership that includes its North American organization.

This partnership underscores Mindray’s long-term, global support for the organization, which works tirelessly to deliver life-changing surgeries, medical training, and lasting healthcare improvements across Africa, a press release states. This collaboration further reinforces Mindray’s mission to advance medical technologies to make healthcare more accessible.

Mercy Ships operates two state-of-the-art hospital ships, Global Mercy and Africa Mercy, providing free surgical care and training programs to underserved communities. For regions with limited access to surgical care, including over 95% of sub-Saharan Africa’s population, these hospital ships serve as a beacon of hope, addressing critical healthcare disparities.

“At Mindray, we are driven by a vision of better healthcare for all. Our partnership with Mercy Ships allows us to live out this mission, ensuring that leading-edge medical technologies reach those who need them most, even in the most challenging environments,” said Wayne Quinn, president, Mindray North America. “By delivering robust, reliable solutions and supporting caregivers with advanced tools, we empower clinicians to provide lifechanging care. Through innovation, a steadfast

commitment to quality, and a focus on meeting clinical needs, we are proud to help break barriers and deliver on the promise of equitable healthcare worldwide.”

Through this partnership, Mindray North America is playing a pivotal role by equipping Mercy Ships with innovative medical technologies that elevate patient care and strengthen healthcare capacity, according to the release. The donation of its technology, including multiple cutting-edge ultrasound systems, highlights Mindray’s ongoing investment in empowering medical teams with best-in-class tools enabling high-quality care in the most challenging scenarios.

Since initiating its relationship with Mercy Ships in 2017, Mindray’s global organization has consistently provided devices and technical support that underpin the success of its medical infrastructure. Today, both ships operate with over 350 Mindray systems, including patient monitors, anesthesia machines, ultrasound machines, defibrillators, and central monitoring solutions. The expanded partnership to include Mindray North America solidifies the company’s role as a critical partner in the Mercy Ships’ life-saving work. Together, Mindray and Mercy Ships aspire to deliver over 50,000 life-changing surgeries while building lasting healthcare capacity – continuously reaching higher to expand access to quality care for those who need it most.

AMX Solutions, a company specializing in portable AMX4+ X-ray systems, is offering a full rebuild service designed to restore units inside and out, extending their useful life for healthcare facilities.

Unlike standard refurbishing, the company said its approach involves a complete rebuild from top to bottom, ensuring units look and function like new.

“There is a world of difference between simply refurbishing and actually rebuilding your AMX unit,” said Lee Ready, president of AMX Solutions.

The rebuild process includes installation of new components such as OEM paint, hardware, GE logo and function labels, a nine-battery set with test block, custom reinforced top cover, rebuilt collimator with front panel and cable, caster wheels with an updated bearing design, a main wiring harness, HV cables, rotor and arm brake cables, drive belts, a hand switch with hanger, bumper pads, wear strips, noise suppressors, filters, grounding cables and a hospital-grade cord reel.

Rebuilt items include the vertical column, horizontal arm, drive wheels, drive motors and drive handle assembly. Tubes are tested, cleaned, sanded and repainted.

AMX Solutions has been in the imaging industry for more than 20 years. The company’s technicians perform all rebuilds, painting and service 100% in house. In addition to complete rebuilds, AMX Solutions offers individual replacement parts and batteries for AMX4+ and Optima units.

“Our mission is to let the industry know that AMX Solutions is still here, with the same team who built our reputation for quality service and customer care,” Lee Ready said. “We want to rekindle old partnerships and create new ones while continuing to provide the same level of excellence people have come to expect from our brand.”

AMX Solutions remains family-owned and operated, led by Ready along with his sons, Campbell and Leland.

Baxter International Inc. has launched the Welch Allyn Connex 360 Vital Signs Monitor, its next generation patient monitoring device. As the latest innovation in Baxter’s connected monitoring portfolio, Connex 360 offers an advanced connectivity and security platform, customizable configurations based on a hospital’s clinical routines, and upgraded capabilities that set the stage for future functionality and enhancements, a press release states. With automated clinical documentation, Connex 360 is designed to simplify the clinician experience and allow more time to focus on patients.

“There is nothing more important than keeping patients safe, especially when time is of the essence,” said Julie Foster, president of front-line care at Baxter. “Care teams rely on vital signs monitoring to help detect changes in their patients’ conditions and make informed decisions. With Connex 360, we are advancing patient monitoring to provide care teams with the timely insights they need at the bedside, so they can make the most of every moment with their patients.”

In today’s complex healthcare environment, care teams and hospital staff are being asked to do more with less, and timely, accurate, and secure patient information is critical. Baxter’s Connex 360 monitor captures vital signs for adult, pediatric and neonate patients, including blood pressure, temperature, pulse rate, respiration rate and blood oxygen levels. Designed for optimized workflows, care teams can obtain a full set of patient vitals in less than one minute and automatically send to the electronic medical record, helping to reduce manual data entry errors and support informed care decisions.

This secure data flow is powered by Baxter’s cloud-based DeviceBridge platform, which works behind the scenes to

help enable accurate data transfer from Connex 360 to hospital IT systems, including the EMR. DeviceBridge also helps support secure device access and clinical data interoperability across Baxter’s ecosystem of connected devices.

Additional key features of Connex 360 include:

• Comprehensive security: Enhanced security features, including end-to-end encryption and certificate-based authentication, help protect patient and facility information.

• Intuitive interface: Baxter’s largest and most responsive color touchscreen allows intuitive navigation and the ability to see more patient data on one screen.

• Enhanced customization: Customizable Early Warning Score protocols alert clinicians to patient deterioration or changes in condition, and fully configurable monitoring modes support the individual needs of the patient.

• Easy upgrades and maintenance: Software upgrades for clinical, operational, and cybersecurity enhancements are streamlined, helping to reduce the burden on hospital IT teams and allowing for enhanced functionality over time.

Baxter expanded its presence in the patient monitoring space through its acquisition of Hillrom and the Welch Allyn portfolio. Welch Allyn has a longstanding history of delivering innovative patient monitoring solutions that support patient care across healthcare settings, from hospitals to outpatient care. Baxter has continued to invest in connected monitoring, with Connex 360 joining the company’s trusted lineup of vital signs solutions. The Connex 360 monitor received U.S. Food and Drug Administration 510(k) clearance and is available for hospitals and health systems to order in the U.S.

Dallas is set to host the Fall 2025 MD Expo. The popular HTM conference will once again feature top-notch education, networking events and an exhibit hall filled with industry-leading companies.

The MD Expo, held November 11-12, 2025, is pre-approved for up to 8 CEUs. Additional CEUs can be earned via the H.O.T. Workshops:

• H.O.T. Workshop: Contrast Injector Operation and PM Training (Session #1 or #2) – 4 CEUs

• H.O.T. Workshop: Ultrasound Systems – 7.5 CEUs

The educational lineup features something for everyone from biomed student to seasoned HTM pro and hospital leadership. Topics on tap include cybersecurity, leadership, troubleshooting, imaging devices, hospital inspections and more.

This year, the fall MD Expo will take place during Veterans Day.

TechNation and parent company MD Publishing have announced a special program honoring veterans as part of the fall 2026 MD Expo. And, as always, MD Expo registration if FREE for all active military members. Register today at MDExpoShow. com.

“MD Expo is honored to host our conference over Veteran’s Day. We plan on paying tribute at the event to those in our industry who have served but need your help in making our vision a reality!” the company announced.

Veterans were invited to submit photos of their time in service along with their name, rank, and branch of military. The photos will be displayed for everyone to take a minute and see the men and women who served in the U.S. Armed Forces and continue to take care of a nation as vital members of the healthcare

Enter the contest and help TechNation celebrate. Fill out the short form at 1technation.com/contest for a chance to win one of 12 prizes, each valued at $150 or more!

Additional entries to win can be acquired by sharing on LinkedIn or submitting a photo. Each month, a winner will be selected and featured in TechNation magazine! September winner is Matt Oetker.

Find out more information on Page 92.

industry.

The MD Expo leadership summit and reverse expo are extra options available to advanced HTM professionals.

Additional special events include a new Lunch and Learn set to be held from 12:30-2:30 on Nov. 11. Young HTM pros are invited to attend the popular Young Professionals at MD Expo social event that serves as an outstanding venue for networking with colleagues. Also, the Women In Leadership (WIL) organization will host a women-only W.I.L. Lounge on Tuesday evening.

Everyone is invited to what is sure to be the biggest event at the fall MD Expo – the Texas Throwdown: A Night of Boots, Beats and BBQ.

Afterall, everything is bigger in Texas.

So, mosey on over Wednesday night for a finale party like no other! The Lone Star spirit will be in full effect. Grab your cowboy boots and denim (the dustier the better) and join new and old HTM community members for an unforgettable evening filled with live music, line dancing, BBQ.

Be sure to check out the curated whiskey tasting, then hit the floor for a round of two-steppin’ to the sounds of a live band. Between dances, swing by the Build-Your-Own Bandana Bar to craft a keepsake – the perfect accessory for the night’s festivities.

Whether you’re a seasoned cowboy or just in it for the BBQ and beats, the Texas Throwdown promises a night of good times, great company and the perfect MD Expo celebration.

Find more information and register today at MDExpoShow.com.

Why do hundreds of HTM professionals attended the TechNation Webinar Wednesday series each year? MD Publishing Webinar Marketing Manager Linda Hasluem used a survey to find out!

Survey results show that 60% prefer the live webinars and 88% of respondents said they would appreciate more interaction with presenters via polls, PDF handouts and a longer Q&A session.

“We haven’t conducted a webinar survey since 2023, and I know we have many new attendees since then. So, I thought it would be the ideal opportunity to test some new ideas we have planned for 2026, but at the same time get updated thoughts/suggestions on how we can improve our webinars, etc.,” Hasluem explained when asked how she came up with the idea to do a survey.

“We had a great response, and I’m sure the chance to win a $100 Amazon gift card helped! The suggestions and ideas were interesting and the overall consensus for our two new ideas was very favorable and will certainly help us plan for next year. We had no negative responses, so that’s a plus point in my books, as it means we are doing a good job in providing the HTM industry with what they want from a webinar,” she added.

The two new ideas for 2026 include a Roundtable Spotlight session and “Unlock and Learn” webinars.

The Roundtable Spotlight will provide five companies exclusive access to participate in a live roundtable panel discussion webinar. Survey participants overwhelmingly showed interest in this option with 90% selecting “Likely” or “Maybe” when asked if they found it valuable.

The “Unlock and Learn” series will offer an engaging and structured learning experience where a company presents a series of webinars. Attendees must pass a post-webinar test with a score of at least 75% in order to access the next webinar in the series.

The survey found that 82% selected “Likely” or “Maybe” when asked if they would watch this type of webinar series.

The 2025 TechNation Webinar Wednesday series continues to be popular among HTM professionals. Registrations through August added up to 1,421 with another 948 registrations for the Tools of the Trade Live Demo webinars this year. Find out more

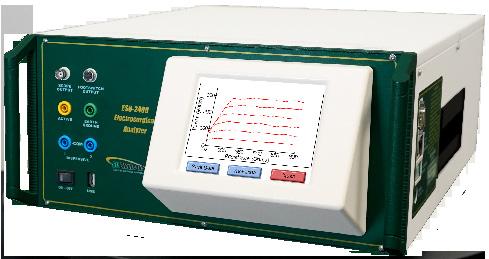

Admar Neuro is a trusted partner for outsourced biomedical and tech support.

It’s goal since 1984 is to provide high-quality, pre-owned EMG/NCV and EEG systems to enhance patient care through precision and reliability. As a leader in neurodiagnostic devices, Admar Neuro is committed to exceptional service and advancing neurological diagnostics worldwide.

The company’s mission is spelled out on its website as, “To empower private practices with reliable biomedical and tech support solutions, ensuring seamless operations through expert service, repair, and replacement of neurodiagnostic equipment.”

Admar Neuro’s vision is, “To be the leading provider of innovative, dependable biomedical services, setting the standard for excellence in neurodiagnostic equipment support and fostering long-term partnerships with healthcare providers.”

TechNation recently interviewed CEO Adriana Muñoz to find out more about Admar Neuro’s 40 years of experience and what is on the horizon going into 2026.

Q: WHAT ARE SOME OF THE SERVICES AND PRODUCTS YOU OFFER? IS THERE A SPECIFIC OR NEW ONE YOU ARE EXCITED ABOUT RIGHT NOW?

Muñoz: At Admar Neuro, we specialize in service, repair,

and refurbishment of neurodiagnostic equipment including EMG, EEG, VNG and TCD systems. We also offer refurbished device sales, rentals and consumables. Right now, we’re especially excited about our expansion into ultrasound repairs.

Q: HOW DOES YOUR COMPANY STAND OUT IN THE MEDICAL EQUIPMENT FIELD?

Muñoz: We are 100% focused on neurodiagnostics. With more than 40 years of experience, our deep specialization enables us to deliver faster turnaround times, higher first-time fix rates, and stronger technical support than general repair providers.

Q: WHAT IS ON THE HORIZON FOR YOUR COMPANY? DO YOU HAVE ANY GOALS YOU WOULD LIKE TO ACHIEVE IN THE NEAR FUTURE?

Muñoz: We’ve launched an asset management program to be the one-stop shop for neurodiagnostic equipment life cycle support – covering everything from preventative maintenance and repairs to rentals and replacements.

Q: IS THERE ANYTHING ELSE YOU WOULD LIKE OUR READERS TO KNOW?

Muñoz: We’re eager to partner with industry peers and OEMs, either by bringing our expertise into their organization or serving as an outsourced provider. Our mission is simple: to be the go-to shop for all things neurodiagnostics.

For more information, call 728-900-3969 or email sales@admarneuro.com.

BY JEANNINE BLAKE, P h .D., RN

It’s 3 a.m. in a busy ICU. Nurses move between rooms, managing a constant stream of patient needs. In one of them, a nurse – working his third shift in a row – is running on four hours of sleep, holding out for 7 a.m. and a few nights off. His patient is critically ill. The room is filled with equipment, a tired family sits vigil, and providers come and go asking questions or performing assessments. Phones ring. Labs are due. Medications need administering.

An infusion pump alarm goes off. He sighs, walks over, and squints at the machine. Another occlusion alarm, again with no clear cause. He opens the pump, taps the tubing, gives it a slight tug, checks the connections, closes the door, and presses start … then mentally crosses his fingers that it will run for more than five minutes. The family watches closely. He offers a reassuring nod and a practiced smile, the kind that says, “Everything’s fine,” even though it doesn’t feel fine because this darn thing won’t stop beeping, but alas, this is just what happens night after night.

This nurse is educated and experienced. He knows the tips and tricks for managing these alarms. But they persist –baffling and disruptive. Is it the pump? The fluid? The patient? The training manuals never cover this in a real-world context. They list what to do, but not why. Not in a way that fits with the reality of clinical care or offers pearls of wisdom to critically think through these kinds of challenges. They don’t account for how fragmented, overloaded and error-prone this environment really is.

Medical device safety cannot rely on users operating at their best. Or even at their mediocre. Real clinical care, especially in high acuity settings like the ICU, happens every day, even on caregivers’ worst days, regularly. We can’t fix this by just adding another training session or telling someone to pay more attention.

The clinical environment is cognitively overloaded, emotionally intense and frequently understaffed.1 Efforts to fill

staffing through shift rotations, floating between units, or travel staff increase the odds that a caregiver will be out of their element, even if they are familiar with the tasks and equipment involved. Mistakes are inevitable, believing otherwise is the biggest error of all.² The system must be designed to prevent human mistakes from becoming patient harm. And in healthcare, part of that system includes the medical devices we use to carry out care.³

Devices must be designed to work with humans, not despite them. We cannot assume that users will recall complex training or be mentally prepared to operate devices “as taught.”⁴ We must start from a different premise: people are fallible, and systems must account for that.

Human factors engineering has long emphasized that education and training should not be the primary method of mitigating use error.³ ⁵ ⁶ And yet, when something goes wrong, clinicians are too often blamed, and then sent to retraining sessions that do little to change outcomes. The message becomes: “Do better.”

Training may be the only option in the short term, but it should NEVER be considered a long-term fix. That fix must come from technology, whether through a software patch, hardware update, or full redesign. Yes, those changes are harder. But they’re also more effective.⁷ And adopting that mindset creates space for innovation rather than defensiveness. It also empowers clinicians to speak up when something doesn’t work, without fearing blame, reprimand or judgement.

Devices must reflect the context in which they’re used. For nurses and other frontline clinicians, this context often includes multitasking, frequent interruptions, fatigue and insufficient support.⁸ And yet, in these environments where the consequences of error are high, the tolerance for uncertainty is low.

Despite these stakes, medical technologies are too-often designed without enough meaningful input from their primary users about how it may fit into their daily workflow. That

disconnect has real consequences, and when systems break down, the burden falls on the human user, in the form of more training on how to navigate the broken system.6 Each system breakdown, and each resulting training burden, is just one more responsibility placed on the human instead of the device.

But human factors principles are clear: if two users make the same mistake, it’s not a user problem. It’s a design problem.

Nurses are highly educated professionals. But they’re still human and human error should be expected, anticipated, and prevented through robust systems, not punished or patched with more training.⁹ We need to shift the way we think about accountability. Errors and lapses are not moral failings or evidence of incompetence.² They are signs that the system, including its devices, is failing to support the people within it and the patients whose care relies upon it.

We don’t need to teach nurses to “try harder.” We need devices built for the messy, high-stakes, beautifully human environments in which nurses operate. Training may patch the system for a while, but only design can truly fix it.

Until we stop blaming individuals and start fixing systems, the same errors will continue, and we’ll keep blaming the same people (or the new ones who replace the ones who’ve burned out). It’s time to build devices for real people, doing real work, under real pressure. Because education is not the answer, design is.

– Jeannine Blake is an assistant professor affiliated with the Elaine Marieb Center for Nursing and Engineering Innovation at the University of Massachusetts Amherst. Opinions and insights are her own.

References

1. Carayon P, Gurses AP. Nursing workload and patient safety — A human factors engineering perspective. In: Hughes R, ed. Patient Safety and Quality: An EvidenceBased Handbook for Nurses. Agency for Healthcare Research and Quality; 2008.

2. Kohn LT, Corrigan JM, Donaldson MS. To err is human:: building a Safer Health System. vol 6. National Academies Press; 2000.

3. Carayon P, Wetterneck TB, Rivera-Rodriguez AJ, et al. Human factors systems approach to healthcare quality and patient safety. Appl Ergon. Jan 2014;45(1):14-25. doi:10.1016/j.apergo.2013.04.023

4. Reason J. Human Error. Cambridge University Press; 1990.

5. Russ AL, Fairbanks RJ, Karsh BT, Militello LG, Saleem JJ, Wears RL. The science of human factors: separating fact from fiction. BMJ Qual Saf. Oct 2013;22(10):802-8. doi:10.1136/bmjqs-2012-001450

6. FDA. Applying human factors and usability engineering to medical devices: Guidance for industry and Food and Drug Administration Staff. 2016. February 3. https://www. fda.gov/regulatory-information/search-fda-guidance-

documents/applying-human-factors-and-usabilityengineering-medical-devices

7. OSHA. Identifying Hazard Control Options: The Hierarchy of Controls. Washington, DC: U.S. Department of Labor.

8. Westbrook JI, Woods A, Rob MI, Dunsmuir W, Day RO. Association of interruptions with an increased risk and severity of medication administration errors. Archives of Internal Medicine. 2010;170(8):683-690.

9. Reason J. Human error: models and management. BMJ. 2000;320:768-70.

As pressures mount for health system leaders nationwide, ECRI convened four virtual roundtables with 17 C-suite healthcare leaders from across the country, representing integrated health systems, children’s hospitals, rural providers, and national associations. The goal was to capture unfiltered insights into what truly drives and sustains patient safety and continuous improvement.

The white paper – published on World Patient Safety Day, September 17 – is the first in a series of articles born from the ECRI C-Suite Roundtables featuring candid insights from healthcare leaders. Download the white paper at www.ECRI.org/News.

ECRI President and CEO Marcus Schabacker, MD, Ph.D., and ECRI Chief Medical Officer Dheerendra Kommala, MD,

moderated the discussions.

“This is a tumultuous time for healthcare leaders and frontline providers in our nation,” said Schabacker. “We launched this roundtable series to dive deeper into the issues they’re facing, and how they elevate patient safety despite these challenges – from shrinking resources to medical misinformation to persistent causes of preventable harm. Together we share what’s truly moving the needle. Only by learning from one another and sharing best practices can we break the cycles that have long held our industry back.”

• Proactive systems prevent harm. Leaders are shifting from reactive models to proactive approaches by hardwiring learning into daily operations and embedding human factors into workflows.

• System design and standardization saves lives. Safety issues can cause longer stays and liability. Welldesigned, standardized systems make the safe choice the easy choice and ensure consistent outcomes across sites.

• Safety is a sound business strategy. Health systems that embed safety and create reliable systems can reduce extended stays, boost staff engagement, strengthen payer negotiations, increase patient satisfaction and improve margins.

There was broad consensus among C-Suite Roundtable participants on the challenges and the path forward. The groups also discussed these challenges, slated for forthcoming publications in the series:

• How organizational culture shapes safety reporting and outcomes

• Navigating care delivery without trusted federal agencies as beacons of truth

• Role of boards and executive leaders in safety and quality

Participants included (in alphabetical order):

• Rick Bassett , MSN, RN, APRN, ACNS-BC, CCRN, FCNS, LSSGB, President of the National Association of Clinical Nurse Specialists, and Adult Critical Care Clinical Nurse Specialist at St. Luke’s Health System;

• Richard Bates , MD, Chief Executive Officer, Thunder Bay Community Health Service;

• Matthew Davis , MD, MAPP, Executive Vice President, Enterprise Physician-in-Chief, and Chief Scientific Officer, Nemours Children’s Health;

• Mindy Dunkerley, MBA, MSN, RN, Chief Quality Officer, Independence Health System;

• Michael Fiorina , DO, FAAFP, Chief Medical Officer, Independence Health System;

• Jonathan Gleason , MD, EVP and Chief Clinical Officer, Prisma Health;

• Djana Harp , MD, MS, MBA, Chief Medical Officer, Norwalk Community Health Center;

• Omar Hasan , MD, MS, MPH, Chief Quality Officer, MaineHealth;

• Mark Leahey, President & CEO, Medical Device Manufacturers Association;

• Kristie Lenze, CEO/CFO, Keystone Rural Health Consortia;

• Tara Jo Manal , PT, DPT, FAPTA, Vice President of Scientific Affairs, American Physical Therapy Association;

• William G. Morice II , MD, PhD, CEO, Mayo Clinic Laboratories;

• Michael Seim , MD, Chief Quality Officer, WellSpan;

• Anne Marie Watkins , DNP, MSHCA, RN, CENP, Chief Nursing Executive, UCI Health;

• Jacqueline Webb , CPNP, Quality, Risk, and Lab Director, Tri-Area Community Health;

• James Werth, Jr. , PhD, ABPP, Chief Executive Officer, Tri-Area Community Health;

For more information, visit ECRI.org.

Mako is a cutting-edge solution that revolutionizes your way of work with plug-and-play simplicity. It’s our most efficient and versatile meter, delivering the highest practical accuracy experienced with the industry’s broadest application range. Beyond the hills of spreadsheets, Ocean NextTM software awaits. Ocean NextTM gathers data from Mako in real-time so you can truly excel. Immerse yourself in a world of streamlined routines and complete traceability, Ocean NextTM.

BY JUSTIN LACKEY

rom hospitals to senior living facilities to medical supply companies, no detail is too small. A single piece of misplaced equipment can delay care, increase operational costs and compromise patient safety. Yet, many facilities still rely on spreadsheets or outdated systems to manage millions of dollars’ worth of medical devices and equipment. For biomedical and healthcare technology management (HTM) professionals responsible for maintaining uptime and compliance, the right tools can prevent daily maintenance challenges.

Modern asset tracking systems offer more than just location monitoring. For hospitals and healthcare networks, the key to effective asset management lies in centralizing life cycle data, streamlining preventive maintenance, and enabling smarter facilities and cleaning protocols. These capabilities are no longer

nice to have; they’re essential in the high-stakes world of patient care.

LIFE

Effective asset tracking provides a full view of the product life cycle, from purchase and deployment to retirement or replacement, enabling teams to go beyond simply knowing a device’s location. Centralized records enable biomedical teams to access a wide range of information, including warranty status, service history, performance benchmarks and cost of ownership.

For example, CHG Healthcare, a leading staffing provider in the medical space, used advanced asset tracking to streamline the management of its equipment across multiple sites. By consolidating monitoring into a single platform, CHG Healthcare not only gained real-time visibility but also reduced the risk of duplicate purchases and unmanaged inventory. Transparency of this kind is particularly critical for hospitals, where purchasing decisions must balance

“When devices are properly tracked, maintained, and optimized, the result is more time for patient care and fewer preventable errors.”

patient care needs on tight budgets.

Life cycle management also plays a vital role in meeting compliance requirements from agencies such as The Joint Commission and the Centers for Medicare & Medicaid Services. Healthcare facilities can avoid last-minute scrambles during audits and maintain a strong regulatory posture year-round with documentation readily available.

One of the most tangible benefits of advanced asset tracking is the transformation of maintenance workflows. Preventive maintenance scheduling shifts operations from being reactive, saving repair and replacement budgets. Immediate benefits include reducing the number of emergency repairs, improving equipment uptime and extending the lifespan of assets.

Biomedical professionals can set up automated alerts for routine maintenance, ensuring that devices are inspected, calibrated, and serviced according to manufacturer recommendations or internal schedules. Maintenance logs are tied to each asset profile, allowing technicians to quickly see what work has been completed, who performed it, and when it was done, thereby avoiding redundant work and enabling better team coordination.

Analyzing maintenance trends enables facilities to identify underperforming equipment and assess total cost of ownership. These insights support more effective capital planning and guide smarter decisions around upgrades or replacements.

While much of the focus in asset tracking centers on clinical equipment, there’s growing recognition of its value in facilities management and infection prevention. Cleaning schedules, disinfection protocols and room turnover procedures can all be standardized and verified through the same asset management system.

When the pandemic heightened scrutiny on infection control, NexClean, a provider of cleaning and disinfection services for healthcare environments, needed greater accountability across its operations. By implementing advanced asset tracking, the team developed digital checklists for cleaning workflows,

monitored equipment usage by location, and documented adherence to CDC-recommended protocols. That level of transparency became critical as environmental services played a direct role in both infection prevention and patient satisfaction.

In-house healthcare maintenance teams can adopt similar models to improve room readiness, monitor HVAC and water filtration systems, and ensure critical areas such as operating rooms or NICUs meet cleanliness standards.

To succeed, asset tracking must be more than a backend system. It needs to be integrated into the daily workflow using mobile-friendly applications and customizable interfaces, with features such as barcode scanning, photo attachments and user-specific access levels. These tools make it easy for teams to update records in real-time, 365 days a year, 24 hours a day, regardless of their location.

Integrating manuals, SOPs and service records into each asset profile provides technicians with all the necessary information at their fingertips. Providing easy access to these assets helps reduce downtime, improves training efficiency and promotes consistency across teams and shifts.

Hospitals face unprecedented challenges, including staffing shortages, supply chain issues and heightened scrutiny of operational efficiency. Asset tracking may not solve all these issues, but it is a foundational piece of the puzzle. When devices are properly tracked, maintained, and optimized, the result is more time for patient care, fewer preventable errors and greater confidence in the equipment that powers modern medicine.

For healthcare professionals, adopting a comprehensive asset management solution is no longer optional. It’s a strategic decision that supports patient outcomes, regulatory compliance and financial stewardship – all from one digital dashboard.

Justin Lackey is the president of Asset Panda, a cloud-based asset management platform.

Watch these webinars on-demand

The recent TechNation Tools of the Trade Live Demo webinar “ESA700 Series Electrical Safety Analyzers” drew strong global interest with 41% of attendees joining from outside the U.S. Sponsored by Fluke Biomedical, the session was eligible for 1 CE credit from ACI.

Fluke Biomedical Technical Sales Engineer Jamie Spragis, CBET, led the demo, sharing expertise and answering questions in real time. He noted Fluke teams worldwide are available to provide training and onsite demonstrations for those wanting a deeper dive into the ESA700 Series.

The ESA700 Series Electrical Safety Analyzers are Fluke Biomedical’s easiest-to-use models to date. Combining a safety analyzer and patient simulator, they deliver precision, versatility and portability in one package. Key features include:

• Small and portable – Run procedures on the go

• Auxiliary battery – Avoid power cycling between tests

• Touchscreen interface – Intuitive and efficient

• Standalone operation – Run procedures without a PC using OneQA workflow software

Spragis encouraged attendees to elevate their electrical safety testing with these tools.

The webinar set new benchmarks for registrations (289) and attendees (109), with 27 requesting follow-up from Fluke. A recording remains available at WebinarWednesday.live.

A trivia prize went to Mark Woodruff of California, who won a Swiss Force Meister Multi-Tool.

Survey feedback highlighted the analyzer’s strengths. Thomas Kockler of Technical Life Care cited “ease of use and adaptability.” David Banister of Clinical Engineering Services noted “automatic pushing of quantitative data to a CMMS.”

Todd Walker of Oregon Health & Science praised its “compact and versatile” design, while Bryan Medical Center’s David Miller called it a “cool package” for ECG and ESIs. Athira Ashokan of One Health added that it “simplifies workflows and improves efficiency while being user-friendly.”

As healthcare environments become increasingly connected, the need to secure biomedical devices while ensuring operational efficiency and patient safety has never been greater. A recent Webinar Wednesday presentation offered an in-depth look at how Claroty empowers biomedical engineering teams to integrate robust cybersecurity and device management into their daily workflows.

Webinar co-presenters David Guffrey and Joe Walker explored:

• How to provide a comprehensive and accurate inventory of connected medical devices.

• How teams gain visibility into patch levels, utilization trends, procurement planning and more.

• How actionable insights support smarter decisions for biomedical engineering technicians.

Attendees were also able to submit questions to the presenters for additional insights.

The webinar was sponsored by Claroty and 75 healthcare professionals tuned in for the live presentation. A recording of the webinar is available for on-demand viewing at WebinarWednesday.live.

Don Bass, who works in the biomedical engineering department at Jackson Park Hospital & Medical Center in

Illinois, won a Swiss Force Meister Multi-Tool.

Attendees provided feedback via a survey that asked “Excluding CE credits, why do you attend Webinar Wednesday?”

“To stay informed and updated on changes in the medical field biological equipment testing,” said Martin O’Brien, biomedical technician instructor, RTS-Medical.

“To stay as current as I can on HTM topics,” said Gerald McNeil, BMET III, GE HealthCare.

“Nowadays, AI is booming, and AI is integrated into our medical devices. This trend exposes our devices’ cybersecurity vulnerability to outside and inside. Thus, I need to know how I can prevent any future threats by attending these types of webinars,” said Tedd Koh, MET, Olive View UCLA Medical Center.

“I attend to expand my BMET knowledge and for exposure to topics and modalities I’m not too familiar with,” said Charitable Roosevelt, BMET, Endeavor IO.

For more information about TechNation’s Webinar Wednesday series, including upcoming webinars, visit WebinarWednesday.live. Find details about continuing education opportunities at the fall MD Expo in Dallas at MDExpoShow.com.

Registration on WebinarWednesday.live. Eligible for 1 CE credit from the ACI.

The FlowAnalyser PRO is IMT Analytics’ flagship benchtop gas flow analyzer, designed for biomedical engineers, independent service providers and medical equipment manufacturers. Engineered to test all types of mechanical ventilators, anesthesia machines and a wide range of other medical devices that generate gas flow and pressure, it combines the full capabilities of the industry-leading FlowAnalyser PF-300 series into one powerhouse. With the addition of an ultra-low-flow channel, the FlowAnalyser PRO can precisely measure across the entire spectrum, from the smallest flow rates and vacuum pressures to hospital gas line pressures and flows up to 300 L/min. Its 5-inch highresolution multi-touch display offers an intuitive, modern,

user interface. Advanced features such as profile handling, on-device testing applications, smart automatic trigger detection and data recording help streamline workflows, reduce handling errors and improve measurement accuracy. When paired with the OR-703 MultiGasAnalyser, a highprecision gas analyzer measuring CO₂, N₂O and all common volatile anesthetic agents, the FlowAnalyser PRO transforms into a complete anesthesia machine testing solution. Whatever the testing requirements are, the FlowAnalyser PRO delivers with the highest precision and seamless user experience.

For more information, visit imtanalytics.com

BY JAMES LINTON

As a BMET professor teaching over 100 students annually at St. Clair College, I’ve learned that while textbooks provide the foundation, real-world application is where students truly come alive. One of the most powerful tools I’ve integrated into my classroom isn’t a physical simulator or advanced diagnostic device — it’s MedWrench.

MedWrench is more than just a forum — it’s a living, breathing ecosystem of working professionals, real-time equipment issues, and community-driven problem-solving. For my students, it offers a unique window into the HTM world as it exists today — not how it was when I started my career long ago.

Here’s how I use MedWrench in my program and why I think more educators and technicians should consider doing the same.

Every week, I have begun discussing with my students a discussion post pulled directly from the MedWrench forums. It might be a service issue with a GE monitor, a strange DICOM error, or someone struggling to get a legacy sterilizer to pass a self-test.

Students are then asked to:

• Analyze the reported symptoms

• Research the equipment’s service manual (if available)

• Draft a hypothetical step-by-step troubleshooting plan During these discussions they’re evaluated not on being “right,” but on how well they think through the problem — this teaches structured diagnostic reasoning, something no multiple-choice test can replicate.

ENCOURAGING STUDENTS TO RESEARCH, ASK AND CONTRIBUTE TO THE ONLINE COMMUNITY

I challenge my more advanced students (especially in their final year) to actively contribute to MedWrench. That means:

• Posting their own questions

• Answering others if they have the expertise

• Sharing a tip they’ve learned from co-op or class

This builds:

• Confidence in their knowledge

• Digital professionalism — knowing how to ask smart questions

• A habit of lifelong learning and community involvement

TEACHING DIAGNOSTIC THINKING THROUGH REAL EQUIPMENT FAILURES

MedWrench provides a constant stream of authentic problems techs are facing in hospitals and clinics. These aren’t theoretical failures — they’re gritty, messy and sometimes unsolved.

I use them in:

• Case studies: We’ll break down an issue as a class, roleplaying as in-house techs or field service reps.

• Sim labs: I recreate the problem on similar devices in our lab, adding faults or failures for them to find.

• Assignments: Students write a mock service report with documentation and repair notes. This process teaches them more than just how to fix things — it instills:

• Accountability

• Logical sequencing

• Communication under pressure

When students see an issue on MedWrench and then experience something similar during their co-op or first job, it validates their preparation. They’re not blindsided because they’ve already walked through it intellectually.

Plus, by seeing how real techs document, communicate, and even disagree in the forums, students learn:

• How HTM professionals think in the wild

• That there’s no shame in asking for help

• That community is key in a field that changes daily

Whether you’re an instructor, manager, or working tech, MedWrench isn’t just a help desk — it’s an educational goldmine.

• Use it to find real examples to supplement your lectures

• Have students present cases in class

• Build assignments that mimic what they’ll face in the field

• Post challenges your department is facing and invite student input

• Use it to spot common issues or training gaps

• Take part in various TechNation challenges to build a sense of community

• Mentor without pressure sometimes even a single reply helps a student grow

In an industry as complex and ever-evolving as HTM, building bridges between generations is essential. MedWrench has become a bridge in my classroom — and it can be one in yours too.

For more information, visit medwrench.com.

Detect

Lightweight,

Stay

Helps

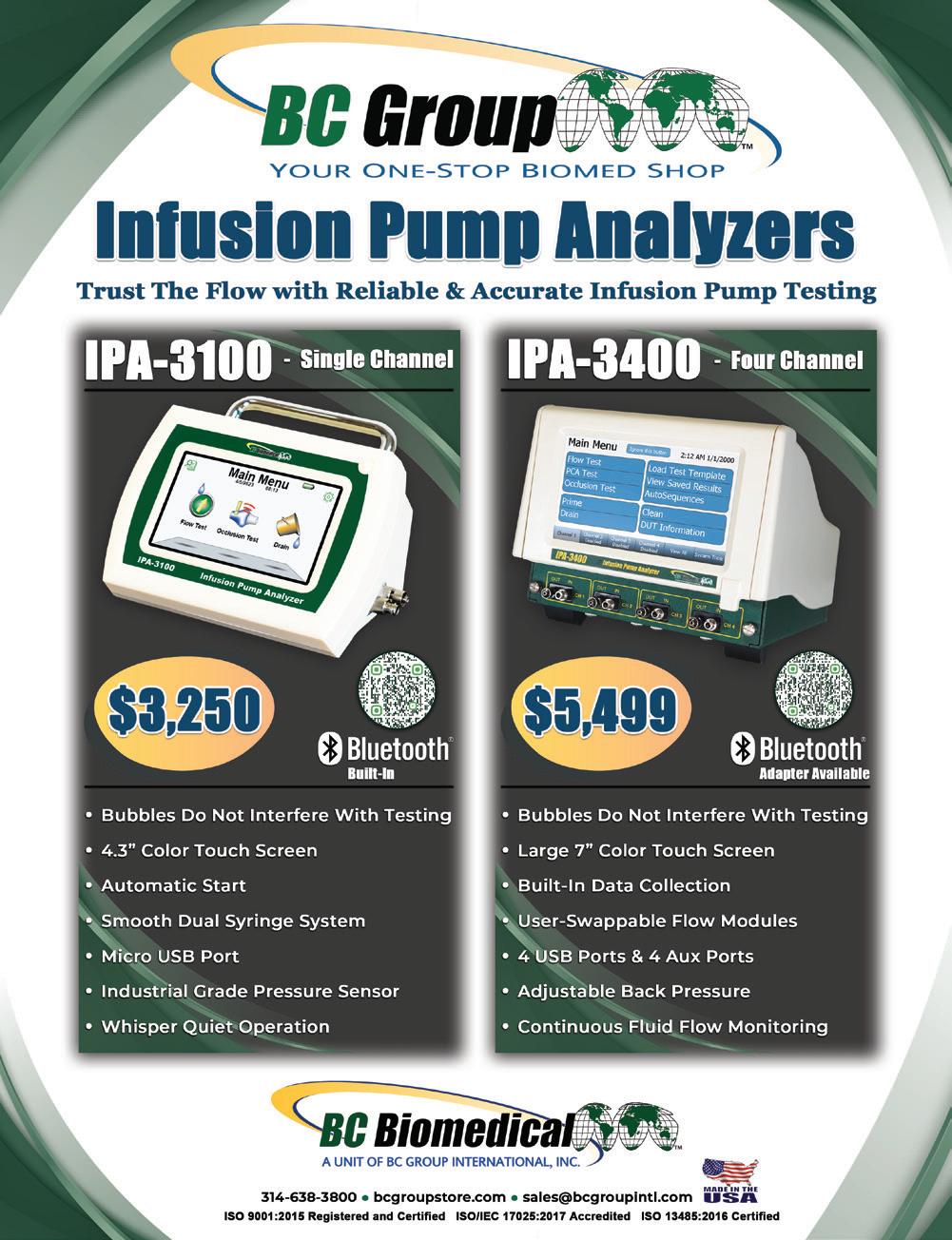

As HTM continues to evolve, the demands placed on test equipment are rapidly expanding – from improved automation and digital integration to enhanced portability, accuracy and reliability. In this Roundtable article, TechNation asked leaders across the test equipment landscape to share their insights regarding the latest trends, challenges and innovations shaping how biomedical professionals service and support medical devices.

Participants in this year’s Roundtable article on test equipment are:

• BC Group International Director of Business Development Justin Barbour;

• Datrend Systems Inc. Director of Business Development Owen Liu;

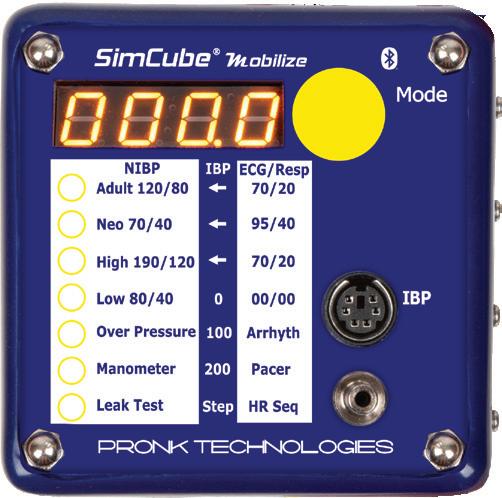

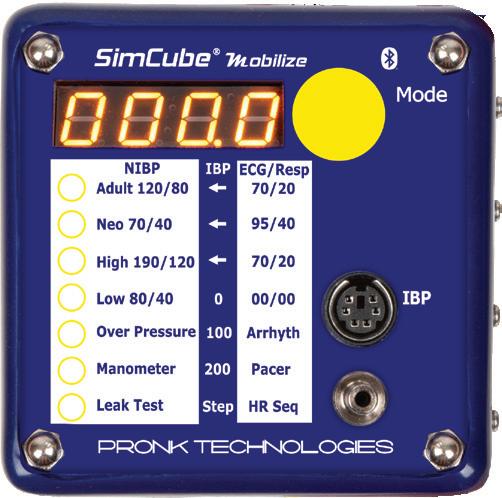

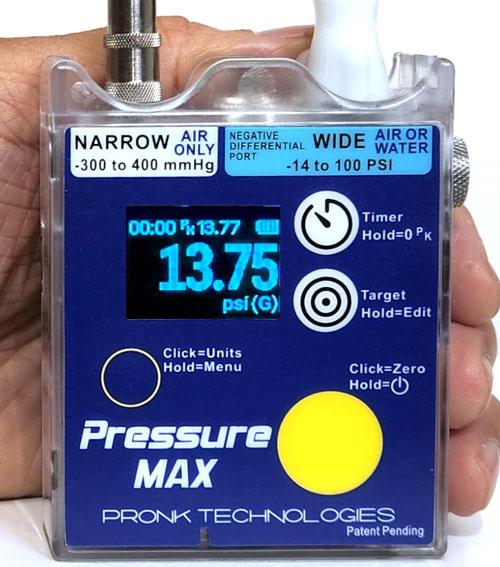

• Pronk Technologies Vice President of Business Development Greg Alkire;

• Rigel Medical Business Development Manager Lewis Lennard;

• RTI Group Vice President of Sales North America Steve Holmes; and

• Southeastern Biomedical Co-Owner Boyd Campbell, CBET, CRES, CHTM.

Q: WHAT TRENDS ARE YOU SEEING IN TEST EQUIPMENT DEVELOPMENT FOR THE SERVICE AND REPAIR OF MEDICAL DEVICES?

BARBOUR: There’s a huge demand for automating technician tasks. Fewer clicks and less user intervention leads to higher efficiency. Most of the largest medical technology service companies in the industry are developing or using automatic data input for CMMS work orders.

LIU: Medical device test equipment is shifting toward greater digitalization and connectivity, enabling more automation, predictive maintenance and integration with hospital IT/CMMS systems. At the same time, regulatory compliance, cybersecurity and interoperability are driving demand for more advanced, automated and traceable

testing tools. Usability, modularity and sustainability are also becoming key differentiators for service and repair applications.

ALKIRE: It’s critical for test equipment to stay current with the latest medical device requirements for performing service. As test equipment manufacturers, we make sure that the test equipment design will meet or exceed the manufacturer’s accuracy requirements as well as specifications and features needed to perform the tests. Beyond this, we provide biomeds with the tools to minimize their workload, such as an app that brings multiple technologies into sync. This allows biomeds to move seamlessly through their service and maintenance responsibilities. Technicians can systematically and efficiently proceed according to the manufacturers’ requirements (or edited versions for spot testing) for both setup and testing with on-the-go smart procedures. These are not simply instructions but dynamic interfaces with ready-to-launch test sequences as well as recordkeeping for CMMS systems or database uploads.

LENNARD: Portability and ease of use are front and center. HTM teams are on the move, and the less bulky the equipment, the better. We’re also seeing more automation and guided workflows built into analyzers, which really helps reduce user error and speed up testing. Displays have improved massively too with clear, color screens that make results easier to interpret at a glance, which makes a big difference in busy HTM environments.

HOLMES: Currently, we see a trend where hospital engineers, ISOs and manufacturers are leveraging the available features in the Ocean software to create automated workflows for service engineers. This reduces the time required for service and minimizes downtime for clinics. We are also receiving more requests for quick turnaround times on equipment calibration to ensure engineers can remain up and running without interruption. Alongside this shift, RTI introduced the Mako X-ray test meter, the most accurate compact platform designed for faster setup and Ocean-driven automated workflows.

CAMPBELL: The biggest trend we see as a test equipment calibration and service company is the growing demand for reliability. More customers are recognizing the value of investing a little more upfront to purchase higher-quality devices. Since most biomedical departments do not have backup test equipment, any downtime for repairs can create serious challenges in completing PMs and service work on schedule. Over time, many users have realized that when the mean time between failure is longer, the total cost of ownership is actually lower. Fewer breakdowns mean less downtime, less disruption, and greater overall efficiency – making reliability one of the most important considerations when selecting test devices.

Q:

BARBOUR: The largest issue seems to be proprietary test equipment ecosystems or existing test equipment software limitations. BC Group has invested hundreds of thousands of dollars into developing software that can be used with any test equipment while providing the flexibility for user customization of their tests. We take feedback from our customers and have a team of engineers constantly improving our software: myBC Mobile app and myBC Connect cloud service.

LIU: HTM professionals often face challenges such as keeping up with rapidly evolving device technologies, ensuring compliance with complex regulations and audits, plus managing a wide range of equipment with limited budgets and staff. They also need test tools that are accurate, easy-to-use and seamlessly integrate with their documentation workflows. Companies like Datrend help address these challenges by developing intuitive, modular and standards-compliant test equipment that automates testing, reporting, supports connectivity with CMMS systems and reduces training burdens – ultimately saving time while ensuring patient safety.