Finally, the features you love most about your favorite ride share app, food delivery app, Angi, UpWork, or TaskRabbit are available for medical imaging equipment maintenance and repair.

Enter a Trace Ticket with one tap to broadcast your repair needs to a network of qualified technicians.

Review Bids to find the best service option for improved repair outcomes with less equipment down time, resulting in a lower overall cost.

Track progress, issue payments and rate services all in a single dashboard.

Speed

Instantly blast your service request to every qualified and vetted service provider

From response times to uptime, you no longer have to rely on service companies to track their own activities and performance

Like your favorite personal apps, get in-app alerts when a service technician is on their way, arrived, waiting for a part, completed a job, etc.

Competitive bidding among service technicians allows you to get the best price and only pay and track one entity

P.12 SPOTLIGHT

p.12 Professional of the Month: TRIMEDX Biomed Jeff Quid

p.14 Next Gen: Morgan Acquafredda

p.16 Association of the Month: The Kentucky Association of Medical Instrumentation (KAMI)

p.18 Department of the Month: VISN 2 New York/New Jersey VA Healthcare Network HTM Department

P.20 INDUSTRY UPDATES

p.20 TechNation Pulse

p.22 News & Notes

p.27 Ribbon Cutting

p.28 Welcome to TechNation

p.30 AAMI Update

p.32 ECRI Update

P.34 THE BENCH

p.34 Biomed 101

p.36 Webinar Wednesday

p.39 Shop Talk powered by MedWrench

p.41 Tools of the Trade: Claroty xDome

p.42 Roundtable: Tool Kits and Cases

p.50 Guide to AAMI eXchange

p.62 Cover Story: AAMI’s Rapid Release of EQ103

P.67 EXPERT ADVICE

p.67 Careers Now

p.68 Health-ISAC

p.71 Right to Repair

p.72 Networking Notes

p.74 The Future

PUBLISHER John M. Krieg

VICE PRESIDENT Kristin Leavoy

VICE PRESIDENT Jayme McKelvey BUSINESS DEVELOPMENT

EDITORIAL John Wallace

CONTRIBUTORS

Roger Bowles

K. Richard Douglas

Jim Fedele

Joie Marhefka

Manny Roman

Steven J. Yelton

ACCOUNT Megan Cabot

EXECUTIVES Emily Hise

ART DEPARTMENT Karlee Gower

Taylor Hayes

Alicia Brown

DIGITAL SERVICES Cindy Galindo

Kennedy Krieg

Haley Harris

EVENTS

Kristin Leavoy

Kristen Register

Sydney Krieg

WEBINARS Linda Hasluem

HTMJOBS.COM

Kristen Register

Sydney Krieg

ACCOUNTING Diane Costea

CIRCULATION Joanna Manjarrez

Rob Bundick, Director HTM & Biomedical Engineering, ProHealth Care

Carol Davis-Smith, CCE, FACCE, AAMIF, Owner/ President of Carol Davis-Smith & Associates, LLC

Nadia ElKaissi, CHTM, Biomedical Engineer, HTM, VA Central Office (19HTM)

Bryant Hawkins Sr., Site Manager, Children’s Hospital of New Orleans

Earl Morris Jr., BMET, Director of Clinical Engineering, Harrison County Hospital

Leticia Reynolds, Clinical Engineering Operations Manager at UCHealth Parkview Medical Center

P.76 BREAKROOM

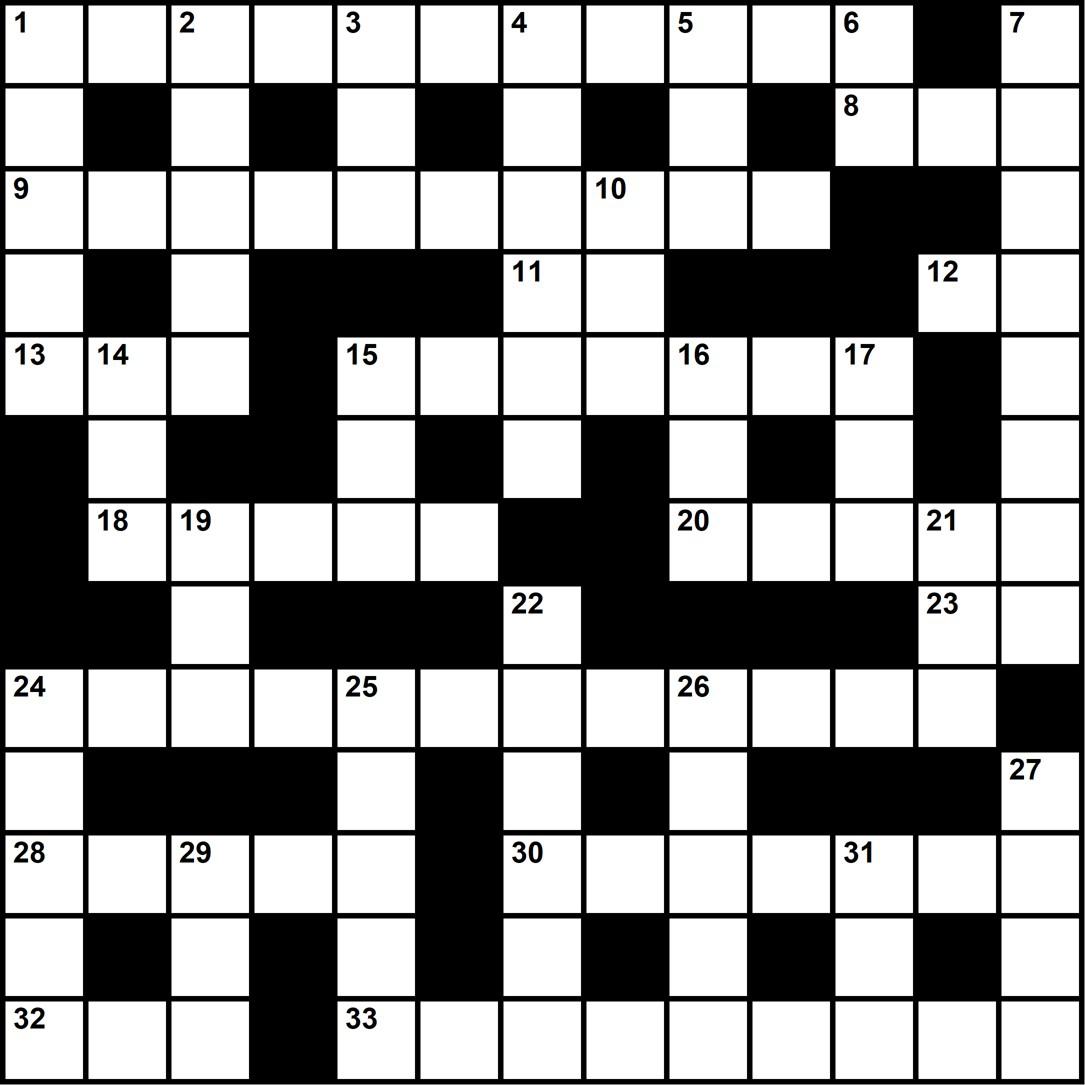

p.76 Biomed Brainbuster

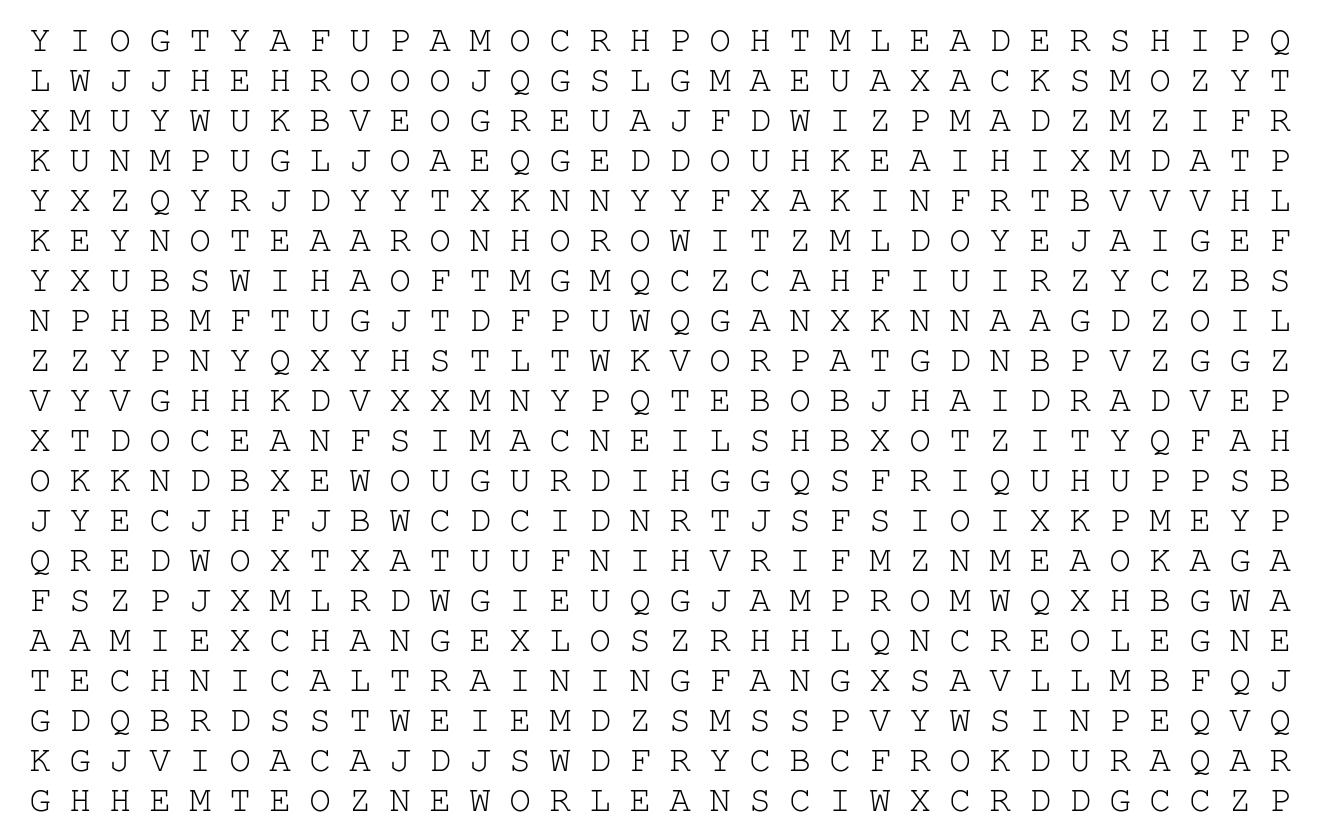

p.77 Word Search

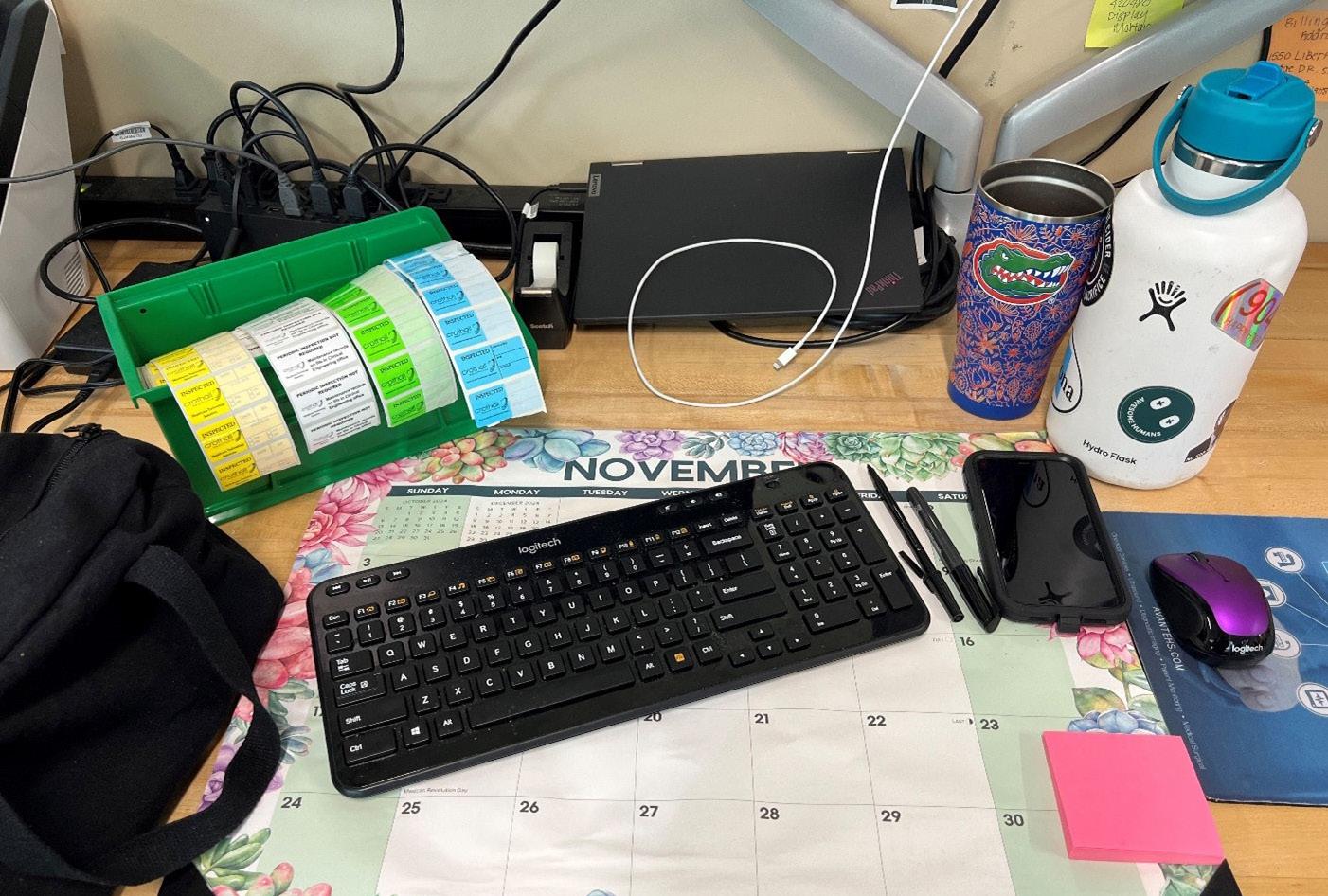

p.77 [Contest] What’s on Your Bench?

p.78 Preferred Vendors

p.82 Service Index

p.85 Alphabetical Index

p.86 Time Capsule

Management.

programs, including our newly launched Dental Equipment Technician training, specifically designe d to advance the skills of industry professionals. Our f lexible, expert-led courses enable your staff to stay ahead in this rapidly evolving field.

CBET’s Virtual Reality (VR) labs offer a flexible and immersive learning experience that adapts to your busy schedule. our VR labs allow you to practice and perfect your skills in a controlled, risk-free environment.

Big changes are on the horizon at CBET, and we can' t wait to share the news with you! From innovative partnerships to fresh opportunities designed to advance your career in

CBET’s Virtual Reality (VR) labs offer a flexible and immersive learning experience that adapts to your busy schedule. our VR labs allow you to practice and perfect your skills in a controlled, risk-free environment.

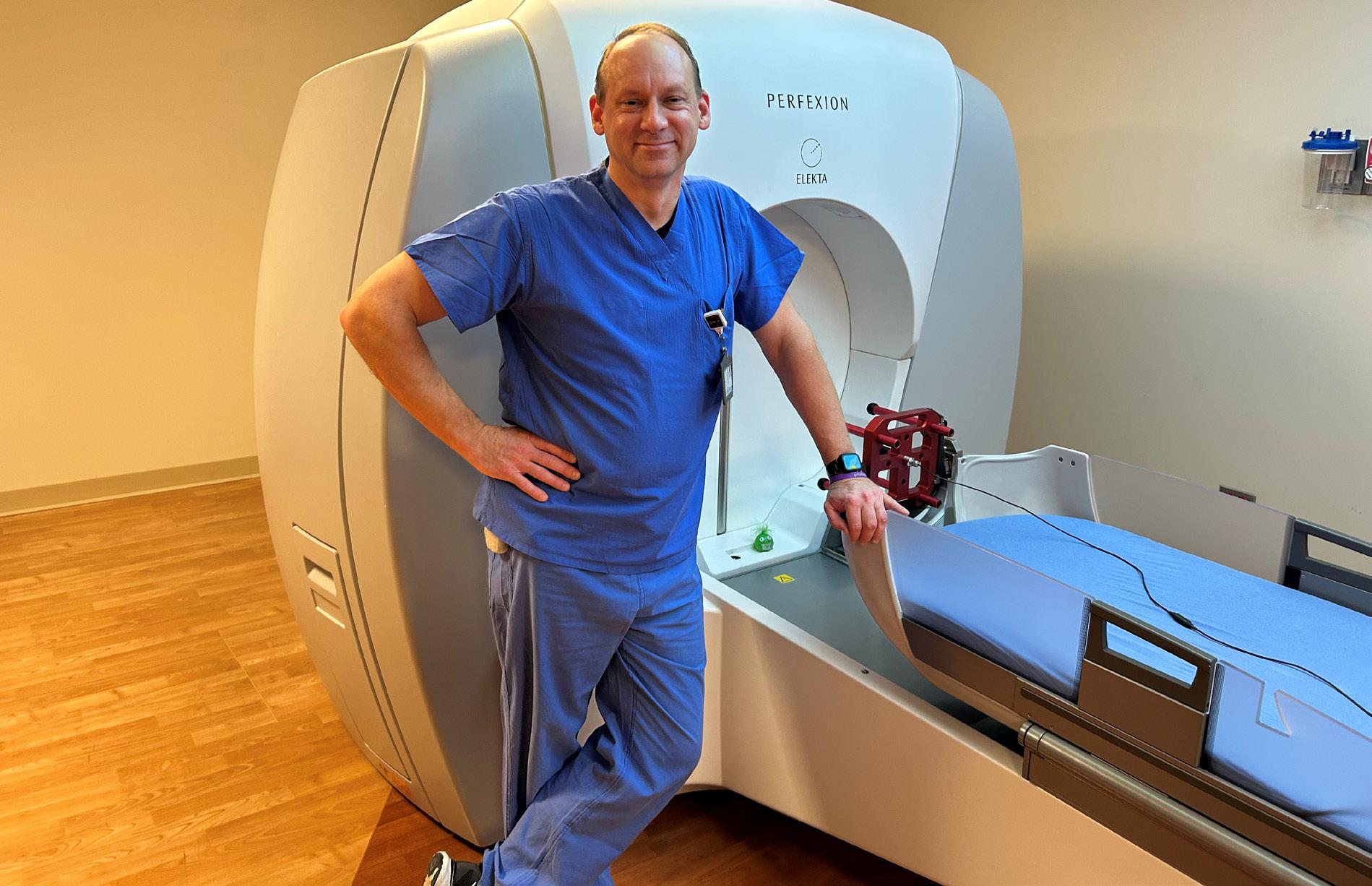

BY K. RICHARD DOUGLAS

TRIMEDX biomed Jeff Quid built and flew model airplanes growing up. He imagined a career in aviation for himself when it came time for higher education. His dad was an electrical engineer, so Quid enrolled in the Avionics Program at Southern Illinois University (SIU) in Carbondale.

“As I progressed through the program, several of my classmates had found another program SIU offered, and that was a B.S. in Advanced Technical Studies with ‘biomed’ as an area of study. I decided after I finished my A.A.S. In Avionics, I was going to move into the biomed degree. I think what changed my mind was a visit to Flying Tigers at O’Hare to see what I would be doing, and with a wind chill at the time of -20, I thought a nice warm hospital would be a much better environment,” Quid says.

When the program ended, Quid was required to do an internship. When an issue prevented the start of the first internship, he landed at his present work location.

“I lived in Schaumburg, Illinois, and so I called a few local area hospitals and the Alexian Brothers shop sounded the friendliest on my initial phone call,” he says.

“I have been a tech within TRIMEDX, still here at Alexian for 29 years now, and I still love what I do. The people here make the job fun, and we have a very family feeling with not only staff but directors and administration. What makes this position so fun and interesting is all the new things I get to learn about. I have learned so much about what other departments do and how we fit in and effect their operations. We also have the advantage here of working directly with administration on capital purchases, projects and ways to improve and integrate our medical equipment,” Quid says.

Over the years, Quid has stayed busy with several projects, utilizing the knowledge of many years in the profession.

“I have been involved in and created many special projects over the years here. Everything from planning telemetry installs, network installs, new equipment distributions in large scale (infusion pumps for example), equipment upgrades [and] capital planning for new construction,” he says.

One example is the installation of new instrument washers in the central sterile department.

“I did not just have to set a date for the vendor, but ensure the physical site was ready prior to install. This started with basics, like will the semi fit into our loading dock – we can handle a 53 foot, but no bigger. Will they fit through the doors and hallways inside the hospital and do I have a route? Elevators? We had to unpack and remove the washers from their crates because they were too tall to move while boxed,” Quid explains.

His next consideration was where to store the units and then scheduling the infection control team to perform an infection control risk assessment (ICRA).

“Meaning, do we need to put up barriers, how to maintain the positive/negative pressure between clean and dirty side. Removal of the units, and then schedule Environmental Services to do a clean/buff and polish of the floor where the old ones were so we have a clean start. I also had to replace the steam valves to each washer prior, because the gates were worn, and they would not shut all the way off. I had to make sure the electrician was available for power requirements and to be able to disconnect the currently hardwired units, and then once installed, reconnect to them,” Quid says.

Even before starting this project, Quid had to ensure that the consumables were available and on a current contract.

“Then, schedule the vendor for the actual install and in-service of staff,” he adds.

Away from work, Quid’s original love of avionics evolved into a hobby along with mountain biking.

“I had always enjoyed building and flying model airplanes, and even met one of our anesthesiologists who was into it as well. I saw a model airplane news magazine on his cart and asked about it, and we got to talking about the hobby,” he says.

“My boss at the time also was into mountain biking, and me and another tech friend of mine in the shop bought ourselves each a mountain bike and competed for several years in the Chequamegon Fat Tire 40. That is a 40-mile, off road mountain bike race from Cable to Hayward, Wisconsin on part of the Birkebeiner trail, logging roads and other places where there is not much of a ‘trail’ to speak of. I did that for about four years,” Quid says.

Quid reflects on his career as a biomed:

“I really enjoy learning, and not just in our little area of equipment, but with processes, procedures, where things are, what to do to if ... I like to understand how things work as a whole, and maybe that includes the corporate process for requesting capital equipment, or why and how we special order consumables for departments. That way, when people ask how do I do something, I may not have access, but I can usually point them to the right person. I don’t think I could ever work in a retail store, or a cubicle where I had the same few hundred square feet to look at for my career. I like the changes that occur as the hospital moves forward. It is really something to look, from where we came when I started, to where we are now,” he says.

The patients and clinicians at Alexian Brothers Medical Center are fortunate to have a caring and dedicated biomed professional who is comprehensive in knowledge and empathetic.

FAVORITE BOOK: James Clavell’s “Shogun”

FAVORITE MOVIE:

“National Lampoon’s Christmas Vacation”

FAVORITE PART OF BEING A BIOMED?

Every day is different, and the people I get to meet are from all walks of life, from all over the world, and in all kinds of situations. I enjoy helping others and solving problems, be it in a policy and procedure, or troubleshooting a difficult case with a patient on the table. I get personal satisfaction for a successful repair, and that being that I was certain the cause of the issue and that I resolved it with my fix.

organ Acquafredda holds an associate of science degree and a Biomedical Equipment Technician certification. Her current role in the HTM field is that of a Service Medical Advisor with iMed Biomedical. TechNation found out more about this budding HTM professional during a recent Q&A.

Q: What do you like most about your position?

A: I appreciate the opportunity to foster strong client relationships, contributing to enhanced customer satisfaction.

Q: What interests you the most about HTM?

Q: Where did you grow up?

A: Suburbs of Dallas, Texas

Q: Where did you receive your HTM training/education?

A: Brown Mackie College, graduated in 2015

Q: How did you first discover HTM?

A: David Francoeur introduced me to the healthcare technology management industry.

Q: Why (or How) did you choose to get into this field?

A: I chose the healthcare technology management industry because I envisioned the opportunity to contribute to patient care while being an integral part of the healthcare sector.

“I am committed to advancing my career within iMed Biomedical and contributing to the expansion of our presence within the DFW metroplex and nationwide.”

A: What interests me most about healthcare technology management is the opportunity to leverage innovative technologies to improve patient care and enhance operational efficiency within healthcare settings. The dynamic nature of the industry, combined with the critical role technology plays in ensuring patient safety and care quality, motivates me to continuously seek solutions that drive both technical and clinical advancements. Additionally, the chance to work at the intersection of healthcare, engineering, and IT allows me to contribute to a field that is both impactful and ever-evolving.

Q: What has been your greatest accomplishment in your field thus far?

A: My biggest accomplishment has been to successfully orchestrate and implement the ground up build of Trinity Regional Medical Center Sachse. I worked closely with regulatory compliance to ensure passing of the Joint Commission Survey.

Q: What goals do you have for yourself in the next 5 years?

A: Over the next five years, I aim to further my education and obtain certification as a healthcare technology manager. Additionally, I am committed to advancing my career within iMed Biomedical and contributing to the expansion of our presence within the DFW metroplex and nationwide. I also aspire to support iMed Biomedical in enhancing and broadening its service offerings to better meet the needs of our customers. I selected iMed Biomedical because of the company’s strong commitment to delivering exceptional value to both its clients and employees through continuous investment in service excellence.

FAVORITE HOBBY:

Motherhood is a significant part of my life, and i find it both fulfilling and enriching.

FAVORITE SHOW OR MOVIE: All the Bachelor franchise shows

FAVORITE MEAL: Chicken Parm

WHAT WOULD YOUR SUPERPOWER BE? Empathetic communication

1 THING ON YOUR BUCKET LIST: Tour Italy and a Mediterranean Cruise

SOMETHING YOUR CO-WORKERS DON’T KNOW ABOUT YOU: I enjoy organizing, designing and remodeling homes.

BY K. RICHARD DOUGLAS

Nicknamed “The Bluegrass State,” Kentucky is the nation’s 15th state, achieving statehood in 1792. Daniel Boone founded one of the state’s first settlements. The state is a major supplier of hardwood, coal and limestone.

Many top-rated healthcare systems can be found in Kentucky. The state has approximately 135 hospitals and healthcare systems. This amount of medical equipment requires a lot of HTM professionals. Those biomeds have been organized under the statewide Kentucky Association of Medical Instrumentation (KAMI).

The association was started in early 2010 when the late Patrick “Pat” Lynch started traveling to Kentucky and meeting with several HTM managers of local shops to see what the interest might be in the state of Kentucky for a biomed association. Lynch’s involvement also helped shorten the learning curve.

“Patrick ‘Pat’ Lynch, the ‘Chief Do-Gooder’ started KAMI. He met with nine other HTM leaders in the area and formed the board. They then filed the paperwork with the state (April 2010) to formally be recognized as a non-profit membership organization,” says KAMI President Jennifer Kizis.

From its beginnings 15 years ago, the organization has found its footing and serves the state’s biomed

community, as well as others. Not all has been smooth sailing as the pandemic threw a wrench into the workings of even the best biomed associations.

“The pandemic was a devastating time and was almost the end of KAMI. We were unsuccessful with virtual meetings and maintaining our regular events. Finally, KAMI was able to reconnect for an event at 3rd Turn Brewing and reorganized their small board into the 12-member board that now exists. The HTM Mixer in 2024 was KAMI’s ‘re-emergence’ and has kickstarted our organization back into our mission,” Kizis says.

She says that in addition to the 12-member board of directors, the group has several committees, including Compliance and Audit, Higher Education, Technology, Programs and Events, Marketing and Promotions.

“We just recently held elections and our fresh new board members are eager to drive our association forward to continue our mission of supporting technicians, engineers, managers, and vendors in the HTM field,” Kizis says.

She says that the organization has almost 50 paying members, but over 300 affiliates through its email communication.

“KAMI also focuses on networking and community service. We partner with SOS International in their mission to improve healthcare access for those in need through recovery and redistribution of surplus medical supplies. We volunteer our medical technology expertise to test the medical equipment, ensuring it is safe and operational,” Kizis says.

Meetings are held quarterly for members and

monthly for the group’s board.

“We also participate in AAMI’s HTM Association Collaborative, where HTMA leaders meet monthly to discuss best practices and association challenges. KAMI is excited to sponsor one of the HTMA’s educational webinars later this summer,” Kizis says.

The association’s inaugural symposium was in November of 2019 at the historic Boone Tavern Inn in Berea, Kentucky.

“The first symposium was just before the pandemic, in 2019. While the attendance was intimate, it was a successful two-day event of education and networking,” Kizis says.

She says that the next annual conference was not

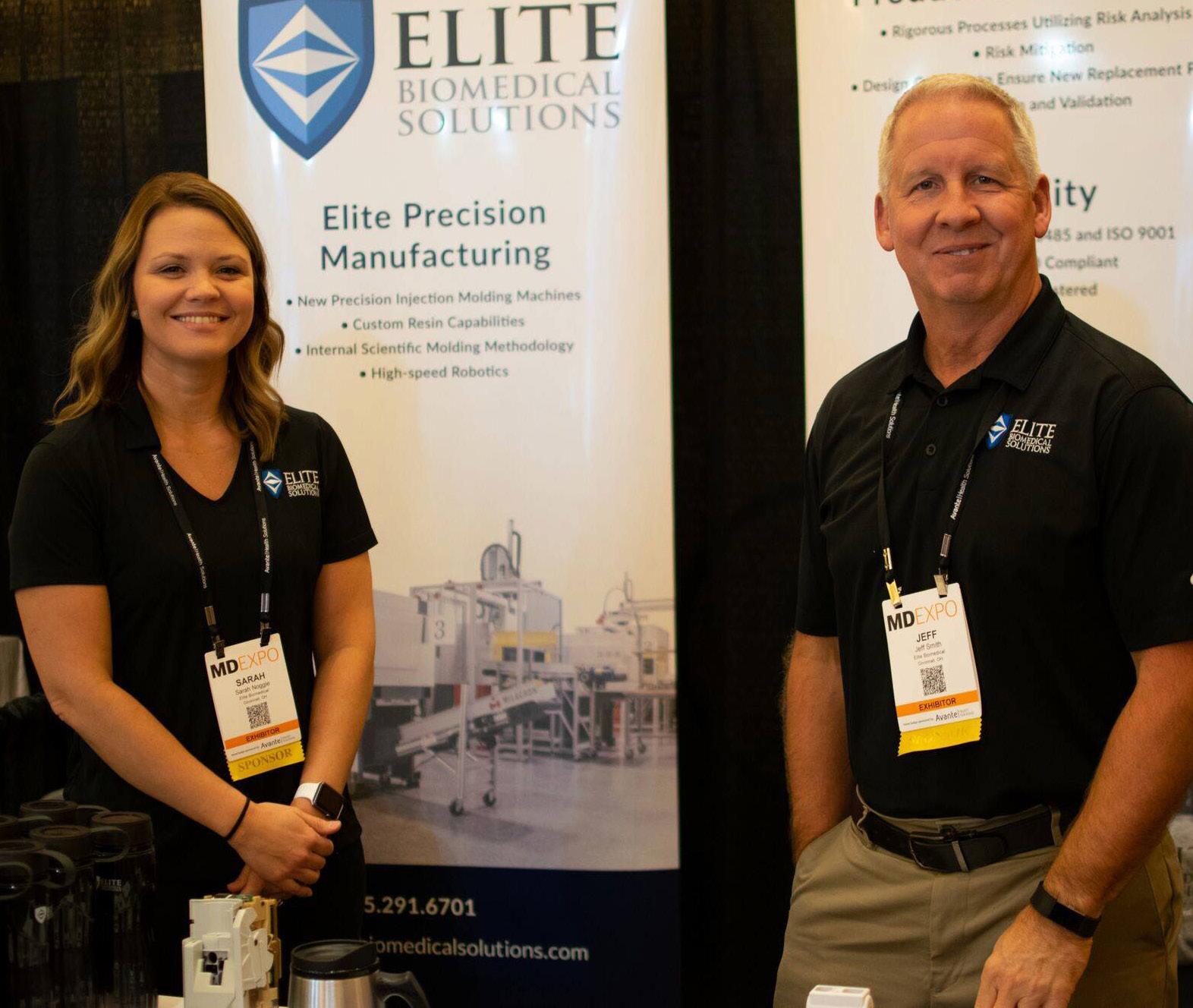

until November 2024, when KAMI partnered with MD Expo to host an HTM Mixer in Lexington, Kentucky.

“The event was a whirlwind of certified education; vendor exhibits and networking with peers. While we may not be able to have an event this large each year, we are looking forward to still providing valuable and engaging events to our HTM community. The HTM Mixer was a blast! The Bluegrass Kick-Off Party made the first night memorable with the live band and bourbon tastings. The venue space was packed as HTMers enjoyed the festivities,” Kizis says.

As associations put some distance in the rearview mirror on the pandemic, some are returning to a normal stride with fresh ideas and perspectives. KAMI is one of those associations.

BY K. RICHARD DOUGLAS

According to the U.S. Department of Veteran’s Affairs, “the U.S. is divided into 18 Veterans Integrated Service Networks, or VISNs — regional systems of care working together to better meet local health care needs and provides greater access to care.”

These regional systems are numbered from the northeast to the southwest.

In the New York and New Jersey region, the VISN is VISN 2. The medical equipment in facilities within VISN 2 is managed by the VISN 2 New York/New Jersey VA Healthcare Network Healthcare Technology Management team. The department’s five-member staff include VISN 2 Chief

Healthcare Technology Manager Arleen Thukral, M.S., CCE, CHTM; VISN 2 Deputy Healthcare Technology Manager Jessica Hudson-Rahming, CHTM; VISN 2 Biomedical Equipment Support Specialist-Biomedical Information Systems (BESS-BIS) Matthew Dilla; VISN 2 Biomedical Equipment Support SpecialistBiomedical Information Systems (BESS-BIS) Nicholas Martorano; and VISN 2 Biomedical Engineer Joseph Gucciardi, M.S., CCE.

The VISN 2 New York/New Jersey VA Healthcare Network Healthcare Technology Management team supports nine facilities with over 3,000 beds, $551 million in medical equipment asset value and more than 45,000 medical devices.

“Service contracts are assigned a Contracting Officer Representative (COR) who is responsible for statement of work, independent government cost estimate, market research, FITARA and submission to contracting,” Thukral says.

She says that the Contracting Officer (CO) will review the

package and clarify expectations.

“The contract bids are reviewed and evaluated by the COR. After contract award, the COR is responsible for reviewing reports and certifying invoices and working with the CO if amendments/modifications are required,” Thukral adds.

How is data collection accomplished on the VISN 2 team?

“While there are automated reports and scheduled jobs that run such as upcoming contract expiration reports and medical device incidents opened yesterday, most dashboards require validation by facility and VISN HTM staff to ensure accuracy of CMMS and SMAK data through the HTM Dashboard which includes medical device inventory, patient safety, medical device sustainment, medical device security, resource and operations, equipment planning, fiscal, staffing and misc,” Thukral says.

She says that technician assignments are managed locally by department managers. Local managers provide training opportunities to ensure competencies in specialty areas such as imaging and critical care.

“VISN 2 has approximately 46,000 networked medical devices, 400 servers and over 2,000 devices with naming standard index. Our dedicated team, led by Matt and Nick, is responsible for medical device security, EHR device interface testing and validation, and configuration management and support,” Thukral says of HTM/IT integration.

She says that HTM has deployed its own virtual server infrastructure and it is robust, supporting various clinical applications and services.

“We’re also integrating AI technologies to assist physicians in reading medical images, which is a big step forward in improving diagnostic accuracy and patient outcomes,” Thukral explains.

The department’s experienced staff have been busy with projects, bringing more advanced technology to its facilities, including software solutions.

“VISN BIS staff, Martorano and Dilla, have worked on an exciting project to deploy Microsoft’s System Center Configuration Manager (SCCM) across VISN 2. SCCM is highly leveraged in IT and outside of healthcare environments,” Thukral says.

She says that HTM has had to manually manage software and images on clinical systems in the past.

“SCCM solution allows HTM staff to automate software installs, updates, and even removal all from one dashboard. There are also capabilities to standardize clinical image rollouts for configuring/managing OS level items to better security and accessibility of managed systems,” Thukral says.

She says that the use of a software management solution will exponentially assist staff in keeping clinical systems aligned with their Software Bill of Materials (SBoM) as well as vulnerabilities kept in check for outdated software.

“They use Microsoft SCCM to manage unsupported operating systems, which means even our older systems get the updates and patches they need to stay secure. For tackling vulnerabilities, they use automated tools to spot and fix risks across the network efficiently,” Thukral adds.

Department staff have taken steps to streamline the onboarding process and to bring greater efficiencies through automation.

“For new employees, there is a lot to learn, from understanding the technology landscape to how-to document in Nuvolo CMMS and ensure SOPs are being adhered to,” Thukral says.

She says that VISN 2 staff have worked to ensure there is a one-stop shop for navigating to important links, reviewing the strategic goals and accomplishments and accessing knowledge articles that provide how-to for everything from contracting to installing a system.

“Nick developed the power app tool to make the interface easy to navigate and provide a Google-like search for looking up knowledge articles. The team has also streamlined communications by implementing an automated process of sending emails with specific characteristics, which are then auto-saved into designated folders within our SharePoint. In addition, I am validating a HTM chatbox that can answer questions about VISN 2 standardized SOPs,” Thukral says.

Off the clock, the department’s manager remains active in bettering the HTM community. Thukral is involved with AAMI standards with the Equipment Committee, including revisions of EQ89 and TIR for EQ103 (see cover story) and the newly formed AAMI HTM Advisory Community group which comprises of Healthcare Technology Leadership Committee.

She is also vice-chair of Healthcare Technology Certification Commission (HTCC), which oversees the CCE certification process, procedures and policies.

An involved manager in all things HTM and an impressive biomed team, who have embraced innovation, provide superior management of the medical equipment inventory in VISN 2.

TechNation is celebrating Healthcare Technology Management (HTM) Week, taking place May 18-25, 2025, with a special contest for HTM professionals. Each weekday, one lucky biomed will win a $100 gift card in a contest sponsored by FSI.

To enter, visit 1technation.com/htmweekcontest and create a fun caption for a selected photo. Winners will be announced daily during HTM week on TechNation’s Facebook and LinkedIn pages.

HTM professionals, mark your calendars! Registration is open for HTM Mixer Denver 2025, a premier regional conference designed to provide hands-on education, networking, and industry engagement. The event will take place on May 15-16, 2025, at the Omni Interlocken Hotel in Broomfield, Colorado.

The HTM Mixer Denver has been approved for 12 CEUs by the ACI.

Also, the HTM Mixer Milwaukee is set for July 31-August 1. It is proudly supported by the Wisconsin Biomedical Association (WBA).

HTM Mixers are known for delivering high-impact education and networking in a more personalized environment compared to larger national conferences. Attendees can look forward to:

The next MD Expo is set for this fall in the Dallas area. Join HTM professionals from throughout the nation November 10-12 at the Renaissance Dallas Addison Hotel.

The deadline for Call for Presenters has been extended to May 15.

MD Expo seeks presenters who can offer:

• First-hand experience implementing new technologies

• Case studies of process improvement in healthcare technology management

• Best practices using techniques to maximize efficiency and reduce costs

• Practical ways to facilitate inter-departmental communication and support within the facility

• Effective promotion of patient safety and risk management programs

• Career development tips for biomedical professionals

HTM Week raises awareness and appreciation for professionals who manage and maintain medical devices and health technology across healthcare systems. TechNation, the leading magazine for medical equipment service professionals, offers valuable resources for those in the biomedical, HTM, imaging, and IT fields.

For more details, visit 1technation.com/htmweekcontest and learn about FSI’s CMMS platform at fsiservices.com.

• Continuing Education Credits – Advance your career with valuable CE opportunities.

• Engaging Exhibit Hall – Discover the latest innovations and solutions from top vendors.

• Unparalleled Networking – Connect with peers and leading professionals in the HTM industry. Find out more at HTMmixer.com.

Dallas, TX • November 10-12, 2025

• Proven leadership methods and models and implementation strategies

Benefits of presenting at MD Expo include:

• Sharing your knowledge and experience

• Being recognized as a leader in the HTM community

• Professional development – add your speaking engagement to your list of achievements

• Networking with others in the HTM industry and gaining awareness of available resources

Find out more at mdexposhow.com.

The 2025 TechNation Tour continues this month at the HTM Mixer in Denver. The tour features a long list of stops where TechNation representatives will give away swag and host some reader parties. Be sure to find the TechNation crowd at the 2025 AAMI eXchange in New Orleans!

HTM professionals are invited to come join the TechNation community!

The list of TechNation Tour stops include these conferences:

• HTM Mixer CO, May 15

• AAMI eXchange, June 20

• HTM Mixer WI, July 31

• NCBA, Aug. 25

• NESCE, Oct. 15

• MD Expo Dallas, Nov. 10

• FBS, Dec. 4

Check 1TechNation.com for updates and additional tour stops!

Enter the contest and help TechNation celebrate. Fill out the short form at 1technation.com/contest for a chance to win one of 12 prizes, each valued at $150 or more!

Additional entries to win can be acquired by sharing on LinkedIn or submitting a photo. Each month, a winner will be selected and featured in TechNation magazine!

March’s winner is Paul Collier.

Find out more information on Page 86.

MARCH WINNER Paul Collier

• TOOL CASE, FIELD SERVICE DESOLDER PUMP

• FILE, FLAT NEEDLE

• FILE, ROUND NEEDLE

• FILE, TRIANGULAR NEEDLE FLASHLIGHT, TACTICAL

“AA” FORCEPS, STRAIGHT 6” W/GRIP

• (2) HANDLE FOR BLADES, DRIVE-LOC

• HANDLE FOR FILES AND MANY MORE!

In an ongoing effort to increase operational readiness, Airmen from the 8th Medical Group executed expeditionary medical support health response team (EMEDS HRT) training Feb. 13.

The training focused on familiarizing the Med Hawks with the EMEDS HRT tent setup and equipment checks, furthering the Wolf Pack’s contingency and deployment capabilities.

EMEDS are modular, scalable, rapid-response medical packages that can be used in humanitarian relief, wartime contingencies and disaster response operations. The package contains three unique building blocks: EMEDS HRT, EMEDS+10 and EMEDS+25 personnel and specialized equipment components. EMEDS HRT is the first and smallest of the EMEDS packages and provides surgical and trauma care, acute intervention and primary care to a risk population of up to 3,000 individuals.

“Our training was to ensure our Airmen knew how to set up the medical tents properly, and function test generators and environmental control units,” said U.S. Air Force Lt. Col. Brian Johnson, 8th

Healthcare Operations Squadron commander.

“Most of our medics haven’t seen an EMEDS+25 or HRT setup, so this training provided them with some familiarization in the process so if we ever need to deploy an EMEDS-HRT here, we will be ready,” said Johnson.

Med Hawk logistics Airmen and biomedical equipment technicians coordinated with the 8th Civil Engineer and Logistics Readiness Squadrons to perform site surveys and deliver equipment in less than 24 hours.

“We are all pretty familiar with the equipment and after this training are very confident in our abilities to get set up,” said Senior Airman Alexander Page, 8th HCOS biomedical equipment technician.

The 8th Medical Group’s EMEDS HRT training is crucial in maintaining the Wolf Pack’s ability to accept follow-on forces. By conducting training, the 8th MDG ensures its personnel are prepared to aid the Wolf Pack and follow-on forces so that they can return to the fight.

Dismissing patient, family, and caregiver concerns tops ECRI’s 2025 list of the most significant threats to patient safety. The global healthcare safety nonprofit organization says time and resource constraints make it increasingly difficult for some clinicians to provide empathetic care that addresses patient and caregiver concerns, potentially leading to missed and delayed diagnoses.

More than 94% of patients reported instances when their symptoms were ignored or dismissed by a doctor, according to a survey from HealthCentral. ECRI says when concerns go unaddressed, patients and caregivers feel like they’re experiencing “medical gaslighting,” which the American Journal of Medicine defines as “an act that invalidates a patient’s genuine clinical concern without proper medical evaluation.” Unlike the popular usage of the term “gaslighting,” medical gaslighting is not considered intentional, and clinicians are often unaware they exhibit the behavior, ECRI experts say.

ECRI says medical gaslighting can happen when clinicians are rushed for time, have biases that reflexively attribute symptoms to issues like mental illness, age, or weight, or make cognitive errors like interpreting new information in a way that confirms a previous diagnosis. This can lead to a missed diagnosis, delayed treatment, and decreased trust between patients and their healthcare providers.

“Most clinicians have a deep commitment to healing and protecting their patients and would never intentionally make a patient feel unheard, but it nevertheless happens with alarming

frequency,” said Marcus Schabacker, MD, Ph.D., president and chief executive officer of ECRI. “Providing high-quality healthcare starts with truly listening to patients. When we value their input, we gain critical insights that improve patient outcomes and build trust. A healthcare system that prioritizes patient voices is one that delivers safer, more efficient, and more compassionate care for all. Unfortunately, too many clinicians are operating under time and resource constraints that fuel substandard care.”

ECRI experts say solutions require a holistic approach that considers how all aspects of a health system – including leadership and governance structures, patient engagement, workforce wellness, and training infrastructure – promote safety.

The 2025 concerns in ranked order are:

• Dismissing patient, family, and caregiver concerns

• Insufficient governance of artificial intelligence

• Spread of medical misinformation

• Cybersecurity breaches

• Caring for veterans in non-military health settings

• Substandard and falsified drugs

• Diagnostic error in cancers, vascular events, and infections

• Healthcare-associated infections in long-term care facilities

• Inadequate coordination during patient discharge

• Deteriorating working conditions in community pharmacies

ECRI’s 2025 report includes recommendations for healthcare organizations to create organizational resilience to navigate the identified threats and strive for total systems safety.

Welcome to GMED ONE, where we have been setting the gold standard in biomedical repair services since 2011. As a leader in the field, we pride ourselves on our reputation for excellence, trust, and unparalleled service.

Our mission is to provide fast, reliable repairs on a wide range of medical equipment, ensuring that healthcare professionals can continue to deliver the highest quality care to their patients.

•

•

•

•

•

•

FSI, a leading healthcare CMMS/EAM provider, recently announced the availability of its certified ServiceNow integration to make work order routing, creation, and assignment easier than ever.

For today’s hospitals and healthcare facilities, finding ways to cut costs and increase efficiency continue to be a key area of focus, while needing to adhere to more complex compliance requirements. Within facilities and clinical asset management, key integrations with broadly utilized tools like ServiceNow can help improve knowledge sharing and drive faster response times – leading to better service to internal and external customers.

“The healthcare market continues to focus on digital transformation and interoperability – on having systems that speak to each other to share data that leads to more efficient work,” said Chris Lang, vice president, product and strategy, FSI. “We’ve heard from our customers a ServiceNow integration with our platform would eliminate duplicative work while giving visibility into what’s happening at the asset level.”

ServiceNow helps organizations automate various

TMA Systems, a global leader in enterprise asset and maintenance management software, has acquired EQ2, a provider of computerized maintenance management systems (CMMS) tailored specifically for healthcare organizations to manage their clinical assets and facility equipment.

“This strategic acquisition brings together two industry leaders to deliver cutting-edge technology and comprehensive solutions that drive operational efficiency, compliance, and safety in healthcare facilities worldwide,” according to a press release.

The combination of TMA Systems’ robust enterprise asset management platform with EQ2’s healthcare-focused HEMS platform will revolutionize how hospitals, clinics, and other medical facilities manage their assets, maintenance, and regulatory compliance, the release adds.

“We are thrilled to welcome EQ2 into the TMA Systems family,” said Mark Simner, CEO of TMA Systems. “With EQ2’s deep expertise in clinical equipment management and our cutting-edge EAM and CMMS technology, we are poised to set a new industry standard for facility management in hospitals and medical institutions. This acquisition underscores our

management workflows across departments. This new integration builds a seamless sharing of data with FSI, which provides the leading CMMS platform designed for hospitals and healthcare facilities.

When a user submits an issue via the incident or case module in ServiceNow, the data pushes to FSI’s CMMS. It automatically triggers a work order – and the system can assign and route it to the technician as soon as it comes in. With the ability to leverage other workflow automation technology, it helps users to focus time on what matters most.

“Advancing healthcare asset and facility management rests on the ability to automate manual tasks, to give lift to teams to focus on more strategic outputs,” said Lang. “From seamless integrations with companies like ServiceNow to integrated automations, our customers can rely on our platform to deliver the tools necessary to do what they need to do, more efficiently and at a lower cost.”

The ServiceNow and FSI integration is currently available to all customers using both platforms.

commitment to providing our clients with the most advanced and reliable solutions available.”

EQ2’s flagship platform, HEMS, has long been trusted by leading healthcare organizations to streamline operations, improve patient safety, and ensure regulatory compliance. By integrating EQ2’s clinical engineering capabilities with TMA Systems’ advanced asset and maintenance management technology, customers will benefit from an unparalleled suite of solutions designed to optimize performance, reduce costs, and enhance patient care.

“Joining forces with TMA Systems represents a powerful opportunity to expand our impact in the healthcare sector,” said Navneet Agarwal, general manager and chief technology officer of EQ2. “Our shared commitment to innovation and customer success makes this partnership a natural fit, and we look forward to delivering even greater value to our clients.”

EQ2 represents TMA’s fifth acquisition since 2021.The acquisition marks a significant step in TMA Systems’ strategic growth plan, further cementing its position as a leading provider of intelligent maintenance and asset management solutions across multiple industries.

Tri-Imaging Solutions introduces a cutting-edge platform that enhances supply chain management, engineer performance, and system monitoring. It provides engineers with diagnostic tools and video tutorials, and streamlines parts ordering and tracking. Designed for efficiency, the platform minimizes downtime and optimizes operations, setting a new standard for reliability in medical imaging.

XperTIS proactively monitors system health, supports engineers in repairs, and enhances the supply chain process by giving teams seamless access to parts ordering and order tracking

XperTIS offers step-by-step repair guidance, helping engineers troubleshoot efficiently while ensuring faster, more accurate parts ordering This helps maximize uptime and minimize repair costs

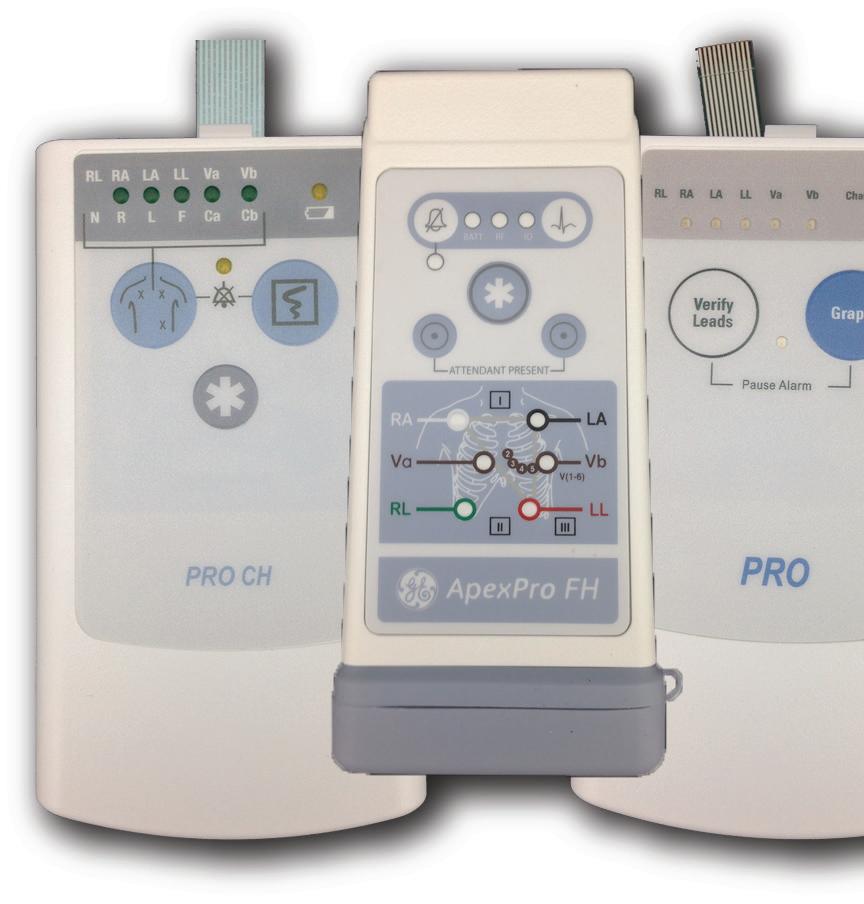

AIV Transmitter Case Kits

Replace all outer plastic and exterior membrane switches in-house

Transmitter Repair

Send to AIV for inclusive at rate repair

Parameter Repair

Send to AIV for at rate repair on TRAM/MMS moduls

Vitalacy provides AI-driven monitoring solutions designed to reduce hospital infections and adverse patient events. Its most popular solutions include hand hygiene compliance monitoring and virtual care for hospitals.

“Currently, we are especially excited about our new AIpowered cameras designed to assist nurses with fall prevention. These cameras generate automatic alerts, allowing staff more time to respond to unattended bed exits,” Vitalacy Vice President of Engineering Dylan Humphrey said.

“The possibilities for AI-assisted care are endless, and we are just beginning to explore them. Our customers often identify the next patient safety need, my team engineers the solution, and as a result, patients receive safer care,” he added.

TechNation recently found out more about Vitalacy Inc.

Q: HOW DOES YOUR COMPANY STAND OUT IN THE MEDICAL EQUIPMENT FIELD?

HUMPHREY: Vitalacy automates data collection on a massive scale for hospitals that traditionally rely on manual tracking. Take dispensers, for example – our system records each dispense event across an entire facility, providing insights into areas that need refilling sooner, identifying popular and underutilized handwashing stations (such as unit entries and nursing stations), and tracking hand hygiene compliance trends.

Additionally, our dispenser sensors detect malfunctioning or unused dispensers, turning what was once a static device into a smart tool that informs decision-making for facilities, operations, and environmental services (EVS) teams.

Q: WHAT IS ON THE HORIZON FOR YOUR COMPANY?

HUMPHREY: At Vitalacy, we are committed to making infection prevention and patient safety solutions more effective, accessible, and user-friendly for hospitals of all sizes. Currently, we are developing lighter, longer-lasting wearables to improve ease of use for staff, ensuring better adoption and sustained compliance.

Beyond our bed monitoring system, we are expanding our patient monitoring capabilities to include chair monitoring, helping hospitals address a broader range of patient safety concerns. We have also been optimizing our compliance dashboard, enabling faster compliance calculations and improving room-level compliance tracking for more precise data.

Additionally, we are enhancing flexible reporting options and moving toward AI-driven compliance reporting, giving hospital leaders predictive insights to proactively improve safety measures. To increase accessibility, we are working on making our solutions available to a broader range of healthcare organizations, ensuring more hospitals can implement infection prevention and patient safety technologies.

These advancements reinforce Vitalacy’s mission to simplify compliance tracking, enhance patient outcomes, and drive innovation in hospital safety technology.

Q: IS THERE ANYTHING ELSE YOU WOULD LIKE OUR READERS TO KNOW?

HUMPHREY: Hand hygiene is one of the most critical components of infection prevention, and it requires a dedicated, data-driven solution – not just an add-on to RTLS tracking. At Vitalacy, our mission is to help hospitals create safer environments by combining real-time compliance monitoring with actionable insights for hospital leaders, infection preventionists, and nursing teams.

Our system provides accurate, real-time hand hygiene data, allowing hospitals to proactively address compliance gaps and improve patient safety. Our solutions were specifically designed to identify patient safety challenges and enhance workflow efficiency. By reducing infections and adverse events, our technology directly supports this mission.

As part of our commitment to advancing healthcare technology, we have launched Vitalacy Virtual Care for AI-powered remote patient monitoring and are developing Workforce Analytics to improve staffing efficiency. By continuously innovating in patient safety and infection prevention, we aim to help hospitals deliver higher-quality care and better outcomes for patients.

For more information, visit vitalacy.ai

Q: WHAT PRODUCT, SERVICE OR SOLUTIONS DOES YOUR COMPANY PROVIDE TO THE INDUSTRY?

Secure Mount provides high-quality, American-made cable management and loss prevention solutions to hospitals nationwide. We are committed to helping hospitals save time and reduce costs by securing expensive equipment that is frequently misplaced within their facilities.

Q: TELL US WHAT DIFFERENTIATES YOUR COMPANY FROM THE COMPETITION?

What distinguishes us from the competition is our over 20 years of experience providing hospitals with a comprehensive range of solutions to prevent the misplacement of cables and lead wires. Additionally, our high end in-house machine shop enables us to deliver custom-built solutions tailored to the specific needs of hospitals.

Q: WHY DID YOU CHOOSE TECHNATION FOR ADVERTISING?

Bryce

Vice President of Operations

We selected TechNation for its extensive reach within our target audience, which will help us raise awareness of our specialized products. By doing so, we aim to assist hospitals in reducing the costs associated with misplaced equipment, ultimately enabling them to reallocate funds toward further advancements that benefit the American public.

For more information, visit securemount.com

BY TRESSA DANIELS

Human factors engineering (HFE), while certainly not new, is having a moment. This article explores the critical importance and methodologies of HFE, highlighting its pivotal role in enhancing safety, efficiency, and user satisfaction in the development of medical devices.

How does HFE accomplish these important goals? Simply put, by designing products that align with human capabilities, expectations, and limitations. HFE is particularly valuable in fields such as healthcare, aviation, and consumer electronics, where it can lead to significant improvements in usability, reduce the risk of use errors, and tailor devices to diverse user needs.

Before conducting usability testing in the design and development phase, several steps are necessary to optimize HFE. Initial research and observation are invaluable to understanding points of user confusion, workflows, workarounds, and environmental considerations involved with predicate or competitor products. This research can assist in identifying user needs as well as understanding user profiles and potential use errors.

Key activities in this phase include:

1. User Research: Understanding user problems and needs through interviews, surveys, and other research methods.

2. Workflow Analysis: Studying how users interact with existing systems and tools to identify pain points and opportunities.

3. Contextual Inquiry: Observing users in their real-world environments to gain insights into their natural behaviors and needs.

In addition to research and observation, a task analysis is an important method used to break down the steps required to complete a task and analyze each step for possible areas of design deficiency. A task analysis can start before a prototype exists by using a similar in-market product or the defined product purpose developed during concept and feasibility.

The Perception, Cognition, and Action (PCA) model is a key part of the task analysis, used to better understand and analyze human interactions with systems, particularly in identifying the root cause of use errors later in design and development formative testing. It involves perceiving relevant stimuli, processing the information to make decisions, and taking actions based on cognitive processing. Here’s a breakdown of PCA:

1. Perception

• Stimuli: Users must perceive (see, hear, touch) relevant stimuli from the environment or device interface.

• Challenges: Issues can arise if stimuli are not noticeable or are misinterpreted.

2. Cognition

• Processing: Users process (understand, comprehend) the perceived information to make decisions.

• Challenges: Cognitive overload, misunderstandings, or incorrect assumptions can lead to errors.

3. Action

• Execution: Users take actions (push, pull, press, twist, etc.) based on their cognitive processing.

• Challenges: Physical limitations, incorrect actions, or delays can cause errors.

By applying the PCA model, potential use errors can be systematically identified and addressed during the design and testing phases, thereby reducing post-market problems. During design and development, the project team will plan a

minimum of two to three formative usability tests. In addition, there are other methods of formative evaluations that can also be conducted. Formative Evaluation Methods involve both analytical and empirical techniques to assess and improve the user interface (user interfaces include software, hardware, IFUs, training material, accessories, and packaging). Analytical methods include task analysis, heuristic evaluations, and expert reviews and do not include feedback from intended users. Empirical methods involve gathering direct user feedback through in-depth interviews, contextual inquiry, cognitive walkthroughs (note: these can be done with or without users), and usability testing.

Formative Testing is an iterative design process to identify and fix user interface problems early. It involves three key steps:

1. First, identifying issues by revealing 90% of design flaws with 8-10 intended users (not employees).

2. Next, modifying the design to eliminate errors and use problems.

3. Finally, confirming effectiveness of the changes by conducting human factors validation testing.

HFE is not complete without Human Factors Validation. Human Factors Validation testing is used to prove that the final design is safe and effective for use. This includes identifying and mitigating potential hazards through risk analysis, iterating on the design to fix issues through formative testing, and proving the design is safe and effective through HF validation testing.

Human Factors Validation Testing requirements include:

• 15 users per intended user group

• All critical tasks be performed

• Final production equivalent product

• Simulated environment of use

• Realistic training scenarios

• Uninterrupted use conditions

Human Factors Validation Testing is essential to demonstrate that the final design is safe and effective for use.

HFE is a specialized skill set that considers all aspects of medical device design holistically. It strikes a balance between safety and usability, focuses on risk reduction, and ensures compliance with global regulations.

And what’s the bottom line on HFE? The return on investment (ROI) for incorporating human factors can be observed in several areas:

1. Preventing costly recalls: Early identification and mitigation of usability issues can prevent expensive recalls.

2. Higher user satisfaction and loyalty: Improved user satisfaction can lead to increased market share.

3. Decreased Ccosts: Addressing usability issues early in the design process can save significant costs associated with redesigns and post-market fixes.

In summary, investing in human factors engineering is not just about meeting regulatory requirements; it’s about creating products that truly meet the needs of your users, customers, and patients.

ECRI partnered with Oxygen CoLab to conduct intensive testing of oxygen devices to identify and catalogue those best for resource-deprived healthcare settings.

More than 1 million deaths occur every year due to hypoxemia in low- and middle-income countries, many of which could be prevented with appropriate access to medical oxygen.

The COVID-19 pandemic exposed major gaps in access to medical oxygen devices, prompting donors, global organizations and supply chain leaders to take action to improve availability long-term. But most of these efforts didn’t address oxygen access for lower-level facilities that serve vulnerable patients in low- and middle-income countries.

ECRI partnered with the Oxygen CoLab – a UK Foreign,

Commonwealth & Development Office-funded initiative – to create a comprehensive directory of oxygen concentrators to aid in the procurement of these devices for low-resource settings.

“We replicated real-world scenarios and tested 11 devices to see how they perform in the harsh conditions where they could potentially be deployed,” said Brad Bonnette, ECRI’s Senior Project Officer, “like in a refugee camp, a field hospital, a community health center, or primary health outpost. Picture a mobile clinic in a remote village without a consistent power supply. We want to ensure patients everywhere have access to safe, quality care – whether they live in a metropolitan area near a high-tech hospital, or in a remote community.”

Oxygen concentrators have a particularly important role in low-resource settings, namely for smaller and more remote health facilities, for both acute and non-critical-care patients. The devices are proven to save lives, yet there are challenges to implementing wide-scale solutions in low-resource settings. Most concentrator models don’t adapt well to settings with unreliable power sources,

and dusty, humid conditions – plus a shortage of staff with specialized training in device maintenance.

With many makes and models available, there has long been a gap in evidence regarding product performance, safety, usability, repairability, electrical resilience and energy efficiency to inform decision-making.

“One of the biggest surprises was the variation in how the units handled the challenging conditions,” said Bonnette. “Some suffered catastrophic failure due to accumulated dust, while others were able to deliver a high concentration of oxygen in the same dusty conditions. Some had a hard time with heat and humidity but did well with dust. We hope buyers can use this information to ensure they acquire equipment that can perform well in their environment.”

Brad Bonnette has been a device safety engineer for ECRI for nearly 20 years. In that time, he has evaluated devices used in infusion therapy, respiratory care, anesthesia, sleep medicine, and consumer health.

ECRI is the only organization in the world to operate independent testing labs where engineers conduct hands-on, rigorous medical device evaluations.

To learn more about this project visit ECRI.org/News

soma@somatechnology.com (800) 438-7662

13485:2016

somatechnology.com @Somatechintl

Lewis Lennard, product manager at Rigel Medical US, shares some insights on the current trends and strategies driving advancements in the biomedical test equipment sector.

There is a trend toward portability in biomedical test equipment to meet the demand for compact, lightweight, and handheld devices. Portable analyzers enable healthcare facility testing and field service applications, expanding access to testing capabilities in remote or resource-limited environments. Several of Rigel’s portable analyzers have been used in harsh, remote conditions, and the durability of the equipment has been recognized.

Integration with IoT technology stands out as another prominent trend. We recently released an app that can generate PDFs and test reports, which helps facilitate real-time data capture and storage, simplifying the management of test results and documentation. As with many other areas in healthcare, workflow automation is becoming a focus in the biomed arena. Most biomedical test equipment companies are now offering some form of automation.

Q. WHAT ARE SOME OF THE BIGGEST CHALLENGES FACING THE BIOMEDICAL TEST EQUIPMENT SECTOR TODAY, AND WHAT STRATEGIES ARE BEING EMPLOYED TO OVERCOME THEM?

Keeping pace with rapidly evolving technology is challenging. Test equipment manufacturers need to be innovative with the next generation of test equipment. Collaborating with biomeds, biomedical equipment technology colleges, and medical device manufacturers keeps us up-to-date on emerging technologies and ahead of the curve.

One of the biggest challenges is connected devices and IoT integration. If biomedical test equipment is on the same networks as patient data, the risk is clearly high. To enhance cybersecurity measures, test equipment must implement encryption protocols and secure network processes in the same way that medical devices do.

Q. HOW DOES YOUR COMPANY ENSURE EFFICIENT, FLEXIBLE SERVICING OF MEDICAL DEVICES, ESPECIALLY IN EMERGENCIES, AMID THE GROWING DEMAND FOR PORTABLE SOLUTIONS IN BIOMEDICAL TESTING?

Rigel is seeing strong growth in testing requirements for smaller, remoter healthcare facilities. The design of portable

test equipment is important so that it can be easily transported to healthcare facilities, clinics, or remote locations during emergencies. These devices are lightweight, compact, and often battery-powered, enabling rapid deployment and onsite testing without the need for a specialized infrastructure. Test equipment solutions need to be diverse, catering to a range of settings, from large metropolitan hospitals to remote communities in Alaska.

Q. WHAT MEASURES DOES YOUR COMPANY TAKE TO ENSURE THE PRECISION AND DEPENDABILITY OF TEST EQUIPMENT CALIBRATION AND SERVICING, PARTICULARLY IN ENVIRONMENTS WHERE ACCURACY IS CRITICAL FOR PATIENT SAFETY?

A test equipment manufacturer must have calibration to standards such as ISO 17025 for calibration laboratories, and at the very least ensure reference standards and calibrated equipment are traceable to national or international standards. This ensures the accuracy and traceability of measurements and minimizes uncertainties in calibration processes. Our service and calibration arm, Calibrationhouse, has [United Kingdom Accreditation Service] (IEC 17025) capabilities for biomedical test equipment and counts worldwide medical device manufacturers and healthcare organizations among its customers.

Q. HOW ARE YOU ASSISTING HTM OFFICIALS IN UTILIZING AND MAINTAINING TEST EQUIPMENT THROUGH TRAINING AND EDUCATIONAL PROGRAMS?

We assist biomedical engineers by providing comprehensive training and education initiatives. These include online webinars, onsite training sessions, and video tutorials covering equipment operation, troubleshooting, and preventive maintenance. Rigel also offers certification programs, continuing education courses, and technical support to address topics, regulatory compliance, and any issues biomeds encounter.

We strongly believe in cultivating the next generation of biomeds. We have donated test equipment to colleges as this greatly benefits students by providing enhanced access to new learning experiences and preparing them for future careers in the field. Through hands-on experience with equipment, students develop crucial technical skills in equipment operation and maintenance. Additionally, networking opportunities with HTM professionals may arise, helping students’ educational experiences.

LOOKING

Management and Technicians achieve more in less time

Integrate with all of your existing systems

Compliance and AEM made easier with the right tools and reports

Our system helps you keep your devices protected

Data and information in formats that fit the needs of all levels of technicians, management, and the hospital as a whole

Implementations and support performed by our in-house, US-based staff

Lewis Lennard is a product manager at Rigel Medical US in Tampa, Florida.

The most recent Webinar Wednesday session was a Tools of the Trade Live Demo highlighting the Tri-Imaging Solutions innovative platform – XperTIS. XperTIS is designed to revolutionize supply chain management, engineer performance, and system monitoring. The XperTIS platform enhances system uptime by enabling system monitoring and equipping engineers with diagnostic capabilities to identify and resolve issues.

The live demo highlighted a library of step-by-step video tutorials and instructions that are available to engineers guiding them through installations and repairs. XperTIS also provides the ability to order parts directly, track shipments, and manage RMAs as it streamlines the parts ordering process.

With a focus on efficiency and empowerment, Tri-Imaging’s XperTIS platform ensures equipment runs at peak performance, reduces downtime, and optimizes supply chain operations setting a new standard for the industry.

Fifty HTM professionals logged in for the live presentation. Keith Hall in Utah was the trivia contest winner during the webinar. He won a multi tool.

The presentation was eligible for 1 CE credit from the ACI. A recording of the webinar also provides 1 CE credit when viewed at WebinarWednesday.live.

The session concluded with an informative Q&A session with Tri Imaging Solutions Vice President of Operations John Drew and his team answering more than 10 questions from attendees.

The questions answered included:

• How is it different than other systems?

• What manufacturers and modalities are you currently monitoring?

• What manufacture and modalities will you do next?

• Are you seeing any PHI?

• How do you accomplish the monitoring of the system, what is the installation process?

TechNation’s Webinar Wednesday recently featured a Tools of the Trade Live Demo of the Soma Capital Equipment Service. The session is eligible for 1 CE credit from the ACI.

In the webinar, Soma’s experienced biomedical engineers were seen navigating maintenance and general troubleshooting procedures on popular medical equipment. The panel of subject matter experts demonstrated how to replace batteries on the Steris 4085 and Skytron 3600B surgical tables. They illustrated battery replacements for the Baxter InfusOR, Alaris PC Unit, and Medfusion 3500 infusion pumps, ensuring proper functionality for medication delivery. Another expert demonstrated how to troubleshoot common issues on the GE OEC 9900 Elite and Orthoscan FD Pulse C-arms, helping to reduce downtime in imaging systems. Finally, attendees saw how to balance a surgical microscope and replace the lightbulb on a Lumera 700, ensuring precision and reliable performance.

This educational session offered practical, hands-on guidance for maintaining critical equipment, making it a valuable resource for biomedical engineers and technicians seeking to refine their skills.

The expert panelists also answered questions during the webinar.

HTM professionals were tuned in for the live webinar. Jody Butler, a biomedical equipment technician with Memorial Hospital of Sweetwater County, Wyoming, won a Swiss Force Meister Multi-Tool during the webinar.

Attendees were asked, “What was your single biggest takeaway from today’s product demo?”

“Having an overall knowledge of the biomedical equipment is necessary; however, specializing in certain modalities, can facilitate efficiency in a maintenance program,” said Fernando Trujillo, Senior Clinical Technology Manager, DHA MEDLOG-HTM.

“Some of the most common problems with medical equipment need just quick and easy fixes,” said Narayanaswamy Ramaswamy, Manager, Biomedical Engineering, Hamad Medical Corporation.

“It touched on real life things that happen in the field,” said Patrick Markle, Integration Engineer, Methodist LebonHeur.

The TechNation Webinar Wednesday session “The Hidden Power of Your RTLS Data: Secrets to Unlocking Asset Performance” presented by Mike Tohill, senior director of customer success at Cognosos, is eligible for 1 credit from the ACI. The webinar was sponsored by Cognosos and free to attend. Access the on-demand recording of the session at WebinarWednesday.live and watch the webinar free to obtain 1 CE credit.

In the webinar, Tohill achieved several objectives including an explanation on how biomeds can best understand the breadth of data captured within their RTLS. He also shared how to identify key performance indicators (KPIs) within RTLS data to track asset health, utilization, and efficiency.

After the session, biomeds had the knowledge to discover hidden patterns and trends in their RTLS data to gain insight into operations. They also can explore real-world examples of how organizations are using RTLS data to improve asset performance and achieve business objectives.

An informative question-and-answer session followed Tohill’s presentation. The Q&A provided additional insights that empower biomeds to achieve their goals.

The webinar was well attended and Andrew Warren, QA Manager with Advent Health Orlando, won a Swiss Force Meister Multi-Tool.

Attendees were asked, “Why do you read TechNation magazine?”

“To stay up to date with changes in the technology industry and have knowledge of added values shared by industry leaders,” said Calvin McDowall, Director, Clinical Engineering, Valley Health System.

“To get current news about my chosen profession,” said Ethan Hertz, Clinical Engineer, Duke University Health System.

“Industry information and catching up on how other biomeds tackle daily issues,” said Ricardo Ortiz, Biomed Manager, United Regional.

“Articles about new products and trends in clinical engineering,” said Doug Hershberger, Supervisor Clinical Engineering, Cleveland Clinic Mercy Hospital.

The recent Webinar Wednesday session “Cybersecurity Insights with Scripps Health: Protecting Healthcare Networks” is eligible for 1 credit from the ACI. The webinar was sponsored by Claroty, formerly Medigate by Claroty.

Presenters Ty Greenhalgh, healthcare industry principal, Claroty, and Luke Karkosh, senior director of enterprise architecture, Scripps Clinic, provided insights and answered questions from attendees during the webinar.

HHS has proposed changes to the HIPAA Security Rule requiring new comprehensive network segmentation and enhanced access controls. Karkosh explored how Scripps has strengthened its medical device cybersecurity with advanced network protection strategies.

Attendees were able to learn how to minimize lateral movement, protect electronic health information (ePHI), and comply with evolving regulations. They gained actionable insights to build a resilient, compliant cybersecurity framework focused on securing medical devices and how to address the unique challenges faced by device owners in healthcare environments.

Key takeaways included:

• How changes to HIPAA will impact HTM and Clinical Engineers

• Why visibility is crucial for effective network segmentation

• How segmentation reduces the risk of intruder access to sensitive systems

The webinar drew 80 attendees for the live presentation and a recording of the webinar is available for on-demand viewing at WebinarWednesday.live. Attendee Grant Kelley, MIS & Clinical Engineering Analyst, BTNRH, NE, won a Swiss Force Meister Multi-Tool.

Attendees were asked, “Excluding CE credits, why do you attend Webinar Wednesday?”

“Want to see how other institutions are dealing with biomed devices and cyber risk,” said Jon Helgason, Biomed Cybersecurity Program Director, Nebraska Medicine.

“I am interested in learning more about the different topics discussed in these webinars, which most of the time introduce new regulations and best practices,” said Ounssa Akhayar, Clinical Engineer, UConn Health.

“To keep informed of existing and upcoming and/or existing policies, software, and devices relevant to the biomedical career field,” said Alan Nicewarner, CBET, BSWH McKinney.

“I like being up to date on any trends or new technologies in the industry,” shared Luis Molina, Clinical Engineering Manager, New York Presbyterian-Lower Manhattan.

Struggling with staffing gaps in your biomedical or clinical engineering department? MultiMedical Systems provides expert short- and long-term staffing solutions to keep your operations seamless From preventative maintenance to equipment repair, our skilled technicians integrate quickly and efficiently with your team minimizing downtime and maximizing patient care.

MedWrench is an online resource for medical equipment service professionals to engage with their peers about medical equipment repairs, source parts and to locate service companies. The following are examples of how the MedWrench community members help each other in the website’s forums.

Q: I have a vip6 that displays level sense errors when attempting to start a clean cycle. Process completes with no errors. When inspecting sensors I find paraffin buildup around sensors. Temps are within ranges. Any ideas?

A: It could be bad level sensors, but the front heater on the retort can fail and it will cause these errors. The retort may feel hot to touch and it will not give an heater errors, you can ohm out the heaters to see if they are out of range.

A: Clean the sensors. You don’t want any build-up on or around the level sensors. Each level sensor has a vertical slot on one side or the other. You need a brush that will get into that slot and clean it thoroughly.

Q: I have a Midmark 623 I am currently working on and the base and back functions on the remote are only controlling the back and not the base (back up controls back up the three other functions lower the back). All the fuses are good on the board so everything should be getting power, I have also checked the

remote on other tables and the remote is wired correctly and works right on other tables. The only thing I can think of would be some damage to where the remote plugs into the base of the table. Any ideas or insight would be much appreciated!

A: While you’re in there I’d check to see if the relays are working right. The service manual in the documents section shows you how on page B-20. It sounds like you may be looking at a new PC board though.

A: You may have solved this. If you are seeing damage to the connector. Otherwise check your cables. Functions not working could be bad actuators, cabling, relays, pcb. But as far as an actuator being activated by the wrong button, the signal has to be going to the wrong place. Only 2 ways to do that, pins in the wrong spot or someone moved connectors around

Q: After the self test it shows me faults 35, 36 and 56. and a reduction in the maximum rate, the maximum power

A: Also, I just saw your earlier posts and it could be a brick going bad (there are 4). Usually that throws a brick failure code but maybe it’s partially working.

Good Luck!

To register for a FREE account on MedWrench, visit medwrench.com

MAY 14

SPONSORED BY

TOOLS OF THE TRADE

Save the date for this live webinar. Participation is eligible for 1 CE credit from the ACI.

MAY 21

SPONSORED BY

WEBINAR WEDNESDAY

Save the date for this live webinar. Participation is eligible for 1 CE credit from the ACI.

Choosing the Best Modern Healthcare CMMS Solution

SPONSORED BY

TOOLS OF THE TRADE Cognosos Asset Management SPONSORED BY An Introduction to Computed Tomography

SPONSORED BY Planning Medical Device Disposal

SPONSORED BY

SPONSORED BY TOOLS OF THE TRADE Downtime Trace Mobile App

All webinars, podcast, and product demos are eligible for 1 CE credit from the ACI.

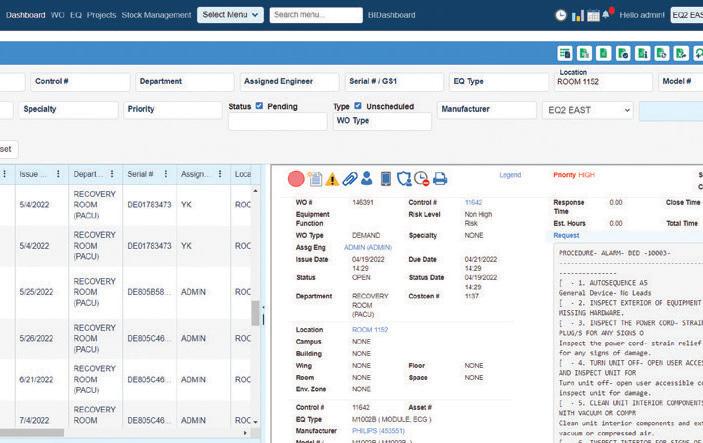

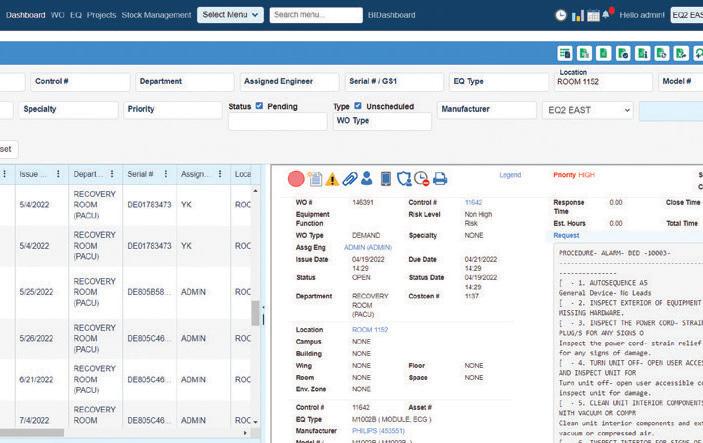

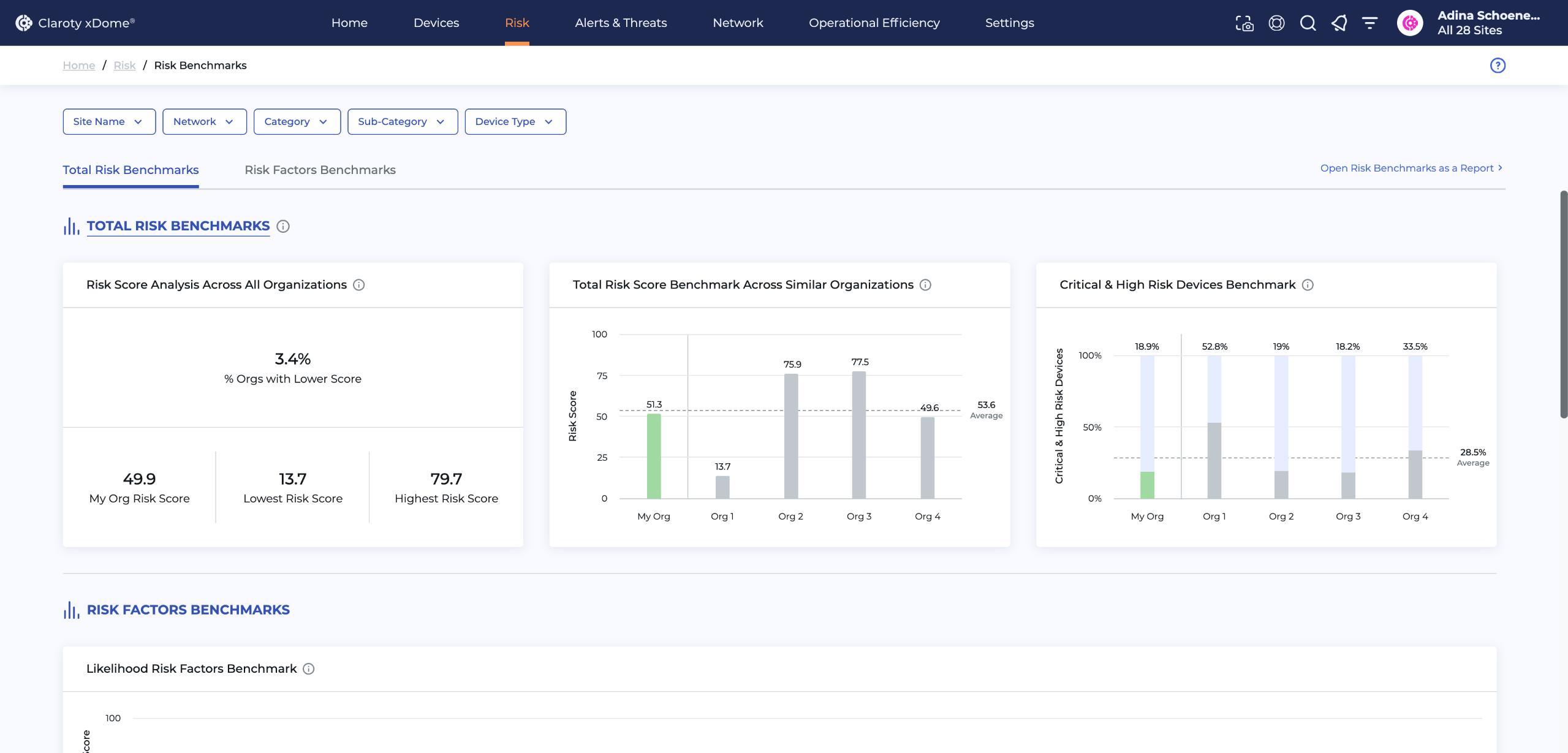

Learn more on how to implement effective and efficient strategies regarding Exposure Management in Claroty xDome for Healthcare. In Claroty xDome, you can benchmark your risk against your industry peers, understand device risk scores and profiles and better manage vulnerabilities and exposures. For more information, visit claroty.com

Possession of the correct tools is just as important as the knowledge needed to maintain and repair medical equipment. One of the most important tools for every healthcare technology management (HTM) professional is a tool kit or case to keep tools safe, close by and ready for use.

TechNation recently asked several industry leaders to share their insights regarding tool kits and cases, including which tools are essential for HTM pros and what are the must-have features every biomed needs when it comes to their tools.

Participants in this roundtable discussion on tool kits and cases are:

• Pronk Technologies Vice President of Business Development Greg Alkire;

• Southeastern Biomedical Co-owner Boyd Campbell, CBET, CRES, CHTM;

• Fluke Biomedical Technical Sales Engineer Jamie Spragis, CBET; and

• South Plains Biomedical Services (SPBS) DFW Branch Manager Chace Torres.

Q: WHAT ESSENTIAL TOOLS SHOULD BE INCLUDED IN AN HTM TOOL KIT FOR BIOMEDICAL ENGINEERS?

ALKIRE: The ideal toolkit will support biomeds with portability, ease of use and multi-functional capabilities. For example, the compact electrical safety analyzer, Safe-T Sim, includes customizable safety autosequences plus ECG and

respiration vital signs simulation. Similarly, a very popular, small, comprehensive multi-parameter patient simulator known as SimSlim offers ECG, respiration, arrhythmia, 4 invasive pressures, YSI 400/700 temperature, and cardiac output – all with an internal battery run time of up to 10 years. For servicing infusion pumps, using an analyzer like FlowTrax that is compatible with any type of infusion device and integrates a very accurate NIST full-featured pressure meter, temperature meter, and digital timer/stopwatch allows biomeds to do more testing while carrying fewer devices.

CAMPBELL: A comprehensive healthcare technology management (HTM) toolkit for biomedical engineers should include a range of essential tools for effective equipment maintenance and repair. The basic hand tools, such as screwdrivers, Torx bits, wrenches, and pliers, are foundational to any toolkit. These tools are commonly found in most electronic toolkits available on the market. However, the key to an effective HTM toolkit lies in selecting tools of high quality and functionality. It’s not just about having the right tools, but ensuring they are durable and reliable for biomedical applications. If a toolkit is only a generic electronics toolkit, it may lack the specific design and features required by healthcare professionals. Thus, a well-curated HTM toolkit should be evaluated and tailored to meet the unique demands of biomedical engineers to ensure optimal performance and safety in healthcare environments.

SPRAGIS: A comprehensive HTM toolkit for biomedical engineers should include essential manual tools like screwdrivers and wrenches, along with advanced diagnostic instruments such as electrical safety analyzers, patient simulators, infusion device analyzers, gas flow analyzers, and defibrillator analyzers. While test instruments are crucial, service manuals, procedural documents, and reliable documentation tools are equally important. A laptop or tablet is necessary for accessing manuals and logging documentation, and network analyzers and communication cables/adapters facilitate troubleshooting networked devices. Additionally, software that automates measurement collection, optimizes workflows, standardizes procedures, and improves documentation and reporting can significantly boost productivity and compliance. Personal protective equipment and cleaning supplies ensure safety.

TORRES: I think overall a tech can be mostly prepared for any job with the following: socket wrench set, bit drive set, screwdriver, assorted pliers set (crimping, needle-nose, tongue & groove, cutter) and, of course, a multimeter.

Q: ARE THERE ANY TOOLS OR CASES THAT ARE FREQUENTLY OVERLOOKED BUT ARE CRITICAL FOR BIOMEDICAL ENGINEERS WHEN SERVICING MEDICAL EQUIPMENT?

ALKIRE: A critical factor is whether or not the devices are capable of having features added in the future. For example, most existing Pronk products in the field can be upgraded with Mobilize wireless connectivity. Our current Mobilize products are also updated with the latest advances in the software. Another vital factor: device durability as

demonstrated by a standard four-year warranty or droptested designs so as to prevent unnecessary downtime. Finally, one would want to look at whether or not the toolkit contains the auxiliary equipment (cables, adapters, etc.) necessary to complete the specific service or maintenance as standard as opposed to an additional purchase.

CAMPBELL: When servicing medical equipment, there are several essential tools and features that are often overlooked in standard toolkits for biomedical engineers.

Some of these include:

• Screwdrivers with insulated shafts – These are critical for safety, as they help prevent electrical shocks when working with powered medical devices.

• Lighted magnifying glass – Useful for reading small, detailed labels or numbers on medical devices, ensuring accuracy during maintenance and repair.

• Magnetizer/demagnetizer – This tool is vital for ensuring that screws and small parts don’t become magnetized, which could interfere with sensitive equipment.

• Cordless screwdriver – A highly practical tool that saves time and effort when dealing with numerous screws in medical devices.

In addition to these tools, the tool case itself plays a crucial role. It should be designed with:

• Large pockets to accommodate various cables, plugs, multimeters, tachometers, and other essential accessories.

• A dedicated space for a tablet or laptop – as these are often used to access manuals, software updates, or diagnostic programs.

• Disinfecting capability – The case and tools should be easy to disinfect to maintain a sterile environment, preventing contamination between different medical devices.

By ensuring these often-overlooked tools and features are included, biomedical engineers can better maintain and service medical equipment in a safe, efficient, and hygienic manner.

SPRAGIS: Critical but often overlooked tools for biomedical engineers include automation platforms that consolidate essential data, enabling seamless integration and efficiency. These systems automatically record results, freeing up engineers to focus on the equipment and enhancing interactions with the clinical team. Additionally, multifunctional test devices that can perform diverse procedures and accurately capture documentation are invaluable. Such devices streamline workflows significantly, offering multiple functionalities in a single unit. This not only improves efficiency but also ensures comprehensive testing and accurate record-keeping, which are crucial for maintaining high standards of patient care and compliance.

TORRES: Carrying cases/tool bags are more personal and preference than anything else, I feel. I like to use a combination. I have a small mechanic tool bag which fits my first look tools for a repair. If I need to get deeper in the trenches, I have a larger utility backpack that holds larger and more unique tools. Overlooked tools include bungie cables, jack stands, spotlight, telescopic pickup magnet,

Greg Alkire

Pronk Technologies

soldering iron/heat shrink, hot glue gun, magnetic screw bin, pick and hook set.

Q: HOW CAN A BIOMED ENSURE THAT THEIR TOOL KITS ARE PORTABLE, YET COMPREHENSIVE ENOUGH FOR THE VARIETY OF MEDICAL EQUIPMENT THEY WORK ON?