Class of 2025

P.14 | PRO OF THE MONTH CHRIS AVILA

P.40 | ROUNDTABLE BEDS & STRETCHERS

P.94 | PREFERRED VENDORS DID YOU KNOW, FUN FACTS

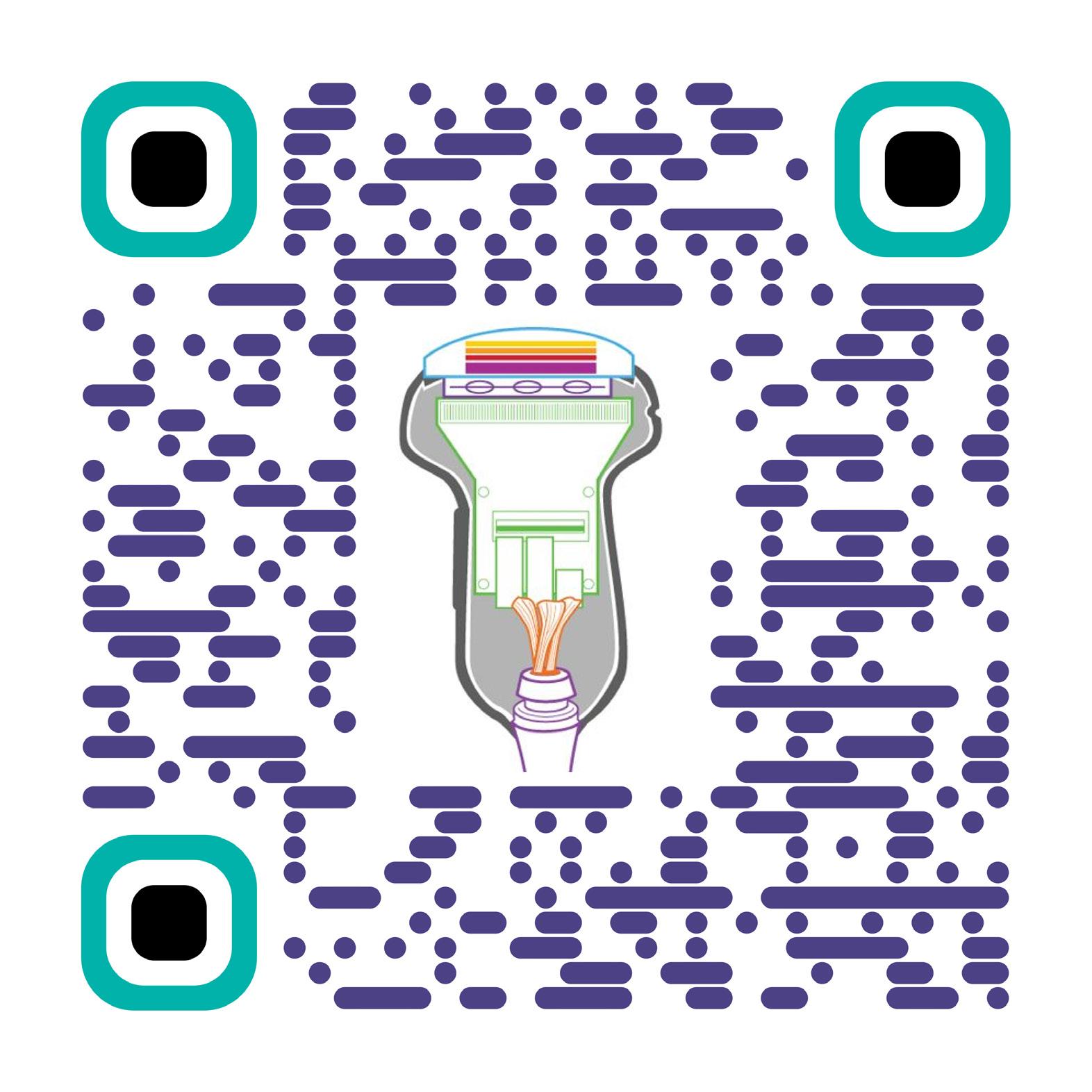

Millions of products, thousands of suppliers, one marketplace. Experience an unmatched selection of biomedical products all in one place. The PartsSource biomedical parts and equipment marketplace has everything from bed parts and accessories to infusion pumps and patient monitoring systems, with thousands of products Ready-to-Ship. You can buy confidently knowing you’ll get what you need when you need it.

Visit www.partssource.com to browse our online marketplace.

Scan the QR code to start shopping

P.12 SPOTLIGHT

p.12 Department of the Month: Children’s Hospital Colorado Clinical Engineering Department

p.14 Professional of the Month: Chris Avila

p.16 Next Gen: Amanda Nyen

p.18 Association of the Month: Arizona Healthcare Technology Management Association (AZHTM)

P.21 INDUSTRY UPDATES

p.21 News & Notes

p.27 Ribbon Cutting: Paubox

p.28 AAMI Update

p.30 ECRI Update

P.32 THE BENCH

p.32 Biomed 101

p.35 Tools of the Trade: AAMI CEU Journal

p.36 Webinar Wednesday

p.38 Shop Talk powered by MedWrench

P.40 FEATURE ARTICLES

p.40 Roundtable: Beds & Stretchers

p.46 Cover Story: Make Succession Planning a Goal: Developing a Sustainable Team

p.50 40 Under 40

P.75 EXPERT ADVICE

p.75 Careers Now

p.76 Leadership

p.80 Health-ISAC

p.82 Networking Notes

p.84 Right to Repair

p.86 The Future

PUBLISHER John M. Krieg

VICE PRESIDENT Kristin Leavoy

VICE PRESIDENT Jayme McKelvey OF SALES

EDITORIAL John Wallace

CONTRIBUTORS Roger Bowles

K. Richard Douglas

Jim Fedele

Joie Marhefka

Manny Roman

Steven J. Yelton

ACCOUNT Megan Cabot

EXECUTIVES Emily Hise

ART DEPARTMENT Karlee Gower

Taylor Hayes Alicia Brown

DIGITAL SERVICES Cindy Galindo

Kennedy Krieg

Haley Harris

EVENTS Kristin Leavoy

WEBINARS Linda Hasluem

HTMJOBS.COM Sydney Krieg

ACCOUNTING Diane Costea

CIRCULATION Joanna Manjarrez

Rob Bundick, Director HTM & Biomedical Engineering, ProHealth Care

Carol Davis-Smith, CCE, FACCE, AAMIF, Owner/ President of Carol Davis-Smith & Associates, LLC

Nadia ElKaissi, CHTM, Biomedical Engineer, HTM, VA Central Office (19HTM)

Bryant Hawkins Sr., Site Manager, Children’s Hospital of New Orleans

Earl Morris Jr., BMET, Director of Clinical Engineering, Harrison County Hospital

Leticia Reynolds, Clinical Engineering Operations Manager at UCHealth Parkview Medical Center

Gain the foundational knowledge and technical skill s you need to thrive in the growing field of Healthcare Technology Management. CBET provides comprehensive online programs, including our newly launched Denta l Equipment Technician training, specifically designe d to advance the skills of industry professionals. Our f lexible, expert-led courses enable technicians to stay ahead in this rapidly evolving field.

Virtual Reality (VR) labs provide a flexible and immersive learning experience tailored to accommodate busy schedules. These labs enable users to practice and refine skills in a controlled, risk-free environment, fostering the development of essential competencies.

BY K. RICHARD DOUGLAS

Ranked by U.S. News and World Report as one of the top 10 children’s hospitals in the nation, Children’s Hospital Colorado has a history that finds its origins in the cowboy days of the late 1800s and a group of tents.

Originally founded in 1908 in Denver, and converting a former residence in 1909, the first patients were admitted in 1910. The current facility was opened in 2007. The hospital is affiliated with the University of Colorado School of Medicine. Each year the hospital is consistently ranked among the best pediatric hospitals.

The Children’s Hospital Colorado Clinical Engineering Department manages the large inventory of medical devices that can be found in the current facilities.

Under the leadership of Director James Grissom and Manager James Stebbins, the CE team includes 28 technicians working across four hospital campuses with associated clinics

and outreach program locations. Many of the techs are CBETcertified and some have B.S. degrees in biomedical engineering.

“We have 27,728 assets in active inventory. The team has approximately 250 years of combined experience,” Grissom says.

In addition to the four hospital facilities – with a combined 600-beds – the CE team manages medical equipment for a level 1 trauma center, two level 2 trauma centers, two urgent care locations, 50-plus anesthetizing locations and more than 30 clinic and outreach programs in multiple states.

The IT and CE teams are unique departments but often work jointly on projects.

“While we are still two separate departments, we maintain a strong working relationship, especially patient monitoring and EMR integration. We worked with IT to create CE user group and a folder with files, programs and service manuals to push to all technician’s accounts,” Grissom says.

The department plays a key role in equipment acquisition.

“The department sits on the capital procurement committee and has created a Biomedical Equipment Acquisition Review (BEAR) Committee to validate and standardize the purchases

“Our vast years of experience are used to review contracts and determine hardware, software and training needed.”

of all medical devices. We facilitate inter-departmental communication and support due to the vast institutional knowledge of the team members that have worked here for more than 15 years,” Grissom says.

He explains that service contracts go through multiple layers of approval and the team is working to bring these in through the BEAR program to provide a central repository for all equipmentrelated contract data.

“Our vast years of experience are used to review contracts and determine hardware, software and training needed. When contracts are proposed, the department workload, as well as quantity across the enterprise go into determining if the service line should be brought in-house. We are working toward integrating our contracts into our computerized maintenance management system (CMMS) to alert technicians of coverage status, as well provide customers with accurate ROI/renewal recommendations,” Grissom adds.

For data collection, Grissom says that new equipment is directed to the department at each facility to be checked and for inventory information entered in the CMMS.

“We align our information with accounting for install date, purchase price and depreciation tracking. We assign four-year inventory validation work orders on all equipment deemed to have no required maintenance per the manufacturer. Manual data validation is performed during preventative maintenance cycles, as well as when specific department requests come in,” he says.

For special projects the team members rely on their years of experience. Those projects run the gamut from upgrading feeding pumps to the challenges posed by the pandemic.

One of those challenges was the need for patient floor expansions.

“We participated in the opening of a new campus during COVID. We provided project and program management on specialized treatment floors to ensure that proper medical

devices are available for that patient population, as well as technical resources for equipment purchases and installation,” Grissom says.

Other projects included research inventory tracking and a feeding pump fleet upgrade.

“Children’s Colorado’s growing research program needed assistance tracking equipment coming in/going out for recall and regulatory compliance. We had a short turnaround time for a system-wide feeding pump upgrade due to nationwide supply chain feeding cassette shortage and successfully coordinated with clinical and non-clinical departments for training, deployment and supplies,” Grissom says.

The team’s abundance of experience serves them well when it comes to problem solving. Grissom says that one example was creating a Philips testing station in department to work with the IT EPIC integration team.

The CE team also worked with anesthesia physicians to accommodate all the ancillary equipment mounted to the anesthesia machines. Team members worked with clinical educators to be called when new feeding pumps fail on the floor, the team responds promptly to witness/troubleshoot.

On the soft skills side, the group created a department flyer to inform customers what they do, how to get a hold of CE, as well as miscellaneous asset tags used in the CMMS if requesting work that is not directly related to a piece of equipment.

They also brought their experience to an MRI upgrade.

Grissom explained that a “manufacturer-performed upgrade led to a quenched magnet” and CE “assisted in facilitating rental and placement of portable MRI while the unit was repaired and re-certified.”

Away from work, members are involved with the Colorado Association of Biomedical Equipment Technicians (CABMET), AAMI and ECRI.

For pediatric patients and their families in Colorado, there is the assurance that they are being treated by a national standout facility, backed by the clinicians and HTM professionals who are up to the same standard.

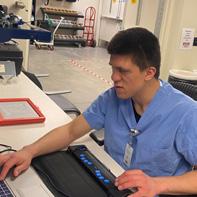

BY K. RICHARD DOUGLAS

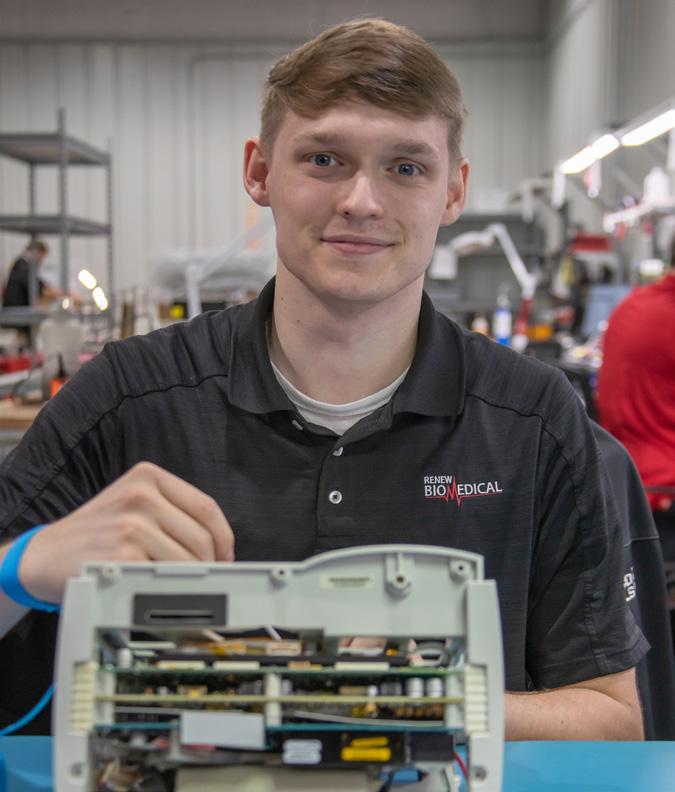

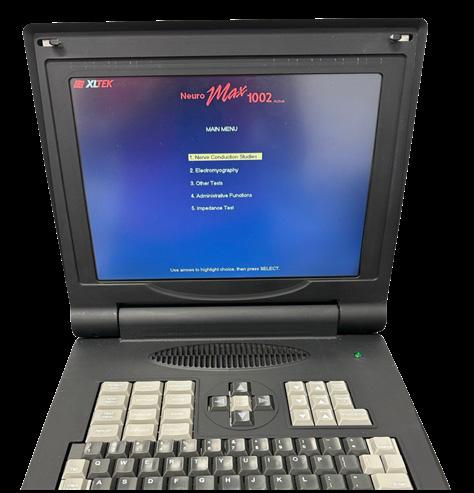

hris Avila, a biomed intern, walks into the shop, sits down at a bench, and begins work on an Alaris pump. Just another day in the life of a biomed; right?

Well, not exactly, Avila should be an inspiration to every biomed. Heck, he should be an inspiration to any person … in any walk of life. Avila is blind.

The sense that most biomeds depend on the most to maintain and repair medical equipment; Avila is doing without. Yet, he sits in his shop working on an important piece of medical equipment.

Avila lost his sight at the age of five as the result of an accident.

“I was born with sight and only went blind due to a car accident. I was five-years-old and was hit by a drunk driver outside of my grandparent’s house while speaking with my stepfather. I lost my sight and am now totally blind; for an example, I could stare at the sun all day and never blink,” he says.

Avila says that he is a braille reader and learned braille over the course of three months.

“I attended Salk Elementary School in Merrillville, Indiana. When I entered fifth grade, after talking with my mother, we decided that I would attend the Indiana School for the Blind and Visionally Impaired (ISBVI). I had been going there for several years at this point, starting when I was in second grade, but only as a short-course student. Short-course was a program that offered students like myself the opportunity to go to ISBVI for one week out of every month while still attending public school,” Avila says.

He says that in fifth grade, he switched to going full-time, which meant he would have to travel back and forth from Indianapolis each week, and stay in the dorms on ISBVI’s campus.

“I continued to go there until my graduation in 2017; my graduating class was less than 15 students and I was the valedictorian. During my time at ISBVI, I was introduced to many assistive technologies, such as screen-readers and braille displays, which I use to this day. I also participated in sports from seventh grade to my senior year of high school; track, goalball, wrestling and swimming,” Avila says.

In his sophomore year, he began taking classes at North Central High School; world history, AP U.S. History (only for a semester), global marketing and business law.

“For college, I originally went to Indiana University-Purdue University Indianapolis (IUPUI), pursuing a business degree, but after a year, decided to give it up and switched majors; thus began my journey as a biomedical engineer. Now, after the divorce of IU and Purdue, I am a Purdue student,” Avila says.

FAVORITE BOOK:

The Wheel of Time series by Robert Jordan

FAVORITE FOOD:

Steak tacos with corn tortilla and a glass of horchata

HIDDEN TALENT:

I am rather good at playing darts, not getting the exact score needed to win a game but hitting the bull’s eye; the most I ever hit in one night was six.

FAVORITE PART OF BEING A BIOMED?

I have always found working with my hands to be quite satisfying; as a child I always loved taking things apart – my toys, radios, engines, etcetera. Being a biomed allows me to do the same with medical devices, and unlike then, I actually can put things back together again and have them work.

He says that over the summer of 2024; he participated in an internship program facilitated by the Gregory S. Fehribach Center at Eskenazi Health.

“I am a biomedical engineering student that was interested in medical devices; specifically, the process of maintaining and repairing them,” Avila says.

The challenges of working as an HTM professional as a blind person were precipitated by the challenges of training a blind person to be a biomed.

“Originally, I wanted to be a business major and work for a shipping company off the East Coast. However, after taking a year of classes I realized it just wasn’t for me, and because of a book I read, ‘23 Years on Fire,’ I chose to then try my hand at biomedical engineering. To [the best of] my knowledge, I am the first blind student in either the IU or Purdue schools to pursue this degree, and it has been quite the challenging experience,” Avila says

He says it wasn’t only a challenge for him, but also for everyone involved; professors, the university staff, and his auxiliary aids.

“We all had to figure out how to best present to me the information being taught, it was a learning curve that just kept going. With new challenges and difficulties seemingly arising every semester; how to present the information, how to navigate programs that were not designed for people without sight, getting course material in a timely manner, etcetera,” Avila says.

How did Avila actually transition to hands-on work?

“In the beginning, I was introduced to many different devices, and was given the task of disassembling and then reassembling said devices. The purpose of which was to familiarize myself with the components of each; when reassembled, everything was tested to ensure I had put things back together again correctly. From there I was shown how to do the PMs for several of the more common devices that came through the shop. I thoroughly enjoyed my time working in the biomed department, and returned for another internship in the spring of 2025,” he says.

The ability to go hands-on with medical equipment repair and maintenance still did not come without challenges. It took some ingenuity and trial and error to move toward a workable solution.

“During my first internship, I very much enjoyed working with the other technicians in the

department; there was an issue however. The programs and software used for the preventive maintenance were inaccessible to me; this made it so that one of the techs would always have to be present when I worked on a PM. Towards the end of that internship – and what I have mainly focused on during this current internship – my objective was to figure out a way to complete a PM independently,” Avila says.

He says that since the Alaris pump is the most common device that needs to be repaired, the Alaris program became the first to be tackled.

“The main challenge was determining how to navigate the Alaris program using a tool called JAWS; a text-to-speech screen-reader. JAWS would read certain things within the application window but not others, and not consistently.

Another challenge was that when mapping out the program, JAWS would not read the different tabs, windows, icons, or buttons in the order they would appear on the screen; if at all,” Avila says.

He says that after weeks of testing, the solution proved to be something called the touch cursor.

“The touch cursor is one of several possible cursors used to move about the screen; this process is slower than I would like, but works. The next steps would be to gain a better understanding of the JAWS script editor. Instead of using the arrow keys to navigate across the screen, I could just press a key on the keyboard and skip directly to the area I want,” Avila says.

Away from his biomed work, Avila has trained in Jiu-Jitsu for about three years and has competed in tournaments. He also spends time keeping his mind challenged.

“Instead of watching TV, I listen to audiobooks, favorite genre as of right now is litRGP. I enjoy studying and playing with numbers to see the different patterns that arise. If I’m feeling particularly adventurous, I experiment with cooking,” he says.

Avila’s family members include six siblings: two brothers and four sisters.

Can a blind person compete in Jiu-Jitsu or repair and test medical equipment? If that person doesn’t know the meaning of the word “obstacle,” they can. When Chris Avila is faced with a challenge; he just figures out a work-around. Obstacle has no meaning.

Amanda Nyen earned an associate of applied science degree in biomedical electronics before serving as a biomedical electronics technician IV/lead with St Luke’s Health System. TechNation recently found out more about this rising HTM star via a Q&A session.

Q: WHERE DID YOU GROW UP?

A: Blair, Wisconsin

Q: WHERE DID YOU RECEIVE YOUR HTM TRAINING/EDUCATION?

A: Western Technical College in LaCrosse, Wisconsin

Q: HOW DID YOU FIRST DISCOVER HTM?

A: Exploring the electronic programs offered at Western Technical College.

Q: WHY (OR HOW) DID YOU CHOOSE TO GET INTO THIS FIELD?

A: I have always been, and continue to be, fascinated by the realms of medicine and electronics. Upon reviewing the description of this program, I recognized it as my true calling.

Q: WHAT DO YOU LIKE MOST ABOUT YOUR POSITION?

A: I take great satisfaction in resolving issues. When I am needed to address a situation involving malfunctioning equipment and I can provide a solution, it is an unparalleled experience.

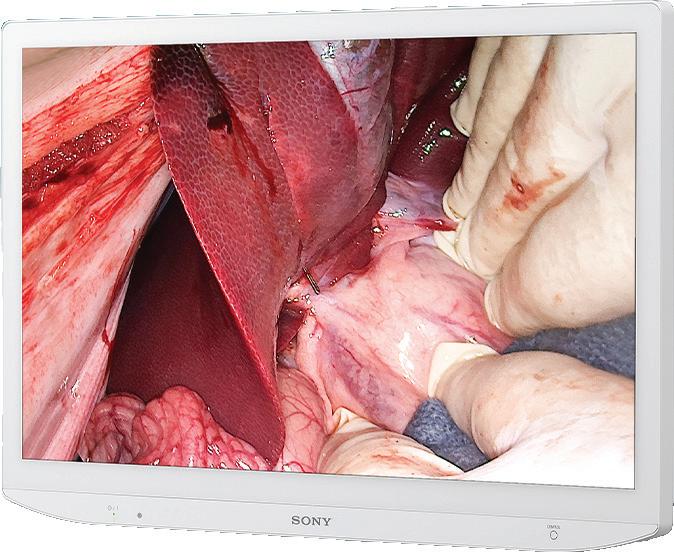

Q: WHAT INTERESTS YOU THE MOST ABOUT HTM?

A: I take great pleasure in my role within the surgery department. The advanced life-support technology, which continually evolves, provides a rewarding experience. Each day presents new challenges due to the diverse range of surgical equipment I encounter.

Q: WHAT HAS BEEN YOUR GREATEST ACCOMPLISHMENT IN YOUR FIELD THUS FAR?

A: Working in a Children’s Hospital has long been a dream of mine, and St. Luke’s has provided me with that opportunity, being the sole Children’s Hospital in Idaho.

Q: WHAT GOALS DO YOU HAVE FOR YOURSELF IN THE NEXT 5 YEARS?

A: My goal is to further develop my leadership capabilities within HTM and to mentor others, enabling them to excel in troubleshooting and repair skills.

FAVORITE HOBBY: I love softball; I have been playing softball for 25+ years.

FAVORITE SHOW OR MOVIE: “Pitch Perfect”

FAVORITE MEAL: Steak and potatoes

WHAT WOULD YOUR SUPERPOWER BE?

I consider myself modest as I continuously seek knowledge and am eager to assist others.

1 THING ON YOUR BUCKET LIST: One day I will swim with a dolphin.

SOMETHING YOUR CO-WORKERS DON’T KNOW ABOUT YOU:

I enjoy exploring literature and shows related to crime and murder, including the series “Dexter.”

BY K. RICHARD DOUGLAS

Arizona is a state of hot summers, winter tourists and snowbirds, the Grand Canyon and the Saguaro cactus. The state is best known for its Sonoran Desert region, although it offers several eco-systems, with pine forests in the north.

Maricopa County contains the largest population center, with the city of Phoenix within it, as well as being the central location for the state’s biomed association.

The Arizona Healthcare Technology Management Association (AZHTM) is the state’s biomed association. The association was founded in March of 2008. Desiree Nielsen is the president.

Prior attempts to gain traction with a statewide biomed association have run out of steam, partly because the state’s population center is in the Phoenix area and other population centers are more remote.

“The association originally founded in 2008 as AZMIA, but had a decline of presence around the time COVID happened. After COVID, the organization resurrected under the name Arizona Healthcare Technology Management Association in 2021 and has been going strong ever since,” Nielsen says.

Like many biomed associations, the pandemic proved to be a big interruption and halted many activities.

“It wasn’t until near the end of 2021 that the association was able to put together in-person meetings and ramp up

attendance,” Nielsen says.

Since 2021, the association has managed to host bi-monthly meetings, which include education sessions to enhance the knowledge of the technicians, engineers, leaders and vendors who attend.

“They are not casted online currently, but it is our goal to do so soon,” Nielsen says.

The group has also been active in promoting the HTM profession.

“Besides education, community outreach to spread the knowledge about this industry is another goal we are focusing on. For example, our Vice President Theresa Heitchler recently manned a booth at a youth spring carnival. The goal was to educate young students on what this field is and expose them to some of the equipment we work on. Our goal is to continue to do community outreach, as the industry will need new people to join the workforce, as the people who are currently in it start to retire,” Nielsen says.

There remains a need for more biomed training programs nationwide and there is some presence in Arizona. AZHTM had contact with one program in the Phoenix area last year.

“We have been in contact with a couple of people from the Maricopa Community Colleges. Representatives from the college system have come to some of the meetings to gain insight on what information is necessary to have in their programs and what type of programs they need to create to get students hired,” Nielsen says.

The reformed Arizona biomed association hosted its first convention this year. The first outing turned out to be a success.

“This year was our first year we were able to successfully host a conference. There were education sessions directed at biomedical and imaging technicians. Some of the topics included: AI in healthcare, lasers, soft skills, and X-ray basics, to name a few,” Nielsen says.

She says that there was also a vendor hall for attendees to peruse and interact with the vendors who participated.

“I think the main highlight from the conference this year is the fact that we were able to pull it off. We have never put on a conference before and we received a lot of positive feedback from the vendors and the attendees. We aim to make it bigger and better next year, now that we know what to expect,” Nielsen adds.

The one-day conference was on February 7 at Desert Willow Conference Center in Phoenix. The AZHTM board members and executive committee planned the conference, and Nielsen says they will likely be the planning committee for future conferences.

“Attendance was pretty decent, with about 100 people, including vendors and members,” she says.

Nielsen says that the turnout was mostly from Phoenix, though she believes that there were some attendees from other cities around the state.

“The goal in the future is definitely to expand the outreach to the northern and southern regions,” she adds.

The group is working to get news of their organization out to the biomed community and those entering the field.

“Our main source of recruiting has simply been through word of mouth and social media. Our association uses LinkedIn predominately to share the word about our association and try to bring in new members. We are currently strategizing a way to get the word out through higher education, as well as youth that are getting ready to leave high school,” Nielsen says.

She says that they have also reached out to those in affiliated professions.

“For example, our meeting in February was a combined meeting with the Central Arizona Society for Healthcare Engineering, which we leveraged to try and get new members from as well,” Nielsen adds.

The state known for cowboys, cacti and pleasant winters is also home to many HTM professionals. The AZHTM gives them an opportunity to network, gain education and unify.

Finally, the features you love most about your favorite ride share app, food delivery app, Angi, UpWork, or TaskRabbit are available for medical imaging equipment maintenance and repair.

Enter a Trace Ticket with one tap to broadcast your repair needs to a network of qualified technicians.

Review Bids to find the best service option for improved repair outcomes with less equipment down time, resulting in a lower overall cost.

Track progress, issue payments and rate services all in a single dashboard.

Speed

Instantly blast your service request to every qualified and vetted service provider

From response times to uptime, you no longer have to rely on service companies to track their own activities and performance

Like your favorite personal apps, get in-app alerts when a service technician is on their way, arrived, waiting for a part, completed a job, etc.

Competitive bidding among service technicians allows you to get the best price and only pay and track one entity

Compass One Healthcare has announced its signature healthcare technology management (HTM) brand: Intelas. Healthcare is evolving rapidly, and the need for integration, standardization, and scale is growing with it. Intelas exemplifies that and represents the next evolution of HTM at Compass One Healthcare, building upon an established foundation of trusted clinical engineering services.

“Healthcare now spans urgent care clinics, ambulatory surgery centers, imaging centers, and more and systems must manage the thousands of devices needed to connect and share data,” said Jim Cheek, president of Intelas. “Intelas captures what we stand for today: data-driven decisions, consistent performance, and a team that brings clarity and confidence to every stage of the equipment life cycle.”

Over the past decade the team has seen tremendous growth, and the new brand is in line with this and continued growth.

Cheek explained that the name itself combines intelligence and telas – Latin for web – which evokes interconnected systems. That’s intentional as it reflects the complexity of modern healthcare and Intelas’ role in bringing order and clarity to that complexity.

Intelas is now its own branded solution under the Compass One Healthcare umbrella with its own structure, specialized

tools, and a clear strategy. What hasn’t changed is the team behind it: experienced leadership, national reach, and the strong backing of resources.

HTM plays a critical role in shaping the healthcare experience for patients and care teams alike. Intelas reflects what the team has been delivering all along – a dedicated, site-based clinical engineering program with 24/7 support and deep expertise in the ongoing management of biomedical and imaging equipment. Now with a name that emphasizes the scale of its impact.

“We are just getting started. Customers will start to see new tools and solutions including forecasting system healthcare equipment maintenance,” Marley Pritchard, vice president of client experience and strategy at Intelas.

Intelas will continue to work alongside its sister sectors –Crothall Healthcare for EVS and support services, Morrison Healthcare for food and nutrition services, and TouchPoint for food and support services.

“Intelas reflects who we’ve become today, through our expanded capabilities and offerings, and use of data and analytics. We’re excited for the future of HTM and smarter asset management,” said Cheek.

The acquisition is complete, and Richardson Healthcare has officially rebranded as DirectMed Imaging.

In early 2025, DirectMed Imaging acquired Richardson Healthcare, investing deeply in expanding its Canon/ Toshiba capabilities, X-ray tube offerings, and training resources. Now, with the rebrand and integration complete, Richardson’s expertise in CT parts, tube repair, and engineer training is fully integrated into DirectMed’s operations.

“This acquisition supports DirectMed Imaging’s goal to deliver the most reliable, responsive, and comprehensive support for the diagnostic imaging community worldwide,” a news release stated.

DirectMed Imaging now offers:

• Canon/Toshiba aftermarket parts inventory

• Exclusive global distribution of ALTA750D and ALTA750G CT X-ray tubes

• Repaired Siemens Straton Z CT tube distribution

• Expanded training programs for Canon/Toshiba CT platforms

Additionally, the Toshiba representative you’ve worked with in the past will continue to be attached to your relationship with DirectMed Imaging moving forward, according to the release.

Fluke Biomedical, a Fortive company and leader in innovative healthcare solutions, recently unveiled the ESA715 and ESA712 Electrical Safety Analyzers. These groundbreaking tools revolutionize electrical safety testing, offering the same advanced capabilities as the recently launched ESA710 but with additional features, facilitating global standards testing and manual measurement mode respectively.

The ESA715 Electrical Safety Analyzer replicates the robust functionality and convenience of the ESA710, but it goes a step further by offering testing to global standards. Similarly, the ESA712 delivers the same advanced testing options but exclusively through Manual Measurement mode. These additional models continue the commitment to enhancing workflow automation, accuracy, and efficiency for healthcare technology management professionals.

The ESA715 and ESA712 maintain the compact design, 5-inch color LCD touchscreen, intuitive user interface as the ESA710, and OneQATM Workflow Automation Software onboard for the ESA715. These features standardize testing procedures, promote procedural adherence, and lead to time and cost savings for healthcare facilities. The onboard software supports automated documentation and integrates with several CMMS/EAM systems for end-toend workflow automation.

Key features of the ESA715 and ESA712 Electrical Safety Analyzers include:

• Global standards testing Manual Measurement mode

• Portable, ergonomic design with integrated handle

• OneQA-enabled workflow automation (ESA715)

• Wireless capability for field testing and automatic result synchronization

• Ten applied parts posts with LED lighting guidance

• Insulation resistance range from 50V, 100V, 250V, and 500V

• Automated test sequences for compliance to electrical safety standards (ESA715)

• ECG waveform tests and dual-lead measurements

• Easy data entry via barcode scanner, external keyboard, or on-screen keyboard (ESA715)

• Robust construction tested for rugged field applications

• Comprehensive service and coverage with the Protect+ Program

“The introduction of the ESA715 and ESA712 Electrical Safety Analyzers, in addition to the ESA710, underlines our dedication to innovation and excellence in healthcare technology management,” said Mike Nguyen, Senior Product Manager at Fluke Biomedical. “These models further our aim to set new standards for electrical safety testing in the healthcare industry.”

A proposed ASTM International standard will provide general principles for generating test report summaries from standards for medical and surgical materials and devices. The proposed standard (WK92947) will also recommend best practices regarding both content and form of these summaries.

ASTM’s medical and surgical materials and devices committee (F04) is developing the proposed standard.

“This proposed guide will help manufacturers and laboratories looking to generate clearly written and structured test reports,” said ASTM member Jove Graham, associate professor, Center for Pharmacy Innovation and Outcomes, Geisinger Health. “It will help those who are

writing new standards to make their report sections more consistent, and it will help the readers users of test report summaries.”

Graham notes that clarity of communication in test reports is important for vendors, purchasers, and regulators of medical and surgical materials and devices.

“A well-structured and well-formatted presentation of the results of premarket testing is necessary to demonstrate how those results support the claims regarding conformance of a test unit to a test method, or more broadly, claims of product conformance to medical device regulations in various jurisdictions,” said Graham.

AllParts Medical, a Philips company, announced two key leadership updates that will strengthen the organization’s growth trajectory and operational excellence. Kelly Feist has joined the company as vice president of sales, and James Akins has been promoted to vice president of operations.

The announcement was shared by Richard Gerler, newly appointed CEO of AllParts at Philips and former vice president of operations for AllParts Medical.

“We’re entering a pivotal time for AllParts Medical as we continue to scale our impact across the healthcare service ecosystem,” said Gerler. “I’m incredibly excited to welcome Kelly to the team and to celebrate James’s well-earned promotion. Both bring outstanding experience, leadership, and vision to our organization.”

Kelly Feist officially joined AllParts Medical on May 19, bringing with her over a decade of experience in healthcare technology and service leadership. She most recently served as managing director of Ascom Inc., where she led transformational initiatives in healthcare information and communications systems.

Feist holds an MBA from Vanderbilt University and a post-graduate certificate in Healthcare IT Leadership from the Harvard School of Public Health.

“Kelly’s ability to align strategy with customer value is unmatched,” added Gerler. “She’s not only a proven leader – she’s also someone who deeply understands the challenges and opportunities within our space.”

In her new role, Feist will oversee the national sales team, focusing on growth, innovation, and maintaining AllParts Medical’s industry-leading customer satisfaction.

AllParts Medical also announced the promotion of James Akins to vice president of operations. Since joining the company in 2014, Akins has served in key roles across sourcing, logistics, technical operations, and supply chain management.

Starting as a Sourcing Specialist III, Akins advanced into operational leadership roles including logistics manager and, most recently, senior manager of repair operations. Under his leadership, the company’s repair and refurbishment services have seen significant improvements in quality, efficiency, and scalability.

“James is a leader who leads with precision,” said Gerler. “He knows our business inside and out, and his steady hand has helped us continuously raise the bar on performance. This promotion is not only well-deserved –it’s critical to our ongoing success.”

In his new role, Akins will lead operations across AllParts Medical’s facilities, ensuring seamless execution, supply chain efficiency, and continued excellence in customer delivery.

The National Fire Protection Association (NFPA) Health Care Section has elected Chad Beebe, AIA, CHFM, CFPS, CBO, FASHE, deputy executive director of the American Society for Health Care Engineering (ASHE), as the group’s next chair. Beebe, who has been a section member since 2000, will start the new role on June 17.

NFPA’s Health Care Section is comprised of health care professionals from across the field – from fire safety officials and facilities engineers to long-term and acute care providers – who work together to minimize risk in health care environments. The section provides a forum to discuss and disseminate pressing issues facing health care in an effort to share ideas, solve problems and exchange information – as well as discuss and review the latest NFPA codes and standards and share opportunities for NFPA code/standard development. The section also reviews changes to the more than 80 NFPA codes and standards that apply to health care, collect section member feedback on the impact of those changes, and present the section’s recommendations to

Veteran and HTM leader Bruce Madden passed away on June 10, 2025. He was born July 27, 1950, in Lynn, Massachusetts where he attended school and graduated from Lynn Trade in 1969. He enlisted in the Air Force and served in weather equipment maintenance while stationed in Orlando; Guam; Washington, D.C.; Weisbaden AFB in Germany; and Pease AFB in New Hampshire.

After his discharge from the Air Force, Bruce went to work at Brigham and Women’s Hospital in the biomedical department and worked his way up to director the biomedical department and was in Boston for 10 years. He relocated with his wife to Fort Lauderdale, Florida, in 1989. He worked at Broward Health Hospital and then went to work at Miami Children’s Hospital where he worked in the biomedical department for 10 years. He then worked at MedEquip Biomedical until he retired in 2016.

Colleagues recall his dedication and hard work.

“Bruce and I worked together for many years, both in Boston and in Miami. In addition to being a pleasure to work with, he was knowledgeable and dedicated to his profession. I consider myself fortunate to have known and worked with him and will always treasure our years together,” Frank Magnarelli shared online.

“Bruce will always be in my heart. He was best man at my

NFPA’s technical committees developing the standards. Finally, the section identifies and delegates members to serve on the various NFPA codes and standards committees to represent health care’s interests.

“Chad’s election to chair of the NFPA Health Care Section gives health care facilities professionals an amplified voice in code and standard development and gives ASHE access to vital cross-field code and standard information that we can share with members,” says Lizzie Ortolano, ASHE’s executive director. “This also further solidifies ASHE’s role as a leader in the health care field and provides the opportunity to share how our work in the health care physical environment impacts patient care and supports better patient outcomes.”

Beebe will serve as chair of the section for a two-year term. In addition to his work at ASHE, Beebe serves on more than 20 NFPA technical committees, including as chair of the Health Care Section Codes and Standards Review Committee.

wedding with Linda, Bruce was (is) my friend. No nonsense leadership in clinical engineering at Brigham and Women’s Hospital, loved by his co-workers, dedicated and committed to healthcare,” Phil Levine wrote online.

His greatest pleasure was traveling, and he enjoyed several cruise trips. Travels included a World Cruise, Alaska, Hawaii, Northern Europe, and Mediterranean cruises.

Bruce is survived by his wife Janice; sister Pamela J. Maden (Sanbornville, N.H.); sister-in-law Cathie Daugherty (Winter Springs, Fl); Sister-in-law Carol Kennedy ( Astatula, Fl); brother-in-law Thomas Clarke (Anderson, S.C.).

Nephews: John Paul Story (Swampscott, Ma). Jeffrey Rains (Anderson, S.C.); Donny (Shelly) Daugherty( Winter Springs); niece Brandi McAlister (Iva, S.C.), grandnephews Joseph Rains, Jeremy Rains, and Wyatt McAlister. grandnieces: Amber Daugherty, Madelynne Daugherty, Lauren Daugherty, Sophia McAlister.

TechNation magazine continues to promote and applaud the men and women of healthcare technology management (HTM) with the third annual Tech Choice Awards. The Tech Choice Awards (also known as the Wrenchies) shine a spotlight on the heroes of HTM.

Nominations are open through August 15, 2025. Visit 1technation.com/techchoiceawards to nominate yourself or someone else.

The newly updated award categories are:

• Professional of the Year

Sponsored by Innovative Radiology

• ISO Professional of the Year

• Young Professional of the Year

Sponsored by Prescott’s

• Military BMET of the Year

Sponsored by College of Biomedical

Equipment Technology

• Educator of the Year

Sponsored by Maull Biomedical

Enter the contest and help TechNation celebrate. Fill out the short form at 1technation.com/contest for a chance to win one of 12 prizes, each valued at $150 or more!

Additional entries to win can be acquired by sharing on LinkedIn or submitting a photo. Each month, a winner will be selected and featured in TechNation magazine!

June’s winner is Alexis Haley.

Find out more information on Page 104.

• Director/Manager of the Year

Sponsored by MW Imaging

• Women in Leadership Award

Sponsored by Avante Health Solutions

• Humanitarian of the Year

Sponsored by Pronk Technologies

• ICON Award

Sponsored by Renovo Solutions

• Industry Influencer of the Year

Sponsored by Soma Tech Intl

• Midsize Department of the Year

Sponsored by USOC

• Large Department of the Year

Sponsored by USOC

• Outstanding Vendor of the Year

• Association of the Year

Sponsored by MultiMedical Systems

The 2025 TechNation Tour rolls on this month after a stop at the HTM Mixer in Milwaukee. The tour features a long list of stops where TechNation representatives will give away swag and host some reader parties.

The next TechNation Tour stop is the 47th annual NCBA symposium being held at the Cherokee Casino Resort and Convention Center August 25-27. The annual Mike McCoy golf tournament will be held on Monday, August 25th followed by a welcome party with golf awards (all are welcome). Tuesday will be a day packed with educational opportunities, annual business luncheon, vendor show and The TechNation After Party where all are welcome. The third day includes more education and lunch with the vendors during exhibit hall hours.

The TechNation party will serve as a TechNation Tour Stop on Tuesday, August 26 at one of the restaurants inside Harrah’s Casino Cherokee from 8-10 p.m. Stop by the TechNation booth to pick up drink tickets during exhibit hall hours (4:30-7 p.m.) on August 26.

Upcoming TechNation Tour stops include:

• NESCE, Oct. 15

• MD Expo Dallas, Nov. 10

• FBS, Dec. 5

aubox is a leader in HIPAA compliant communication and marketing solutions for healthcare organizations. Trusted by over 7,000 customers, including DeVry University, Cost Plus Drugs, and Covenant Health, Paubox allows healthcare organizations to send secure, seamless messages without portals or passwords.

Its HITRUST certified platform includes outbound email encryption, inbound threat protection, and secure marketing capabilities that integrate with Google Workspace, Microsoft 365, and Microsoft Exchange. Every email is encrypted by default, reducing risk and ensuring HIPAA compliance without disrupting workflows.

Paubox Email Suite provides secure email encryption, advanced inbound threat protection, data loss prevention, and workflow automation. Paubox Marketing is the only HIPAA compliant marketing platform that lets recipients read personalized emails with PHI directly in their inbox. Paubox Email API makes it easy to integrate HIPAA compliant communication into applications and systems – no portals or logins required.

One of the newest features, Paubox ExecProtect+, blocks phishing and impersonation attempts before they reach the inbox – something traditional tools often miss. Paubox [Tags] brings instant clarity to inboxes by authenticating incoming emails that are sent by verified, safe senders, helping staff quickly identify legitimate communications. Paubox Transcription automatically converts voicemail messages into text and delivers them via encrypted email, enabling faster follow-up without compromising HIPAA compliance. Together, these tools enhance security, streamline workflows, and reduce friction for both staff and patients.

Paubox COO and Chief Compliance Officer Rick Kuwahara has over 15 years of strategic leadership in various industries from telecom to non-profits. He has established and developed Paubox’s information security and compliance program to

become the first known email encryption solution to receive HITRUST certification. He recently shared more information about Paubox.

Q: HOW DOES YOUR COMPANY STAND OUT IN THE MEDICAL EQUIPMENT FIELD?

KUWAHARA: Paubox plays a critical role in securing the communication infrastructure that supports the healthcare industry. Whether you’re a provider, vendor, or partner exchanging PHI, email remains the most common – and vulnerable – channel in healthcare. Paubox is HITRUST certified, rated #1 in HIPAA compliant messaging software by G2, and trusted by over 7,000 customers. Our platform encrypts every email by default and blocks inbound threats – without portals or passwords – helping healthcare organizations meet compliance standards and protect patient data with minimal IT overhead.

Q: WHAT IS ON THE HORIZON FOR YOUR COMPANY?

KUWAHARA: In keeping with our focus on using customer feedback as our roadmap for what to build and when, we continue to leverage AI to provide exceptional value in the following areas: email encryption, security, archiving, and data loss prevention (DLP). In the near future, we will ship enhanced email threat detection powered by large language models (LLMs).

Q: IS THERE ANYTHING ELSE YOU WOULD LIKE OUR READERS TO KNOW?

KUWAHARA: Email security is often taken for granted – until something goes wrong. Last year, 60% of healthcare organizations experienced an email-related security incident, and many didn’t discover it until patient data had already been compromised. At Paubox, we’re on a mission to change that. Our tools work quietly in the background, helping healthcare teams protect sensitive information, reduce risk, and focus on what matters most: patient care.

For more information, visit paubox.com.

Coasting has never been Sheila O’Donnell’s style. Even in retirement, she remains deeply invested in the healthcare technology management (HTM) field, where she spent over three decades – including nearly 10 years at Crothall Healthcare.

Her path to HTM, however, was anything but routine. O’Donnell began her career focused on supply chain issues, rising steadily at the University of Virginia to become associate director of materials management. Along the way, she deepened her expertise with coursework in purchasing and material management – earning the coveted Certified Purchasing Manager credential. Never one to stand still, she later returned to her alma mater, James Madison University, to complete an MBA and strengthen her leadership acumen.

That same curiosity proved invaluable at Crothall, where she served as senior vice president of the technical resources group. Her reach was broad – touching everything from quality and informatics to cybersecurity and capital planning. Under her watch, the company earned ISO 13485:2016 recertification – a key benchmark for medical device organizations.

O’Donnell became known for her high standards and steady hand. But it was her guiding philosophy – evolve or fall behind – that truly defined her leadership style.

That mindset served her well as she navigated the evolution of HTM. “One of the coolest things in the last 10 years has been seeing the rapid evolution of IT needs in HTM,” she says.

During O’Donnell’s tenure at Crothall, many HTM departments moved away from block-and-tackle CMMS platforms and adopted smarter systems – tools that did more

than track work orders. These platforms supported real-time dashboards and deeper analytics into equipment performance, repair history, and service costs. Watching the transformation unfold, she says, was both exciting and rewarding.

“Clients’ demand for data transparency has pushed the industry to improve real-time data quality,” O’Donnell says. She likens it to a patient medical record: “We must enter data into the system on time, ready for instant consumption by our clients. Now, clients can have even greater confidence in their clinical engineering team, as real-time dashboards show exactly how their program is performing.”

Artificial intelligence, she believes, will push things even further – predicting system failures, fine-tuning labor needs, and driving smarter purchasing decisions.

“It’s an exciting new world,” she says.

Also exciting – and surprising, O’Donnell says – is the growing adoption of ISO 9001 and ISO 13485:2016 standards, which she views as a major force reshaping healthcare. These quality management systems have significantly reduced medical device risk and improved patient safety – cutting defective part rates for imaging equipment from double digits to under 2%. To O’Donnell, that shift stands out as the most unexpected innovation of her career.

While technology transformed HTM, O’Donnell’s leadership proved just as critical – especially early in her career, when she was tasked with rebuilding a team plagued by years of

instability. With morale low and an internal bet she wouldn’t last two years, she took a methodical approach. In her first 90 days, she focused on understanding the team’s challenges, then launched a three-pronged strategy built on client service, team building, and operational excellence.

“I started with planes, trains, and automobiles,” she says, “trying to learn everything that I could.”

At the heart of her plan: hiring “wow” candidates – the kind who made interviewers stop and say, “Wow, this person brings something special.” But mapping out a plan with her team made the biggest difference. “I’ve always found that the more you share and discuss with your teams, the better buy-in and support you’ll receive,” O’Donnell says. “The financial performance modeled the results of the improvements in the other areas.”

Two years later, the team had reclaimed its spot as a top performer.

O’Donnell’s advice to rising HTM leaders is simple but powerful: stay curious, stay informed, network widely, and never stop learning. “Think positive,” she adds. “That’s the No. 1 thing that opened doors for me. Have a ‘can do’ attitude!”

She emphasizes that while AI can synthesize information, human strengths – like communication, emotional intelligence,

and a relentless focus on quality – remain the bedrock of leadership.

One of the most important – yet often overlooked – skills, she says, is the ability to present ideas with clarity and conviction. “I actively sought out opportunities to present and sharpen my abilities, always welcoming feedback from my peers,” O’Donnell says. “And my peers encouraged me because they knew that improvement comes from practice.”

Throughout her career, she invested in sharpening those communication skills – training with Dale Carnegie, Toastmasters, and Ty Boyd. “The ability to tell a story that moves teams to action is critically important,” she says. Strong presentation skills, she believes, are one of the biggest differentiators in leadership – and something AI can’t replicate.”

“Seize the opportunity to develop this essential skill,” she encourages the next generation.

Grounded in curiosity, operational discipline, and powerful storytelling, Sheila O’Donnell continues to raise the bar in healthcare operations – bringing energy, insight, and innovation to every chapter. Even in retirement.

Editor’s note: O’Donnell continues to also serve on the AAMI Foundation Board of Directors. She shared more about this for the AAMI Foundation newsletter.

In today’s complex healthcare environment, the push toward becoming a high reliability organization (HRO) is not just aspirational – it is essential. HROs operate under the principle that even in high-risk, high-complexity industries, harm can be reduced or eliminated through systemic design, culture transformation, and relentless learning. For healthcare providers, this means zero preventable harm to patients and staff.

Yet, reaching high reliability is not a solo journey. It requires robust support, collaboration, and access to actionable insights. That’s where patient safety organizations (PSOs) step in – serving as critical accelerators for health systems striving toward high reliability.

High reliability organizations are those that achieve consistently safe operations over long periods despite high levels of complexity and inherent risk. In healthcare, this translates to systems and cultures that:

• Prioritize safety over hierarchy or production pressure

• Respond proactively to risk

• Learn continuously from errors and near misses

• Promote resilience and adaptability in crisis

• Empower staff at all levels to speak up and take action Moving from awareness to implementation, however, requires deep structural and cultural shifts – something many healthcare organizations struggle to sustain alone.

Becoming an HRO is a complex transformation. PSOs help healthcare providers navigate several common barriers:

• Fear of reporting – By offering federal confidentiality protections, PSOs reduce fear and encourage staff to report

safety issues early.

• Data silos – PSOs aggregate safety data across settings, breaking down silos and providing a more comprehensive picture of risk.

• Inconsistent learning – With standardized frameworks and shared insights, PSOs promote continuous, system-level learning.

• Cultural inertia – PSOs help organizations engage leadership and frontline staff alike in a shared commitment to safety and reliability.

The ultimate goal of high reliability is zero preventable harm – not only to patients but to the caregivers who support them. Partnering with a PSO can accelerate improvements in both domains:

• Improved Patient Outcomes – Safer systems lead to fewer medical errors, better clinical outcomes, and greater trust from patients and families.

• Enhanced Staff Safety and Morale – When staff feel safe to speak up and know that systems – not individuals – are held accountable, burnout decreases, and engagement increases.

• Resilience in Crisis – PSOs help organizations prepare for and adapt to emerging risks, whether it’s mitigating external factors like public health threats or an internal systems failure.

Patient safety organizations, designated under the Patient Safety and Quality Improvement Act of 2005, provide a legally protected environment for healthcare organizations to report, analyze, and learn from patient safety events without fear of litigation or public disclosure.

Here’s how ECRI’s PSO directly contributes to advancing high reliability:

1. Safe Learning Spaces: HROs thrive on learning – but true learning requires candor. PSOs offer a confidential environment where organizations can share errors, near misses, and system vulnerabilities without blame. This transparency is critical for identifying patterns and driving continuous improvement.

2. Systems Approach to Improvement: A preoccupation with failure begins with a deep, data-driven understanding of how and why things go wrong. PSOs support this by helping organizations systematically collect and analyze patient safety data to uncover patterns, identify root causes, and reveal latent system vulnerabilities. This holistic view enables proactive improvements that address failures across all levels of the organization – before harm occurs.

3. Aggregated, Actionable Intelligence: By collecting and analyzing safety event data across multiple organizations, PSOs identify systemic issues that may not be apparent within a single institution. These insights help providers anticipate risks and implement best practices grounded in collective experience – not just isolated cases.

4. Expert Guidance from Patient Safety Advisors: In HROs, frontline expertise is valued and elevated. ECRI’s Patient Safety Advisors embody this principle by providing hands-on guidance from seasoned professionals with deep clinical and operational knowledge. They work directly with

your teams to interpret data, navigate complex safety challenges, and implement best practices tailored to your environment. Their support ensures that decisions are informed by real-world experience – enhancing your organization’s capacity to learn, adapt, and lead with safety.

5. Culture Transformation Tools: ECRI’s PSO offers safety culture assessments, leadership engagement strategies, and just culture training – all of which align closely with HRO principles. These tools help organizations shift from reactive, punitive models to proactive, learning-focused environments.

6. Accelerated Implementation of Safety Practices: Through expert guidance and data comparison, PSOs help healthcare systems implement proven safety strategies more rapidly and effectively. This shortens the cycle from incident to improvement and helps spread innovations system-wide.

High reliability is not a destination – it is a disciplined, ongoing pursuit. In this journey, PSOs provide guidance, protection, and data-driven insights healthcare organizations need to succeed. By working with a PSO, health systems do not just aim for zero harm – they build the foundation to achieve it. Discover how ECRI’s PSO can help your organization achieve high reliability and put safety at the center of care.

• Over $3000 in free PM kits available with training

• Massive Troubleshooting Library

• 100s of Error Codes not found in OEM Lit

• Online and Onsite Training Available • Training BMETs since 2008

BY ROHAN PATEL

In the complex and ever-evolving world of healthcare, biomedical equipment technicians (BMETs) hold a vital yet often overlooked role. Charged with maintaining, calibrating, and repairing life-saving medical equipment, these professionals carry responsibilities that extend far beyond the technical. At the heart of their work lies a series of ethical decisions – some clear-cut, others mired in ambiguity. In the context of healthcare technology management (HTM), ethics can be defined as the principles and standards that guide responsible behavior in the development, use, and maintenance of medical technology, with an emphasis on patient safety, accuracy, transparency, and respect for human dignity. Defining and applying ethics in this field is no simple task; it requires navigating a landscape shaped by clinical needs, confidentiality, corporate pressures, and rapid technological advancement. Unlike written procedures or mechanical standards, ethical guidelines are not always concrete. They are influenced by personal values, organizational culture, and the ever-shifting expectations of society.

This essay explores the ethical challenges BMETs face, emphasizing the difficulty of outlining universal ethical standards in a field where the stakes are high and the margins for error are razor thin.

Consider a situation where a BMET is urgently called to troubleshoot a malfunctioning infusion pump in an intensive care unit. A patient is waiting on critical medication, and clinical staff are understandably anxious to get the device working again. The technician identifies the issue quickly and realizes that a temporary fix – bypassing a safety protocol – would bring the pump back online almost immediately. However, completing a proper, validated repair would take several hours and render the equipment unusable in the meantime.

Here, the technician is faced with a dilemma that many professionals in the field eventually encounter: solve the problem fast with some compromise, or take the time to ensure the equipment meets safety standards before being used again. It’s not a matter of right versus wrong in a

clear-cut way – it’s a balancing act between immediate clinical needs and the potential consequences of cutting corners.

In these moments, the core ethical principles that guide BMETs come into focus. Patient safety must always be the top priority. A quick fix that compromises the integrity of the device might help in the moment but introduces unknown risks. If something were to go wrong – if the machine malfunctions again or delivers the wrong dose – the consequences could be serious, even life-threatening. The ethical duty of a BMET is not just to get machines running, but to ensure they are reliable and safe for every patient who depends on them.

Navigating this kind of scenario requires more than just technical know-how. Communication plays a critical role. The technician should clearly explain the situation to the clinical staff: what the issue is, why a temporary repair isn’t safe, and how long a full repair will take. If there’s backup equipment available, it can be used to meet the patient’s needs while the repair is carried out properly. In some cases, consulting with a supervisor or referencing institutional policies can help support the technician’s judgment and relieve some of the pressure to rush.

Documentation is another key part of the process. Keeping accurate records of what was found, what was done, and why, not only provides accountability but also reinforces the technician’s commitment to transparency and professionalism.

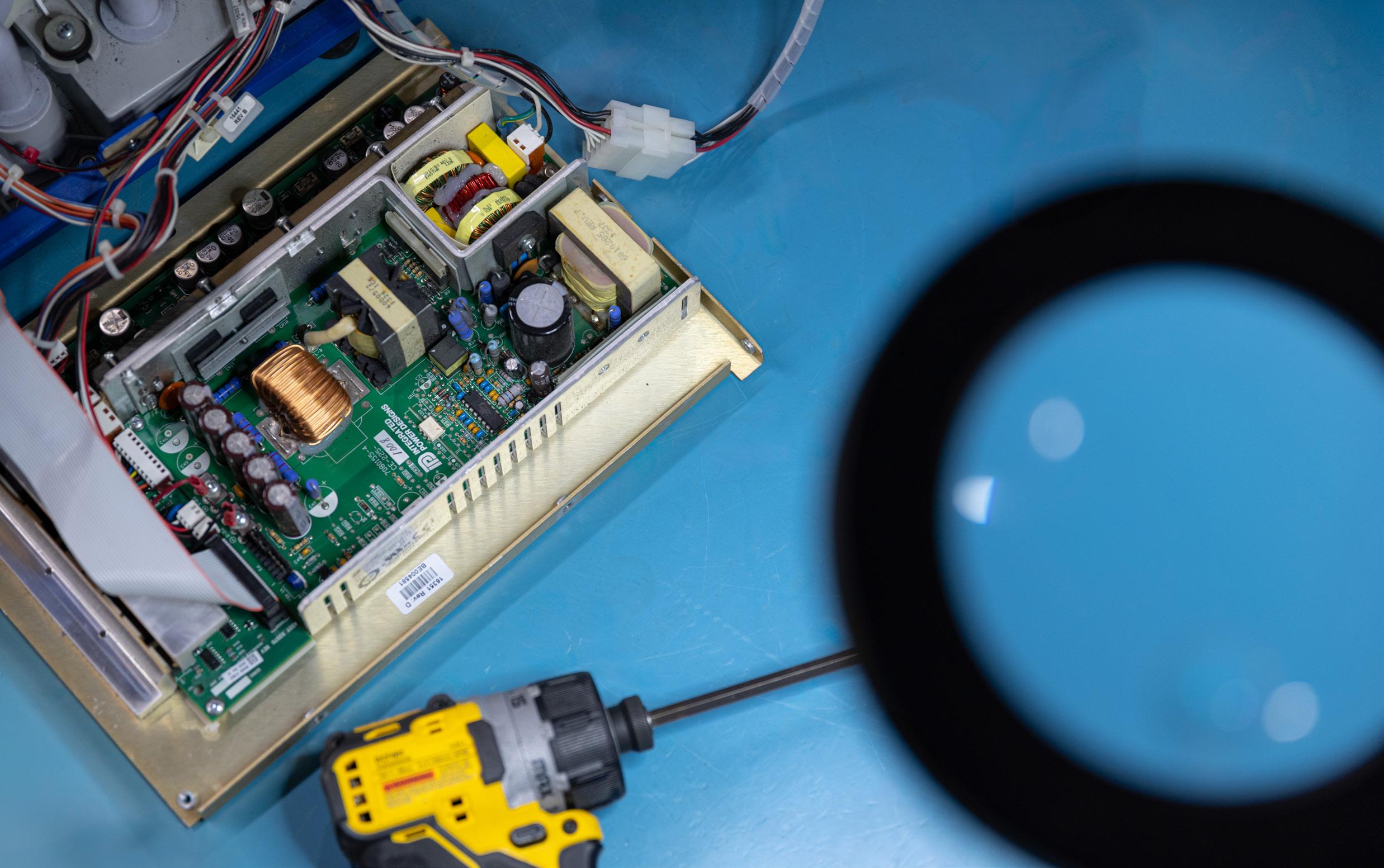

Another common ethical challenge BMETs face involves the decision to repair or retire outdated medical equipment. Imagine a technician is asked to fix an aging defibrillator that has been reliable in the past but no longer meets updated manufacturer specifications or current safety standards. Replacement parts are increasingly difficult to find, and although the device could be repaired to function temporarily, it lacks the precision and performance of newer models. The hospital, however, is working under a tight budget and cannot immediately afford a replacement. In this situation, the BMET must carefully weigh technical feasibility against ethical responsibility.

From an ethical standpoint, the main concern is patient safety. Even if obsolete equipment appears functional, its

reliability may be compromised. Devices past their expected life cycle may fail unpredictably, lack modern safety features, or not meet current clinical requirements – all of which could impact patient outcomes. Continuing to use them may create a false sense of security for healthcare providers and expose patients to unnecessary risk (ECRI Institute).

At the same time, healthcare institutions operate within real-world constraints. Limited funding, especially in smaller or underserved facilities, often means extending the life of older equipment as long as possible. BMETs are thus caught in a difficult position – tasked with maintaining equipment that they know may be less safe or effective while also trying to support patient care with limited resources.

To navigate this ethical dilemma, technicians and clinical engineers can adopt a strategic, evidence-based approach:

1. Conduct a Risk Assessment: Evaluate the equipment’s history of performance, current condition, and known failure risks. This can help determine if continued use is justifiable or presents an unacceptable level of danger to patients.

2. Assess Clinical Need: Consult with healthcare staff to understand how critical the device is to patient care. If alternative equipment or procedures exist, retiring the device might not have a significant impact.

3. Review Regulatory Guidelines: Refer to manufacturer end-of-life recommendations and compliance standards to ensure continued use does not violate safety codes or facility policies (AAMI).

4. Consider Total Cost of Ownership: Sometimes the cost of frequent repairs, downtime, and lost productivity outweighs the investment in a replacement. Highlighting this to decision-makers can strengthen the case for new equipment.

5. Document and Report: If a BMET believes that using obsolete equipment poses a serious risk, it’s important to document those concerns clearly and escalate them to clinical or administrative leadership.

The long-term ethical implications of using outdated technology can’t be ignored. Beyond immediate patient care, continued reliance on aging devices may slow the adoption of better, safer technology and contribute to systemic inequality in care quality. BMETs have a duty not only to fix what is broken, but also to advocate for progress and safety within their institutions.

By grounding their decisions in risk analysis, open communication, and professional integrity, BMETs can play a vital role in balancing resource constraints with ethical obligations to patients. The choice to repair or retire isn’t just a technical one – it’s a reflection of the values that guide modern healthcare.

Rohan Patel is a Biomedical Technician I with Mountainside & Pascack Valley Hospital-New Jersey.

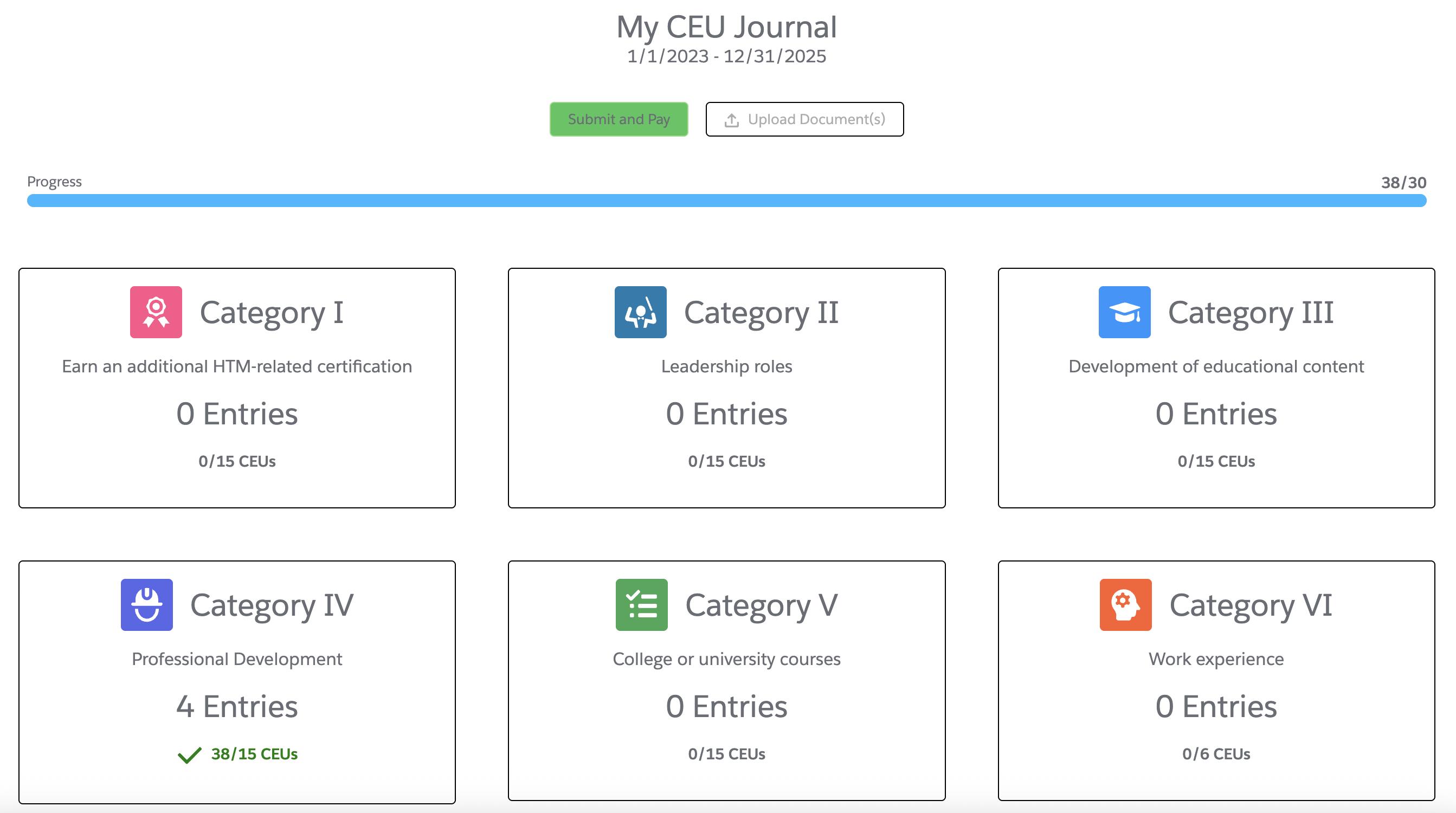

Danielle McGeary, CHTM, PMP, Vice President, HTM AUG 20 at 2PM ET

Registration on WebinarWednesday.live.

Eligible for 1 CE credit from the ACI.

There is tremendous value and impact that comes with earning ACI certifications, including the qualifications, expectations, and long-term benefits of maintaining them. ACI certification recognizes healthcare technology management professionals who demonstrate advanced knowledge of medical devices and clinical practices, along with strong technical and problem-solving skills critical to the maintenance and

repair of healthcare technology. AAMI has a new CEU journal and tracking process, which now allows certified individuals to update and manage their CEUs in real time. This improvement is designed to streamline recertification and make it easier than ever to stay on top of your professional development.

For more information, visit aami.org.

All webinars, podcast, and product demos are eligible for 1 CE credit from the ACI.

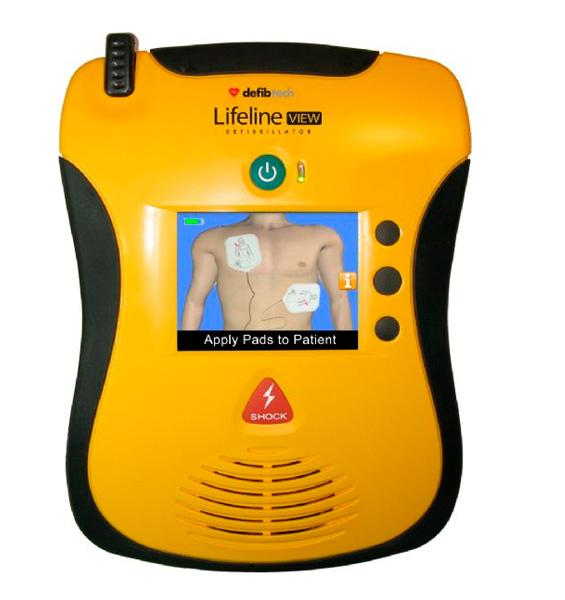

The Webinar Wednesday session “AEDs Under the Microscope: Why Testing is Non-Negotiable” delivered critical insights into these lifesaving devices. It was sponsored by Rigel Medical and eligible for 1 CEU from the ACI.

Automated External Defibrillators (AEDs) save lives – but only if they work when it counts. Rigel Medical North America

Product Manager Lewis Lennard dove into the science of cardiac arrest and the vital role of defibrillation and CPR in emergency survival. He examined why regular AED maintenance and functional testing are essential, not optional. Biomeds were able to learn the legal mandates around AED deployment, how to ensure the devices are ready for action, and the consequences of missed testing.

In summary, the webinar helped HTM professionals understand the life-saving importance of regular AED maintenance and testing during cardiac emergencies. It explored the science behind cardiac arrest and the role of CPR and defibrillation in improving survival outcomes. Attendees also discovered more about legal requirements for AED availability and why accurate detection of shockable rhythms through routine testing is critical.

The webinar also included a live Q&A session where Lennard fielded queries from attendees and provided insightful answers that delivered additional insights.

Almost 200 individuals registered for the webinar with 98 logging in for the live presentation. A recording of the webinar is available for on-demand viewing and 1 CEU from the ACI at WebinarWednesday.live.

Alan Nicewarner, CBET, BSW Health in Texas won a Swiss Force Meister Multi-Tool during the webinar.

Attendees provided feedback via a survey that included the question, “Excluding CE credits, why do you attend Webinar Wednesday?”

“I enjoy hearing different perspectives and advice from experienced technicians,” said Joshua Abner, BMET III, Cape Fear Valley.

“Keeps biomeds such as myself informed of upcoming and/or existing policies, software, and devices relevant to the biomedical career field. Helps keep my medical device knowledge a little sharper,” Nicewarner said.

“I value continuing my education in this industry which is constantly evolving,” Biomedical Equipment Technician 1 Cody Gutierrez said.

Watch these webinars on-demand at webinarwednesday.live

The Webinar Wednesday Tools of the Trade Live Demo “Strategic Data Analysis and Planning for HTM Departments” featured FSI’s Capital Planning and Analytics tools. It was sponsored by FSI and eligible for 1 CEU from the ACI.

Presenters Joe Stockman, director of product experience at FSI, and Justin Ryan, a product owner with CMS Analytics at Enstoa Strategic, provided analysis of historical data and how it is essential for effective future planning in HTM departments. They showed how it enables teams to optimize day-to-day operations while aligning with long-term departmental goals.

The webinar explored how to use tools within FSI’s CMMS to evaluate department performance metrics, develop and communicate future plans, and monitor progress over time.

Attendees were able to view a live demo of FSI’s Capital Planning and Analytics tools and learn how to leverage them together for maximum impact. Capital Planning centralizes departmental budget data, making it easier than ever to track spending and create budget plans – directly from the dashboard and without messy spreadsheets. Analytics, developed in partnership with Enstoa, helps teams optimize resource allocation through data-driven insights and clear, actionable views of key metrics for ongoing tracking and reporting.

An informative question-and-answer session delivered additional insights to attendees.

The webinar was popular among HTM professionals with almost 100 HTM professionals registered for the webinar. Those who missed the live presentation can watch an on-demand recording of the webinar and earn 1 CEU from the ACI at WebinarWednesday.live.

Columbus Regional Health Imaging Biomedical Technician Michael Lucas won a Swiss Force Meister Multi-Tool during the webinar.

Attendees provided feedback via a survey that included the question, “What was your single biggest takeaway from today’s product demo?”

“Data analysis is important,” said Marco Guerra, a biomedical equipment analyst with UC San Diego Health.

“I enjoyed a glimpse into a mature data analytics platform. We’re currently building out similar dashboards with data from our CMMS,” shared Ernest Oates, a director of HTM and QA with Renovo Solutions.

“The importance of the implementation of the modernized and updated CMMS,” said Zach Wilbur, BMET 2, UMH-Sparrow.

“I like that everything is in a single package and can be quickly accessed,” shared Brett Hayes, CBET, Ochsner LaFayette, General Orthopaedic Hospital.

Onsite

On-demand BMET/HTM Technician(s) & Manufacture Remediation/Recall Support

Repair estimate within 48 hours, quick turnaround time & extensive list of loaners available at no charge

MMS will deploy a team of technicians to your facility to complete Annual Periodic Maintenance on your Infusion Pumps All types of medical equipment - new or refurbished

MedWrench is an online resource for medical equipment professionals (biomeds, HTMs, imaging professionals, etc) to engage with their peers about medical equipment repairs, source parts and locate a service company. The following are examples of how the MedWrench community members help each other in the website’s forums.

Q: I have a AMSCO Eagle 10 autoclave which the 5V power supply went bad and replaced for another 5V 3A power supply. The problem now is that the temp reading is unstable and the digits are blinking on the display. The temp reading doesn’t goes over 102 C and is giving error code E98. I removed the thermistor connection and when checking the temp reading on menu F1, still unstable and blinking.

A: E98 is “Abnormal rapid rise in temperature (greater than 10F in seconds)”. Double check water is making it into the reservoir? The Air Vent or fill solenoids could be leaking letting all the stream out which would stop it from getting much above 100C.

Q: During self test at about 84%, the “self test failure” message is show on display. Reading infocounter, the last error, one month old is HC204002, but nothing about actual state. Monitoring serial output, the last message is “JVM Zip Error: C :\jars\dicomToRI.jar.: Fatal error wihile inflating....” Any advice will be appreciated.

A: Hey, that “JVM Zip Error” with dicomToRI.jar is a pretty clear sign your Java environment or one of the app files is corrupted. The self-test failing at 84% ties into that because the software can’t properly load a critical component. Here’s what I’d suggest:

• Try reinstalling or repairing the Java Runtime Environment on the DryStar — sometimes it gets corrupted.

• If you have access, replace or reflash the dicomToRI.jar file (or the whole software package if possible).

• Check your system disk or storage for any errors that might cause file corruption.

• If this machine uses a recovery or service disk, consider running a full software reinstall.

This isn’t a hardware failure per se, more of a software/data problem causing the system to fail its self-test. Hopefully that points you in the right direction!

For more FREE forum information, visit medwrench.com/forums.

Two qualities matter when choosing a clinical engineering partner: skill and responsiveness. Highly trained Agiliti biomed techs and imaging engineers respond quickly when you need help repairing and maintaining medical equipment — so it’s always patient ready when your clinicians need it.

• Beds and Stretchers

• Infusion Pumps

• Ventilators

• Monitors

• Anesthesia

• Ultrasound

• Imaging Equipment

• And more

e chNation invited HTM professionals to share tips, advice and insights regarding the maintenance and repair of beds and stretchers for this installment of the popular Roundtable feature article.

Participants in this month’s Roundtable article are:

• Chris Braaten, Regional Director of Operations, Gulf Coast Region, Intelas;

• Chad Dyches, Resident Regional Manager, Intelas;

• Israel Garcia, Senior Director of Field Operations, MultiMedical Systems; and

• Brian Herty, Senior Director of Solution Management, Clinical Engineering, Agiliti

Q: WHAT ARE THE MOST COMMON ISSUES YOU ENCOUNTER WITH HOSPITAL BEDS AND STRETCHERS?

BRAATEN: One of the most common challenges that operations teams face around the management of

beds and stretchers is the lack of designated storage space. When storage space is limited, beds and stretchers may be left in hallways or tucked into corners, which not only creates clutter and potential safety hazards but also makes it difficult to track their status. The need for consistent processes and implementing a standardized workflow for equipment triage will flag problems and notify the appropriate teams, like clinical engineering, with support in escalating repairs when needed, and making more beds available quicker.

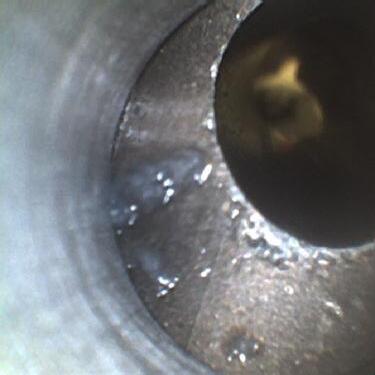

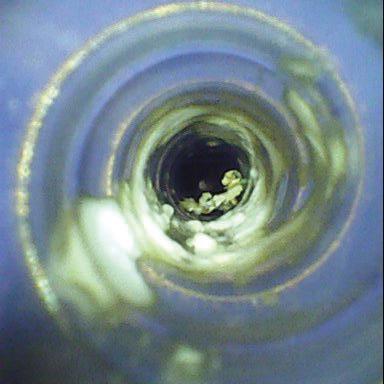

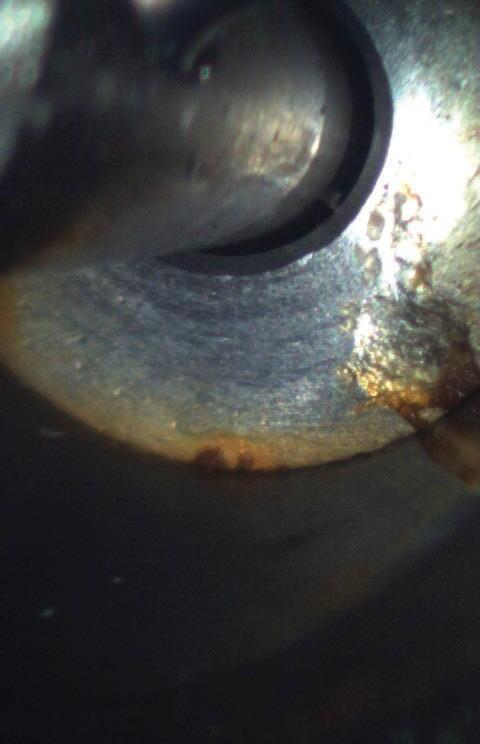

DYCHES: Biomedical equipment technicians (BMETs) frequently encounter recurring issues with hospital beds and stretchers, both of which endure constant use in clinical environments. Common problems with hospital beds include electrical failures such as broken controls, faulty motors, and damaged wiring, as well as actuator wear, brake system malfunctions, mechanical damage to components like side rails, battery issues, and faulty sensors or limit switches. Infection control is also a concern when surfaces are cracked or damaged. Stretchers often present

hydraulic system leaks, brake and steering issues, structural damage from impacts, worn mechanical linkages, degraded mattresses, and malfunctioning control handles. Across both device types, BMETs contend with broader challenges, including a lack of manufacturer support for older models, difficulties in sourcing parts, incomplete or outdated documentation, and frequent damage because of staff misuse or rough handling.

GARCIA: Bed adjustment failures (head, foot, height): Often due to motor failure or broken actuators. Stretcher height mechanism failure: Manual or hydraulic lifts can become stuck or inoperable. Brake failures: Worn-out or misaligned brake components are a safety hazard. Wheel/caster damage: Makes beds and stretchers hard to maneuver, especially over uneven surfaces. Side rail damage: Bent or broken rails may not lock properly, creating fall risks.

HERTY: Bed maintenance is one of the most underappreciated responsibilities of a clinical engineering team. Hospitals own a lot of beds, and they are high-use devices that are constantly moved and exposed to fluids and cleaners. Without proper upkeep, failure is inevitable. The most common issues we see are side rails that won’t lock or release, broken brakes or casters, failed controls and mattress/surface damage. These types of repairs directly impact safety, staff efficiency and patient flow. Staying ahead of these issues is a great way for CE to build credibility with nursing and operations.

Q: WHAT ARE THE BIGGEST SAFETY CONCERNS DURING REPAIR OR MALFUNCTION OF BEDS/ STRETCHERS?

BRAATEN: The most significant safety concerns a team can encounter is related to infection control. Teams need clearly defined and consistently followed processes, to ensure patient safety. Closely following that is the concern around patient falls, such as instances with faulty pillow speakers or bed alarms. Addressing these concerns requires a dual focus: reinforcing infection control protocols with clear workflows and ensuring that all communication tools and safety mechanisms are regularly tested and promptly repaired.

DYCHES: During the repair or malfunction of hospital beds and stretchers, significant safety concerns arise because if the complex electromechanical systems involved, posing risks to both technicians and patients. Key hazards include uncontrolled movement, which can cause crush injuries, electrical shocks from exposed