““The poignance of being a human being is that you are the place where the invisible becomes visible and expressive in some way. ”

- Akiko Busch

Happy December Clay Folks!

A little housekeeping as we near the end of the session:

Our beloved instructor Amber Mooers will be opening her very own studio in Pasadena! Sadly, that means this will be her last session teaching at Live Oak Park, but we wish her all the best. Go follow @StoneCoyoteLA to keep up with her next endeavor!

We are stoked to announce that Eilen Stewart will be teaching Thursday evenings starting in January!

Glazed pieces for the reduction kiln are now being stored outside, on carts in the kiln pad. We are excited for this change because it means your work will be handled much less before firing, meaning less mishaps like unwanted fingerprints and chipped glaze. Glaze cookies are now stored below the Oops! shelf.

The studio will be closed for the holidays starting December 16 and will reopen for Open Lab on January 7.

Mark your calendars, winter registration is nearly upon us! We recommend setting an alarm, classes fill up fast. Remember: the portal opens at 6am!

RESIDENT: MONDAY 12/8

NON RES: MONDAY 12/15

Folks looking to sign up for the Monday night or Saturday morning Intro classes will be automatically waitlisted in order to reserve space for first time participants!

Join us at the Ceramics Studio on Monday December 15 at 10am to help us wrap things up for the year!

We’ll be cleaning up, eating up and sharing our work with each other! Please bring a dish to share and a piece to swap. All personal items must be removed from the studio by 5pm, including all cubby contents.

Potluck and Pot Swap: 10am-1pm Clean Out: 1-5pm

REMINDER: The ceramics studio will be closed from Tuesday, December 16 through Thursday, January 8.

Are you a clay person but are jewelry curious? Have you ever wanted to melt metal with a torch for fun? Well, my friends, you won’t want to miss out on this workshop!

Join us at the Manhattan Beach Art Center for a silver casting workshop with Eilen Stewart. Participants will carve a ring from wax, learn how to make a mold and cast their piece out of sterling silver.

A few very good scenarios that you may experience:

Show off for the holidays. Come to the party dripping in your own jewelry! Impress your friends and family!

Give the gift of art! Handmade is better and everyone knows it. Give your loved one a piece from the heart! Sign up with your Mom! Sign up with your Dad! Bring a friend or loved one! Make some memories by melting silver. It’s sure to make an impression!

Silver Casting: Clay Cast Ring

10:00-1:00PM #46637

Saturday, December 20

The studio may be closed for class and open lab starting Tuesday, December 16, but the staff will be here to fire your wares! YOU READ THAT RIGHT FOLKS!

If you ’ ve made work and it’s not finished before we close up shop, we’ll be doing our very best to get it fired before the holidays.

Feel free to drop by during the times listed below.

Reminder: if the studio is closed a

Sunday December 21 10-5pm Monday December 22 9-12pm

Tuesday December 23 11-4pm

*Any work made within the last two weeks of Fall session may not be ready to pick up until two weeks after the start of the Winter session.

Bisque firing, what is it and why do we do it? Let’s do an overview of the importance of this initial firing, what happens in the kiln and a few common mistakes that can occur.

At Live Oak Park, bisque firing is the first of (usually) two firings. We use an electric kiln and slowly bring the temperature to Cone 06, 1828F

Tip #1: If your greenware piece feels cold, it still has moisture and is not ready to be bisqued.

Tip #2: If you have a hollow form, put a pin hole in it so steam can excape!

e reasons talk about

hen there oiling

m and do ccumulate hnically

e to fire a re without a successfully, ’d have to that baby for Who has the r that?

Now, you are probably wondering, the reason that your bisqueware won’t turn into mush is because of...

Quartz Inversion happens at 1063F and once your clay reaches this temperature, it can no longer be recycled and reused. This is a critical point in the firing and must be done slowly. The transition is so important, in fact, that the cool down process must be slow, too!

Let’s fast forward a bit

The bisque is has finished and your piece is ready to be glazed. At this stage, the clay has chemically changed. It is less fragile, it’s changed color and it’s quite porous.

This porous pottery is ideal for glazing, don’t you agree? The glaze dries before your very eyes!

There are potters out there, in the wild, slinging pots off the wheel, glazing and single firing them. It’s more sustainable, sure. But it also requires quite a bit of technical skill. Bisque firing is the studio standard because it gets your pieces through critical firing stages safely and it makes glazing much easier.

Alright, dear reader. Our overview of the bisque firing process has reached it’s conclusion. I fully encourage you to discuss quartz inversion at your next dinner party and watch your guest’s eyes glaze over right in front of you. Cheers!

Anything exceeding the size limits will not be fired.

1 6 " H i g h 12" Wide

1/2" Thick

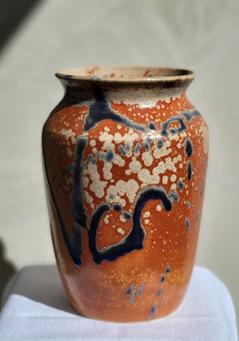

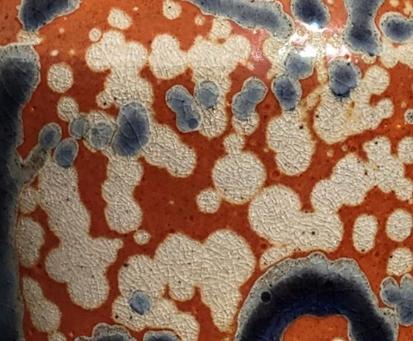

Sometimes glazes have a long historic background, case in point, Shino glazes. Shino glazes originated in Japan back in the 16th Century. At that time, the glazes were primarily white and were used on tea bowls. Most often, shino was used on stoneware clay and wood-fired in reduction over 2-3 days. The reduction fire would give the glaze orange flashed colors, especially in areas where the glaze was thin

In the mid 20th Century, artists in the United States started to attempt to re-create the glaze using local materials, designing it for a standard reduction firing. Their experiments included adding different materials to the glaze recipe, creating new effects and color tones. Our studio glazes, Thick White Shino and Coleman Carbon Trap Shino, both originated from those experiments. They are called American Shinos.

All shinos are fairly unique relative to other glazes. First, they are very stable (i.e., not runny) When applied on the thick side, they actually do the opposite of run – they crawl! Crawling is when glaze pulls away from the clay body during firing and leaves bare patches and lumps of glaze. Note to potters – do not put shino over other glazes. That glaze stability, over a standard glaze will cause the glaze combo to blister. A key phrase to remember: Shino first or you ’ re cursed!

One of the key materials within shino is the high level of sodium. A high sodium level can create “flashing” and “carbon trapping.” Both of our shinos are high in sodium (symbol Na in the periodic table). The majority of the sodium within the glaze comes from two key ingredients; Nepheline Syenite and Soda Ash You can actually see the sodium in our glazes. Ever see one of the shinos unmixed? There is a amber brownish layer of water over the top of the rest of the mix. That tint is the sodium!

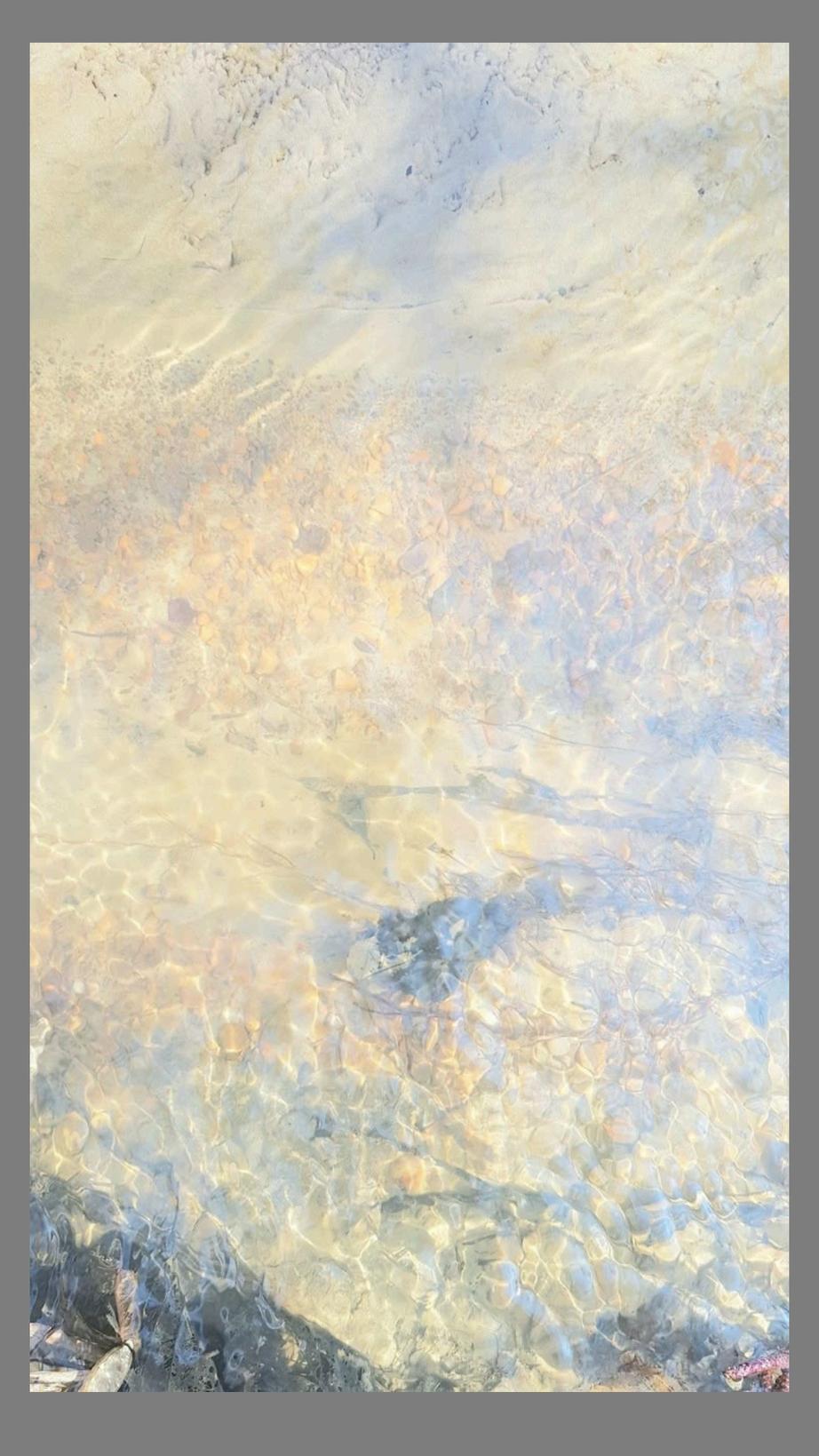

As the shino on a pot dries, some of the sodium rises to the surface You can observe this phenomenon by placing a recently glazed shino piece in the sun for about 2 hours or so. Watch how the dried glaze color changes and you get what appears to be a white, salty looking surface in spots (photo on next page). If your piece is stored in the shade, the crystal growth will be more limited but still can show.

What does that crystal growth do? It creates a “flashing” effect during a reduction fire, where the sodium on the surface changes the color of the glaze (middle photo - Carbon Trap Shino on BMix). On the right you can see the flashing up close.

Sodium on Surface Pre-Fire

Sodium Flashing

One really cool effect is that you can use wax resist on the top of the shino to prevent any sodium from rising to the surface in those waxed areas. That design will then show up on the pottery post firing!

But Wait, there’s more! Another feature is the potential for carbon trapping. During the reduction phase of the firing, carbon molecules can attach themselves to the sodium portion of the glaze, creating an amazing black-ish dust effect The carbon trapping can even create a halo effect around a second layer of glaze used on top.

The picture on the left shows carbon trapping on our Thick White Shino glaze. On the right is wax resist over Carbon Trap Shino.

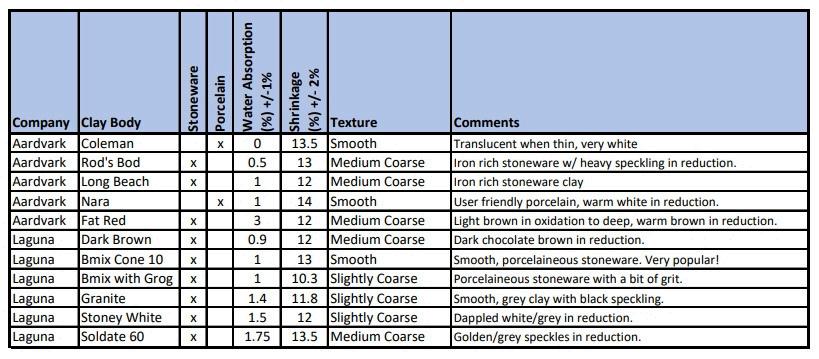

We’ve got a slew of clays to choose from here at Live Oak Park and it can be hard to know which clay to choose. Let’s discuss the properties of various clay types and how to decide which one will work best for you!

We can’t have a discussion about clay without talking about grog. According to Merriam Webster: Grog (n): refractory materials (such as crushed pottery and firebricks) used in the manufacture of refractory products (such as crucibles) to reduce shrinkage in drying and firing. So, it’s what makes clay gritty and coarse. Grog helps give your clay structure and decreases the risk of cracks. When you are handbuilding, you want grog in your clay to help give it strength. It’s been my (Michelle’s) experience that the larger you want to build, the groggier the clay you will want to use. At our studio, my favorite handbuilding options, in no particular order, are Long Beach, Rod’s Bod, Dark Brown, Fat Red, Soldate and, of course, B Mix with Grog.

Next up, we’re going to have to discuss plasticity. This is the term for clay that can bend and stretch. Groggy clays tend to be less plastic because they have large, coarse particles. They’re strong clays, but they don’t like to s t r e t c h. If you prefer to throw clay, you’ll probably gravitate toward clay that can withstand the bending and stretching that occurs on the wheel. These clays have finer particles and a little less...exfoliation when you throw with them. My favorite stoneware throwing clays at our studio, again in no particular order, are B Mix, Granite, Stoney White and B Mix with Grog.

Alright, we’ve covered a lot here. Let’s talk about PORCELAIN! All previously mentioned clays are considered stoneware. This term means that the clay is fired to a high temperature (cone 10 here,) is opaque and non-porous or impervious to water when fully vitrified (fired to maturity.)

Porcelain has unique qualities that require a category all it’s own. This type of clay is very fine, has translucent properties and is very white when fired. Because porcelain has no impurities and the particles are very fine, this clay maintains it’s strength when thin. A skilled potter can thow this clay until it’s thin enough to become translucent when fired. Porcelain can bend and stretch with ease, but it’s a difficult dance. The lack of grog in this clay means it warps easily, shrinks a lot and can easily lose it’s form when in process of taking form. It does not behave quite the same as the other clays and has a reputation for being finicky. You may have heard that throwing with porcelain is like throwing with cream cheese and I’ve found that to be true! If you’re new to porcelain, I would recommend Nara, which is the more forgiving of the two options at our studio. If you’re feeling confident and looking for a challenge, Coleman is one of the most translucent porcelains on the market and absolutely gorgeous. Since these clays are bright white, they make glazes POP!

schmearkeepthat offmybagel!

If you want the look of porcelain without the trouble, you can paint porcelain slip over your stoneware clay body!

FYI, porcelain shrinks more than most stoneware clays, so cracks are a possibility.

Sunday Monday Tuesday Wednesday Thursday Friday Saturday

Open Lab

9:00 - 1:00

Open Lab

1:00 - 5:00

Open Lab 9:00 - 1:00

Ceramics Class (Noah) 1:00 - 4:00

Teens Class (Noah) 4:30-6:00

Ceramics Class (Chris) 6:30 - 9:30

Ceramics Class (Lowell) 10:00 - 1:00

Ceramics Class (Lowell) 1:15 - 4:15

Ceramics Class (Alan) 6:30 - 9:30

Ceramics Class (Mitsuko) 10:00 - 1:00

Ceramics Class (Mitsuko) 1:00 - 4:00

Kids Class (Kate) 4:30-6:00

Ceramics Class (Alan) 6:30 - 9:30

Open Lab 10:00 - 2:00 Open Lab 2:00 - 6:00

Ceramics Class (Kathryn) 10:00 - 1:00

Ceramics Class (Kathryn) 1:00 - 4:00

Ceramics Class (Eilen) 6:30 - 9:30

Ceramics Class (Noah) 10:00 - 1:00

Ceramics Class (Noah) 1:00 - 4:00

Kids Class (Kate) 4:30-6:00

Ceramics Class (Michelle) 6:30-8:00