Catalina Mihu, Editor-in-chief

Catalina Mihu, Editor-in-chief

Your commments or suggestions are always appreciated: e-mail: mihu@foodmultimedia.de

The European Parliament passed the EU AI Act on March 13, with 523 votes in favor and 46 against. It is the world’s first legislation governing the fast-growing field of Artificial Intelligence, and it aims to establish a “humancentric AI”, as the press conference following the plenary vote underscored. According to the new regulation, AI systems used in the EU must be safe, transparent, traceable, non-discriminatory and environmentally friendly. Moreover, AI systems should be overseen by people, rather than by automation, to prevent harmful outcomes.

A connection to Asimov’s sci-fi laws is hard to miss here, with a shared approach to ensuring human safety. In the real-life spring of 2024, this regulatory green light means that “AI systems posing unacceptable risks” will be banned in six months from this date. Nine months from now, codes of practice will apply, followed by having general-purpose AI systems comply with transparency requirements by this time next year. ‘High-risk systems’ will have 36 months to comply with the requirements.

The classification makes some necessary differentiations. The highest threat comes from AI deemed to pose ‘unnaceptable risks’. These include AI systems that enable “cognitive behavioral manipulation of people of vulnerable groups”, “social scoring” (classifying people based on certain characteristics), biometric identification/categorization of people, and real-time and remote biometric identification systems, such as facial recognition. Transparency is also a requirement, according to the new law. Generative AI, such as the ubiquitous ChatGPT, although not classified as high-risk, must comply with transparency and copyright laws – the content must contain an ‘AI-generated’ disclosure and the AI System must be designed with a lock on generating illegal content.

Interesting conversations are sure to build around AI applications in bakery, as innovations aim to bring us ever closer to fully-automated, smart factories. There is no doubt that bakery manufacturing can benefit immensely from integrating AI systems. Automation is already a stringent necessity, especially given the lack of workers in the production plants. And, for the people who are already there, the technology must remain human-centric, while providing any benefits required, related to making the process easier, perfectly consistent and safe, with excellent results. The field promises effective new developments, and the conversation remains open.

Catalina Mihu

12

At the beginning of 2024, the Polish industrial bakery NOWEL opened its new production facility near Warsaw. More than EUR 200 million is to be invested in the plant by the final expansion stage. 06

16

Precision mixing technology brings undeniable benefits to consistently forming dough exactly as needed, time after time. When choosing the best equipment to perfect the process, technologies for batch and continuous mixing can bring the best-suited functionalities for each product range, manufacturing plant and operation. ©

OPTIMUM PROCESSING, EUROPEAN DIVERSITY

No two sourdoughs are the same; its value lies in its diversity. Perfecting different sourdough specialties relies on process accuracy and stability, with optimum kneading and mixing parameters for each type of product. ©

Georg Heberer has been President of AIBI since 2022.

Fully automating kneading and mixing is an ambitious endeavor, given the complexity of the process, and the diversity of raw ingredients. However, bakeries now have the solutions to make major strides in this direction, for improved product consistency and to alleviate growing staff shortages.

GETTING A GOOD GRASP OF CHOCOLATE

Read the interview with baking+biscuit international. ©

Chocolate coating is a tasty addition to bakery goods, but it also creates challenges when handling compounds in the manufacturing process.

BAKERIES

06 NOWEL, Poland: Big changes rely on big decisions

KNEADING AND MIXING

12 VMI: Mulling over mixing? Benefits in batch and continuous mixing

16 Reading Bakery Systems: A fully-automated flow

SOURDOUGH

18 DIOSNA: Optimum process for a world of sourdoughs

24 Puratos: “All sourdoughs harbor a different consortium of micro-organisms” – Interview with Karl de Smedt, sourdough librarian

BREAKFAST SPECIALTIES

28 Anton Paar, Buhler: Quick characterization of waffle flours

INTERVIEW

34 Georg Heberer, AIBI President: “The functioning of AIBI is a shared responsibility of our industry”

CHOCOLATE, PART II

40 AAK: Getting a good grasp of chocolate

49 Dawn Foods: The US enjoys European-style chocolate

SCIENCE

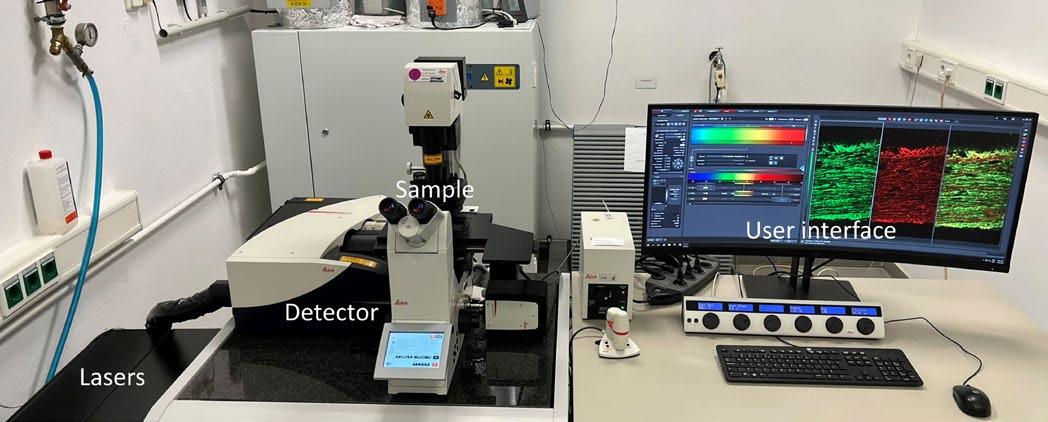

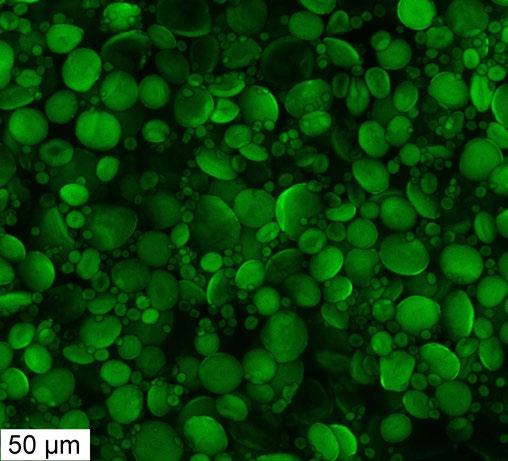

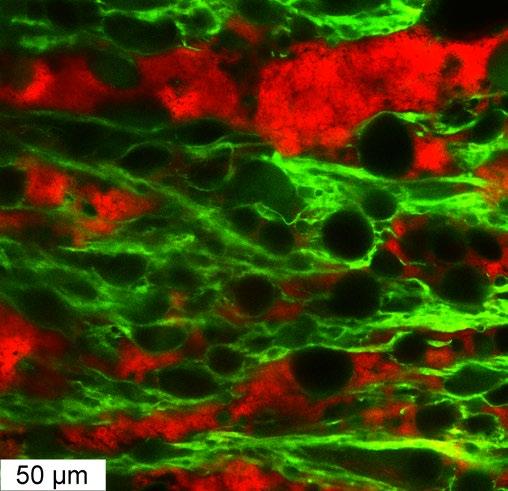

44 ttz Bremerhaven: Microscopy – take a closer look at your products, they are worth it!

50 Grainar: Spelt – An ancient grain with a bright future

Our specialist journal concentrating on production professionals in large companies in the industrial and chain-store sectors.

Published six times a year in the English language.

Our Review series provides in-depth analysis of clearly defined issues. This involves market analyses and is a comprehensive, informative presentation of the state of the art in process engineering.

The f2m dictionary translates bakery terms into a mulitude of different languages.

At the beginning of 2024, the Polish industrial bakery NOWEL opened its new production facility near Warsaw. More than EUR 200 million is to be invested in the plant by the final expansion stage.

bbi: You produce frozen baked goods, some of which are non-branded products for baking stations, as well as ranges in the clean label, organic and artisan segments, where products are left to rest for more than 12 hours. You also make packaged goods for the end consumer market under the ‘Home Bakery’ brand. What and how much of this goes to the domestic market?

Elzbieta Zajezierska: A lot has happened in terms of production volumes since 2020. We now produce around 400 tonnes of baked goods every day. Of this, 70% goes to supermarkets, discounters and petrol stations throughout Poland. The remaining 30% goes to our partners in international markets. These are both basic products in our range –bread rolls, ciabattas, as well as premium bread with various ingredients, usually baked in a stone belt oven. A growing category – both in Poland and the rest of Europe – is snacks. Europeans have taken a liking to quick but tasty and healthy meals on the way to work or on the move. A sales hit in neighborhood shops or petrol stations in Poland are hot dogs, for which we also produce buns in various varieties and supply them to the largest chains operating in Europe. ‘Home Bakery’ was a short-term project that we launched in response to demand during the COVID-19 pandemic. We have already discontinued the concept.

bbi: You export to more than 30 countries. Were there any significant shifts in ranks during the pandemic? And what do exports look like today?

“We now produce around 400 tonnes of frozen baked goods every day. Of this, 70% goes to supermarkets, discounters and petrol stations throughout Poland. We supply the remaining 30% to our partners in international markets.”

Elżbieta Zajezierska, President of the Board, NOWEL

Karolina Zajezierska: There have been several global events in recent years that have affected us as consumers and consequently all producers, not just food producers, had to adapt to these changes. The COVID-19 pandemic, the outbreak of the war in Ukraine, global inflation and economic challenges have significantly altered the capacity of consumers’ wallets, their approach to budget management and redefined their priorities. Today, Europeans are much more careful with their spending when shopping, including basic purchases such as bread. Compared to the past, they are more likely to choose to buy bread in a supermarket or a discounter because they appreciate its quality, and enjoy a very wide range of choices with a high degree of availability. Studies show that there is a large group of customers who have, until recently, bought their bread from smaller, artisan bakeries – which were often four to five times more expensive than their competitors – and who are now shifting their purchases in favor of retail chains. We see this as a

horizontal shift in sales. This group of consumers is oriented towards price reduction.

On the other hand, we also see a vertical shift, which brings wealthy consumers who used to shop at high-end artisanal bakeries to look for everyday alternatives in the discounters. As a result, this makes the premium category in bake-off stations grow despite the general inflationary pressure. Another trend we are observing is that consumers can no longer afford as many luxury products as they used to and are therefore looking for pleasure in their food. Bread became one of the categories that lifted the consumer’s spirit, opening a wide path for product innovation. In other words, from the consumer's point of view: “Maybe we cannot afford long-distance holidays as often as before; but, we can compensate for it with great, savory, crunchy, sourdough bread. And we can have it daily.”

bbi: At the beginning of this year, you opened your new production facility in Nowy Modlin near Warsaw. What will be produced there and for which markets?

Michał Zajezierski: We will continue with the bread range and products that have been successful in our current location. We will not, however, simply duplicate the existing technology, but, as always, strive for innovation and unique solutions. It is a bit of a paradox because, most of the time, in order to really make a difference on the market, you have to take risks with prototypes. Big changes require big decisions, but, at the same time, quality results from small, harmoniously coordinated details.

bbi: More than EUR 200 million will be invested in the plant over the coming years. What does the production facility look like today and what will the final expansion stage bring?

Michał Zajezierski: It is an ultra-modern bakery that will ultimately allow us to double our current production capacity and launch new products. We have planned the site in such a way that we will be able to commission additional production lines as required over the next few years. For us, it is a very important moment in the company’s development. We have been developing an existing plant for almost 15 years, making it one of the most modern in Europe. We have meticulously planned the new site from scratch, designing every element in such a way that our work will be even more efficient, safer and give us new possibilities in the future.

bbi: Inflation, wars and weakening purchasing power in many countries – is demand falling or shifting in the markets you serve? Is there pressure on prices? And, if so, how are you reacting to this?

Elzbieta Zajezierska: As already mentioned, we are observing both horizontal and vertical shifts in consumer behavior as a result of inflationary pressure. This translates into a growing demand for bake-off products. Some events influence the demand more abruptly but short-term (like

NOWEL produces frozen bakery products (breads, small baked goods) for the bake-off sector at two plants in Legionowo (around 30 kilometers from the Polish capital Warsaw) and in Nowy Modlin (near Warsaw). In addition to leading Polish retailers, the wholesale baker supplies food retailers and discounters in other European countries such as the Netherlands, Germany, the Czech Republic and Hungary. Other export markets are the USA and Canada.

The export share is around 30 %. With around 500 employees, NOWEL generated sales of around PLN 247 million (approx. EUR 53.25 million) in 2020, making it one of the top five bakery companies in Poland, by its own estimation. In its domestic market, NOWEL is considered the market leader in the Kaiser roll and Wachau roll segment (stamped bread rolls) as well as in some mixed and wholemeal breads. NOWEL is majority-owned by the Zajezierski family. The owner family includes Elżbieta Zajezierska (President of NOWEL Sp. z o.o., pictured in the middle above), Michał Zajezierski (Vice President) and Karolina Zajezierska (Commercial Director). The Polish investor Credit Value Investments (CVI) holds less than 30 %.

the war in Ukraine) and some have more of a long-term effect, such as inflation. We appreciate that our main commercial partners, retail chains, try their best to keep the products as affordable as possible for the end consumer. And we have every intention of participating in that process. That is why we do our best to close long-term commodity contracts while, at the same time, leaving space for spot purchases that can help balance out the final price of the raw material. This difficult time has also shown us how important it is to work hand in hand with reliable partners on both ends of the process. Being challenged by the market so many times in the past years, all the participants understood that we really should work as one team. Looking for solutions together helps us to satisfy the end consumer, grow the business and support the economy in surviving the turmoil. However, unfortunately, this does not mean that the yearly negotiations have gotten any easier.

bbi: You now run two production sites. How is production distributed between the two sites? How much of it is bread, compared to small baked goods (such as bread rolls), and breakfast pastries such as croissants? What about pastries and cakes?

Michał Zajezierski: Currently, in both plants, we focus on bread products including rolls, breads, baguettes, premium products and hot dog buns. In Legionowo, we do not currently produce pastries, but we are not excluding this range from our future investments.

bbi: To what extent is the new plant already automated and digitized? What is the timetable for this?

Michał Zajezierski: Compared to Legionowo, we went even further with automatization in our new plant in Nowy Modlin. We have introduced a number of new solutions, particularly in the area of raw material supply, but also in production, that will result in even better quality products. Some of these solutions are unique for the bakery industry. NOWEL will be the first bakery to use them in industrial production.

As far as digitalization is concerned, the new plant will be supplied with a new, state-of-the-art, digital managing system, that will allow us to control every detail of our manufacturing process online, in real-time.

bbi: What is the status of the other plant, in this regard?

Michał Zajezierski: Our other plant in Legionowo is already highly automatized. We use fully automatic lines, which also feature automatized multi-step fermentation processes and robotized mixing solutions. In this regard, it is one of the most highly automated production facilities in Europe.

“At our new plant near Warsaw, we have introduced a number of new solutions, not only in the area of raw material supply, but also in production, that will result in even better quality products. Some of those solutions are unique for the bakery industry.”

Michał Zajezierski, Vice President of the Board, NOWEL

bbi: You want to create 800 new jobs in the new plant. Is it a problem to find qualified personnel for this?

Karolina Zajezierska: Ultimately, the new plant will have up to 800 employees. The recruitment of personnel for the first part of the investment started a few months ago. Nowadays, building and maintaining qualified teams is, obviously, a big challenge, not only in Poland. All of Europe is facing it. Today, a modern bakery is a place where every process is automated, digitized and only supervised by qualified staff. In our company, we have developed a system of staff training programs and skills development in various areas. NOWEL employs representatives of several generations of families. The oldest ones, who have been with us for more than 30 years, remember our beginnings in cooperation with retail chains, which were just starting to appear in Poland at that time. Their children have joined our company at a time when the processes were being automated. We believe that we can be an interesting alternative for many young people in the labor market. We combine tradition and craftsmanship with modernity and have 100 years of experience in this.

bbi: What can you tell us about energy efficiency and the issue of sustainability not only in regard to the new plant, but also the company as a whole?

Michał Zajezierski: Sustainability is one of the key drivers for our current operations and future development. The plant in Legionowo is already using multiple solutions that use recovered energy or heat in various processes. NOWEL is also in the process of building a solar power plant that will supply approximately 30% of the electrical energy needs for the Legionowo site. We draw the rest of our electricity requirements from a combined heat and power plant operated by the city of Legionowo, which supplies the city with thermal energy and hot water and delivers electricity to local companies, including NOWEL.

Our new plant was designed using all available technologies to lower its carbon footprint and prepare it to become

carbon neutral. We will use heat pumps, solar power plants, electric trucks, and other solutions from the first day of the bakery’s operation. NOWEL is also cooperating closely with production line manufacturers on new developments that will make the production process more energy-efficient.

bbi: Until recently, you have primarily been a supplier to food retailers and the catering trade. At the end of the year 2022, you went directly to the end consumer market with two sales bistros in Warsaw. Will the bistros be operated by a separate company from NOWEL?

Karolina Zajezierska: The concept is formally part of the parent company NOWEL. It is merely another department in the company structure.

bbi: Can you tell us more about the idea behind this concept, will it remain limited to Poland? Or do you want to roll it out internationally, for example, in large cities or at the airports?

Karolina Zajezierska: In a way, history has come full circle. My great-grandfather, who started everything in our family bakery, was baking bread at night to sell early in the morning to neighbors and friends heading to work. This contact with people, relationships, conversations, hustle and bustle in our home bakery was significant and was engaging the

next generations; thanks to this, we were able to grow. Now, we are returning to this atmosphere and direct contact with customers with our brand “Żywioły Bread&Bistro” (Elements Bread&Bistro). At the end of 2022, a flagship location was created in the center of Warsaw – in an iconic and well-known store, Dom Towarowy Braci Jabłkowskich (Jabłkowski Brothers Department Store). It is a combination of a restaurant and a deli, and the so-called heart of our brand. A chef prepares seasonal dishes; you can enjoy time with family or friends, and buy fresh bread or sweets on the way out. At our second location, we bake bread and rolls on-site. There is also a large selection of sandwiches, cakes and snacks for sale. We are currently working on other locations in and around Warsaw. We want to open at least a few new bistros in 2024. It should become a nationwide concept. We are monitoring the market situation in Poland’s largest cities. That’s where we see the growth potential for our concept.

bbi: Could you give us a brief insight into the Polish bakery market? How is the market developing? How does it differ from the bakery markets in Western Europe, for example?

Karolina Zajezierska: Certainly, the Polish bakery market is comparable to the markets of Western Europe. Apart

from local conditions resulting from culture or tradition, we see many similarities both in terms of consumer trends and leading categories. Poland’s baked goods market size is growing in value. According to Noble Fund, the size value of the frozen baked goods market in the country amounts to approximately PLN 3.5 billion. According to the Central Statistical Office (GUS), in 2022, the entire baked goods market in Poland was worth more than PLN 14 billion.

Poles, like other Europeans, buy bakery products mainly in hyper- and supermarket chains. The share of frozen baked goods in total on the market is still quite smaller than, for example, in Germany or France; but, we predict that the share will grow year-on-year.

Still, not all retail chains in the country have invested in the frozen goods baking infrastructure, although it seems to be only a matter of time. As in the rest of Europe, consumer’s interest in premium baked goods has been growing in Poland in recent years. They are paying particular attention to the quality of raw materials, clean labels and taste. It is also an extremely competitive market because, historically, bread has always been perceived as cheap and affordable in Poland. That is why, in European statistics, the price per kilo of bread in Poland is one of the lowest in the region, even after inflation. Also, there are many good and reputable producers who operate on the market with large-scale production as well as thousands of medium-scale bakers, so one really needs to have a good strategy to grow.

bbi: What about the competition from muesli, porridge, and the like?

Karolina Zajezierska: These products are, of course, competing for their place on the consumer’s table, but we prefer to focus on product development strategies that result in quality, for which demand is growing.

bbi: Over the past 20 to 30 years, a number of industrial baked goods manufacturers have emerged in Poland, some as subsidiaries of international groups that primarily

“The share of frozen baked goods in the total market in Poland is still smaller than, for example, in Germany or France, but we predict that it will grow year on year.”

Karolina Zajezierska, Vice President of the Board, NOWEL

serve the export market. Who serves the Polish market today: the artisan sector or does the business primarily run via food retailers and therefore industrial manufacturers?

Karolina Zajezierska: Many good and reputable producers operate on the market with large-scale production and they mainly work with retailers, although some specialize in the HoReCa segment and also develop their individual distribution channels on the so-called traditional market –privately owned stores, smaller supermarkets, etc. Mediumscale bakers also work as fresh distributors with some retailers, although their primary distribution goes through their own bakery outlets. The market, especially in large cities gives room for artisanal bakeries to thrive, but, they are usually single-point, local-scale businesses.

bbi: Are bakery products in Poland today mainly eaten at home or in the catering trade, in cafés, bistros, or fast food outlets?

Karolina Zajezierska: As a result of the pandemic, many Europeans have scaled back going out to restaurants or bars, in favor of eating at home. Many studies even speak of a ‘generation of hermits’ who, as a result of the COVID-19 pandemic, have been holed up at home, work remotely, do most of their shopping online and use public transport less frequently. The service industry has certainly suffered from it, with far fewer users than before the pandemic. In Poland, bread is a basic product. It is served at virtually every breakfast, dinner, as a snack, or as a nutritious meal at different points of sale. +++

American Pan understands the importance of finding the right pan for your bakery’s unique products and needs. Our team of experts can design an innovative solution tailored for your bakery, offering a variety of materials and pan strengthening features, as well as:

• Sizes & Arrangements: Customize your overall pan size, cavity arrangements, and dimensions.

• Cavity Designs: Choose a standard croissant cavity or create a unique design for signature products.

• Coatings: Select one of our world-class, proprietary coatings, designed to aid in the easy release of a variety of dough formulas.

Want to prolong the life of your bakeware? Your pans can be cleaned, recoated, and returned to your operation like-new with our bakeware refurbishment services.

Precision mixing technology brings undeniable benefits to consistently forming dough exactly as needed, time after time. When choosing the optimum equipment to perfect the process, technologies for batch and continuous mixing can bring the best-suited functionalities for each product range, manufacturing plant and operation.

+Continuous or batch mixers? The answer is not a simple, linear, ‘either/or’ choice, when choosing the best fit for a range of products, a production line – or several, a baking facility, or a network. There is a strong case that justifies each, in any given (baking) circumstance.

Continuous mixing machines excel in delivering consistent results. They are the technology of choice for forming raw, par-baked and frozen dough, and are not only often seen in the production of bread and baguettes but also puff pastry, and Viennese pastry, where their cooling capacity is especially beneficial. “Continuous mixers, such as our Verymix, are valued for their ability to ensure consistency and stability in single-product operations,” VMI elaborates.

However, their versatility extends further, considering that various technologies are perfected for continuous mixing. For instance, continuous vacuum mixers, such as VMI’s Continuum range, can also be used to process dough for soft products such as sandwich breads. Further developments are underway: “We are also exploring new applications with the Continuum, such as biscuit/cookie production,” VMI highlights – although there are several established reasons why batch mixing remains the traditional choice in segments such as biscuits and cookies.

One key factor as to why batch mixers make sense in cookie production is the nature of the dough, which tends to be less structured compared to bread dough, for instance. Continuous mixing systems need to work with dough that is well-bound for peak performance that facilitates smooth

circulation within the mixing tank. However, it is possible to use a continuous mixing technology to make biscuits and cookies, VMI believes; several successful trials have already confirmed the hypothesis.

“Batch mixers with removable bowls also excel in the efficient management of the different dough processing phases, such as resting periods and autolysis.”

VMI specialists

Another reason why batch mixers are a tried and tested, valid choice for these applications is the flexibility they offer for recipe changeovers. Batch mixers with removable bowls are especially well-suited for fast handling, making them a widely popular choice, particularly for the production of biscuits and cookies: “One key aspect is the ease of changing production setups, allowing for quick transitions between different products. When considering batch mixers, there are various configurations available, including automated, semi-automated, or manual configurations. This allows for adaptation of the process to meet the customer's needs, budget, and desired level of flexibility,” VMI illustrates. Batch mixers with removable bowls also excel in the efficient management of the different dough processing phases, such as resting periods and autolysis. “This versatility empowers producers to customize their processes according to specific recipes or production requirements,” the French specialist explains.

Looking at their different needs in terms of teams, resources and end products, continuous mixing will require a learning curve for the staff when first adopted, as it is not yet as widely used as batch mixing. However, it is a highly efficient technology once assimilated. Moreover, it is nimble regarding resource requirements, with most processes being automated. Batch mixing systems, by contrast, define the level of resources needed to operate according to their level of automation in the line: manual systems need substantial resources, while fully automated setups have considerably lower needs.

The end product manufactured plays a decisive role in the choice of mixing technology. It should be noted, however, that there is no one-size-fits-all solution in this regard, even if certain technologies may be recommended for specific products. The choice of the technology to use largely depends on the operation’s requirements, the desired quality of the dough, and the characteristics of the end product.

Comparing the mixing process for batch and continuous mixers is a challenging enterprise, even when looking at similar production volumes and products, as it can vary significantly on each production floor. Several parameters may differ, including the volume of the mixer, the number of bowls, the automation level and mixing tools, for example. “But, it is entirely possible to present two offers to the same customer for the same product and requirements – one using batch mixers and the other using continuous mixers,” VMI underlines. The specific needs and priorities of each operation will determine the technology of choice.

Among factors that often steer the choice towards continuous mixers, VMI observes:

+ The need for high-level stability and regularity in dosing ingredients, that minimizes the risk of human error and ensures product uniformity;

+ Consistency in product quality;

+ Easy operation with precise dosing and a highly regular output;

+ Cooling capacity: continuous mixers can cool the dough during the process due to the large contact zone between the dough and the double-jacketed tank with glycol circulation.

Alternatively, factors that favor the choice of batch mixers usually include:

+ Batch mixers offer greater flexibility, allowing for easy adjustments in production setup, especially when producing a large range of products;

+ Automated systems with batch mixers can be equipped with Clean-in-Place (CIP) systems, simplifying the cleaning process of the bowl;

+ They can handle a wide array of different ingredients,

accommodating a diverse range of products. On continuous mixers, since dosing is automated, a dosing unit will be needed for each ingredient in the recipe, even minor ingredients, which brings additional cost- and space-related considerations into the equation;

+ Most batch mixers only limit dough heating, they do not cool the dough – only some models offer this feature.

However, there is no major difference in terms of productivity or production rate as this will entirely depend on the process and equipment chosen, the French specialist highlights.

Cleaning and maintenance will also vary for each type of technology. Continuous mixers like the Verymix offer a mobile Clean-in-Place (CIP) system that allows the liquid dosing units to be cleaned efficiently. The tank requires manual cleaning, but the stainless steel bowl is easy to clean. Additionally, continuous mixers have minimal wearing parts, making maintenance straightforward.

Automated batch mixing systems, on the other hand, may include CIP to clean the bowls, streamlining cleaning processes. However, cleaning mixing tools manually might still be necessary for recipe changes, VMI observes. Maintenance will depend on the specific technology and the process (i.e., the type of dough, mixing duration, etc.).

Looking at the bigger picture, the production facility itself and its setup should also be carefully considered when choosing a mixing technology, VMI recommends: “Batch mixers with removable bowls offer flexibility, especially in semi-automated setups, making them adaptable to various environmental constraints. They integrate well into existing workflows and allow for easy scalability by adding more mixers to increase production capacity. Conversely, the compactness of continuous mixers depends on the recipe and the number of dosing units required. Recipes with numerous ingredients, such as Viennese pastry, may require many dosing units, affecting the system's footprint.”

Continuous mixing is particularly adapted and often highly efficient for single-product productions. However, when manufacturers decide on new investments, they may hesitate to opt for this technology, VMI observes, even in cases where it appears to be more beneficial than batch mixing. Unfamiliarity with the technology is often the underlying cause: “For example, production teams might hesitate to switch from batch mixing to continuous mixing due to the potential disruption of their working habits and familiar manufacturing practices, despite the ultimate efficiency of the solution. This underscores the crucial need for dedicated support throughout the transition process,” VMI explains.

Without a doubt, continuous mixing technology is surging in popularity. Consequently, it is also expanding into new applications, a prime example being in the production of donuts. “This technology offers unparalleled consistency and is especially efficient for products that require careful fermentation control,” VMI concludes.

Process control is paramount to ensuring consistent results, for any production setup. Both batch and continuous mixing technologies can incorporate process controls through Human-Machine Interface (HMI) systems. However, continuous mixers often offer more precise and comprehensive control as they fully automate the process, from dosing to pre-mixing and mixing. In this way, consistency and accuracy are ensured throughout the entire mixing process.

Mondelēz International launched its fifth annual global consumer trends study, called State of Snacking™. The report, developed in partnership with The Harris Poll, reveals that amidst ongoing global economic uncertainty, consumers continue to prioritize, purchase and prefer snacks. The past half-decade of tracking attitudes and behaviors among thousands of consumers across 12 countries has shown a consistent trendline of consumers demonstrating a preference for snacks over meals. Snacking behaviors continue to

In turn, batch mixers may also feature advanced process controls, especially when looking at automated systems, which allow precise monitoring and adjustment of parameters; process control capabilities will largely depend on the level of automation in the line, in this case. “When batch mixing systems are not fully automated, it is common for the dosing part to be separated from the main system. This means that the dosing control may not be integrated into the batch mixing system itself, leading to potential variations in ingredient proportions,” VMI illustrates.

It is a complex decision-making process, with many variables to be taken into consideration. However, the goal of achieving high-end results remains constant. +++

grow, including notable growth in mindful snacking, with the chocolate category in particular closely associated with joy.

Mondelēz also debuted a stand-alone, complementary State of Snacking: Future Trends report this year, showcasing longer-term consumer macro trends shaping the future of snacking. Both are available for download. The macro trends analyzed include: shifting demographic landscape, increasingly fluid lifestyles, people and planet impact imperative, health and wellbeing ubiquity, and resurgence of experience economy. These macro trends provide additional context on changing behaviors from a big-picture perspective, further exploring how the snacking world may evolve in the future. +++

Closing up to 120 bags per minute with state-of-the-art motion control, ethernet, and wireless communications, the speedy 893 C Automatic Bag Closing Machine has efficiency baked right in. LEARN MORE AT KWIKLOK.COM

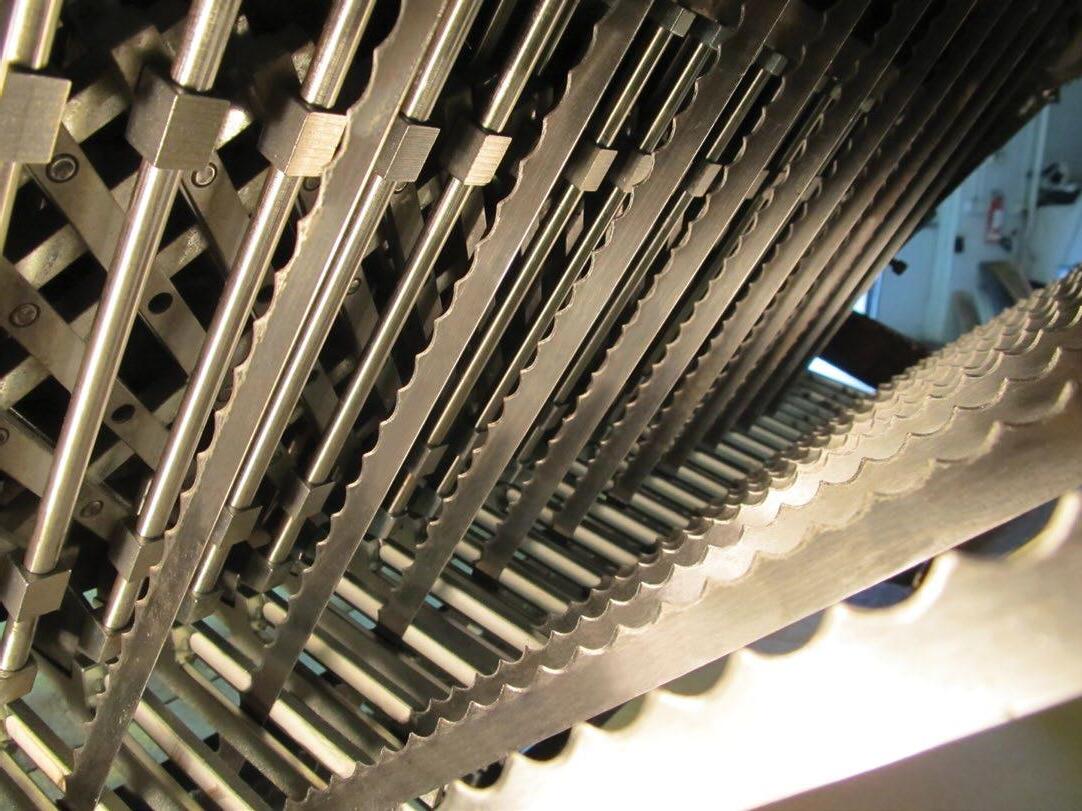

Fully automating kneading and mixing is an ambitious endeavor, given the complexity of the process, and the diversity of raw ingredients. However, bakeries now have the solutions to make major strides in this direction, for improved product consistency and to alleviate growing staff shortages.

+Reading Bakery Systems (RBS) has fully automated the mixing process wth their continuous mixing systems. The ultimate goal is to have systems running independently, without any need for staff intervention. And, while mixing may be among the most complex manufacturing processes in a bakery, today’s mixing technology is very close to this goal. “This is because, complex as it may be, the process consists of sequenced, measurable and controllable steps. Not only are the latest mixers controllable, but the control packages are rich in data to demonstrate the process is repeatable,” specialists from RBS emphasize. Integrated controls can already address decision points instead of an operator who requires training and experience. With fully automated mixers, “Quality and consistency are confirmed at the beginning of the baking process and not at the end of the process,” they add. Continuous mixing systems can take input from other parts of the line, such as hopper levels, operation status of downstream equipment, and data inputs such as temperature, and use it to automatically adjust the mixing system parameters to assure consistent production and product quality.

Bulk handling is a similar process for continuous and batch mixers, throughout every step of the mixing process:

+ Dosing: The benefit of automated continuous mixing is that the accuracy of the recipe is guaranteed, at any given moment of the day, or season. “The dosing by metering equipment is critical to this step. It is important that gravimetric metering, not volumetric is used, to guarantee the high degree of accuracy needed. Loss-in-weight feeders are used for powders and pump and flow meters are used for liquid ingredients,” RBS explains. Solid fats, or delicate components (berries, for example) require more specialized equipment.

+ Mixing: RBS has been perfecting specialty mixers based on the premise that no single mixer can be used to make

all kinds of bakery products. This is why the American specialist offers five types of continuous mixers, each in 4 to 6 sizes, for different production volumes. The different models vary in shear applied, energy input, mixing properties, and other design factors. Selecting the correct type of mixer for specific products is the key to perfecting automated production.

+ Discharge: Managing dough discharge from batch mixing can be a challenge; by contrast, this is not the case for continuous mixers. The dough exits the mixer in a ‘log’ or a steady stream of dough. “A knife at the discharge of the mixer cuts the log into manageable-sized pieces, so that they are suitable for transport on a belt. This dough can then go directly into the downstream forming equipment, eliminating the large dough handling equipment needed after the batch mixer to cut the dough into smaller, usable pieces.

“With fully automated mixers, quality and consistency are confirmed at the beginning of the baking process and not at the end of the process.”

Reading Bakery Systems specialists

Process monitoring is instrumental in automating the mixing process. It enables the mixing system to make automatic adjustments that account for variations outside of the mixing scope. It outlines process variables, highlighting constant values and less stable parameters, for a deeper understanding of the process that supports further advancements. “Instantaneous variations should be ¼% for liquids and ½% for dries or less. Typically, a variation of more than ½% for more than 5 seconds will create an alarm for the operator.

However, the system is self-correcting and these alarms are rare after commissioning,” RBS explains.

The actual variation required to define an alarm is an adjustable input. Usually, three levels of alarms can be set, with timings that are preset by RBS during commissioning:

+ Level 1: The parameter moves out of range. The system begins to self-correct.

+ Level 2: If the system has not self-corrected within the time selected by the operation (usually 5 seconds), the alarm is activated. The system continues to self-correct, or the operator can intervene.

+ Level 3: If the system has not self-corrected and the operator has not intervened after a set period of time (usually 15 seconds), the system will shut itself down until the operator restarts the system. This can occur when an ingredient cannot be metered properly (i.e., it runs out), when the processing line stops somewhere downstream, or when the hopper to the forming equipment fills up.

Automated mixing systems adjust the throughput to keep the hopper at a constant fill level, using a photo eye above it. They can also stop the process altogether if they receive a signal from downstream equipment that the line has stopped working.

Process parameters that are automatically monitored during continuous mixing and recorded also include:

ingredient rates vs. process value, ingredient temperatures and finished dough temperature, all mixer parameters, work input, total throughput, and dough total since the last changeover, RBS lists. “Any process condition the bakery wants to track can be recorded and saved to a database known as trending,” the specialist explains.

Currently, with a fully automated mixing system, an operator is only needed for a few minutes every hour. Their main task is only to address the occasional alarm and to observe the dough to confirm quality. This type of solution can answer ever-increasing staff shortage issues, a driver for its adoption rate. By comparison, batch mixing remains labor intensive.

The initial investment in a continuous mixing system is higher than in batch mixing. The total cost of the latter will depend on the level of automation of the batch mixing system and the dough capacity of the line. In an estimation that also factors the reduction of labor costs, the return of investment with a continuous mixing system is usually between half a year and two years, RBS calculates. Where applicable, “The initial investment is worth it with this payback, and the additional benefits continuous mixing offers including more consistent dough, less energy usage in ovens, lower safety and food safety risk, less dough handling equipment investment and more.” +++

No two sourdoughs are the same; its value lies in its diversity. Perfecting different sourdough specialties relies on process accuracy and stability, with optimum kneading and mixing parameters for each type of product.

+To optimize sourdough processing, the best place to start is by learning the starter itself. An important characteristic of starter cultures is stability: they must be stable in terms of microbiological quantity (concentration of microorganisms) and quality (representation of the background species). The starter cultures ensure the repeatability of the fermentation and, therefore, the sourdough’s stability – which is determined by the pH and TTA parameters. Stable fermentation parameters such as temperature, time, dough yield and percentage of starter or mother sourdough also contribute to the consistency of the resulting sourdough. Working with user-friendly starter cultures also goes a long way to maintaining their stability. DIOSNA’s starter cultures, for instance, can be used as semi-solid starters, which are easy to crumble, or as liquid starters. Both can be used for artisan production as well as for industrial solutions.

A useful classification

Europe is home to a flavorful diversity of sourdoughs. General trends can be observed across the continent – for example, in Northern, Central and Eastern Europe, rye is frequently preferred, whereas wheat is used across Europe, the dough specialist observes. Niche, specialty sourdoughs are also prepared: gluten-free variations usually comprise fermented rice, buckwheat, or some mixture of starch and flours.

Rye sourdoughs can be divided into solids, which are prepared in bowls, and liquids – fermenters are used for their preparation. Stiff rye sourdoughs are more demanding in terms of preparation and space, which is why bakeries tend to prefer using liquid sourdoughs. Liquid sourdough, in turn, can be divided into active and stable sourdough. Active

“Recipes are commonly developed based on the properties that are expected of the final product, in terms of smell, taste, crumb, elasticity, volume, and other characteristics. ”

DIOSNA specialists

sourdough has a certain leavening power and requires cooling. Stable sourdoughs are characterized by a higher acidity and a long fermentation time without the need for cooling. A special stable fermentation is used for bread fermentation, for which it is possible to ferment up to 50% of the weight of the flour in the sourdough.

From a processing standpoint, rye sourdoughs can be divided into single or multi-stage fermentation. For the most part, there is a preference towards using single-step rye sourdoughs. Depending on the bakery and the region, active and stable rye sourdoughs are chosen.

Wheat pre-doughs can be divided into two groups of their own: yeast pre-dough (pre-dough), which uses yeast as a starter (examples include biga, poolish, or opara), and sourdough – for which lactic bacteria are used as a starter. Wheat pre-dough can either be stiff or pumpable. Solid pre-doughs are fermented in bowls or boxes and are more demanding in terms of preparation, handling and space. By contrast, liquid pre-doughs are prepared in fermenters –meaning that it is possible to cool them and extend their usability. “The equipment for wheat pre-dough can work according to our standard yeast pre-dough and sourdough parameters, or according to the client´s parameters if requested,” DIOSNA explains. The choice between wheat

yeast pre-dough and sourdough can vary according to the character of the product and the region’s established preferences.

Recipes are commonly developed based on the properties that are expected of the final product, in terms of smell, taste, crumb, elasticity, volume, and other characteristics. Various alternatives are available to choose from, according to how well they match these expectations: wheat sourdough, rye sourdough, or wheat yeast-pre-dough (or other scalding dough and aroma pre-dough (AromaStück®).

The product is then trialed, made with one or more pre-/ sourdoughs with different amounts of pre-dough, and evaluated. When the optimum dough recipe is identified, the corresponding pre-dough system is then calculated and designed, according to the recipe and the capacity needed by the production line (or lines).

Conveniently, sourdoughs are not partial to a specific kneading technology – they can be processed with optimum results on universal kneaders, i.e., wendel mixers, as well as spiral mixers from DIOSNA's portfolio. The choice between available options is determined by the recipe: mid-soft and soft types of dough for products such as bread, buns and ciabatta, or soft yeast doughs, both wendel and spiral kneaders are suitable choices.

For special doughs, or hard and cold doughs such as those used in pastries, or cold dough for freezers, DIOSNA recommends the wendel mixer.

To optimize kneading parameters, the correct timings are given by attributes such as:

+ The flour: wheat or rye content: wheat dough needs much more energy to develop the gluten structure

+ DY level: softer doughs need longer kneading time, while stiffer doughs need less time for the process

+ Tool(s): spiral, wendel, L-shape mixers and others; using the wendel mixer, 1/2 to 2/3 of the kneading time can be achieved compared to the spiral mixer

+ Mixing style: two gears or more steps with Frequency inverter (FI)

+ The type of dough: doughs with a higher content of sugar, eggs, fats and oxidants in the recipe need longer mixing times

+ pH: the lower the pH of dough and reductants, the shorter the kneading times

+ Dough temperature

+ Pre-dough content: using more pre-dough can result in a shorter mixing time requirement (0-10% of mixing time)

The mixing time is defined by the dosing speed of flour and water, the intensity setting of the blending process and by the kind of flour. Blending and mixing pre-/sourdough are done quickly, usually within 15 minutes after filling the fermenter (for wheat with 200 Dough Yield (DY) and rye sourdough with ≥ 220 DY). The mixing process itself is more complex for wheat flour, which must avoid creating lumps through adequate stirring. Dosing can be carried out automatically, in the fermenter, where the intended amounts of water and flour are simultaneously brought together and mixed with high intensity, or in the

mixing pump, from where the homogenous suspension is delivered to the fermenter. Using pre-dough or sourdough can reduce the kneading time required by up to 10%, depending on the type of dough as well as the kind and amount of pre-/ sourdough. For reference (detailed in Tables 1-2), a full bowl of standard wheat dough will require 9 minutes for kneading with a DIOSNA spiral kneader: 3 minutes running at the first speed, followed by 6 minutes using the second speed. With a wendel kneader, kneading a full bowl of the same mix will require 5 minutes (1.5 for the first speed, and respectively 3.5 minutes at the second speed).

For fermentation, the ideal time is defined according to the kind of sourdough used. For example, DIOSNA’s standard fermentation times for DIOstart/yeast are the following: 42 hours for bread fermentation, 18 hours for wheat sourdough, and 4 hours for yeast wheat pre-dough. Fermentation times also vary according to the proportion of mother sourdough in the sourdough, if some is used to refresh/replicate the sourdough. Fermentation times of formulations with 5% mother dough range between 13 to 16 hours; for a ratio of 15% mother dough, the appropriate fermentation time is 7-9 hours; when 25% of the mix is mother dough, the fermentation time needed is 4-6 hours.

The optimal fermentation process is the result of the correct balance between time and temperature. To control the product temperature, fermenters have cooling or cooling/ heating units, connected to the facility’s central cooling/ heating systems. AromaStück®, for example, has a standard heating time of 3 hours at 65°C. The process is enzymatic, and no microbiological fermentation occurs.

Scalding dough has a heating time of 0.5-2 h, depending on the raw material (e.g., 0.5 h for flour, flakes; 2 h for whole grain). In this case, the main process is gelatinization.

Temperature changes, from the process and from the environment, should be accounted for. In the fermenter, the pre-dough is cooled by coming into contact with the fermenter’s surface. “The cooling time is defined by the temperature of the cooling medium, the flow of the cooling medium, the intensity of stirring and the temperature gradient between the pre-dough and cooling medium,” DIOSNA explains. Cooling may not always be required: rye bread with a long fermentation time can work well at room temperature

Table 1:

Tool Bowl Tool Bowl

Table 2:

Tool Bowl Tool Bowl

(22-26°C), without the need for cooling the fermenters, for instance.

Examples of fermentation temperatures:

+ Rye, wheat and spelt sourdough:

- At warmer guiding (> 28°C), a strong aromatic taste of the baked goods is achieved

- At colder guiding (26-28°C) high gas activity, the yeast can be reduced in this case

+ Bread fermentation:

- First stage temperature (isofermenter): 32°C

- Starting temperature: 28°C; after 16-24 h: max 32°C

+ Gluten-free sourdough

- With warmer guiding (> 32°C), the result is an aromatic, strong taste in the baked goods

- With colder guiding (28-32°C), results in a yoghurt-like taste

+ AromaStück ®: the fermentation temperature is 65°C

+ Scalding dough: the fermentation temperature is 75-85°C

The processing time of sourdough is also dependent on the storage temperature. The processing times for wheat sourdough and rye sourdough are:

+ 8 hours (without cooling)

+ 24 hours (with cooling, i.e. cooling to around 15°C after the fermentation time)

+ 48 hours (with cooling, i.e. cooling to around 10°C after fermentation)

+ 72 hours (with cooling, i.e. cooling to around 6°C after fermentation)

The processing time of wheat yeast pre-dough is shorter than that of wheat sourdough. In industrial bakery operations, the processing time of rye bread is four days – without cooling. When manufactured in a craft bakery environment, a week is required.

Would you like to know how you can sustainably save time, energy costs, and storage space in your bakery, while still ensuring high-quality laminated pastries?

We would be pleased to inform you about this.

Product properties and consistency rely on process control, which is especially important when long-term fermentation products are made, such as products made using sourdoughs. The sourdough system shares information about the current processing step (filling fermenter, fermentation, cooling, ready to use), the amount of sourdough (kg), the age of the sourdough (h), its temperature (°C), and style of blending. The most important parameters are the time and temperature of each process step.

To monitor the sourdough throughout the mixing and kneading process, the pH meter is an option, as its values provide information that can be used to evaluate the sourness of the dough. The correct time and temperature as defined by the sourdough’s recipe are controlled

automatically by the cooling (or cooling-heating) medium. The system keeps these two parameters within predefined values for each step. The result: sourdough with stable properties. +++ ©

Lesaffre and Qair, an independent renewable energy company, signed an 18-year contract for the direct purchase of renewable electricity (CPPA) from an agrivoltaic plant –a synergy between agricultural production and photovoltaic energy.

Covering a forecast annual purchase volume of around 34 GWh, this additional CPPA ensures the supply of green electricity from an agrivoltaic project developed by Qair in the Hauts-de-France region. With construction starting in 2025 and operation scheduled for 2026, the plant will avoid the equivalent of around 630 tonnes of CO 2 emissions per year, and inject 68 GWh of green electricity per year into the French power grid. +++

Koenig Group introduced a new fully automated machine for dough dividing and rounding in March 2024: the Industrie Rex V AW EC. The system has a dough throughput of 6.5 tons per hour – meaning an hourly output of up to 50,400 pieces per hour in 14-row operation, and features Koenig’s ‘Easy Clean’ design.

“With this innovation, we have built the machine of the future,” says Koenig CEO Hannes Stelzer about the new development. The new Industrie Rex V AW EC is the most powerful machine to date in Koenig’s portfolio in this equipment category. It handles weights ranging from 22 to 180g, with a weight accuracy of +/-1%, depending on the dough.

AAK and Checkerspot are joining forces to develop, scale, and commercially produce an alternative source of structuring fats and oils. As consumers and global brands continue to push for new plant-based options, developments for new fats and oils need to meet three criteria: they can be produced at scale, provide unique consumer experience, and are less vulnerable to climate change, Checkerspot highlights in an announcement.

“Checkerspot’s growing portfolio of unique oils and their expertise in microalgae fermentation make them the ideal partner for us to collaborate with to meet the growing demand for alternatives that are both functional and sustainable,” said Kim Olofsson, Global Head of R&D at AAK. +++

2100 lines installed worldwide and we are always around the corner.

Tasteable quality secured by over 85 subsidiaries worldwide

“All sourdoughs

a different consortium of micro-organisms”

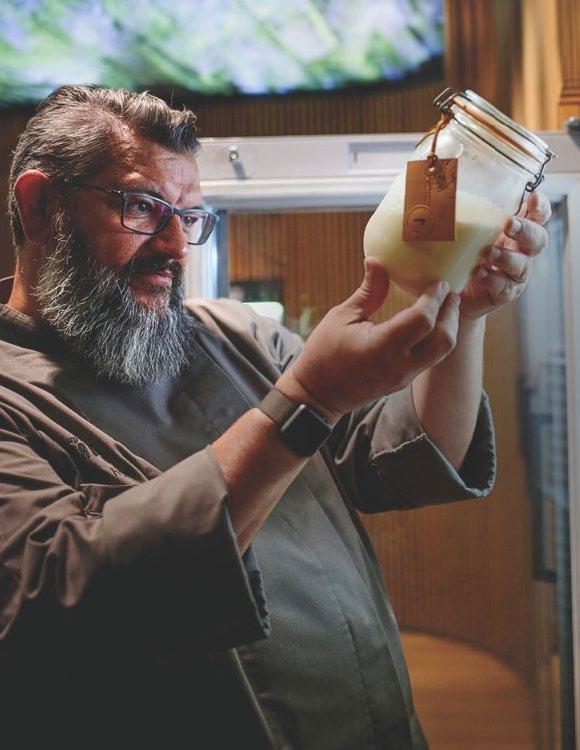

With a unique culture and a longstanding tradition, sourdough is used in new interpretations for unique creations. Karl de Smedt, sourdough librarian at Puratos, shares insights into the bustling scene of European sourdough creations, how to maintain a strain’s profile and how to work with sourdough in large-scale operations.

+Catalina Mihu: What is an overview of the sourdough diversity in Europe, and the products traditionally made with them, in certain countries?

Karl de Smedt: To date, there have been no comprehensive studies of how sourdoughs vary between different countries throughout Europe, but we do know some demographics prefer certain sourdough flavor profiles. Geography also has an impact on the character and bread quality of sourdough, as factors like climate can affect its microbial diversity. What we do see after preserving a sourdough in the sourdough library is that each sourdough is unique. We have currently 153 samples from 31 countries. All of them harbor a different consortium of micro-organisms.

Mihu: What flavor differences can be observed throughout Europe?

Karl de Smedt: Every sourdough culture is unique, with its own history and specific taste, but certain regions across Europe have distinct quirks that make them stand out, such as using different flour combinations. Greece has a long history of making wheat-based sourdough, for example. There’s one variety that originates in Mount Athos, a holy mountain that has been home to 20 monasteries for over 1,000 years. It’s based on the traditional ‘sourdough of the Cross’ – and is made with 40% durum flour, 40% white flour and 20% whole wheat flour, resulting in a tangy sourdough that is very dense. Further away in Finland, rye-based sourdough is more typical – driven by a long history of cultivating rye on home

soil, without the need for imported ingredients. Sourdough is crucial to adding structure to rye bread, while the rye brings a darker color and a stronger, more bitter taste to loaves. Rye-based sourdough continues to be extremely popular among Finnish people thanks to its satiety benefits, as well as its great taste and long shelf life. From our Quest for Sourdough research, we discovered that people in Eastern Europe describe their sourdough as tasting more like cereal compared to those who live in southern or northern Europe, where they say it is more fruity and sour/acidic.

Mihu: And what new developments are noteworthy, in terms of ingredient combinations, processes and end products?

Karl de Smedt: Sourdough brings a variety of different flavor profiles to end products, including roasted, creamy, fruity, sour/toasted and sour/tangy, that appeal to wide-ranging demographics. So, it’s not surprising that we’re seeing consumer demand grow for sourdough options that go beyond bread, such as pizza and pastries, as people want to recreate the same great taste in other products, too. For example, we’ve seen bakeries develop products like sourdough blueberry brioche tarts, which have a velvety cream cheese filling that offsets the tart blueberries.

Mihu: How should sourdough best be preserved over time/multiplied, to retain its characteristics? Please share examples.

Karl de Smedt: The age of the starter or creation date, the type of flour it is fed with, how often it is fed and where the yeast comes from can all affect the final sourdough result. Maintaining a sourdough starter is crucial to creating end products with consistent taste and quality – it must be fed regularly. However, it can be preserved for longer periods under the right conditions; sourdough starters can be kept for two months in an airtight jar, in the fridge at 4°C, without feeding them –which is how we keep them in the sourdough library. People have been seen drying their starter, freezing it, or keeping it in the fridge unfed for more than two months, but this is not recommended as some of the micro-organisms might not survive the harsh conditions and stress they are subjected to.

Mihu: What are the benefits of comprehensively mapping sourdough’s microbiome? And how can it be accomplished?

Karl de Smedt: Although bread has long been a part of society, we are still learning about its microbial communities and how they affect the taste, texture and appearance of final products. It’s therefore important to map out the microbial ecology of sourdough starters, to build a better picture of the influencing factors. We still don’t know how variations in flour, water, geography and even the microbes on bakers’ hands can have an impact on the sourdough. A study we did into the microbes on bakers’ hands showed that it’s actually the sourdough that influences what lives on some bakers’ hands. Each sourdough starter tells a

story of its heritage, but cultures are fragile and can sometimes be lost or damaged – which is where safeguarding them comes in.

Our Puratos Sourdough Library in Sankt Vith, Belgium, was created to collect and preserve the biodiversity of starters. Over 100 bakers from across the globe have sent samples of their sourdough cultures for safekeeping, allowing scientists to analyze the microbes, to see how they differ from starter to starter. Not only does this help roadmap taste heritage in different regions but it means bakers’ livelihoods are futureproofed, too. So far, over 1,500 strains of wild yeast and bacteria have been examined at the Sourdough Library – and it is home to 153 sourdoughs now.

Mihu: How can a sourdough be adjusted in case flavor profile changes occur over time?

Karl de Smedt: The microbial composition – the wide diversity of lactic acid and bacteria – of sourdough has a significant impact on the flavor profile of end products. The duration and temperature of the feeding process can also influence taste; the warmer it is, the more lactic acid is produced, giving the sourdough a more creamy flavor, while the colder it is, the more acetic acid is produced, hence the more tangy flavor. The type of flour used is significant, too – changing from all-purpose white flour to whole wheat or a different type of grain, like rice, barley, or rye, can contribute to different flavor developments. Feeding schedules are crucial when adjusting the flavor profiles of a sourdough starter. For instance, keeping the time between feeding with fresh flour short, such as every four to six hours, keeps the sourdough very active, with low acidity development. Leaving

a starter for 12, 18, or 24 hours can increase acidification, which can weaken fermentation power, and increase the tanginess of the final product.

Mihu: What types of sourdough best answer to the growing trend for healthier foods, from a nutritional standpoint?

Karl de Smedt: More and more consumers are embracing fermented foods like sourdough for their health-promoting properties, as well as their unique flavor profiles. In fact, 62% of consumers worldwide think sourdough is healthier than other bread options, according to our ‘always-on’ Taste Tomorrow research insights. Scientific studies show that sourdoughs are more digestible than non-sourdough bread types.1 This is down to the pre-digested complex carbohydrates and proteins created during the fermentation process, meaning the body has less work to

“The age of the starter or creation date, the type of flour it is fed with, how often it is fed and where the yeast comes from can all affect the final sourdough result.”

Karl de Smedt

do, which may help individuals feel lighter. Sourdough also has a lower glycemic index, making people feel fuller for longer and avoid fatigue and cravings after eating. What’s more, sourdoughs offer enhanced absorption through a special mechanism that helps to release minerals from the grains, so that the body can easily absorb and make use of them. 2,3 Consumers are attracted to sourdough products for their gutfriendly effects, too. Depending on its composition, active sourdough may have prebiotic potential by supporting the gut’s microbiome balance. Bakers

are also increasingly adding nutrientand fiber-rich inclusions, like sprouted grains, to boost the health ‘halo’ of sourdough products even more.

Mihu: How can sourdough product consistency be ensured? What are the limitations?

Karl de Smedt: It takes years for a sourdough to change, particularly a mature starter, even by changing its location or feeding it. As long as it’s kept in optimal condition, a sourdough can remain in good health and ultimately, ensure product consistency.

However, even kept in its place of origin, starters have been seen to evolve. In an experiment last year, we asked for samples from 17 bakers who had donated their sourdough to the library in the past decade and saw that some samples had lost their diversity. That’s why we believe the sourdough library is an important project as it saves the original biodiversity of the sourdough and stores it for the future. What’s interesting to see is that in the library, biodiversity has also evolved the same way as in the sourdough’s place of origin which raises a lot of questions, paving the way for new areas of research. The sourdough library captures discoveries that overwise would have been lost.

Mihu: What are some best practices for large-volume operations?

© Puratos

Karl de Smedt: Choosing the right partner for quality and consistency is absolutely crucial when it comes to sourdough. We've encountered numerous customers with ambitions to produce their own sourdough, but who ultimately found success by allowing us to create a custom solution tailored to their specific needs. The key ingredient here is consistency. Sourdough is a living entity, influenced by external factors like temperature, time, and flour. Gaining a comprehensive understanding of these elements is a skill that most bakeries struggle to acquire. Even if they do, it's often concentrated in just one or two individuals and if those people leave, or move into different roles, inconsistency and uncertainty in the sourdough’s environment are introduced – this really should be avoided. At Puratos, we can achieve a level of quality and stability that exceeds what could be managed in-house. When we collaborate with customers on their sourdough production, we are committed to ensuring their success. +++

1 C Rizzello et al., ‘Sourdough Fermented Breads are More Digestible than Those Started with Baker’s Yeast Alone: An In Vivo Challenge Dissecting Distinct Gastrointestinal Responses’, Nutrients, 11(12), 2019, 2954.

2 H Lopez et al., ‘Prolonged fermentation of whole wheat sourdough reduces phytate level and increases soluble magnesium’, J Agric Food Chem., 49(5), 2001, 2657-62.

3 H Lopez et al., Making bread with sourdough improves mineral bioavailability from reconstituted whole wheat flour in rats, Nutrition, 19(6), 2003, 524-30.

Series: specialty topics

Title: Sustainability and innovations supporting it

Publication: 2023

200 pages, EUR 49*

*Price with VAT, for hard copy and e-copy. Transport costs not included.

Waffle recipes are quite simple and do not need many ingredients. To obtain the adequate waffle sheet structure, the flour used should meet certain characteristics when it comes to protein and gluten content.

By: Emmerich

By: Emmerich

+Waffles only require a few ingredients, with flour being the main component, to which water is added. Milk, sugar, salt, baking improver and/or fat may be added. Most waffle masses are fluid and pumpable. The flour used should be weak, with low protein and wet gluten content, in order to obtain a complete structure of the waffle sheet. The water absorption rate of waffle flours should be low so that a small water addition can achieve a dough that can be easily pumped.

For industrial production, the waffle mass is pumped through a tubing system. In this process, mechanical energy is imposed into the mass, which leads to a viscosity change if gluten protein is present. The so-called gluten aggregation can influence dosing and thus leads to waffle forms not filling properly, or to unwanted side effects such as cracks in the baked product. It is also possible that clots are formed, which lead to a blockage of the dosing dies. A quick and reliable method for characterizing the main flour parameters (wet gluten, protein content and water absorption) is of great importance for manufacturers of waffle products. The evaluation of flours with a Brabender GlutoPeak, and the ‘Rapid Flour Check’ GlutoPeak evaluation provide such a method, which implements a quick characterization of flours by mixing a small quantity of flour and water within a controlled environment, to analyze and monitor the gluten development

within that dough. As a newer development, the ‘Low Protein Check’ (LPC) method, which is specifically designed for properties of low-protein flours, can now also be employed. For the project analyzed, these GlutoPeak methods were tested and implemented for 20 different flour samples. The aim of this test was to check if these methods give reliable results and offer the same possibilities to obtain information in regard to mixing and baking waffle products within a short time.

For the project, 20 different wheat flours were used, typical waffle or cookie flours. As a baking test, standard ice cones were produced. All flour samples were tested with

the GlutoPeak and standard laboratory analyses (following ICC) prior to the waffle dough preparation and then baked into ice cones. With the exception of one sample, all other samples fulfilled the basic requirements of a waffle dough.

The first analysis was carried out with the GlutoPeak following the ‘Rapid Flour Check’ standard method and the available evaluation algorithm. After defining the moisture content of the flour sample, approx. 9 g of water was filled into the measuring bowl and inserted into the GlutoPeak. By using a connected thermostat, the measuring opening in the housing was heated up to 36°C for consistent test

conditions. After two minutes, when the temperature was distributed evenly within the water-filled measuring bowl, the corresponding flour quantity (depending on the water content of the specific flour) was added.

Depending on the flour properties, the measurement takes 2-5 minutes at 2,750 min-1. Due to the high energy input, a gluten network develops, corresponding to the quality and quantity of each type of gluten, showing a peak as the highest value (torque). Afterwards, the network is destroyed due to the mechanical energy input, the curve declines and the measurement ends. A typical curve diagram is depicted in pic. 1.

After the test ends, the highest torque is listed as peak (BEM/max. torque), and the necessary time (PMT/Peak Maximum Time) is evaluated. Additional measuring points are the torque every 15 seconds before and after the maximum (AM/PM). Up to eight measurements per hour were possible, thanks to this rapid test procedure and the machine’s fast cleaning capability.

The ‘Low Protein Check’ (LPC) method, which was developed during the project, was used in a second step. Hereby approximately 12 g of water per 11 g flour are weighed. This method is done with a reduced speed of 2,500 min -1 and a temperature of 180°C. The earlier mentioned evaluation is not changed by using this method. All tests were carried out as triple measurements and the results were collected and evaluated with the integrated software (MetaBridge).

1.2 Producing waffle dough

In fixed order, water and sodium bicarbonate were put into an IKA laboratory stirrer equipped with a R1300 blade mixer, and mixed at moderate speed until a complete homogenization was reached. Following the next process steps, flour was inserted and the mixer speed was increased. After adding all the flour, the waffle mass was mixed again until complete homogenization was reached. In the next step, a 1:1 pre-prepared mixture of

sunflower oil and soy lecithin was added to the mass and mixed for an additional 60 seconds.

Immediately after mixing, the viscosity was measured using a gravity feed cup of 100 ml and an 8 mm-diameter die (according to ASTM D 333). In case the measured viscosity showed a deviation from the defined viscosity, the water measurement of the recipe was adjusted and a new waffle mass was prepared.

By adjusting the viscosity of each dough to 20-second levels (+/- 1 sec.), the mechanical behavior during baking is similar for all flours, assuming that the product properties can only depend on the flour itself.

1.3 Baking waffles (casted cones)

Cones were baked with an electrically heated laboratory instrument of the LB-SWAK_STAK type, equipped with an industrial baking pan and a corresponding core plate. The pan was heated up to 180°C, whereas the cores were heated up to 190°C. Using a spraying device, a 7 ml waffle mass was inserted and baked for 80 seconds. Prior to closing the carrier for the final baking process, it was closed and opened twice (so-called breathing: 2 sec. open, 2 sec. closed) to allow steam to evaporate. After baking, the cones were removed from the open baking pan and left to cool at room temperature for approximately 10 minutes. The cooled cones were packed in PE wrapping, hot sealed, and stored at 8°C until the texture analysis took place.

1.4 Waffle texture analysis

The texture analysis was carried out with a TA.XT.plus Texture Analyzer (Stable Micro System) using an ice cream cone pan (A/ICC). This tool measures the force necessary to create a crack by pressing a ball-like item of a certain diameter and weight against the cone.

The most important texture parameters are the distance the ball moves, as well as the force that is necessary to break the cone. To carry out the texture

analysis for every flour, 10 cones were tested.

2.1 GlutoPeak ‘Rapid Flour Check’ vs. standard analysis

The GlutoPeak method ‘Rapid Flour Check’ was developed for flours destined for baked goods, which require medium to high gluten levels. Although flours for waffle production do not require high standards concerning their protein content, the method should be verified for its applicability.

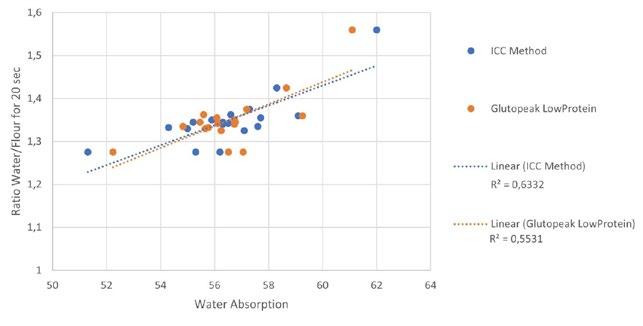

Comparing the results of the ‘Rapid Flour Check’ with the results obtained with the standard analysis, in principle, the correlation of all relevant parameters (protein content, wet gluten, and water absorption) were good. However, they were showing relatively high deviations. The GlutoPeak method underestimated the results of the standard measurements and showed measurements somewhat lower in protein content, by around 3.5%, and by 11% for the wet gluten content. To maximize the potential of the GlutoPeak results and optimize their relevance for waffle flours, Brabender included the newly-developed ‘LowProtein’ method in the course of the test series. The already-obtained data was re-evaluated and then compared with the results of the ICC method. The results showed a good correlation between both methods, which is commented on later in the course of this study.

2.2 Process parameters adapted to basic GlutoPeak data

To verify a correlation between the water quantities required – respectively, the product weight and flour parameters – the data of the standard analysis and the GlutoPeak analysis are dealt with separately. Primarily, a correlation of standard laboratory data is shown here. Following, it is tested for whether a correlation with standard laboratory data is also observed for the GlutoPeak data. Correlations and results of the ‘Low-Protein’ method are listed separately.

2.2.1 Standard analysis

The basic correlation of the required amount of water (for a determined dough viscosity) and the flour’s water absorption is well-known for waffle production and can also be illustrated for similar flours.

Flours with a higher water absorption level need more water to reach a defined dough viscosity. This can be a disadvantage during waffle baking, as the baked waffle normally has a water content of 1-2%. Therefore, the water included in the waffle mass has to evaporate during baking, when it acts as a leavening agent, thus leading to very brittle or even incomplete products (inaccurate distribution of the mass within the baking pan).

An easily-detectable effect concerning water requirements is the product density and the resulting weight. The higher the water amount, respectively the water demand, the lower the density of the waffle product (i.e. product weight).

Considering these additional influencing factors during baking, it suggests that the correlation of the product weight with the water absorption is less significant than the correlation with the water demand in dough preparation. More importantly, this impacts batch baking of waffle sheets on a laboratory scale, where significant differences in waffle density may occur.

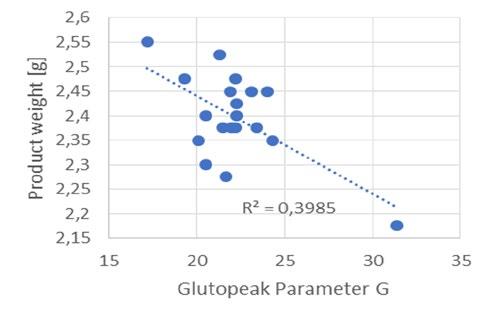

2.2.2 GlutoPeak data

A good correlation is achieved with the ‘Rapid Flour Check’ GlutoPeak method when the parameter G (wet gluten content) is selected instead of the parameter WA (Pic. 2 and 3).

2.3 Predicting product properties on the basis of GlutoPeak data

Predicting waffle properties from flour data is difficult, as not only the dough influences the product, but also the temperature, temperature deviations in the oven, and dosing (quantity, speed).

As the flour only partially influences the waffle’s quality, a direct correlation, even with the data obtained with standard analysis, is difficult (pic. 4). Often, flours with high water absorption tend to form low-stability products. As an example, sample W700 with its high water absorption of > 60% results in less stable products, compared to the other flours.

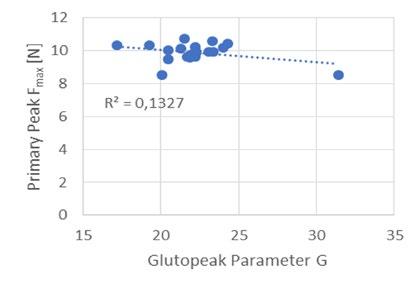

However, also flours with lower water absorption can result in less stable products. This principle process is also exhibited if correlated between the designated primary peak value Fmax with the GlutoPeak parameter G (see pic. 5).

3. GlutoPeak method – modification for low-protein flours

As the test results of the Rapid Flour Check (RFC) method did not produce optimum information, the test evaluation was carried out with the newly developed Low Protein Check Method.