SERVICE MANUAL

Part number 84605841

1st edition English May 2012

system

Fan and drive

Selective Catalytic Reduction (SCR) exhaust treatment

Powershift transmission

Powershift transmission external controls

Powershift transmission internal components Four-Wheel Drive (4WD) system

Contents INTRODUCTION Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Engine and crankcase Air cleaners and lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.202 Engine lubrication system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.304 Aftercooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.310

Engine cooling

Engine

sub-group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.AAA T ransmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

generic

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Drive shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23.314 Front axle system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Powered front

bevel

drive hub,

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25.108 Rear axle system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27.100

axle Front

gear set and dif ferential Final

steering knuckles, and shafts

Powered rear axle

ferential . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27.106

and final

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27.120 Brakes and controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

service brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33.202 Hydraulic systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84605841 14/05/2012

Rear bevel gear set and dif

Planetary

drives

Hydraulic

Hydraulic systems V ariable displacement pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35.106

system

Pilot

Main control valve

loader arm

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35.701 Steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Auxiliary steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41.910 Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Front wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44.51 1 Cab climate control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Air conditioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50.200 Electrical systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Electrical system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55.000 Fuel tank system 1 Engine cooling system Engine control system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55.015 Service brake electrical system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55.030 Parking brake electrical system Hydraulic system control Steering control system Heating, V entilation, and Air-Conditioning (HV AC) control system . . . . . . . . . . . . . . . . . . . . . . . 55.050 Cab Heating, V entilation, and Air-Conditioning (HV AC) controls . . . . . . . . . . . . . . . . . . . . . . . . . 55.051 Harnesses and connectors Engine starting system Cold start aid Alternator Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55.302 External lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55.404 84605841 14/05/2012

Auxiliary hydraulic valves and lines Front

hydraulic system

External lighting switches and relays W

harnesses and connectors

Cab controls

Cab lighting

Wiper/W asher system

Cab brake controls

Cab controls (Lift Dipper , Bucket) Selective Catalytic Reduction (SCR) electrical system

arning indicators, alarms,

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55.408 Loader arm and bucket

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55.415

and instruments

control system

Cab/Platform

F AUL T CODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55.DTC Platform, cab, bodywork, and decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . operator seat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90.124 Cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90.150 84605841 14/05/2012

INTRODUCTION 84605841 14/05/2012 1

Contents INTRODUCTION T orque – 621F T orque Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 621F 621F T orque – 721F T orque Specifications 5 721F 721F Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 621F 621F 721F 721F Consumables - Biodiesel Fuel Hydraulic contamination 84605841 14/05/2012 2

INTRODUCTION

T orque – 621F T orque Specifications

621F 621F Axle Wheel mounting nuts 640 - 720 N·m ( 472 - 531 ) Front axle mounting bolts 651 - 678 ( 480 - 500 ) Rear axle trunnion pin bolts 325 - 353 N·m ( 240 - 260 ) Chassis Cab mounts 773 - 854 ( 570 - 630 ) Exhaust stack hood - N·m ( - ) Counterweight mounting bolts 955 - 1075 N·m ( 704 - 793 ) Articulation pivot pin bolts 224 - 278 N·m ( 165 - 205 ) Articulation mount pin retainer bolts ( ) Seat mounting bolts - N·m ( - ) Steering wheel retaining nut N·m ( ) Hydraulic oil filter mounting bolts - N·m ( - ) Steering cylinder base end pin retaining bolt 290 - 375 ( 214 - 277 ) Steering cylinder rod end pin retaining bolt Bolts must turn freely Horn mounting bolt - N·m ( - ) Hood - rear grill bolts 9 - 1 1 ( 7 - 8 ) Hood hinge bolts - ( - ) Steps - lower entry strap bolts - N·m ( - ) Cooling Fan fan hub - ( - ) Fan hub motor shaft (no impact tools) - N·m ( - ) Radiator hose clamps - 1 N·m ( - ) Hydraulic tank cover nuts - N·m ( - ) Hydraulic tank sight gauge 2.75.5 ( 2.04.1 ) Diesel Exhaust Fluid (DEF) System Heater valve bolts - N·m ( - ) Dosing module bolts 7 - 8 ( - ) DEF control module / pump assembly mounting bolts - N·m ( - ) Driveshafts Coupling flywheel - ( - ) Driveshaft coupling - ( - ) Front driveshaft yoke nut 339 - 373 N·m ( 250 - 275 ) Carrier bearing mounting bolts - 128 N·m ( - ) 550R U - joints - ( - ) 410R U - joints - N·m ( - ) Dust cover mounting bolts - N·m ( - ) 84605841 14/05/2012 3

Engine Engine mounting brackets 1 - 133 N·m ( - ) Engine rubber isolator mounts (Qty 244 - 298 ( 180 - 220 ) Brake pump engine mounting - N·m ( - ) Brake pump gear nut (no impact tools) - N·m ( - ) T urbo turbo exhaust elbow clamp 5 N·m ( 4 ) Muf fler turbo elbow exhaust clamp - ( - ) Front muf fler bracket engine block 1 - 133 N·m ( - ) Muf fler brackets muf fler 1 - 128 N·m ( - ) Charge Air Cooler (CAC) hose clamps (Qty - 1 N·m ( - ) Air cleaner turbo hose clamp 10.1 - 1 1.3 ( 7.48.3 ) Alternator pulley (no impact tools) - N·m ( - ) Starter mounting nuts - N·m ( - ) Loader loader linkage bolts 650 - 732 N·m ( 479 - 540 ) guide link nuts 240 - 305 N·m ( 177 - 225 ) Loader link pin keeper 325 - 373 N·m ( 240 - 275 ) T ransmission T ransmission rubber isolator mounts (Qty 890 - 1000 N·m ( 656 - 738 ) T ransmission upper mounting bracket bolts 251 - 319 N·m ( 185 - 235 ) T ransmission lower mounting bracket bolts (Qty 481 - 590 ( 355 - 435 ) Hydraulic pump transmission mounting 335 - 375 N·m ( 247 - 277 ) Cooler clamps 10.1 - 1 1.3 N·m ( 7.48.3 ) Hydraulic pump suction hose clamp flange - N·m ( - ) Steering priority manifold pump - ( - ) T ransmission fill tube bolts - N·m ( - ) T ransmission sight gauge bolts - N·m ( 2 - 4 ) Wheels Wheel nuts Initial torque: 298 ( 220 ) Final torque: 640 - 720 N·m ( 472 - 531 ) RCPH10WHL320AAH 1 the following initial and final torque procedures: T ighten wheel nuts initial torque 298 ( 220 ) sequence shown figure T ighten wheel nuts a final torque 640 - 720 N·m ( 472 - 531 ) sequence shown figure 84605841 14/05/2012 4

INTRODUCTION

INTRODUCTION

T orque – 721F T orque Specifications

721F 721F Axle Wheel mounting bolts 640 - 720 N·m ( 472 - 531 ) Front axle mounting bolts 765 - 855 ( 564 - 631 ) Rear axle trunnion pin bolts 651 - 678 N·m ( 480 - 500 ) Chassis Cab mounts 773 - 854 ( 570 - 630 ) Exhaust stack hood - N·m ( - ) Counterweight mounting bolts 955 - 1075 N·m ( 704 - 793 ) Articulation pivot pin bolts 224 - 278 N·m ( 165 - 205 ) Articulation mount pin retainer bolts ( ) Seat mounting bolts - N·m ( - ) Steering wheel retaining nut N·m ( ) Hydraulic oil filter mounting bolts - N·m ( - ) Steering cylinder base end pin retaining bolt 290 - 375 ( 214 - 277 ) Steering cylinder rod end pin retaining bolt Bolts must turn freely Horn mounting bolt - N·m ( - ) Hood - rear grill bolts 9 - 1 1 ( 7 - 8 ) Hood hinge bolts - ( - ) Steps - lower entry strap bolts - N·m ( - ) Cooling Fan fan hub - ( - ) Fan hub motor shaft (no impact tools) - N·m ( - ) Radiator hose clamps - 1 N·m ( - ) Hydraulic tank cover nuts - N·m ( - ) Hydraulic tank sight gauge 2.75.5 ( 2.04.1 ) Diesel Exhaust Fluid (DEF) System Heater valve bolts - N·m ( - ) Dosing module bolts 7 - 8 ( - ) DEF control module / pump assembly mounting bolts - N·m ( - ) Driveshafts Coupling flywheel - ( - ) Driveshaft coupling - ( - ) Front driveshaft yoke nut 339 - 373 N·m ( 250 - 275 ) Carrier bearing mounting bolts - 128 N·m ( - ) 550R U - joints - ( - ) Dust cover mounting bolts - N·m ( - ) Flex plate flywheel bolts - N·m ( - ) Carrier bearing bolt 150 - 164 N·m ( 1 1 1 - 121 ) Drive line mounting bolts 136 - 149 ( 100 - 1 ) 84605841 14/05/2012 5

Engine Engine mounting brackets 1 - 133 N·m ( - ) Engine rubber isolator mounts (Qty 244 - 298 ( 180 - 220 ) Brake pump engine mounting - N·m ( - ) Brake pump gear nut (no impact tools) - N·m ( - ) T urbo turbo exhaust elbow clamp 5 N·m ( 4 ) Muf fler turbo elbow exhaust clamp - ( - ) Muf fler bracket muf fler 1 - 128 N·m ( - ) Charge Air Cooler (CAC) hose clamps (Qty - 1 N·m ( - ) Air cleaner turbo hose clamp - 1 N·m ( - ) Alternator pulley (no impact tools) - ( - ) Starter mounting nuts - N·m ( - ) Loader loader linkage bolts 650 - 732 ( 479 - 540 ) guide link nuts 240 - 305 N·m ( 177 - 225 ) Loader link pin keeper 325 - 373 N·m ( 240 - 275 ) T ransmission T ransmission rubber isolator mounts (Qty 890 - 1000 ( 656 - 738 ) T ransmission upper mounting bracket bolts 251 - 319 N·m ( 185 - 235 ) T ransmission lower mounting bracket bolts (Qty 481 - 590 N·m ( 355 - 435 ) Cooler clamps 10.1 - 1 1.3 ( 7.48.3 ) Hydraulic pump suction hose clamp flange - N·m ( - ) Steering priority manifold pump - N·m ( - ) T ransmission fill tube bolts - N·m ( - ) T ransmission sight gauge bolts 2.75.5 ( 2 - 4 ) Wheels Wheel bolts Initial torque: 298 N·m ( 220 ) Final torque: 640 - 720 ( 472 - 531 ) RCPH10WHL320AAH 1 the following initial and final torque procedures: T ighten wheel bolts initial torque 298 N·m ( 220 ) sequence shown figure T ighten wheel bolts a final torque 640 - 720 ( 472 - 531 ) . sequence shown figure 84605841 14/05/2012 6

INTRODUCTION

Capacities

621F 621F 721F 721F

621F

NOTE: Machines are shipped from the factory with break -

INTRODUCTION

and Specifications Engine T ype oil CASE A KCELA E NGINE OIL 15WCapacity (with filter change) 13.25 l ( 14.0 ) T otal system capacity 15.1 l ( ) Cooling System System capacity 26.8 l ( 28.4 ) Hydraulic System T ype fluid CASE A KCELA - TRAN® U LTRA ™ HYDRAULIC TRANSMISSION OIL T otal system capacity l ( gal ) Reservoir capacity 90.8 l ( 24.0 gal ) Fuel System System capacity 246 l ( 65.0 gal ) T ransmission T ype oil CASE A KCELA NEXPLORE™ FLUID Service capacity (with filter change) 26.7 l ( 28.2 ) Axles T ype oil CASE A KCELA NEXPLORE™ FLUID Standard front axle l ( 23.2 ) Standard rear axle l ( ) Optional front axle l ( 37.0 ) Optional rear axle l ( 37.0 ) Diesel Exhaust Fluid (DEF) T otal capacity l ( gal ) Grease Fittings required CASE A KCELA M OLY GREASE

Capacities

84605841 14/05/2012 7

721F Capacities and Specifications

NOTE: Machines are shipped from the factory with break -

INTRODUCTION

Engine T ype oil CASE A KCELA E NGINE OIL 15WCapacity (with filter change) 13.25 l ( 14.0 ) T otal system capacity 15.1 l ( ) Cooling System System capacity 28.4 l ( 30.0 ) Hydraulic System T ype fluid CASE A KCELA - TRAN® U LTRA ™ HYDRAULIC TRANSMISSION OIL T otal system capacity l ( gal ) Reservoir capacity l ( gal ) Fuel System System capacity 253 l ( 66.8 gal ) T ransmission T ype oil CASE A KCELA NEXPLORE™ FLUID Service capacity (with filter change) l ( 35.9 ) Axles T ype oil CASE A KCELA NEXPLORE™ FLUID Standard front axle l ( 37.0 ) Standard rear axle l ( ) Optional front axle l ( ) Optional rear axle l ( 37.0 ) Diesel Exhaust Fluid (DEF) T otal capacity l ( gal ) Grease Fittings required CASE A KCELA M OLY GREASE

84605841 14/05/2012 8

NOTE: Use engine oil pan heater engine coolant heater may required when operating temperatures are W inter Arctic conditions.

INTRODUCTION Engine Oil V iscosity / T emperature Range

1WHL023F 1

RCPH1

T ransmission Oil V iscosity / T emperature Range

2 84605841 14/05/2012 9

RCPH10WHL453BAH

Hydraulic / Brake System T emperature Range

RCPH10WHL006EAL 3

Coolant Solution

Only use ethylene - glycol coolant solution the cooling Use good quality ethylene - glycol that has a high boiling point with additives prevent leakage. not use non - approved anti - rust additives.

NOTICE: Anti - rust additives and ethylene - glycol can mix and work against each other , reducing anti - corrosion forming deposits the cooling and causing damage the cooling system and radiator Contact your dealer who can supply you with the suitable coolant solution.

Anti - freeze / Anti - corrosion

Use anti - freeze all seasons protect the cooling system from corrosion and risk freezing. For areas where the ambient temperature over - ( - ) use a blend % ethylene - glycol based anti -

For areas where the temperature below - (32.8 ) - advisable use a blend % water and % anti -

Fuel

• Use diesel fuel suitable for the ambient temperature conditions (ASTM - D -

• Use fuel which ASTM (American Society for T esting and Materials) D975

• Use grade 2 The use other types fuel can result a loss power the engine and may cause high fuel

• For very low ambient use a mixture fuels 1 and 2 necessary Consult your fuel supplier for appropriate fuel supply

• the temperature falls below the fuel cloud point (point which wax begins form, the wax crystals will cause power loss will prevent the engine from

• cold weather , fill the fuel tank the end the work order prevent the formation

Fuel Storage

Prolonged storage fuel can lead the accumulation impurities and condensation the Engine trouble can often traced the presence water the

The storage tank must placed outside and the temperature the fuel should kept low Drain f water and impurities regularly

INTRODUCTION

84605841 14/05/2012

Hydraulic Fluid

CASE A KCELA - TRAN® U LTRA ™ HYDRAULIC TRANSMISSION OIL specifically designed for high pressure tions and for Case hydraulic Y our Case Dealer can provide hydraulic fluid fulfill dif ferent climate / ature Refer the charts the beginning this

T

ransmission Component Oil

Extreme pressure oil should used for enclosed transmission Choose oil that manufactured for your climate / temperature conditions such CASE A KCELA NEXPLORE™ FLUID See charts the beginning this

Grease

The type grease use depends ambient temperature such as: CASE A KCELA M OLY GREASE

Environment

Before servicing machine and disposing and follow all environmental not drain oil fluids the ground into containers that leak. Check with your local environmental recycling center your dealer for correct disposal

Engine Oil

CASE A KCELA E NGINE OIL 15W - recommended for your This oil insures correct lubrication your gine all working See charts the beginning this section choose the correct oil for climate /

CASE A KCELA E NGINE OIL 15W - cannot use only oil the API SER VICE - 4 category

NOTE: not put any Performance Additive other ditive the Oil change intervals shown this ual are based tests carried out utilizing Case

RCPH10WHL012AAD 4

INTRODUCTION

84605841 14/05/2012 1 1

Consumables - Biodiesel Fuel

Fatty Acid Methyl Ester Biodiesel (Biodiesel Fuel) consists a family fuels derived from vegetable oils treated with methyl

NOTICE: Biodiesel fuel blends are approved for your engine only they comply with Specification Standards 14214 ASTM

NOTICE: V erify with your local dealer which blends are approved for your engine. Use biodiesel fuel that does not comply with the Standards EN14214 ASTM D6751 could lead severe damage engine and fuel Use non - approved biodiesel fuels may void warranty

Biodiesel Fuel Usage Conditions

Biodiesel fuels must purchased from a trusted supplier that understands the product and maintains good fuel quality Biodiesel fuels must pre - blended the supplier Mixing biodiesel fuels site can result incorrect mixture which can damage engine and fuel

Engine performance fected the use biodiesel There may percent reduction power torque depending the blend

NOTICE: NOT modify the engine and / fuel injection pump settings recover reduced

The reduced power must accepted using any biodiesel fuel

NOTICE: The use high biodiesel fuel blends not recommended cold weather

Using biodiesel fuels may require changing engine engine oil and fuel filter elements more frequently Biodiesel fuels can remove rust and other particles that adhere the inside the fuel These particles are trapped vehicle filters and may cause shortened filter life filter Blockages are more common cold weather conditions. Consult your dealer for information cold weather operation and proper maintenance intervals when using any biodiesel fuel

Biodiesel fuel may degrade natural rubber gaskets and hoses, more solvent than petrodiesel. Frequently inspect hoses and other engine components when using biodiesel

NOT allow water collect the fuel storage Biodiesel fuel attracts moisture from the Keep fuel tanks and storage tanks full possible limit the amount air and water may necessary drain machine fuel filter more frequently Potential oxidation and stability could create a problem with fuel stored the machine.

Biodiesel Storage

NOTICE: NOT store machines for more than three months with biodiesel blends the fuel NOT store biodiesel fuel - site storage tanks for more than three months.

long periods storage are run the machine for hours using regular diesel fuel flush the biodiesel fuel from the engine fuel system.

NOTICE: Biodiesel fuels must not stored - site storage tanks for more than 3 months. Any spillage biodiesel fuels must cleaned immediately before can cause damage the environment the paint finish the Before using biodiesel fuel you should consult with your dealer receive full information about the approved blend for your machine and any detailed conditions its Failure follow the requirements and conditions biodiesel fuel usage will void your s warranty

NOTE: B7 the highest biodiesel (7% blend) that should used this

INTRODUCTION

84605841 14/05/2012

Hydraulic contamination

Contamination the hydraulic system a major cause the malfunction hydraulic Contamination any foreign material the hydraulic Contamination can enter the hydraulic system several

(A) When you drain the oil disconnect any line.

(B) When you disassemble a

(C) From normal wear the hydraulic

(D) From damaged worn

(E) From a damaged component the hydraulic

All hydraulic systems operate with some contamination. The design the components this hydraulic system mits ficient operation with a small amount increase this amount contamination can cause problems the hydraulic The following list includes some these

(A) Cylinder rod seals

(B) Control valve spools not return

(C) Movement control valve spools dif ficult.

(D) Hydraulic oil becomes too

(E) Pump and other parts wear rapidly

(F) Relief valves check valves held open

(G) Quick failure components that have been

(H) Cycle times are slow; machine does not have enough power .

your machine has any these check the hydraulic oil for There are two types contammicroscopic and

Microscopic contamination occurs when very fine particles foreign material are suspension the hydraulic These particles are too small see Microscopic contamination can found identification the following problems testing a laboratory Examples the problems:

(A) Cylinder rod seal

(B) Control valve spools not return NEUTRAL.

(C) The hydraulic system has a high operating

V isible contamination foreign material that can found sight, touch, odor . V isible contamination can cause a sudden failure Examples visible contamination:

(A) Particles metal dirt the

(B) Air the

(C) The oil dark and

(D) The oil has odor burned oil.

(E) W ater the

you find use a Portable Filter clean the hydraulic

INTRODUCTION

84605841 14/05/2012

CONSUMABLES INDEX Consumable P AGE CASE Akcela Engine oil 15WCapacities 7 CASE Akcela - TRAN® Ultra™ hydraulic transmission oil Capacities 7 CASE Akcela NEXPLORE™ fluid Capacities 7 CASE Akcela NEXPLORE™ fluid Capacities 7 CASE Akcela Moly grease Capacities 7 CASE Akcela Engine oil 15WCapacities 8 CASE Akcela - TRAN® Ultra™ hydraulic transmission oil Capacities 8 CASE Akcela NEXPLORE™ fluid Capacities 8 CASE Akcela NEXPLORE™ fluid Capacities 8 CASE Akcela Moly grease Capacities 8 CASE Akcela - TRAN® Ultra™ hydraulic transmission oil Capacities 1 1 CASE Akcela NEXPLORE™ fluid Capacities 1 1 CASE Akcela Moly grease Capacities 1 1 CASE Akcela Engine oil 15WCapacities 1 1 CASE Akcela Engine oil 15WCapacities 1 1 84605841 14/05/2012

SER VICE MANUAL Engine 621F 721F 84605841 14/05/2012

Contents EngineEngine and crankcase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.001 621F , 721F Air cleaners and lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.202 621F , 721F Engine lubrication system 621F , 721F Aftercooler 621F , 721F Engine cooling system 621F , 721F Fan and drive 621F , 721F Selective Catalytic Reduction (SCR) exhaust treatment 621F 621F 721F 721F Engine generic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.AAA 621F , 721F 84605841 14/05/2012

CONSUMABLES INDEX Consumable P AGE DEF / AdBlue® Engine - Remove 10.001 / DEF / AdBlue® Engine - Remove / DEF / AdBlue® Engine - Remove / DEF / AdBlue® Engine - Remove / DEF / AdBlue® Engine - Remove / DEF / AdBlue® Engine - Install / DEF / AdBlue® Engine - Install / DEF / AdBlue® Engine - Install / DEF / AdBlue® Engine - Install / DEF / AdBlue® Engine - Install / CASE Akcela Engine oil 15WEngine - Install / Loctite® 242 Radiator - Install / DEF / AdBlue® Diesel Exhaust Fluid 10.500 / DEF / AdBlue® Diesel Exhaust Fluid / DEF / AdBlue® Diesel Exhaust Fluid / DEF / AdBlue® Diesel Exhaust Fluid 10.500 / DEF / AdBlue® Diesel Exhaust Fluid / DEF / AdBlue® Diesel Exhaust Fluid / DEF / AdBlue® Diesel Exhaust Fluid / DEF / AdBlue® Diesel Exhaust Fluid / DEF / AdBlue® Diesel Exhaust Fluid 10.500 / DEF / AdBlue® Diesel Exhaust Fluid / DEF / AdBlue® Diesel Exhaust Fluid / DEF / AdBlue® Diesel Exhaust Fluid 10.500 / DEF / AdBlue® Diesel Exhaust Fluid / DEF / AdBlue® Diesel Exhaust Fluid / DEF / AdBlue® Diesel Exhaust Fluid / DEF / AdBlue® Coolant control valve - Remove / DEF / AdBlue® Coolant control valve - Remove / DEF / AdBlue® Coolant control valve - Install / 84605841 14/05/2012

84605841 14/05/2012

EngineEngine and crankcase - 001 621F 721F 84605841 14/05/2012 10.001 / 1

Contents EngineEngine and crankcase - 001 SER VICE Engine Remove 4 Install 84605841 14/05/2012 10.001 / 2

CONSUMABLES INDEX Consumable P AGE DEF / AdBlue® Engine - Remove 10.001 / DEF / AdBlue® Engine - Remove / DEF / AdBlue® Engine - Remove / DEF / AdBlue® Engine - Remove / DEF / AdBlue® Engine - Remove / DEF / AdBlue® Engine - Install / DEF / AdBlue® Engine - Install / DEF / AdBlue® Engine - Install / DEF / AdBlue® Engine - Install / DEF / AdBlue® Engine - Install / CASE Akcela Engine oil 15WEngine - Install / 84605841 14/05/2012 10.001 / 3

Engine - Engine and crankcase

1 Place a bar pipe through the strap loop inside the hood and attach the strap a suitable lifting Then raise the hood with the strap release tension the lifting motor

T and disconnect the camera wire harness (if chine equipped with a camera.)

RAPH12WEL0601AA

Cut wire ties and remove camera wire harness from Then place f the side a safe (If machine equipped with a camera.)

RAPH12WEL0602AA

RAPH12WEL0600AA 1 1

84605841 14/05/2012 10.001 / 7

14. Remove mount bolt (1) and backup alarm wiring ness clamp from cooler Then tag and move hood ground wire (2) from cooler

T and disconnect hood wiring harness connector from rear chassis wiring harness connector

Have another person balance the hood and LOOSEN the hood hinge mounting bolts (arrows) from the cooler frame.

NOTE: not remove the hood hinge mounting bolts this

Engine - Engine and crankcase

RAPH12WEL0603AA

RAPH12WEL0604AA

84605841 14/05/2012 10.001 / 8

RAPH12WEL0605AA

17. Remove the pin from the bottom the lifting motor cylinder where attaches the loader

RAPH12WEL0606AA

Put the master disconnect switch the Then, retract the lifting motor cylinder (2) , replace pin and disconnect wiring harness (1)

RAPH12WEL0062AA

Put master disconnect switch (1) OFF Remove the battery cover and disconnect ground lead from the batteries (2) . Y may replace battery cover desired give you a place

RAPH12WEL0608AA

- Engine

Engine

and crankcase

84605841 14/05/2012 10.001 / 9

Have another person balance the hood and remove the hood hinge mounting bolts (arrows) from the cooler frame.

Carefully raise and remove hood from loader Lower hood onto suitable platform and disconnect lifting

NOTE: Radiator overflow hose may interfere with left hand hood hinge movement and hood

T and disconnect engine wiring harness connector from air filter restriction

Engine - Engine and crankcase

RAPH12WEL0605AA

RAPH12WEL0609AA

84605841 14/05/2012 10.001 /

RAPH12WEL0610AA

Engine - Engine and crankcase

T and disconnect engine wiring harness connector from air inlet humidity sensor

Loosen clamp (1) the crankcase ventilation hose (2) and disconnect hose.

RAPH12WEL0612AA

Loosen clamps turbocharger and air filter

Then remove the intake air Cover turbocharger inlet prevent debris entry .

RAPH12WEL0613AA

RAPH12WEL061 1AA

84605841 14/05/2012

/ 1 1

10.001

26. Loosen the clamp the turbocharger for the after cooler inlet elbow

Loosen the clamp the hose the after cooler inlet and remove the tube.

Loosen clamp the air inlet hose the air filter

Engine - Engine and crankcase

RAPH12WEL0614AA

RAPH12WEL0615AA

84605841 14/05/2012 10.001 /

RAPH12WEL0616AA

29. Remove bolts from the cooler box (1) and the ter support bracket (2) securing the air inlet hose Then remove air inlet hose and

RAPH12WEL0617AA

Remove four the bolts securing the air filter housing the mounting support bracket. Then remove air filter

RAPH12WEL0618AA

Remove the four mounting bolts from the belt cover Then remove the cover

NOTE: After removing the belt cover , remove the cover mounting bracket from the left rear side machine frame.

RAPH12WEL0619AA

Engine - Engine and crankcase

84605841 14/05/2012 10.001 /

32. Remove the drive belt from the engine.

loader equipped with air identify , tag, and disconnect the engine wiring harness nectors from air compressor clutch connector (1) and high pressure switch (2) Then remove the three mounting bolts (3) for the compressor and carefully set the left battery cover

T and disconnect the wiring from the alternator

Engine - Engine and crankcase

RAPH12WEL0620AA

RAPH12WEL0621AA

84605841 14/05/2012 10.001 /

RAPH12WEL0622AA

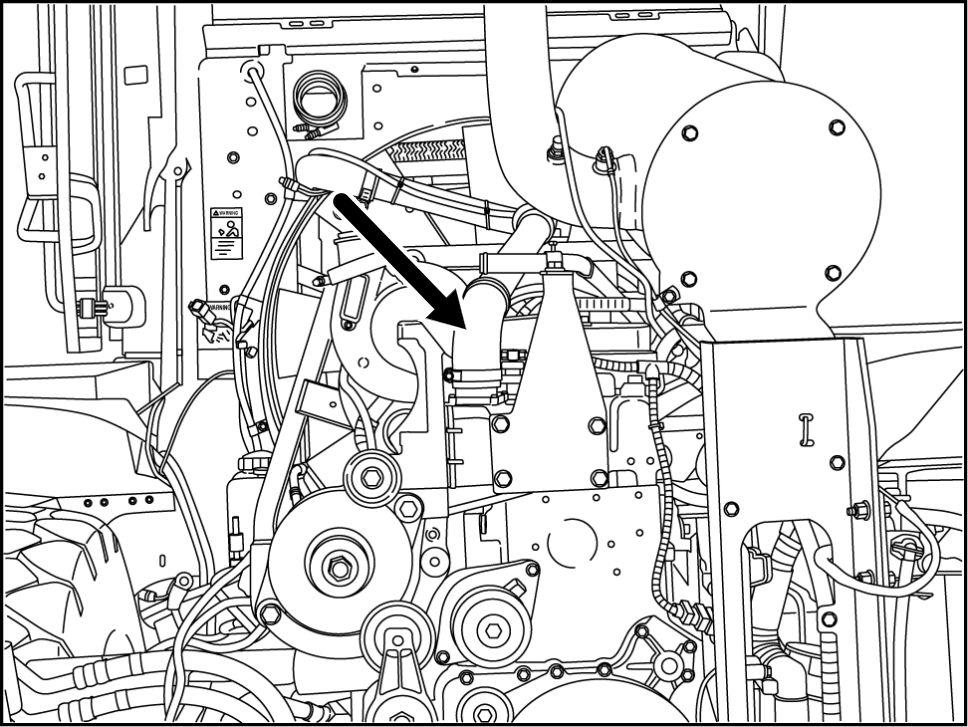

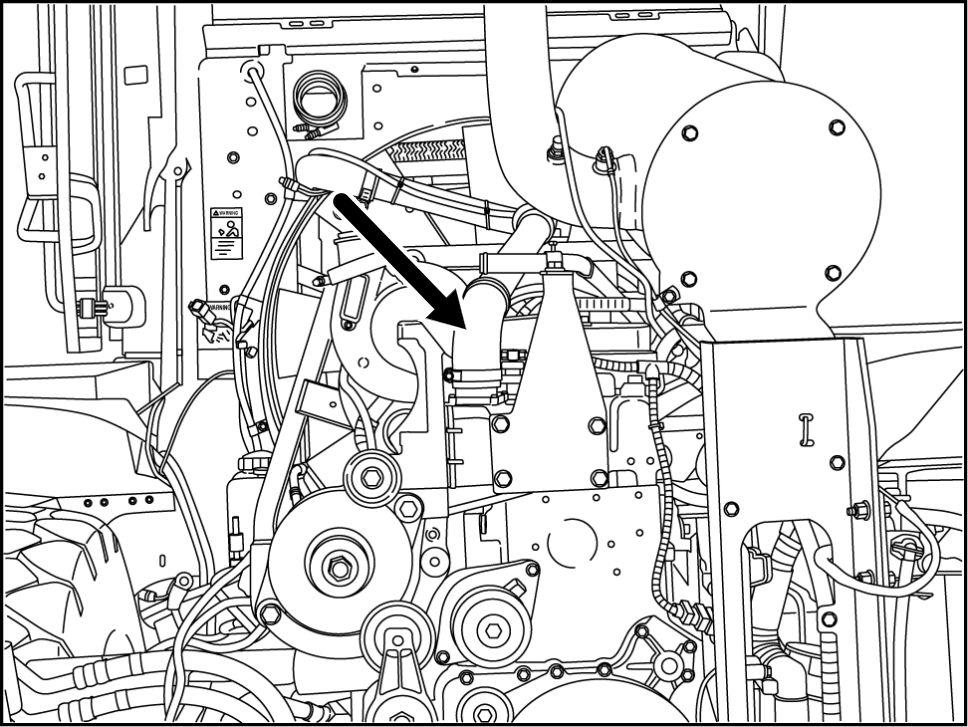

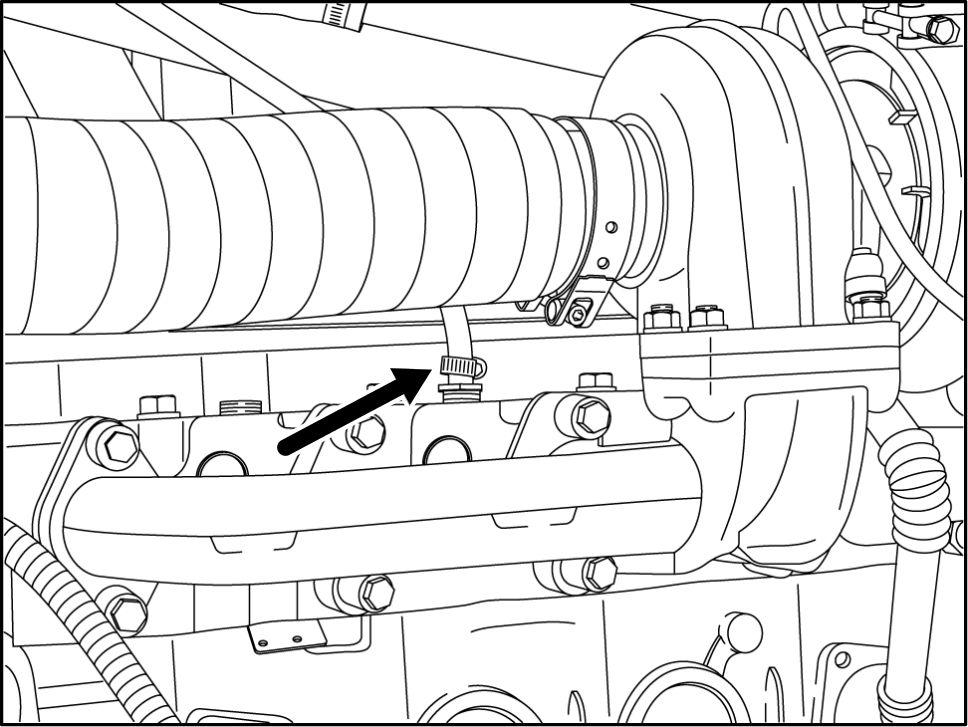

35. Remove SCR coolant return line.

RAPH12WEL0623AA

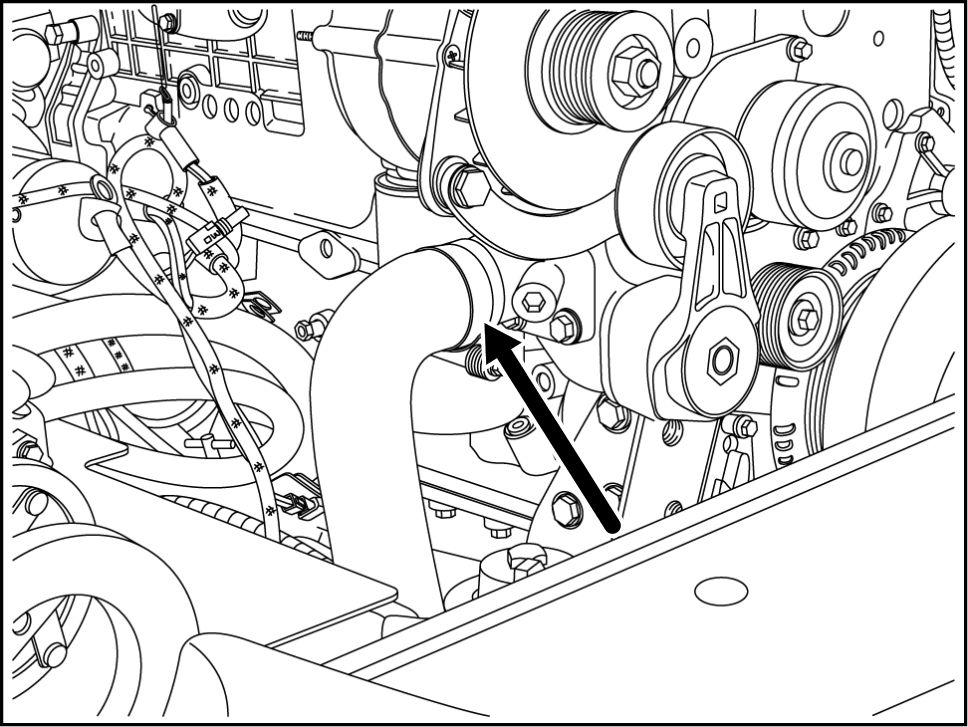

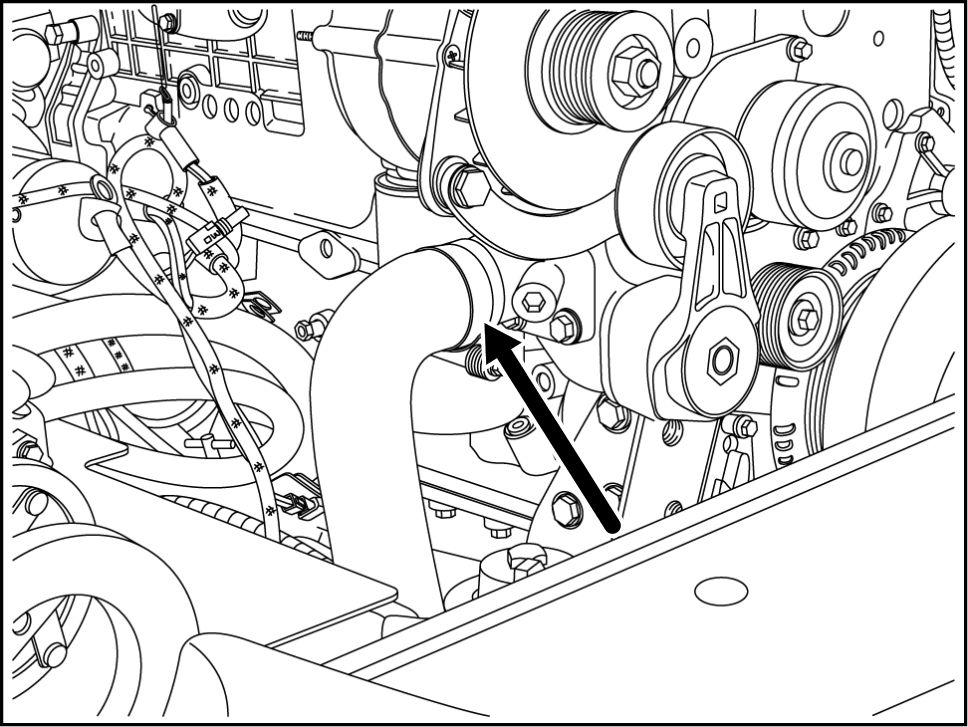

T and remove the wires from the starter solenoid (1) , the ground cable (2) , and ground strap (3) from the starter

NOTE: Move the starter cables away from the

RAPH12WEL0624AA Remove bolts securing wiring harness clamps

RAPH12WEL0625AA

Engine - Engine and crankcase

84605841 14/05/2012 10.001 /

38. Remove ground wires from the engine.

NOTE: Move the wiring harness away from the

the machine unplug the engine block heater and set aside.

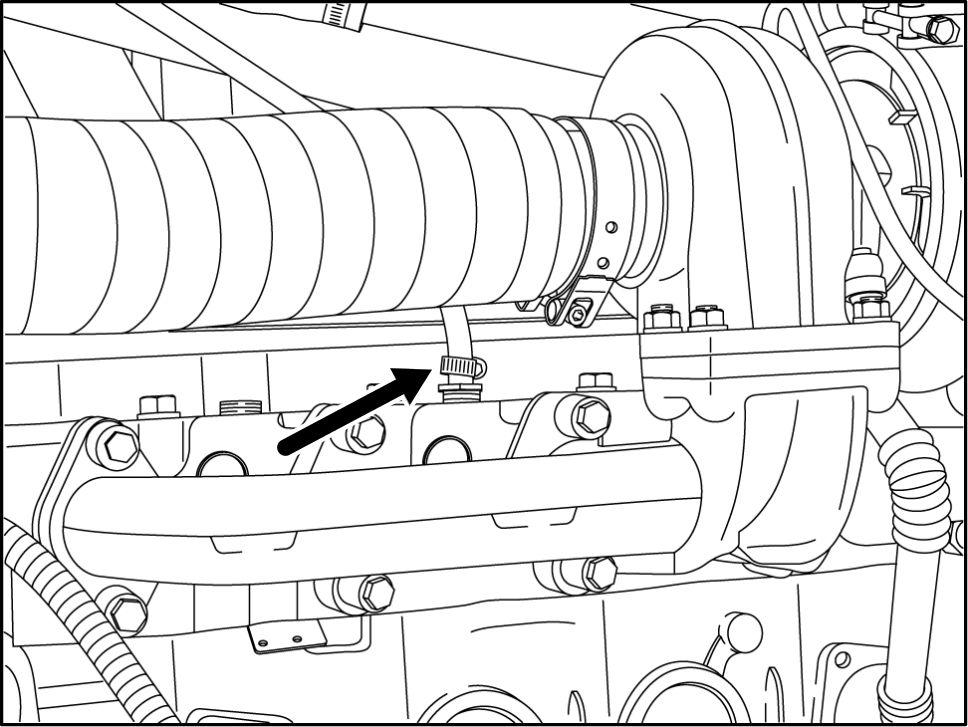

Loosen the exhaust clamp from the turbocharger

Engine - Engine and crankcase

RAPH12WEL0625AA

RAPH12WEL0626AA

84605841 14/05/2012 10.001 /

RAPH12WEL0627AA

Suggest:

If the above button click is invalid.

Please download this document first, and then click the above link to download the complete manual.

Thank you so much for reading

41. Disconnect the engine coolant vent hose from the

RAPH12WEL0628AA Loosen clamps and remove lower coolant hose from the engine.

RAPH12WEL0629AA Remove the radiator hose from the

RAPH12WEL0630AA

84605841 14/05/2012

Engine - Engine and crankcase

10.001 /