5 minute read

SERVICE MANUAL

Part number 84605841

1st edition English May 2012 system

Advertisement

Fan and drive

Selective Catalytic Reduction (SCR) exhaust treatment

Powershift transmission

Powershift transmission external controls

Powershift transmission internal components Four-Wheel Drive (4WD) system

External lighting switches and relays W harnesses and connectors

Cab controls

Cab lighting

Wiper/W asher system

Cab brake controls

Cab controls (Lift Dipper , Bucket) Selective Catalytic Reduction (SCR) electrical system

Introduction

T orque – 621F T orque Specifications

Introduction

T orque – 721F T orque Specifications

Capacities

621F 621F 721F 721F

621F

NOTE: Machines are shipped from the factory with break -

721F Capacities and Specifications

NOTE: Machines are shipped from the factory with break -

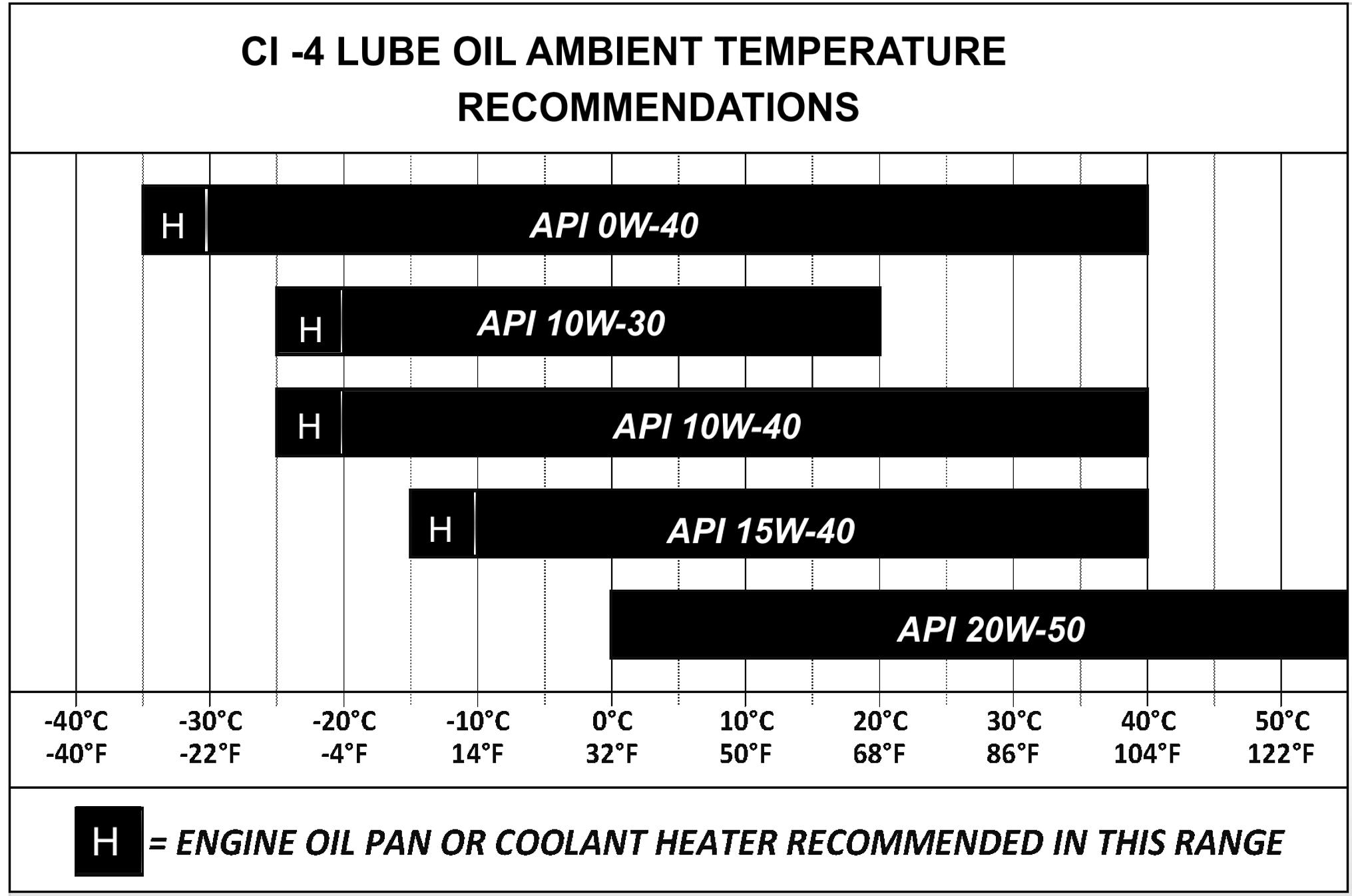

NOTE: Use engine oil pan heater engine coolant heater may required when operating temperatures are W inter Arctic conditions.

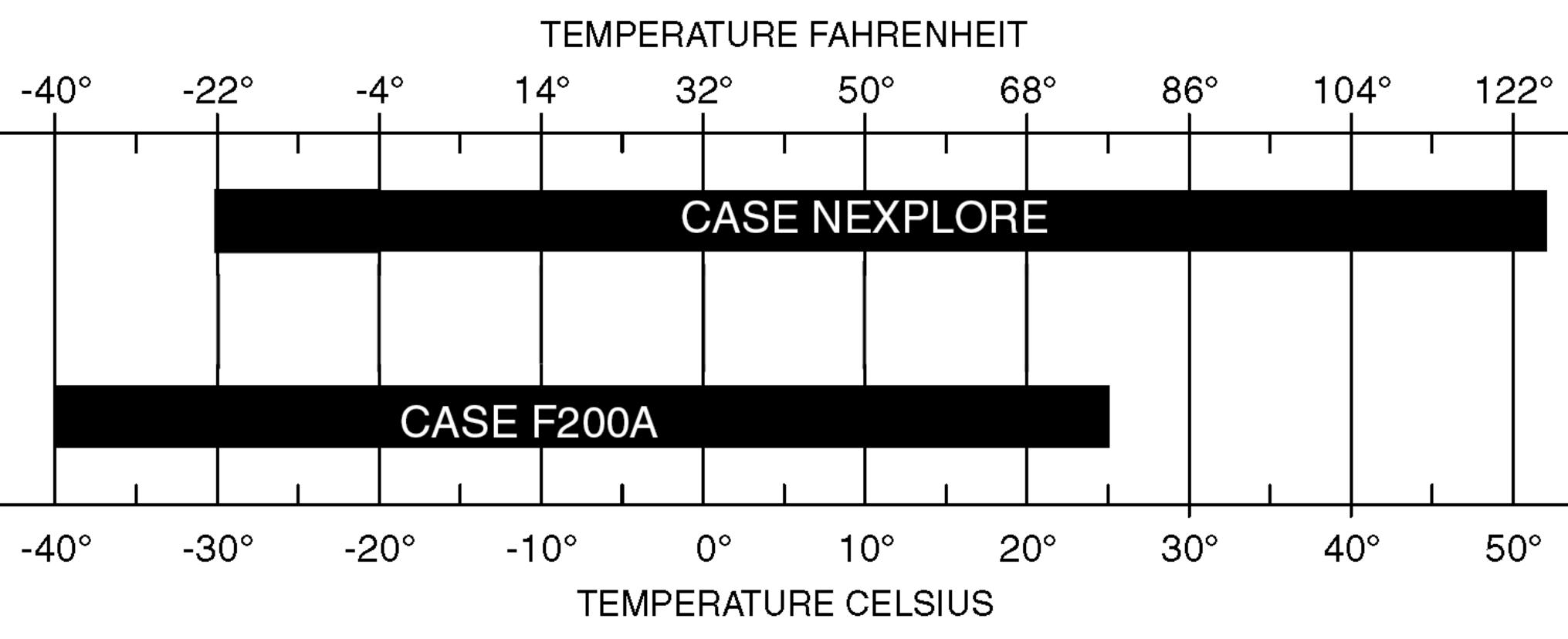

Hydraulic / Brake System T emperature Range

RCPH10WHL006EAL 3

Coolant Solution

Only use ethylene - glycol coolant solution the cooling Use good quality ethylene - glycol that has a high boiling point with additives prevent leakage. not use non - approved anti - rust additives.

NOTICE: Anti - rust additives and ethylene - glycol can mix and work against each other , reducing anti - corrosion forming deposits the cooling and causing damage the cooling system and radiator Contact your dealer who can supply you with the suitable coolant solution.

Anti - freeze / Anti - corrosion

Use anti - freeze all seasons protect the cooling system from corrosion and risk freezing. For areas where the ambient temperature over - ( - ) use a blend % ethylene - glycol based anti -

For areas where the temperature below - (32.8 ) - advisable use a blend % water and % anti -

Fuel

• Use diesel fuel suitable for the ambient temperature conditions (ASTM - D -

• Use fuel which ASTM (American Society for T esting and Materials) D975

• Use grade 2 The use other types fuel can result a loss power the engine and may cause high fuel

• For very low ambient use a mixture fuels 1 and 2 necessary Consult your fuel supplier for appropriate fuel supply

• the temperature falls below the fuel cloud point (point which wax begins form, the wax crystals will cause power loss will prevent the engine from

• cold weather , fill the fuel tank the end the work order prevent the formation

Fuel Storage

Prolonged storage fuel can lead the accumulation impurities and condensation the Engine trouble can often traced the presence water the

The storage tank must placed outside and the temperature the fuel should kept low Drain f water and impurities regularly

Hydraulic Fluid

CASE A KCELA - TRAN® U LTRA ™ HYDRAULIC TRANSMISSION OIL specifically designed for high pressure tions and for Case hydraulic Y our Case Dealer can provide hydraulic fluid fulfill dif ferent climate / ature Refer the charts the beginning this

T

ransmission Component Oil

Extreme pressure oil should used for enclosed transmission Choose oil that manufactured for your climate / temperature conditions such CASE A KCELA NEXPLORE™ FLUID See charts the beginning this

Grease

The type grease use depends ambient temperature such as: CASE A KCELA M OLY GREASE

Environment

Before servicing machine and disposing and follow all environmental not drain oil fluids the ground into containers that leak. Check with your local environmental recycling center your dealer for correct disposal

Engine Oil

CASE A KCELA E NGINE OIL 15W - recommended for your This oil insures correct lubrication your gine all working See charts the beginning this section choose the correct oil for climate /

CASE A KCELA E NGINE OIL 15W - cannot use only oil the API SER VICE - 4 category

NOTE: not put any Performance Additive other ditive the Oil change intervals shown this ual are based tests carried out utilizing Case

RCPH10WHL012AAD 4

Consumables - Biodiesel Fuel

Fatty Acid Methyl Ester Biodiesel (Biodiesel Fuel) consists a family fuels derived from vegetable oils treated with methyl

NOTICE: Biodiesel fuel blends are approved for your engine only they comply with Specification Standards 14214 ASTM

NOTICE: V erify with your local dealer which blends are approved for your engine. Use biodiesel fuel that does not comply with the Standards EN14214 ASTM D6751 could lead severe damage engine and fuel Use non - approved biodiesel fuels may void warranty

Biodiesel Fuel Usage Conditions

Biodiesel fuels must purchased from a trusted supplier that understands the product and maintains good fuel quality Biodiesel fuels must pre - blended the supplier Mixing biodiesel fuels site can result incorrect mixture which can damage engine and fuel

Engine performance fected the use biodiesel There may percent reduction power torque depending the blend

NOTICE: NOT modify the engine and / fuel injection pump settings recover reduced

The reduced power must accepted using any biodiesel fuel

NOTICE: The use high biodiesel fuel blends not recommended cold weather

Using biodiesel fuels may require changing engine engine oil and fuel filter elements more frequently Biodiesel fuels can remove rust and other particles that adhere the inside the fuel These particles are trapped vehicle filters and may cause shortened filter life filter Blockages are more common cold weather conditions. Consult your dealer for information cold weather operation and proper maintenance intervals when using any biodiesel fuel

Biodiesel fuel may degrade natural rubber gaskets and hoses, more solvent than petrodiesel. Frequently inspect hoses and other engine components when using biodiesel

NOT allow water collect the fuel storage Biodiesel fuel attracts moisture from the Keep fuel tanks and storage tanks full possible limit the amount air and water may necessary drain machine fuel filter more frequently Potential oxidation and stability could create a problem with fuel stored the machine.

Biodiesel Storage

NOTICE: NOT store machines for more than three months with biodiesel blends the fuel NOT store biodiesel fuel - site storage tanks for more than three months.

long periods storage are run the machine for hours using regular diesel fuel flush the biodiesel fuel from the engine fuel system.

NOTICE: Biodiesel fuels must not stored - site storage tanks for more than 3 months. Any spillage biodiesel fuels must cleaned immediately before can cause damage the environment the paint finish the Before using biodiesel fuel you should consult with your dealer receive full information about the approved blend for your machine and any detailed conditions its Failure follow the requirements and conditions biodiesel fuel usage will void your s warranty

NOTE: B7 the highest biodiesel (7% blend) that should used this

Hydraulic contamination

Contamination the hydraulic system a major cause the malfunction hydraulic Contamination any foreign material the hydraulic Contamination can enter the hydraulic system several

(A) When you drain the oil disconnect any line.

(B) When you disassemble a

(C) From normal wear the hydraulic

(D) From damaged worn

(E) From a damaged component the hydraulic

All hydraulic systems operate with some contamination. The design the components this hydraulic system mits ficient operation with a small amount increase this amount contamination can cause problems the hydraulic The following list includes some these

(A) Cylinder rod seals

(B) Control valve spools not return

(C) Movement control valve spools dif ficult.

(D) Hydraulic oil becomes too

(E) Pump and other parts wear rapidly

(F) Relief valves check valves held open

(G) Quick failure components that have been your machine has any these check the hydraulic oil for There are two types contammicroscopic and

(H) Cycle times are slow; machine does not have enough power .

Microscopic contamination occurs when very fine particles foreign material are suspension the hydraulic These particles are too small see Microscopic contamination can found identification the following problems testing a laboratory Examples the problems:

(A) Cylinder rod seal

(B) Control valve spools not return NEUTRAL.

(C) The hydraulic system has a high operating

V isible contamination foreign material that can found sight, touch, odor . V isible contamination can cause a sudden failure Examples visible contamination:

(A) Particles metal dirt the

(B) Air the

(C) The oil dark and

(D) The oil has odor burned oil.

(E) W ater the you find use a Portable Filter clean the hydraulic