1 minute read

A Vision for the Meat Industry

from JLS Magazine #3

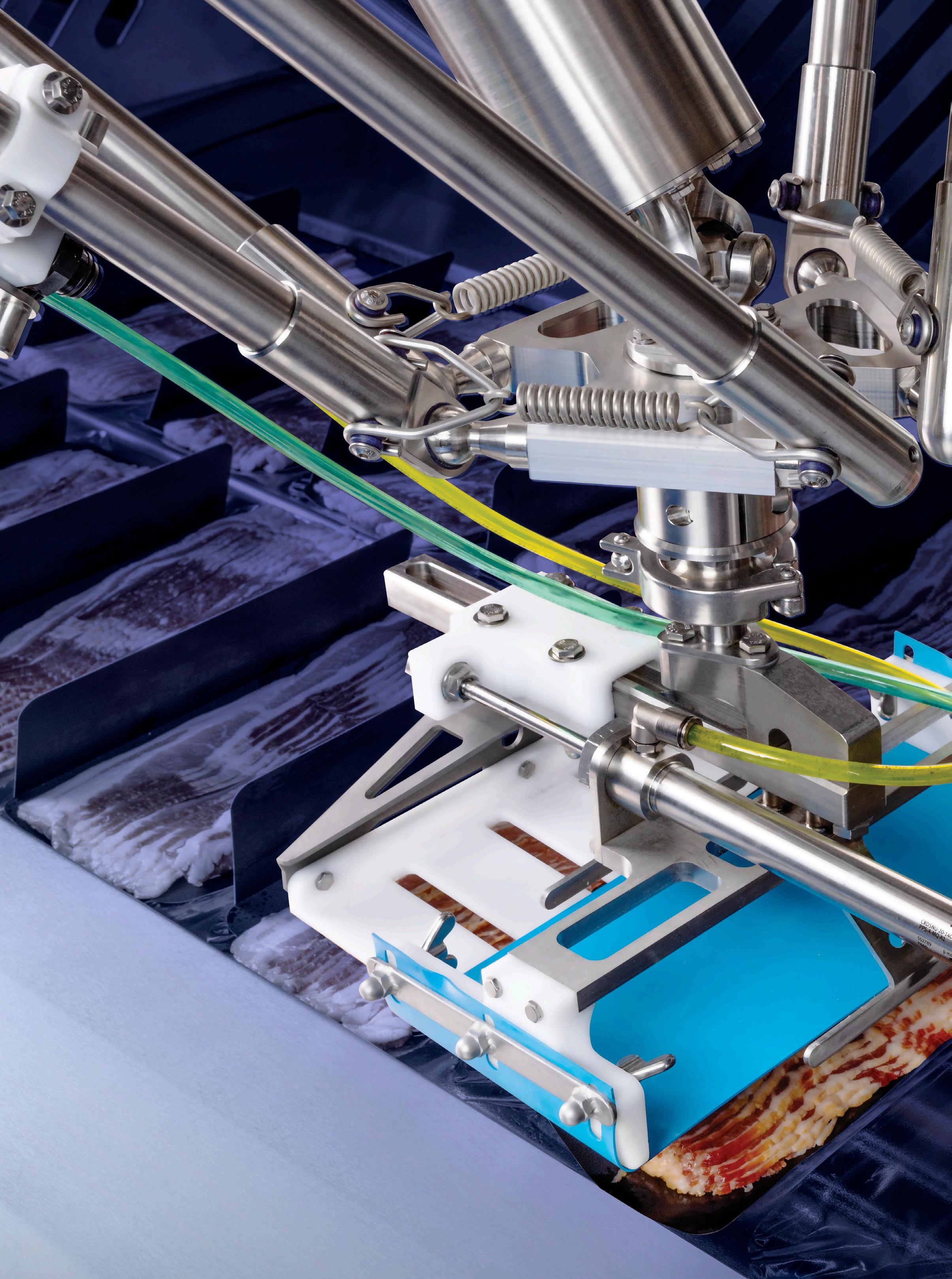

I’d like to share a few thoughts with you about technology. We see advances throughout the broad field of robotics, but certainly vision sensing and advanced tooling are key enablers to allow us to tackle more and more of the demanding requirements for handling meat–both animal and plant-based. We just shipped a standard Osprey case packer incorporating 3D vision that was the same price as our 2D solutions have been. 3D vision is driving us quickly into handling applications that we simply could not address with 2D cameras. In addition, we have developed a variety of mechanical tools for handling a variety of cuts of meat and have partnered with Soft Robotics on some impressive technology to handle a variety of cuts and formats.

This is the third edition of our JLS “VISION” magazine, but this one has a different angle to it. Since meat is one of our largest segments for our hygienic food handling solutions, we felt it was appropriate to dedicate an issue specific to the meat industry.

JLS has been providing meat handling solutions since 2009 with our initial focus being on primary product handling including fresh cooked and partially cooked sausages. Since that time, we have migrated downstream and provide carton loading, case packing and complete line solutions that include palletizing.

Our focus on hygienic robotic packaging solutions is more relevant than ever with the enormous challenges that our customers face in finding and retaining a viable labor force. Applications that may not have met yesterday’s ROI requirements are now on the priority list for funding, as in many cases, labor shortages are choking output. Additionally, the competitive pressures for the labor pool have driven wages to unthinkable levels pre-pandemic.

I am so excited about what we have accomplished in the meat industry on applications like sandwich assembly and our recently launched solution – the Harrier – for automatic bacon draft loading. Sandwich assembly lines require a significant amount of labor and with our solutions, these sandwiches are constructed and packaged without the human hand touching them. As a result, not only is labor addressed, but so is food safety.

Our continued partnership with Reiser allows us to offer thermoformers as part of an integrated solution with machines available from Repak as well as Variovac. Loading of thermoformers and case packing downstream has been a mainstream solution for JLS in the meat industry since our very first application over a decade ago. We look forward to partnering with many new customers as well as our growing list of existing customers to solve the challenges of automation for packaging operations in meat handling.

Craig A. Souser, President and CEO