Software Development for Railway Bridge Deck Slab Using IRS Code

Manmohan Sharma1, Shashikant Dhobale2

M.E Scholar1 , Assistant Professor2 Department of Civil Engineering, Jawaharlal Institute of Technology, Borawan, Khargone

Manmohan Sharma1, Shashikant Dhobale2

M.E Scholar1 , Assistant Professor2 Department of Civil Engineering, Jawaharlal Institute of Technology, Borawan, Khargone

ABSTRACT

Visual Basic has recently emerged as one of the most frequently utilized event-driven programming languages in the world. An event-driven language responds to events like as pressing a button, selecting an item from a list, navigating away from a control, and so on. Many programmes written in the Visual Basic programming language are effectively used in the banking and finance industries. The Visual Basic language has a lot of promise for developing software for the analysis and design of civil engineering structures. from traditional, linear programming approaches. The software is based on the idea that we must define the section, material of the bridge component, and apply the load that will have the most unfavorable effect on the component over its service life. The software will do calculations for stresses, deflection, and reinforcement. These stresses and deflections should be within the limits allowed by the appropriate IRS and IS codes. If the calculated values of stresses and deflection do not fall within acceptable limits, the section must be altered and the analysis procedure must be restarted. This exercise must be repeated until the safe section of the bridge component is reached.

Keywords– Railway bridge, IRS Code, software development.

INTRODUCTION

The deck slab of a railway bridge must be designed to meet the relevant wide gauge loading requirement. For analysisanddesignpurposes,thedeckslabisseparatedinto two parts: cantilever slab and internal panel. For concentrated loads due to PQRS loading, the cantilever sectionofthedeckslabmustbeassessedusingtheeffective widthapproachasspecifiedinclause24.3.2ofIS456:2000.

The inside panel of the deck slab is monolithic and continuous,madeofPSCgirderanddiaphragm.Theinside panelissusceptibletoconcentratedloadsfromtrainwheels aswellasderailmentloadsintheeventofatrainderailment overabridge.Therearetwowaysforanalysingsuchslabs: Pigeaud'stheoryandWestergaard'stheory.Pigeaud'stheory isusedtoassesstheinsidepanelinthisproject.Thesoftware wascreatedtoanalyseanddesigndeckslabs

OBJECTIVE

Software Development for Railway Bridge Deck Slab UsingIRSCODES

METHODOLOGY

Indefinesectionofsoftwarefollowinginputsareto beprovided.

(a) Design data

The following design data are to be provided as inputindefinesectionofthesoftware.Wehavetoclickthe Definebuttononmenubartoaccessthedefinesection.

•Lengthofspan

•Distancebetweencentrelineofbearings(Effectivespan)

•Overalllengthofdeckslab

• Centretocentrespacingofgirders

• No.ofdiaphragms

• Thicknessofenddiaphragm

• Thicknessofintermediatediaphragm

• Outtooutdistanceofgirderflanges

• Overallwidthofdeckslab

(b) Material properties

ThematerialpropertiesofConcreteareconsideredasper cl.5 of IRS Concrete Bridge code – 2004 and material properties of HYSD bars are considered as per IS 1786 –1985.

Thematerialspropertiesaretobedefinedindefinesection of the software. We have to click on Accept button on the Designdataformtoaccessthematerialpropertiesform.The GUIofmaterialpropertiesformisillustratedinFigure4.2. Wehavetoselectexposurecondition,gradeofconcreteand gradeofsteelfromcombobox.Thematerialpropertieswill beprovidedbydatabase.

(c) Section

Thesectionofdeckslabistobedefinedindefinesectionof the software. We have to click on Accept button on the materialpropertiesformtoaccessthesectionform.TheGUI

ofsectionformisillustratedinFigure4.7.Wehavetoenter dimensionsofdeckslab,ballastretainerininputboxes.

(d) Loading

As per cl. 2.1 of IRS Bridge Rules, the following loads are considered for the purpose of analysis and design of deck slab.

DeadLoad(DL)

SuperImposedDeadLoad(SIDL)

Superimposeddeadloadincludesloadduetotrack, ballast,wearingcoatandballastretainer.

LiveLoad(LL)

The live load is to be considered as per cl. 2.3.4.1 and cl. 2.3.4.2ofIRSBridgerulesforrelevantloadingstandard.

DynamicAugment(I)

Thedynamicaugmentisconsideredaspercl.2.4.2.1ofIRS Bridgerulesforrelevantloadingstandard.

Incaseofballasteddeckslabbridges, Coefficient of Dynamic Augment = [2-(d/0.9)] x [0.15 + 8/(6+L)]x0.5

Here,

d=depthofballastcushioninmetres

L=Loadedlengthofspaninmetres

PQRSloading

ThePQRSloadingisconsideredaspercl.2.15ofIRSBridge rulesforanalysisanddesignofcantileverslab

Derailmentload

The Derailment load is considered as per cl. 2.14 of IRS Bridgerulesforanalysisanddesignofinteriorpanel.

Theloadingondeckslabistobedefinedindefinesectionof the software. We have to click on Accept button on the sectionformtoaccessdefineloadingform.TheGUIofdefine loadingformisillustratedinFigure4.7.

(e) Analysis

On completion of define process, we have to click the Analysisbuttononmenubarandselectdeckslabtoaccess the analysis section of deck slab. In analysis section of softwareallcalculationsareperformedbythesoftwareon clickingofCalculatebutton.

Loadandmomentcalculations

TheGUIofLoadandmomentcalculationsformisillustrated inFigure5.1.ClickonCalculatebuttontocalculateLoadand moment.

ANALYSISANDDESIGNOFRCCDECKSLABANDDIAPHRAGM

GENERAL :The superstructure consists of the precastPSC (posttensioned) girderandcastin situdeckslab. The variousassumptionsmade in the design and specification used are asbelow

condition- moderate Grade of concrete usedforPSC girderandRCC deckslab= M- 40

IS

1985 Fe 415 Grade HYSD bars tobe usedforRCC works

VALIDATION OF SOFTWARE

A.3 ANALYSIS AND DESIGN OF DECK SLAB

A.3.1 Material properties

Concrete(Ref:cl.5ofIRSConcreteBridgecode–2004)

Exposurecondition-Severe

Characteristicscompressivestrength(fck)=40.0N/mm2

Unitweightofconcrete=25kN/m3

Modulusofelasticityofconcrete=31.0kN/mm2

HYSDsteel(Ref:IS1786–1985)

Characteristicsstrength/Yieldstrength(fy)=415.0N/mm2

A.3.2Design data

C/Cofgirder=2.300m

Overallwidthofdeckslab=4.800m

Thicknessofdeckslab=0.220m(Ref:cl.16.9.6.1ofIRSCon. Bridgecode-2004)

Widthofflange=0.750m

Thicknessofwebofgirder=0.300m(Ref:cl.16.9.6.2ofIRS Con.Bridgecode-2004)

A.3.3 Load calculations

A.3.3.1 Cantilever slab

Dead load (DL)

Deckslab=1x0.22x25=5.5kN/m

Super imposed dead load (SIDL)

Ballastretainer=0.15x0.75x25=2.81kN

Wearingcoat=1x0.08x22=1.76kN/m

Ballast=1x0.6x19=11.4kN/m

Live load (LL) due to PQRS

(Ref:IRSBridgeRulescl.2.3.4.2,cl.2.15andAppendix-X)

Calculations for section at B – B

Effectivewidthmethod(Ref:IS456:2000cl.24.3.2)

Concentratedload(W)=98.1kN

a1=0.211m, a=0.81m

bef=1.2a1+a=1.0632m

Distanceofconcentratedloadfromend(x1)=0.5m

Distancebetweenconcentratedloadsparalleltosupported edge(x2)=2.5m

Overhang(bef/2-x1)=0.0316m

Overlap(bef-x2)=0m

e=2bef-Overhang–Overlap=2.0948m

Effectiveloadincludingimpact(1.44W/e)=67.44kN.

A.3.3.2Interiorpanel

Deadload(DL)

Deckslab=1x0.22x25=5.5kN/m2

Superimposeddeadload(SIDL)

Wearingcoat=1x0.08x22=1.76kN/m2

Ballast=1x0.6x19=11.4kN/m2

Track=3.87kN/m2

Liveload(LL)duetoheaviestaxleofMBGloading

Concentratedload=245.2kN

Derailmentload

(Ref:IRSBridgeRulescl.2.14andAppendixIX)

Concentratedload=100.0kN

A.3.4 Bending moment calculations

A.3.4.1 Cantilever slab

Table A.23: Bending moment for cantilever slab

BM due to At section B - B

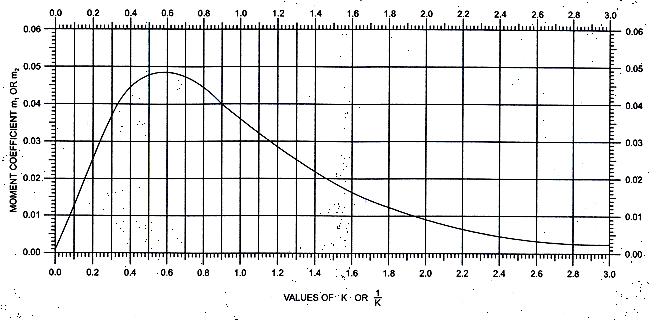

m1=0.04, m2=0.003

Momentalongshortspan=(m1+0.15xm2)W=10.97kNm

Momentalonglongspan=(m1x0.15+m2)W=2.44kN.

BendingmomentduetoLL(Pigeaud’stheory)

MBGLoading-withtype-Isleepers

(Ref:IRSBridgeRulescl.2.3.4.1andcl.2.3.4.2)

A.3.4.2Interiorpanel

BendingmomentduetoDLandSIDL(Pigeaud’stheory)

Panelsize L=6.02m, B=2.0m

Totaldeadload(W)=22.53x6.02x2.0=271.3kN

Constantkand(1/k)

k=(shortspan/longspan=B/L)=0.33

(1/k)=3.01

AssumingPoisson’sratio=0.15

m1andm2fromgraph

Panelsize L=6.02m, B=2.0m, U=2.0m, V=0.734m

Effective load on panel (W) = (245.2 x 1.44 x2.0/3.225) = 219.0kN

k=(shortspan/longspan=B/L)= 0.33

AssumingPoisson’sratio=0.15

m1 and m2 from graph for U/B = 1 and V/L = 0.12

m1=0.10, m2=0.05

Momentalongshortspan=(m1+0.15xm2)W=23.54kNm

Momentalonglongspan=(m1x0.15+m2)W=14.24kN–m

BendingmomentduetoDerailmentload(Pigeaud’stheory)

Panelsize L=6.02m, B=2.0m, U=0.48m, V=0.48m

Effectiveloadonpanel(W)=(1.44x100)=144.0kN

k=(shortspan/longspan=B/L)= 0.33

AssumingPoisson’sratio=0.15

m1andm2fromgraphforU/B=0.24andV/L=0.08

m1=0.22, m2=0.14

Momentalongshortspan=(m1+0.15xm2)W=34.70kNm

Momentalonglongspan=(m1x0.15+m2)W=24.91kN–m

A.3.5DesignofDeckslab

Overalldepthofslab=220mm

Clearcover=30mm

Diaofbar=12mm

Effectivedepthofslab(d)=184mm

Widthofslab(b)=1000mm

A.3.5.1Cantileverslab

DesignBMduetoultimateload(M)=43.0kN.m

(2SIDL+1.4DL+2LL)

Ultimate moment of resistance (0.15 fck b d2) = 203.14

kN.m

(Ref:IRSCon.Br.Codecl.15.4.2.2.1)

Theoveralldepthprovidedisadequateandsectionisunder reinforced.

Areaofmainreinforcement(As)=676mm2

C/Cspacingofmainbars=167.3mm

Provide12mmbar@150mmc/c

A.3.5.2Interiorpanel

Calculationofreinforcementalongshortspan

DesignBMduetoultimateload(M)=69.03kN.m

(2SIDL+1.4DL+2LL)

Ultimate moment of resistance (0.15 fck b d2) = 203.14 kN.m

(Ref:IRSCon.Br.Codecl.15.4.2.2.1)

Theoveralldepthprovidedisadequateandsectionisunder reinforced.

Areaofmainreinforcement(As)=1116mm2

C/Cspacingofmainbars=101.3mm

Provide12mm#bars@90mmc/c

Calculationofreinforcementalonglongspan

DesignBMduetoultimateload(M)=33.35kN.m

(2SIDL+1.4DL+2LL)

Ultimatemomentofresistance(0.15fckbd2)=177.5kN.m

(Ref:IRSCon.Br.Codecl.15.4.2.2.1)

Theoveralldepthprovidedisadequateandsectionisunder reinforced.

Areaofmainreinforcement(As)=560mm2

C/Cspacingofmainbars=202.0mm

Provide12mm#bars@120mmc/c

Shrinkage and temperature reinforcement (minimum reinforcement)

(Ref:IRSCon.Br.Codecl.15.9.9)

As>= Kr(Ac-0.5Acor)

Kr=0.005

Ac(Areaofgrossconcretesection)=220000mm2

Acor(Coreareaofconcrete)=0

As=1100mm2

Shrinkage and temperature reinforcement (minimum reinforcement) shall be distributed uniformly around the

perimeter of the concrete section and spaced at not more than150mm.

Areaofreinforcementrequiredateachfaceodeckslab(As/ 2)=550mm2

C/Cspacingof10#bars=142.80mm

CONCLUSION

The accuracy of software is primary requirement of any software development work. To validate the results of software, the analysis and design of 4.8-meter-wide deck slabPSCofrailwaybridgeisdonebyhandcalculationsand results are presented in paper. The analysis and design results for various components of this bridge are also obtained by the software. The results of software are in conformitywithresultsobtainedbyhandcalculations. Soit can be concluded that the accuracy of software is beyond doubt.Itispossibletodesignanotherbridgewithdifferent span, loading standard and design data, without rigorous hand calculations, with the help of software. The detailed designreportcanbeobtainedfromsoftwareandcanbeused withoutfurtherformatting.Itmeansthesoftwareisusefulin savingtimeandeffortduringaccurateanalysisanddesignof railwaybridges.

REFERENCES

1. Anil kumar H and B S Suresh Chandra (2015), “FlexuralBehaviourofLongitudinalGirdersofRCTBeamDeckSlabBridge”,Int.J.forSci.Res.&Develop., Volume3,Issue5,pp.639-642, Available at: http://www.ijsrd.com/articles/IJSRDV3I50447.pdf.

2. BudiRyantoWidjaja(1997),“AnalysisandDesignof Steel Deck– Concrete Composite Slabs”, Ph. D, Polytechnic Institute and State University, Virginia Tech., Available at: https://vtechworks.lib.vt.edu/handle/10919/30759.

3. Haymanmyintmaung and Kyawlinnhtat (2011), “InvestigationofIntegralBridgeEffectunderDynamic Loading”,Int.J.ofSci.andRes.Publi.,Volume7,Issue 5, pp. 567-574, Available at: http://www.ijsrp.org/research- paper-0517/ijsrpp6565.pdf.

4. IbrahimS.I.Harba (2011),“EffectofSkewAngleon Behavior of Simply Supported R. C. T-Beam Bridge Decks”, ARPN J. of Engg. and Appli. Sci., Volume 6, Issue 8, pp. 1-14, Available at:http://www.arpnjournals.com/jeas/research_pape rs/rp_2011/jeas_0811_532.pdf.

5. Kearthi. S, Kalpana Mohan Sivasubramanian.S. L, Deepan. R and Gopinath. M (2016), “Analysis of T –Beam Bridge Deck Slab”, Int.J. of Res. and Innov. in

Engg.Tech.,Volume 2,Issue12,pp.22–27,Available at:https://www.researchgate.net/publication/3051 13203_ANALYSIS_OF_T_-_BEAM_BRIDGE_DECK_SLAB.

6. Kalpana Mohan and S. P. Vijay Kumar (2016), “Analysis of Bridge Girder with Beam and Without Beam”,Int.J.ofCivilEngg.andTech.,Volume7,Issue 5,pp.337–346,Available at: http://www.iaeme.com/MasterAdmin/Journal_uploa ds/IJCIET/VOLUME_7_ISSUE_5/IJCIET_07_05_038.pdf.

7. Lindsay Edward Klein Piers (2006), “Finite Element AnalysisofaCompositeBridgeDeck”, Ph.D. dissertation, Dept. of Engineering & Surveying Research Project, University of Southern Queensland, Available at: https://core.ac.uk/download/pdf/11036283.pdf.\