BRAND-NEW

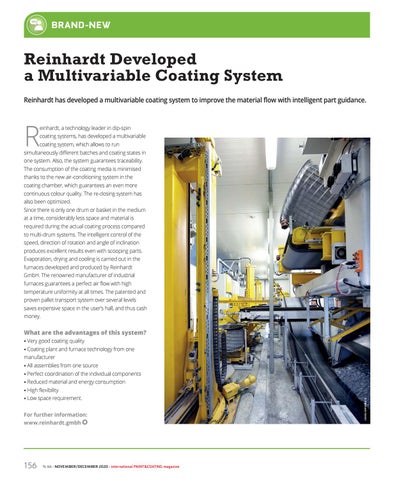

Reinhardt Developed a Multivariable Coating System Reinhardt has developed a multivariable coating system to improve the material flow with intelligent part guidance.

R

einhardt, a technology leader in dip-spin coating systems, has developed a multivariable coating system, which allows to run

simultaneously different batches and coating states in one system. Also, the system guarantees traceability. The consumption of the coating media is minimised thanks to the new air-conditioning system in the coating chamber, which guarantees an even more continuous colour quality. The re-dosing system has also been optimized. Since there is only one drum or basket in the medium at a time, considerably less space and material is required during the actual coating process compared to multi-drum systems. The intelligent control of the speed, direction of rotation and angle of inclination produces excellent results even with scooping parts. Evaporation, drying and cooling is carried out in the furnaces developed and produced by Reinhardt GmbH. The renowned manufacturer of industrial furnaces guarantees a perfect air flow with high temperature uniformity at all times. The patented and proven pallet transport system over several levels saves expensive space in the user’s hall, and thus cash money.

What are the advantages of this system? • Very good coating quality • Coating plant and furnace technology from one manufacturer • All assemblies from one source • Perfect coordination of the individual components • Reduced material and energy consumption • High flexibility

For further information: www.reinhardt.gmbh

156

N. 66 - NOVEMBER/DECEMBER 2020 - international PAINT&COATING magazine

© Reinhardt GmbH

• Low space requirement.