TIGER COATINGS

From left to right: Thomas Loibl (COO)

Reinhold Freiseisen (CFO)

Elisabeth Berghofer (Chairwoman of Supervisory Board)

Kurt Berghofer (Chairman of Advisory Council)

Clemens Steiner (CEO)

your partner industrial

Verona Impianti designs, manufactures, and installs tailor-made coating plants, pretreatment lines, and drying systems. Reliability, competence, and experience: these are the three nouns that best describe the team of VERONA IMPIANTI 2002.

Disrupting markets by inventing the future: a new paradigm in innovation strategy

OF

Portrait of a successful company. TIGER Coatings: 95 years of innovation,vision, and family passion

Lechler Tech redefines Soft Touch: the new generation of ultra-matt, eco-friendly and high-performance clearcoats is born

The unique plant solution chosen by Merletti to meet the high coating requirements of the aerospace industry

Deltrian Italia: air filtration solutions for clean, safe, and sustainable coating

The new Mapei paints for motorsport circuit: sustainability takes to the track

OF THE

Galstaff Multiresine: innovation, sustainability, and a global vision for high-added value chemicals

The new frontier of sublimation: i.dek’s four collections

ON TECHNOLOGY

A new VR-tracking robot raises the coating standards at Quality Painting

The development of Kazakhstan’s coatings sector: an emerging hub of the chemical industry in Central Asia 68 SUCCESS STORIES

Arzuffi PVD improves multi-sector production with PECVD surface treatments 72 SUCCESS STORIES

Efficient, sustainable and ergonomic painting with edrizzi® at Liebherr Hausgeräte Lienz

Powder coatings with purpose: functional technologies for hygiene, safety, and surface protection

ON TECHNOLOGY

A new liquid + powder coating plant for maximum production flexibility and quality consistency

ON TECHNOLOGY

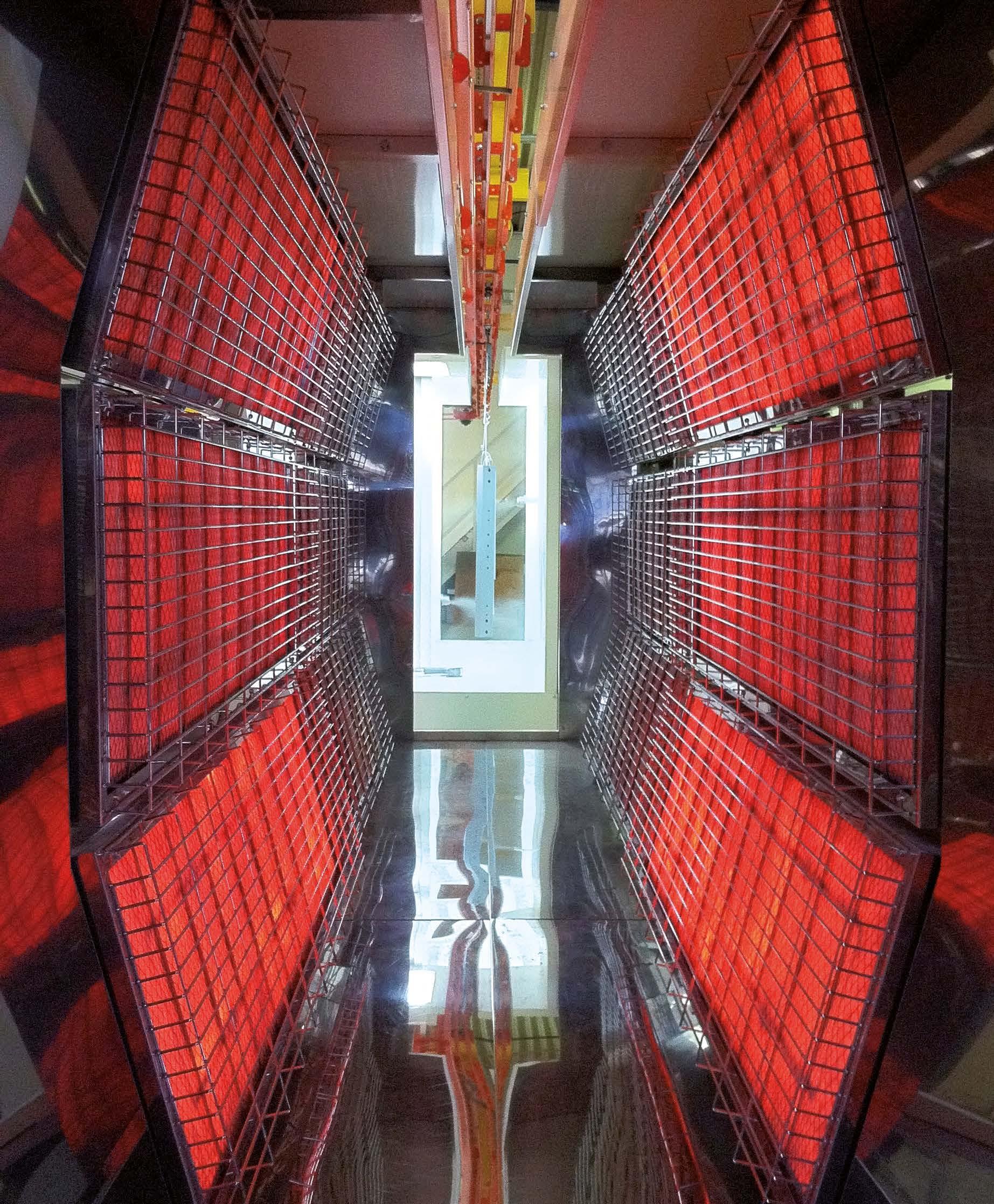

In just 160 m², a powder coating line with an IR RHT tunnel for sheet metal 3D products

90 ROAD TO 2050

Future-proof chemical pre-treatment process for vertical powder coating lines

An

Volvo Car Gent modernizes paint shop in record time

At Zimetal, extending the conveyor optimised the coating plant’s efficiency without increasing its footprint

Towards Qualisteelcoat approval with Dollcoat RS 103: a joint project to optimise pre-treatment

When the paint supplier’s technical support is key to the high performance of protective coatings for electrical transformers

Twenty years of innovation, quality, research, and development: the history of Decoral America

Where everything is regenerated: Magix’s virtuous production cycle thanks to a new water treatment plant

Basca is changing the rules with its automated solutions for cleaning industrial tanks and containers

LECHSYS DE-AROMATIC: the sustainable evolution of Lechler’s tintometric system

Verniciatura Vannucci’s winning choice: a semi-automatic powder coating plant and a single-phase pre-treatment product

coating line

The architecture of performance: a technical examination of a triple resin coating system

SPECIALIZED TRAINING

ipcm® Academy: a complete course for Industrial Surface Finishing Process Technologists

TRAINING

Academia and industry come together to promote innovation, research, and digitalisation

Innovating is sharing: where can the exchange on finishing take place today?

Nanobell 803 Straight

Nanobell 801 Straight

electrostatic automatic atomizer

Nanobell 801 head

Nanobell 801 Robotic (Full Wrist)

Nanobell 803 Robotic (Full Wrist)

Nanobell 801 Robotic (Hollow Wrist)

Nanobell 805 Robotic (Hollow Wrist)

EDITOR’S LETTER

Alessia Venturi Editor-in-chief Direttore Responsabile

For many entrepreneurs, a business is not just an economic activity, but a genuine extension of their identity, a project that reflects their values, their vision, and often, even their character traits. Their business represents everything they have invested in, in terms of both know-how and way of being, including their most personal and relational aspects: passion, a sense of duty, creative energy, and determination become the driving force behind a company that often starts as a person’s idea and then grows alongside them. However, a company must be able to evolve and interact with the world around it without becoming self-referential and closed in on itself. In a constantly changing economic context, entrepreneurs need to be open to new ideas, to the outside world, to diversity. This means accepting that innovation does not always come from within, that collaboration is a valuable asset, that interesting skills can also be found outside the company, and that fair competition is a healthy tool for growth.

Being open to new ideas means engaging with different cultures, distant markets, new approaches. Cross-fertilisation can become a powerful lever for transformation. Embracing diversity and exploring alternative paths means cultivating a broad and forward-looking vision, which is increasingly necessary to compete on a global scale.

By opening to new markets and different cultures and investing considerable resources in the internationalisation of information, the ipcm® magazine also offers its customers the opportunity to assess the potential of new markets and of promoting their message and technology in different economic and cultural contexts – also accepting the possibility of failure or lack of interest, aware that the professional and human experience will still bear fruit. This is the reason behind ipcm®’s missions to trade fairs in emerging countries with rapidly growing and developing economies, which offer significant potential but undoubtedly also greater risks than developed markets.

In July, we travelled to India for the 5th edition of Surface & Coating Expo, organised in Chennai (the heart of the Indian automotive industry) by the Confederation of Indian Industry (CII). India is one of the largest and most dynamic emerging markets in the world, characterised by a young and growing population, extensive investment in human capital, and a rapidly expanding technology sector. We found a high demand for technical information and a significant interest in our magazines, with over 300 copies distributed to visitors from various industries.

In May, we were in Mexico at one of three editions of Fabtech, the manufacturing exhibition dedicated to the North American market, for which this country - another emerging market, strategically located near the United States and with a strong manufacturing industry - acts as a bridge between the growing markets of Latin America and the mature markets of North America.

Richiedi la versione in italiano a info@ipcm.it

Next September, we will be back at Fabtech, this time in Chicago, a technical event aimed at a market with a strong economy and high consumer purchasing power. This edition is expected to record a significant turnout from Europe, thanks in part to the work of ipcm® as an exclusive agency for Europe. We will see the impact that the tariffs threatened by the Trump administration will have on such a high level of development potential. This ipcm® issue is particularly rich in stories of companies that started out as extensions of individuals or families and then evolved into structured, global, innovative organisations capable of making a difference on an economic, technological, and social level. In some articles, you will find the label ‘On show’ alongside the logo of one of the three events at which we are going to distribute the magazine: Fabtech (Chicago), K (Düsseldorf), and Paint & Coatings (Milan). It means that the suppliers of the surface finishing technologies presented in the articles will be exhibiting at these trade fairs. Ultimately, a company is a reflection of its leaders: if the entrepreneur has a forward-looking mindset, so will the business. And this is the real driver of growth: not size, but the ability to think big.

Disrupting markets by inventing the future: a new paradigm in innovation strategy

Victoria Scarborough, Ph.D. Vice President, Collaborative Innovation, The ChemQuest Group, Inc. Cincinnati (OH), United States vscarborough@chemquest.com

Exploring the intricate interplay between market dynamics, regulatory environments, funding ecosystems, and the commercialization of emerging technologies can provide a compelling framework for understanding how innovation can not only meet existing demands but also redefine entire markets. By critically analysing these elements, we can better understand how industry leaders might move from ideation to impact in a rapidly evolving global economy.

What does market disruption really mean?

Market disruption involves the introduction of a product, service, or innovation that fundamentally alters how an industry operates. Such changes are often driven by technological advancements or shifts in business models, and they often originate outside of established frameworks. In practical terms, disruptive innovation challenges incumbent players, opens new revenue streams, and reshapes consumer expectations. A clear example of this in the coatings industry is the evolution of cool roof coatings. These products, which reflect more

sunlight and absorb less heat than standard roofing materials, have disrupted the building materials market by offering energy savings, regulatory compliance, and environmental benefits. They exemplify how innovation, aligned with market needs and regulatory shifts, can create entirely new value propositions.

Another example is using paint performance films (e.g., car wraps) to provide protection and colour to the surface of automobiles and trucks while also providing intricate graphics and designs that are not easy to do with paint. This eliminates the traditional paint booth within a factory and reduces the hazardous air pollution and energy use in the facility.

Understanding markets: the foundation of innovation

Before any innovation can be commercialized effectively, a deep understanding of the target market is essential. The key elements in market analysis include:

Revenue and growth potential – Innovation must address markets with clear value and growth trajectories, quantified through metrics like market size and compound annual growth rate (CAGR).

Market dynamics and competition – Identifying who the players are, where growth is occurring, and what disruptions are already underway informs both strategy and investment.

Regulatory constraints – Compliance with environmental and

Figure 1 - The technology market pool.

safety regulations (e.g., VOC limits, PFAS bans) is increasingly critical. The antimicrobial coatings market illustrates how regulatory pressures limit available chemistries, thereby creating a gap that innovation must fill.

Investment levels – Whether an industry is mature or in a growth phase affects its openness to new technologies and solutions and shows whether the market is growing or declining.

Understanding these factors provides innovators with the insights needed to tailor technologies that address specific pain points and opportunities within a given industry.

The innovation landscape: a web of opportunity

When scouting for innovation, the ecosystem is represented by a technology market pool (Fig. 1) that includes:

Universities and research institutes

Government laboratories

Start-ups and small enterprises

Adjacent industries to your business

Raw material suppliers

Large industrial corporations. This landscape is highly fragmented, and each node brings unique capabilities and challenges. For example, universities may produce breakthrough research but lack the commercialization expertise and take longer to commercialize technology, if ever. Startups are agile but often under-resourced and need a great deal of guidance and financial assistance from

others. Government labs may support foundational R&D but struggle with market-facing applications, as they lack industrial experience. Navigating this ecosystem requires the strategic orchestration of partnerships, funding, and technical validation. Technology scouts and innovators must not only develop technology but also map the right path to market by leveraging the most appropriate resources.

The role of government funding in driving innovation

A critical enabler of market-driven innovation is government funding. Agencies like the U.S. National Science Foundation (NSF) invest in programs aimed at bridging the gap between academic discovery and commercial application. These programs aim to de-risk early-stage innovation and provide critical validation for market entry. Use-inspired research is a model that prioritizes practical relevance and application over abstract inquiry. Perhaps the most transformative initiative within the NSF is the National Innovation Corps Program (I-Corps). The program trains university research teams to explore market opportunities through direct engagement with potential customers, culminating in the development of a refined value proposition that might serve as the basis for starting a business based on NSF-funded university research. It is a rigorous program that teaches the value of customer discovery and focuses on speeding up the path from lab to market.

Figure 2 - Markets with large potential.

Material science and strategic focus areas

There are many areas where material science can rapidly transform markets and where innovation is most likely to yield impact. Several markets with larger % CAGRs were chosen to illustrate this point (Fig. 2).

The paints and coatings market has been growing at a steady rate for years, on an average of about 4%. Other markets within that space are projected to see much larger growth.

For instance, coatings and adhesives for electric vehicle batteries represent a burgeoning market, with a projected CAGR of 30% and an expected value of $8 billion by 2030. Similarly, 3D-printed construction materials, another high-growth segment, are poised to revolutionize the building industry by reducing labour costs, speeding up construction, and enabling more sustainable practices.

Regulatory requirements are mandating the rapid remediation of perfluoroalkyl substances (PFAS), and technologies that effectively rid the environment of PFAS are clearly in demand. Similarly, regulations are limiting the number and use of many antimicrobials (AM), and the development of AM additives that are effective but less harmful to the environment continues to be needed to fill the void.

Multifunctional coatings that provide colour and protection through smart mechanisms, like triggered on-demand release, will continue to drive interest within the coatings industry. These examples demonstrate the need to understand the market drivers within the coatings industry in order to push ahead of the competition.

From idea to impact:

building the next generation of innovation

The tendency to be enamoured of new technology is sometimes an occupational hazard. However, chasing novel technologies without a clear path to market is sometimes called ‘shiny object syndrome’ and must be avoided to save time and resources. Effective innovation must balance three pillars:

Market attractiveness – Is there a real demand? How large is the market?

Commercial viability – Can the product be competitively positioned? Is there a compelling value proposition?

Technical feasibility – Is the solution achievable with current technology? What are the development risks?

By understanding the financial and business impact of these three pillars, you can evaluate and filter opportunities using unbiased, data-driven criteria. A decision matrix, first developed by Stuart Pugh, allows for a criteria-based approach to scoring potential solutions to a problem and is a standard part of Six Sigma methodology. Adapting this method for scoring new business opportunities can help narrow the field to the best opportunities to pursue and ensure that resources are allocated to innovations with the highest potential for impact.

Ultimately, innovation is not just about having a great idea: It’s about creating real market value. This journey involves rigorous market analysis, strategic alignment, technical validation, and ecosystem orchestration (Fig. 3).

Lead the next wave

The question that all innovators must answer is: “Does your innovation create market value?” If the answer is yes, then it has the potential not only to succeed commercially but to transform entire industries. The blueprint for how companies and innovators can thrive in a rapidly evolving marketplace hinges on adopting a market-driven approach to innovation, leveraging government and institutional support, and rigorously vetting opportunities so that businesses can position themselves at the forefront of change and transformation. As the chemical and coatings industries face increasing pressure to adapt to global trends, climate change, regulatory shifts, and digitalization, those who disrupt markets by inventing the future will lead the next wave of progress.

Figure 3 - The essential path to market-driven innovation.

Atlas Copco introduces advanced coating technology in DZS 600 and DZS 1200 VSD+ vacuum pumps

These vacuum pumps from Atlas Copco provide reliable, oil-free operation, as well as designed with enhanced coatings to extend the lifespan of critical components.

Atlas Copco has incorporated cutting-edge coating technology in its DZS 600 VSD+ and DZS 1200 VSD+ dry claw vacuum pumps, setting a new benchmark for durability and performance in industrial applications. One of the standout features of the DZS VSD+ series is the PEEKCOAT coating. This advanced coating is applied to process-wetted parts and rotors, offering exceptional protection against wear, corrosion, and harsh environmental conditions. The PEEKCOAT technology ensures that the pumps maintain peak performance over time, even in demanding applications, reducing maintenance needs and downtime. The result is a longer operational life, making these pumps a cost-effective and sustainable solution for industries that require high reliability and minimal maintenance.

“The DZS VSD+ are simple and modular in design. They consist of the pump and gear chambers, which are separated by seals. Their energyefficient, low-wear operation is based on a special coating of the wetted parts and rotors as well as their simple operating principle. Two claws rotate contactless in opposite directions in the pump housing. This draws air into the pump chamber, compresses it and expels it again under pressure. In the gear chamber, two gear wheels synchronize the claw rotation. The non-return valve in the inlet flange prevents air from flowing back into the vacuum chamber when the pump is switched off. The pumps are driven directly by a flange-mounted motor via a coupling,” has stated Ahmed Elshaffie, the responsible product manager.

In addition to the PEEKCOAT, the DZS VSD+ models also come equipped with several other innovative features aimed at optimising performance and ease of use. The vacuum relief valve prevents overheating during prolonged operation at ultimate vacuum levels, while the inlet non-return

valve isolates the pump from the process when switched off, further enhancing reliability. The integrated VSD+ inverter drive regulates the pressure setpoint, contributing to energy-efficient operation.

These advanced coatings, combined with the pumps’ energy-efficient operation and user-friendly control features, make the DZS 600 VSD+ and DZS 1200 VSD+ vacuum pumps an excellent choice for applications where durability, performance, and sustainability are paramount.

Key coating and performance features of the DZS VSD+ models

PEEKCOAT coating: Provides superior protection for process-wetted parts and rotors, ensuring long-term durability and minimal wear.

Vacuum relief valve: Prevents overheating during extended operation at ultimate vacuum levels.

Inlet non-return valve: Isolates the pump from the process when switched off, enhancing safety and reliability.

Silencer: Reduces operational noise, ensuring a quieter working environment.

Integrated VSD+ inverter drive: Ensures efficient pressure regulation for optimal performance.

“We have been using the robust, reliable claw technology in vacuum technology and other areas for many years. With the DZS 600 VSD+ and DZS 1200 VSD+ models, Atlas Copco therefore offers a simple, reliable pump that can support customers in their processes for a long time without interruption,” has added Ahmed Elshaffie.

For further information: www.atlascopco.com

DBM Tecnologie celebrates 40 years in business

A leading Italian company in the design of painting and surface treatment systems, DBM looks to the future with the aim of strengthening its presence on international markets and expanding the applications of its technologies.

On 30 May 2025, the D.B.M. Group, an industrial company based in Casale sul Sile (TV, Italy), celebrated a double milestone: 40 years of activity for DBM Tecnologie and 25 years for E-Chem. To mark the occasion, the company organised a special day dedicated to its employees and their families.

The event began with a visit to the group’s factories, which were opened exceptionally to employees’ families, followed by a convivial evening at a tavern.

The symbolic theme of the event was the orchestra, chosen to represent the importance of collaboration between departments, the enhancement of individual skills and the team spirit that distinguishes the group.

“Our strength lies in our ability to offer customised solutions, bucking the trend of an increasingly standardised market. We support our customers as true partners, ready to tackle ambitious challenges with solid technical expertise and structured planning,” has stated Nicoletta Mattiuzzo, head of organisation and planning at DBM.

Founded in 1984, DBM Tecnologie is now a benchmark in the design and manufacture of advanced systems for industrial cleaning, coating and

surface treatment. Alongside it, E-Chem, founded in 1999, is involved in the production of detergents and equipment for industrial cleaning, as well as research, testing and analysis.

The group, now wholly owned by the Mattiuzzo family, has grown over time to include three production plants, 60 employees and a consolidated presence on international markets, with systems installed in Europe, Asia-Pacific and the Americas.

“In the coming years, we aim to grow further in foreign markets and develop complementary sectors, such as metal impregnation. We will continue to combine an efficient organisational structure with the creativity typical of Made in Italy. This is an important anniversary, therefore, which represents not a milestone but a new starting point for a company that has always believed in innovation, collaboration and quality. Because, as they say at DBM: You don’t just choose the plant, you choose the company that produces it,” has added Alessandro Mattiuzzo, head of technical and commercial development at DMB.

For further information: www.dbmtec.com

© DBM Tecnologie

Dürr expands EcoProWet pretreatment system to include cathodic electrocoating

Dürr is expanding its modular pretreatment system, EcoProWet EC, to include cathodic electrocoating. With its compact design, the wet system requires significantly less space than conventional continuous systems, making it ideal for small to medium production capacities of up to 30 units per hour.

In vehicle painting, pretreatment remains one of the most spaceintensive process steps. This is due to the large tanks required for both basic cleaning and electrocoating, which are designed to accommodate the largest car body dimensions and longest process times. Dürr developed the modular EcoProWet pretreatment system, making the process more flexible, compact, and scalable. Previously, the company introduced the EcoProWet PT pretreatment system. Now, it has expanded the system to include the EcoProWet EC cathodic electrocoating system.

Cathodic electrocoating: flexible, compact, and scalable

After pretreatment, the bodies are conveyed to the cathodic electrocoating system. This process ensures that a seamless primer coat is applied to the body’s surfaces, providing corrosion protection and serving as an adhesive base for future topcoats. In contrast to conventional PT/EC systems, EcoProWet is the only system on the market that is scalable and sets new standards in terms of space requirements, sustainability, and investment costs.

The innovative design of the EcoProWet EC system features individual compact basins instead of continuous systems filled with paint. Two independently controllable pendulum towers lift the car bodies from the roller conveyor and gently guide them into the bath. With an immersion angle of up to 60 degrees, automakers can customize the immersion process for different models. Each dip tank supports up to ten units per hour. During the three- to five-minute dip, the paint is energized, forming a thin even coating on the body surface.

The EcoProWet system is ideal for small to medium production capacities. Its modular design allows for staged expansion from 7.5 to 30 units per hour without significant operational disruptions. This enables automotive manufacturers to scale the system according to their production needs, reducing paint and operating costs compared to continuous systems. Additionally, it minimizes the space required for a paint shop while allowing for a flexible layout.

For further information: www.durr.com

EcoProWet EC has an innovative system design. The EcoProWet PT/ED system

CHEMICAL MAKING SOLUTIONS

TRATTAMENTO ACQUE

WATER TREATMENTS

PREVERNICIATURA E NANOTECNOLOGIE

COATING PRETREATMENT AND NANOTECHNOLOGIES

SGRASSANTI INDUSTRIALI DEGREASERS

SVERNICIANTI

PAINT STRIPPERS

Artificial Intelligence drives efficiency gains at Audi with implications for paints and coatings

With AI integration accelerating, Audi is setting new standards not only for automotive production efficiency but also for the precision and quality of paints and coatings - critical elements in vehicle durability and aesthetic appeal.

Audi is harnessing the power of artificial intelligence (AI) to significantly enhance efficiency and quality across its production and logistics operations, with important knockon benefits for paints and coatings processes. The car manufacturer is fully exploiting AI and data analytics both in its internal workflows and the customer experience, aiming to set new industry benchmarks. Currently, AI’s greatest impact is in production and logistics, where it helps save both time and costs. Gerd Walker, Member of the Board of Management for Production and Logistics, describes AI as a “game changer” in automotive manufacturing. By strategically

deploying AI, Audi is creating a production environment that is more efficient, costeffective, and quality-driven, while also improving support for employees. This includes expanding AI applications wherever they are viable and beneficial.

More than 100 AI projects are underway in Audi’s production facilities, many gradually being integrated into series production. A key focus is AI-driven quality monitoring, which has direct implications for the paints and coatings stages of vehicle manufacturing. For instance, AI tools are now used to inspect the correct application and labelling of technical data on vehicles - a crucial factor for

paintwork conformity and surface treatment accuracy. The “IRIS” image processing system checks label placement and content accuracy, helping to ensure that coating processes align precisely with specifications. This tool alone saves about one minute per vehicle in production time.

Audi is also advancing AI-supported inspections in the body shop, an area closely linked to paint and surface quality. In partnership with Siemens, the company has introduced the “Weld Splatter Detection” (WSD) application, which identifies weld splatter on vehicle underbodies - metal deposits that could compromise paint adhesion and cause defects. From summer 2025, a robotic arm will automatically remove such weld splatter - enhancing production efficiency while improving workplace ergonomics and safety. The company’s investment in AI is underpinned by a robust data infrastructure, with hundreds of petabytes of production data leveraged to drive its 360factory strategy - a vision for a fully connected, data-driven, and sustainable manufacturing environment.

Audi is also using AI beyond production lines, including a new tool called “Tender Toucan” that streamlines the evaluation of supplier bids by automatically analysing specifications, saving up to 30% in processing time. This efficiency will contribute to smoother sourcing of paints, coatings, and related materials.

Roudabeh Heshmatazad joins ChemQuest as a Director

The ChemQuest Group, a global consulting firm focused on tailored business strategy and optimization, technology acceleration, market intelligence, and M&A advisory services for the specialty materials industry, is pleased to announce the appointment of Roudabeh (Rudi) Heshmatazad as a director.

Heshmatazad is a strategic and forward-thinking business leader with decades of experience translating consumer insight into innovative, marketwinning products. Known for building and expanding portfolios through a deep understanding of market dynamics, data analytics, and consumer behavior, she excels in driving cross-functional collaboration across R&D, marketing, and operations to deliver impactful, scalable solutions.

Over the course of her career, Heshmatazad held several positions with BEHR Paint Co., including senior product formulation chemist, product marketing manager, and senior manager of new business development, before joining Bosch Home Appliances Corp. as senior manager of consumerdriven innovation and new business development. Most recently serving as director of new business exploration and product innovation for Delta Faucet, she is also the founder and CEO of RAIRE Chocolate, a luxury premium nutraceutical chocolate brand.

Heshmatazad holds a bachelor’s degree in chemistry from Azad Tehran University, an MBA from DeVry University, and a business strategy certification from Harvard Business School Online.

“With over 25 years in the chemical industry, I’ve had the privilege of leading innovation, product development, and business growth across categories ranging from consumer goods to coatings and specialty materials,” Heshmatazad said. “While at BEHR, I worked closely with the ChemQuest team to explore strategic opportunities beyond our core business. Together, we built a robust M&A pipeline and evaluated adjacent markets. Through that work, I also got to know Dan, whose consumer-first mindset and thoughtful, human-centered leadership made a lasting impression. I’m excited to now be part of a team that brings such depth, clarity, and impact to clients navigating technology development, market expansion, and transformative growth.”

“I am thrilled to welcome Rudi to the ChemQuest team,” said Daniel Murad, CEO. “Along with the rest of the world, are clients are seeking guidance on how best to navigate the evolving challenges of today’s economic and geopolitical climate. Through her extensive and diverse background, Rudi will lend her considerable expertise to supporting our clients in identifying and developing strategies that prioritize long-term profitable growth.”

For further information: https://chemquest.com

© The ChemQuest Group, Inc.

AkzoNobel marks 50 years of manufacturing excellence through CNH partnership

With exceptional durability, performance, and color consistency, AkzoNobel’s Interpon Powder Coatings are empowering CNH to thrive on the global stage.

The paints and coatings supplier AkzoNobel celebrates a 50+ year partnership with CNH, one of the world’s leading manufacturers of agricultural and construction equipment (ACE).

CNH was one of the pioneers in adopting powder coatings to protect its combine harvesters, balers, and forage harvesters. Twenty-five years ago, the company transitioned from AkzoNobel’s industrial paints to its advanced Interpon ACE powder coatings. AkzoNobel supported CNH in converting its existing liquid coating line to accommodate powder application—without requiring additional floor space or oven capacity.

CNH was also among the first to implement Interpon’s low-cure technology (Interpon ACE 2010 Low-E), enabling significant reductions in energy consumption and carbon emissions.

“We chose AkzoNobel because it has the global capability to develop the powder coatings we needed to adapt to new market demands, and the demands of our own production facility,” has stated Frank Verhoye, head of the Paint Central Manufacturing at CNH in Belgium.

To align with evolving regulatory and environmental standards, CNH

transitioned to a new generation of TGIC-free polyester powder coatings. This shift ensured compliance with updated health and safety regulations while reinforcing the company’s commitment to sustainability. The Interpon team played a key role in developing colors that precisely matched CNH’s specifications. Given that CNH machinery is predominantly used during the summer months, excellent UV resistance was a crucial advantage. The coatings also provide strong protection against corrosion from high humidity and exposure to substances such as diesel and oil.

“We are very much looking forward to working with CNH on developing new product solutions that will help it to further reduce its carbon footprint and increase the long-life of the machinery and the future of its brands,” has added Lösgen, Global Segment and Key Account Manager ACE and CV at AkzoNobel Powder Coatings.

For further information: www.interpon.com/it/en

© AkzoNobel

Blasting technology meets modern design: Sinto AGTOS launches new website

With this relaunch, Sinto AGTOS combines innovation with approachability, positioning itself as both a technology leader and a reliable partner in surface preparation.

Sinto AGTOS, an internationally active manufacturer of wheel blast machines and now part of the Japanese Sinto Group, has unveiled its brand-new website — a fresh digital presence that reflects the company’s modern identity and forward-thinking approach.

The site was developed using a state-of-the-art content management system to meet high design standards while ensuring an improved user experience. Its streamlined structure and responsive design make it particularly easy to navigate, even on mobile devices.

Keen to strengthen its connection with users, Sinto AGTOS has integrated numerous contact options, offering visitors multiple ways to get in touch. Strong emphasis was placed on delivering highquality, accessible content. The website provides clear, user-friendly explanations of machines and processes, along with insights into key areas such as technology, sustainability, and the company’s workforce. A dedicated guide is also available for newcomers to blasting technology, helping them gain the essential knowledge needed to make informed investment decisions.

For further information: www.agtos.com

Efficient and space-saving powder management, equipped with OptiSpray All-in-One application pump technology and DualSpeeder. The OptiCenter uses MultiColor Switch technology, which enables the fastest switching between OptiSpeeder containers and the cleanest color change between alternating colors.

Portrait of a successful company. TIGER Coatings: 95 years of innovation, vision, and family passion

Interview with Kurt Berghofer, Chairman of the Advisory Council

Clemens Steiner, CEO

Elisabeth Berghofer, Chairwoman of the Supervisory Board, People & Culture at TIGER Coatings

TIGER Coatings began as a small Austrian paint shop in the 1930s and has grown into a leading, independent global company—now the world’s fifth-largest in powder coatings—maintaining both professional management and strong family involvement. A shining example of a business that combines innovation and responsibility, valuing every employee as an active part of a “liberating organism” looking towards a future in which quality & service, creativity and independence remain key pillars.

The path of some families is inextricably linked to business. Entrepreneurial spirit runs through their veins and a risktaking and innovative instinct creates the perfect conditions for building a successful company destined to make history in its industry.

The Berghofers, the founders of TIGER Coatings, are one such family. The company that introduced the 2.5-kg powder coating mini-pack, the first to set foot into the US, the one that has expanded its powder coating colour and effect range to infinity, that has been focusing on metallic effects and high-added value market niches, that has made quality its vocation and batch uniformity its focus, is celebrating its 95th anniversary. To mark this milestone, it has chosen ipcm® to tell its story for the first time. What we are

Kurt Berghofer

Clemens Steiner

sharing is a vivid portrait of a family and a company that have invested everything in a vision: the development of a technology – powder coating – in its infancy, contributing to its present-day success as the finish of choice for many industries, from niche sectors calling for excellent aesthetics and ever-more captivating colours and effects to sectors where functionality and performance are crucial.

A unique story of innovation, vision and entrepreneurial courage

The history of TIGER Coatings dates back to the 1930s, a period of political and economic instability in Europe. Three of the eleven children of the Berghofer family opened a small shop selling paints and varnishes in the centre of Wels, in the federal state of Upper Austria. A trailblazing spirit characterised the Berghofers’ business from the very beginning: at the Hanover trade fair, which was the premier technology trade fair at the time, they purchased the first equipment for producing liquid paints. In the late 1960s, TIGER’s pioneering phase in the powder coating world began with the second generation of the Berghofer family, represented by Kurt. His firm belief in the potential of powder coatings, which were then in a very early stage of development, guided the company’s strategic decisions, leading to its rapid emergence as a global player.

ipcm®: This year, TIGER is celebrating its 95th anniversary, just a few steps away from its centenary. Could you briefly tell us about the history and vision behind its foundation and growth, as well as the reasons behind its distinctive name?

Kurt Berghofer: “TIGER was founded by my father and two uncles, who started out producing liquid paints for DIY in 1930. They began with very

simple products: oil-based paints, solvents, and fillers. Then, the three brothers gradually developed a whole range of solutions based on new chemical technologies: for example, two-component sealants for floors and protective anti-rust paints for iron. They created a very interesting assortment that included a wide variety of products, from paints and dispersions to primers and finishes, and was very well received by consumers because it incorporated cutting-edge technology for the time. The name TIGER was coined with the company itself: our surname, Berghofer, was difficult to pronounce and remember, so they chose a short, memorable and striking word. It proved to be an excellent choice for the DIY market, as well as later on for the powder coating division: it was understandable in every country, recognisable and easy to pronounce in any language. I joined the company in 1962, immediately after completing my technical studies in Vienna. My uncle had passed away from a heart attack and my father also suffered from heart problems. So I was ‘dragged’ into the company without any work experience. Within 3 years, I became the managing director, as my father was forced to retire. I was a very young and inexperienced CEO, but fortunately, many employees with a wealth of experience in the sector taught me a great deal and guided me towards becoming a leader.”

When did you start considering producing powder coatings?

Kurt Berghofer: “I had stayed in touch with a fellow student in Vienna, who started working for a German manufacturer of polyester resins. He told me about a new idea that was still in its infancy stage: powder coatings. At that time, there was no real market for them – nor finished products. However, I decided to go and see him because I was intrigued and I started gathering contacts and suggestions on people I could visit throughout Europe to learn more about powders. I began travelling with a technician from my company and over the course of a year and a half, we made 16 visits to various European countries, including the Netherlands, Germany and Switzerland. We visited large paint producers, chemical companies, plant manufacturers. We gained insights from each. We also got in touch with manufacturers of extrusion and grinding systems. It was real Sherlock Holmes work! At that point, the problem of convincing my father arose: TIGER was 100% focused on DIY, with no experience in the industrial sector. Why on earth should we start producing powder coatings?

Still, I was convinced that this was a good idea, a promising technology with excellent prospects. I wanted to enter the industrial paint sector, but I knew it would take a new, cutting-edge technology to set ourselves apart from our competitors. In 1966, I suggested to my father that we initially invest only in a laboratory with equipment capable of producing small quantities. Faced with such a clear perspective, such a precise vision and such strong motivation, he agreed. It was a significant investment: to get a quick return, we did research and development

Elisabeth Berghofer

during the day and produced small batches at night and on weekends. We immediately saw some signs of interest from potential customers. There were already some application plants in what was then Yugoslavia and we managed to make our first contacts there so that, while we were developing our first product, we already had two companies ready to buy and use it.”

Powder coatings require a completely different application process to liquid products: it entails electrostatics, melting, cross-linking...in short, this was a disruptive change for the market.

Kurt Berghofer: “That’s true. In those years, many of today’s players in the powder coating sector were still in the early stages of development. We decided to test our powders abroad and found that we could truly compete with other manufacturers. We also managed to establish excellent relationships with the basic chemical industry, which was very interested in working with a smaller, more agile company than big giants requiring a lot of time to test new materials. We were able to provide quick and accurate feedback and such speed of response made TIGER an attractive partner with which to establish a profitable, dynamic and stimulating collaboration.”

So you saw the potential of this market right away: you never considered it a gamble.

Kurt Berghofer: “Yes, exactly. The advantages were so obvious that we were sure this technology had a great future ahead of it. And when you are truly convinced of something, you are much more likely to succeed.”

Well, TIGER’s history proves that it was indeed a successful choice, as we are here discussing it just a few steps away from its 100th anniversary.

Kurt Berghofer: “The 1990s saw the beginning of the aesthetic and functional evolution of powder coatings, which also offered the environmental advantage of zero VOC emissions. TIGER decided to invest in high-quality production equipment, develop the bonding technology to improve metallic effects and open new market niches. At the same time, the advent of Baumärkte, large hardware stores with their own paint brands, increasingly reduced our turnover in the paint segment. About 10 years ago, we therefore decided to discontinue the production of DIY paints and to focus solely on manufacturing powders under the name TIGER Coatings (formerly TIGERWERK). Today, we sell powder coatings worldwide and have production facilities in 6 countries. At the same time, we are also developing and growing in other areas, such as digital inks. Based on our estimates, TIGER ranks as the fifth-largest company globally in the powder coating sector, while not focusing so much on operating at large volumes. Instead, we aim at small and medium-sized production runs, complemented by excellent service and high quality, particularly in terms of batch consistency. High-quality paint covers larger surfaces more effectively and efficiently and consistency among batches ensures reliable performance at all times. The basic formulation of our products is excellent, but repeatability in production is another key to our success. Today, powder coatings are among the best solutions for high-quality applications. TIGER has played a leading role throughout their evolution and has contributed significantly to it with its innovation rate and R&D activities.”

The CentoNew building in Rostock, Germany, headquarters of the biotechnology company Centogene AG.

The headquarters of the European Central Bank in Frankfurt, Germany.

What were the most decisive moments in the company’s growth?

Clemens Steiner: “Without a doubt, the first was the decision to invest in a technology that was so embryonic as to be practically non-existent. At the time, it was a huge investment, accounting for 10% of the company’s annual turnover.

I still love to tell our 1,400 employees, whom we like to call TIGERs, about the pioneering spirit of that period that enabled us to enter the Austrian and German markets.

Afterwards, Kurt Berghofer took another very bold step: he invented the 2.5-kg mini-pack. Back then, the range of powder coating colours available was limited to five shades of white, a few greys and one black: to get a customised shade, the minimum quantity was 300 kg. When TIGER introduced its mini-pack, the market was stunned. No one could understand how it was possible: it looked like a pharmaceutical product. That was the turning point that enabled us to enter the American market. Indeed, in the 1980s, Kurt Berghofer took another strategic step: entering the US market, where we achieved great success thanks to the flexible supply of small quantities in the complete range of RAL colours. It was a glorious beginning, a real revolution. The next milestone came in 1995, when I joined the company full-time and began developing the Asian and South-American market. This was the era when the so-called “Four Asian Tiger States” (Singapore,

Malaysia, Taiwan and China) were emerging. Kurt and I drew up a longterm action plan for the Asian and South-American market, which led to us opening 3 production plants in China, one in Vietnam and one in Brazil, as well as our subsidiaries throughout Asia.

In 2007, we took another significant and innovative leap forward: we began designing and producing digital inks. In 2015, we used our polymer-related know-how to develop high performance plastic materials for 3D printing in additive manufacturing. We also developed a technology for digitally depositing powder particles, which we call tattoo technology and with which we can create high-resolution, highly durable decorations.

Over time, TIGER has created a veritable TIGERverse comprising all its powder finishing and digital decoration solutions. I sincerely believe that if we removed TIGER from the world today, many products would not be as beautiful as they are. Giving a ‘skin’, an interface with the world, to objects, is our purpose and reason for existing and our contribution to society.”

You have a very close relationship with the Italian market. Why is that?

Kurt Berghofer: “Because I am a huge fan of Italy! I love the people, the language, the food, the landscapes, their variety. Apart from that, Italy is the cradle of design and beauty: what other market could be more

The Art Center in Singapore.

The Banco de Crédito Cooperativo – Grupo Cajamar Financial Center in Almería, Spain.

receptive to our powders? At the same time, I must admit that we struggled to enter it, due to competition from local companies and above all, the devaluation of the lira caused us to lose quite some business.

Building a market depends largely on people and we were fortunate to find the right person in Klaus Karner. Thanks to his acumen, he managed to identify some promising market niches. Klaus and his wife, Astrid, did an excellent job in Italy, and now Alberto Zancan and Marzia Brambilla have taken up the baton, achieving a significant increase in turnover in just 2 years. For Italy we have great plans and we look forward to increasing our presence there.”

From the TIGERverse to reality: how TIGER combines creativity and performance

What distinguishes your powder coatings from those of your competitors?

Clemens Steiner: “To explain this, I often refer to the Ferrari brand and the concept of

Passion and Power, which was the secret to Enzo Ferrari’s success. Metaphorically speaking, I consider our powders to be like a Ferrari car. However, buying a Ferrari and knowing how to drive it fast are two different things. Similarly, much of our success stems from demonstrating to our customers how to maximise the benefits of our coatings and inks. For us, the job is not done once we sell a box of paint or IBC of ink, but only when we hold a profile painted with a TIGER powder in our hands and can say it has the most beautiful metallic colour we have ever seen, without any imperfections and with perfect film properties or the most amazing print resolution. That is when our job is finished. In addition to the refined chemistry of our products, we also offer an excellent customer assistance service to help each company get the most out of them. That is why we always ask our customers not to judge us on the cost per kilogram of our powders or inks but on the cost per square metre required to finish a surface.”

How important is design in your approach to products?

Clemens Steiner: “I would say that our contribution – as I mentioned earlier, what we call the ‘skin’ of objects – is essentially based on two elements. The first aspect is functional: protection against corrosion and weathering and the assurance that the product will not rust, fade or become unusable. The other element is aesthetics: our mission has always been to bring square metres of beauty to the world. Therefore, design is pivotal. This approach has become even more concrete with our investments in digital printing. It is in this area that the concept of the metaverse is best realised – a concept we have adapted to our little world by calling it TIGERverse. In this virtual ecosystem, architects and designers can access digital files of all available TIGER finishes whenever they feel inspired regardless of the time of day, integrate them into their projects, examine them virtually and thus save valuable time. The TIGERverse is always there for those who need it, providing creative freedom and reducing selection and sampling times.”

How does this significant investment in Research & Development translate into tangible results?

Clemens Steiner: “Our customer base is actually quite diverse: on the one hand, there are contractors and OEMs, who know how to ‘drive our Ferrari’; on the other hand, there are designers and architects, the ones responsible for choosing the special effects and colours to be used. Each of them speaks a different language: we use a technical (think: thicknesses, pre-treatments, etc.) and cost-related language with contractors, for example, whereas we have entirely different conversations with designers and architects. Years ago, in the United States, I spoke to an architect from New York who showed me a beautiful maple leaf that had all the shades of red, orange and brown. He asked me, ‘Can you reproduce this colour?’ I replied in a

© TIGER Coatings

From left to right: Alessia Venturi from ipcm®, Elisabeth Berghofer, Kurt Berghofer, and Marzia Brambilla, COO of TIGER Coatings Italy.

humorous way, ‘There are about 5,000 colours on this leaf. Which one in particular would you like to reproduce?’ This goes to show that to communicate effectively with architects and achieve business results, one needs to invest a significant amount of time and learn to operate in a different sphere.

I believe this is one of TIGER’s distinctive skills: transforming investment in R&D into tangible results. Our TIGERs have different abilities and we can pair the more technical ones with coaters and contractors and the more creative ones with designers and architects. The latter establish the colour code, the former ensure correct application. In the end, we all find ourselves in front of the painted building or structure, knowing that its owners will be happy for many decades to come.”

Can you share an example of innovation that has changed TIGER’s course of action?

Clemens Steiner: “Without a doubt, entering the world of digital printing technologies. With this, we launched a decoration system consisting of panels and profiles coated with powders and digital inks. Our digital technology enables the precise positioning or overlapping of every single drop of ink to create a tactile, 3D printing-like effect. The combination of both finishes thus offers great design freedom with the advantage of coming from a single supplier, a single warehouse and a single partner responsible for everything.”

How did the market react to this innovation?

Clemens Steiner: “Extremely positively. Until 20 years ago, the market was pleased with sublimation. However, in recent years, this technology has lost some of its appeal because the younger generations find the effect achieved too artificial, flat and soulless. They do not want an imitation of another material: they want real, high-resolution, tactile effects. Moreover, digital printing satisfies the desire for personalisation, exclusivity and uniqueness that pervades today’s market.”

Tradition, management, and participation: the advanced structure of TIGER

TIGER remains a family-run business, albeit with a managerial approach. How do you balance these two sides of the company?

Elisabeth Berghofer: “For all of us, this combination of approaches is a great benefit and strengthens our position in the market. Privately held companies have long-term strategies, can make decisions very quickly and put people first. At the same time, hiring managers means seeking skills and expertise outside the family and the resulting combination of different perspectives strengthens and complements us.”

Clemens Steiner: “I believe that over the last 10-15 years, this combination of family ownership and professional management, with a family behind it that really knows the business and is entrepreneurial at heart, has become a great strength. A while ago, many young people wanted to work for large companies: the bigger the name, the more

attractive the employer. Yet, with all the instability we see today and the impersonal nature of these large firms, where every employee is just a number, we have noticed a reverse trend. More and more people are approaching us because they feel the company’s leadership is present in all daily activities: our doors are always open, we regularly visit the production departments and we interact every day with both our TIGERs and our customers. This human touch, this stability built up over 95 years, is a fundamental element in the management of TIGER, together with the enthusiasm to welcome and assess any idea and to implement it quickly if it is worthwhile.

Furthermore, our Liberating Organism-centred corporate culture implies that those who join TIGER do so not only because they need a job, but also because they feel a passion and a vocation for this job. For our employees, entering this company is not a springboard to build a career elsewhere, but an opportunity for personal and professional growth. Fifteen

The unit of TIGER Coatings' headquarters in Wels that houses the offices. The façade has been decorated with TIGER's digital technology.

TIGER Coatings

years ago, I told our shareholders, ‘Every day, I talk to some of our 1,400 TIGERs and say I expect them to think and act like entrepreneurs. To close the circle, we should also give them a share of our profits.’ The shareholders understood this, and we quickly created TIGER’s profit-sharing system, which now means that each of the 1,400 TIGERs around the world participates in the profit the company makes.”

In your opinion, what are the strengths and potential risks of being a family-founded company?

Clemens Steiner: “Being founded by a family is something that happened 95 years ago. Today, we have an ecosystem made up of family shareholders and 1,400 employees whom we view as entrepreneurs and partners. It is essential that the most capable leaders guide the company and that the family pursues the goal of keeping it healthy. An organization

is comparable to an organism: a body can only function if the brain, heart and liver work perfectly and communicate with each other. But if the heart thinks, ‘I only care about myself, I am uninterested in the other organs,’ and maybe it is not even the smartest heart in the world, then that becomes a problem. If roles and responsibilities are clear and precise and family members agree to leave most of the profits in the company because they are needed for innovation, training and growth, stability will be guaranteed for our 1,400 TIGERs and the 6,000 dependants in their families.”

Is it difficult to preserve your strong identity as a global company?

Clemens Steiner: “I think we are good at preserving and conveying our identity because everyone feels equally involved, even those working on the other side of the globe. The first pillar is maintaining human relationships in a

digitalised world. We invest a lot of resources in getting together in person. One thing that many people fail to understand is that a virtual meeting or a video call on Teams is not the same as a physical get-together. In person, our hearts can receive and send signals from 8 metres away and there are billions of cells that can also perceive non-verbal language. Every year in September, we organise a large meeting of all TIGER leaders who meet here in Wels for 5 days and work intensively to plan the next 12 months. A second meeting is scheduled for March to review the progress of the annual plan. Additionally, we travel twice a year, in the spring and autumn, to various regions to foster mutual trust, ensuring that when we cannot meet in person but need to resolve issues quickly, phone calls are sufficient.

The second pillar is having the company run by technicians, not lawyers specialising in mergers and acquisitions who have never held a spray gun in their hands. Frankly, I do not know how you can possibly motivate thousands of people without having any idea what they are doing and what is at the core of our business and technology.”

The concept of Liberating Organism (LO): empowering employees

Can you tell us more about the corporate culture at TIGER Coatings?

Elisabeth Berghofer: "Cultivating a good company culture is crucial for a successful and sustainable company. It primarily defines how we work together, it creates identity, promotes reliability, gives orientation and makes a company more resilient especially in difficult times. In 2009 we began a journey of enhancing our company culture. We invited all our employees to develop our Vision and our Core Values jointly. I would say, this was a real milestone in our history!

The Liberating Organism (LO) is based on a simple yet powerful concept, associating with a natural organism in which all organs

© TIGER Coatings

The Wels headquarters is home to 550 of the nearly 1,400 "TIGERs" around the world.

are aware of the purpose, having the possibility to discover themselves, communicate actively with each other in a dynamic and constant manner and focus together on a common goal. Hierarchy still exists, but it is no longer based on commands, which means that we are working together on eye-level. Another principle of LO is, ensuring that decision making takes place within the team’s area of expertise. This includes taking over responsibility and asking for advice of the relevant stakeholders. Ultimately this means, the teams are manging themselves.

The philosophy of Liberating Organism is caused by the basic need of human beings to live their life self-determined. It is liberating for an individual to feel free to decide, having room for creativity and experimentation and having the freedom to contribute ideas and to join a project which one is passionate about. This approach allows developing people´s intrinsic motivation and leads to more involvement and commitment to the company."

What are your current priorities in people and culture management and what strategies are you implementing to attract young talent?

Elisabeth Berghofer: “The main priority and at the same time the biggest challenge, is attracting qualified employees for the production area. A

challenge that reaches far beyond Europe.

One of our measures to counteract this trend was the implementation of our successful apprenticeship programme. We offer several incentives and benefits while prioritizing a state-of-the-art work environment.

Ensuring that we move with modern work trends such as remote work opportunities. Additionally, we invest in conveying the values of our corporate culture through social media and our website. This not only allows us to share our core philosophy with the outside world, but means that people who want to approach us are already familiar with our culture, including the concept of Liberating Organism.

Generally, we enjoy a good reputation in Upper Austria, which helps us to attract new talents. Valuing our TIGER’s as the best representation of who we are."

Powder

coatings and green transition: technical challenges and ethical

responsibility

What are the main technological and environmental challenges for powder coatings and what role does sustainability play in TIGER’s longterm strategy?

Clemens Steiner: “The main technical challenge is to find a balance

Follow the unseen. Something is coming...

between high paint reactivity, i.e. low curing temperatures and optimal stability during transportation and storage. A powder that cures at 60 °C would be ideal, but this would require enormous energy efforts to maintain ideal conditions throughout the logistics chain. Today, we have reached a good balance between reactivity and stability in storage and during transport. TIGER has just introduced its TIGER FlexCURE technology, which marks a paradigm shift from the low-cure technology that has dominated the last 20 years. Whereas customers used to opt for low-cure paints to increase productivity, today they are looking for greater flexibility in the curing window. Our TIGER FlexCURE products meet precisely this need.

From an energy perspective, powder coatings are at a disadvantage compared to liquid paints, as they undergo 3 heating/ cooling cycles: in resin production, in powder

production and in the final melting and curing phase. Their entire life cycle is therefore highly energy-intensive.

Another major challenge is integrating sustainable or renewable raw materials. We could currently incorporate a sizeable portion of green components into our formulations, but the market is not yet prepared to bear the costs of equivalent performance. Sustainability is one of TIGER’s three strategic pillars, alongside innovation and digitalisation. In recent years, we have made the most progress in this area internally by reviewing our processes and production cycles. Personally, I also run an organic farm and agriculture has taught me a lot about the concept of circularity, which is also applicable to industry. Since the 1990s, we have been using environmental balance sheets and energy analyses, adopting groundwater cooling systems and exploiting solar energy with photovoltaic systems. For over 30 years,

we have been committed to making our business increasingly sustainable. The real challenge today is to make the market realise that the price of a product also includes global and human responsibility. Unfortunately, such awareness still struggles to spread.”

Quality, independence and vision: the values that guide TIGER into the future

What are the core values that still guide this company today?

Kurt Berghofer: “Our fundamental core value is to formulate and manufacture highquality coatings with the most accurate and consistent batch-to-batch uniformity possible. Our commercial strength also lies in having one of the largest warehouses in Europe, with over 1,500 products in stock. Obtaining the desired quality is relatively simple but maintaining it consistently over time across so many products is difficult. I believe this is one of the most significant achievements of TIGER in its nearly one-hundred-year history. To attain this, we have equipped all our factories worldwide with the best production equipment. It is an expensive choice, but it is the only one that enables us to guarantee perfect batch consistency. We can do this because we focus on small and medium-sized batches and highadded value market niches.”

Is there any particular project you are especially proud of?

Kurt Berghofer: “Our success. Simple as that!” Clemens Steiner: “I feel very proud of every project that our 1,400 TIGERs have managed to complete. Among others, I can mention the Louis Vuitton building in Shanghai, the Singapore Arts Centre and the Grand Hyatt Hotel in São Paulo.”

Elisabeth Berghofer: “I am particularly proud that our company is still independent while continuing to perform well in the powder coating industry. We are currently ranked fifth in the global powder coating market, which is a significant achievement considering that we

© TIGER Coatings

The powder coating production plant is highly automated, with automatic palletizing, conveying and dosing systems for resins.

are competing with large groups and other well-known competitors. I do hope that this will remain in the future, so that we are able to pass on a successful and resilient company to my children and my nephews. I am additionally proud of that we continue to identify and develop specific niches in increasingly complex market dynamics. In these changing environments, the role of our people is increasingly important. Their motivation, commitment and willingness to go the extra mile are essential. We acknowledge that our great TIGERs are a key pillar of our success."

Where do you see the company in the next 10 years?

Clemens Steiner: “I see a leading company in the aesthetic enhancement of industrial products and buildings through sustainable printing and coating materials. I see TIGER remaining independent. Indeed, maintaining our independence is our biggest goal.”

Kurt Berghofer: “Our policy will not change and it would be great if the next chapter of the company will be led by the family’s new generation, which is already showing great commitment and interest in the company. The most important factor is being motivated and having a clear goal. Our ambition is to continue growing – not quickly, but rather step by

step, expanding into new countries, such as Brazil and Argentina, where a quality-oriented market is emerging. Today, we are present in China, Vietnam, Mexico, Canada and the United States, while Wels is our only production facility in Europe. We have just completed a ten-year development plan that involved replacing all old machines with new ones at all our sites worldwide, ensuring the same level of quality and batch consistency across the board. We are now ready to implement our next ten-year development plan.”

Read the box on the next page

Say goodbye to masking

Overspray free paint application with EcoPaint Jet

Revolutionar y pr e cision in automatic appl ic ation br ings ef f icienc y to pr o duc t customization. Dürr’s solution EcoPaintJet applies sharp-edged paint lines on surfaces, pushing the limits for efficient and resources av ing co ating: No over spr ay, no mor e masking of your product

Year of Foundation: 1930

Affiliated Companies Worldwide: 22

Production Plants Worldwide: 8

TIGER Coatings at a glance

Employees: 1,365, of which 550 are based at the headquarters in Wels, Austria

Consolidated Revenue 2024: €306 million

The headquarters of TIGER Coatings, and the company’s European production site, is in Wels, in Upper Austria, where it was founded in 1930 by the Berghofer family. This site includes:

a dedicated polyester resin production plant;

a powder coating production plant;

a metallic bonded powder coating production plant;

a digital printing ink production unit;

the company’s executive, administrative, sales, and marketing offices;

a tower housing laboratory, the research and development area, a bistro, and a recreational space.

The powder coating production plant is highly automated, with automatic palletizing, conveying and dosing systems for resins and other raw materials. Formulation recipes for each coating are managed by an integrated ERP-system, which automatically sends the list of ingredients to the operator’s PLC.

The plant also includes:

an automated box folding, gluing and pad printing line,

an automated filling line for standard 20 kg boxes,

a filling line for 2.5 kg minipacks.

In line with its “less is more” philosophy and its commitment to resource conservation, TIGER Coatings has launched the Eco-Pack service — an environmentally friendly bridge between TIGER’s standard products and the specific batch sizes required by coaters. This is a custom refill service ranging from 1 kg to 19 kg, available for TIGER’s current standard range. Thanks to precise kilogram-level refilling, the company supplies exactly the quantity needed by the coater, eliminating disposal costs and capital commitment.The Wels warehouse offers an assortment of over 1,500 colours and effects from the entire TIGER product range.

TIGER headquarters in Wels, Austria.

The trade fair duo showcases modern, future-oriented sheet metal working, presents complete process sequences and, thanks to the exhibitors in 9 exhibition halls broken down into 5 thematic areas , impressively demonstrates the industry’s performance capabilities. It attracts highest levels of interest and is accompanied by a world-class supplementary programme, including the honouring with the “best Award 2025” innovation prize.

WHERE WE HAVE BEEN

ADVANCEMENTS

Lechler Tech redefines Soft Touch: the new generation of ultra-matt, eco-friendly and high-performance clearcoats is born

Edited by Lechler Como, Italy

Lechler Tech has launched 31555 Clear Soft Ess&re and 31556 Clear Velvet Ess&re, two new matt clearcoats marking a radical evolution that redefines the qualitative and ecological parameters of soft-touch coatings.

The painting of the future is built today, at the convergence of technological progress and environmental responsibility. In this scenario, while consolidating its experience in the sector of highperformance technical paintworks, Lechler Tech presents the new 31555 Clear Soft Ess&re and 31556 Clear Velvet Ess&re, two matt clearcoats marking a radical evolution that redefines the qualitative and ecological parameters of soft-touch coatings. Ultra-matt (3–4 gloss) with a distinctive and refined touch, they are capable of enhancing every surface both from an aesthetic and functional point of view when overapplied on matt bases, thus giving a soft-touch and velvety haptic effect. These formulations combine haptic materiality, advanced sustainability and mechanical resistance in a perfect balance between sensoriality and technology. Both solutions are part of the new ess&re line, the Lechler range dedicated to paints formulated with raw materials of renewable origin, to meet the growing demand for sustainability in design and industry.

Soft touch, bio-based heart

31555 Clear Soft Ess&re is characterised by a “rubber” soft-touch effect, that is warm and enveloping as well as perfect for surfaces that invite haptic interaction. 31556 Clear Velvet Ess&re, on the other hand, offers a silkier and more velvety sensation, that is ideal for environments and objects requiring a touch of minimalist elegance. The most revolutionary aspect of the Clearcoat Ess&re paint processes lies in the adoption of a bio-based formulation, which uses raw materials derived from renewable biomass. The entire package (finish, hardener and thinner) has percentages of modern carbon (bio-based) that exceed 50%, with the 13802 Soft Ess&re Hardener boasting a green share of over 40%, while the 01162 Soft Ess&re Thinner exceeds 25% of bio-based content.

This technology allows to significantly reduce the environmental footprint: the use of the BIO version of the new clearcoats compared to the standard version boasts a reduction of CO₂ equal to 1,42 kg for each kg of product applied, all while maintaining or even improving performance.

High performance: top durability and resistance

Clear Soft Ess&re and Clear Velvet Ess&re offer exceptional performance; at the end of the paint process the products stand out for greatly improved performance:

Extremely high scratch resistance, that is ideal for surfaces subject to intensive use;

Total absence of organotin compounds (TIN-Free), which guarantees safety even for applications in direct contact with skin;

Enhanced chemical and mechanical stability, with resistance to depolymerization over three times higher than the previous version;

Thoroughly uniform matt appearance, without halos or variations even on curved or three-dimensional surfaces.

Versatility for sectors with high aesthetic and technical value

Ess&re Clearcoat paint processes are designed to offer superior performance, distinctive aesthetics and greater sustainability, making

them ideal for a wide range of industrial sectors. Thanks to excellent adhesion even on complex plastic materials such as ABS, PC and PC/ABS blends, they are positioned as a reference solution for all those contexts in which design combines with functionality and durability over time.

Sporting

Designed for the world of sport and leisure, where surfaces are subject to intense mechanical stress, they guarantee:

High resistance to scratches, which is essential for products intended for everyday use or in outdoor environments.

High tolerance to depolymerization, to maintain functional characteristics unaltered even in the presence of environmental variations (humidity, temperatures).

Uniform matt surface, which gives a technical and refined look, enhancing plastic and composite materials.

Fashion & Design

In the fashion sector, especially for accessories, cosmetic packaging and wearable devices, the aesthetic quality and safety of materials are essential:

Total absence of organotin compounds (TIN-FREE), which improves sustainability and reduces health risks.

Excellent resistance to hand cream, a crucial test for items in contact with skin and with cosmetics.

Velvety and soft-touch haptic effect, which enhances the sensory experience of the end user, thus increasing the perceived value of the product.

Interior Design & Habitat

For furnishing and interior design – both residential and contract – they represent an excellent technical and aesthetic choice:

Uniform matt effect that eliminates unwanted reflections, while enhancing geometries and volumes.

High resistance to scratches and chemical agents, which is ideal for surfaces subject to frequent cleaning such as furniture, panels, furnishing accessories.

Durability over time, even in environments exposed to prolonged artificial or natural light, thanks to the proven resistance to hydrolysis (over 2000h in WOM Test ASTM G155).

Transportation – Interior Parts

In the transport sector, in particular for automotive and railway interiors, the coating must meet specific requirements of aesthetics, safety and resistance:

Very high durability of surfaces subjected to daily wear, impacts and thermal stresses.

Soft-touch effect that adds perceived value to vehicle interiors, while improving visual and haptic ergonomics.

Excellent adhesion on critical substrates, such as black PC/ABS, with no post-test stickiness, confirmed by minimum ΔE even after 2000h of WOM.

An added-value proposal: efficiency and air quality

In addition to an obvious environmental advantage, the new finishes also bring benefits in the application phase:

Energy efficiency: less energy required for drying

Improved air quality: thanks to low emissions and the absence of hazardous substances

Long service life: higher durability that extends maintenance paint processes and reduces waste

With the new 31555 and 31556, Lechler Tech raises the concept of soft touch to a higher standard, while demonstrating that sensory innovation, sustainability and performance can coexist in a single formula, designed for professionals who want to shape the future of design through intelligent surfaces that are beautiful to look at and touch.

31555 Clear Soft Ess&re is characterised by a “rubber” soft-touch effect, that is warm and enveloping as well as perfect for surfaces that invite haptic interaction; while 31556 Clear Velvet Ess&re offers a silkier and more velvety sensation, that is ideal for environments and objects requiring a touch of minimalist elegance.

The unique plant solution chosen by Merletti to meet the high coating requirements of the aerospace industry

Monica Fumagalli, ipcm®