INNOVATIVE MATERIALS

Photo: EFPL

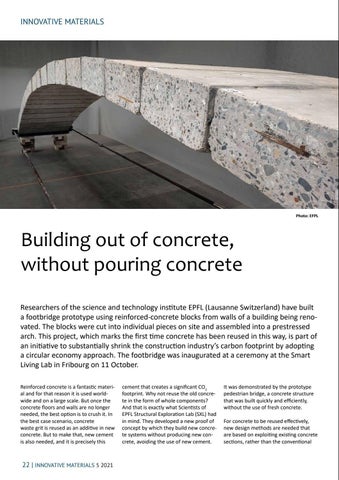

Building out of concrete, without pouring concrete Researchers of the science and technology institute EPFL (Lausanne Switzerland) have built a footbridge prototype using reinforced-concrete blocks from walls of a building being renovated. The blocks were cut into individual pieces on site and assembled into a prestressed arch. This project, which marks the first time concrete has been reused in this way, is part of an initiative to substantially shrink the construction industry’s carbon footprint by adopting a circular economy approach. The footbridge was inaugurated at a ceremony at the Smart Living Lab in Fribourg on 11 October. Reinforced concrete is a fantastic material and for that reason it is used worldwide and on a large scale. But once the concrete floors and walls are no longer needed, the best option is to crush it. In the best case scenario, concrete waste grit is reused as an additive in new concrete. But to make that, new cement is also needed, and it is precisely this

22 | INNOVATIVE MATERIALS 5 2021

cement that creates a significant CO2 footprint. Why not reuse the old concrete in the form of whole components? And that is exactly what Scientists of EPFL Structural Exploration Lab (SXL) had in mind. They developed a new proof of concept by which they build new concrete systems without producing new concrete, avoiding the use of new cement.

It was demonstrated by the prototype pedestrian bridge, a concrete structure that was built quickly and efficiently, without the use of fresh concrete. For concrete to be reused effectively, new design methods are needed that are based on exploiting existing concrete sections, rather than the conventional