10 minute read

Stackable ceramic facade prototype

from IM20215EN

Pedestrian bridge, detail. (Photo’s: EPFL) References

Advertisement

Fivet C, Brütting J. ‘Nothing is lost, nothing is created, everything is reused: structural design for a circular economy.’ Struct Eng. 2020;98(1):74–81.

http://infoscience.epfl.ch/record/273663

Brütting J, Vandervaeren C, Senatore G, De Temmerman N, Fivet C. ‘Environmental impact minimization of reticular structures made of reused and new elements through Life Cycle Assessment and Mixed-Integer Linear Programming.’ Energy Build. 2020 May;215:109827.

https://doi.org/10.1016/j.enbuild.2020.109827

Küpfer C, Fivet C. Déconstruction Sélective – ‘Construction Réversible: recueil pour diminuer les déchets et favoriser le réemploi dans la construction.’ Federal Office for the Environment FOEN; 2021.

https://zenodo.org/record/4314325#. YWVA8xpBxPZ

More at EPFL>

According to Corentin Fivet, a tenuretrack assistant professor at EPFL and head of the Structural Exploration Lab (SXL), this project opens up promising new research horizons for SXL. Most buildings in Switzerland are made out of concrete, and producing this raw material accounts for 7% of CO2 emissions. What’s more, concrete makes up 50% of demolition waste. When the material reaches its end of life, it’s at best broken down into gravel or granulate to create recycled forms - but that consumes a lot of energy. Instead, cutting up concrete blocks and reuse them, could both prevent the need to produce more concrete and eliminate the inert waste. The carbon emissions from this process wouldn’t necessarily be zero, but they would be drastically reduced. This would delay the need to downcycle obsolete concrete. Under this circular economy approach, demolition companies - which until now have been at the end of the value chain - would also become producers, kicking off a new cycle. The SXL team’s project is a call to action for the construction industry. ‘No other new concrete footbridge has a carbon footprint as small as ours,’ says Fivet. ‘Imagine if every obsolete concrete structure out there was cut into blocks and used to meet some of the global demand for new concrete. That would be a big step towards addressing some of the most pressing climate-change challenges.’

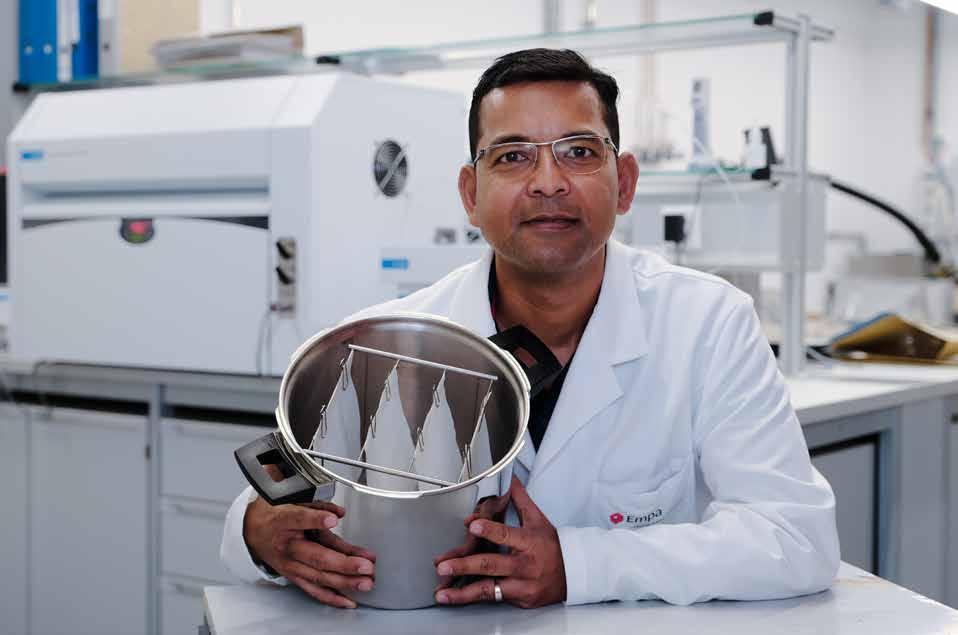

Fireproof and comfortable

Wash-durable flame retardant cotton textiles are produced by treating the fabric with flame retardants, which chemically links to the cellulose in the cotton. Until now, only a group of substances was suitable for this: formaldehydebased chemicals. Formaldehyde however is classified as a carcinogen. And there are more drawbacks: the -OH groups of cellulose are chemically blocked, which considerably reduces the capability of cotton to absorb water, which results in an uncomfortable textile. Empa scientists managed to circumvent this problem by creating a physically and chemically independent network of flame retardants inside the fibres, preserving the positive properties of cotton. Sabyasachi Gaan, a chemist and polymer expert who works at Empa’s Advanced Fibres lab, Switzerland, has spent many years developing flame retardants based on phosphorus chemistry that are already used in many industrial applications. Now, Gaan and his colleagues Rashid Nazir, Dambarudhar Parida and Joel Borgstädt utilized a tri-functional phosphorous compound (trivinylphosphine oxide), which has the capability of reacting only with specifically added molecules (amines like piperazin) to form its own network inside cotton. This makes the cotton permanently fire-resistant without blocking the favourable -OH groups. In addition, the physical phosphine oxide network also likes water. This flame retardant treatment does not include carcinogenic formaldehyde, which would endanger textile workers during textile manufacturing. The phosphine oxide networks, thus formed, does not wash out. After fifty launderings, 95 percent of the flame retardant network is still present in the fabric. This newly developed phosphorus chemistry and its application is protected by a patent application.

Cost effective: Sabyasachi Gaan uses steam from a commercial pressure cooker to flame retard samples of cotton fabric. Image: Empa More at Empa>

The article ‘In-situ phosphine oxide physical networks: A facile strategy to achieve durable flame retardant and antimicrobial treatments of cellulose,’ was published last summer in Chemical Engineering Journal. It’s online>

Kom in actie

voor kankeronderzoek

kwfthuismarathon.nl

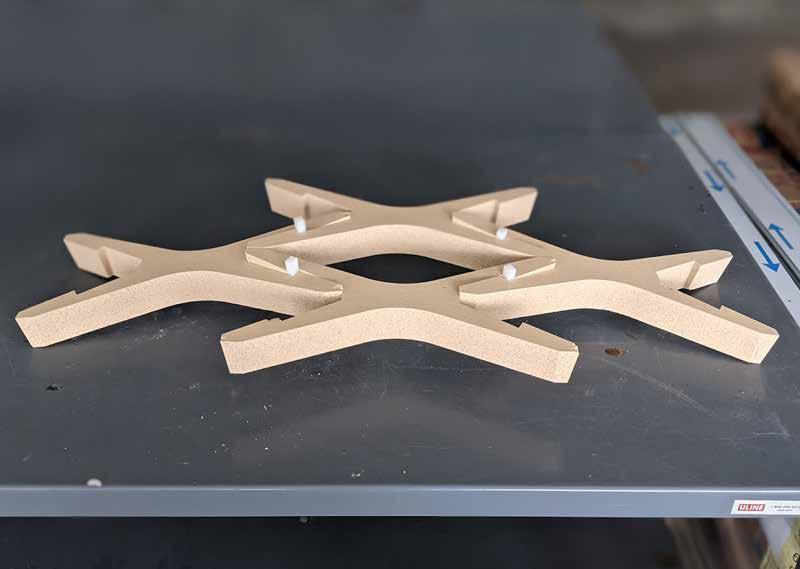

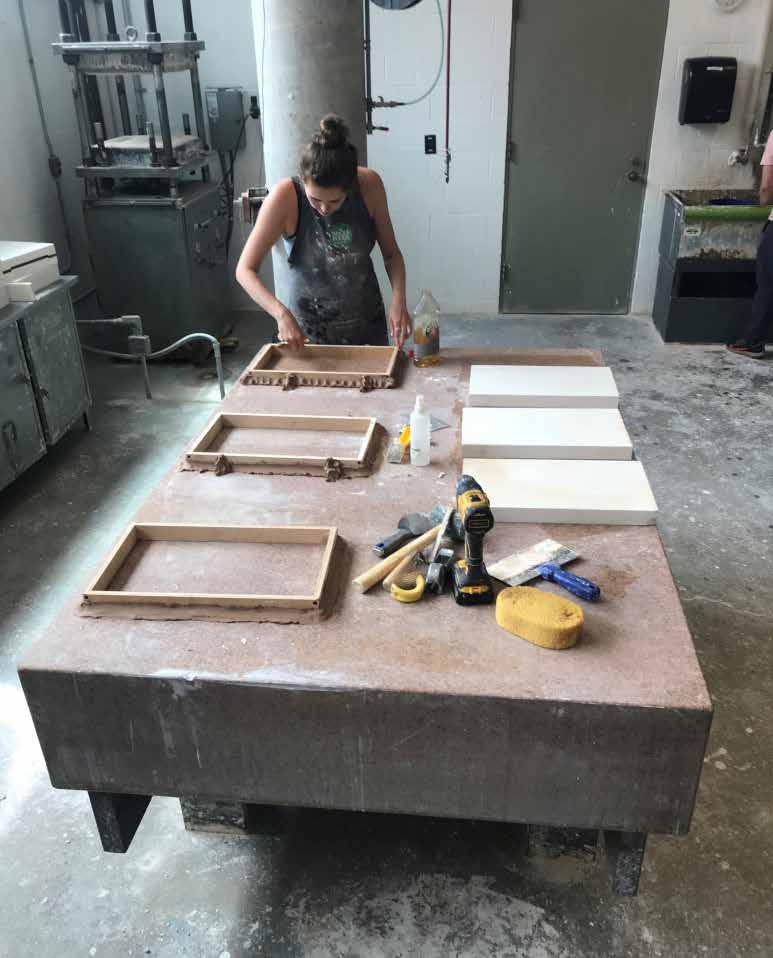

Stackable ceramic facade prototype

A team of University of Buffalo (UB) architecture faculty has developed a stackable ceramic terracotta facade system that opens new possibilities in so-called user-generated architecture. The research, being pursued with a team of faculty and students from Alfred University’s College of Ceramics, was presented at the 2021 Architectural Ceramic Assemblies Workshop (ACAW), which took place virtually on August 19. The facade prototype developed by UB employs a system of uniform terracotta units that are stacked and locked into place using fastening techniques derived from traditional wood joinery. The design and materials expertise of Alfred University in the field of ceramics has been combined with the knowledge of UB in the field of digital fabrication and the design of facade systems with terracotta.

Much of the research has unfolded over the past year in UB’s Sustainable Manufacturing and Advanced Robotic Technologies (SMART) Fabrication Factory in Parker Hall on the South Campus. The terracotta units were cut and shaped using the facility’s industry-grade, five-axis, waterjet cutter. A system of 3D-printed dowels, also designed and fabricated by the UB team, allow the pieces to ‘lock’ into place. The Alfred team was involved in the design and glazing of the terracotta tiles, which are formed using a mold and then cut with the waterjet before being fired and glazed.

The modular character and the reconfigurability of the interlocking parts allows interaction with the architecture. For example, a screen wall can be stacked high in the summer for shading and then lowered in the winter to allow for more light. The natural heat-retaining abilities of terracotta also support passive heating and cooling.

Much more at the University of Buffalo>

Photography: University of Buffalo

Glass ceramics from husk and ashes

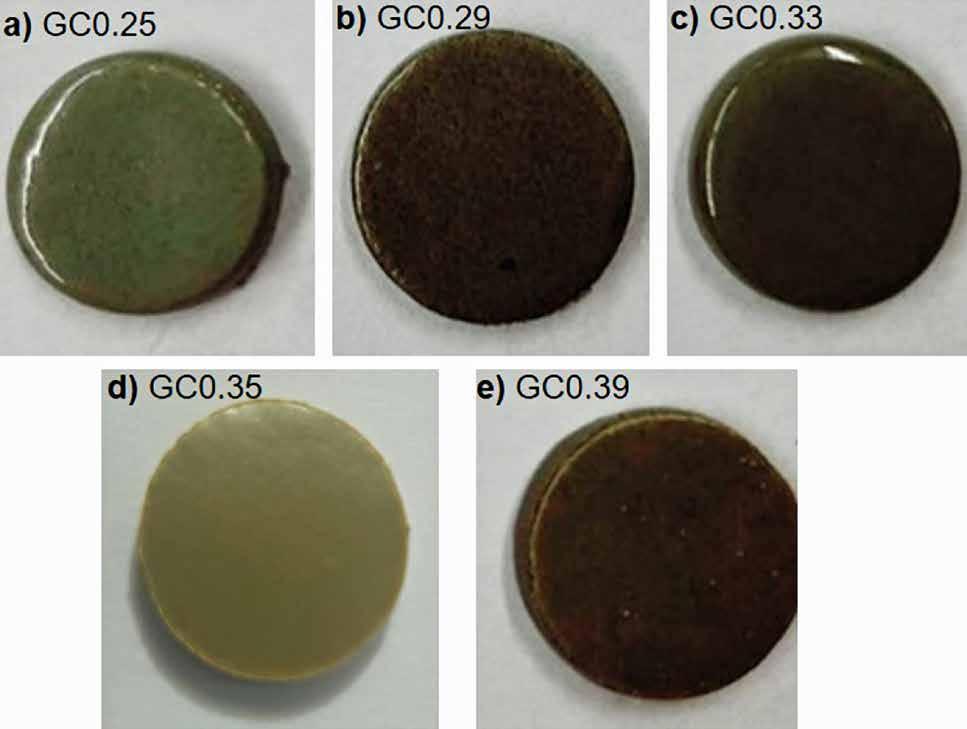

In Colombia, industrial wastes such as rice husk or coal ashes are disposed of in landfills generating high environmental impact. Therefore, scientists of the University of Valle (Colombia) and Eduardo Torroja Institute for Construction Science (Spain) decided to investigate whether the waste material could be used for something more useful, for the production of glass-ceramics for instance. Glass-ceramics are polycrystalline materials produced through controlled crystallization of base glass. Glass-ceramic materials combine the strength of ceramic and the hermetic sealing properties of glass. The results of this Colombian-Spanish research were published earlier this year in Boletín de la Sociedad Española de Cerámica y Vidrio. The scientists obtained coal ash from the Lago Verde brick company and rice husk ash from the La Esmeralda rice company, both Colombia. After crushing the ash and commercial calcium hydroxide in a ceramic ball mill, they mixed the powder with the network modifier zinc oxide (ZnO) and sodium tetraborate (Na2B4O7), which acts as the fluxing agent. The glasses were obtained by melting the powders at 1450 °C for two hours, and the melted powder was then poured into water. To obtain the glass-ceramic material, the temperature of the glass thermal treatment, which was generally lower than 1000 °C in all cases, was determined by differential thermal analysis. In the end, the new glass-ceramics were microstructurally, physically and mecha-

Sintered samples (Illustration from article)

nically characterized. In addition, the durability was determined in acidic and alkaline environments (HCl and NaOH solutions). Glass-ceramics with densities of 2607–2739 kg/m3, water absorption below 0.1%, Vickers hardness above 600 MPa and elastic modulus of ∼96 GPa were obtained.

The fracture toughness Kic was in the range of 0.39–0.59 MPa m1/2. The chemical durability was considered excellent (with mass losses of ∼0.5 mg/ cm2). According to the researchers these glass-ceramics could be good candidates for applications as construction materials, tiles, ceramic plates, coatings, among others.

The article ‘Preparation of glass-ceramic materials from coal ash and rice husk ash: Microstructural, physical and mechanical properties’ is online>

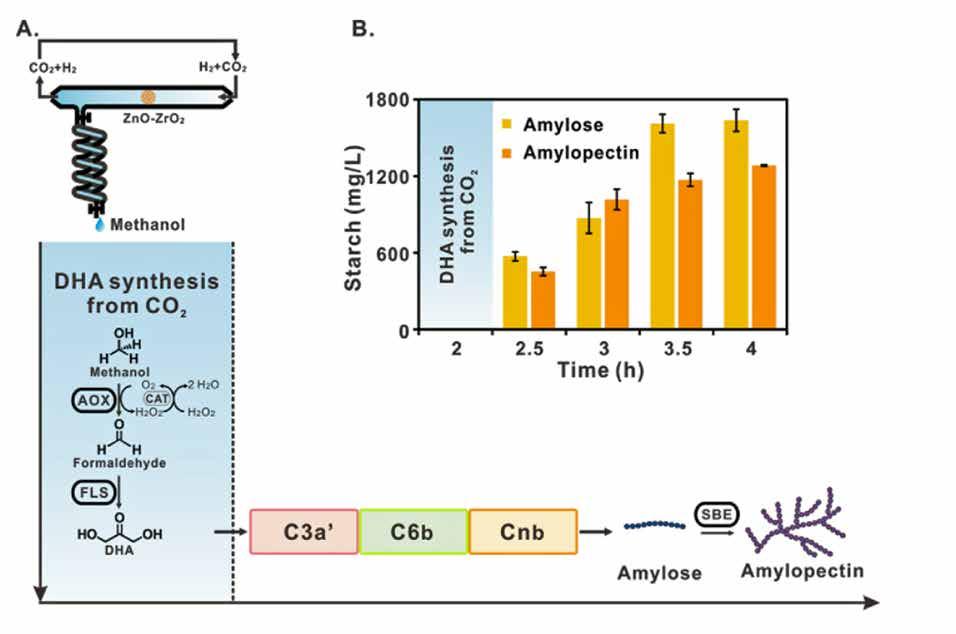

From CO 2 to starch

Starch is the major component of grain as well as an important industrial raw material. At present, it is mainly produced by crops such as maize by fixing CO2 through photosynthesis. This process involves about sixty biochemical reactions as well as complex physiological regulation. The theoretical energy conversion efficiency of this process is only about 2%. Scientists meanwhile believe that sustainable starch production and CO2 sequestration are urgently needed to deal with global problems such as food scarcity and climate change. Designing novel routes other than plant photosynthesis for converting CO2 to starch is an important issue.

Scientists at the Tianjin Institute of Industrial Biotechnology (TIB) of the Chinese Academy of Sciences (CAS) designed a chemoenzymatic system as well as an artificial starch anabolic route consisting of only eleven core reactions to convert CO2 into starch. The results were published in Science last September (DOI: 10.1126/science.abh4049).

According to CAS the artificial route can produce starch from CO2 with an efficiency 8.5-fold higher than starch biosynthesis in maize. The new route makes it possible to shift the mode of starch production from traditional agricultural planting to industrial manufacturing, and opens up a new technical route for synthesizing complex molecules from CO2. In addition, it would also help to avoid the negative environmental impact of using pesticides and fertilizers, improve human food security, facilitate a carbon-neutral bioeconomy, and eventually promote the formation of a sustainable bio-based society.

Chinese Academy of Sciences>

Starch synthesis via artificial starch anabolic pathway (ASAP) from CO2 (Image by TIBCAS)

WE KUNNEN NIET ZONDER NATUUR

Word nu lid op natuurmonumenten.nl en ontvang 4 x per jaar het magazine Puur Natuur

Polymer coating makes ceramics less likely to shatter

3D printed ceramic cracks easily under stress. But when the material is covered with a thin, flexible coating of epoxy polymer cured under ultraviolet light, the same materials appear to have a much better chance of remaining whole. Researchers at Rice University’s Brown School of Engineering have developed a method for coating so-called schwarzites (an allotrope of carbon), in this case complex carbon lattices that only existed in theory for decades, but can now be made with 3D printer. The results of their research appeared in Science Advances in early July. Schwarzites, named for German scientist Hermann Schwarz, who hypothesized in the 1880s the ‘negatively curved’ structures could be used wherever very strong but lightweight materials are needed, from batteries to bones to buildings. With added polymers, they come to resemble structures found in nature like seashells and bones that consist of hardened platelets in a biopolymer matrix. Materials scientists of Rice University have now carried out experiments and simulations to show that thin polymeric coatings as thick as 100 microns make fragile schwarzites up to 4.5 times more resistant to fracture. The structures can still crack under pressure, but they won’t fall apart.

The team, with members in Hungary, Canada and India, created computer models of the structures and printed them with a polymer-infused ceramic ‘ink.’ The ceramic was cured on the fly by ultraviolet lights in the printer, and then dipped in polymer and cured again. Along with uncoated control units, the intricate blocks were then subjected to high pressure. The control schwarzites shattered as expected, but the polymer coating prevented cracks from propagating in the others, allowing the structures to keep their form. The researchers also compared the schwarzites to coated solid ceramics and found the porous structures were inherently tougher.

More at Rice>

The article ‘Damage-tolerant 3D-printed ceramics via conformal coating‘ was published on 7 juli in Science Advances. It is online>