7 minute read

Large-scale production of bioplastics from residual flows one step closer

from IM20215EN

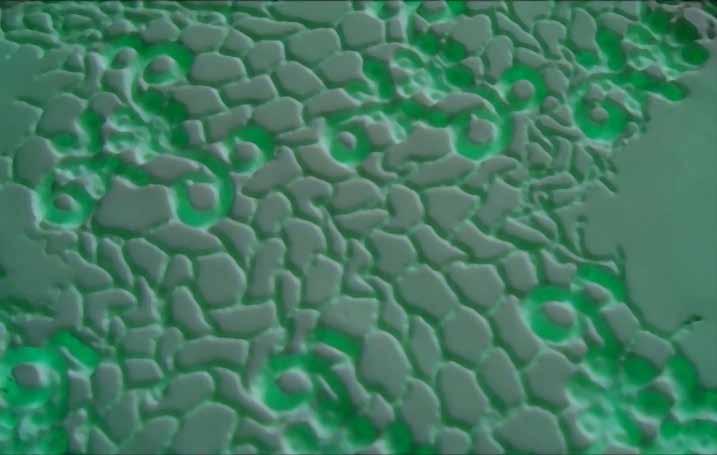

Towards a sustainable production of bioplastics from residual flows, PHA2USE and the Interreg NWE project WoW! recently took another important step. In the first extraction campaign on a pilot scale, more than 18 kg of PHBV from sewage sludge was produced. This PHBV, a fully biodegradable bioplastic, is now being tested by companies on various commercial applications.

The production of bioplastics from wastewater takes place by means of bacteria in sewage sludge from wastewater treatment plants. These bacteria are able to convert organic substances in the wastewater into the bioplastic PHBV. This PHBV is then stored by the bacteria in their cells. To make the PHBV suitable for use, it must first be removed from the cells. This is done by means of extraction. Until now, this extraction has only been performed on a smaller scale. PHA2USE and Interreg NWE project WoW! have now also succeeded in extracting PHBV on a larger scale. This paves the way for large-scale bioplastic production from wastewater. This extraction is the lead-up to the production of larger quantities in the PHA2USE project. The installation required for this is under construction and will be commissioned in early 2022.

Advertisement

The more than 18 kg of PHBV that has been extracted will initially be made available to four companies that are active in the processing of (bio)plastics. These companies will look at the application of the PHBV in their products. A major advantage of PHBV is that it is strong but can also be completely degraded under natural conditions. This makes the PHBV interesting for temporary applications such as in agriculture.

Cooperation

This milestone in the scaling up of PHBV production has been made possible by a unique collaboration between five Dutch water authorities, HVC, Paques Biomaterials and research partners Wetsus and Avans University of applied sciences.

Paques Biomaterials>

WoW! (Wider business Opportunities for raw materials from Wastewater)>

Towards a zero-emission cement factory

Together with its business partners, the Finnish research institute VTT has developed a solution that can bring a significant reduction in carbon dioxide emissions in the production of cement and quicklime. As one of the ingredients for concrete, cement is the world’s most used building material and is responsible for around 7% of the world’s carbon dioxide emissions. By using low-emission electricity instead of combustion for decomposing calcium carbonate - a central part of cement production - and by capturing the carbon dioxide produced in the production process, it is possible to run a cement plant with close to zero carbon dioxide emissions. This is made possible by using a gas-tight, electrically-heated rotary kiln. With this new technology, the pure carbon dioxide from the limestone can be captured and then either stored or utilised in, for example, the manufacture of lowemission products.

The Decarbonate project, led by VTT, involved constructing a twelve metre electrically-heated rotary kiln which was then used to test out, together with VTT’s business partners, the precalcination of the raw powder for cement and the production of both quicklime and also the lime mud used in pulp mills. The project involves key Finnish players in the sector, including Finnsementti, Nordkalk and UPM. According to VTT the test kiln could also be used for reducing emissions in other industrial sectors, such as the battery and asphalt industries. According to VTT, in the EU, at the current price level, a decrease of one tonne in carbon dioxide emissions means a savings of EUR 60 for the company. For a medium-sized cement plant, for example, a one-third reduction in emissions would mean savings of several million euros per year. In addition, the electric kiln produces a new product: purified carbon dioxide. In other words, electrically-powered calcination could be economically viable already at current prices, but assessing its feasibility at the industrial scale and the investments required for this will require further studies.

More at VTT>

Voeg informatie toe aan de Kennisbank Biobased Bouwen

De Biobased Economy speelt een belangrijke rol in de duurzame ontwikkeling van Nederland en biedt nieuwe kansen voor het bedrijfsleven. Via de kennisbank kunt u kennis vergaren en delen over de beschikbaarheid en toepassingsmogelijkheden van biobased materialen, producten en bouwconcepten. Samen versterken we zo de biobased economie.

Ruim dertig partijen in de bouwsector ondertekenden de green deal biobased bouwen. Deze producenten, architecten, adviseurs en kennisinstellingen delen hun kennis rond kansrijke mogelijkheden van biobased bouwen. Ook de ministeries van Binnenlandse Zaken (Wonen en Rijksdienst), Economische Zaken, en Infrastructuur en Milieu ondersteunen de green deal.

Bouw ook mee aan de biobased economie en voeg uw project- of productbeschrijvingen toe aan deze kennisbank.

Kijk op www.biobasedbouwen.nl voor meer informatie>

MAKE IT MATTER

MAKE IT MATTER is compiled in collaboration with MaterialDistrict (MaterialDistrict.com). In this section new, and/or interesting developments and innovative materials are highlighted.

New Delft Blue

New Delft Blue, a project by Dutch architectural design company Studio RAP, reinterprets the world famous design of Delft Blue porcelain, fusing 3D clay printing, computational design and artisanal glazing. The large scale redevelopment Nieuw Delft will be applied at the PoortMeesters building block, which is framed by two large entry gates. The gates are four metres wide, eight metres high and twelve metres deep. They will be covered in approximately 4,000 ceramic tiles.

More at MaterialDistrict>

The Production of Fatigue

The Production of Fatigue is a printing process revealing the creative potential of fatigue and exposing its unexpected aesthetic qualities. Designer Léa Mazy uses this printing method for the tile industry and envisions to inspire and challenge more manufactories to sustainable and innovative visions in existing production processes.

More at MaterialDistrict>

Tex-Tiles

As porcelain is translucent, there is the possibility to add LED lights behind the tile. By shining light onto, and through, the tiles, the special character of the tiles is revealed. Due to the variation of thicker and thinner material, dark and light lines and shapes appear in the tile, making the imprint very clear. The tiles are hand-shaped, and in this way it is possible to create unique tiles with an imprint related to the building or environment.

More at MaterialDistrict>

Ceramic sand Ceramic sand

What is the effect of sand on the colour and structure of cera-What is the effect of sand on the colour and structure of ceramic pieces? Using various kinds of sand from various places, mic pieces? Using various kinds of sand from various places, designer Marin Jansen experimented with adding sand to clay. designer Marin Jansen experimented with adding sand to clay. In addition, she also used sand to make glaze. The same sand In addition, she also used sand to make glaze. The same sand added in a glaze but fired in different ways (oxidation, added in a glaze but fired in different ways (oxidation, 1.260 1.260 °C, reduction and oxidation 1.050 °C) gives different °C, reduction and oxidation 1.050 °C) gives different interesting interesting results. results.

More at MaterialDistrict> More at MaterialDistrict>

Wooden floor tiles Wooden floor tiles

The wooden floor tiles of OSBvloeren.nl are made of FSC The wooden floor tiles of OSBvloeren.nl are made of FSC & PEFC certified zero-formaldehyde OSB (Oriented Strand & PEFC certified zero-formaldehyde OSB (Oriented Strand Board). The material is made of chipped wood, mixed with a Board). The material is made of chipped wood, mixed with a little formaldehyde-free resin, pressed into solid wood boards. little formaldehyde-free resin, pressed into solid wood boards. The fact that it is formaldehyde-free makes it a suitable pro-The fact that it is formaldehyde-free makes it a suitable product for interior use, as opposed to ‘normal’ OSB. All floors are duct for interior use, as opposed to ‘normal’ OSB. All floors are produced exclusively to order, since manufacturer OSBvloeren. produced exclusively to order, since manufacturer OSBvloeren. nl doesn’t want to produce more than necessary. nl doesn’t want to produce more than necessary.

More at MaterialDistrict> More at MaterialDistrict>

Waterweg

Waterweg is a circular concrete made out of dredged sediments. Dredged sediment is a muddy waste stream from our rivers and canals. Dredge currently knows only low value applications, although it causes high costs, a lot of CO2 emissions and wasted time. By applying dredge in a circular concrete, Waterweg makes sure it can have a high value application. Because of the use of a waste stream and the low energy production process this product can get up to 50% CO2 reduction compared to conventional concrete.

More at MaterialDistrict>

Kerloc

Kerloc is a sustainable technical ceramics which is being used for facades. For its production process low-value, residue materials (Dutch poplar wood) are being used. This makes it a biobased product. The production process is unique as there is no additional heat (oven). Therefore, Martens keramiek calls it cold ceramics. According to the manufacturer, Kerloc is 100% circular.