7 minute read

Wood that can cut like steel

from IM20215EN

Hard materials are in high demand in engineering applications. Widely used hard materials, like alloys and ceramics, are often not renewable and expensive. Their production requires high energy consumption and often leads to negative environmental impacts. Scientists of the University of Maryland (UMD) now demonstrated a potential low-cost and sustainable hard material made from natural wood.

The advantages of wood as a structural material are legion: renewable, lightweight, naturally durable and strong, and possessing a lower lifecycle cost than most other materials. Through a simple and effective approach, bulk natural wood can be processed into a hardened wood (HW) with a 23-fold increase in hardness. The trick is in optimizing the cellulose structure. Cellulose - the main component of wood - has a higher strength-to-density ratio than most engineering materials, such as ceramics, metals and polymers. But in ordinary wood, such as that used in construction, these possibilities are not exploited. That’s because wood only consists of about half of cellulose, the rest is binder, especially hemicellulose and lignin. The UMD researchers have now managed to remove the weaker components without destroying the cellulose skeleton. This is done in two steps. First, the lignin is removed by cooking the wood with chemicals. This leaves a flexible cellulose skeleton that is then hot pressed into a rock hard material. Finally, it is coated with mineral oil to extend its life.

Advertisement

Knife

To demonstrate the potential applications of HW, the UMD scientists demonstrated that an HW table knife can be made nearly three times sharper than commercial table knives. An HW nail can be as functional as a steel nail with comparable performance but is immune

Illustration: UMD

from rusting, a key failure mechanism of steel nails. These encouraging applications suggest the promise of HW as a renewable and low-cost alternative for conventional hard materials with the potential to replace plastic table utensils and steel nails.

A mineral oil coating prevents water damage, making the knife a washable and reusable alternative to throwaway utensils. The material also has potential for hardwood flooring or wherever else super-tough wood is needed.

‘Hardened wood as a renewable alternative to steel and plastic’ door Bo Chen, Ulrich H.Leiste, William L. Fourney, Yu Liu, Qiongyu Chen and TengLi was published on 20 oktober in Cell. (DOI:https://doi.org/10.1016/j. matt.2021.09.020)

More at UMD>

Skin-inspired sensors show how our body moves

Scientists at the University of Groningen have created wearable, stitchable, and sensitive sensors from flexible polymers and bundles of carbon fibre. Like our skin, these sensors respond to pressure and can measure body position and movement. They could be used to measure disease progress in Parkinson’s disease, or sense joint movement in athletes, for example.

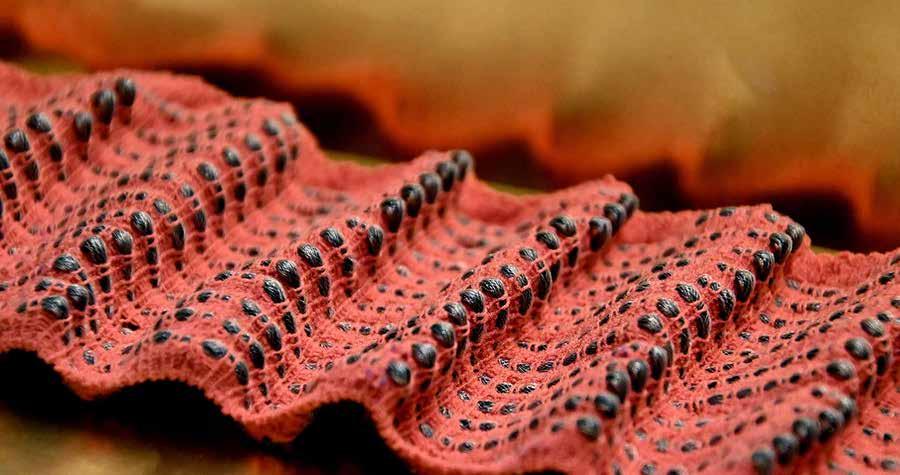

Sensors can be useful to monitor our health. However, this requires flexible sensors that will not cause discomfort to the user. Wearable sensors, stitched into clothing, would be useful as well. Ajay Kottapalli, assistant professor at the Engineering and Technology institute Groningen (ENTEG, part of the University of Groningen), together with his PhD student Debarun Sengupta, has already developed different types of sensors, often inspired by nature. He has now created sensors that can mimic the sensory capabilities of our skin. Kottapalli used electrospun carbon fibres1 for his sensors. These fibres are piezoresistive, which means that their conductivity changes when they are stretched. Sensors are made by embedding the fibres in a flexible elastomer in a perpendicular pattern, creating ‘pixels’ where two fibres cross. Electrospinning is similar to the way in which fabric is made, and the material of Kottapalli can be stitched, whereby it is possible to use conductive yarn that can act as an electrode. The sensors can therefore be integrated into everyday clothing or gloves, or applied as patches on joints. They will measure bending movements, but they are also sensitive to pressure.

The research was presented in the Nature Partnership Journal (NPJ) Flexible Electronics on 14 October, titled ‘Electrospun bundled carbon nanofibers for skin-inspired tactile sensing, proprioception and gesture tracking applications’. It’s online>

More at Rijksuniversiteit Groningen>

1 Electrospinning is a fiber production method

which uses electric force to draw charged threads of polymer solutions or polymer melts up to fiber diameters in the order of some hundred nanometers. More>

Waar ren jij mee? Ga naar rentegenkanker.nl

Photo: MIT/ MIT Media Lab/University of Uppsala/KTH Royal Institute of Technology

New fibres can make breath-regulating garments

Scientist of the Massachusetts Institute of Technology (MIT), the university of Uppsala and the KTH Royal Institute of Technology, Swede), have developed a new kind of fibre that senses how much a fabric is being stretched or compressed, and then provides immediate tactile feedback in the form of pressure, lateral stretch, or vibration. Such fabrics could be used in garments that help train singers or athletes to better control their breathing, or that help patients recovering from disease or surgery to recover their breathing patterns.

The multilayered fibers contain a fluid channel in the centre, which can be activated by a fluidic system. This system controls the fibres’ geometry by pressurizing and releasing a fluid medium, such as compressed air or water, into the channel, allowing the fibre to act as an artificial muscle. The fibres also contain stretchable sensors that can detect and measure the degree of stretching of the fibres. The resulting composite fibres are thin and flexible enough to be sewn, woven, or knitted using standard commercial machines.

The soft fibre composite, which resembles a strand of yarn, has five layers: the innermost fluid channel, a silicone-based elastomeric tube to contain the working fluid, a soft stretchable sensor that detects strain as a change in electrical resistance, a braided polymer stretchable outer mesh that controls the outer dimensions of the fibre, and a nonstretchy filament that provides a mechanical constraint on the overall extensibility. The fibres, dubbed OmniFibers, have been presented last October at the Association for Computing Machinery’s User Interface Software and Technology online conference.

The paper ‘OmniFiber: Integrated Fluidic Fiber Actuators for Weaving Movement based Interactions into the ‘Fabric of Everyday Life’ was written by Ozgun Kilic Afsar, a visiting doctoral student and research affiliate at MIT; Hiroshi Ishii, the Jerome B. Wiesner Professor of Media Arts and Sciences; and eight others from the MIT Media Lab, Uppsala University, and KTH Royal Institute of Technology in Sweden.’ It is online (pdf)>

MIT>

Video

Unbreakable glass inspired by seashells

Scientists from McGill University, Canada, have developed stronger and tougher glass, inspired by the inner layer of mollusk shells. Instead of shattering upon impact, the new material has the resiliency of plastic and could be used to improve cell phone screens in the future, among other applications. Drawing inspiration from nature, the scientist created a new glass and acrylic composite material that mimics nacre or mother of pearl.

Nacre has the rigidity of a stiff material and durability of a soft material, giving it the best of both worlds. It’s made of stiff pieces of chalk-like matter that are layered with soft proteins that are highly elastic. This structure produces exceptional strength, making it 3000 times tougher than the materials that compose it.

The scientists took the architecture of nacre and replicated it with layers of glass flakes and acrylic, yielding an exceptionally strong yet opaque material that can be produced easily and inexpensively. They then went a step further to make the composite optically transparent. By tuning the refractive index of the acrylic, they were able to make it seamlessly blend with the glass to make a truly transparent composite.

McGill University > ‘Centrifugation and index-matching yields a strong and transparent bioinspired nacreous composite,’ by Ali Amini, Adele Khavari, Francois Barthelat, and Allen J. Ehrlicher was published in September 2021 in Science. DOI: https://doi.org/10.1126/science. abf0277

Vitrum flexile

Flexible glass is supposedly a lost invention from the time of the reign of the Roman Emperor Tiberius Caesar (42 BC - AD 37). As the story goes, an unnamed inventor brought a drinking bowl made of the material - vitrum flexile - before the Emperor. When the bowl was put to the test to break it, it only dented instead of shattering. The inventor could easily repair the bowl with a hammer. After the inventor swore he was the only person who knew how to produce the material, Tiberius had the man executed, fearing that the glass would devalue gold and silver because it might be more valuable.