SUMMARY

VOLUME 1 2025

HOVERLIGHT: LIGHTWEIGHT, RIGID, AND VIBRATION-DAMPING

MATERIALDISTRICT UTRECHT 2025

JEC INNOVATION AWARD 2025

TOR ALVA: WORLD’S TALLEST 3D-PRINTED CONCRETE TOWER

BACTERIAL MINI BIOPLASTICS FACTORY GETS TURBO MODE

HOVERLIGHT: LIGHTWEIGHT, RIGID, AND VIBRATION-DAMPING

MATERIALDISTRICT UTRECHT 2025

JEC INNOVATION AWARD 2025

TOR ALVA: WORLD’S TALLEST 3D-PRINTED CONCRETE TOWER

BACTERIAL MINI BIOPLASTICS FACTORY GETS TURBO MODE

This is a summary of the most recent edition of Innovative Materials. Would you like to read the entire articles? You will find more information about subscriptions HERE.

Innovative Materials is an interactive, digital magazine about new and/or innovative applied materials in civil engineering sector, construction, architecture and design.

A team of researchers from Penn State has successfully utilized a new 3D printing method to produce complex metal structures that previously could only be made by welding.

PV cells made from lunar dust

Shipping material into space is very expensive: transporting one kilogram to the moon costs a million euros. So it makes sense to use the resources available locally. A research team of the University of Potsdam and Dr. Stefan Linke of the Technical University of Berlin combined lunar regolith with ultrathin perovskite to produce efficient lunar solar cells.

Wall Reef: Innovative solution against heat and water nuisance

December last year, the innovative 3D-printed coral reef, the Wall Reef, was unveiled by a resident at the Tweespan and Vierspan residential complex in Rhoon. The project is a collaboration between senior housing provider Woonzorg Nederland and Urban Reef, the developer of the coral reef.

Stronger, lighter, cheaper: improving carbon fiber production

Scientists at King Abdullah University of Science and Technology (KAUST, Saudi Arabia) have developed a method to manufacture high-performance carbon fibres from low-value refinery residues.

In collaboration with Hochschule Bremen (City University of Applied Sciences) and the Fraunhofer Institute for Production Technology and Advanced Materials (IFAM), they aim to convert this waste into high-quality 3D-printed products.

Researchers at the Fraunhofer Institute for High-Speed Dynamics at the Ernst Mach Institute (EMI) have developed a technology that makes it possible to continuously extract carbon fibers from composite materials without compromising material quality.

In order to be climate neutral by 2050, not only must our energy be generated sustainably, but it must also fit into a circular economy. TNO is working with a number of partners within the three-year CIRCLE4WIN project on a method that can be applied commercially for recycling composite wind turbine blades.

Researchers at the National Institute of Standards and Technology (NIST) have found special atomic patterns, called quasicrystals, in 3D-printed aluminum alloys. The researchers discovered that quasicrystals increase the strength of 3D-printed aluminum, making it suitable for use in lightweight, highstrength objects such as aircraft parts.

Winners Cellulose Fibres Innovation Award 2025 announced

During the Cellulose Fibres Conference 2025, mid-March 2025, the winners of the ‘Cellulose Fibre Innovation Award 2025’ were announced.

The Dutch textile industry stands at a crossroads. Fast fashion and overconsumption are driving an ever-growing mountain of waste, while the Netherlands is committed to achieving a fully circular textile chain by 2050. But how do we get there?

Shade screens with rollable solar foil combines energy generation and climate controll

TNO, Verzuu Screen Development, and partners have developed and tested a shade cloth with rollable solar foil in a greenhouse. This innovative system combines energy generation with climate control.

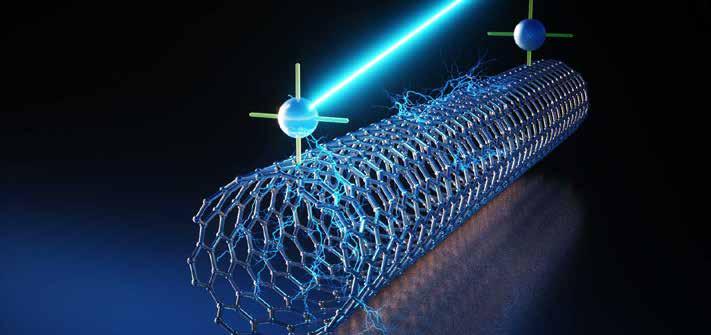

Researchers at the Swiss Federal Institute of Technology Zurich (ETH Zurich) have developed an affordable sensor that is selective, efficient, and reliable in detecting tiny amounts of oxygen in gas mixtures. The sensor is based on so-called carbon nanotubes.

lightweight, rigid, and vibration-damping

The Fraunhofer Institutes for Machine Tools and Forming Technology (IWU) and for Manufacturing Technology and Advanced Materials (IFAM) announced a breakthrough earlier this year with the development of a new composite material: HoverLIGHT. This material is lightweight, rigid, and vibration-damping, achieved through the combination of aluminum foam and particle-filled hollow spheres.

Researchers at Washington State University (WSU) have developed a new method for recycling wind turbine blades without the use of harsh chemicals. This process enables the recovery and reuse of glass fibers and resins, allowing the materials to be repurposed for new products.

From 12 to 14 March, the 18th edition of MaterialDistrict Utrecht was held in the Werkspoorkathedraal in Utrecht. The annual event attracted an audience of designers and architects looking for the latest developments in sustainable, innovative, biobased, circular and regenerative materials. From ‘ceramic’ stones made from date pits and nettle filament for 3D printing to a fur coat made from reed and acoustic building materials made from mycelium and shell waste: it was all there.

MaterialDistrict Utrecht 2025: SOL-R&D

Solar panels that don’t look like solar panels? According to Rotterdam-based company SOL-R&D, this is possible. The company believes that any surface has the potential to generate electricity without sacrificing aesthetics, whether it’s a building or a product.

MaterialDistrict Utrecht 2025:

IOUS studio in Rotterdam developed bio-receptive 3D-printed ceramics: a combination of traditional craftsmanship and advanced technology. According to IOUS, natural, recyclable clay and living moss are used together to create sustainable, functional and visually appealing surfaces.

MaterialDistrict Utrecht 2025:

Inspired by nature and driven by a passion for natural shapes and textures, Nature@Home develops and imports sustainable interior decorations and wall panels made from residual materials. The company, based in Roosendaal, uses raw materials sourced from nature’s byproducts and transforms them into aesthetically unique wall panels. These materials are obtained through fair trade from developing countries.

MaterialDistrict Utrecht 2025: Growmoulding

Growmoulding, based in Enkhuizen, specializes in producing biobased materials - mainly mycelium and hemp - for the furniture industry. Using a semi-industrial biocomposite production process, the company manufactures a variety of precisely tailored shapes as alternatives to materials like expanded polystyrene (EPS), expanded polypropylene (EPP), and cast polyurethane foams.

MaterialDistrict Utrecht 2025:

Dijkstra Friese Kleiwarenfabriek is active in four specialisms: Architects & Designers, Traditional building ceramics, Tiles and plate painting and Restoration. For restoration, the company can supply many different ceramic products to measure. Because there is an in-house laboratory, all glazes are developed in-house and made to match the original. In addition to restoration, the factory also produces traditional building ceramics such as chimney pots, ridges, window sill stones or pirons.

Rebrick specializes in the circular use of bricks. Rebrick harvests one million bricks from demolition projects each year (and according to the company, two million next year) and supplies them to the construction industry. The starting point is that used bricks from demolition projects do not have to be used as rubble in the road foundation. Chipping off and reusing them is also possible.

Each year, the JEC Composites Innovation Awards recognize pioneering projects that highlight the transformative potential of composite materials. Organized by the JEC Group, the awards aim to foster innovation within the composites industry and raise public awareness of its advancements. The winners of this year’s awards were announced in advance of JEC World 2025, held on March 5 - 6 in Paris.

The world’s tallest 3d-printed concrete tower is in the Alps

A striking structure has stood in the mountains of the Swiss village of Mulegns, located in the canton of Graubünden, since last year: the so-called White Tower (‘Tor Alva’). At 30 meters tall, it is currently the world’s tallest 3D-printed structure. The White Tower was built in close collaboration with the cultural foundation Nova Fundaziun Origen, ETH Zurich (ETHZ), and local, national, and international partners.

switch bacterial bioplastics mini-factories into turbo mode

A team of scientists of the Wageningen University & Research (WUR) and the German Max Planck Institute has managed to significantly boost the growth of the soil bacterium Cupriavidus necator by modifying its metabolism at the molecular level.

An international research team led by the Karlsruhe Institute of Technology (KIT) has developed mechanical metamaterials with exceptionally high elastic energy density.

Architect@work Belgium 11 - 12 May 2025, Kortrijk

Houtbouwbeurs 13 - 15 May 2025, ‘s-Hertogenbosch

De Nederlandse Metaal Dagen 21 - 23 May 2025, ‘s-Hertogenbosch

8th Conference of the Serbian Society for Ceramic Materials 18 - 20 June 2025, Belgrado

ESMC2025 7 - 11 July 2025, Lyon

ECerC 2025 4 September 2025, Dresden

Eurocor 2025 7 - 11 September 2025, Brussels

AM Expo 16 - 17 September 2025, Luzern

A@W Hamburg 17 - 18 September 2025, Hamburg

Renewable Materials Conference 22 - 24 September 2025, Siegburg/Cologne

PARTEC 23 - 25 September 2025, Nuremberg

Solids Rotterdam 1 - 2 October 2025, Rotterdam

Metavak 2025 7, 8 en 9 October 2025

Gorinchem

Barcelona Design week 2025 7 - 17 October 2025

Barcelona

Staalbouwdag 2025 9 October 2025 Leusden

K Messe 2025 8 - 15 October 2025, Düsseldorf

Holz 14 - 18 October 2025, Basel

Vakbeurs Recycling 2025 11 - 13 November 2025, Gorinchem

A@W Stuttgart 12 - 13 November 2025, Stuttgart

Precisiebeurs 2025 12 - 13 November 2025, ‘s Hertogenbosch

Formnext 2025 18 - 21 November 2025, Frankfurt

Advanced Recycling Conference 19 - 20 November 2025, Cologne

A@W Düsseldorf 3 - 4 December 2025, Düsseldorf

BLE.CH 2026 11 - 13 March 2026, Bern

Wij leveren complete installaties voor ontstoffing, luchtreiniging en pneumatisch transport

Technieken voor o.a.:

- Ontstoffing van productieruimtes (MAC)

- Reduceren van geuremissies (NER)

- Reduceren van stofemissies (NER)

Componenten die wij o.a. kunnen leveren:

- Natfilters & Droogfilters

- Cyclonen

- Gaswassers

- Topsteen- / Frogreinigers

- Naverbranders

Projecten kunnen turn-key worden uitgevoerd

Wij garanderen de emissie & grenswaarden

Engineering, bouw en onderhoud in eigen beheer

Mesys Industrial Air Systems BV

Molenstraat 27, 6914AC Herwen

+31 (0) 316 248744

www.mesys.nl

Info@mesys.nl

What does the NKV do?

• Facilitates knowledge sharing, collaboration, meetings, and information exchange with other (ceramic) organizations, institutes, and associations, both domestically and internationally

• Promotes education and research in the field of ceramic materials

• Provides a network of contacts for its members

• Actively spreads knowledge about ceramics and ceramic materials

• Engages in collective promotion of the use of ceramics

Want to know more about membership? Visit www.ceramics.nl. Click here>

International meeting place for innovators, companies and brands, investors and policy makers to develop and shape the future renewable carbon economy.

• Fine Chemicals Topics in 2025

• Defossilisation of the Chemical Industry

• Lignocellulosic Biorefineries and Lignin Utilisation

• Fossil -free Plastics

• Setting the Frame for Renewable Carbon

• Biodegradation

> 70 Presentations • 18 Panel Discussions • 10 Interactive Workshops • > 500 Participants expected

Independent, dedicated, objective research and consultancy. ISO 17025 accredited. Center of expertise for materials characterization.

We are pleased to support you with research and analysis of your innovative materials. Call us on +31 26 3845600 or email info@tcki.nl www.tcki.nl