Australian Manufacturing Awards winners revealed at gala event

The winners of the Australian Manufacturing Awards have been revealed at a gala event in Sydney, with over 400 guests on hand to pay tribute to the best and brightest of Australian industry.

The big winners were Eilbeck Cranes, who picked up the prestigious St.George Bank Manufacturer of the Year prize, and Dave Vinther of Moduplay, who won the individual Gold Award for Excellence

in Manufacturing, sponsored by Investment NSW.

John Notaras of Atom Industries was also honoured with the Lifetime Acheivement Award for his decades of service to the industry, presented by SugarCRM.

The event, held at the luxurious Sofitel Sydney Wentworth, was a true celebration of the manufacturing sector, handing out 22 prizes that covered every corner of industry.

Hosted by respected journalist

Tracey Spicer, the night began with keynote addresses from Tim Ayres, Federal Minister for Industry and Innovation, and Amber Stanley of Investment NSW, before the Awards were handed out.

Health and wellness manufacturers Morlife were the most successful

Continues page 22

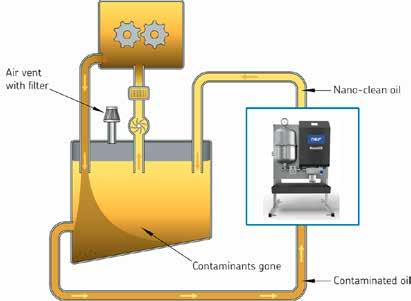

Meet the oil filtration revolution

that every manufacturer needs to know

about

Oil is at the heart of manufacturing, quite literally greasing the wheels that keep machines running, industry humming and processes moving along.

Given the centrality of oil, manufacturers must constantly be vigilant about how they treat it, especially in avoiding damage to expensive machinery and equipment.

Oil filtration is at the heart of maintenance, ensuring that everything can keep running smoothly without costly breakdowns or expensive changeover processes.

Continues page 44

Why the personal touch matters in bearings

Besa Deda and John Spender of William Buck, Scott Filby of Industry Update and Matt Kelly of St.George Bank

The

All Lasers come with our National CNC Support and Service, commissioning, testing and operator training.

•

•

•

•

• Local Service and Support

• Oxygen & Nitrogen Regulators with hoses included

• Five-year factory warranty on - Bodor Thinker Control System, Bodor Power Laser Source, Bodor Genius Laser Head See Website for T&C’s

Publisher SCOTT FILBY scott@industryupdate.com.au

Advertising & Sales Manager

PAUL FERRIS paul@industryupdate.com.au

Editor MIKE WOOD editor@industryupdate.com.au

Sub Editor RENATA GORTAN subeditor@industryupdate.com.au

Universities & Collaboration Editor DAVID SLIGAR unieditor@industryupdate.com.au

Publisher’s Assistant and Administration Manager

JERIN BURZACOTT jerin@industryupdate.com.au

SCOTT FILBY scott@industryupdate.com.au

Marketing Manager DUMINSHA UDESHIKA marketing@industryupdate.com.au

Creative Director EDWIN KWONG production@industryupdate.com.au

Production Manager DUMINSHA UDESHIKA copy@industryupdate.com.au

Video Editor & Producer CHARLIE LOUGHLIN video@industryupdate.com.au

Office Admin JESSICA SUDESH admin@industryupdate.com.au

Finance & Accounts

MICHELLE ALCOCK michelle@industryupdate.com.au

Consultant TRACY FILBY tracy@industryupdate.com.au

Accounts Receivable LYN SLIGAR lyn@industryupdate.com.au

Subscription Coordinator GUSTAV RHEEDER info@industryupdate.com.au

Circulation Coordinator RHYS MITCHELL info@industryupdate.com.au

Printer IVE Group

Automation experts make key appointment in Australia & NZ

Swisslog, a leading provider of best-in-class warehouse automation and software, has announced the promotion of Steve Dimitrovski to Director of Sales for Australia and New Zealand.

He has a strong background in the retail sector with experience spanning more than 19 years, including several senior leadership and business development roles.

Dimitrovski started with Swisslog Australia and New Zealand in 2021 and was instrumental in delivery of major warehouse automation projects with market leading blue-chip companies.

He holds a Bachelor of Commerce with a double major in Economics and Marketing from the University of Wollongong and a Master of Business Administration from the Australian Graduate School of Management (AGSM).

“Steve is focused on leading our sales team to build on the momentum we are seeing in the market for automation solutions that deliver tangible and measurable results for customers,” said Dan Ulmamei, Managing Director of Swisslog Australia and New Zealand.

“His comprehensive understanding of consumer trends and customer challenges, combined with his deep industry expertise, will enable Steve and his team to work closely with our customers to bring value to their operation and ensure

our automation solutions help them meet their business objectives.”

As Director of Sales for the Australia and New Zealand region, Dimitrovski will bring a transformational focus to understanding customers’ unique needs and helping them understand Swisslog’s best-in-class solutions and software, including its CycloneCarrier shuttle system, ACPaQ automated mixed case palletiser, multi-temperature AutoStore solutions, ItemPiQ robotic piece picking, IntraMove AMRs and SynQ management software.

Swisslog automation experts work closely with customers to determine which solution best fits their facility constraints, operational needs and business objectives.

“I’m excited to step into this new role, where I can work with leading Australian and New Zealand companies to utilise data-driven and robotic solutions to improve throughput, optimise space, cut energy usage and enhance delivery performance,” said Dimitrovski.

“Australia and New Zealand are embracing automation as a way to solve challenges. Now that industry is readily adopting automation, the key is to think intelligently about the future and implement the right solution now to enable flexible, sustainable and scalable growth.”

Swisslog - swisslog.com

Steve Dimitrovski is the new Director of Sales for Australia and New Zealand at Swisslog

• Extended reach: Units available with reaches between 5m to 28m

• Cost effective: Reduces labour reliance and improves throughput

• Warranty coverage: Backed by a 2-year / 4000-hour warranty for reliability and performance confidence

• Enhanced safety systems: The use of safety bars, e-stops and audible beacons provide greater peace of mind for operators and businesses

FROM THE PUBLISHER

Publisher Scott Filby

Thank you to all Australian Manufacturing Awards sponsors and finalists! What a night it was!

The first Australian Manufacturing Awards is in the books, and we can all reflect on the amazing event at the Sofitel Sydney Wentworth. It was exceptional for our sector to have its name up in lights at a glamorous location and with such a successful outcome.

When I first thought of this idea, it was because I believed it was a long overdue event for our industry.

I am truly astonished that so many people outside the manufacturing industry are so unaware of how much our sector impacts their daily lives. Forget death and taxes - manufacturing is everywhere from the moment we are born to the second we die!

I have made it my personal ambition to help people understand how manufacturing intertwines with everything we do.

Two-thirds of the world would go into meltdown without their phones, but more of that another time.

For a long time, we have hidden our light under a bushel as a sector, content to put in the hard work but rarely willing to shout from the rooftops

about what manufacturing brings to Australia. That’s true in economics - and we’re still over a million workers and 5% of GDP - but also in more broad terms around innovation and progress, where our industry adds expertise and value in more intangible ways.

It was humbling and rewarding to see so many faces in the audience of people finally being rewarded.

Among that crowd were manufacturing stars that I have known for over 30 years, long-standing advertisers and friends, who backed this event wholeheartedly through sponsorship, and without whom it would simply not have been possible.

That longevity of purpose is at the core of what Industry Update does, and it was humbling to see it reflected at the Awards.

I thank all of our sponsors, advertisers, nominees and winners as well as the wider manufacturing community without whom Australia would be in deep trouble.

With a heart full of joy and pride, I say thank you to everyone!

Many faces were new to me, especially among the finalists, proving that no matter how long you have been in this game, there is always a pioneer for you to meet.

That excitement about the future is what keeps manufacturing moving forwards, at the cutting edge of the Australian economy. I thank all the finalists, and all the companies that nominated, and of course, I congratulate the winners.

Perhaps most impressive of all was Minister

for Innovation and Industry Tim Ayres, who travelled straight from trade talks in Washington DC to attend the awards..

A direct link between my table and Donald Trump’s certainly wasn’t in the planning for the Awards, and it would have been easy for Tim to pull out given the circumstances, but to see the Minister undertake such a journey to be present in front of our industry underlined both the importance of the event and the Minister’s personal commitment to manufacturing.

I thank him for that, and for his kind words. If you’ll permit me the indulgence, here are a few paragraphs.

“It makes an enormous contribution for manufacturing firms, for people interested in manufacturing policy to have somebody who’s prepared to put their heart and soul into publishing the journal, engaging with the industry, advocating for the industry, lifting the profile,” he said of me.

“It’s a really important contribution to the country, Scott, so thank you very much for that.”

For someone who has worked over 30 years in this sector, it means a lot. Manufacturing never stops, however, and neither do we.

We are already working on the 2026 Awards, which will be held in Melbourne, and I encourage anyone who wants to come onboard as a sponsor or partner to get in touch today - we have already received five sponsorship bookings which is just incredible.

Once again, a big heartfelt thank you - and long live manufacturing!

Editor Mike Wood

There’s a lot of fun to be had in this job. Working with manufacturers every day is, of course, a pleasure, as is the chance to travel all over and see the cutting edge of our industry first hand.

Few things, however, can compete with this edition’s special features.

Myself and Scott had a long, fruitful meeting with Federal Minister for Innovation and Industry Tim Ayres, a great chance to take the temperature of Australian industry with one of the most important figures in it.

There was the Awards, too, a real triumph for both Industry Update - in terms of getting that many people into a room, but also reading all the nominations, seeing so many friends in person and celebrating our great manufacturing community.

There was even a trip out to Kardex, who opened a new factory in Sydney with full Swiss regalia, including alphorns.

Cede the floor, however, for the best of the best: this edition’s St.George Bank case study special with the Cookie Man.

Yes, there’s great value for the reader in understanding how financial partners can help classic Aussie brands. There’s plenty in there on how an old name moved to the forefront of automation.

There’s even something in the chance to talk food manufacturing, one of the most important areas of our sector. But top of the list is sending humble, hungry magazine editors to biscuit factories.

I love a steel fabrication facility, a metals smelter and a heavy manufacturing plant as much as the next man, but come on: more cookies, please.

Rethinking workplace safety: From compliance to competitive advantage

Most Australian businesses approach workplace safety through the lens of compliance. Regulations set the minimum standard, and companies work to meet them.

But treating safety as just a compliance exercise can leave major blind spots and productivity opportunities on the table.

The real cost of an incident isn’t just the fine or the audit finding. It’s the downtime when a production line is halted. It’s the forklift that’s out of action. It’s the employee who doesn’t come back to work for months.

Safety failures ripple outward, hitting productivity, morale, and even customer relationships.

Forward-thinking operators are beginning to shift their approach. They’re moving beyond just compliance and starting to treat safety as a strategic driver of productivity and business resilience.

This is where integration - bringing barriers, guarding and systems together - becomes critical.

When barriers and guarding are installed reactively, one near miss

here, one compliance notice there, the result is a patchwork of fixes.

Each might address an immediate risk, but gaps inevitably remain. Worse still, uncoordinated systems can slow workflows, frustrate operators and create new bottlenecks.

By contrast, integrated safety systems address the whole environment. They separate people and vehicles at every crossing point. They secure machinery in a way that still allows efficient access. They flex and adapt as layouts evolve.

Nick O’Kane, National Sales Manager at Barrier Group, puts it simply.

“We see two kinds of facilities,” he said.

“The ones that treat safety as a necessary cost, and the ones that treat it as a performance enabler.

“The latter group has fewer disruptions, stronger morale and better productivity. Safety pays for itself when it’s done properly.”

For managers looking to reframe safety as a productivity enabler, here are three areas to prioritise:

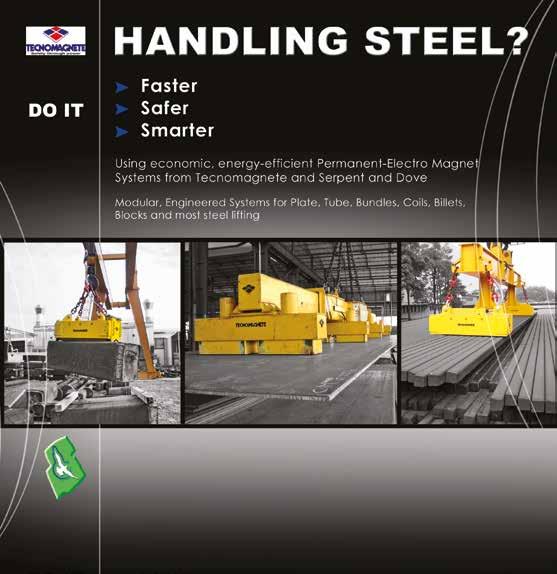

REDUCE MAINTENANCE COSTS ON OVERHEAD CRANES

1. Vehicle-Pedestrian separation

Forklifts remain one of the leading causes of workplace injuries. Vehicle incidents are the single biggest cause of workplace deaths in Australia, accounting for 42% of all worker fatalities.

That’s why physical separation between people and forklifts isn’t optional: it’s the frontline of protection. Polymer systems like FlexGuard absorb impacts, protecting both workers and assets.

2. Machine Access Control

Machinery incidents are often severe and commonly preventable. Modular guarding systems, such as ISF Machine Guarding, provide robust protection while still enabling efficient operator access. Integration with interlocks and controls ensures productivity isn’t sacrificed for safety.

3. Scalability and adaptability

Facilities evolve. A good safety system should evolve with them. Modular designs allow barriers and guarding to be reconfigured as workflows change, avoiding the sunk cost of ripping out and reinstalling outdated infrastructure.

The push toward integrated safety isn’t just best practice, it’s becoming unavoidable. As automation spreads, new collision risks emerge between people, forklifts, Automated Guided Vehicles (AGVs) and robots.

Insurers are tightening requirements, with premiums and exclusions increasingly tied to proactive guarding and controls.

At the same time, labour shortages mean retaining skilled operators can depend on providing a

visibly safe environment.

While in procurement, safety performance is now often an ESG marker: major customers routinely score and benchmark suppliers on it.

Together, these pressures make integrated safety systems not only a productivity driver, but a competitive necessity.

The value of integrated safety goes well beyond compliance:

• Reduced downtime: Fewer incidents mean fewer stoppages

• Lower costs: Damage to forklifts, racking and machinery is minimised

• Stronger reputation: Clients, insurers and regulators trust facilities that demonstrate visible, proactive safety measures

• Employee engagement: Workers who feel protected are more focused, productive and loyal.

Industrial safety is often seen as simply a compliance matter, but forward-thinking businesses see it as an asset.

By moving from a compliance mindset to an integration mindset, businesses protect not just people, but performance.

Barrier Group has been helping Australian facilities make this shift for decades, delivering turnkey solutions that combine our extensive range of safety solutions, including the FlexGuard polymer barriers and ISF Machine Guarding, into one seamless system.

Because the safest workplaces aren’t just compliant, they’re the ones best equipped to keep moving, no matter what.

Barrier Group are at the forefront of workplace safety

NSW INDUSTRY NEWS PRESENTED

INVESTMENT NSW

NSW launches strategy to create Sydney’s Silicon Valley

Acorridor of central Sydney

could become Australia’s Silicon Valley after the NSW Government announced a new strategy to bring the best in innovation to Australia.

The Tech Central Economic Development Strategy will see six square kilometres designated as ‘Tech Central’, spanning from South Eveleigh to Camperdown to Haymarket in the immediate southwest of Sydney’s CBD.

The area is already home to globally significant businesses such as Atlassian, SafetyCulture and Canva, as well as world-leading research institutions such as UTS and the University of Sydney.

The new strategy will see policies around housing, business, tourism and industry come together to attract new start-ups to the area - as well as a $5 million investment from the NSW Government to help relocations.

That cash comes on the back of $80m in the state budget for this financial year as part of the 2035 Innovation Blueprint, just less than half of which was already set for

$66m boost for

Renewables manufacturing in NSW has received a major boost thanks to a $28 million deal from the Minns Government to build a new Renewables Manufacturing Hub in Blacktown.

The investment is designed to make the state the home of renewables manufacturing in Australia, and will form just a part of a wider $66m investment, with Sell & Parker, a long-established name in the sector, to provide the other $38m in co-investment.

The cash comes out of the Renewable Manufacturing Construction Ready Stream of the NSW Government’s $480 million Net Zero Manufacturing Initiative, a major investment in domestic manufacturing capability and the transition towards Net Zero.

Around 140 people are expected to be employed over the lifetime of the project, which will create turbine anchors, torque tubes and other infrastructure items for renewable energy sources such as wind and solar.

“The Minns Labor Government

Image credit: UTS

Tech Central.

“Tech Central is already home to a thriving tech ecosystem, producing more research and inventions than anywhere else in NSW,” said Minister for Industry and Trade Anoulack Chanthivong.

“The time is now to define our vision for Tech Central’s future

– one that is supported by innovators, for innovators.

“With a world-class metro system opening the precinct to more Sydneysiders than ever, and unicorn companies like Atlassian building its new Australian HQ in the precinct, our strategy ensures we consider the whole picture – from housing to

nightlife – to secure the precinct’s success for years to come.

“The Tech Central Economic Development Strategy provides a shared roadmap for Tech Central’s future, with industry, university and government collaboration at its core.”

renewables manufacturing in Western Sydney

is driving new jobs and this new Renewables Manufacturing Hub is a perfect example of the way NSW is building the industries of the future right here at home,” said Minister for Climate Change and Energy, Penny Sharpe, at the announcement.

“This facility will not only deliver the steel components needed

for renewable energy projects across the state, but it will also strengthen Western Sydney’s role as a powerhouse of innovation and manufacturing.”

Sell & Parker have 60 years of steel manufacturing experience and are Australian-owned, with a pre-existing facility in Smithfield.

“Fast-tracking our build of steel turbine anchors, solar trackers components and transmission monopoles means we can supply more renewable projects with Aussie steel made right here in Western Sydney,” said Simon Preston, Group General Manager, Sell & Parker.

Turbine and solar manufacturing in Western Sydney has received a major boost

Swiss automation giant opens new Sydney hub to serve ANZ manufacturers

Manufacturers are rarely the kind of people to toot their own horn - so sometimes, you need someone else to do it for you.

That was the vibe at Kardex’s office opening event in Lidcombe, Sydney, where the Swiss-based brand rang in their brand new office and showroom with a full Alpine horn show and bell-ringing.

Swiss Consul General Elisabeth Bösch Malinen was on hand to cut the ribbon, while assembled guests, media and clients were given a tour of Kardex’s landmark automation infrastructure.

Industry Update was present and managed to sit down with Alan Gemmell, Kardex Head of Commercial for Kardex Remstar and Grant Smith, Director of Business Development AutoStore, to talk through the global plans and local expansion.

“We’re really proud of how we’ve come together to pull this all off,” said Smith of the office, which is the culmination of years of work.

“The collaboration between Kardex, which has been long established in the Australian market and the new division that came about in 2021 with AutoStore, gave us the ability to take a different focus.

“We probably underestimated the growth potential in the Australian market and the appetite for AutoStore in particular, but now, we have a suite of products that cater not only to those dipping their toe into automation but also to

well-established organisations.

“The most important thing is knowing where the right solution fits and that’s something we’re discovering more and more.

“There’s a real interest in the market for education - understanding how automation works for businesses, regardless of size.”

Gemmell, who travelled from Europe for the event, could reflect the universality of Kardex Remstar’s Vertical Lift Module (VLM), which continues to lead the market after several decades at the top and the breadth of industries globally that use it.

“Every year our board in Switzerland ask me if something disruptive is going to come along and replace the VLM, because it’s our cash cow,” he joked.

“The reason it’s hard to replace is that it’s so versatile.

“One of the interesting things about working with Kardex is the sheer number of industries we serve.

“For example, in the US, our number one customer is the American government - primarily the military - who buy hundreds of these each year for naval and army bases, both domestic and abroad, storing everything from food and bedding to ammunition and weapons.

“In Spain, where I’m based, we have over 500 hospitals using VLMs or VCM (Vertical Carousel Module) models for storing anything from bedding and clothing to blood samples at minus 30 degrees.

With the new Sydney office,

Kardex will be able to better apply that global expertise locally, with the necessary adaptations to ANZ market conditions.

In particular, Smith underlined how small businesses, which are more predominant in Australia and New Zealand over larger companies, could use the VLM and AutoStore products to access automation where they are, without having to go the whole hog at a huge upfront cost.

“We’ve often seen a tendency to over-automate,” he said.

“The thinking is: if you’re going to automate, go all in - automate packaging, handling and every other element.

“For smaller businesses, that’s not just unjustifiable, it’s often irrelevant. You can still gain the benefits of automation without doing everything at once.

“For instance, the first system we installed in New Zealand was over 6,300 bins. In comparison, our largest installation in Europe is 234,000 bins.

“That’s a massive difference, but it shows automation has a place in businesses of all sizes - whether that’s VLM, AutoStore or another product from our suite.

“We help take customers on that journey to assess what’s appropriate and it’s not an extensive or overwhelming process.

“Customers always want to know: what’s our value proposition? What are we doing differently?

“One of the key things we’ve focused on globally is speed to market - our ability to respond quickly and help customers make informed decisions from the outset about whether automation is the right fit.”

Gemmell added that, as a company, Kardex valued longevity in the market and products that customers could buy once and use for a long

time, with the company on hand to support throughout.

“I’ve been with Kardex for 10 years, and from a sales perspective, our quality is almost too goodcustomers don’t want to replace the machines because they still work perfectly after 30 years,” he said.

“But from a service perspective, it’s fantastic. Customers want to maintain and keep them going. That quality really sets us apart.

“Competitors may imitate, but they can’t duplicate the quality, reliability and innovation that define our solutions. That’s the Kardex difference. The VLM’s strength lies in its versatility - seamlessly adapting as customers scale, diversify, or reconfigure their product lines. From tiny components to oversized parts, the VLM stores it all. It’s modular, scalable, and a technology designed not just for today’s challenges, but for tomorrow’s growth.”

About Kardex

Kardex is a leading global partner for intralogistics solutions in an attractive and growing market. The Group offers premium automated products, standardised systems, and life cycle services that guarantee high availability and low total cost of ownership. Kardex provides an intelligent entry into automation with its dynamic storage and retrieval systems, offers integrated material handling systems, small parts storage systems, and acts as a global AutoStore partner, offering flexible and modular storage and order fulfillment solutions. The Group employs around 2,500 people in over 30 countries. Kardex Holding AG has been listed on the SIX Swiss Exchange since 1989.

Kardex - kardex.com

Swiss Consul General Elisabeth Bösch Malinen cuts the ribbon

There was a Swiss feel to the event

Australian made to last: Why quality matters to BAC Systems

At BAC Systems, we like to help customers store their tools effectively - and this means letting them know the usable storage.

With the patented BAC Modular Drawer System, BAC can help you choose your dimensions from our large range, select your drawer heights to suit your tools, and select a suitable number of drawers.

We can also offer to you a selection of toolbars for your drawers, tool clips, posts and dividers – all of which can be used to give you an ordered means to store your tools.

Australians expect longevity and value for money.

A Rollcab from BAC Systems is built with large roller bearings instead of telescopic runners - and these bearings don’t wear down for many decades, despite the tool weights in your drawers, and drawers always run smoothly and reliably.

BAC Single Drawer Locks, a thumb-operated latch on the front of the drawer, are the most reliable method for preventing a cascade-tip on your trolley, while still allowing you the freedom to choose to open

more than one drawer at a time.

The Single Drawer Lock is prominent and is reliable – you will never have a jamb!

The Rollcabs manufactured by BAC Systems, more commonly referred to as BAC Trolleys, are built to be reliable and user-friendly.

They are built to take hundreds of kilograms of tools, and to give you ready access to these instantly.

They are built to be safe, but not to hinder you with nanny-like one-drawer-at-a-time features forced upon you.

BAC Trolleys are built in Australia and offer fantastic value for money compared to the other big-name toolboxes. BAC Trolleys, most importantly, are modular and can be set-up to suit your inventory of tools and how you wish to access them.

To have a look at our range of BAC Trolleys, rollcabs, toolboxes and mobile storage solutions for your workshop, contact our BAC Technical Sales Team to arrange a free site visit to help you work out a suitable storage solution here.

BAC Systems - bacsystems.com.au

BAC Systems are a world-leading provider of cabinets, made in Western Sydney

By Bob Griffin, BAC Systems

FROM THE MINISTER

Understanding the biggest pro-manufacturing agenda in Australia’s history

The whole of my working life to date has been spent in and around Australia’s manufacturing, construction and engineering sectors.

As a trade union official with the AMWU, I advocated not just for the rights and conditions of ordinary Australians in the industrial relations context, but also for the importance of the sector as a whole in national interest terms.

I took that line with various governments and public sector regulators, because I knew that an Australia lacking in strong and resilient manufacturing capability was in fact an Australia lacking in strength and resilience, full stop.

The work that Australian apprentices, workers, supervisors, owners and investors do in the manufacturing sector really matters for the living standards of every Australian citizen.

The past few decades have been tough for this sector.

Despite the hard work, capital investment, skills upgrades and world-class research that happens every day in Australian manufacturing, there has been a tendency on the part of some to talk Australian industry down.

I’ve always resisted that, and I continue to resist it.

Because Australia’s history and geography, as well as its place in a rapidly changing world, make this country’s sovereign manufacturing capability as vital as it has ever been.

This is a really important moment for Australia. There is zero room for complacency about Australia’s capacity to meet some of the big national challenges in front of us.

The geopolitical situation is tougher than it has been at any previous moment in my adult life. The region in which we live, Southeast Asia and the Pacific, is the theatre for so much of that competition and uncertainty.

There are challenges for Australia’s economic resilience, demonstrated by the trade volatility at the moment; the imposition of tariffs on our economy and many economies around the world; subsidies in some economies that unfairly tilt the terms of trade in favour of Australia’s economic competitors.

That’s to say nothing of the challenge of decarbonising Australian industry, reducing carbon emissions in ways that enhance, rather than undermine, good blue-collar jobs in Australia’s regions.

Together, those challenges point me to a few conclusions.

First, manufacturing and industrial capability are going to be central to Australia and Australians being able to navigate our way through the next few decades.

Second, the structural decline in Australia’s industrial capability over the last two decades is nothing less than a self-imposed handicap on our ability to rise to the occasion.

The weak productivity growth, the declining diversity of Australia’s export mix, the decline in private sector investment in research and development; each of these things is driven, at least in part, by the erosion of our manufacturing sector.

Since the Albanese Labor Government came to office, we have been delivering the biggest pro-manufacturing agenda in Australia’s history.

That agenda includes $22.7 billion Future Made in Australia package, comprised of production credits, tax incentives and other measures; the National Reconstruction Fund, which involves $15 billion worth of capital for strategic investment in industries where Australia will enjoy a future competitive advantage; and the Strategic Examination of Research and Development, which will report to me on how Australia’s R&D system can get the very best value out of Australia’s smartest researchers.

And I’ve been consulting with industry on the design of the new $5 billion Net Zero Fund, which will repurpose some of the National Reconstruction Fund’s capital to crowd-in the much-needed investment that will drive electrification and emissions reduction in Australian heavy industry.

In October, I accompanied the Prime Minister on his trip to the United States. Our extraordinary and successful visit to Washington D.C. reaffirms for me that Australia’s purposeful engagements overseas have an important role to play in creating opportunities and jobs in

Minister for Industry and Science Tim Ayres

manufacturing here at home.

The core outcome of the visit was a new Critical Minerals Agreement between Australia and the United States that builds on all of Australia’s existing competitive advantages.

The Prime Minister is fond of saying that Australia has the whole periodic table underneath our feet. He’s right, of course.

This continent is rich in every sort of critical mineral that really matters in the twenty-first century economy – for clean energy and battery technologies, defence supply chains and IT manufacturing.

In addition, Australia has the world’s best wind and solar resources. And we are geographically located on the doorstep of the fastest growing markets the world has seen yet.

The agreement delivers on the promise of a Future Made in Australia by securing joint investment, from the governments of the United States and Australia – and in the case of one project, our partners in Japan as well – in new critical minerals mining and processing initiatives.

That partnership means the Alcoa workforce in Western Australia will start extracting, processing and refining gallium, a critical mineral that the world needs to produce semiconductors and to feed into defence supply chains.

It will mean that Arafura’s Nolans Rare Earths project in the Northern Territory will produce neodymium and praseodymium – key components in the powerful magnets needed in electric motors, fibre-optic cables and much else.

In sum, the agreement offers an $8.5 billion pipeline of investment, and that is just the start.

The Alcoa facility in Western Australia could be producing 10% of the world’s gallium products before long, and the Arafura project in the Northern Territory could be the source of 5% of the world’s Rare Earths.

There is a long way to go, of course. But a really strong foundation for rejuvenating regional industries, preserving good jobs and lifting Australia’s economic resilience has been laid.

The Critical Minerals Agreement shows that Australia and its partners are invested in the future of sovereign industrial capability in this part of the world.

And thanks to the manufacturing sector’s highly engaged workforce, talented managerial leadership, vocational education and training settings and its vibrant networks of ideas – Industry Update foremost among them – I have no doubt that Australian industry will rise to the challenges of the moment and turn them into opportunity.

Industrial strength solutions to keep manufacturing workspaces clean

In manufacturing environments, performance and safety go hand in hand. While equipment maintenance and staff training are key to a safe and efficient workplace, cleaning often plays an underestimated role.

Oil spills, grease, rusted surfaces and hard water build up aren’t just unsightly, they’re hazards that can cause injuries or equipment downtime.

The importance of equipment reliability and maintenance lies in ensuring consistent productivity, minimising costly downtime and safeguarding both workers and assets from preventable failures.

According to Safe Work Australia, slips, trips and falls remain one of the leading causes of workplace injuries, responsible for more than 21% of serious claims - over 30,000 2 preventable incidents each year.

In workshops and factory floors where oily surfaces are common,

the right cleaning solutions can help minimise these risks while supporting productivity.

Trusted by Australian industries for decades, CLR offers two multi-purpose cleaning solutions designed to handle the toughest grime without introducing new hazards.

Surface rust, calcium and mineral deposits can compromise equipment and infrastructure over time.

CLR Calcium, Limescale & Rust Remover is a powerful industrial strength solution that is formulated to dissolve rust, oxidation and limescale, making it ideal for sinks, wash bays, glass and metal surfaces.

Its antibacterial action kills 99.9% of germs, and also tackles algae, soap scum and fibreglass yellowing, delivering a cleaner, safer workspace.

Recognised under the EPA’s Safer Choice Program, CLR’s phosphate-free, bleach and ammonia-free, biodegradable formula provides

Multi-Purpose

heavy-duty cleaning performance while supporting safer and more sustainable workplace practices.

CLR Grease & Oil Remover is a fast-acting, industrial-strength cleaner that cuts through grease, oil, tar and built-up grime on floors, driveways, engines, machinery and tools.

The non-flammable, non-acidic, solvent-free formula makes it safe for use in enclosed spaces where fumes could endanger workers.

Simply apply, allow to rest for five minutes, scrub, then rinse with cool water for a clean surface that reduces slip risk.

Proudly made in Australia, CLR’s range is engineered for diverse manufacturing environments, from mechanical and automotive workshops to fabrication and processing facilities. By combining industrial-grade performance with safer chemistry, CLR helps maintenance teams reduce hazards, minimise cleaning time and maintain compliance with workplace safety standards, helping to keep productivity on track.

CLR - clrclean.com.au

Calcium Limescale & Rust Remover can help prevent workplace accidents

Return of the Cookie Man: How an Aussie favourite came roaring back

Cookie Man was once a fixture of Australian life, a family favourite with retail outlets across the country dating back to 1958.

The famous brand disappeared from shopping centres over a decade ago, but thanks to ingenuity, supportive finance and - surprisingly - a global pandemic, they have returned stronger than ever, with a plan to grow bigger than ever before.

In fact, thanks to smart strategic thinking, it’s possible that Cookie Man products are now more widely consumed, not to mention more profitable, than at any point since they hit the market more than half a century ago.

Industry Update travelled out to their manufacturing facility in Mount Kuring-gai to learn how the Cookie Man came back - and how St.George Bank helped them to revive an Australian favourite.

“Cookie Man has been around since 1958, so it’s not a new business - though most people think of it as one,” explained Michael Elligett, Managing Director at Cookie Man.

“Originally, it was a retail business, franchised across shopping centres around the country. At its peak in 2008–09, we had 60 or 70 stores.

“Then Mrs. Fields bought Cookie Man and converted all of the stores into Mrs. Fields locations, effectively retiring the Cookie Man brand.”

The name lay dormant for a decade, until the unlikely intervention of the pandemic - not to mention some gold old-fashioned manufacturing smarts - helped kickstart it back to life.

“In 2020, I developed a plan to relaunch Cookie Man as a wholesale business, selling into supermarkets, petrol and convenience (P&C), export markets, anywhere we could

took a chance on us, even though the brand hadn’t been in the market for ten years.

“They launched two SKUs into their in-store bakery section. That’s where the modern Cookie Man began again.”

Alongside the Cookie Man throughout was St.George Bank. They were able to see the potential, provide the financing and understand the challenges that would come along the way.

“After relaunching Cookie Man, we were almost debt free, but we were growing fast and needed help to sustain that growth. That’s where St.George came in,” said Elligett.

“With our previous bank, it didn’t feel like a partnership. With St.George, it wasn’t just lip servicethey followed through.

“I’d only dealt with one bank in 15 years, so I assumed all banks worked the same. This was different.

“St.George sat down with us and genuinely worked out what the business needed to grow. It wasn’t about fitting into a pre-built box, it was about tailoring solutions to suit our operations.

“Our previous bank didn’t understand manufacturing. With St.George, I didn’t have to teach someone how manufacturing works for them to understand our business case. The story and the numbers aligned.”

The support and financing enabled a three-fold growth in turnover, as well as a huge expansion in automation that can help sustain that success long into the future.

apart from retail,” said Elligett.

“The vision was to diversify. We were heavily reliant on the franchise model and had a factory with a huge amount of underused capacity.

“I had everything ready to relaunch in March 2020 - then COVID hit. Oddly enough, it gave us the opportunity to relaunch properly. We had no retail to run when everything was shut down, so we had time to redevelop the Cookie Man brand and innovate.

“We developed our “loaded cookie” product, a high-inclusion, indulgent cookie with fillings and extras like choc chips or nuts. That became our game changer.

“We worked out how to automate it during COVID, partnering with equipment manufacturers and mechanics to figure it out.

“By the end of the pandemic, we launched with a fresh, innovative line we could scale. Woolworths

“Initially, when we were only supplying our own retail stores, automation was minimal,” explained Elligett.

“We relied heavily on manual processes, with much of our equipment over 40 years old.

“The first step was modernisation, then as St.George came on board, we moved into automation.

“In the cookie space, automation can be tricky, but we went from manually handling every product to running full lines where no human touches a cookie until it’s on the retail shelf.

“In the last six months, we’ve doubled the size of our facility. We were bursting at the seams, and St.George supported us in that expansion.

“Our next goal is to go to $50 million turnover in five years - we’ve got the capacity, and we’ve got the backing from St.George Bank.”

St.George Bank - stgeorge.com.au

The Cookie Man are back - with help from St.George Bank

Tente underline commitment to manufacturing mobility with Foot Master addition

Combining movement with stability has been a long-standing problem in industrial and technical settings - but industry staple Tente might have a solution that fits all uses.

They have added Foot Master levelling castors to their range, providing a practical answer by integrating a transport wheel with a stabilising foot for optimal functionality.

These castors allow heavy or sensitive equipment to be rolled into position with ease. Once in place, the levelling foot lowers to the ground, creating a secure, vibration-free base.

This mechanism ensures precision, prevents unwanted movement, and safeguards delicate machinery from misalignment. Their versatility has made them a trusted choice across industries. Laboratories rely on them to keep

instruments steady, workshops use them to support machinery, and healthcare facilities benefit from their mobility and safety. By reducing the effort needed to reposition equipment, they also improve workplace ergonomics and efficiency.

What sets Foot Master apart is its consistent focus on quality engineering. Constructed with robust materials and designed for longterm performance, their levelling castors balance durability with ease of use.

For businesses seeking adaptability without compromise, Foot Master levelling castors represent more than just a component - they are an essential tool that redefines the relationship between mobility and stability.

Tente - tente.com.au

Foot Master levelling castors are now

Everything manufacturers need to know about SBR

By Sean Wengel, Partner Restructuring & Insolvency and Helen Ali-Haapala, Senior Manager Restructuring & Insolvency

It is no secret that business insolvencies in Australia have been on the rise since the COVID relief measures were rolled back by Federal and State Governments after the pandemic.

Insolvency numbers would have been much higher had the Government not introduced a groundbreaking new debt relief measure during that period, the Small Business Restructure (SBR).

Four and a half years after the introduction of SBRs into the Corporations Act 2001, the Australian Securities and Investments Commission (ASIC) has released a report card on the regime, Report 810 Review of small business restructuring process: 2022-2024.

Looking into 3,388 SBR commencements since July 2022 (ASIC Review Period) the report has found that SBRs play an important role in assisting struggling small businesses to survive.

What is an SBR?

This initiative offers a fresh approach to insolvency, allowing company directors to maintain control while working with creditors to develop a plan for settling existing creditor debts and ensuring the continuity of the business operations.

A qualified Restructuring Practitioner (an ASIC Registered Liquidator) is engaged by the struggling company to review its financial position, put a pause on debt collection actions by creditors, and make an offer to creditors that will give them a better financial outcome than if the company were to simply liquidate.

In circumstances where financial pressures might typically signal the end of a business, SBR offers a lifeline for eligible businesses, enabling them to restructure their debts and operations under the expert guidance of a Restructuring Practitioner.

When to consider an SBR

The circumstances that may give rise to an SBR appointment can include a loss of key customers, significant bad debt exposure and other unexpected, out-of-the-ordinary events affecting the company’s profitability and cashflow.

To qualify for the SBR program, businesses must meet certain criteria:

• Total debts must be under $1 million.

• There must be sufficient compliance with taxation lodgement obligations, with payment of all tax debts not a requirement.

• Employee entitlements, including superannuation guarantee amounts, must be up to date.

• Current or recent company directors must not have participated in an SBR within the past seven years.

How does Small Business Restructuring work?

The SBR process is quick, taking 35 business days from the date of appointment of the Restructuring Practitioner to the final date for approval of the restructuring plan by creditors. If needed, this period can be extended by an additional 10 business days.

The proposed plan for a business restructure could be designed in various ways, such as through future trade contributions, debt or equity contributions.

However, upfront cash payments to creditors with a clear timeframe for payment are often the most appealing, as they provide a quick resolution and reduce the risk associated with longer term proposals.

How successful are SBRs?

The recent ASIC report into SBRs found that, of the SBR restructuring plans that commenced during the ASIC Review Period, 87% were

WilliamBuck can assist with all manufacturing accountancy needs

approved.

This success rate is encouraging for companies that are struggling under unmanageable debt and considering whether to explore their eligibility for an SBR.

93% of the companies that fulfilled their commitments under a restructuring plan remained registered as at 30 April 2025.

This is a ringing endorsement for the success of the regime and should encourage companies considering an SBR to put forward a realistic plan to creditors that they can fulfil.

Choosing an appropriately qualified and reputable Restructuring Practitioner is important to ensure that the highest chance of success is realised when putting a restructuring plan together.

It is important to choose a practitioner that can quickly understand your business, can formulate a unique plan to suit your circumstances and who knows how to communicate with your specific creditors.

In the ASIC review period, only 46% of Registered Liquidators took an SBR role – so not every liquidator is experienced in this type of engagement.

Tax debts

It is important to note that appointing a Restructuring Practitioner is a valid response to a non-lockdown Director Penalty Notice, or DPN,

issued by the ATO. This action allows directors to avoid personal liability for tax debts.

During the ASIC Review Period around 87% of funds distributed and categorised as unsecured creditor payments was paid to the ATO (approximately $88 million). The median dividend rate was 20 cents in the dollar (average: 21 cents in the dollar).

This insight shows us that the ATO was by far the largest creditor and on average they agreed to accept plans proposing 20 cents in the dollar as full and final satisfaction of their debt.

In just over four years SBRs have evolved as a very effective tool for struggling businesses to be given a lifeline, a second chance at making it work.

With the right advice and a realistic SBR restructuring plan in place there is a high likelihood that unmanageable debt will become a thing of the past and business owners can put their resources back into what they do best and focus on the future.

Contact your local William Buck Restructuring and Insolvency advisor if you would like any further advice on the Small Business Restructuring Regime.

William Buck Australia williambuck.com

The final frontier for manufacturing set for lift off after landmark deal

Western Sydney is set to become a centre of space manufacturing in Australia after the signing of a new partnership between the NSW Government, the Bradfield Development Authority (BDA) and leading Australian space technology business Space Machines Company (SMC).

The Rapid Australian Production & Integration for Distributed Space (RAPID) agreement will place the Advanced Manufacturing Readiness Facility (AMRF) in the new suburb of Bradfield at the heart of NSW’s space industry, bringing high-paid jobs and inward investment with it.

Under the provisions of the partnership, it is expected that the SMC will use the capacity of the AMRF to build 30 units per year, which could triple or more by the end of the decade.

SMC produce satellites which can help repair other satellites which are already in space, and, thanks to this deal, hope to be able to manufacture them at scale in the Second Building - next to the current First Building in Bradfield - as part of a

new Hyperscale Satellite Production Facility.

“Western Sydney is the ideal location to establish Australia’s sovereign space manufacturing capability,” said Rajat Kulshrestha, CEO of SMC.

“Through our partnership with BDA and the AMRF, we are not just building satellites – we’re creating the critical infrastructure that will safeguard space for Australia and our allies.

“Space production at scale is essential for national security in the modern era. This partnership enables us to build from tens of spacecraft annually and scale toward producing hundreds by 2030, giving Australia and allied nations the rapid response capabilities essential for protecting our critical space infrastructure.

“As space becomes increasingly contested, having sovereign manufacturing capability ensures we can both defend our interests and protect the space-based systems that underpin our modern way of life.”

The partnership was heralded by the Minns Government as a key

pillar in the sovereign space manufacturing capacity of both NSW and Australia, as well as a new pathway for global space technology to be made in Western Sydney.

“This agreement is part of growing Bradfield’s role as Australia’s new high-tech manufacturing and advanced industries capital,” said BDA CEO and AMRF Chair Ken Morrison.

“The Second Building will be a cornerstone of this transformation, enabling advanced semiconductor packaging and micro-electronic capabilities that are critical not only for satellite production, but for the broader space ecosystem we’re building here in Western Sydney.

“By fostering collaboration between industry, researchers, and Government, we’re laying the foundation for sovereign space capability and positioning Bradfield as a global hub for innovation, resilience and economic growth.”

Advanced Manufacturing Readiness Facility (AMRF) amrf.sydney

Western Sydney is set to become Australia’s space manufacturing hub

The Second Building will be the centre of the AMRF’s space programme.

Have a problem to solve or innovative idea?

The Advanced Manufacturing Readiness Facility (AMRF) is where ideas find momentum.

Located in the heart of Bradfield City’s innovation-enabled ecosystem purpose built for collaboration, the AMRF helps turn potential into progress and drive business growth. It’s where industry, research and imagination come together to shape the future of Australian manufacturing. Here, you can test, trial and transform with confidence, guided by world-class expertise and powered by advanced technology.

At the AMRF, innovation isn’t reserved for the few. It’s where every organisation with a bold idea can scale and create what’s next.

amrf.sydney nsw.gov.au/bradfield

Australian Manufacturing Awards winners revealed at gala event

company present, picking up two separate awards in the Best Medium Business and Best Regional Manufacturer categories.

Other notable victors were Packserv, who scooped the Best Small Business Award, and the Aluminium Revolutionary Chassis Company, who won the prestigious Australian Made Award.

“These Awards were designed to recognise the huge impact that manufacturing has on the Australian economy,” said Scott Filby, Publisher of Australia’s largest circulating manufacturing magazine, Industry Update, organisers of the Australian Manufacturing Awards.

“To see so many people in the room enjoying themselves and celebrating our industry was truly inspiring.

“Industry Update started these Awards to shine much needed light on our sector, and from day one, we knew they would be a success.

“The reception from industry in terms of sponsorship, then in nominations and finally tonight in attending the event only vindicates the decision further.

“I would like to thank our sponsors, our independent judging panel and our event team - and to congratulate all of our winners!”

Let’s talk.

Quality, Service & Delivery

AUSTRALIAN MANUFACTURING AWARDS 2025

The amazing story behind the Australian Manufacturing Awards trophy

The Australian Manufacturing Awards (AMA) were a groundbreaking event for the manufacturing industry, and required a suitably spectacular statue to mark the occasion.

That’s why Industry Update called in the experts to make a trophy that not only looked great, but also meant something significant to our sector.

The AMA Trophy is designed and printed by the Advanced Manufacturing Readiness Facility (AMRF), based in the new city of Bradfield, using the most advanced printing and design techniques to showcase the capabilities present at their First Building site in Western Sydney.

The AMRF exists to help manufacturers to accelerate their research and development, providing a crucial link between design and market, offering businesses the chance to enhance productivity and speed to market by accessing the most modern and advanced manufacturing capabilities available in Australia.

The internal structure incorporates a body-centered cubic (BCC) unit cell. The cell map, which defines the layout of where each unit cell

within a lattice will go, conforms to the curves of the helix geometry.

Each award was designed in nTop and Solidworks software, produced from Inconel 625 supplied from Tekna, programmed with Autodesk NetFabb, processed using the Additive Industries MetalFab Metal 3D Printer, and sliced with a Fanuc Robocut Wire EDM.

“It’s exciting to partner with Industry Update to produce the 2025 awards, designed and manufactured entirely in-house at the AMRF,” said AMRF Director of Manufacturing Technology Steve Milanoski.

“The design was inspired by the distinctive helix geometry seen in drilling and milling - a product that with each iteration unlocks new levels of productivity for manufacturing.

“The concept pays tribute to this simple tool while showcasing the innovation and complexity made possible through emerging manufacturing methods such as metal additive manufacturing.

Industry Update provided a brief to create a trophy that represented the complexities of manufacturing,

but also the inherent similarities that every manufacturer will recognise from their own processes.

“We didn’t just want a trophy for the winners - we wanted a story, a piece of manufacturing art that nodded to both the past of manufacturing and the future of the industry,” said Scott Filby, Publisher of Industry Update.

“The AMRF is one of the most

exciting developments in the NSW manufacturing sector that I have seen in 30 years of working in the sector in the state, so to partner with them and show off the amazing things that they can do was a perfect opportunity for our first Awards.

“We’re so excited to show the trophies off - and to see the faces of the winners when they pick one up!”

The Australian Manufacturing Awards trophies are here!

AUSTRALIAN MANUFACTURING AWARDS 2025

Gold Award for Excellence in Manufacturing

Winner: Dave Vinther, Moduplay Group

Sponsor

Finalists

• Automation Engineering Services - Tony Vercoe

• Camcast - Troy Rath

• Lindner Quality Socks - Andrew Lindner

• Moduplay Group - Dave Vinther

Manufacturer of the Year

Winner: Eilback Cranes

Sponsor

Finalists

• Apollo Engineering

• Nissan Casting

• Plasser Australia

• Southern Ocean Subsea

• Tindo

• Eilbeck Cranes

AUSTRALIAN MANUFACTURING AWARDS 2025

Australian Made Award Innovation Award

Winner: Aluminium Revolutionary Chassis Company

Winner: Innovate Ag Finalists

•

AMTIL Advanced Manufacturing Award

Winner: BlockTexx

Safety Award

Winner: McNeall Plastics

AUSTRALIAN MANUFACTURING AWARDS 2025

AUSTRALIAN MANUFACTURING AWARDS 2025

Why getting your bearings in-person still makes all the difference

Why sourcing your bearings still needs the personal touch.

Manufacturing can often seem to be an increasingly automated process.

While that can be convenient, it can also miss out on the nuances that can make or break a purchase, especially in the critical manufacturing sector.

Industry has traditionally relied upon Part Numbers, prefixes, suffixes and brand lines to ensure correct supply - but a more hands on relationship with your supplier is always recommended.

Action Bearings, who have been in the game for 50 years, have noticed the shift since Covid that has occurred with customers increasingly buying product online.

Their business can boast welltrained, experienced staff and an ability to match products to processes as a result of in-field history.

Our industry has become smaller with an online presence,” said Jason Bradley, Director at Action Bearings.

“We want people to know that there’s someone on the other end of the phone who wants to help and has the reliable information required, at their fingertips.

“Nearly all of our guys at both our branches have had 20 years of experience in the bearing industry.

“We’re finding that instead of trying to get into a generic, pricedriven space, we want to be a place

where people can come and get help, and have someone on the end of the phone who knows what they’re talking about.

Action have found that their expertise has been able to move with the times, dialling in knowledge on their own products and using that to help customers solve increasingly complex technical problems.

“From where we started - just being a bearing company - we’ve expanded into the automation area,” said Bradley.

“We haven’t gone outside of what we’re experts in. We don’t sell tools and bolts. We’re generally a bearing service company, with an add-on for some aluminium profiles and anything that’s going to be automated in the future.

“We’ve geared ourselves around that, and all of our staff have been trained accordingly. So the person on the end of the phone knows what they’re selling. They’re not guessing.”

That expertise has enabled Action to get a jump on bigger companies you can offer more products, but have less ability to find the correct one for their clients, particularly in manufacturing where needs are constantly bespoke.

“The Australian market has shrunk, the manufacturing market has shrunk and there’s not as many orders as there once were,” said Bradley.

“We’ve found that the big multinationals have now decided that, to

either increase turnover or increase sales, they’ve opened the market to a lot of players.

“Where it was once important to be a distributor of a particular brand, now nearly everyone in the industry now has access to three, four, five, six, even seven brands. There’s no brand loyalty anymore.

“A lot of bearing companies have seen the market disappear and they’ve tried to get into other markets.

“Whether it’s selling tools, nuts, bolts - they want to become basically a Bunnings for bearings.

“We’re more an old-school “pick up the phone and talk to someone” type of business. We design, build and install - and follow the project right from its initial concept through to the end.

“Our hands are on it the whole way and work with the customer and their requirements to meet whatever their needs are.”

That approach allows Action to function across multiple industries in the manufacturing sector, from food & beverage to pharma and beyond.

Their niche and bespoke approach can help reduce downtime, and sometimes even save machinery that otherwise would have had to be replaced entirely.

“In the bearing industry, the bigger services are basically only in Queensland and WA for mining - that’s the bulk of the bearing

industry,” explains Bradley.

“The rest of it is in food, pharmaceuticals, which are much smaller in scale. You don’t see the volume you would see out of Western Australia or Queensland from mining.

“For food and pharmaceuticals, we specialise in self-lube stainless steel bearings that are used in washdown areas.

“In the foam and plastics industry, we’ve built whole conveyor lines. There’s a lot of pick-and-place and automation work.

“In injection moulding, the buckets come out and need to be picked, packed and placed. We’ve supplied linear robots and cobots as well as conveyors.

“Sometimes there’s a breakdown and they can’t replace something - for example, motors and pumps are often throwaway items in some industries - but in others, where the gearboxes are larger and cost more to replace, they have to be rebuiltwe can come in. We can identify and replace a part pretty much straight away.”

Action Bearings can be found at either of their Victorian locations: 48 Industrial Drive in Braeside or Unit 5, Cnr Arden & Lloyd St in Kensington.

Action Bearings actionbearings.com.au

Action Bearings are all about the personal touch

Raising the standard in efficiency in the logistics sector

The logistics sector across Australia and New Zealand continues to evolve under the influence of e-commerce growth, labour availability and increasing compliance requirements.

With over a billion parcels delivered across Australia each year, these factors are encouraging businesses to look closely at how they manage loading and unloading trucks and containers, a stage of the supply chain that remains both labour-intensive and high-risk.

Adept Conveyors see this as an area where measurable improvements to efficiency can be achieved.

To support this, they have partnered exclusively with ConveyXpress, a global specialist in telescopic conveyor technology.

Telescopic conveyors extend directly into trucks or containers, helping to reduce unnecessary product movement and manual handling while shortening vehicle turnaround times.

More importantly, the technology continues to develop in ways that

address the operational, safety and compliance priorities of modern logistics.

Key Advancements

• Extended reach

Units available with reach between 5m to 28m.

• Enhanced safety systems

The use of safety bars, e-stops and audible beacons provide greater peace of mind for operators and businesses.

• Cost effectiveness Reduces labour reliance and improves throughput, to deliver strong long-term ROI.

• Warranty coverage

Backed by a 2-year or 4000-hour warranty for reliability and performance confidence.

• High quality components

Exclusively uses high quality components, including Nord Drive units and Schneider Inverters

• Integrator-friendly

Designed for seamless parcel handling and easy deployment within broader automated systems. The benefits are tangible: faster

dock operations, safer working environments and more consistent product flow.

For consultants, integrators and logistics operators, telescopic conveyors offer an opportunity to design facilities that are more efficient and better aligned with evolving industry requirements.

As the sole importer and distributor of ConveyXpress telescopic conveyors in Australia and New Zealand, Adept Conveyors is committed to more than supplying equipment.

They work closely with customers to support smarter logistics strategies, enabling technology that helps operations run more safely, efficiently and reliably.

Loading and unloading is a critical part of the supply chain – and by applying the right technology, it can also become a key source of operational improvement.

Adept Conveyors adeptconveyor.com.au

Adept Conveyors are efficiency experts

MOTORS & DRIVES

Aussie expansion, global backing with SEW-Eurodrive

Motors and drives keep manufacturing running - and if you’re in the business of keeping them going, then you probably know SEW-Eurodrive.

They’re not only one of the world’s leading names in drives, but also one of Australia’s fastest growing.

Already a huge player in the sector, they’ve superpowered that in the last few years with a string of expansions designed to get their services and products closer to the end users, adding convenience and expertise where it is needed most.

In the last 12 months, SEWEurodrive have opened new facilities in both South Australia and Queensland, complementing their existing network of sites that covers all major manufacturing and mining centres.

Industry Update has followed their entire expansion journey, and sat down with Rob Merola, Managing Director of SEW-Eurodrive Australia, to reflect on a huge period in the company’s history.

“Our most recent journey when it comes to investment has occurred during and since COVID,” he said.

“During that period, we were extremely busy. We remained open because we were considered an essential service - providing drives and servicing for food and beverage, which was critical at the time. Downtime was not an option.

“We had the privilege of working through that period without losing a

single day. Due to the large inventory we’ve always kept, we became even busier.

“As other supply chains dried up, more people came to us. We were selling everything off the shelf - even the slow-moving items that hadn’t sold in years. Business wide, it was an amazing period.

“Since then, as normality has returned and supply chains have improved, we’ve become a bit slower. Competitors have product to sell again, and they’re trying to reassert themselves in plants and installations they missed out on recently.

“Business has become cutthroat, competitive and political. That’s not a bad thing - it keeps us sharp.

“During that time, we decided to invest strongly in service. We saw a large gap in the market with service levels.

“Many of our competitors don’t provide anywhere near the levels of service we’ve offered for over 40 years. So our investments went into new service facilities - servicing everything from small geared motors right through to large mining-sector drives.

“In fact, we began servicing our competitors’ drives, which were neglected. That built rapport and credibility.

“When those drives reached the end of their serviceable life, we were able to offer bespoke, drop-in replacement units. That’s been a growing part of the business.”

facilities there as well. That site has also gained strong traction since opening nearly a year ago.

“In Melbourne, we’re spacepoor, so we’ve leased two buildings around the corner in Tullamarine. They’re also at full capacity.

“So we haven’t been sitting on our hands for the last few years. We’ve spent tens of millions of dollars solidifying our position as the optimal service provider in the industrial gear market.

“We must be where our customers are. We must deliver what they want, when they want it.”

This expansion has not gone unnoticed. SEW-Eurodrive is a huge global company with 5,000+ employees at the headquarters in Germany alone.

Now, their Australian division is being used as a poster child for successful growth with smart strategic underpinning.

That was the start, and SEWEurodrive took the initiative and run with it.

“To do all this service work, the formula is simple: you need space and you need people. So we started by acquiring or building space,” said Merola.

“We set up in Mackay around seven or eight years ago - that was our pilot project for the service model. It was an instant success. The original plant was around 1800 square metres, and we recently added another 1000 square metres, which is already nearing capacity.

“The biggest problem isn’t the space - it’s finding good, competent people. Sadly, it’s a boom or bust cycle in the mining sector.

“When resource prices are high, mines throw obscene salaries at people, and they chase the money.

“They become like mercenaries - working two or three years, then disappearing when a bust hits. Then they come looking for jobs with companies like SEW-Eurodrive again. That’s the nature of the beast.

“In the last few years, we’ve also built a new dedicated service facility in Newcastle - three and a half thousand square metres - which has gained traction quickly. We installed load testing facilities in both Mackay and Newcastle.

“Then we set our sights on Adelaide. We purchased an old, rundown facility in Wingfield and refurbished it, installing load testing

“SEW-Eurodrive globally has always followed the model of centralised manufacturing with decentralised assembly. We’ve applied that same model to service,” explained Merola.

“In Australia, I believe we’re cutting edge - world leaders within SEW-Eurodrive in terms of industrial gear service. No other country in the group has the network we do or does what we do.

“We punch well above our weight for a small country of 27 million. We probably represent only 2-2.5% of the global turnover - yet we’re leading in many ways.

“They (the global team) have been incredibly supportive. The confidence and backing we’ve received for our business plans and investment requests has been amazing.

“Our business cases stack up. Everything we’ve planned and delivered has been successful - no white elephants.

The expansion is getting huge buy-in from the bosses back in Europe - and there might be more to come.

“With a track record like that, it’s hard for them to say no,” said Merola.

“They know Australia is a unique market - because of our natural resources and the number of industrial gears being used and sold here. So yes, we’ve delivered - and the results speak for themselves.”

SEW-Eurodrive sew-eurodrive.com.au

SEW Eurodrive have undergone a massive expansion

SEW-Eurodrive celebrating as another new facility opens

This has been a huge year for SEW-Eurodrive - and it’s about to get even bigger with the opening of another new location.

Fresh on the back of an expansion to activities in South Australia thanks to a site in Wingfield that was launched at the start of the year, the company will end 2025 with a second ribbon-cutting ceremony, this time at Bundamba in Queensland.

The official event is scheduled for October 24, but the team has been on site amid the building work for several months, after taking ownership last year and then supervising a complete re-fit to suit SEW’s purposes.

“It was a new building, not purpose-built for us, so we’ve retrofitted it, installed all the new assembly lines, refurbished the cranes, extended the office space to cater for more staff,” explained Jason Forrester, Queensland Sales Manager at SEW-Eurodrive.

“Over the last 12 months, we’ve been balancing the upgrade while also working out of the facility. The plan is to have it all up and fully functional by the official opening in October.

“A lot of the credit - basically all the credit - has to go to our operations manager Chris Jarvis. He’s the one who’s been driving and project managing this upgrade from start to finish.

“We’ve been working out of the same facility. We moved into the facility in December and basically had to work around the works being done.

“It was all very cosy while the office was being extended, but now that it is complete, we’ve added about 400 square metres of office space to cater for all our different divisions and teams here in Brisbane.

Located on the outskirts of the city, close to Ipswich, the building is just over 4,400 square metres in total with about 800 square metres of office space available, which should enable greater manufacturing capability and service offering, while also lowering turnaround times for in-state customers.

“The fundamental purpose of our Bundamba facility is to increase our capability of building our standard product line of gearmotors - to be able to service Queensland from Queensland for all new builds, end

users and OEMs,” said Forrester.

“Basically, any industry that requires a standard gearmotor with a short lead time, we can now facilitate.

That is good news for the diverse client base that SEW-Eurodrive services.

“Here in Queensland, most of our clientele are end users in the food and beverage industry,” said Forrester.

“As you can imagine, downtime for them is critical. Having a local gearbox company that can assemble a gearbox within 24 hours - or even

within a couple of hours in some cases - and get their machines back up and running, that’s what we’re here for.

“That’s how we differentiate ourselves from some of the other manufacturers who have their assembly facilities in New South Wales or Melbourne. Their products have to be transported up here. We don’t have to worry about that now.”

SEW-Eurodrive sew-eurodrive.com.au

Quality, Service & Availability

SEW-Eurodrive’s new facility in Bundamba, Queensland

MOTORS & DRIVES

How Deprag’s technology keeps manufacturing motoring along

On mine sites and industrial areas, with wet, dirty or explosive environments are unavoidable, air motors provide an ideal solution. Pneumatic motors are also perfect for high start or stall torque as required.

Compact air motors run cool, are available in sealed versions and many have ATEX approvals for use in hazardous areas.

Despite the vast performance offerings, sealed or ATEX approved electric motors can be expensive and are often much larger than standard pneumatic motors. Unfortunately, air motors have some design challenges.

Typical air motor systems can be expensive to run on long duty cycles - a typical 1kW vane powered air motor would need a 10kW compressor to run continuously. The energy costs can be very significant over time.

Another issue of using an air motor to drive these applications is that air motors’ load specifications are rated at half of their idle speed. If there is no load on the equipment, a vane motor will run at

twice its rated speed, and the air consumption will increase to 130% of the rated consumption. This high speed can damage the pump, conveyor, mixer and even the motor. When using a pneumatic vane motor on this type of equipment, operators need to ensure that the motor is always under load or decide how to handle the low-load situation.

Another disadvantage of vane motors is that they require regular maintenance and larger motors need lubrication.

Assembly Technologies: a proud supplier of Deprag pneumatic motors for over 19 years

Deprag, originally from Germany, has over 80 years of experience in air motor design and manufacture, addressing and improving upon all the limitations of typical air motor systems.

Since they entered the industry, industrial air motors have developed from piston motors to the current, modern vane motors - and now,

Deprag is pioneering industry-leading new technology to revolutionise the air motor industry.

Their new range of ATEX approved turbine powered air motors offer a significantly more efficient solution to the standard vane motors.