ing industry’s night of nights.

There are 22 awards up for grabs, with a rigorous judging system ready to

ing industry’s night of nights.

There are 22 awards up for grabs, with a rigorous judging system ready to

assess nominations as they come in.

Tickets for the event are now available with an Early Bird discount of 10% and can be purchased directly from

Industry Update, who turn 30 this year, have organised the Awards to celebrate the best and brightest of the manufacturing industry in the last 12 months.

Judging will be independent and conducted in association with the University of Technology Sydney (UTS), who have convened a panel of experts from across business, academia, peak bodies and government to scrutinise nominations.

Continues on page 10

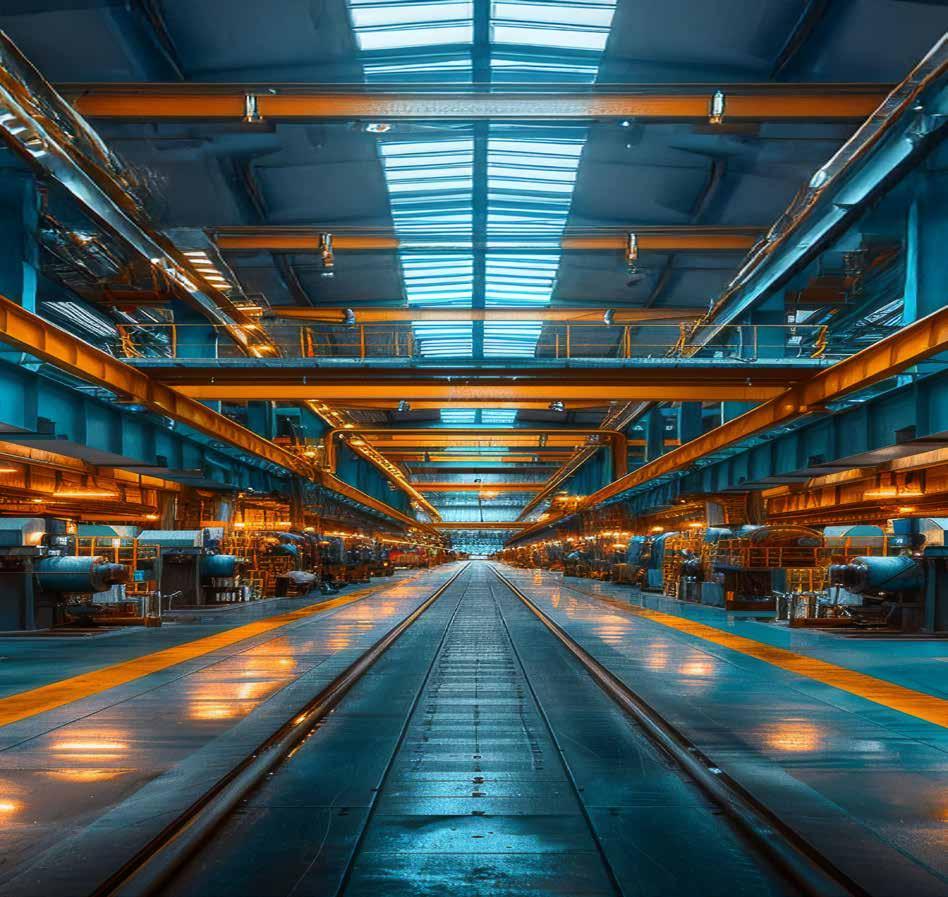

xcitement is building ahead of CeMAT Australia 2025, as Sydney Olympic Park prepares to welcome the region’s most comprehensive gathering for the intralogistics, supply chain, manufacturing and packaging sectors.

Held from July 22–24, the event returns bigger than ever, featuring the flagship CeMAT Australia show alongside the debut of Industrial Transformation Australia (ITA), a dedicated zone for Industry 4.0, digital manufacturing and smart factory solutions, as well as the Continues on page 28

US President Donald Trump’s tariff policies have sent shockwaves across the global economy - and the Australian manufacturing industry is feeling the ripples.

While our domestic sector has been hit directly by some of the tariffs, particularly around food exports and metals, we have mostly been subject to secondary impacts around supply chain disruptions and global commodity prices.

The main target is China, and for Australia, that can be an opportunity. In the last Trump presidency, our nation was positioned as a friendly partner to both sides of the trade war,

Continues on page 43

Reduce system downtime with more accurate measurement of critical flow and temperature conditions with the FS+ sensor from Turck. Detect leaks or blockages with this easy-to-use sensor. Not only does the FS+ measure the flow rate of liquids in pipes, it also monitors temperature. Plus, no moving parts or rotating sensor components reduce the chance of failure or introducing contamination into the system.

• Accurate and easy to use

• Rated to IP69K for harsh conditions

• Rugged, rotatable stainless-steel housing

• Switching or analog outputs

• Long lasting - no moving parts to wear out

Contact your local Turck sales representative to learn more.

In the ever-evolving landscape of industrial machinery, Chicago

Pneumatic has once again set a new benchmark with their latest innovation – the CPVS 75-120 oil-injected screw compressor.

This compressor, ranging from 55 to 90 kW, is the result of dedicated investments in research and development, as well as in-house developed key components.

At the heart of the CPVS range lies an in-house designed compression element, paired with an IE4 efficiency motor.

This powerful combination not only enhances performance but also ensures lower compression temperatures and unparalleled reliability.

These compressors are designed to thrive in environments with ambient temperatures of up to 46°C thanks to superior component design.

Integrated dryers are available across the entire industrial range. For units equipped with an integrated dryer, an internal water separator is also included in the air cooler, ensuring optimal performance and efficiency.

The new generation compression element, crafted in Belgium, provides superior performance and improved capabilities.

With improved volumetric efficiency and reduced pressure losses, the CPVS 75-120 delivers up to 4% more free air while consuming up to 3% less power.

There is also an Interior Permanent Magnet (iPM) motor, another marvel of in-house Belgian engineering.

This oil-cooled motor provides optimal cooling at all speeds, making it eco-friendly and highly efficient. Its IP66 rating further underscores its robustness and suitability for high-speed operations.

Noise reduction is a critical factor in industrial settings, and the CPVS 75-120 addresses this with its innovative silencing baffle.

The filter mats pre-filter incoming air, ensuring superior air quality and low noise levels, making it ideal for operations close to the point-of-use.

The separate oil and air coolers are designed for high-quality cooling and extended lifespan. With a 5°C reduction in element outlet temperature

and easy access for cleaning and maintenance, these coolers exemplify thoughtful engineering.

The proven in-house designed inlet valve optimises the flow to the screw element, offering maintenance-free operation and a low total cost of ownership.

Similarly, the in-house casted oil separator vessel with an integrated minimum pressure valve (MPV) ensures optimal oil separation and minimal oil carryover, eliminating leakage risks.

Control and connectivity are at the forefront with the next-generation ES4000T touchscreen controller.

This user-friendly, full colour graphical display with touchscreen functionality, coupled with integrated connectivity through ICONS, helps optimise operations and achieve significant energy savings.

Finally, the in-house designed inverter, featuring Imperium –Variable Speed Technology, is tailor-made for screw compressor applications. Its robust industrial design, complete with IP5X protection, ensures durability and reliability.

Chicago Pneumatic are a leading provider of oil-injected screw compressors

The CPVS 75-120 oil-injected screw compressor is a remarkable blend of innovation, efficiency, and reliability. Chicago Pneumatic has again demonstrated its prowess in delivering state-of-the-art solutions that meet the demanding needs of modern industrial environments, all while significantly enhancing energy savings.

Chicago Pneumatic cpcompressors.com.au

Publisher SCOTT FILBY scott@industryupdate.com.au

Advertising & Sales Manager PAUL FERRIS paul@industryupdate.com.au

Editor MIKE WOOD editor@industryupdate.com.au

Sub Editor RENATA GORTAN subeditor@industryupdate.com.au

Writer LUCY JONES writer@industryupdate.com.au

Universities & Collaboration Editor DAVID SLIGAR unieditor@industryupdate.com.au

Assistant to the Publisher JERIN BURZACOTT jerin@industryupdate.com.au

Advertising Sales Director SCOTT FILBY scott@industryupdate.com.au

Advertising & Sales Manager PAUL FERRIS paul@industryupdate.com.au

Marketing Manager DUMINSHA UDESHIKA marketing@industryupdate.com.au

Creative Director EDWIN KWONG production@industryupdate.com.au

Production Manager DUMINSHA UDESHIKA copy@industryupdate.com.au

Video Editor & Producer

CHARLIE LOUGHLIN video@industryupdate.com.au

Office Admin

JESSICA SUDESH admin@industryupdate.com.au

Finance & Accounts

MICHELLE ALCOCK michelle@industryupdate.com.au

Consultant TRACY FILBY tracy@industryupdate.com.au

Accounts Receivable LYN SLIGAR lyn@industryupdate.com.au

Subscription Assistant GUSTAV RHEEDER circ@industryupdate.com.au

Finding staff remains one of the biggest topics in the Australian manufacturing industry - and one specialist charity has sounded a warning that, without significant change, the sector might wither further.

transfer means workers are missing out on the latest skills and technologies needed to keep pace with modern manufacturing demands,” he said.

“Challenges like supply chain disruptions, workforce disengagement and rising energy costs are real. Manufacturers who invest in training the next generation will be best positioned to lead the way.”

The issue is not a new one, but as more and more experience leaves the sector due to the rising age profile of leadership within manufacturing, the problems that come from a lack of adequate replacements only continue to grow.

Apprenticeships Are Us, a registered non-profit set up to help build the next generation of manufacturing leaders, have sounded the alarm on the staffing problem, with General Manager Phil Cooksey detailing how years of expertise are walking out of the door without their place being filled.

“From our research and firsthand experience, it’s clear that much of the manufacturing sector is stagnating,” he said.

“While senior management often hold up-to-date qualifications, the wider workforce typically only possesses the most basic certifications.”

Cooksey added that manufacturing businesses often failed to invest in personnel development, leaving the next generation to be trained in an informal manner.

“This kind of ad-hoc knowledge

The Australian manufacturing sector can tap into a reservoir of talent through Apprenticeships Are Us, who exist to support businesses when they take on apprentices.

“We receive daily enquiries from individuals keen to start apprenticeships in fields like carpentry, plumbing, electrical work, machinery operation, and software development,” said Cooksey.

“We’ve seen the power of pairing enthusiastic new apprentices with experienced host businesses willing to share their skills. Expanding into new sectors allows us to make even more career dreams a reality.

“Mentorship is at the heart of what we do. We don’t just place apprentices. We support them with personal guidance, practical life skills and employability training.

“It’s about helping people turn ambition into long-term career success.”

Publisher Scott Filby

We’ve been celebrating a lot this month - and well we should, because it’s our 30th anniversary!

Most start-ups don’t survive three years, let alone three decades.

Think about how much the media landscape has changed since 1995: no smartphones, very little internet…but Industry Update keeps going, and growing - in print and online - and now with our most glamorous product to date the Australian Manufacturing Awards.

Since the pandemic, we have seen a steep uptake of manufacturing businesses using print media, bucking the trend across the wider media industry.

The vast majority of advertisers are not getting the exposure that is essential to their survival. What many businesses still do not realise is that Google does in fact have a ceiling.

Many new and previous advertisers are now advising us that print is back in favour and Industry Update is enjoying the resurgence and benefits of the realisation that print is desirable to readers.

Real book sales (the printed type) are also up in Australia with an increase in recent years.

In 2022, the Australian book market reached $1.3 billion in sales with 70.9 million units sold, marking an 8.2% year-on-year increase. This growth is also significant when compared to pre-pandemic levels, with a 16% increase in sales compared to 2019.

IU history has always defied market trends. This issue of Industry Update is also the highly anticipated 30th Anniversary edition and will leave a lot of people wondering if their ‘online only’ presence is rather short sighted.

That’s not to say we neglect online, either. 2025 is already our best ever year for website traffic, with numbers exceeding all of 2024 combined by the middle of May.

These have been interesting times for our industry, with trade wars and actual wars, tariffs and elections. But year after year, Industry Update has defied market trends.

The publication became market leader in 2008 - right as the GFC hit the world markets - but this worked to Industry Update ’s favour and we have never looked back!

With statistics showing that the manufacturing industry is turning a corner and looking to invest again, the magazine is set to enjoy continued growth.

With the first Australian Manufacturing Awards - nominations are open, by the way!coming up in October, we will enter our fourth decade stronger than ever.

For those involved with marketing in the manufacturing industry, print, online and awards media platforms are 100% the best options. And that is the market speaking!

It is also important to note that Industry Update Media is now the only truly independent manufacturing media business in Australia. We put real and credible journalism above all else and we hope that shines through to the final products that we publish.

Finally, I take this opportunity to say thank you to our advertisers and readers that have made Industry Update possible all these years. And for many more to come!

See you at the inaugural Industry Update Australian Manufacturing Awards on 23 Oct 2025. Tickets are now on early bird offer, so get in touch!

Editor Mike Wood

Sometimes, it helps to tell readers how the editorial sausage is made.

When there’s a big event that we know is coming up - a Federal Election, for example - we will write an article about it well before it happens to claim the SEO real estate on the issue.

Then, as the story develops, we can amend to add the latest news as it comes in, update the timestamp and, hey presto, Google’s algorithm throws you back up the rankings.

As a result, everyone who searched for answers on what each parties’ policies were would have found our article on the subject, tracking announcements in real time.

It’s pretty standard journalistic practice these days, and you’ll now notice it whenever you search ‘What time does State of Origin start?’ or ‘Who is presenting the Logie Awards?’.

The reason I mention it is because, in the recent Federal Election, the article we wrote was very lopsided.

Anthony Albanese made manufacturing a key pillar of his pitch to the electorate thanks to the Future Made in Australia policy and, of course, entered as incumbents, allowing them to dispense with big giveaways on the campaign trail.

Peter Dutton, on the other hand, limited the policy to long lunches for SMEs, unwinding

Labor’s pledges to manufacturing and ending work from home, a policy on which they backflipped.

They did have significant announcements around nuclear energy and lowering inflation, which would have affected manufacturing, but their main focus was around reining in excessive spending, which meant little new for industry.

Industry Update has always taken a neutral stance on elections and has worked with every government on both sides of the aisle. That would have remained the same regardless who won.

With Labor returning with a thumping majority, manufacturing now has clarity going forward.

Reaction from across industry reflects this, with everyone from the trade unions to the employers’ associations welcoming the clarity that comes with majority government.

The worst possible outcome would have been a hung parliament of any description, which would have only added to the myriad uncertainties faced by the sector.

Now, we welcome the summit on productivity that Albanese will convene later this year, where stakeholders from across Australia - and especially from manufacturing - can discuss how to build our economy over the next three years.

Nominations are now open across the following awards:

• Gold Award for Excellence in Manufacturing (individual)

• Manufacturer of the Year (company)

• Lifetime Achievement AwardHall of Fame

• Best medium business

• Best small business

• Best start-up

• Australian Made Manufacturer of the Year

• Innovation Award

• Supply Chain Award

• Defence Award

• Safety Award

• Digital Transformation Award

• Advanced Manufacturing Award

• Sustainability Award

• Community Impact Award

• Best Regional Manufacturer

• Trade Show Award

• Environmental Champion Award

• Rising Star Award (under 35)

• Apprentice of the Year

• Secondary School Award

• Manufacturing Worker of the Year

The event will be held at the

luxurious Sofitel Sydney Wentworth on Thursday 23 October 2025, and is sure to be an enthralling evening of entertainment.

The Awards are presented by St.George Bank and sponsorships for all the Gold Awards have been sold to leading brands such as Combilift, Lapp and SugarCRM,

as well as official support from the NSW Government.

“The response to the Awards, both in terms of nominations and sponsorship, has been exceptional,” said Scott Filby, Publisher of Industry Update

“It vindicates our decision to launch such a major event in our 30th year of operation. Manufacturing has often

failed to celebrate itself properly, but we have never been afraid to talk up our industry.

“We look forward to reading through the many nominations and picking out the best - so get yours in today!”

Australian manufacturing isn’t known for blowing its own trumpet too much - and we at Industry Update are just as guilty as anyone else in that regard.

Our industry is made up of quiet achievers, people who get on with the job and let others shout from the rooftops.

We’re looking to change that with the launch of the Australian Manufacturing Awards, and in the interests of practising what we preach, we thought it would be a good time to share some great news from our publication.

As of the middle of last week, we topped 100,000 unique visitors to our site for the year, surpassing the whole

of 2024 in just over five months.

“This news shows just how much Australian manufacturing is responding to what we are doing,” said Industry Update publisher Scott Filby.

“IU turns 30 this month, but we are always looking forward, whether that is by launching the first Australian Manufacturing Awards, creating impactful social media content like our viral Reel from 2024

- 40 million views and counting! - or through meaningful journalism that adds value to our sector.

“We have revamped our online strategy to focus on the news that matters for the manufacturing sector while growing our print magazine through in-depth features that

provide real insights that decision makers in industry can use to get ahead.

“There has never been a better time to be involved in our industry

- or to advertise on Industry Update The numbers prove that what we are doing is working - and we can’t wait to chase the next story!”

Australian manufacturing has had a fraught relationship with the United States since the return of Donald Trump to the White House at the start of the year - and now the numbers are in to prove it.

The National Travel and Tourism Office (NTTO) in the USA reported that business travel to the country has dropped 9% compared to the previous April - itself a massive fall as numbers had been up in March, which could be attributed to people who booked before the extent of Trump’s border controls and tariff plans were known.

Within those numbers, there was a 17.7% drop from Europe and a 35% drop in travel from Canada by car, with one leading tourism trade body suggesting that the cost of the change might be close to $20 billion AUD across the year.

“While other nations are rolling

out the welcome mat, the U.S. government is putting up the ‘closed’ sign,” said Julia Simpson, President and CEO of the World Travel and Tourism Council.

“Tourist detentions and steep tariffs have damaged the country’s reputation as a destination.

“This is a wake-up call for the U.S. government. The world’s biggest travel & tourism economy is heading in the wrong direction, not because of a lack of demand, but because of a failure to act.”

Flight Centre, a leading Australian provider of business travel, reported to the ASX that it is expecting a drop in profits as a direct result of what it called ‘recent US developments’, confirming that there had been a 16% fall in tourism compared to the equivalent period in 2024.

“People from Europe, the United Kingdom and Australia really don’t want to go to the States, given what’s

Australia’s leading designer and manufacturer of compressed air systems... for over 40 years

Pilot Air's air compressor solutions are designed and manufactured for Australian conditions.

We utilise advanced technology, materials and parts for high-performance, superior efficiencies and unmatched quality.

Our qualified team eliminate the need to outsource consultancy, design, manufacture, installation or servicing. We can take care of your system from the start to finish.

Working with Piot Air you’ll be sure of

• Professional advice

• Customised systems No reliance on third-parties

• Measurable cost and time savings

• Complete customisation Improved efficiency

• Reduced downtime

• Unmatched service timeframes

• Future-proofed systems

happening there. We’re hearing more and more people don’t want to go through passport control,” said their chief executive Graham Turner to the Australian Financial Review.

Speaking again to the ABC, Turner added that there might be an element of hearsay at play.

“People hear these sad stories of people being detained,” he said.

“It’s probably been happening normally but people hear more of it now. The unsettled climate in business has affected us as well.

“We’re pretty sure it’ll be a shortterm phenomena, particularly if

Trump does come to bargain with more and more countries.”

The Australian Government has not changed its guidance for travel to the United States, but has issued warnings, especially around border controls.

Wording has hardened, with issuance that border controls “actively pursue, detain or deport people who are in the country illegally” and that devices may be searched, as “officials may ask to inspect electronic devices, emails, text messages or social media accounts.”

Queensland’s leading boat dealer, Spirit Marine, has been appointed as the distribution partner for the world’s largest solar electric yacht company, Sunpower Yachts. The Gold Coastbased business will be the exclusive distributor for Sunpower, promoting their range of Solar e-Cruiser, Solar e-Sail, Solar e-Poweryachts and Solar e-Superyachts solely to the Queensland market. Australian-owned Sunpower is now the world’s largest solar electric yacht company, since its recent acquisition of Alva Yachts.

“Sunpower is at the forefront of solar electric yachting, consistently setting a benchmark in efficiency, performance, comfort and environmental responsibility, whilst still producing sleekly designed vessels,” said Peter Nicholson, founder of Spirit Marine.

“Following its recent acquisition of Alva Yachts GmBH, the firm is well-positioned to build on its existing reputation as a leader in the luxury eco-yacht market. This combination of cutting-edge technology, performance and luxury is why Spirit Marine is so excited about this announcement as we see this having the potential to become

one of the country’s leading boating brands,” said Nicholson.

Spirit Marine is a leading Australian boat dealer with operations spanning Queensland and are currently partnered with Beneteau offering their outboard power and sailboat ranges, including the highly successful Antares range.

Sunpower Yachts is an innovator in solar electric yachting and has already sold 12 yachts ranging from 44ft-90ft. With the world’s largest fleet of eco-friendly vessels, they are setting the standard for sustainable luxury on the water. Their yachts combine cutting-edge solar technology with exceptional design, offering a seamless blend of performance, elegance and environmental responsibility.

“Partnering with reputable boat dealers like Spirit Marine is part of our strategy to build the prominence of our brand and educate the boating community about the positive attributes of our vessels, along with the environmental benefits gained by choosing a Sunpower vessel,” said Grant Hudson, spokesperson for Sunpower Yachts.

150% for farmers, 64%

The Victorian Government’s unpopular Emergency Services and Volunteers Fund Levy (ESVFL) is set to kick in from the start of next month despite an ongoing drought that has caused many rural firefighters to hang up their helmets.

The new levy, which replaces the pre-existing Fire Services Property Levy, is slated for July 1 and will see farmers charged more for emergency services provision, despite many actually being members of those same emergency services as volunteers.

The Country Fire Service, which is volunteer-staffed, has seen several farmers resign their jobs in protest at the new law, which passed a late-night session of the Victorian legislature in May.

All Victorians pay towards the levy, but primary production land is taxed at a higher rate, creating a situation where farmers pay far more to protect their land.

The increase is variable, however it is expected to be 150% for farmland. Manufacturers are also at risk, as rates for industrial land will also spike, going up 64% - and was

already the highest to start with.

While residential and commercial rises are also close to 100%, the average home or shop is far smaller than manufacturing areas, which are themselves smaller than farms, meaning this tax will be felt more harshly. Fires are more common in rural areas, but largely not in private land such as farms. The bulk occur in

forests and national parks, or on the roads - all of which are owned by the government.

The levy kicks in with large parts of southern Australia in drought conditions, including western Victoria. According to the Bureau of Meteorology, rainfall was below average to very much below average in most of southern Western

Australia, South Australia and Victoria across all of May.

This is worrying for many, as the bulk of annual rainfall for SA and western Victoria usually falls in winter, and the lack of this ground moisture could contribute to bushfires in the warmer months.

Eagle Lab Pack, Overpack and Salvage Drums from Global Spill &

handling and transportation

esa Deda is one of Australian manufacturing’s most trusted voices - so the news that she has been appointed as the first ever Chief Economist at accounting giants William Buck was greeted warmly by the industry.

Deda has built a reputation as a trusted commentator on economic issues through regular media appearances, backed up by years spent in business banking, first with St.George and then with Westpac, where she was the first female Chief Economist.

She has made a career out of turning complex economic issues into digestible, actionable advice for businesses, making her a perfect fit for William Buck, who work across the SME sector, particularly in manufacturing.

To celebrate her new job, Industry Update sat down with Deda to discuss the uncertainty that has dominated headlines in 2025 so far, and to get her reaction to the rate cut that has changed the economic landscape for businesses across Australia.

“Markets and the business community are now thinking about what’s coming next,” she told us.

“Three more rate cuts are fully priced in and it will depend on how global conditions as to how many rate cuts transpire, especially with tariff policy being volatile and unpredictable.

“Underlying inflation has entered

the Reserve Bank’s target band and policymakers appear more comfortable about inflation risks.

“The pause on reciprocal tariffs ends in July, but the RBA board meets just before that.

“Shorter-dated bond and swap yields are pricing in the risks of further easing from Australia’s central bank.”

Deda emphasised that, while the rate cuts were priced in, the uncertainty was still out there in the long-term.

“At the longer end of the Australian yield curve, bond yields are rising, partly because US longterm yields have undergone a sharp rise,” she said.

“The US bond market is the largest and most liquid in the world, and it strongly influences global bond markets.

“The Australian and US 10-year yields are closely correlated, so at the longer end of the yield curve, you’re seeing borrowing costs rise, and that will impact financial conditions more broadly.”

For Australian manufacturing, the uncertainty seems here to stay.

”If you’re a manufacturer who imports or exports, there is also ongoing uncertainty in supply chains due to unpredictable US tariff policy,” said Deda.

“The global trade norms and rules as we have known them for a long time are changing.

“If you’re importing, your costs

might be lower - for example, if China is trying to shift volume to non-US markets and discounts to help it do so - but if you’re exporting to the US, it is tougher.

“Take Australian steel, which was facing a 25% tariff entering the US, our second-biggest export market for steel. Then, Trump announced plans to double that tariff to 50%.

“It demonstrates that there are also a lot of changing rules around tariffs and trade at the sectoral level.”

Tariffs remain top of mind for many in the industry - not just for their impact on exports to the USA, but also because of their effects on the Australian dollar and global currency markets.

“When Trump introduced tariffs, he suggested it was to reduce the US trade deficit. The logic was that by making imports more expensive, US producers would bring production onshore,” explained Deda.

“That reduces the need for foreign inputs and foreign currency, which should cause the US dollar to rise relative to other currencies in other economies.

“If the US dollar rises, US exports become less competitive, all else being equal, and the trade balance might not change all that much - so that suggests the rationale has flaws.

“In reality, the US dollar index – a measure of the US dollar’s value relative to a basket of foreign currencies - has declined.

“That’s partly due to uncertainty from tariff policy and concerns about the US fiscal outlook, but also because a big spending bill was recently passed through the US House of Representatives, which will increase the US federal deficit significantly.

“The bond vigilantes are back and they’re worried about the sustainability of the fiscal balance. They’ve sold off US Treasuries quite sharply at the longer end, causing a sharp lift in longer-dated US Treasury yields.

“Longer-dated bond yields have also risen in other major economies, more notably in Japan but unlike the US, Japan’s government bonds are mostly owned by domestic investors.

“Further, Japan’s longer-end yields are rising for some different reasons, including the end of decades of deflation.

“Normally, rising US bond yields would help lift the US dollar, but we are seeing the opposite – one of the reasons is because investors want more compensation for holding US long-term debt.

“This is reflected in the US term premium. So, we are seeing divergences open up between bond markets and currencies. There is still more to play out and a space worth watching.”

William Buck Australia williambuckaustralia.com

By Besa Deda, Chief Economist, William Buck

Manufacturers are facing a period of transformation. There are initiatives from the Federal government that are fostering growth in areas such as clean energy, green metals and critical minerals processing.

However, the industry is also facing challenges due to the fragmentation of globalisation and the unpredictable nature of US tariff policy.

These factors are impacting the outlook for global economic activity and the growth prospects of Australia’s major trading partners.

The US government announced a 90-day pause on reciprocal tariffs on 9 April, but the baseline universal tariffs of 10% remain.

Further, there are tariff announcements occurring at the sectoral level, such as for steel and aluminium. This has unleashed persistent and elevated uncertainty.

In today’s rapidly changing economic landscape, understanding possible scenarios is more important than ever.

Manufacturers will need to continue adopting technology and strengthening supply chains to build resilience. Making strategic investments will also be crucial.

Meanwhile, domestic economic activity is set to pick up, as recent rate cuts boost consumer spending growth and elevated public spending props up activity.

A slowing in inflation pressures opened the door to rate cuts. More

rate cuts are on the way. Interestrate markets are anticipating at least two more rate cuts before the end of this year.

The path of monetary policy will highly depend on global conditions, trends in household spending and the health of the jobs market.

Manufacturers must stay sharp on exchange rates when pricing and managing costs.

Volatility is high for currency markets and there are divergences in markets appearing. US government bond yields on longer-dated maturities have risen, pushed higher

by escalating concerns over the federal fiscal deficit.

However, the rise in long-end yields is not confined to the US or just the bond market. The US dollar has also depreciated against a basket of major currencies. Can this depreciation continue and what does it mean for the Australian dollar?

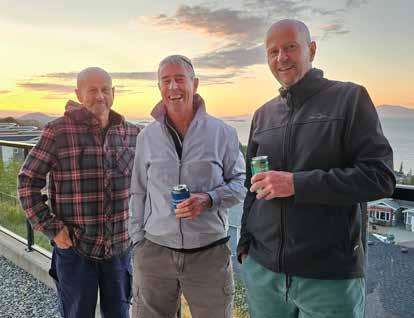

Seeking insights that matter to your business? Register your interest for the next Manufacturing iLAB — a quarterly, invitation-only luncheon hosted by William Buck, St.George, Coleman Greig Lawyers and AON, held in Parramatta.

now

Designed for Western Sydney’s manufacturing leaders and supporting professionals, each session offers practical takeaways for CEOs, CFOs and business owners.

You’ll hear insights from industry experts, explore sector challenges and connect with those shaping the future of Australian manufacturing.

Register your interest

It is a great honour for me as the new Minister for Industry and Innovation and Minister for Science to be able to play a modest part in taking Australian scientific and industrial endeavour forward.

Industry policy is my passion.

It’s my passion, because I believe in an active social democratic state that works for every Australian.

I want Australia to be a manufacturing powerhouse in an increasingly digital world.

To be the indispensable industrial, technological, energy and strategic partner to the region in which we live.

And to do that by deploying our strengths in energy and resources, leveraging our proximity to the fast-growing Asia Pacific region, and backing our brilliant research institutions and our smart, skilled and resilient people.

Together with Dr Andrew Charlton, Assistant Minister for Science, Technology and the Digital Economy, I want to deliver world-class industry policy that is informed by evidence and driven by purpose.

The task before us is very clear.

Australia must build its economic complexity and resilience – and do it with purpose and urgency.

When the Prime Minister first shared his vision of our Future Made in

Australia policy in April 2024, he said we needed to be clear-eyed about the times we live in.

He said we needed sharper elbows when it came to marking out our national interest, and we needed to be willing to break with old orthodoxies.

The Prime Minister was not heralding a retreat into protectionism, or the rise of a hulking government crowding out private investment.

What he was signalling was a need to move past arid, think tank platitudes about the role of government and old binaries.

Government needs to work alongside the private sector to grow the economy, boost productivity and secure prosperity.

Combining market tools with government action to create opportunity for generations of Australians.

We’ve got to build state capacity, and private sector capacity, and not see those imperatives as in conflict with each other.

We can make Australia stronger by investing in what matters – and drawing on our shared values and strengths.

We also have a unique opportunity to join up our research and innovation system with our Future Made in Australia framework.

Given we have a productivity

challenge, this is an opportunity we can’t miss.

Australia must have competitive advantage in high productivity, high skill jobs and industries of the future, including advanced manufacturing.

And the Australian Government and Australian firms must harness technological advancement and innovation, like artificial intelligence to deliver investment, economic growth and lift lagging productivity.

All of us, public and private, State and Commonwealth, research institutions and civil society, the physical sciences and the social sciences must lift together and pull our weight.

Working together, to build the capacity of Australia to meet this historical moment and build a secure, sustainable future for Australia and Australians.

Our Future Made in Australia plan is about maximising the economic and industrial benefits of the global move to net zero emissions and attracting substantial international investment to do so.

My predecessor, Ed Husic, and my Cabinet colleagues, put important policy structures in place during our first term in office. Much has been achieved.

My task, in this coming term, will be about coordination, delivery and impact. To join up our research and innovation

system with our Future Made in Australia framework.

I want to focus on coordination of national resources and programs and deepen the cooperation between industry and our great research institutions.

I look forward to receiving the recommendations of our strategic review of existing R&D frameworks when that is completed later this year.

In the meantime, I will be meeting stakeholders and consulting to help inform my own views about how we maximise our efforts and investments.

Delivering a world-class industry policy isn’t an abstraction.

It is at the heart of the Albanese Government’s plan for long-term growth and jobs, for security in its broadest sense, for lifting our productive performance and making sure that every Australian is part of our national project and shares in its success.

Let’s get cracking!

Are you sure you can do this”, the gruff shearing contractor asked as I arrived for my first day working for him in the red dust of Thargomindah in remote Queensland.

I was a long way from home with a newly minted aerial stock mustering endorsement.

But after months of chasing my dream, unsuccessfully in the cities, this was my shot.

“I am definitely up for it!”

There and then, near the outback town they still call Thargo, it was my time to fly. And fly I did, in a very small plane, in very tight circles, very close to the ground.

I had already learned the path to becoming a female pilot was going to be tough. Too many people weren’t ready for someone like me in the left hand seat at the front of the plane.

But that didn’t stop me. I kept dreaming. I worked. I studied. I failed. And then I flew.

It took time. A lot of hard work, and a few tears too.

Aviation isn’t one of those vocations you can just step into. You have to earn your wings.

And I earned mine.

That was good enough for the boys in the blue singlets in the shearing sheds of western Queensland. And it was good enough for me. I could fly.

The wisdom of those workers, who built our prosperity with calloused hands and strong backs, has always been my North Star.

Looking back, I wonder how they would react knowing that a 20 year old bush pilot from the city was now the Leader of the Federal Opposition.

What would those boys from the bush tell me to say about Glass Cliffs?

What I do know is it is the greatest honour of my life to have been elected as Leader of the Liberal Party of Australia.

And to be the first woman to have reached that role fuels my fire all the more.

I am proud that as my granddaughter grows up, this moment will inspire her to dream bigger and run further.

My biggest motivation will always be to create an even better Australia for all my grandkids.

They call me Glamz, I want them to see Glamz succeed.

The support I have received from colleagues and the community has been overwhelming.

But, some believe I face the ‘Glass Cliff’. That is where a woman is ‘given a mess to clean up that she will inevitably fail at.’

When I put myself forward for the leadership, Glass Cliffs weren’t front of mind.

No one told me about Glass Cliffs when I placed ads in regional papers across the country to try and land a job as one of the first Australian female mustering pilots.

No one warned me about a Glass Cliff when I went to uni, with a baby in a capsule, as our family struggled to make ends meet.

No one asked me about Glass Cliffs when I hooked up my caravan, painted it Liberal blue, and drove up and down the Murray to run for Parliament.

Glass Cliffs didn’t feature in the analysis of my appointments

as Health Minister, Environment Minister, nor as Deputy Leader of the Opposition.

As far as political analysis goes, it is just wrong.

You see, politics is another one of those vocations you don’t just step into.

In politics, just like flying, you need focus, discipline and nerve

Sometimes it’s clear and bright, but more often than not there are stormy skies.

For over 20 years I have served in the national parliament. I have been a Cabinet Minister in three different governments.

For three years I served as the Deputy Leader of Opposition, and I have fought hard every single day for the Australians who do so much, but ask for so little.

I earned my spot.

There is no doubt that all too often women are left to clean up the mess.

Whether that is in broken homes or in corporate boardrooms, women are often asked to clear higher hurdles and pass different tests.

But when the most successful political party in our nation’s history picks a leader, it doesn’t do so based on chromosomes.

I earned my shot.

I am the leader for this moment. I am here to listen, to rebuild and to modernise the Liberal Party. I am not interested in the noise or in echo chambers. I am focused on working hard for Australians each and every day.

With hard work and humility, we can win back the trust of the community.

And as for ‘Glass Cliffs’, I couldn’t give a stuff about them.

I intend on steering my party skyward, into smooth air and sunlight. Cliffs don’t matter when you’ve got your wings.

With over 118 years of engineering experience, Boge can provide an efficient one-stop solution for your compressed air requirements.

Whether for process air, plant air, packaging or other applications, Boge has the solutions that you need.

Dedicated Class 0 certified compressed air systems for all industries. offering guaranteed oil-free air for safe and high-quality end products.

Process filtration plays a critical role in maintaining product quality, ensuring safety and meeting regulatory standards in industry.

In any production plant, compressed air and nitrogen have an important function across different stages, ensuring product excellence and safety.

From dairy and baked goods to beverages and snacks, one common thread runs through it all: the need for uncompromised air purity.

For critical applications within the plants, you need ISO 8573-1 Class 0 oil-free air to ensure the highest standards of quality and safety.

To ensure that your production facility is operated safely, and that

all of the equipment is protected, it is crucial that the compressed air meets the relevant quality standards.

The most important of them is ISO 8573-1. This internationally recognised air quality standard is divided into air quality classes for the three main types of contaminants (moisture, oil and particles) and defines how many contaminants the air may contain at a specific point in the compressed air system.

Boge is offering the following products along with complete downstream air treatment components as well as high pressure boosters for PET bottling, which is an integral part of any packaging plant.

Reduced speed, low compressor temperatures and extremely low wear. The oil-free SO-3 screw compressor achieves top ratings for free air delivery with low specific power consumption.

The compressor is particularly suitable for industries that require high-quality, oil-free compressed air in large quantities.

Produces Class 0 quality oil-free compressed air from oil lubricated compression, while eliminating expensive condensate disposal.

The principle is absolutely safe and unbeatably priced, making it the ideal solution for oil-free compressed air, especially for sensitive industrial applications.

Super-compact, quiet and with a low vibration level, the EO series enhances the oil-free segment and literally fills any gap.

It is particularly recommended for sensitive applications in which oil-free air and unobtrusive operation are essential. Smart control allows scroll airends to be switched on or off as required.

The completely oil-free piston compressors of the new PO Series produce high quality compressed air for even the most sensitive applications. Piston compressors of the K Series

work with an innovative, oil-free pushrod system in an all-new compact size for small requirements.

Traditionally, companies sourced the required N2 & O2 for their production processes from external suppliers, delivered in bulky containers that required storage space along with huge storage losses and inefficiencies.

On-site N2 generation makes the operations independent of an external gas supply and very low generation costs.

On-site nitrogen and oxygen generation brings a wide array of benefits.

• Cost efficiency

• Customised purity

• Streamlined operations

• Continuous supply

• Enhanced safety

• Environmental impact

• Peace of mind

BOGE Compressors www.boge.com/en-au

Australia’s brewery industry plays a vital role in the national economy, with around 878 businesses contributing an estimated $16 billion in economic activity and supporting 100,000 jobs across the supply chain.

From large-scale breweries to independent craft producers, the sector has experienced remarkable growth over the years.

However, operating in a country with the world’s third-highest beer tax presents significant challenges, increasing financial pressure, squeezing profit margins and reducing market competitiveness.

To stay ahead of these challenges, many breweries are turning to automation - particularly smart automation - to streamline operations and improve efficiencies.

No stranger to the sector, Rod Ryan, Head of Business Development (End Users) at SMC Corporation has been collaborating with SMC’s customers for more than three decades.

“SMC has worked hand-in-hand with the sector since our early days in the market,” he said.

“We have a sound understanding of their needs and continue to evolve with them. Today, we are able to support all aspects of the production process on-site.”

Rod also emphasises the importance of working with Original Equipment Manufacturers (OEMs) that supply plant systems to Australia’s leading breweries.

Like many industries, breweries are

increasingly focused on energy efficiency across their production lines.

“We work closely with OEMs to ensure they provide scalable, energy-efficient systems,” he said.

“We continue to see rising demand for energy-saving systems as producers recognise the importance of saving on energy bills, reducing their carbon footprint and improving efficiencies.”

One of the most effective ways to achieve savings in a compressed air system is by simply reducing pressure.

“Globally, SMC is committed to energy efficiency initiatives,” said Ryan.

“By lowering pneumatic line pressure from the standard 7 bar to 4 bar, our customers can reduce energy costs by up to 29%.

“SMC’s team will review your site and advise on next steps for an energy saving audit.

“Any subsequent system optimisations are conducted at a plant level (rather than focusing solely on individual machines) to ensure savings across the board.”

Demand is growing for smart, modular and flexible production systems that allow independent brewers to adapt and change quickly and wireless products are central to this mission.

“This is particularly exciting for independent breweries wishing to scale at will,” says Ryan.

“SMC is working closely with our customers to deploy new-generation technologies that will not only save installation time and reduce downtime, but also allow us to perform updates both on and off-site.”

SMC’s EX series continues to make waves as a unique product offering that delivers a host of big benefits, highlighting the EX260 as a compact, cost-effective fieldbus solution for output applicable to SMC’s most popular directional control valves such as the SY series.

“Technologies such as these have shown themselves to be integral to process control and upgrades,” added Ryan.

“In fact, we have seen customers save as much as two days’ worth of shutdowns by simply deploying a solution such as this one.”

“It can control up to 32 solenoids in one manifold and is suitable to all major protocols such as EtherNet/ IP, Profinet, EtherCAT, Profibus-DP, DeviceNet and CC-Link.”

The EX260 series has standard dual-port connectivity, eliminating the need for switches or branch connectors. In addition, its IP67 enclosure rating ensures protection against

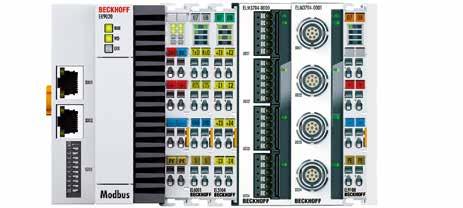

Italian motion control specialist

CMZ Sistemi Elettronici – represented in Australia by authorised distributor LAPP Australia – has released its advanced SBD series of brushless servo drives, offering high-performance control and decentralised flexibility for a wide range of industrial automation applications. Designed for brushless motors from 0.7 kW to 7 kW, and available in both 230 VAC and 400 VAC versions, the SBD servo drive supports currents from 5 to 20 A. Built to streamline installation and simplify motion control, the drive features a compact form factor

that integrates essential elements such as EMC filters, braking resistors and Safe Torque Off (STO SIL3) functionality for enhanced safety.

The SBD programmable integrated PLC model stands out with its built-in IEC 61131 structured text, allowing it to operate independently in many decentralised applications.

When paired with expansion modules and an HMI via RS-485 Modbus RTU, it enables complete standalone control for simple motion sequences. PLC capabilities include jogging, positioning (absolute and relative), homing, gearing and touch probe functions.

dust and washdown environments.

The EX600, on the other hand, offers a full suite of diagnostics and programmable parameters to meet the most stringent requirements.

“This series offers excellent flexibility including digital input, digital output and analogue input unit options,” says Rod.

“With the use of D-sub output blocks, a maximum of 9 remote D-sub manifolds can be attached to one EX600 communication module.”

“SMC is more than just a supplier of automation components, we actively collaborate with our customers - and OEMs - to develop tailored solutions that address both their current and future needs.

“I strongly believe that real energy savings can only be achieved when we work together, and this is why we are so focused on partnering with OEMs from the get-go.

“Through innovative technology and energy-efficient strategies, SMC continues to support the brewery industry in optimising performance and maintaining competitiveness. We look forward to where the next decade takes us.”

SMC - smcworld.com

Engineered for easy configuration, tuning and diagnostics, the drive is supported by CMZ’s SDSetup software. Connectivity is robust, with CANopen, EtherCAT, Profinet and pulse/direction interfaces, plus a micro-USB port and configurable I/Os.

It supports feedback via resolver, TTL incremental and Hiperface absolute encoders.

“With a combination of internal programmability, versatile communications and integrated safety, the SBD servo drives offer a smart, space-saving solution for OEMs and machine builders,” says LAPP

Australia Industrial Automation Manager, Robert Lloyd.

LAPP Australia lappaustralia.com.au

Caught between higher costs, smaller runs and distance from global markets, Australian manufacturers must work smarter to compete, survive and thrive.

With agile robots, sensors and software now more accessible than ever, learn how these Aussie makers punch above their weight on the world stage.

“Australian manufacturers must think differently,” explained Dr Paul Wong, founder of Applied Robotics.

“While European or Asian factories might dedicate entire facilities to a single product line, our market requires solutions that can handle greater variety with shorter runs, all without sacrificing profitability.”

For decades, manufacturing automation was built on fixed systems perfect for mass production, but not economically viable when producing low volumes or custom product variations, leaving Australian manufacturers in a tough spot, with:

• More product variants with shorter production runs

• Higher operating costs that needed to be offset with greater efficiency

• Need for faster response to changing demands

The emergence of adaptive automation changed everything, enabling rapid reconfiguration through software updates rather

‘100% bespoke’: Why custom automation cells are perfect for manufacturing

Automation and robotics can seem like something designed for big manufacturers, operating at scale with huge amounts of throughput.

One business, however, is looking to change that.

Bayer Engineering are experts in specialised robotics and automation machinery designed around the customer, with fully custom-built solutions that can help manufacturers of any size to introduce automation into their systems.

“It’s all custom-built based on the customer requirements. No two machines are alike. No machine is off the shelf. It’s really, really purpose-built,” explained Simon Bayer.

“What we’re doing is split into two parts.

“The first is jigs and fixture development - design and manufacturing for all sorts of environments, particularly CNC machining and assembly.

“The other is automation and robotics. In that area, we design and build robot cells, automation cells, automated jigs and fixtures, and it’s all for the manufacturing industry.”

For Bayer, the process is all about building out around the customer’s issues.

“Usually the clients come up with a problem they’re having and need a solution for,” he explained.

“They want to make their process more reliable, more repeatable, they want to make it quicker, or they just need a solution for something that’s not there yet.

“When they tell me what the problem is, I start thinking about solutions. They may already be out there somewhere and could be modified, or it might require me to come up with new solutions.

“I generally sketch something up roughly and show them if that’s going in the right direction. If it is, I detail it a bit more and start building the machine from there. It is a constant exchange with the client to ensure that their needs are met.

“It’s all 100% bespoke. We use off-the-shelf components from recognised brands, but the machinery and the solutions are all bespoke.”

Bayer Engineering bayer-eng.com

than mechanical retooling.

“It’s not about replacing human labour. It’s about reimagining the entire manufacturing process to create competitive advantages through adaptability,” said Dr Wong.

The payoff is significant: faster changeovers, economic smallbatch production and the ability to produce customised products at competitive prices.

Continues next page

Walk into advanced Australian factories today and you’ll see four key technologies working together to pivot as quickly as the market demands:

1. Robots with powerful and precise product handling

At the heart of this revolution are machines that move with precision:

• Articulated robots: Multi-jointed arms reach into tight spaces or lift loads up to 1 tonne.

• SCARA robots: ‘Selective Compliance Articulated Robot Arms’ execute up to 60 precise movements per minute to assemble small components.

• DELTA robots: Suspended from above, these parallel robots zip around at dizzying speeds – up to 120 picks per minute – their synchronised movements resemble a choreographed dance.

• COBOTs: Unlike their caged counterparts, ‘Collaborative Robots’ work shoulder-to-shoulder with humans with in-built safety systems, combining human judgment with mechanical precision.

2. Smart motion systems

Intelligent transport and gripper systems create factory-wide coordination:

• Programmable work carriers smoothly shuttle components between operations

• Smart grippers with tactile sensing can handle anything from delicate biscuits to heavy metal

• Soft servo technology allows robots to apply precise, controlled force for delicate assembly

• Autonomous Mobile Robots (AMRs) navigate freely, not on fixed paths, adapting routes in real-time

This creates what Dr Wong describes as ’a dance of coordinated movement’ where products flow smoothly through production without traditional rigid infrastructure.

3. Advanced 3D sensing for a soft touch

The ability to adapt to variations makes the difference:

• 3D vision systems identify and inspect components regardless of orientation

• Force and torque sensors allow precision assembly with a gentle touch

• Soft guarding systems create safe human-robot workspaces without physical barriers

Capral Aluminium’s packing system uses 3D cameras to identify over 6,000 unique and reflective aluminium profiles and then determines optimal picking and packing strategies on the fly.

4. Advanced software ‘brains’ using data and AI Manufacturing Execution Systems (MES) and other advanced software – once only affordable for large enterprises – now act as the affordable, cloud-based brains behind the operation, tying everything together:

• AI algorithms that make complex decisions without explicit programming

• Digital twins that simulate processes before implementation, eliminating costly mistakes

• Automated programming that translates CAD models into robot instructions in minutes, not days

“When we deployed Australia’s first AI-based factory automation system for Capral in 2018, the intelligent algorithm could identify, grasp and nest each unique extrusion shape in real-time. A concept also central to Arnott’s revolutionary biscuit assortment system, which processes up to 105 biscuits per second,” said Dr Wong.

The business case for adaptive automation goes well beyond labour savings. Applied Robotics has helped deliver competitive advantages ideally suited to Australian conditions.

When Legrand Australia needed to maintain local light switch manufacturing in the face of offshore competition, they turned to adaptive

automation.

We designed a system that handles configurations from single switches to six-gang units with minimal changeover time, doubling production output while reducing

“When products can’t be produced cost-effectively locally, they inevitably move offshore,” said Dr

“Adaptive automation helps Australian manufacturers compete on factors beyond just labour cost – enabling some operations to be brought back onshore.

Unlike fixed automation, modern systems can be reprogrammed to meet new requirements, protecting capital investments over the long term. The results speak for themselves.

Capral Aluminium’s implementation of AI-powered robotic packing slashed freight volumes by 50% while accelerating distribution and improving quality and handling an ever-changing range of 6,000 unique profiles.

At an Australian audio technology manufacturer, our innovative assembly system achieved a 95% first-pass success rate, reducing the number of operators required from 2-3 to a single operator.

After guiding over 700 automation projects across diverse industries, Dr Wong and the Applied Robotics team have seen the good, the bad and the costly.

“Without thoughtful planning, the hard truth is that up to 80% of manufacturing projects fail to achieve either business case target costs or timelines, despite no limitations with the technology itself,” he said.

To avoid becoming part of that statistic, Applied Robotics apply three human-centred principles:

1. Start with the big picture

Look beyond individual machines to the entire process flow. Consider how materials, information and finished products move through your operation to avoid bottlenecks elsewhere.

2. Sweat the small stuff

Successful implementations require meticulous attention to specifications, edge cases and integration points. These can make or break commercial success over time. Rigorous testing and validation are essential investments.

3. Champion your project

Every successful automation project needs a dedicated leader who can bridge technical and business perspectives while driving the project to completion. Without this champion, even the best technology can falter.

Australian manufacturers are discovering that their traditional disadvantages – smaller runs, higher customisation – can become strengths with the right technology.

“The planning phase has the most influence on final results. The most brilliant project management or technology solution cannot overcome a poorly conceived business case,” explained Dr Wong.

“Since 1985, our driving vision has been to transform Australian industry into a globally competitive manufacturing powerhouse. With these technologies, local manufacturers can not just survive but lead in global markets.

For Australian manufacturing, success isn’t about competing on volume.

Adaptive automation breathes new life into the local industry with systems that adapt as quickly as market demands change, turning traditional disadvantages into our greatest strengths - and the transformation is just beginning.

Price pressure and competition for skilled workers is fierce in the protein industry.

To be successful, food producers like Maple Leaf Foods must find better ways to capture more value from the equipment on their plant floors –and attract, train and retain workers.

Paired with the tight talent landscape, the global demand for food continues to grow.

Food manufacturers are under increased pressure to adopt automation and carbon-neutral methods to improve operational efficiency, seamlessly integrate equipment, gain visibility across their systems and secure IT and OT networks.

As the world’s first carbon-neutral food company, Maple Leaf Foods has embraced automation and digital transformation at every level to drive efficiency and quality.

The company has formed strategic partnerships and launched innovative programs at multiple facilities.

These programs allow facilities to try new applications for automation and digital transformation technology – gaining a competitive edge by using the latest technologies to improve quality and productivity.

With a strong reputation for quality and innovation through brands like Maple Leaf, its Schneiders meat brand and Greenfield Natural Meat Co., the food producer leads the industry by integrating cutting-edge technologies that enhance

Iproduction and sustainability.

Project 1: Using Augmented Reality (AR) and Digital Twin Technology to Empower Workers

Leadership at Maple Leaf Foods’ Guelph Manufacturing Plant identified a need to improve overall equipment effectiveness (OEE) and worker training. Maple Leaf Foods, along with Rockwell Automation and PartnerNetwork members HarpakULMA Packaging and PTC, set out to develop an AR-based training program using Vuforia Expert Capture.

Harpak-ULMA deployed its embedded OEE Application, which automatically calculates, monitors and reports packaging line performance in real time.

Next, Harpak-ULMA deployed the entire library of PTC AR applications and created its own machinebased AR experiences.

Most AR user experiences leverage the machine’s digital twin, a dynamic model that virtually represents the physical machine.

The pilot project quickly demonstrated the value of AR in a packaging line. For example, the OEE application delivers self-diagnosing machine reports that identify machine downtime and high-priority action items by shift.

Using remote connectivity, the

Harpak-ULMA team monitors these reports daily, identifies any high-frequency stoppages – and then builds step-by-step AR-based remediation routines that operators can access in real time.

AR-based training is underway, and the company is in the process of evaluating the benefits.

They anticipate that the interactive, visually intensive training will help minimise language barriers, decrease worker error – and reduce training cycles in an environment that often experiences high staff turnover.

Rockwell Automation rockwellautomation.com

AI’s Modular Cartesian Robot Systems offer a highly adaptable and efficient automation solution for various industrial applications. Thanks to their modularity and tailored functionality, these systems require significantly less space than traditional articulated robots, making them an ideal choice for operations where space is at a premium.

Each robot is configured with only the necessary axes and functions, resulting in streamlined, space-conscious designs without compromising performance.

IAI provides a broad range of Cartesian robot systems that can be configured with 2 to 6 axes, using either servo motors for high-performance operations or more economical stepper motors.

These servo motor options are available in standard and

high-precision configurations, offering flexibility for different application demands, from simple pick-and-place tasks to more complex automation needs.

For cost-sensitive projects, IAI offers an affordable alternative in the form of its RoboCylinder series. These stepper motor-driven Cartesian robots are part of the expanding IAI portfolio and are known for delivering reliability at a lower price point.

The latest addition to this line is the RoboCylinder IK Series, which now comes equipped with a battery-less Absolute Encoder.

This innovation reduces the complexity of the design and assembly process and eliminates the need for battery replacement, simplifying long-term maintenance.

Performance has also been

enhanced with the RCP6 Series of RoboCylinders, which can achieve higher speeds than previous models, making them suitable for high-throughput environments where cycle time is critical.

Another standout feature of IAI’s modular Cartesian systems is their extensive configurability.

With up to 516 available combinations, users can select from a wide range of setups to precisely match their operational requirements.

Recent innovations include a table-type model (TA) featuring a Z-axis and a variant with a ZR unit that incorporates vertical and rotational movement.

These additions further broaden the system’s versatility, making designing compact, efficient and purpose-built automation solutions easier.

IAI’s Modular Cartesian Robot

Systems offer an optimal balance of space-saving design, modular flexibility and cost-effective automation. Whether using high-precision servo models or budget-friendly stepper variants, these systems provide tailored solutions to meet a wide variety of industrial needs.

Treotham Automation treotham.com.au

Rotary encoders are used almost everywhere in automation.

They are commonly used to monitor speed or provide positioning feedback and can be used where there is a rotating shaft, such as on a motor or a conveyor idler.

With a wheel attachment they can be used in linear applications, such as monitoring the speed of a conveyor belt, and with a wire draw attachment they can provide pointto-point position feedback even when the target object moves on more than one axis.

Incremental encoders provide output pulses that can be timed to measure speed or counted to measure position.

If power is lost and the equipment moves during this time, an incremental encoder will not detect that movement, and the equipment will need to move to a known position to zero the encoder. Using the A and B outputs, incremental encoders can determine the direction of rotation.

Absolute encoders provide precise

positioning information on where they are in a full 360° rotation.

They are more expensive and more difficult to integrate than incremental encoders, but they always provide correct position information, even if there has been movement during a power outage.

Absolute encoders can also be absolute multiturn where they don’t just measure where they are in a single rotation, they also know how many rotations have been made, providing much more extended position determination capabilities.

Common outputs from absolute encoders are greyscale binary, SSI and a variety of fieldbus formats.

All standard mechanical encoders are either solid shaft, where the encoder shaft sticks out of the device and is usually coupled to a shaft on the equipment, or a hollow shaft where the encoder clamps directly around the machine shaft.

Either way, these encoders have seals to prevent ingress of particles or moisture and they also have bearings. As far as the physical

By Ken Collishaw, Product Manager, Turck

drive goes, standard encoders are mechanical devices with moving parts. They will wear out over time.

Non-contact encoders are exactly that. They work like standard encoders, but they don’t require a mechanical coupling between the rotating equipment and the encoder.

If we compare traditional encoders with non-contact encoders, particularly those that utilise inductive resonance technology, there are some major points of differentiation. Because non-contact encoders have no moving parts, they can Continues next page

Continued from previous page

be fully potted. This has multiple advantages.

1. Non-contact encoders are robust and exceptionally well suited to high vibration applications. They will survive and be accurate where traditional encoders fail.

2. Non-contact encoders are rated to IP67/IP69K and are the ideal choice in severe wash down applications. Stainless steel housing variants are available.

3. Non-contact encoders can tolerate a level of misalignment, and this means slightly bent or off-centre shafts will not destroy the device.

4. Inductive resonance non-contact encoders are immune to interference from magnetic fields.

5. Non-contact encoders use industry standard M12 electrical connectors, rather than expensive specialist connectors.

6. Non-contact encoders can be user parameterised, meaning one spare will cover multiple different applications.

7. Non-contact encoders do not have mechanical ‘end of life’, so they will need replacing less frequently.

8. The positioning elements for non-contact encoders can be fitted with a variety of reduction

bushings for different sized shafts.

9. Non-contact encoders are reasonably priced, making it possible to standardise on a single type of device in both your challenging and your simple applications.

10. Non-contact encoders do not require maintenance. Any faults are highlighted by their LEDs, which are visible from a distance.

The best way to work out if non-contact rotary encoders are the solution for you is to ask one simple question: Are we regularly replacing encoders?

If the answer is yes, then ask why

(hint – the answer is probably covered in the list above).

Once you have that knowledge it is easy to determine if non-contact encoders are the solution you need. Even if the answer is no, it may still be worth using non-contact encoders, just to make sure the answer does not change in the future. Making your equipment more reliable saves time, cost and waste.

If you want to know more talk to an expert and find out how non-contact encoder technology can help you.

Turck Australia Pty Ltd turck.com.au

As the local wine sector grapples with the challenges posed by fluctuating market and environmental conditions, coupled with workforce shortages, the need for an innovative approach has never been greater.

“New technology could help solve these problems, enabling a more efficient, sustainable and resilient production without compromising on the quality or craftsmanship associated with traditional winemaking,” says Darryl Blackeby, Regional Sales Manager (SA/WS) of IFM Efector, a leading provider of specialist monitoring solutions, including sensors, controllers, software and other digital solutions for industry.

“While some of these automated solutions are perceived to be expensive or complex, we offer a range of products that are cost effective and easy to set up, making them ideal even for small to medium wineries.”

To help local winemakers better understand how digital solutions can optimise their operations and support top-quality wine production, IFM will be exhibiting at the upcoming 2025 Wine Tech Exhibition (taking place from 21 to 23 July at the Adelaide Convention Centre).

“Wine Tech is the ideal platform to connect with the industry and to showcase a range of easily implemented automation solutions,” said Blackeby.

“The products on show are proof that we listen and design products suited to the needs of local winemakers.”

One of IFM’s popular innovations for industry, the SM Foodmag

hygienic flow meter – specially developed for the food & beverage sector - will be on display at the upcoming Wine Tech Exhibition.

This sensor detects and transmits information (such as temperature) to the control system remotely, providing winemakers with a clear overview of process conditions and performance.

“IFM tools ensure that flow rates remain consistent and that the conditions for filtration, fermentation and mixing are optimised to control the quality and consistency of the wine,” says Blackeby.

“With the SM Foodmag, there’s no need for time - and labour-intensive - manual monitoring.”

Interestingly, the SM Foodmag device can display up to 20 events at any one time, while up to 200 events can be stored, viewed and downloaded.

“Having access to this data for analysis is valuable, as trending data helps winemakers work towards better process performance and, ultimately, better product quality,” explained Blackeby.

The SM Foodmag is easy to install, programme and use, with an intuitive app-based menu structure.

Its customisable configuration also makes it easy to integrate into existing plant systems. It also features a fully welded, stainless-steel housing with temperature resistance up to 150 °C.

“This is a robust, reliable longterm monitoring solution,” said Blackeby.

“In addition, it’s ideal for confined spaces due to its compact nature and can work reliably even in wet environments.”

IFM will also be showcasing its temperature monitoring solutions at the Wine Tech Exhibition, including temperature sensors that can be monitored remotely or via a screen.

“Being able to control the temperature means having greater control of the biological processes involved in fermentation and processing,” said Blackeby.

“This is a critical and helpful tool in ensuring the wine quality meets brand requirements.”

“With market conditions as they are, coupled with the agricultural workforce shortage and more extreme environmental factors affecting grape yields, winemakers have to become more efficient in order to survive.

“Having smart monitoring capabilities is key to the improved efficiency, driving a more productive and profitable business operation and ensuring the best quality of wine.”

“With a five-year warranty on all of our products, which have been purposefully designed to optimise the winemaking process, IFM is a trusted partner for the wine industry.

“We look forward to being part of the future of the wine industry and engaging with Australian winemakers at the Wine Tech Exhibition.”

IFM - ifm.com

One of the leading lights of the Industry 4.0. wave, Professor Henrik von Scheel, has been announced as the headline speaker at the inaugural Industrial Transformation Australia conference.

The new trade show is organised by Hannover Messe and will be held alongside their showpiece event, CeMAT Australia, at Sydney Olympic Park over the week of 22–24 July.

Professor von Scheel is a world-leading futurist and is known as the father of Industry 4.0, a

term that he coined to refer to the Fourth Industrial Revolution, which involves the adoption of AI and digital technologies in manufacturing.

He will journey from Switzerland to Australia for the show to deliver a speech that is set to cover the paradigm shift of the Industry 4.0 evolutionary stages and the key megatrends that will influence advanced manufacturing in Australia.

“We are in one of the most disruptive periods in human history, which provides great opportunities to innovate and change the way we live

for the better,” he said.

“Australia is at a pivotal moment with the big question hanging over its head: Is Australia ready to lead in the Fourth Industrial Revolution or will it be left behind? I’m looking forward to exploring this question in July and connecting with the local industry.”

von Scheel will also be present on day two of the event, where he will speak at the Processing & Packaging Pavilion, which will showcase leading manufacturers, distributors and importers of packing and processing machinery who are at the forefront of the food, beverage, pharma, e-commerce, chemicals and other manufacturing sectors.

“Professor von Scheel will both challenge and inspire our local sectors providing a detailed understanding of what lies ahead and the key influences that will shape the future,” said Mike Nissen, Commercial Director, Hannover Fairs Australia.

“Having Industrial