Beverlin Specialty Tube is proud to announce the acquisition of Perforated Tubes. This exciting partnership brings together over 100 years of combined expertise in perforated cores, filter elements and welded assemblies, forming a unified powerhouse poised to set new industry standards. By joining forces, we are now able to offer an even broader range of exceptional products and services, while continuing to deliver the unparalleled experience our customers expect. Together, we’re expanding our reach across sectors and increasing our impact on the market.

To learn more, visit beverlin.com and perftubes.com or call us at 616.949.5990.

616.949.5990

Solution Center: LAM-X Bringing Innovation to the Industry

Greening Filter Media at the Roots of a Natural Skyline By Adrian Wilson, International Correspondent, IFN

Exploring Bio-Electrostatic Options Can Biopolymers Power the Future of Air Filtration? By Yasar Kiyak, PhD

Harvest from Natural Materials Trends in Sourcing for Filter Media Applications By Jason Chen, International Correspondent, IFN

Fine-Tuning the Performance of Membranes for Liquid Filtration By Adrian Wilson, International Correspondent, IFN

Innovations & Trends in Residential IAQ and Ventilation

Plus: Excerpts from the Experts – Going the Extra Mile By Dr. Iyad Al-Attar, Global Correspondent, IFN

Filtration Particulars

The Difference Between a Separator and a Filter for Cleaning Industrial Liquids By James J. Joseph

FILTCON 2025 Honors Excellence

Plus: EDANA’s FILTREX 2025 Explores Sustainability By Caryn Smith, Chief Content Officer & Publisher, IFN

Caryn Smith

Chief Content Officer & Publisher, INDA Media csmith@inda.org

Adrian Wilson International Correspondent adawilson@gmail.com +44 7897.913134

Dr. Iyad Al-Attar

Global Correspondent, Technology & Innovation, Visiting Academic Fellow Cranfield University i@driyadalattar.com

Yasar Kiyak, PhD, PMP, CAFS R&D Manager Gessner Filtration, a MATIV Brand yasar.kiyak@mativ.com

Dr. Iyad Al-Attar

Global Correspondent, Technology and Innovation

We live in an era defined by rapid technological advancement and a growing awareness of the intricate relationship between our environment and well-being. We are privileged to introduce Dr. Iyad Al-Attar, a distinguished mechanical engineer, air quality consultant, and academic luminary, who will focus specifically on the critical intersection of filtration technologies and their impact on public health and diverse industrial applications.

Dr. Al-Attar’s credentials speak volumes about his expertise and dedication to the field. He holds a Ph.D. from Loughborough University, preceded by Master’s and Bachelor’s degrees from Kuwait University and the University of Toronto respectively, with an academic foundation in engineering. His pursuit of knowledge extends beyond traditional engineering boundaries, encompassing executive education from MIT and Harvard Business School, specializing in sustainability, business, and strategy. This unique blend of technical acumen and strategic insight positions him as a visionary leader capable of navigating the complex landscape of global technological innovation.

Currently, Dr. Al-Attar serves as a Visiting Academic Fellow at Cranfield University, focusing on air quality and filter performance relevant to land-based gas turbines. This specialized expertise underscores his deep understanding of the intricacies of filtration in demanding industrial settings. His role as the first associated air filtration consultant for Eurovent Middle East and, more recently, as the Indoor Air Quality (IAQ) patron for EUROVENT, the voice of the European HVACR industry with global reach, further solidifies his position as a leading authority in air quality and filtration.

As an IFN correspondent, Dr. Al-Attar will leverage his extensive experience and profound knowledge to explore and disseminate cutting-edge advancements in filtration technologies. His focus will be multifaceted, addressing the importance of appropriate filtration in promoting public health and well-being while simultaneously highlighting its role in advancing diverse applications such as filter media manufacturing and performance, in vitro fertilization (IVF), power generation, urban planning, and city design, among other forwardthinking filtration topics, as a catalyst for positive change, bridging the gap between cutting-edge research and real-world applications.

James J. Joseph

Author and Consultant Joseph Marketing +1 757.565.1549 josephmarketing120@ gmail.com

Jason Chen International Correspondent jasonchen200501@hotmail.com

Philippe Wijns is a Certified Expert in Sustainable Finance, Climate Finance, and Renewable Energy from the Frankfurt School of Finance and Management. He began his professional journey with global leaders in the nonwovens industry before transitioning to the filtration sector, where he specialized in filtration technologies across a wide range of applications and markets – including industrial and automotive systems, HVAC, household appliances, medical and life sciences, as well as power storage solutions such as fuel cells, hydrogen systems, and battery separators. Over the years, he has established himself as a recognized expert in filtration media.

Building on a successful career with global market leaders in these fields, Philippe recently founded CleverSustainability, a consultancy dedicated to sustainable business development. Through this platform, he helps companies develop and implement sustainability strategies, ensure compliance with the EU legal reporting requirements, and enhance their sustainable business growth, product portfolio and development, and market positioning.

Wijns holds a bachelor’s degree in medicine and chemistry from the Catholic University of Leuven, an MBA in Strategic Marketing from the Maastricht School of Management, and a postgraduate degree in International Business and Finance. Born in Brussels and now based in Frankfurt, he considers the city his home.

Wijns shares his commentary in our NEW Green Economy column. To connect, email philippe.wijns@ cleversustainability.com or visit https://www. linkedin.com/in/philippe-wijns-5b95741.

CSMITH@INDA.ORG +1 239.225.6137

“Innovation

Steve Jobs is my hero of innovation. Every time analysts say Apple is dropping in the technology popularity contest, his innovative company follows his legacy of innovative thinking and wows us with new cool ideas like a computer in your watch! From iMac to iPod to iPad to iWatch, Apple makes technology fun, friendly and trendy. His inspiration rings truer than ever for industry leaders in any niche. Innovation is not just a buzzword; it is the force that sets leaders apart from followers, inspiring us to challenge the status quo and redefine the possibilities.

Keeping pace or outpacing competitors means we must dare to forge new paths, even when the way forward is uncertain. When it comes to filtration and green technologies, the industry is waiting for others to forge the path due to prohibitive costs and lack of consumer buy-in. Yet, someone needs to lead.

In this issue of IFN, contributors explore how creative thinking and experimentation can shape the future of filtration, leading the way for greener options:

• Urban Greening: Filter Media at the Roots of a Natural Skyline by Adrian Wilson, page 20, examines how nature and filtration can transform cityscapes, supporting greener, healthier urban environments.

• Exploring Bio-Electrostatic Options: Can Biopolymers Power the Future of Air Filtration?, page 24, by Yasar Kiyak, PhD, delves into the promise of biopolymer-based

filters–demonstrating that sustainable materials can deliver high performance while reducing environmental impact.

• Harvest from Natural Materials: Trends in Sourcing for Filter Media Applications by Jason Chen, page 28, highlights the shift toward renewable, biodegradable resources, reflecting a broader industry move toward eco-friendly solutions.

• Fine-Tuning the Performance of Membranes for Liquid Filtration by Adrian Wilson, page 32, shares research from Professor Steffen Schütz, senior manager of membrane development at MANN+HUMMEL, outlining the key markets and applications for membrane technologies in liquid filtration, emerging new developments and challenges involved in balancing performance requirements and environmental legislation.

• Innovations & Trends in Residential IAQ and Ventilation by Dr. Iyad Al-Attar, page 36, interviews Andrew Guido, most recently a recipient of the GIA Global Innovation Home of the Year from the National Association of Home Builders (NAHB).

As you read, I encourage you to reflect on how innovation shapes your own work and organization. Are you leading, or are you following?

Caryn Smith Chief Content Officer & Publisher, INDA Media, IFN

R. Vijayakumar, Ph.D., Chair

AERFIL

Tel: +1 315-506-6883

Email: vijay@aerfil.com

Tom Justice, CAFS, NCT

ZENE, LLC Filtration

Tel: +1 757-378-3857

Email: justfilter@yahoo.com

James J. Joseph

Joseph Marketing

Tel/Fax: +1 757-565-1549

Email: josephmarketing120@gmail.com

Wenping Li, Ph.D.

Agriltech Research Company

Tel: +1 337-421-6345

Email: wenpingl@agrilectric.com

Rishit R. Merchant

Parker Hannifin

Tel: +1 805-604-3519

Email:rishit.merchant@parker.com

Thad Ptak, Ph.D.

TJ Ptak & Associates

Tel: +1 414-514-8937

Email: thadptak@hotmail.com

If you would like to utilize your expertise to help shape the content in the IFN , consider applying for the IFN Editorial Advisory Board. We welcome participation through input on trends and innovations, new story ideas and overall thought leadership. This is a collaborative board that meets quarterly to discuss the state of the industry. Send an email to Caryn Smith at csmith@inda.org for consideration.

Large-area filtration faces the challenge of high costs, maintenance efforts, and time-consuming changeover and cleaning activities, and it becomes even more challenging with increasing rPET content. BB Engineering (BBE) in Germany has addressed these issues with the company’s new COBRA filter, which combines continuous and automated large-area filtration with integrated intermediate filter cleaning –setting a new standard in efficiency, ease of use and resource saving, and finally meeting the demanding requirements of recycling processes.

Recyclers are dealing with a dilemma when it comes to filtration. Increasing recycling quotas with insufficient availability means that lower input qualities are being considered for recycling, resulting in challenging contaminants. At the same time, higher-quality applications are being targeted, which further intensifies the requirement for fine filtration. There are systems for large quantities of contaminants, but they do not filter as finely as a candle filter. There are also candle filters that provide excellent filtration but cannot cope with high levels of contamination.

The new COBRA filter can do both. It was developed for demanding filtration tasks with high levels of contamination, particularly in PET recycling. COBRA unites large-area fine filtration with simultaneous, fast and effortless cleaning, and is able to handle higher contamination rates, which common candle filters would fail on. However, this allrounder

can also be used for other applications, e.g. in synthetic fiber spinning.

As a continuous filter, the COBRA filter has two filter inserts, one of which is always active in production mode and the other either in stand-by mode or in intermediate cleaning. The automated switchover ensures a smooth changeover between the inserts. The status of the filter inserts is constantly checked by the system and, if necessary, the COBRA filter automatically initiates the cleaning and changeover process. All the operator has to do is confirm this on the user interface. The process thus continues to run stably and safely without interruption. Operator-related deviations in the switching process, errors or delays, all of which could affect the process, cannot occur.

The highlight of the COBRA filter is the integration of BBE’s White Filter Cleaning technology (WFC). This process enables chemical-free and environmentally friendly intermediate cleaning of the filter inserts using hot steam alone and extends the filter’s service life many times over. BBE has already had WFC in its product portfolio as a stand-alone solution for several years. Now, for the first time, the cleaning system is integrated directly into a filter, bringing additional advantages, like cleaning speed and wear-reduction. Production and cleaning become an alternating interaction. Only after multiple operating/cleaning cycles (the exact number depends on product and degree of soiling) is it necessary to completely remove

the filter insert for a service check and full cleaning. The WFC cleaning process only takes around 10 hours, whereas conventional cleaning takes several days. Filtration and cleaning form a self-contained, automated system that guarantees process and operating safety in equal measure: The operator does not have to handle melt or chemicals.

BB Engineering pursued clear objectives when developing the COBRA filter: In addition to adapting the system to the growing challenges arising from increasing levels of contamination in recycling, BBE focused on simplifying filter changes and cleaning processes through automation as well as savings in operating costs.

Comparing the COBRA filter with other fine filters with a throughput of 2000 kg/h reveals a saving of 40% in pure operating costs. One significant part of the savings comes from the reduction of melt loss through backflushcycles. Another key point is the continuous operation with significantly longer service life thanks to the integrated cleaning with steam. This is linked to reduced use of spare parts and consumables due to the gentle treatment, conversion costs and a lower energy requirement, as no heating and cooling phases and generally lower cleaning temperatures are required. Costs of chemicals are completely eliminated. Further more information, contact Pia Kürtenkuerten.pia@bbeng.de. www.bbeng.de

For details on how to submit your company’s technology for consideration as a “Technology Spotlight” in IFN , contact Ken Norberg at ken@filtnews.com or +1 202.681.2022.

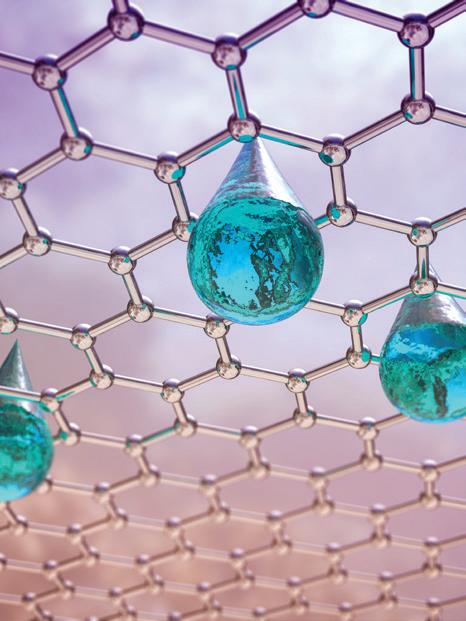

Singapore-based

Memsift Innovations, an emerging leader in advanced membrane technologies, in partnership with the Murugappa Group, announced the commercial launch of the GOSEP™ ultrafiltration membrane and the opening of a cutting-edge membrane manufacturing facility. This milestone marks a significant leap forward in making one of the most advanced membrane chemistries accessible at scale, reinforcing Memsift’s commitment to revolutionizing the water treatment and separation industries.

The two companies formalized a partnership with an MOU signed in June 2023.

Gosep ultrafiltration membranes are made with innovative, chemically resistant, and highly durable membrane chemistry. They have applications in industrial wastewater treatment, resource recovery, pre-treatment for desalination, and chemical separation.

Memsift said that the commercial availability of Gosep membranes is expected to significantly reduce operational costs and enhance efficiency for industries seeking sustainable water treatment solutions, including microelectronics, textiles, chemicals, and pharmaceuticals. www.memsift.com

Parker Bioscience Filtration, a division of Parker Hannifin, the global leader in motion and control technologies, announced the launch of SciLog ® NFF+ PF. This innovative solution is specifically designed to assist biopharmaceutical manufacturers in seamlessly integrating Pre-Use Post-Sterilization Integrity Testing (PUPSIT) into their filtration processes, ensuring the highest product safety and quality standards.

The SciLog ® NFF+ PF system addresses the complexities of implementing PUPSIT in biopharmaceutical manufacturing environments. This fully automated, multipurpose Normal Flow Filtration (NFF) system features an onboard PUPSIT solution. It is designed with a compact footprint, making it ideal for Good Manufacturing Practice (GMP) operating environments.

In response to the updated EU GMP Annex 1 guidelines, PUPSIT – an essential procedure for verifying the integrity of sterilizing filters before use – has become mandatory in most sterilizing filtration applications. This requirement is integral to quality risk management strategies aimed at validating filter integrity prior to its application.

However, implementing PUPSIT can introduce increased risks, such as a higher number of connections and elevated operating pressures, which can lead to human error and necessitate additional operator training. Operational errors can result in product waste, potentially affecting supply chains.

Parker has integrated single-use flow paths, advanced sensing technology, and automation within the SciLog® NFF+ PF system to mitigate these challenges. This design guides operators through the PUPSIT process and overall bioprocessing via an intuitive interface, significantly reducing the risk of human error. Operators can configure fully automated sequences to monitor, adjust, and record pressure and flow rates, optimizing processing times and maximizing filter life and efficiency. The system executes the sterile filtration sequence, with PUPSIT seamlessly integrating as a key step in the process, ensuring filter integrity is validated before product filtration. www.parker.com

Mott Corporation, headquartered in Connecticut, announced a $40 million agreement with a large U.S. dairy farm operation to deploy its custom filtration solutions. This strategic partnership will involve deploying advanced filtration systems to treat over two million gallons of wastewater daily.

The custom-designed system was specifically tailored to address the dairy industry’s unique requirements, providing an efficient and cost-effective solution for wastewater treatment. This collaboration highlights Mott’s ongoing commitment to delivering innovative

solutions that improve operational efficiency and promote sustainability for its clients.

Installing Mott’s proprietary Microfiltration (MF) and Sub-Induction Time Reverse Osmosis (SIT-RO) systems simplifies processes and enhances efficiency. Additionally, this approach reduces the need for common chemicals and other additives, leading to lower operating costs. www.mottcorp.com

CLEANR has launched a new offering that will enable U.S. universities to reduce their microplastic emissions significantly. Under the program, CLEANR will deploy its breakthrough microplastics filter to on-campus washing machines to prevent microplastics from going down the drain and entering the environment.

CLEANR first debuted its filters at Case Western Reserve University (CWRU) as part of its sustainability efforts.

Ahlstrom, a global leader in fiber-based specialty materials, enhances its offering for its patented lignin-based filtration media. A proven, high-performance alternative to traditional filtration materials further supports customers in making sustainable choices.

“By focusing on washing machines, U.S. universities can join in stopping up to a third of microplastics from entering our waterways,” said Max Pennington, Co-Founder & CEO of CLEANR. “Our filtering technology makes the job almost as simple and easy as removing lint from a dryer for university communities and makes a measurable impact on microplastic emissions.”

According to the International Union for Conservation of Nature, washing machine wastewater is the world’s largest source of microplastic pollution. CLEANR’s filter – based on its core VORTX technology – was recently certified by the prestigious Shaw Institute to remove over 90% of microplastics as small as 50 microns. www.cleanr.life

Rensa Filtration’s Advanced HEPA Filters Certified to Meet the UL 900 Safety Standards

Rensa Filtration, a leading manufacturer and distributor of consumable, mission-critical air filtration solutions, announced that its SuperFlo HEPA V-Bank and HEPA Deep Pleat filters have been evaluated by UL Solutions to meet the requirements of the UL 900 Standard for safety for Air Filter Units. The UL Mark underscores Rensa’s commitment to providing safe, high-quality filtration products and confirms that these filters have undergone rigorous third-party testing and verification by UL Solutions.

Brandon Ost, CEO and Founder of Rensa Filtration, said, “We’re excited that our

SuperFlo HEPA V-Bank and Deep Pleat filters now have UL 900 Classification. These filters are essential for critical industries like data centers, healthcare, and advanced manufacturing, where high-performance air filtration is critical. Our ongoing investment in our offering of HEPA filters helps us stay at the forefront of the air filtration industry.”

Rensa SuperFlo HEPA V-Bank and Deep Pleat filters are engineered to perform in adverse, critical, and sensitive conditions. These filters provide superior performance with high dust-loading capacity and low resistance to airflow, offering 99.97% and 99.99% efficiency at 0.3 microns. Constructed with a 40% lighter high-impact plastic frame and Rensa Filtration’s proven mini-pleat technology, they deliver superior filtration, resulting in enhanced performance, improved energy efficiency, and a lower total cost of ownership. www.rensafiltration.com

Ahlstrom ECO™, introduced in 2023, combines a proprietary lignin-based impregnation, replacing fossil-based resin with a renewable, bio-based cellulose filtration media. This innovation significantly reduces reliance on non-renewable resources while maintaining exceptional durability, mechanical strength, and filtration performance.

Designed for liquid and air filtration, Ahlstrom ECO™ is ideal for engine oil and engine air intake filtration, as well as for industrial filtration systems operating under challenging conditions. Delivering superior filtration performance helps optimize equipment protection while contributing to a lower environmental impact.

Ahlstrom estimates that the lignin-based impregnated filter media displays a lower carbon footprint than a standard fossil-based resin media. Additionally, the lignin-based impregnation significantly reduces 50–70% of formaldehyde emission during the curing process. This makes the filter media an industry-leading choice for manufacturers seeking to improve sustainability without compromising performance or reliability. A flame-retardant version is also available for air filtration applications requiring enhanced fire safety. www.ahlstrom.com

Walmec North America’s WNA AMD-035 Membrane dryer is a prime option when compressed air applications require Ultra-Clean and Ultra-Dry air.

According to Walmec North America, the WNA AMD-035 Membrane dryer has a four-stage pre-filtration that is critical to its longevity and function. It has a flow rating of 35 SCFM and maximum working pressures of 150 PSI.

The first and second-stage filters remove moisture, liquids, dust, rust, scale, and other contaminants to five microns. An automatic float drain under the second stage filter opens and expels all collected liquids whenever an ounce or more is present. It is fully automatic with no continuous air loss. The third and fourth stages remove any remaining particles down to .01 microns and absorb any remaining

American textile company Vidalia Mills based in Vidalia, Louisiana, has implemented a technologically advanced digital tracking system that asks the industry to reconsider how companies trace cotton products throughout the supply chain. This technology, unprecedented within textile manufacturing, guarantees full accountability for all the products Vidalia Mills creates.

The digital tracker, embedded into the cotton fibers themselves, enables Vidalia Mills to monitor the journey of their products from

moisture or oil vapors. The Membrane Dryer lowers humidity by venting it harmlessly into the surrounding atmosphere. A flexible input hose assembly eliminates the hazards of damage from vibrations in piped compressed air systems and allows the Membrane Dryer to be installed in any position.

The four-stage pre-filtration includes differential pressure gauges and comes complete with mounting brackets. The differential pressure gauges provide a visual indication of required maintenance which is easily done by installing the appropriate service kits. No need to remove the unit from the compressed air system.

www.walmecna.com

the initial stages of cotton cultivation to the final finished goods.

By integrating this advanced tracking system, Vidalia Mills aims to provide its customers with complete assurance regarding their cotton products’ origin, quality, and sustainability. Vidalia Mills’ digital tracking system is now available for all its cotton products, including its signature artisanal canvas and denim fabrics. Customers can access detailed information about the origin and journey of their clothing

by scanning a unique QR code on the garment’s label.

The digital tracking information will be readily available for each product, providing customers with a comprehensive understanding of the item’s journey from seed to shelf.

www.vidaliamills.com

ZwitterCo announced the availability of a new product line of sanitary superfiltration (SF) spiral membrane elements featuring its second-generation SF technology. These membranes are FDA-compliant for whey processing, including producing products such as whey protein concentrate (WPC) and whey protein isolate (WPI).

ZwitterCo, a leader in developing and commercializing organic

fouling-immune membrane technology based on the extreme hydrophilicity of zwitterions, has focused primarily on high-strength water and wastewater treatment to date. With this new sanitary product line, the company is now pursuing dairy and food processing.

“ZwitterCo’s anti-fouling membranes enable dairy processors to fully recover performance with a shorter, faster cleaning program that reduces chemicals, water, and energy requirements and saves time and money,” said Jon Goodman, ZwitterCo’s Vice President for Food Processing & Specialties. “ZwitterCo is developing anti-fouling membranes that are the next evolution of membrane technology for food and dairy processors.“ www.zwitterco.com

Compiled by Caryn Smith, IFN Chief Content Officer

IFN highlights significant research from universities and institutions around the world. If you are a part of a project you would like to highlight, email csmith@inda.org. Please write “IFN Emerging Research Submission” in your subject line in order to apply. Please send a completed press release and/or summary of the research as you would want it to be printed, a link to the university online story (if applicable), and all high resolution photographs/charts/graphs, short researcher bio(s). All selections could be edited for length.

Curtin University researchers have developed a new technique to make glass water-repellent, a feature that could improve safety in vehicles, reduce cleaning costs for buildings and enhance filtration systems.

The research, published in the prestigious journal Advanced Functional Materials, shows how an innovative and non-toxic process using ultrasonic sound waves can alter the surface of glass, making it either hydrophobic (water resistant) or electrically charged.

Lead researcher Associate Professor Nadim Darwiwsh, an ARC Future Fellow at Curtin’s School of Molecular and Life Sciences (MLS), explained that the process uses ultrasound to trigger a chemical reaction that permanently alters the surface of glass.

“The sound waves create microscopic bubbles in a diazonium salt solution, which then collapse rapidly creating tiny bursts of heat and pressure,” Associate Professor Darwish said.

“This triggers a reaction that forms a stable, organic layer to the glass, making it either permanently water-repellent or positively charged, depending on the type of diazonium salt used. Unlike conventional coatings that wear off over time, our method creates a chemical bond at the molecular level, making it far more durable and environmentally friendly.”

Study co-author Dr. Tiexin Li, a Research Associate at Curtin’s School of MLS, said the ability to modify glass surfaces in a simple and sustainable way has far-reaching implications across multiple industries.

“Glass is used everywhere – from cars and buildings to industrial filters – but its natural tendency to attract water limits its performance,” Dr. Li said.

“Unlike traditional coatings this film won’t peel off, dissolve in water or deteriorate so it’s ideal for real-world applications where reliability and durability are key. This could mean clearer

p Schematic of the ultrasonic fabrication of diazonium films on glass. Increased glass hydrophobicity was visually demonstrated by changes in wettability and the slipping of food coloring dyes. a) Glass was functionalized by reacting with 4-heptylbenzene diazonium (in acetonitrile) under ultrasonic conditions (400 W, 24 kHz). b) Sonochemical reaction of glass and silica-terminated silicon surfaces with acetonitrile solutions of bis-diazo. The surface functionalization reaction is accelerated in the presence of trace amounts of water, suggesting the involvement of H• and HO• radicals generated by cavitation. The longer lifetime of H• compared to HO• creates a reducing environment, where electrons lost by H• reduce diazonium groups to surface-reactive aryl radicals. c) Schematic representing the interaction of glass modified with bis-diazo and 4-heptylbenzene diazonium with microorganisms including microalgae (C. vulgaris), bacteria (E. coli), and yeast (S. cerevisiae). Curtin University

windshields in heavy rain, self-cleaning skyscraper windows and solar panels that stay dust-free.”

Co-author Zane Datson, also from Curtin’s School of MLS, highlighted another unexpected benefit–the ability of the modified glass to attract bacteria, fungi and algae.

“This is very exciting as we can tailor glass properties for specific uses including in advanced filtration systems and biofuel production,” Mr. Datson said.

“For example, the coated glass can help bind yeast in brewing, capture bacteria in wastewater filtration systems or act as a

chemical barrier to microorganisms in air filters.”

The research team is now seeking industry partners to test and scale up the technology, particularly in the automotive, construction and environmental sectors.

This research was supported by the Australian Research Council and highlights Curtin University’s leadership in materials science innovation. It was conducted in collaboration with The University of Queensland, Flinders University, The University of Western Australia and Charles Sturt University.

The full paper titled, ‘Sonochemical Functionalization of Glass,’ can be found online at the link below.

READ: https://www.curtin.edu.au/news/ media-release/a-clear-game-changer-curtinswater-repellent-glass-breaks-new-ground/ The full research: https://advanced.onlinelibrary. wiley.com/doi/10.1002/adfm.202420485

Despite improvements to air filtration technology in the aftermath of the COVID-19 pandemic, some of the smallest particles — those of automobile and factory emissions — can still make their way through less efficient, but common

filters. An interdisciplinary team of researchers from Drexel University’s College of Engineering have introduced a new way to improve textilebased filters by coating them with a type of two-dimensional nanomaterial called MXene.

Recently featured in C–Journal of Carbon Research, the team’s research reports that a non-woven polyester textile — a low-cost material with low filtration efficiency — coated with a thin layer of MXene nanomaterial can turn it into a potent filter capable of pulling some of the finest nanoparticles from the air.

“It can be challenging for common filters to contend with particles less than 100 nanometers, which include those emitted by industrial processes and automobiles,” said Michael Waring, PhD, a professor in Drexel’s College of Engineering, and coauthor of the research. “Being able to augment a filter, through a simple coating process, to make it effective against these emissions is a significant development.”

The researchers report that a polyester textile coated with a titanium carbide MXene can reach approximately 90% filtration efficiency for particles as small as 15-30 nanometers — the size of viruses and the finest dust particles — meaning that it could be effective as an augmentation process to air filters located in urban or industrial environments.

MXenes, a family of nanomaterials discovered by Drexel researchers in 2011, have previously demonstrated proficiency in filtration applications, including water treatment, kidney dialysis, and hydrogen capture. The materials have also shown

p Yury Gogotsi, PhD, Distinguished University and Bach professor in the College of Engineering.

p Michael Waring, PhD, a professor in Drexel’s College of Engineering, and coauthor of the research.

that they can enhance filters that remove airborne viruses in medical settings.

“With increasing manufacturing volume and decreasing price, MXenes are finding an increasing number of applications,” said Yury Gogotsi, PhD, Distinguished University and Bach professor in the College of Engineering, who led the material’s development and was among the researchers who discovered MXenes and founded MXene, Inc., a company that now manufactures them. “Particularly in the fields that require large amounts of material.”

The latest discovery is a significant step in the exploration of the nanomaterials because it shows their capability to contend with some of the smallest particles in the air and that they can easily be integrated into a filter manufacturing process.

“Our ongoing research continues to reveal the potential of MXene coatings,” Gogotsi said. “The fact that this highly conductive nanomaterial is also hydrophilic means that it can be dispersed in water to produce a coating that can easily be applied to virtually any substrate, including air filters. We are just scratching the surface of its capabilities.”

In the processes of testing the MXenecoated filters, the team made an additional discovery, that pretreating the filters with magnesium salt assisted in the MXene coating process and improved the filter’s performance by 25% – to achieve a maximum efficiency of about 90% for virus-size nanoparticles, which many common filters don’t capture.

The addition of alkaline earth metal ions, such as magnesium, improved the MXene coating process. According to the

researchers, this sort of chemical preparation further activates the surface of the MXene, which helps the material spread uniformly across the filter, creating a thicker coating and more complex channels through the material, which all contribute to better filtration capability.

The researchers tested untreated; MXene-coated; and MXene-coated and magnesium ion-treated filters in a vacuum-sealed chamber containing aerosolized sodium chloride (rock salt), and measured removal for particles ranging from 5.6 to 560 nanometers. The filters that had been MXene-coated and magnesium ion-treated performed significantly better than the other two at capturing particles of all sizes in the range, down to 15 nanometers.

In addition to their ability to improve filtration, MXenes are also highly conductive – a trait the researchers theorized could be leveraged to enable the filters to clean themselves. They tested the idea by applying an electric current to the MXene-coated filter, which raised its temperature to 100 degrees Celsius – enough to carefully burn off some particles and debris on the filter and restore its original filtration quality.

“Studies like this are encouraging for real-world application of MXenes in air filtration,” said Prastuti Upadhyay, a Materials Science and Engineering undergraduate student in the College of Engineering, who was mentored by Drexel postdoctoral researcher Stefano Ippolito, PhD, and was the lead author of the paper. “But it should be noted that our air filters could still be improved by focusing on optimizing the MXene structure, pretreatment ions and the filter substrate. This leaves room for many exciting possibilities for this line of research.”

This research was funded by the Army Research Laboratory.

In addition to Upadhyay, Gogotsi and Waring, Bita Soltan Mohammadlou and Ippolito, from A.J. Drexel Nanomaterials Institute, participated in this research.

Read: https://drexel.edu/news/archive/2025/February/MXene-coated-air-filters

Full Paper: https://www.mdpi.com/23115629/11/1/13

Cutting acid and base treatments from conventional desalination plants could save billions of dollars globally, making seawater a more affordable option for drinking water.

Water desalination plants could replace expensive chemicals with new carbon cloth electrodes that remove boron from seawater, an important step of turning seawater into safe drinking water. A study describing the new technology has been published in Nature Water by engineers at the University of Michigan and Rice University.

technology that’s fairly scalable and can remove boron in an energy-efficient way compared to some of the conventional technologies.”

Boron is a natural component of seawater that becomes a toxic contaminant in drinking water when it sneaks through conventional filters for removing salts. Seawater’s boron levels are around twice as high as the World Health Organization’s most lenient limits for safe drinking water, and five to 12 times higher than the tolerance of many agricultural plants.

“Most reverse osmosis membranes don’t remove very much boron, so desalination plants typically have to do some post treatment to get rid of the boron, which can be expensive,” said Jovan Kamcev, U-M assistant professor of chemical engineering and macromolecular science and engineering and a co-corresponding author of the study. “We developed a new

In seawater, boron exists as electrically neutral boric acid, so it passes through reverse osmosis membranes that typically remove salt by repelling electrically charged atoms and molecules called ions. To get around this problem, desalination plants normally add a base to their treated water, which causes boric acid to become negatively charged. Another stage of reverse osmosis removes the newly charged boron, and the base is neutralized afterward by adding acid. Those extra treatment steps can be costly.

“Our device reduces the chemical and energy demands of seawater desalination, significantly enhancing environmental sustainability and cutting costs by up to 15 percent, or around 20 cents per cubic meter of treated water,” said Weiyi Pan, a postdoctoral researcher at Rice University and a study co-first author.

Given that global desalination capacity totaled 95 million cubic meters per day in 2019, the new membranes could save around $6.9 billion annually. Large desalination plants – such as San Diego’s Claude “Bud” Lewis Carlsbad Desalination Plant – could save millions of dollars in a year.

p Jovan Kamcev, an assistant professor of chemical engineering and macromolecular science and engineering at U-M, places a filter membrane between two electrodes, which measure how well the membrane conducts electricity. This helps his team predict how well it can purify water.

This diagram shows how boron is removed by the researchers’ electrodes. First a majority of the salt ions are removed with reverse osmosis. Then the water flows into a cell containing a membrane with positive (pink) and negative (orange) layers. Similarly charged electrodes face the membrane layers, and when a current is applied, water molecules at the interface of the membranes split into hydrogen and hydroxide ions. The hydroxide ions stick to boron, causing it to stick

the

electrode.

Kamcev, Kamcev Research Lab, University of Michigan, and Weiyi Pan, Elimelech Research Lab, Rice University

Those kinds of savings could help make seawater a more accessible source of drinking water and alleviate the growing water crisis. Freshwater supplies are expected to meet 40% of demand by 2030, according to a 2023 report from the Global Commission on the Economics of Water.

The new electrodes remove boron by trapping it inside pores studded with oxygen-containing structures. These structures specifically bind with boron while letting other ions in seawater pass through, maximizing the amount of boron they can capture.

But the boron-catching structures still need the boron to have a negative charge. Instead of adding a base, the charge is created by splitting water between two electrodes, creating positive hydrogen ions and negative hydroxide ions. The hydroxide attaches to boron, giving it a negative charge that makes it stick to the capture sites inside the pores in the positive electrode. Capturing boron with the electrodes also enables treatment plants to avoid spending more energy on another stage of reverse osmosis. Afterward, the

hydrogen and hydroxide ions recombine to yield neutral, boron-free water.

“Our study presents a versatile platform that leverages pH changes that could transform other contaminants, such as arsenic, into easily removable forms,” said Menachem Elimelech, the Nancy and Clint Carlson Professor of Civil and Environmental Engineering and Chemical and Biomolecular Engineering at Rice University, and a cocorresponding author of the study.

“Additionally, the functional groups on the electrode can be adjusted to specifically bind with different contaminants, facilitating energy-efficient water treatment,” Elimelech said.

The research is funded by the National Alliance for Water Innovation, the U.S. Department of Energy, the U.S. National Science Foundation, and the U.S.-Israel Binational Science Foundation. The electrodes were studied at the Michigan Center for Materials Characterization.

READ: https://news.umich.edu/new-water-purification-technology-helps-turn-seawater-into-drinkingwater-without-tons-of-chemicals/

STUDY: A highly selective and energy-efficient approach to boron removal overcomes the Achilles heel of seawater desalination (DOI: 10.1038/s44221024-00362-y)

p (From left) SNUs Department of Mechanical Engineering researcher Seongmin Jeong (co-first author), Korea Institute of Science and Technology researcher Jaeho Shin (co-first author), and SNU's Professor Seung Hwan Ko (corresponding author).

Professor Seung Hwan Ko’s Research Team at Seoul National University Develops Filter-Free Microbubble Air Purification System. It solves both fine dust and CO2 problems using water-based purification inspired by the human respiratory and circulatory systems.

Seoul National University College of Engineering announced that a research team led by Professor Seung Hwan Ko from the Department of Mechanical Engineering has developed an eco-friendly air purification system using microbubble filters instead of conventional solid filters.

Enclosed indoor environments cause air pollution due to reduced oxygen and carbon dioxide accumulation, as well as fine dust and volatile organic compounds. In this case, ventilation carries the risk of introducing external contaminants, requiring more advanced purification methods.

The filters used in conventional air purification systems are unsuitable for enclosed rooms because they deteriorate due to the accumulation of fine dust and struggle to remove molecular substances, such as volatile organic compounds. Furthermore, the waste generated from filters that require regular cleaning and replacement has contributed to environmental

pollution, highlighting the increasing demand for a new, eco-friendly air purification technology.

In response, the research team has developed a comprehensive air purification system inspired by the gas exchange principles of the human respiratory and circulatory systems. This innovative system not only removes indoor fine dust but also expels accumulated carbon dioxide and volatile organic compounds outdoors while supplying fresh oxygen to address oxygen deficiencies.

The human circulatory and respiratory systems prevent the entry of external pollutants while supplying oxygen to cells via the bloodstream and expelling unnecessary carbon dioxide. This process involves natural gas exchange in the alveoli and capillaries, effectively blocking the infiltration of fine dust. Simultaneously, waste materials are excreted through the

p Figure 2. Actual configuration of an air filtration system simulating the human circulatory system/respiratory tract. (a) Schematic of a circulating air purification system consisting of water, a gas exchange unit, and a circulation pump. (b) Structure of the gas exchange unit and elastic micro-pore filter using microbubbles. (c) Actual appearance of the MEF and an optical‐microscope image showing the micro‐holes array within the MEF. (d) Photograph taken with an ultra-high-speed camera during actual microbubble generation.

Seoul National University College of Engineering

4. Animal test to identify and resolve the problem of indoor oxygen deprivation/carbon dioxide buildup due to breathing (top). Measured activity of rats with and without a circulating air purification system (bottom).

Seoul National University College of Engineering

Figure 3. Evaluation of particulate matter and CO2 removal performance of human-simulated circulating air purification systems. Seoul National University College of Engineering

(a) Photograph of the particulate matter (PM) removal process in an enclosed space.

(b) Filter efficiency measurement results for different PM sizes.

(d) Photo of CO2 removal process in an enclosed space.

(f) Measurement of CO2 removal performance as a function of water circulation rate.

kidneys, ensuring the body’s efficient purification and detoxification mechanisms.

Inspired by this principle, the research team developed a water circulation system that mimics blood circulation. Through this innovation, they demonstrated the ability to maintain normal carbon dioxide levels in indoor air. Additionally, they proved that an elastic filter, developed using laser technology, can generate smaller and more uniform microbubbles compared to traditional bubble production methods.

The microbubble-based gas exchange system features a simple principle and structure, enabling easy scalability by increasing the size or number of devices. The research team experimentally demonstrated its applicability across a range of settings, from compact tabletop and vehicle-mounted units to larger spaces such as offices and conference rooms.

Professor Seung Hwan Ko said, “This environmentally friendly technology, which replaces traditional filters with a simple water-based mechanism, purifies both particulate and molecular pollutants without generating filter waste, providing a sustainable alternative to existing filtration systems.”

The results of the research, which was supported by the Ministry of Science and ICT and the National Research Foundation of Korea, were published on October 10 2024 in Advanced Materials, an internationally renowned journal in the field of materials.

READ: https://en.snu.ac.kr/research/ highlights?md=v&bbsidx=151077

Bacterial contamination remains a critical concern across industries, particularly in hospitals, where infections pose significant risks to patient safety. LAM-X initially developed a safer, more effective, and environmentally friendly solution for patients. The result was the LAM-X Solution – an innovative antimicrobial nanomembrane that was successfully tested on hospitalized patients, reducing the infections rates. After that we have successfully adapted that nanomembrane to deal with bacterial contamination in other sectors such as water and air filtration. Existing filtration solutions in these fields often compromise environmental safety, damage equipment, or pose risks to consumers. The LAM-X Solution addresses these challenges head-on.

At the core of LAM-X’s breakthrough is a patented three-step process that delivers superior antimicrobial performance:

Trap: Optimized fiber sizing creates a dense nanofiber network capable of efficiently trapping microbes.

Prime: Embedded organic photosensitizers, activated by safe blue light (avoiding harmful UV exposure), prime the fibers for antimicrobial action.

Kill: Activated nanofibers interact with surrounding oxygen to eliminate microbes in their immediate vicinity, achieving 99.999% bacterial reduction while preventing biofilm formation.

Available in both biodegradable and synthetic versions, our nanofibers meet diverse industry requirements without compromising on environmental responsibility.

LAM-X delivers more than just a product–we provide solutions tailored to the evolving demands of the filtration market. Our approach centers on three key pillars: Innovation:

• Advanced polymer compositions designed for maximum microbial elimination.

• Embedded photosensitizers for continuous antimicrobial activity.

• Blue light activation ensures safe and efficient use.

Flexibility:

• A multidisciplinary team with deep expertise in antimicrobial technologies.

• Solutions adaptable to specific customer needs and complex challenges.

• Creative problem-solving to meet diverse industry applications.

Environmental Responsibility:

• Use of biodegradable polymers for sustainable solutions.

• Free from heavy metals (e.g., silver) and harmful chemicals like titanium dioxide.

• Effective against all viruses and bacteria, including resistant strains, without environmental compromise.

LAM-X is committed to partnering with industry leaders to develop customized solutions that enhance safety, performance, and sustainability. Discover how our cutting-edge technology can elevate your filtration systems.

https://lamxnano.com/

By Philippe Wijns Principal, CleverSustainability

What’s Next for CSRD, ESRS, Regulations, and Sustainable Innovation in Filtration?

In February 2025, the European Commission introduced the European Clean Industrial Deal, a major new initiative that builds on the Green Deal by shifting focus toward sustainable industrial growth and competitiveness. Closely linked to the September 2024 Draghi Report on strengthening Europe’s global position, this strategy responds to the urgent need for more innovative, more resilient industrial policies. For sectors like filtration and nonwovens – at the crossroads of clean technology, environmental protection, and industrial manufacturing – it presents both significant challenges and exciting new opportunities for innovation and leadership.

Why did Europe shift from the Green Deal to the Clean Industrial Deal? Although the Green Deal implemented over 150 measures to reduce emissions and expedite the energy transition, it did not establish a solid industrial policy. The Clean Industrial Deal fills this gap by focusing on sustainable growth, industrial resilience, and competitiveness, especially in light of recent economic and geopolitical pressures such as inflation, energy insecurity, and shifting global trade dynamics. It is built on five key pillars: affordable clean energy, green public procurement, circular economy and resource efficiency, industrial finance and innovation, and regulatory simplification and skills development. The message is clear and forward-looking at its core: Sustainability is not a cost but a key driver of longterm competitiveness and industrial strength.

Philippe Wijns is Principal at CleverSustainability, and serves as a Filtration Expert and Sustainable Business Development Advisor. He is a Certified Expert in Sustainable Finance, Climate Finance, and Renewable Energy from the Frankfurt School of Finance and Management. He began with global leaders in the nonwovens industry before transitioning to the filtration sector, where he specialized in filtration technologies across a wide range of applications and markets – including industrial and automotive systems, HVAC, household appliances, medical and life sciences, as well as power storage solutions such as fuel cells, hydrogen systems, and battery separators.

Wijns recently founded CleverSustainability, a consultancy dedicated to sustainable business development to help companies develop and implement sustainability strategies, ensure compliance with the EU legal reporting requirements, and enhance their sustainable business growth, product portfolio and development, and market positioning.

The Clean Industrial Deal brings both relief and fresh opportunities for filtration companies operating in or trading with the EU. Many small and midsized firms will no longer be directly bound by heavy regulations like the CSRD (Corporate Sustainability Reporting Directive) or CSDDD (Corporate Sustainability Due Diligence Directive). However, this does not mean that sustainability can be ignored.

Larger clients – especially OEMs in automotive, pharma, HVAC, and food processing – remain under reporting obligations. They will continue to demand detailed ESG data from their suppliers, including Scope 3 emissions, carbon footprint per product, lifecycle assessments, and material origin. For example, a HEPA filter supplier to a pharmaceutical cleanroom operator may be asked to prove how their product affects the client’s overall emissions or waste reduction targets. A nonwoven producer supplying cabin air filters for an automotive brand will likely be asked to document their media’s recyclability or carbon intensity – especially as many OEMs integrate these into their product-level environmental declarations.

Continuing voluntary ESG reporting is not only wise for reputation and customer trust but increasingly necessary for staying in supply chains. ESRS topics most relevant to the filtration industry include: ESRS E1 – Climate Change, which requires reporting on greenhouse gas emissions (including Scope 3), energy use, and transition plans, highly relevant to filter production processes and product design; ESRS E2 – Pollution, which covers air, water, and soil pollution and links directly to the role filters play in capturing pollutants and how production processes manage emissions and waste; ESRS E5 – Resource Use and Circular Economy, crucial for filtration as it addresses the use of virgin vs. recycled materials, product durability, repairability, modularity, and recyclability; ESRS S2 – Workers in the Value Chain, with growing importance on responsible sourcing and working conditions in raw material supply chains, such as those involving polymers or activated carbon; and ESRS G1 – Business Conduct, which includes ethics, compliance, and sourcing practices, especially important for companies importing filter components or chemicals from outside the EU.

Filtration companies that design biodegradable filters, use renewable or traceable raw materials, or integrate innovative features for monitoring usage and replacement can apply for these funds and receive preferential treatment in public tenders. For instance, a filtration company developing a sensor-equipped HVAC filter that alerts users when it needs replacing – made from compostable nonwovens – would be well aligned with EU funding priorities and evolving customer expectations. In short, even with relaxed regulations for smaller players, the market pressure to become greener, smarter, and more transparent is only increasing.

The Clean Industrial Deal also makes the circular economy more critical in the EU. A new law will push companies to create products that are easier to recycle and better designed for the environment. For filtration companies, this means using one type of material (mono-material), making filters with parts that can be reused or replaced, and using biodegradable materials. Filters used in buildings, vehicles, and cleanrooms must meet these new expectations. Some companies are already working on compostable filters, reusable frames, and smart filters. These changes help reduce waste, lower costs, and support Europe’s resource-saving goals.

Buyers – both public and private – are becoming more selective. Public procurement now favors low carbon, locally made products and sustainable supply chains, giving an edge to filtration companies producing in Europe with certified materials. Private buyers like car and pharma companies also ask for carbon footprint data, energy use, and recyclability. Suppliers who support their clients’ climate goals are more likely to win business – even at a higher price.

Competitive differentiation means using sustainability to stand out–not just to comply with rules. Filtration companies can gain an edge by developing eco-friendly products, adding smart monitoring features, sharing precise ESG data, and helping customers reach their net-zero goals. This turns them into valuable long-term partners, not just suppliers.

Filtration companies should act now to make the most of the Clean Industrial Deal. First, check if the new CSRD rules apply to you. Even if not, continue voluntary ESG reporting to show you’re a reliable partner. Invest in innovation using recyclable materials and energy-saving designs and explore EU funding options. Review your operations to find ways to save energy and reduce waste. Train your team in eco-design and digital tools. Finally, get

involved in industry groups like EDANA or Inda to help shape future rules.

Digital tools and AI are creating new opportunities for filtration companies. Smart factories can now use real-time monitoring to track energy use, material waste, and machine efficiency, helping to reduce costs and improve ESG performance. AI is also being used in eco-design and engineering, making it easier to design filters that use fewer resources, last longer, and are easier to recycle. These technologies support better planning, reporting, and innovation. EU funding is available to help companies adopt these tools. Digital Product Passports (DPPs), coming soon, will show how products are made, used, and recycled–boosting transparency and customer trust. Companies that advance in digitalization and AI will gain a strong market advantage.

For global filtration companies active in Europe and non-European companies looking to enter or manufacture in the EU, the Clean Industrial Deal sends a clear signal: Aligning with EU sustainability goals is not just expected; it’s a smart business move. While the regulatory pressure is easing, expectations from European customers, public buyers, and investors remain high. Companies offering low-carbon, recyclable, and responsibly sourced filtration solutions will have a strong advantage. Foreign firms setting up in Europe can benefit from funding, access to skilled workers, and participation in a growing clean-tech market. By meeting EU standards early and embracing digital tools and eco-design, global players can strengthen their position and become trusted partners in Europe’s clean industrial future.

Aligning with EU sustainability goals is not just expected; it’s a smart business move.

Filter Media at the Roots of a Natural Skyline

By Adrian Wilson, International Correspondent,

Many landmark buildings around the world are now beautified by green roofing structures, which are heavily reliant on nonwoven-based filtration, separation, growth nurturing, and drainage systems.

Beyond simple aesthetics, the installation of grass, plants, and even trees on a building’s roof works to absorb rainwater and release it slowly back into the atmosphere through evaporation or, if there’s too much build-up, allow the water to trickle slowly into drainage systems to ensure they don’t become overwhelmed.

There are other benefits, too, including insulation and cooling properties for buildings and the promotion of biodiversity in built-up areas.

This has seen green roofs become important elements in many countries. In addition to being highly visible, they also very effectively provide a distinctive image to buildings and development projects.

One leader in the installation of these systems is Optigrün, based in Krauchenwies-Göggingen in southern Germany. Together with around 140 partner companies in its network, Optigrün is involved in over 10,000 green roof and rainwater management projects annually, equating to over five million square meters of substrate materials laid and subsequently cultivated.

A flagship Optigrün project is the roof of the converted World War 2 bunker that has dominated the landscape of the St. Pauli district of Hamburg in Germany for over eighty years. Built on the orders of Adolf Hitler to provide shelter for up to 25,000 people

in response to the bombing of the city, it has now been converted into a five-story leisure center that comprises restaurants, event spaces, and a hotel, with 7,600 square meters of roof-top gardens across its different levels. A 560-metre walkway encircles the exterior of the building, and the freely accessible roof gardens consist of almost 23,000 plants maintained by a highly sophisticated rainwater management system.

The plants provide relief for the entire building, acting as a natural air conditioning system by insulating it in winter and protecting against heat in summer, which saves money on energy costs. In addition, with assistance from appropriate backing materials, the plants filter fine dust from the air and significantly reduce sound reflection due to their mass.

Protecting the roof surface from extreme temperature fluctuations and mechanical damage can also almost double the roof’s service life, according to Optigrün.

In a recent interview with Deutsche Bank, which has backed the company for many years, Optigrün CEO Uwe Harzmann explained that sealed surfaces in Hamburg’s city center often turn into heat islands, especially in the summer months.

“The city heats up and causes air temperatures to rise sharply, and the hot air then rises rapidly, dragging moist air from the surrounding area with it,” he said. “In higher air layers, this moist air cools down quickly, leading to sudden and heavy

downpours. These water masses overload the sewer system and frequently result in flooding.”

In response to this problem, the St. Pauli Bunker is equipped with retention roofs, which act as sponges, absorbing a large part of the precipitation and preventing rainwater from running directly into the sewers.

Containers under the nonwoven substrates collect the water, filtering only as much as necessary. If imminent rain were to overload the roof, the water would be drained into underground storage tanks or the sewer system. Meanwhile, sensors collect data and monitor factors such as heat storage and evaporation processes to supply a personalized weather forecast for the building.

In May 2020, Freudenberg, a leading nonwovens manufacturer headquartered in Weinheim, Germany, acquired Low and Bonar, a London, UK-based company. This merger brought together two of the leading companies with extensive experience in green roofing and a wide portfolio of substrates.

For foundational layers, for example, Freudenberg’s EnkaDrain consists of a durable synthetic drainage core of fused, entangled filaments and a nonwoven fabric thermally bonded to one side. For maximum strength and continuous flow even under high loads, the entangled filaments are molded into a square waffle pattern or a U-groove configuration. The filter fabric is a spunlaid nonwoven with excellent filtering performance through its uniform open structure. It is dimensionally and thermally stable and exhibits high tensile strength per unit weight. It is also thin and flexible yet possesses excellent tear and puncture resistance. For seamless installation, the nonwoven fabric overlaps the drainage core along one edge of the roll.

As an all-in-one drainage and water retention layer meanwhile, EnkaRetain&Drain combines EnkaDrain with a highly absorbent lightweight water-retention fabric.

This fabric is made of recycled synthetic fibers and holds more than 7.5 times its weight in water. The geocomposite comes in a convenient roll format and is water-vapor permeable.

EnkaDrain does not need aggregate, reducing the total roof weight. The matting is installed with the nonwoven filter layer uppermost.

The fabric of EnkaRetain&Drain absorbs water for continuous hydration of plant roots. It is in direct contact with the growing medium and, therefore, readily accessible by the plants. At the same time, excess water passes through the drainage core below.

Through its Xeroflor subsidiary, Low and Bonar was involved in many green roofing projects even before becoming part of Freudenberg.

These include two New York landmarks – the Jacob K. Javits Convention Center in Manhattan and, most iconic of all, the Empire State Building.

Xeroflor systems are employed to stunning effect on the 6.75-acre green roof of the Javits Center, one of the largest in the USA and a wildlife sanctuary for dozens of local and migratory bird species, several bat species, and thousands of insects.

Research published by Drexel University and Cooper Union has demonstrated

The 6.75-acre

A typical five-layer Xeroflor construction. Freudenberg

that over a year, the roof retains more than 75% of the rain that hits it, which mitigates nearly seven million gallons of stormwater runoff annually.

First installed in 2014, the center was expanded in 2021, resulting in the creation of a one-acre roof-top working farm and a 10,000-square-foot orchard of apple and pear trees. The expansion was built to hold at least one million pounds of soil in an 18-inch-deep bed.

Lightweight Xeroflor green roof systems were also installed on the 21st, 25th, and 30th floors of the Empire State Building as part of a $550 million ‘green’ retrofit, reducing its energy consumption by some 38% annually.

Xeroflor’s lightweight, nonwoven green roof systems range from weights of only eight to 12 pounds per square foot to applications of 31 pounds per square foot. Extensive green roofs generally use low-

maintenance vegetation such as sedums or short grasses and, are less than six inches deep and are typically two to four inches in depth. Their light weight makes them ideal for retrofit projects on older buildings or any structure with limits on the total weight load. Generally, extensive green roofs require minimal maintenance and can thrive in most temperate climate zones.

A typical five-layer Xeroflor construction consists of a pre-vegetated sedum mat on top of the growing medium, water retention layers, drainage mats, and root barriers.

This layered system is placed above the conventional roofing membranes.

Freudenberg also supplied glass-fiber reinforced polyester nonwovens made from recycled PET bottles for the landmark twin towers of the Bosco Verticale in Milan, Italy, with its 900 trees and over 2,000 plants.

These materials are employed in green roof structures not only as drainage and storage layers of filter media and carriers for bituminous membranes, but, in many cases, as the nutrient substrate.

For projects such as the Bosco Verticale, materials supplied by Freudenberg were a natural extension of the company’s long experience in the fields of both roofing membranes and geotextiles, for which Freudenberg now recycles around seven million PET bottles a day at its European facilities in France and Italy.

Combining the flexibility of polyester with the stability of glass creates excellent runnability, particularly at higher temperatures and for use in bitumen production lines. In addition, the bitumen membrane creates excellent long-term dimensional stability and endurance. The use of glass reinforcement also eliminates the phenomenon of thermal memory –once installed on a roof, the membrane will no longer shrink when temperatures fluctuate.

Bitumen roof membranes last more than 20 years on average; then, the damaged roofs are completely replaced, or the damaged points repaired. This is an important advantage of this technology

compared to other sealing systems, particularly in maintenance work. Manufacturers can also recycle waste from bitumen roof membranes by grinding them into a powder, which can then be used as a raw material, further improving the product’s sustainability.

Of course, not all buildings are quite as grand as those mentioned so far, but greening the roofs of standard houses can still be beneficial and economical through products such as the M-Tray, developed by Wallbarn, based in South Croydon, UK.

Such modular green roof systems consist simply of an initial nonwoven separation and filtration layer on top of which are placed trays pre-planted with a diverse selection of fully established flowering sedum.

Engineered to seamlessly click together and create a continuous, lush green sur-

face, M-Trays are designed with carefully spaced drainage holes to optimize water retention, allowing plants to absorb more rainfall effectively. This enhances the growth and health of the vegetation and contributes to the attenuation of stormwater, reducing runoff.

Wallbarn says that the initial investment in the MTray system can yield long-term savings through reduced energy costs and extended roof lifespan. One of its most significant advantages is its ability to provide immediate green coverage upon installation.

The pre-grown modules are delivered with a minimum of 90% vegetative cover, ensuring that a lush, verdant surface is created as soon as the modules click together. This instant aesthetic appeal is in stark contrast to traditional green roof systems, which may take months or even years to establish a fully covered and visually appealing green space.

Adrian Wilson is an international correspondent for International Filtration News . He is a leading journalist covering fiber, filtration, nonwovens and technical textiles. He can be reached at adawilson@gmail.com.

By Yasar Kiyak, PhD

Passive electrostatic filtration media mainly rely on fossilbased polymeric electret fibers, which have refined through decades of research. However, the increased use of fossil-based materials is contributing to higher carbon emissions, global warming, and climate changes. The growing concern over the environmental impact of non-biodegradable plastics arises from the fact that most end up in landfills or oceans, while only a small portion is ever recycled. So, these pressing environmental issues have intensified a push for renewable energy and sustainable resources. To replace traditional fossil fuel-based insulation materials, biobased, biodegradable, and compostable alternatives must

achieve or closely match the electrical, mechanical, and thermal properties of their synthetic counterparts.

Electrostatic fibers offer two major benefits:

1. Higher efficiency at the same resistance to airflow – They provide superior filtration without increasing pressure drop.

2. Enhanced submicron particle capture – Electrostatic forces are particularly effective for particles below 1 micron, as illustrated in Figure 1.

Table 1 summarizes how some important filtration parameters effect key fil-

tration mechanisms, revealing that while a reduction in fiber diameter enhances efficiency across all four mechanisms, a decrease in filtration velocity produces more nuanced effects: diffusion and electrostatic attraction increase, interception remains unchanged, and impaction declines1, 2, 3. Understanding these interactions is critical for optimizing filter design, particularly because their combined effects typically result in a most penetrating particle size (MPPS) between 100–300 nm, representing the most challenging particles to capture efficiently.

To evaluate the potential of biopolymers for electrostatic fiber applications, their electrical, mechanical, thermal, and

structural properties must be examined, as electret performance depends on both intrinsic polymer characteristics and fiber manufacturing conditions (Figure 2).

Key considerations include:

• Dielectric constant (affecting charge storage),

• Dielectric tangent loss/dissipation factor (representing charge retaining)

Additionally, polymer polarity is important in determining how materials interact with electric fields, while volume resistivity measures the material’s resistance to electrical flow. Other factors such as hydrogen bonding, surface energy, and hydrophobicity also play significant roles in determining the material’s adaptability in electrostatic filtration applications.

Dielectric materials are electrical insulators with a permanent dipole moment, allowing them to store energy through polarization. Most polymers function as dielectrics, accumulating charge when polarized.

The dielectric constant (ε) indicates a material’s ability to store electrical energy, defined as the ratio of charge storage in the material to that in air or vacuum. Measured via ASTM D150, it uses parallel plate capacitance to evaluate energy storage performance. Several factors

influence dielectric measurements, including frequency, temperature, and relative humidity. While rigid materials like films facilitate straightforward testing, fibrous materials present measurement challenges due to air interference between fibers4, 5, 6, 7. According to the literature, biopolymers such as PLA, PHA, and PHB exhibit higher dielectric constants than polypropylene (PP).

• The dielectric constant value holds particular importance across multiple applications. Polymers with low dielectric constants are especially valuable for:

• Electrostatic filter media

• High-frequency circuit design

• Power transmission systems

• High-speed network infrastructure

The dissipation factor (tan δ) serves as a critical indicator of energy loss in electrical insulation and capacitor dielectrics,

significantly affecting both performance and operational lifespan. Maintaining a low dissipation factor is critical for preserving insulation integrity, as it minimizes undesirable energy dissipation.

Key factors influencing the dissipation factor include:

• Moisture absorption, which elevates the dissipation factor and consequently degrades insulation properties

• Material composition, where higher dielectric constants typically correlate with increased dissipation

• Contaminant removal, as extracting oils or impurities can improve insulation efficiency by reducing energy loss

Understanding and controlling the dissipation factor is crucial for optimizing the charge retention performance of electrostatic articles1, 3, 6. While dissipation factors vary widely, biopolymers such as PLA and PHB typically exhibit higher dissipation factors than polypropylene (PP).

Another key factor to consider is electrical resistivity. Although polymers are generally showing insulating behavior, they can still exhibit a conduction under a DC field. A material with a volume resistivity above 10⁹ Ω·m is considered a good insulator, with resistivity being inversely proportional to the dielectric constant. Even trace impurities can significantly alter electrical resistance. Several factors influence resistivity, including:

• The type and concentration of additives

• Moisture content

• Material degradation due to prolonged use.

Note that while volume resistivity is essential for assessing bulk insulating properties, surface resistivity is expected

to play a more critical role in electret fibers8, 9. Various resistance values have been reported in the literature, with PLA and PHB exhibiting values comparable to those of polypropylene (PP).

Nonpolar plastics exhibit a low dielectric constant and high resistivity, primarily due to their symmetrical molecular structures and minimal polarity. The extent of their polarity depends on the electronegativity differences between constituent atoms. Common examples include:

• PTFE (Polytetrafluoroethylene)

• PE (Polyethylene)

• PP (Polypropylene)

• PS (Polystyrene)

These materials generally demonstrate high resistivity, low dielectric constants, and balanced dipole arrangements (e.g., PTFE’s alternating – CF₂– groups). Polarity is assessed in Debye units (D) via dipole moment calculations. Key factors influencing polarity include:

• Electronegativity differences between atoms

• Molecular geometry (e.g., symmetry)

• Polar bonds (e.g., C=O, O-H)

• Conformational defects (e.g., helical distortions in polymer chains)

In bioplastics, materials with hydrocarbon chains or weakly polar functional groups tend to display lower polarity. For instance:

• PLA (Polylactic Acid) is relatively low in polarity compared to other biopolymers, owing to its hydrocarbon backbone – though its ester groups introduce slight polarity.

• PHA (Polyhydroxyalkanoates) exhibits moderate polarity due to its ester functionalities.

Another property to consider is hydrogen bonding forming between hydroxyl (-OH) groups, such as those in cellulose, and can significantly influence a material’s dielectric behavior. Increased hydrogen bonding enhances polarization, leading to a higher dissipation factor in certain polymers.

Key Examples:

• Polyamide (Nylon 6): Contains amide groups (–NH–(C=O)–), with one amide per six carbon atoms. These groups attract and retain water molecules, resulting in moisture regain and altered dielectric properties.

• Polylactic Acid (PLA): Features polar carbonyl (C=O) groups, where the electronegative oxygen facilitates hydrogen bonding with water, affecting its dielectric response.

• Polyhydroxybutyrate (PHB): Also contains carbonyl groups that enable hydrogen bonding with water, further influencing dielectric performance.

• Crystalline regions have tightly packed polymer chains, restricting water penetration and hydrogen bond formation.

• Amorphous regions are less densely packed, allowing water molecules to interact more freely and form hydrogen bonds.