5 minute read

Membranes for Liquid Filtration

in order to achieve various properties such as increased hydrophilicity or to reduce fouling to cut down on necessary cleaning periods, as well as energy use.

Grafting processes can involve the polymers being attached to the membrane surface or molecules being grown from it.

The modification of surface charge can also be influenced by the grafting of zwitterionic molecules such as amino acids.

Polydopamine coatings are also a biocompatible surface treatment to increase hydrophilicity and selectivity, as well as reducing fouling.

Surface Charge

The creation of defined surface charges can result in high selective separation of protein molecules and is to be found, for example, in high-quality products in the dairy industry.

In LBL (layer-by-layer) technology, different combinations of polyelectrolyte coating layers are employed to control flux and separation efficiency, with the Zeta potential of the layers steered by the coatings. Additional crosslinking by glutaraldehyde increases ion rejection and layer stability.

Another process that is being explored to achieve specific functionality is graphene oxide coating, either by vapor deposition or ink jet printing. In order to achieve specific selectivity, the channel height between the graphene oxide layers can be controlled for high water flux due to the low molecular friction in the carbon channels.

Aquaporine

In another R&D area, biomimetic UF and NF membrane structures have been developed involving aquaporine protein molecules with water conductive channels being embedded in proteoliposomes. Fixation of the molecules is achieved by polyamide coating and a high water conductivity of up to three billion molecules per second has been recorded in a single aquaporine channel, making such structures competitive with RO membranes in terms of water flux performance at moderate salt concentrations.

The current challenge in development here, is in perfecting low-throughput production and cleaning, since it would create a bottleneck in high volume series production.

Surface Coatings for RO Membranes

Functional surface coating polyamide chemistry is state-of-the art for water desalination RO membranes, creating thin film composites with a UF support membrane. Polyamide coatings are mostly used here, applied by interfacial polymerization and a chemical toolbox of different amines and acidic chloride monomers for steering permeability and salt rejection. New research results focusing on the structural details of the PA coating allow further optimization of RO membrane performance.

The classic trade-off in the application of RO membranes is between water flux and salt rejection and local coating density structure and thickness determine performance. On the one hand, thin and dense PA layers with almost hidden water channel structures lead to limited water transport, whereas with a less dense PA layer and a more open water channel structure, higher water transport is enabled, with lower salt rejection.

The current benchmark membrane, however, can achieve up to 99.9% salt rejection even in sea water desalination. The microscopic design of support membrane structures can also be manipulated to influence the performance of the PA coating.

Emerging developments include the incorporation of sacrificial interlayers into smooth PA coatings and the use of nanofillers to increase hydrophilicity.

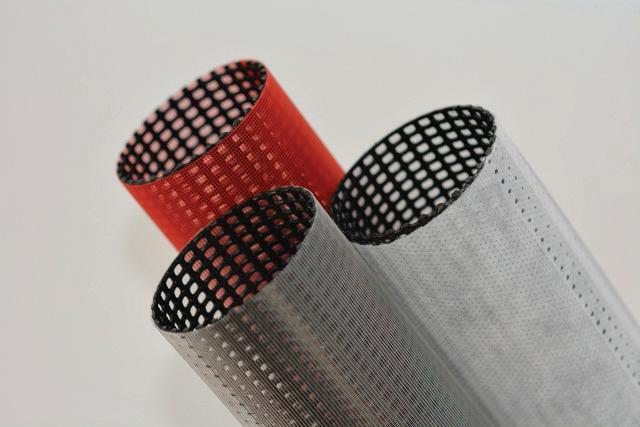

MANN+HUMMEL Bio-Cel membrane bioreactor module (MBR). MANN+HUMMEL

Ridge/valley structures on the molecular scale have also been created to increase the effective membrane’s surface area and the application of surfactants has been exploited to further enhance the surface potential.

Green Energy

Moving on to the use of membranes in green energy applications, Professor Schütz cited their deployment in redox flow batteries as high-capacity, high-power stationary energy storage devices and also the use of ion exchange membranes at the core of ion transfer during charging and discharging.

The focus now, is on the development of new membrane concepts that are fluorine-free and both cost and energy efficient.

In the green hydrogen economy, membranes are being employed in water preparation for the provision of highly purified water and also as a core component for energy efficient ion transfer within electrolysis cells.

They are then further employed for the removal of water and oxygen residuals for safe hydrogen transport and storage.

Challenges

There are, however, a number of regulatory challenges to be overcome, including the ban of PFAS, so-called ‘forever chemicals,’ with classic PFAS molecules applied to membranes for their surface protection properties as well as in water repellent agents.

Fluorine containing polymers, such as PVDF and PTFE, are also potentially components which will not be allowed in the future.

Further restrictions by REACH are also imminent on widely used solvents such as N-Methyl Pyrrolidone (NMP), N,N Dimethylformamide (DMF) and N,N Dimethylacetamide (DMAc) in membrane production and alternative green solvents are now being explored.

This is leading to a lot of work on the development of new membrane recipes and production parameters and while performance is being achieved, there is as of yet, no long-term experience of industrial performance.

These regulations are also resulting in a lot of work in achieving new certification in industries such as food and beverage and pharmaceuticals.

A further ban on Bisphenol A (BPA) molecules which is applied as a polymerization starter for polysulfone (PSU) as another relevant membrane polymer is also likely to shortly come into effect.

New Opportunities

“Membranes will be a key technology in life sciences, environmental protection and sustainable green energy systems,” Professor Schütz said in conclusion. “Major innovations are currently taking place in terms of membrane surface chemistries and structures, as well as in applying alternative materials and application specific tuning for higher selectivity and performance.

“The current key challenges are the replacement of relevant membrane production materials to ensure sustainability and the transfer of scientific results into series products, along with achieving the necessary certification across a range of end-use industries.

“Nevertheless, the development of such new materials and new markets being created by energy-related applications, in addition to recycling membrane products, is providing a lot of new opportunities going forward.”

About the Presenter

Apl. Prof. Dr.-Ing. Steffen Schütz received his diploma in Process Engineering in 1993 and his PhD in Process Engineering in 1999, both at the University of Stuttgart. In 2005 he completed his Habilitation in Mechanical Process Engineering, and he received his Venia Legendi in 2006. In 2009 he was appointed Adjunct Professor at the University of Stuttgart. Until end of 2010 Steffen Schütz was working at the Institute of Mechanical Process Engineering of the Stuttgart University. His research focus was on computational fluid dynamics, filtration, separation, and mixing technology.

In January 2011 Steffen Schütz joined the Advanced Technology department of MANN+HUMMEL GmbH in Ludwigsburg,

Germany, and he became responsible for membrane development. His working focus is on polymeric and ceramic filtration membranes and on nonporous ion exchange membranes for green energy applications. Since February 2023 Steffen Schütz is head of the Center of Competence “Flat Sheet Membranes” at MANN+HUMMEL in the Business Unit “Water & Membrane Solutions.” He is author or co-author of more than 70 scientific papers within his research and development fields and he holds more than 20 patents in membrane technology together with other patentees.

Adrian Wilson is an international correspondent for International Filtration News. He is a leading journalist covering fiber, filtration, nonwovens and technical textiles. He can be reached at adawilson@gmail.com.

• Rigid plastic cores

• Flexible tubular sleeves

• Flow channel spacers

• Media, pleat support

• Welded tube overwraps

• You design it, we create it!