5 minute read

A

Clear Game-Changer: Curtin’s WaterRepellent Glass Breaks New Ground

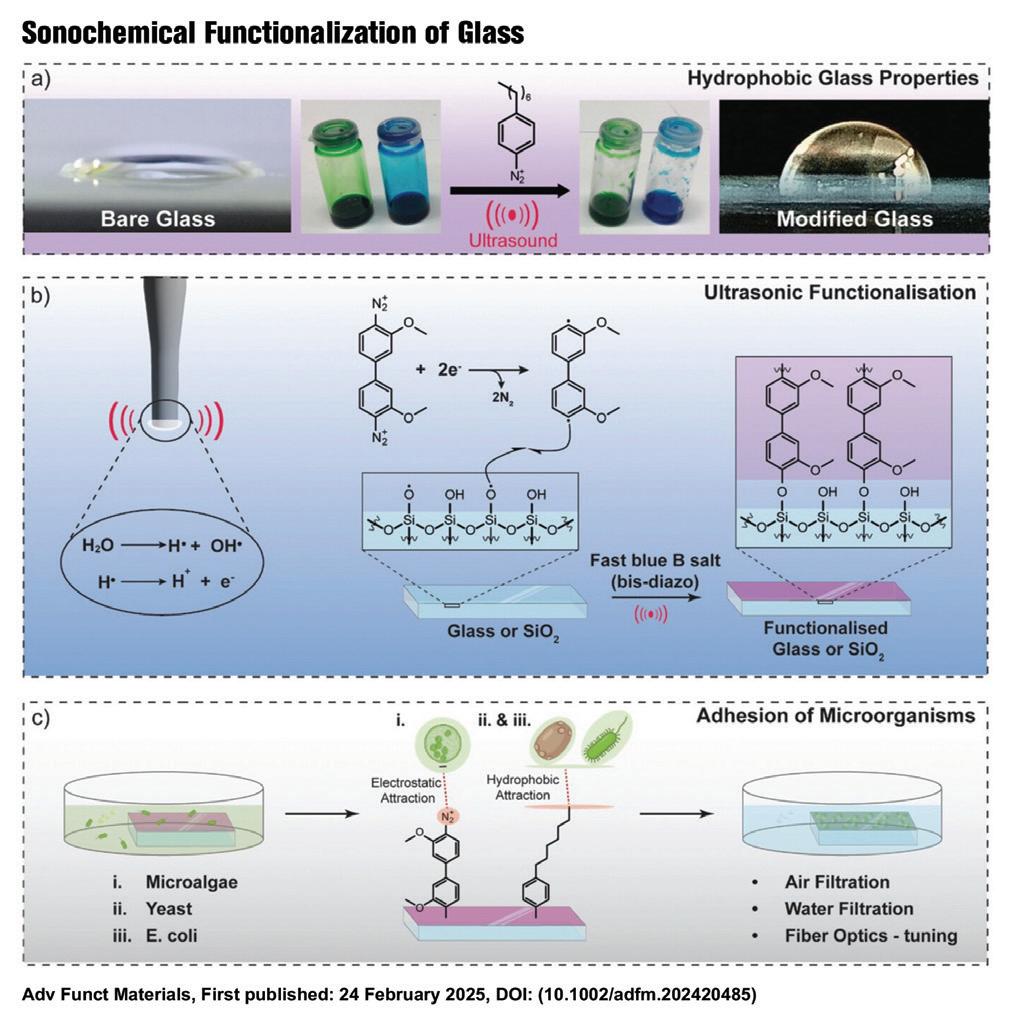

Curtin University researchers have developed a new technique to make glass water-repellent, a feature that could improve safety in vehicles, reduce cleaning costs for buildings and enhance filtration systems.

The research, published in the prestigious journal Advanced Functional Materials, shows how an innovative and non-toxic process using ultrasonic sound waves can alter the surface of glass, making it either hydrophobic (water resistant) or electrically charged.

Lead researcher Associate Professor Nadim Darwiwsh, an ARC Future Fellow at Curtin’s School of Molecular and Life Sciences (MLS), explained that the process uses ultrasound to trigger a chemical reaction that permanently alters the surface of glass.

“The sound waves create microscopic bubbles in a diazonium salt solution, which then collapse rapidly creating tiny bursts of heat and pressure,” Associate Professor Darwish said.

“This triggers a reaction that forms a stable, organic layer to the glass, making it either permanently water-repellent or positively charged, depending on the type of diazonium salt used. Unlike conventional coatings that wear off over time, our method creates a chemical bond at the molecular level, making it far more durable and environmentally friendly.”

Study co-author Dr. Tiexin Li, a Research Associate at Curtin’s School of MLS, said the ability to modify glass surfaces in a simple and sustainable way has far-reaching implications across multiple industries.

“Glass is used everywhere – from cars and buildings to industrial filters – but its natural tendency to attract water limits its performance,” Dr. Li said.

“Unlike traditional coatings this film won’t peel off, dissolve in water or deteriorate so it’s ideal for real-world applications where reliability and durability are key. This could mean clearer p Schematic of the ultrasonic fabrication of diazonium films on glass. Increased glass hydrophobicity was visually demonstrated by changes in wettability and the slipping of food coloring dyes. a) Glass was functionalized by reacting with 4-heptylbenzene diazonium (in acetonitrile) under ultrasonic conditions (400 W, 24 kHz). b) Sonochemical reaction of glass and silica-terminated silicon surfaces with acetonitrile solutions of bis-diazo. The surface functionalization reaction is accelerated in the presence of trace amounts of water, suggesting the involvement of H• and HO• radicals generated by cavitation. The longer lifetime of H• compared to HO• creates a reducing environment, where electrons lost by H• reduce diazonium groups to surface-reactive aryl radicals. c) Schematic representing the interaction of glass modified with bis-diazo and 4-heptylbenzene diazonium with microorganisms including microalgae (C. vulgaris), bacteria (E. coli), and yeast (S. cerevisiae). Curtin University windshields in heavy rain, self-cleaning skyscraper windows and solar panels that stay dust-free.”

Co-author Zane Datson, also from Curtin’s School of MLS, highlighted another unexpected benefit–the ability of the modified glass to attract bacteria, fungi and algae.

“This is very exciting as we can tailor glass properties for specific uses including in advanced filtration systems and biofuel production,” Mr. Datson said.

“For example, the coated glass can help bind yeast in brewing, capture bacteria in wastewater filtration systems or act as a chemical barrier to microorganisms in air filters.”

The research team is now seeking industry partners to test and scale up the technology, particularly in the automotive, construction and environmental sectors.

This research was supported by the Australian Research Council and highlights Curtin University’s leadership in materials science innovation. It was conducted in collaboration with The University of Queensland, Flinders University, The University of Western Australia and Charles Sturt University.

The full paper titled, ‘Sonochemical Functionalization of Glass,’ can be found online at the link below.

READ: https://www.curtin.edu.au/news/ media-release/a-clear-game-changer-curtinswater-repellent-glass-breaks-new-ground/ The full research: https://advanced.onlinelibrary. wiley.com/doi/10.1002/adfm.202420485

DREXEL UNIVERSITY’S COLLEGE OF ENGINEERING

Closing the Gaps –Coating Air Filters With MXene Nanomaterial Can Enhance Performance and Reusability

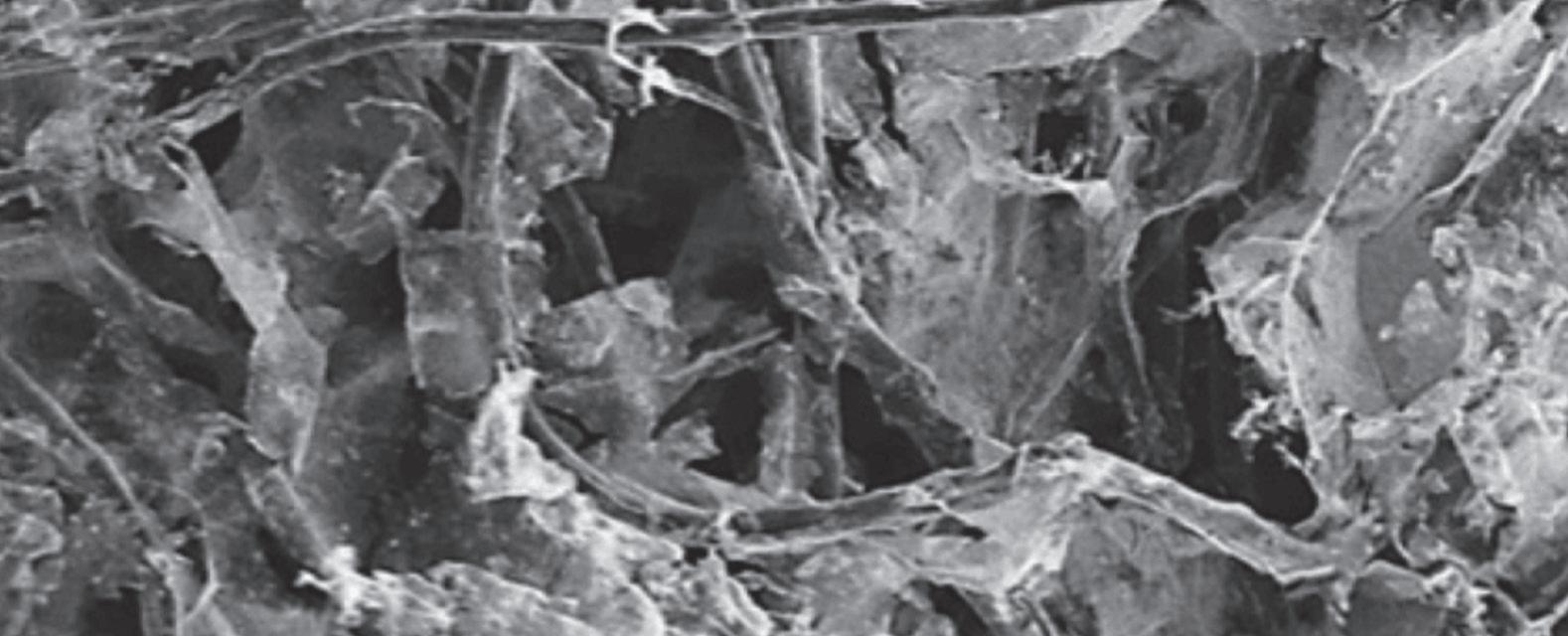

Despite improvements to air filtration technology in the aftermath of the COVID-19 pandemic, some of the smallest particles — those of automobile and factory emissions — can still make their way through less efficient, but common filters. An interdisciplinary team of researchers from Drexel University’s College of Engineering have introduced a new way to improve textilebased filters by coating them with a type of two-dimensional nanomaterial called MXene.

Recently featured in C–Journal of Carbon Research, the team’s research reports that a non-woven polyester textile — a low-cost material with low filtration efficiency — coated with a thin layer of MXene nanomaterial can turn it into a potent filter capable of pulling some of the finest nanoparticles from the air.

“It can be challenging for common filters to contend with particles less than 100 nanometers, which include those emitted by industrial processes and automobiles,” said Michael Waring, PhD, a professor in Drexel’s College of Engineering, and coauthor of the research. “Being able to augment a filter, through a simple coating process, to make it effective against these emissions is a significant development.”

The researchers report that a polyester textile coated with a titanium carbide MXene can reach approximately 90% filtration efficiency for particles as small as 15-30 nanometers — the size of viruses and the finest dust particles — meaning that it could be effective as an augmentation process to air filters located in urban or industrial environments.

MXenes, a family of nanomaterials discovered by Drexel researchers in 2011, have previously demonstrated proficiency in filtration applications, including water treatment, kidney dialysis, and hydrogen capture. The materials have also shown p Yury Gogotsi, PhD, Distinguished University and Bach professor in the College of Engineering. p Michael Waring, PhD, a professor in Drexel’s College of Engineering, and coauthor of the research. that they can enhance filters that remove airborne viruses in medical settings.

“With increasing manufacturing volume and decreasing price, MXenes are finding an increasing number of applications,” said Yury Gogotsi, PhD, Distinguished University and Bach professor in the College of Engineering, who led the material’s development and was among the researchers who discovered MXenes and founded MXene, Inc., a company that now manufactures them. “Particularly in the fields that require large amounts of material.”

The latest discovery is a significant step in the exploration of the nanomaterials because it shows their capability to contend with some of the smallest particles in the air and that they can easily be integrated into a filter manufacturing process.

“Our ongoing research continues to reveal the potential of MXene coatings,” Gogotsi said. “The fact that this highly conductive nanomaterial is also hydrophilic means that it can be dispersed in water to produce a coating that can easily be applied to virtually any substrate, including air filters. We are just scratching the surface of its capabilities.”

In the processes of testing the MXenecoated filters, the team made an additional discovery, that pretreating the filters with magnesium salt assisted in the MXene coating process and improved the filter’s performance by 25% – to achieve a maximum efficiency of about 90% for virus-size nanoparticles, which many common filters don’t capture.

The addition of alkaline earth metal ions, such as magnesium, improved the MXene coating process. According to the researchers, this sort of chemical preparation further activates the surface of the MXene, which helps the material spread uniformly across the filter, creating a thicker coating and more complex channels through the material, which all contribute to better filtration capability.

The researchers tested untreated; MXene-coated; and MXene-coated and magnesium ion-treated filters in a vacuum-sealed chamber containing aerosolized sodium chloride (rock salt), and measured removal for particles ranging from 5.6 to 560 nanometers. The filters that had been MXene-coated and magnesium ion-treated performed significantly better than the other two at capturing particles of all sizes in the range, down to 15 nanometers.

In addition to their ability to improve filtration, MXenes are also highly conductive – a trait the researchers theorized could be leveraged to enable the filters to clean themselves. They tested the idea by applying an electric current to the MXene-coated filter, which raised its temperature to 100 degrees Celsius – enough to carefully burn off some particles and debris on the filter and restore its original filtration quality.

“Studies like this are encouraging for real-world application of MXenes in air filtration,” said Prastuti Upadhyay, a Materials Science and Engineering undergraduate student in the College of Engineering, who was mentored by Drexel postdoctoral researcher Stefano Ippolito, PhD, and was the lead author of the paper. “But it should be noted that our air filters could still be improved by focusing on optimizing the MXene structure, pretreatment ions and the filter substrate. This leaves room for many exciting possibilities for this line of research.”

This research was funded by the Army Research Laboratory.

In addition to Upadhyay, Gogotsi and Waring, Bita Soltan Mohammadlou and Ippolito, from A.J. Drexel Nanomaterials Institute, participated in this research.

Read: https://drexel.edu/news/archive/2025/February/MXene-coated-air-filters

Full Paper: https://www.mdpi.com/23115629/11/1/13